Patents

Literature

146results about How to "Simple processing equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

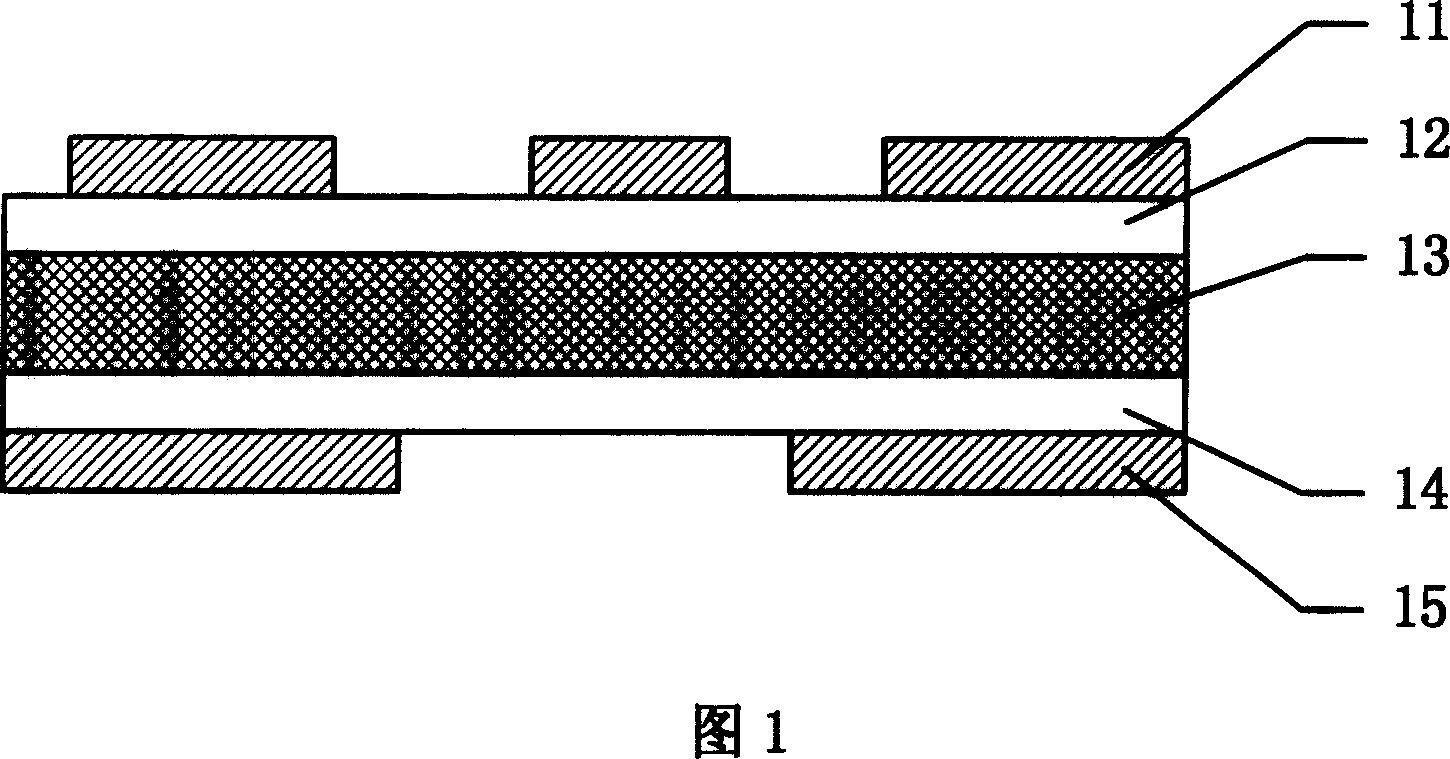

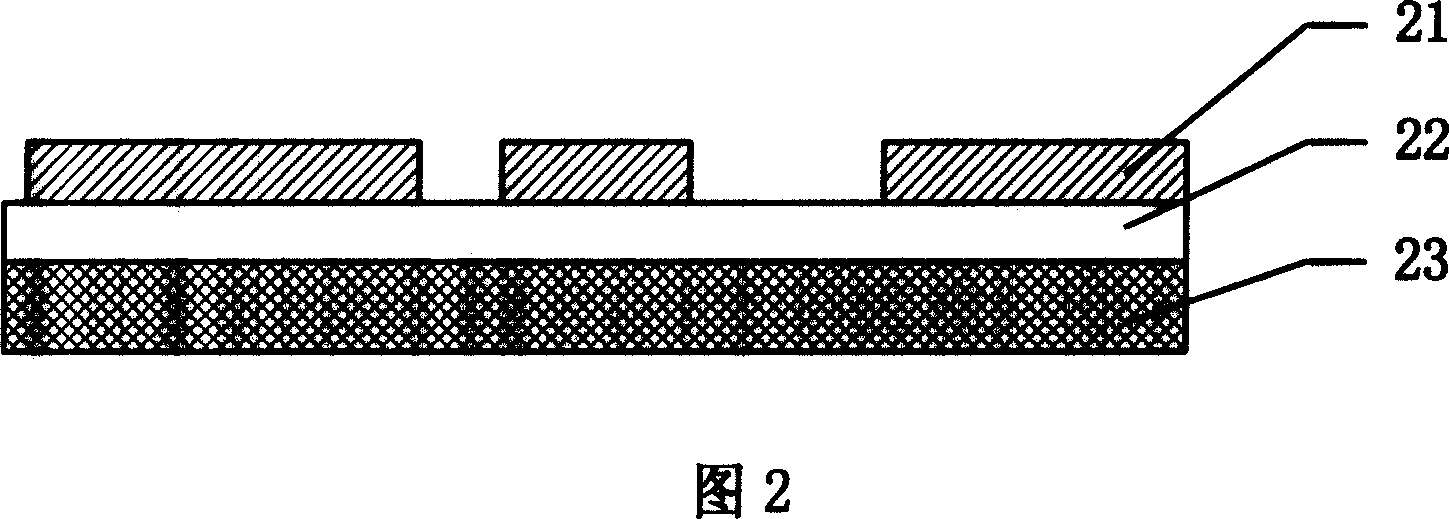

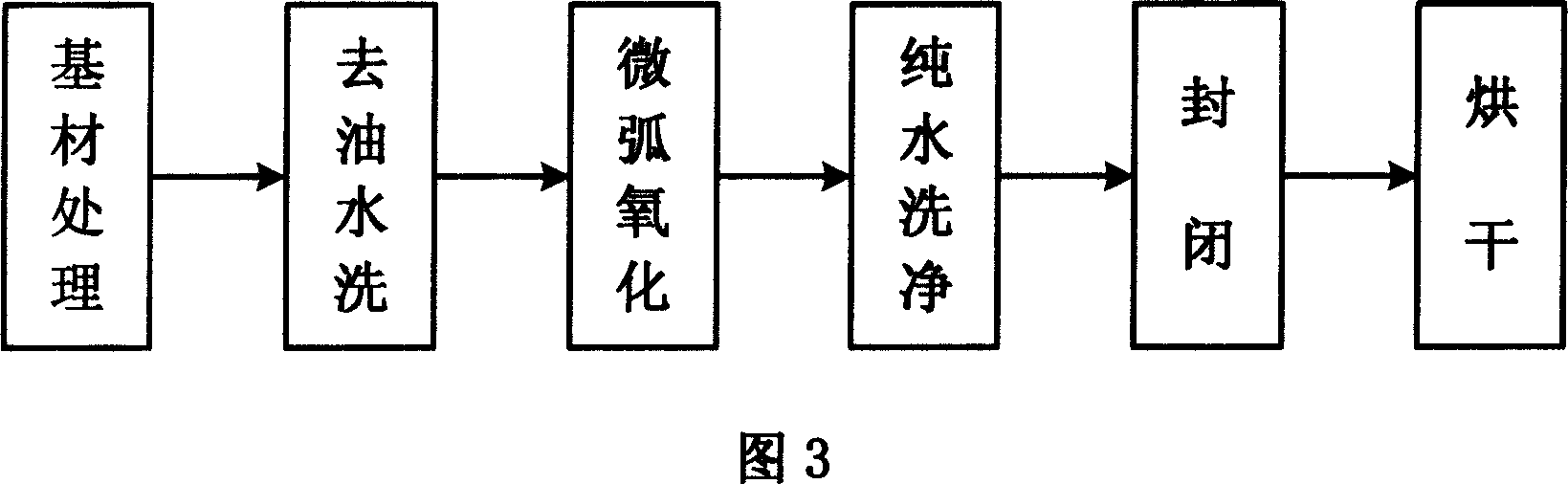

Aluminum-base printing circuit board and its production

InactiveCN101076224AReliable workmanshipSimple processing equipmentPrinted circuit manufactureCircuit susbtrate materialsInsulation resistanceMicro arc oxidation

The bottom layer of invention uses aluminium baseboard; the intermediate layer is a heat conduction insulation layer; the surface layer is an electric conduction layer. It features the following: the heat insulation layer is a ceramic-like thin film layer with 10-400 micron thick and >=100Momega insulation resistance, which chemical composition is aluminium oxide. The preparation method comprises: making pretreatment, de-oiling and washing for the surface of the aluminium baseboard using mechanical method or chemical method to form a clean workpiece plane; using the microarc oxide treatment and the microplasma surface ceramic method to make a heat conduction insulation layer on the workpiece surface; finally, overlapping an electric conduction layer on the heat conduction insulation layer; etching circuit pattern.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

