Drip irrigation band for printing labyrinth flow-path and processing method

A technology of labyrinth flow channel and drip irrigation tape, which is applied in the direction of chemical instruments and methods, botanical equipment and methods, spraying devices, etc., can solve the problem of reducing the wall thickness and weight of drip irrigation tape, high production cost of drip irrigation tape, and farmers can't afford it, etc. problems, to avoid deformation and strength decline, easy quality control, and simple processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

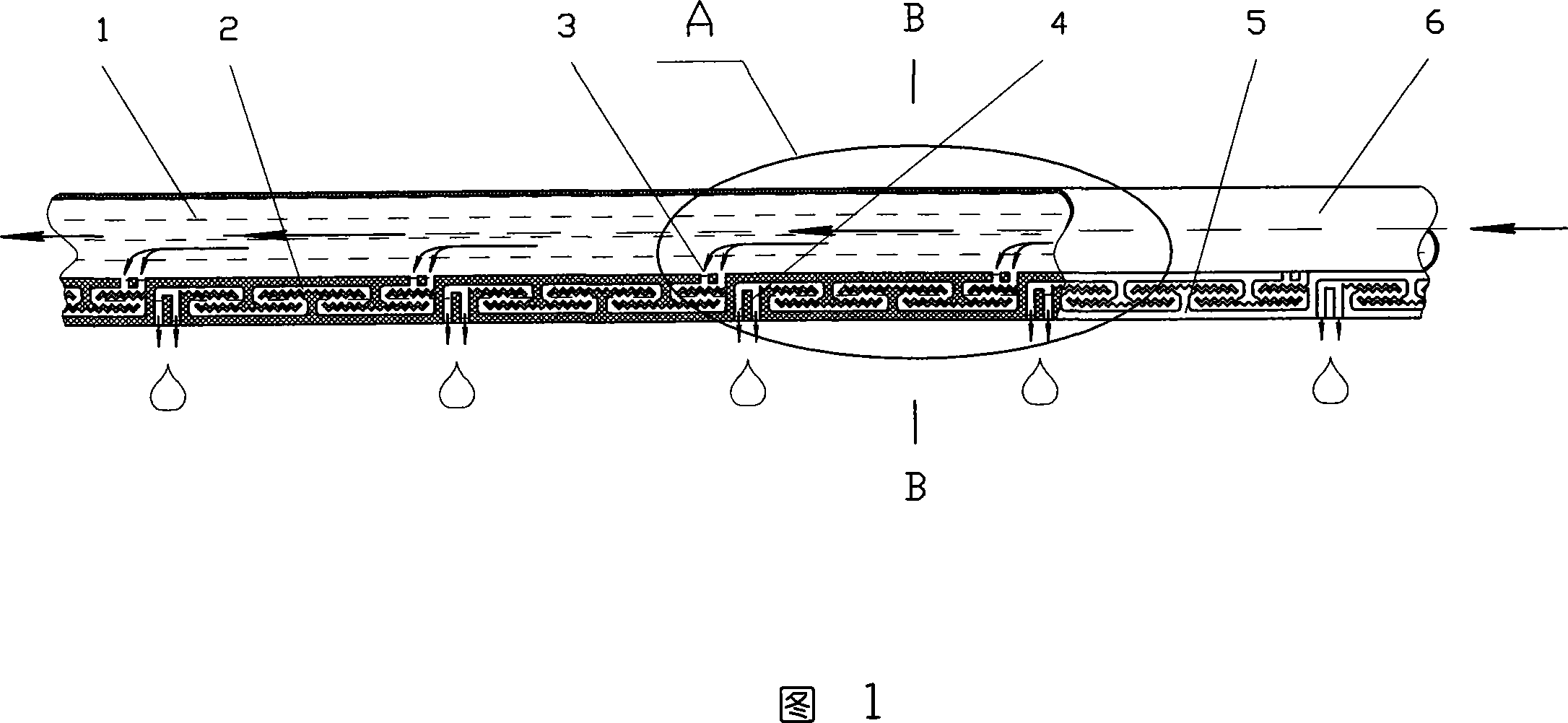

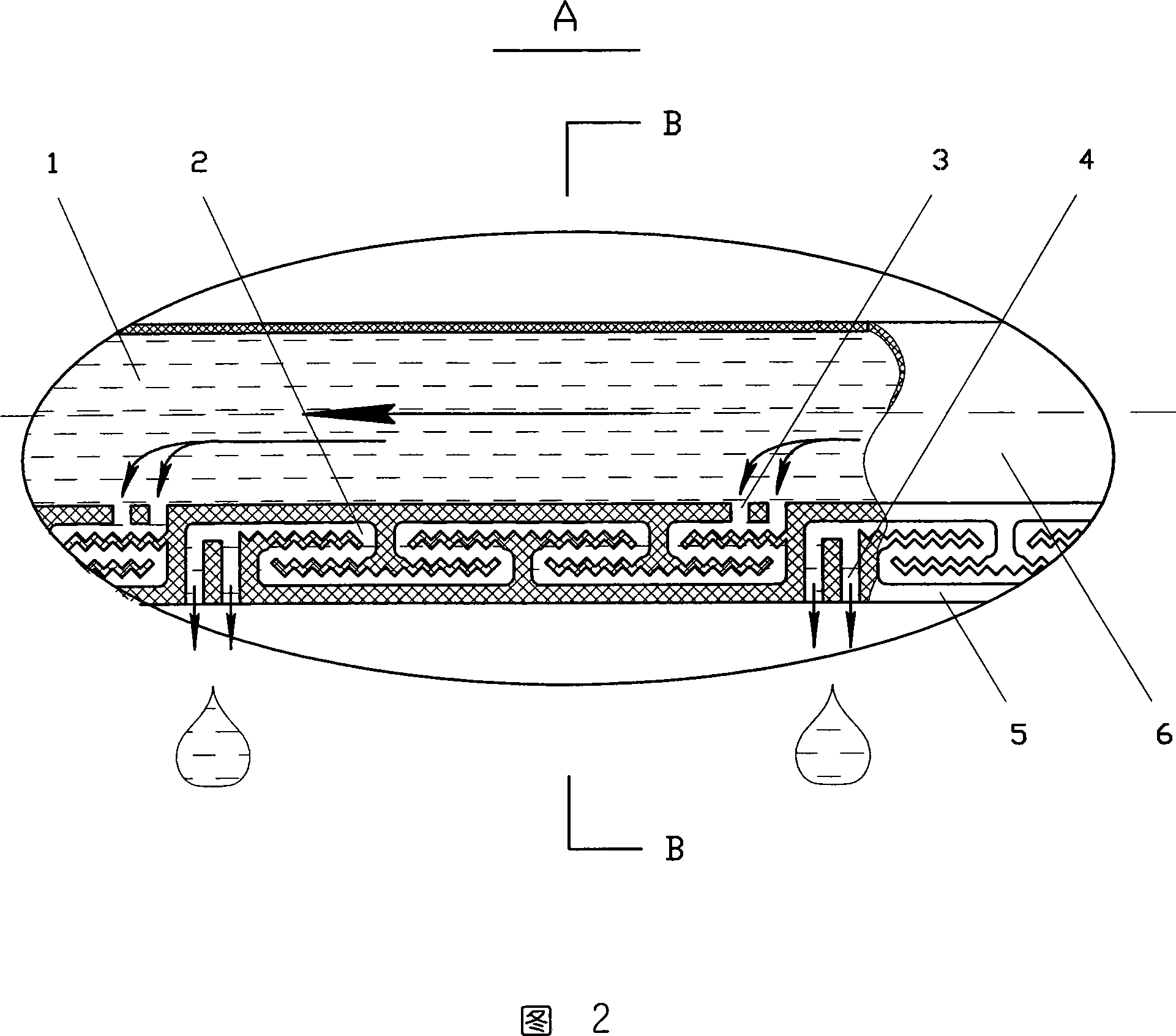

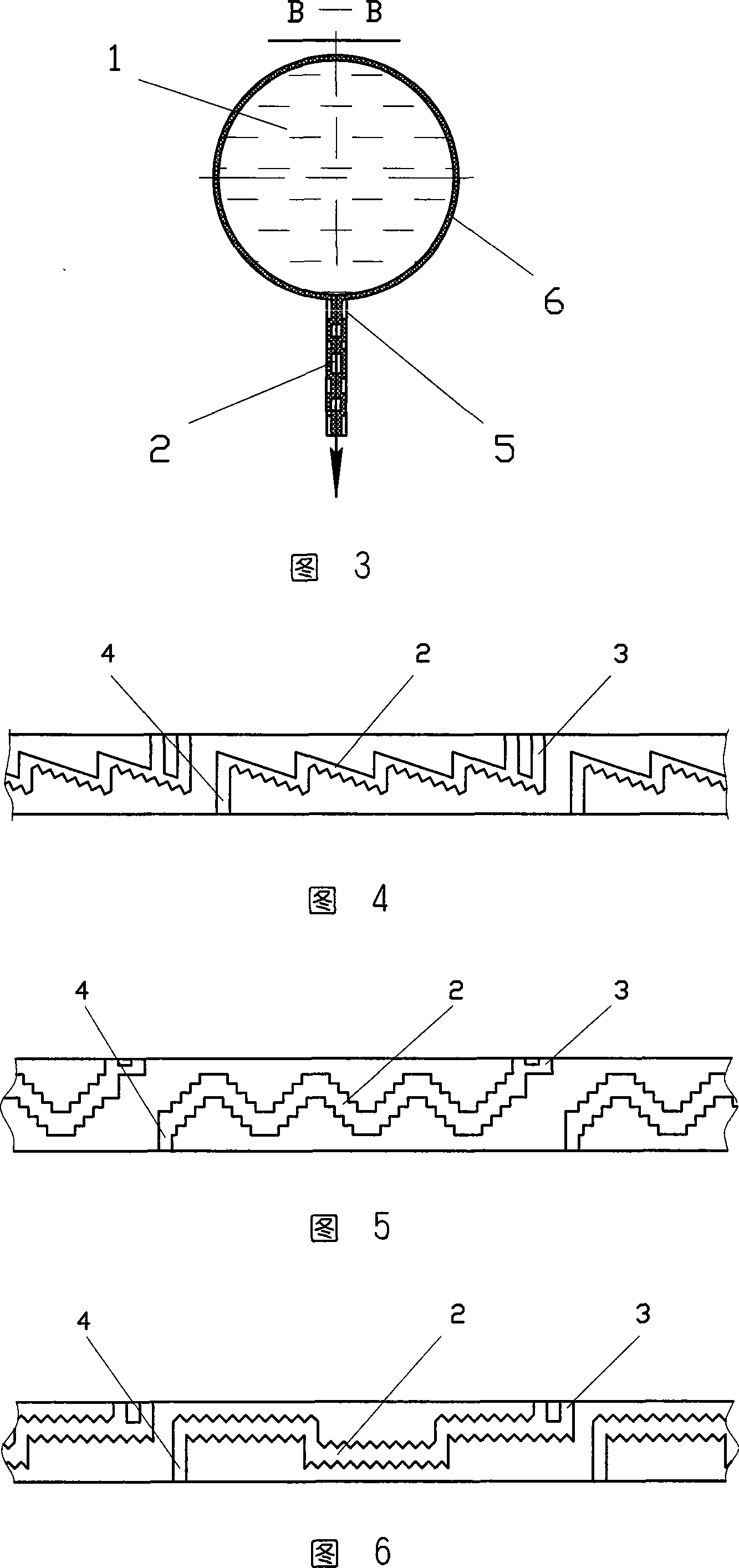

[0024] The structure schematic diagram of the printed labyrinth flow channel drip irrigation tape of the present invention shown in Fig. 1 after water filling, this drip irrigation tape has no concave-convex stretching surface before water filling, and is no different from the general light belt, and the labyrinth flow channel can be printed in theory Make any polyline shape.

[0025] As mentioned above, the main innovation point of the present invention is to solve the problem that the thin-walled drip irrigation belt is not easy to absorb and stretch and the cost of vacuum absorbing equipment is too high, and the blown film widely used in the packaging industry is used to print on the film. Composite and heat-sealable labyrinth flow channel 2, and then press the hot pressing edge 5 that has not been printed with the labyrinth flow channel through the hot pressing flat roller to form the labyrinth flow channel, and the manufacturing cost is much lower than the existing extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com