Simultaneous and quick aligning and locking device for multi-roll ring of section steel straightener

A locking device and straightening machine technology, which is applied to the field of simultaneous rapid alignment and locking device for multiple roller rings of roller-type steel straightening machines, can solve the problem of high alignment accuracy requirements for roller rings and roller shafts, prone to errors, and time-consuming And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

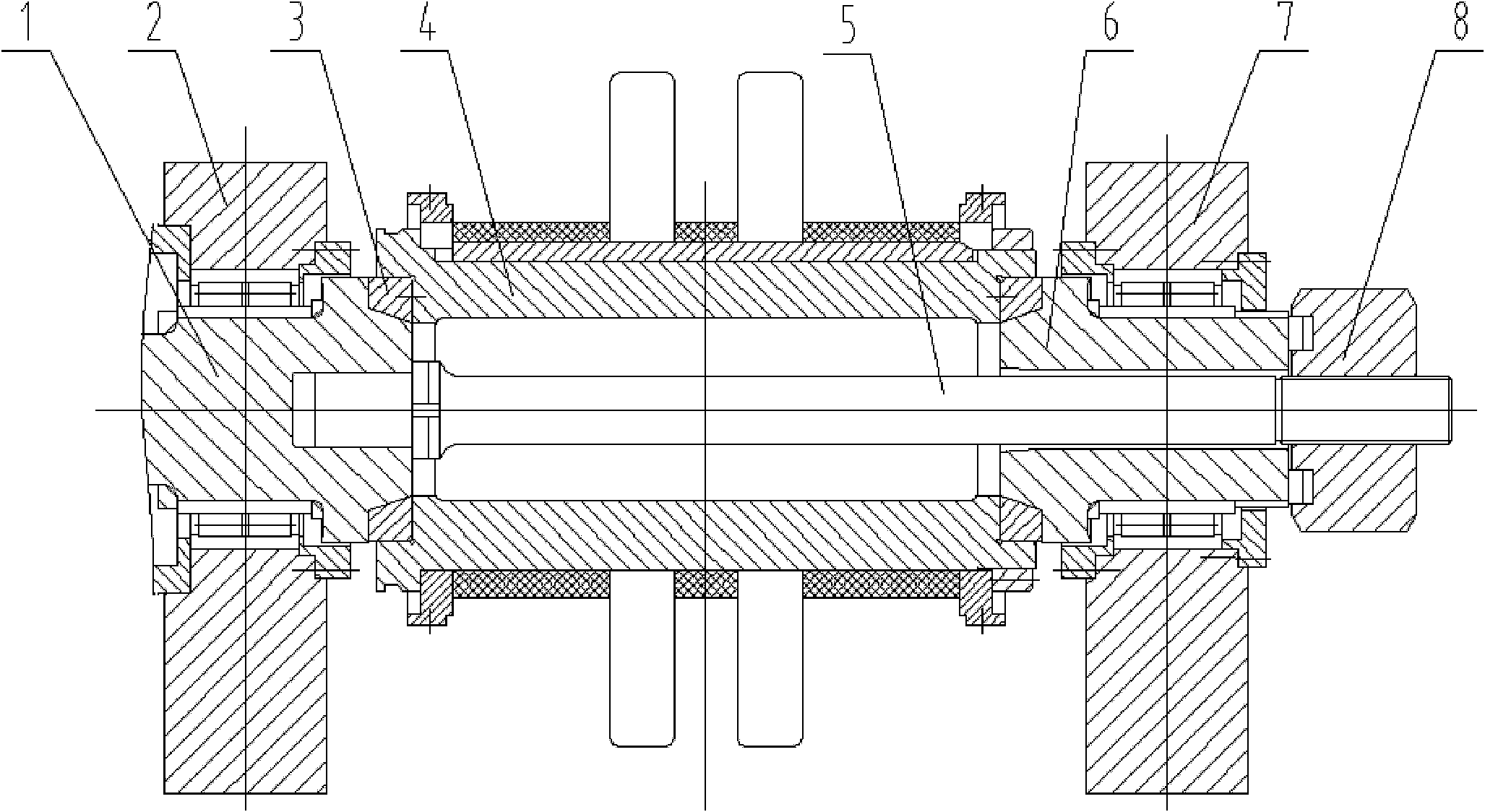