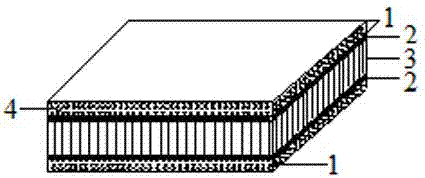

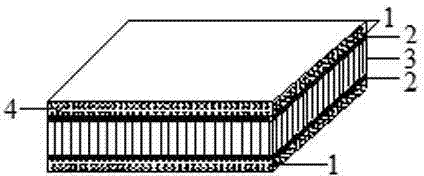

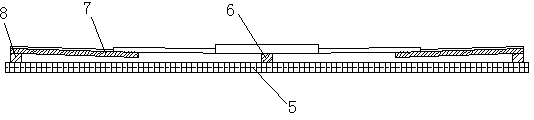

Honeycomb-structure sheet material having fiber-reinforced thermoplastic skin and preparation method thereof

ActiveCN102476475AImprove bindingOvercoming Disadvantages of DisengagementSynthetic resin layered productsLaminationUltimate tensile strengthThermoplastic composites

The invention discloses a honeycomb-structure sheet material having a fiber-reinforced thermoplastic skin, characterized in that the honeycomb-structure sheet material comprises fiber-reinforced thermoplastic skins, a film, and a thermoplastic honeycomb core, wherein the thermoplastic honeycomb core is arranged between two fiber-reinforced thermoplastic skins and is bonded with the skins though the film. According to the invention, by using bidirectional continuous fibers to reinforce the thermoplastic composite material skins, the advantages of high strength and good toughness are achieved; simultaneously, by using the film to bond, the amount of glues is easy to control, and the phenomenon that liquid enters in honeycomb holes when using liquid glues to bond is not easy to happen; and by using a hot-press roller secondary forming method, the advantages of simple processing devices, easy control of product quality, high production efficiency, easy realization, and convenient popularization are achieved.

