Segment assembly robot for miniature shield machine

A technology of robots and shield machines, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of inability to meet the spatial layout of miniature shields, and achieve the effect of meeting precise requirements, ensuring special requirements, and having a compact and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

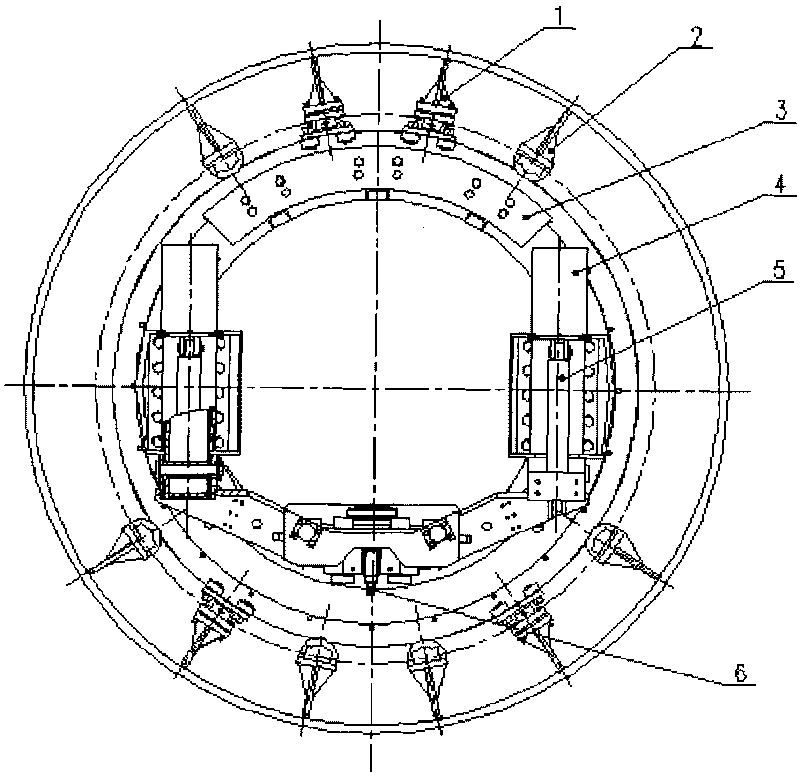

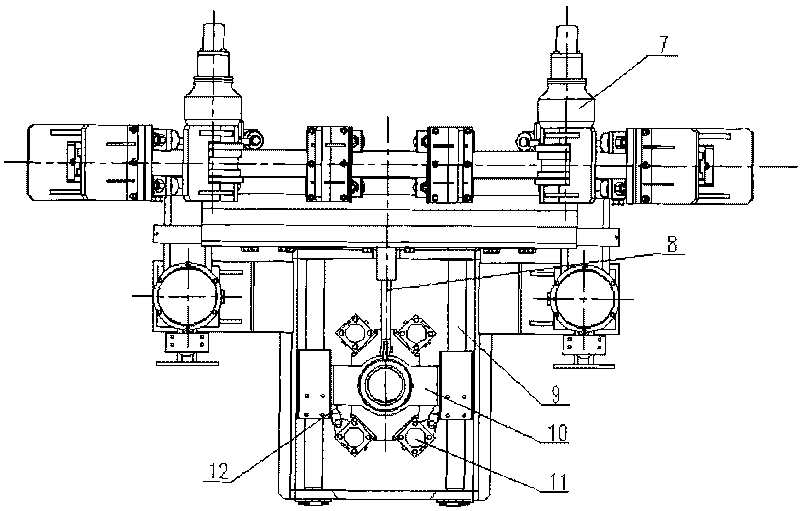

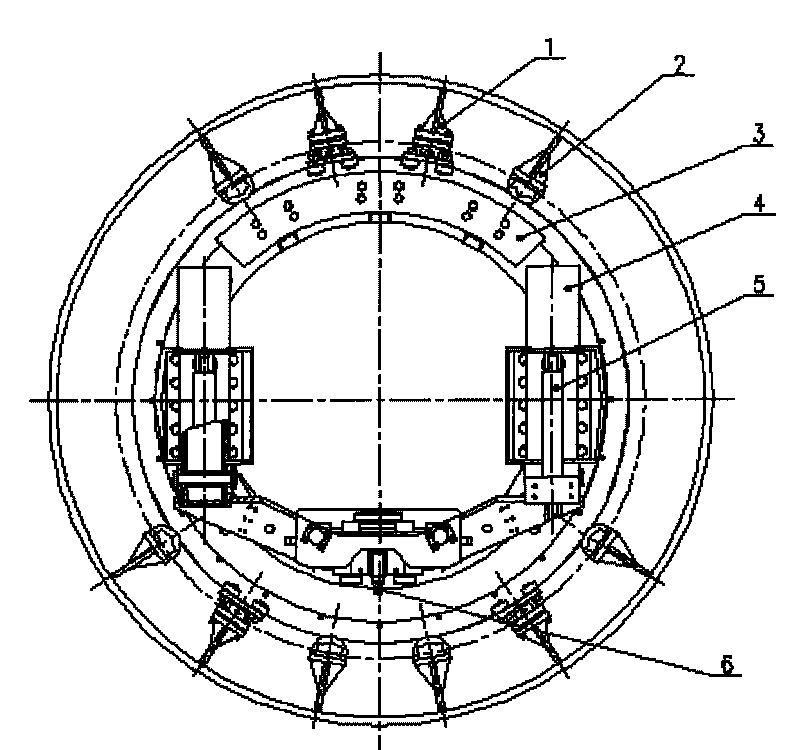

[0010] Referring to the accompanying drawings, a segment assembly robot for a micro-shield machine consists of a guide wheel 1, a support wheel 2, a rotating ring 3, a lifting guide rod 4, a lifting cylinder 5, a segment lifting pin 6, and a driving device 7 , translation cylinder 8, horizontal guide rail 9, grabbing head 10, fine-tuning cylinder 11, and swing cylinder 12. The guide wheel 1 and the support wheel 2 are respectively welded to the inner wall of the shield, and also serve as the support for the assembly segment robot to rotate along the X axis The track; the driving device 7 is fixed on the shield bracket, and the pinion gear in the driving device 7 meshes with the large gear in the rotating ring 3; the cylinder part of the lifting cylinder 5 is connected with the lifting guide rod 4, and the piston rod of the lifting cylinder 5 The end is connected with the horizontal guide rail 9 through the mechanism, and the fixed end of the lifting guide rod 4 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com