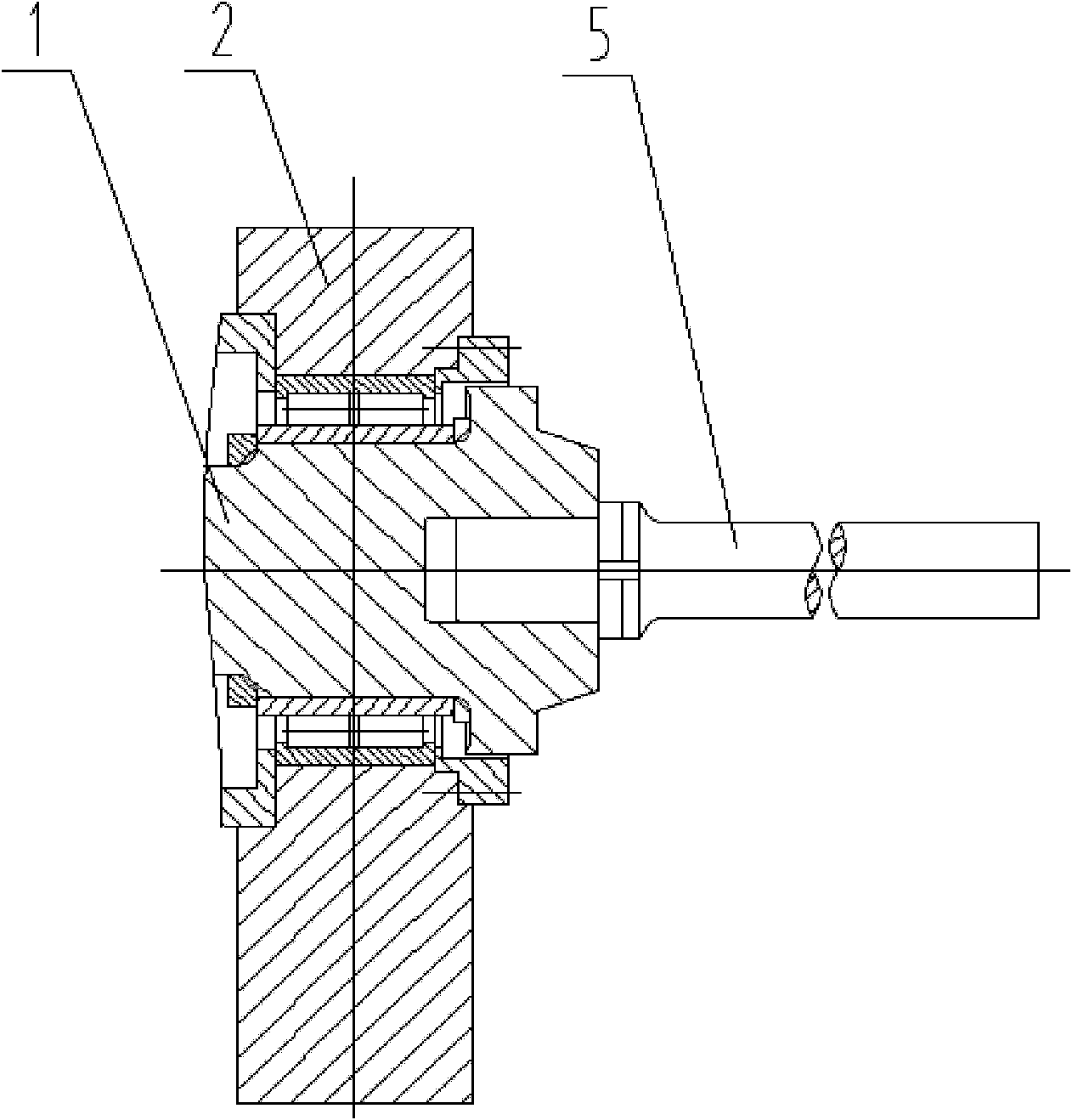

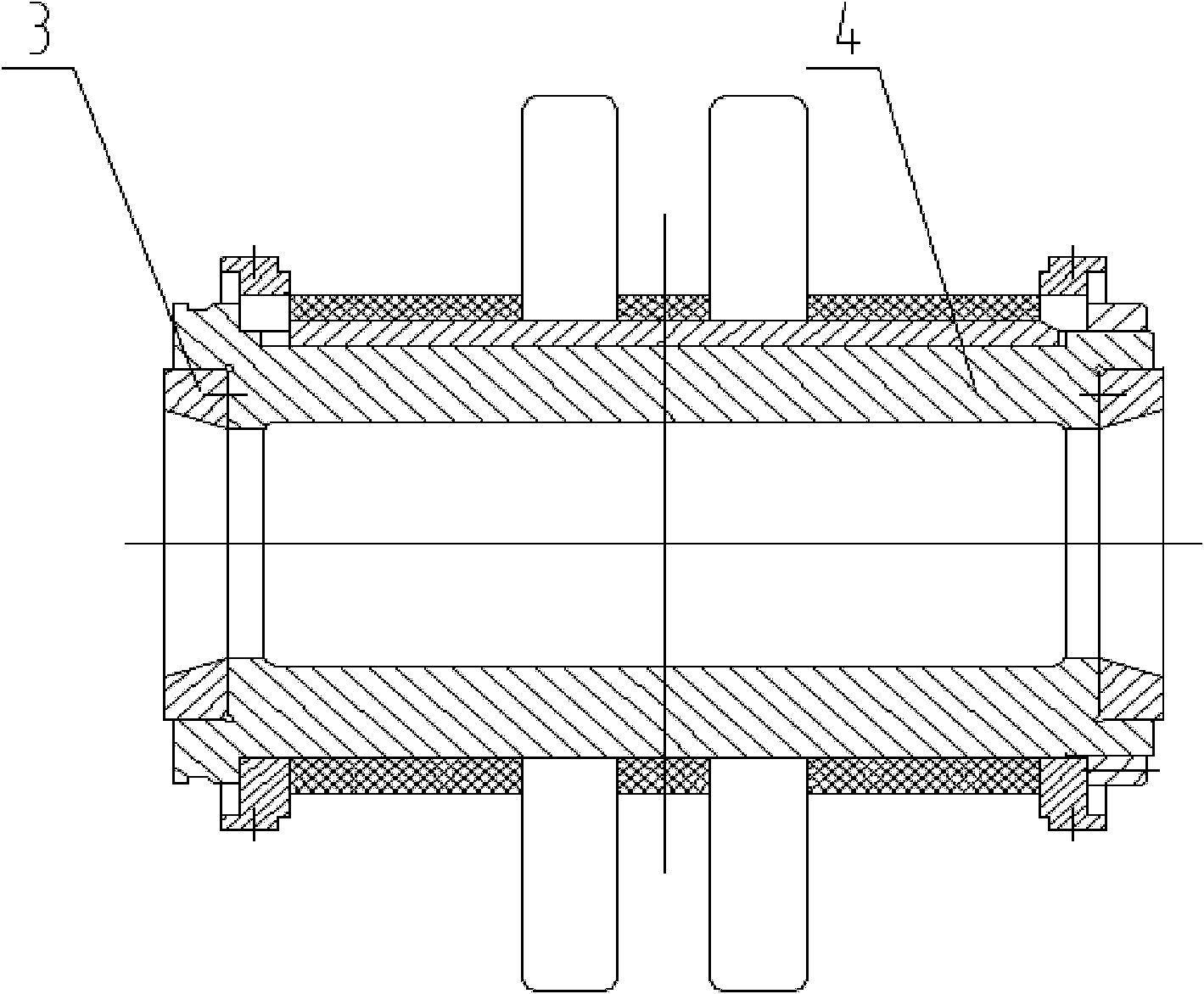

[0013] Referring to the accompanying drawings, a multi-roller ring of a section steel straightening machine is quickly aligned and locked at the same time. 5. The moving side taper shaft 6, the moving side bearing seat 7, and the hydraulic nut 8 are composed. The fixed side taper shaft 1 is installed on the fixed side bearing seat 2. The tapered end and the end of the roller shaft 5 are threaded. The other end passes through the combined roller ring 4 and the moving side cone shaft 6, the two ends of the combined roller ring 4 are bolted to the tapered hole ring 3, the moving side cone shaft 6 is installed on the moving side bearing seat 7, and the moving side Taper shaft 6 has a taper hole at the end of the taper surface and a guide device. The roller shaft 5 can pass through the mobile side taper shaft 6 and connect with the hydraulic nut 8 along the guide device, so that the fixed side taper shaft 1 and the moving side taper shaft 6 will be connected to each other. The comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com