Owner:LIAONING LIAOJIE SCI & TECH

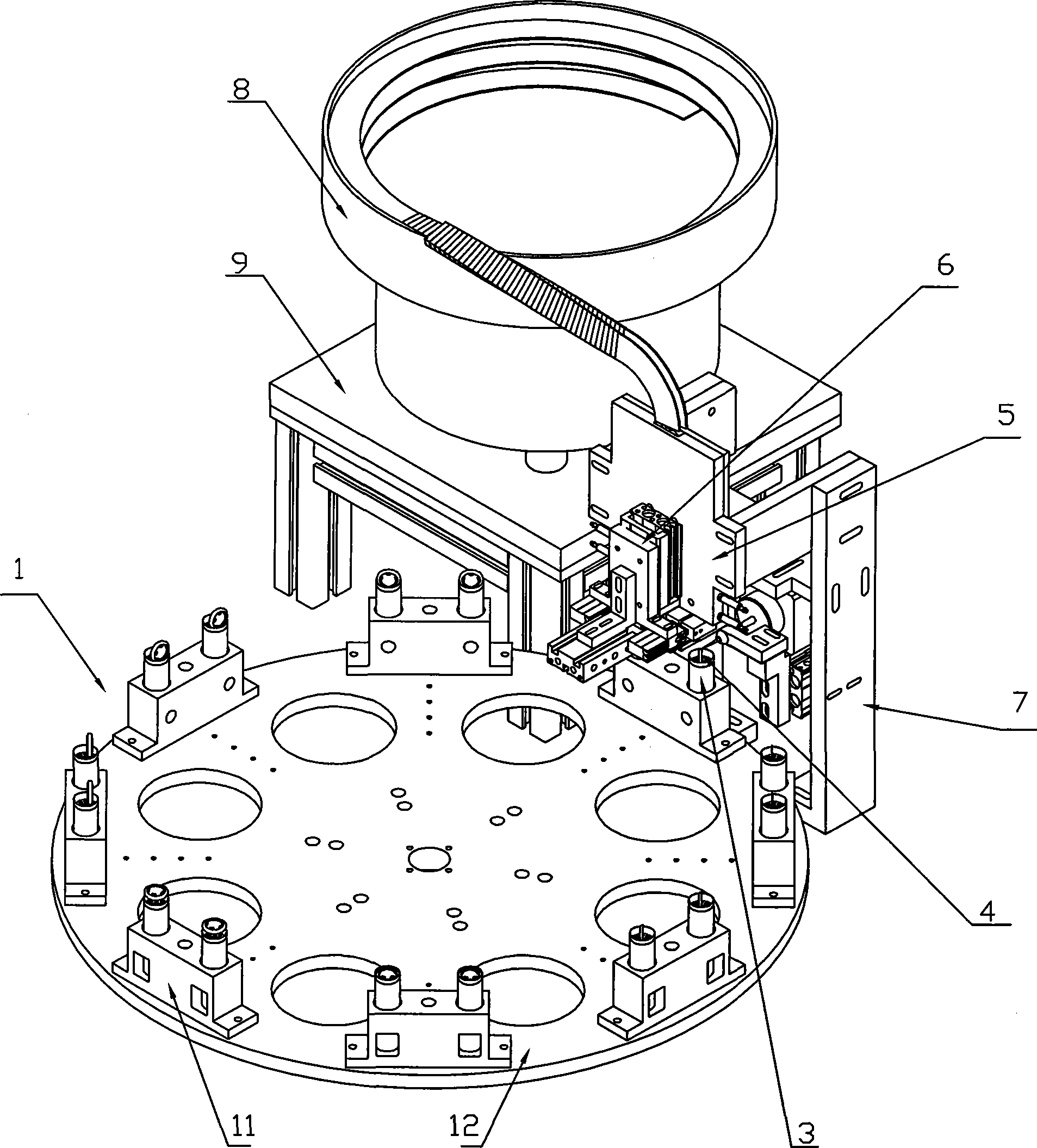

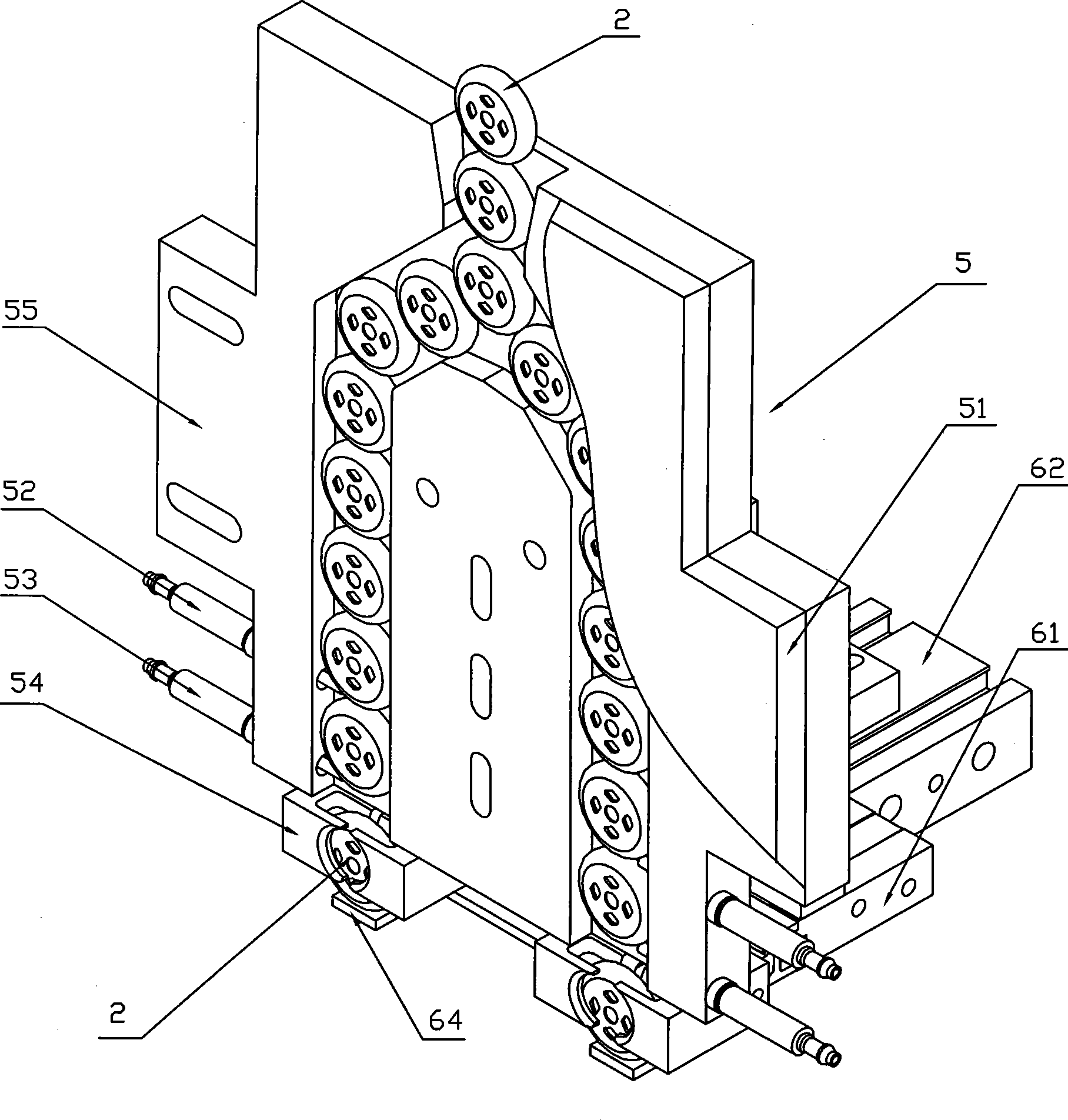

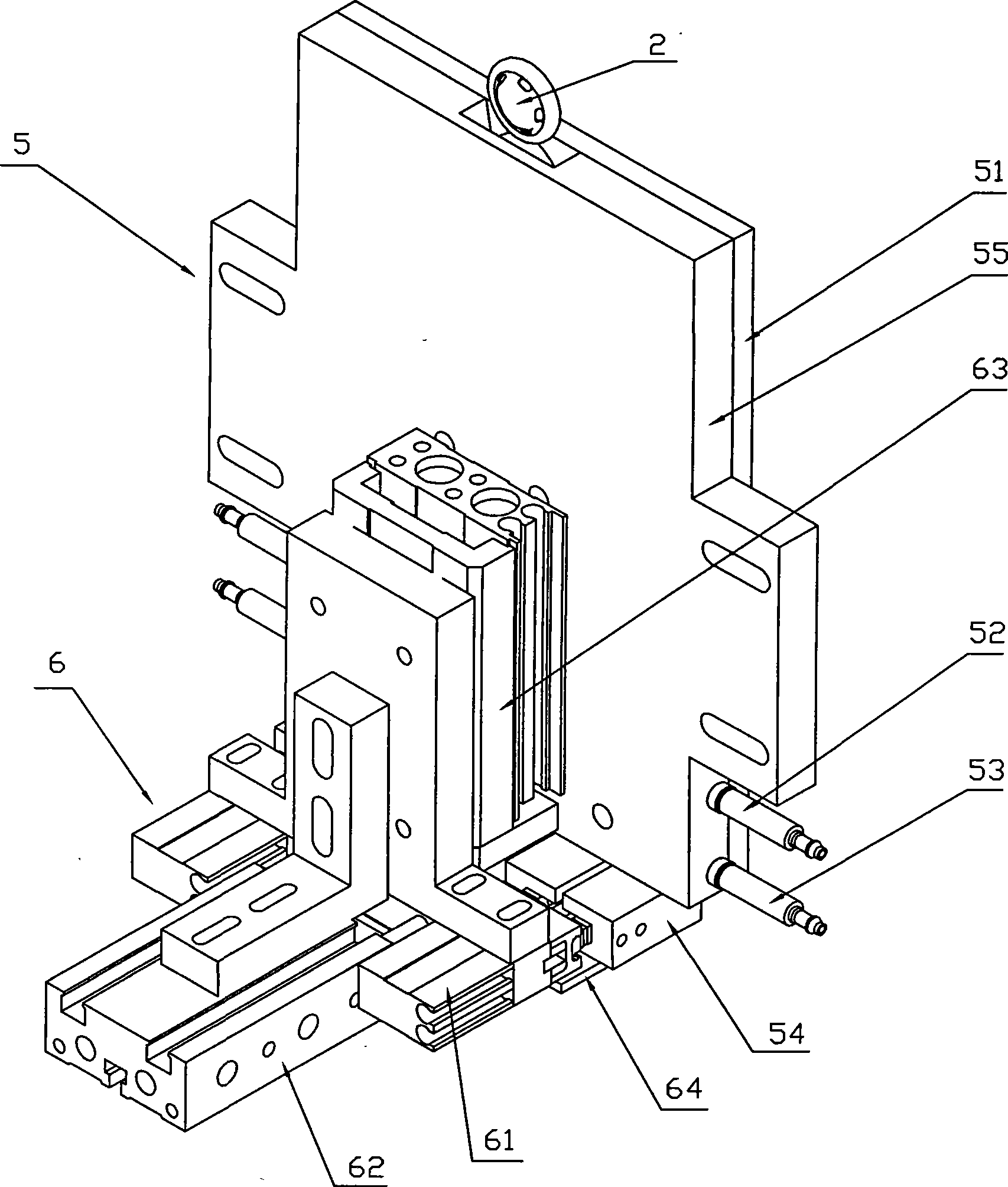

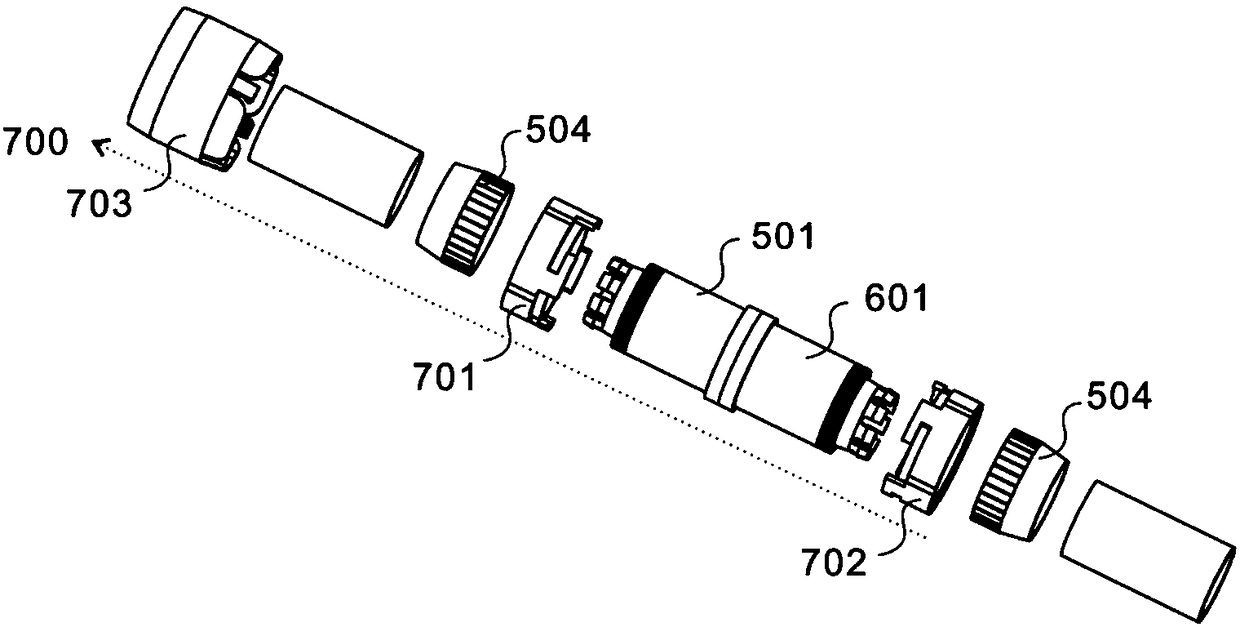

Spot welding device for battery cap and tab

ActiveCN101434008ASimple structureCompact structureWelding/soldering/cutting articlesMetal working apparatusControl systemSpot welding

The invention relates to a cell cover and polar ear spot welding device, which comprises a cell feeding mechanism which can send cells to be processed into spot welding stations, a cover guiding mechanism which can lead in covers and automatically and progressively arrange the covers in order, a cover feeding mechanism which accommodates the covers sent by the cover guiding mechanism and sends the covers into the spot welding stations, a laser spot welding mechanism which welds the cell covers and cell polar ears sent into the welding stations, and a control system which can control the motion of various mechanisms, wherein the cover feeding mechanism and the cover guiding mechanism are in matched connection and arranged above the cell feeding mechanism, so that the covers contact upper polar ears of the cells; the laser spot welding mechanism is positioned aside the cell feeding mechanism; and a laser emitting center of the laser spot welding mechanism is in the same line with the contact points of the covers and the upper polar ears of the cells. The invention provides a laser spot welding processing apparatus which can automatically send the cylindrical cells and the covers into the welding stations and perform spot welding connection on the upper polar ears of the cells and the covers.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

