Apparatus for reducing friction resistance between shield machine shield body and tunneling wall

A technology for excavating tunnels and friction resistance, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of increasing manufacturing costs, increasing the starting torque of the main propulsion motor, and not being able to reduce the power consumption of main propulsion friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

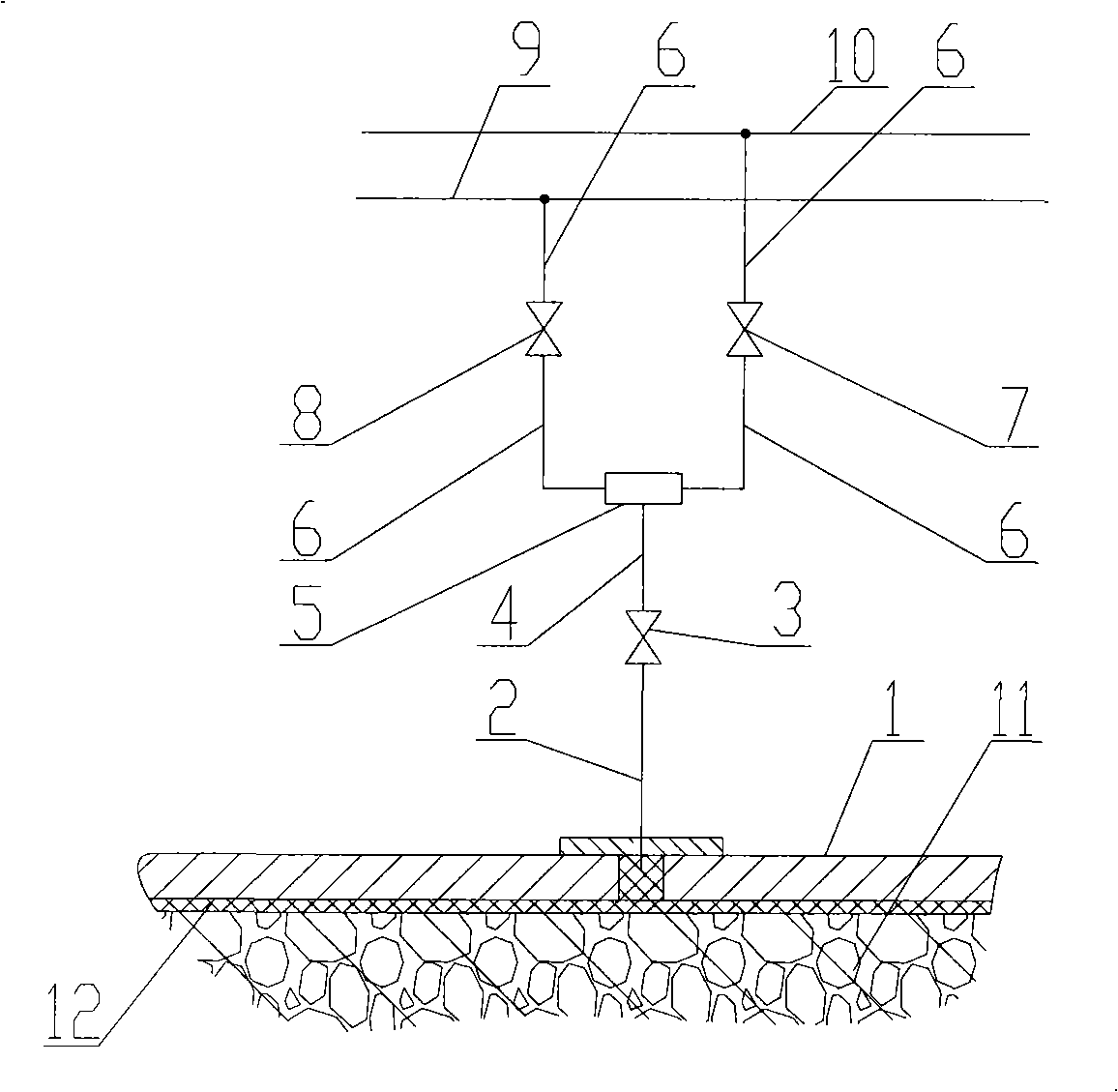

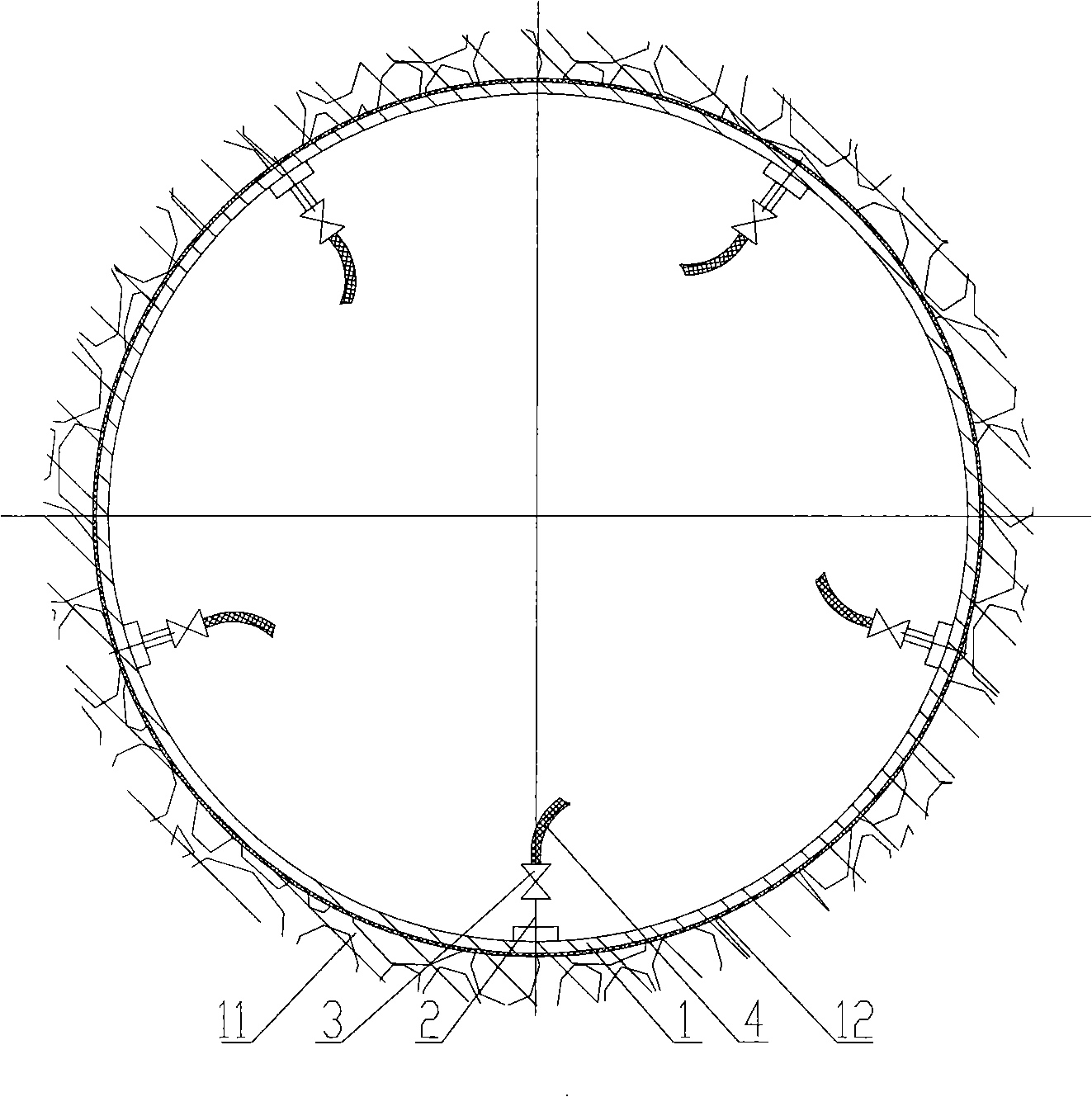

[0010] Referring to the accompanying drawings, the device for reducing the frictional resistance between the shield body of the shield machine and the wall of the excavated tunnel includes a shield body 1, a steel pipe 2, a valve 3, a lubricant pipeline 4, a distributor 5, a pipeline 6, a first Control valve 7, second control valve 8, foam system pipeline 9, bentonite mud system pipeline 10, tunnel wall 11, lubricant 12, one end of the valve 3 is connected with the steel pipe 2 welded on the inner side of the shield body 1 and connected with the excavation The tunnel wall 11 communicates, and the other end is connected with the lubricant pipeline 4, and the lubricant pipeline 4 passes through the distributor 5, the pipeline 6, the first control valve 7, the second control valve 8 and the foam system pipeline 9 of the shield machine 1. The bentonite mud system pipeline 10 is connected, the steel pipe 2 communicates with the excavated tunnel wall 11 through the hole of the shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com