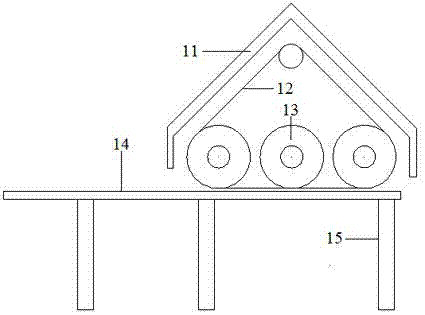

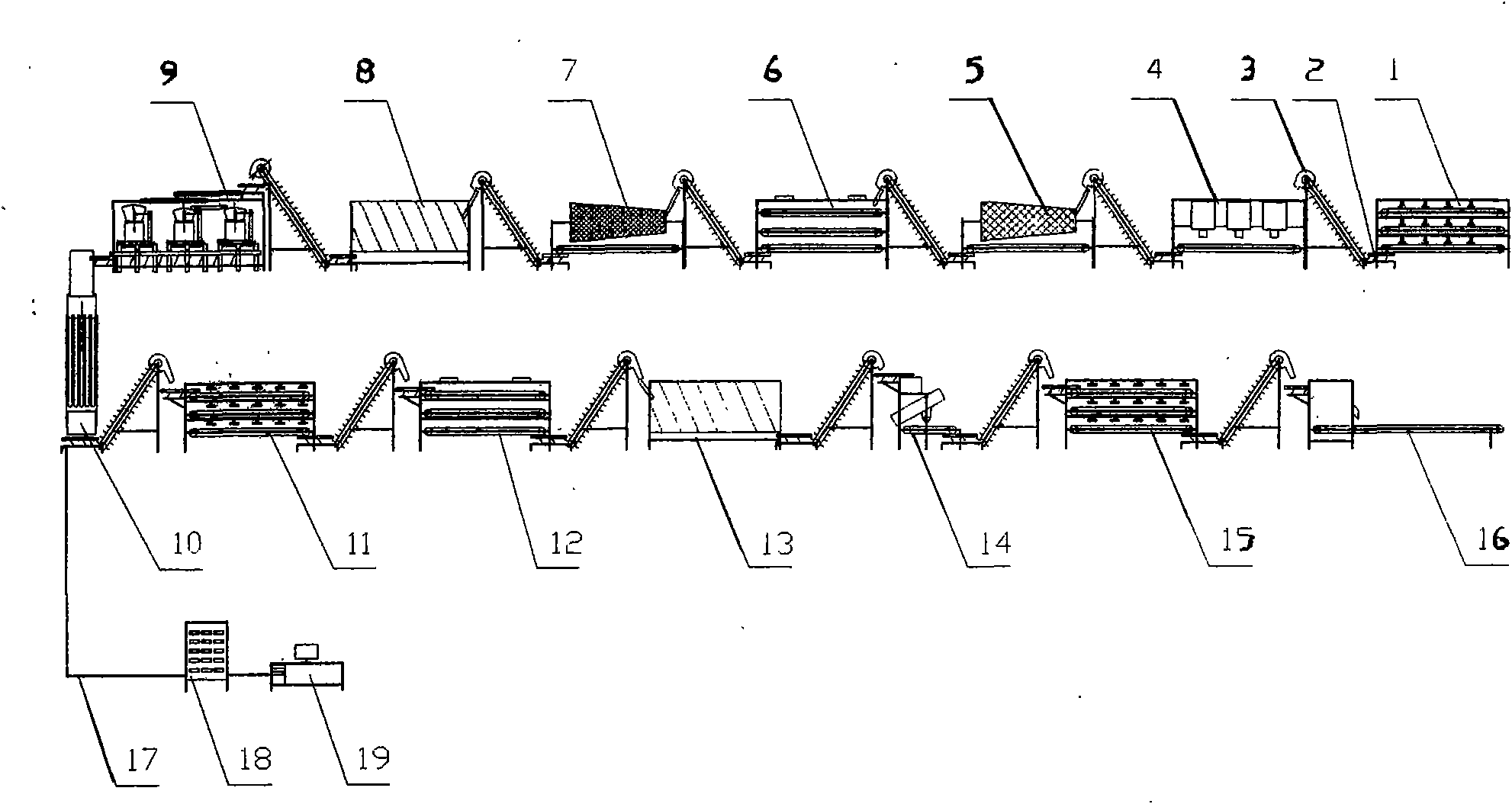

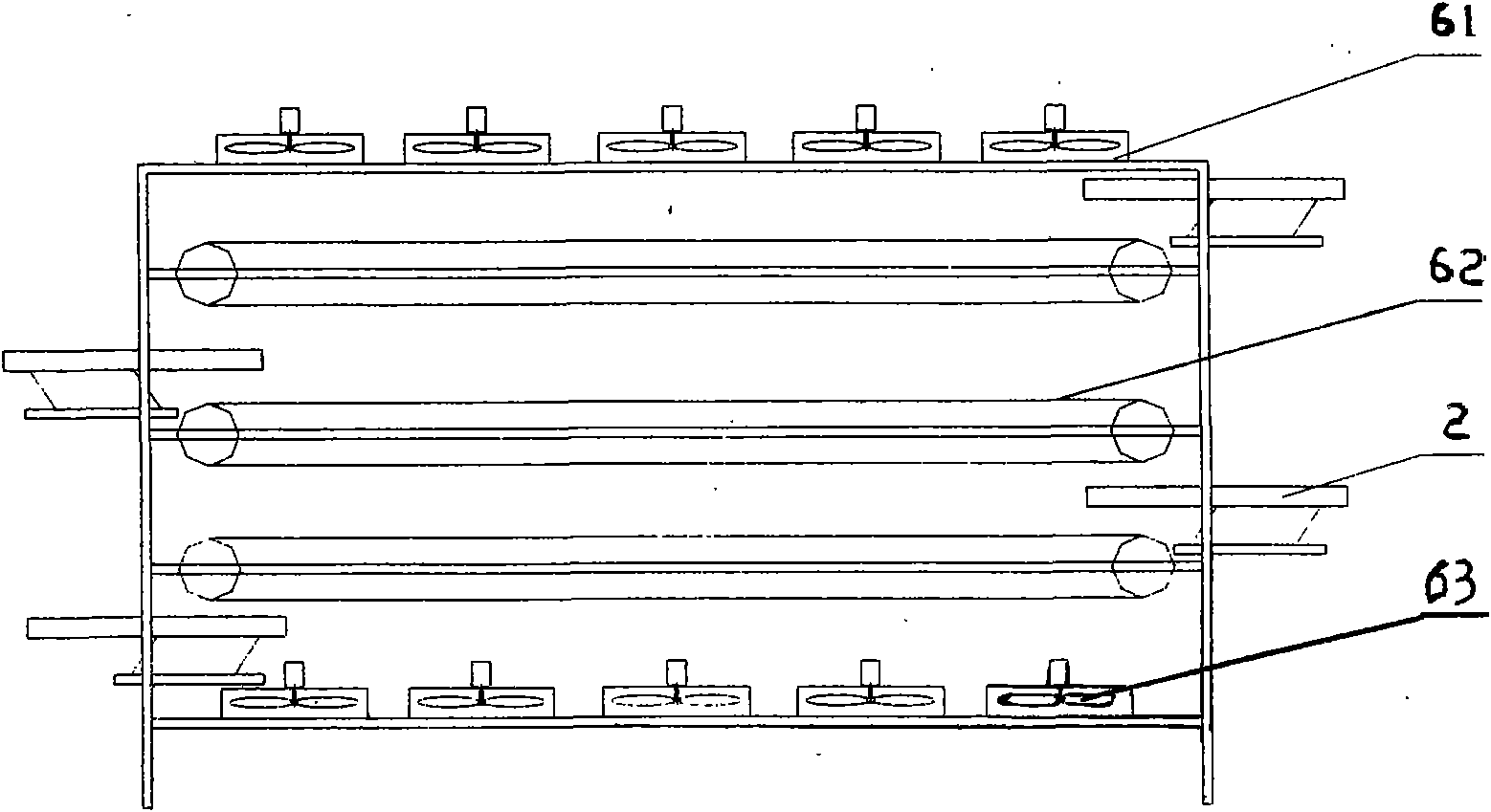

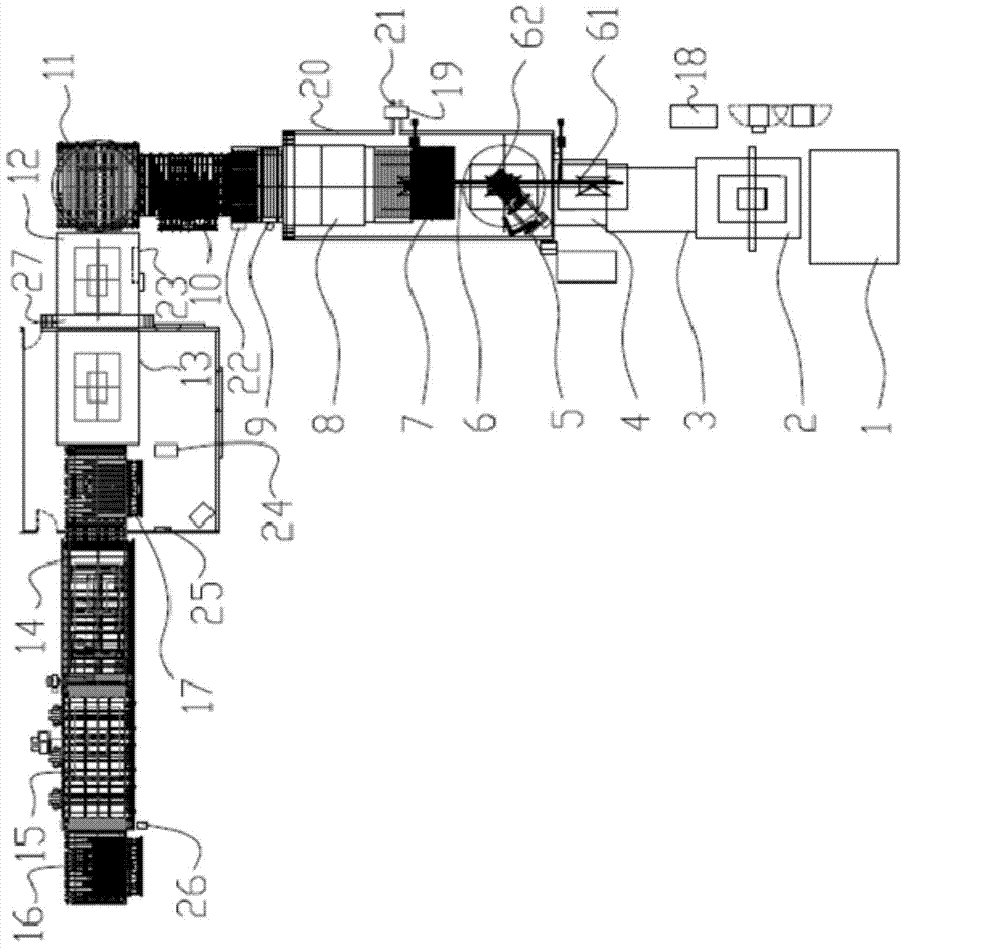

Tea mechanization and clean production line

InactiveCN101953405ASimple processing equipmentAvoid secondary pollutionPre-extraction tea treatmentMicrocomputerElectric machinery

The invention relates to a tea mechanization and clean production line, which belongs to the technical field of tea processing equipment. The invention provides a tea production line which is mechanized, standardized, automated, serialized, clean and dimensions scaled. The production line comprises various process devices which are composed of a cleaning machine, a dehydrater, a grader, a green-unfolding machine, a green-shaking machine, a rotary-drum removing green machine, a knead entwist machine, a multislot pot type continuous strip-managing machine, a low temperature far infared baker, a WXTL, a treating pot machine, a tea color sorter a high temperature far infared baker and a tea package mechanism, a material conveying mechanism composed of an elevator and a conveyor and a control mechanism composed of a microcomputer and a central control cabinet; the adjacent process devices are respectively connected by the conveyor and the elevator; electrical machines of the various process devices and the electrical machine of the material conveying mechanism both are variable frequency motors which are controlled by the control mechanism.

Owner:ANHUI AGRICULTURAL UNIVERSITY +1

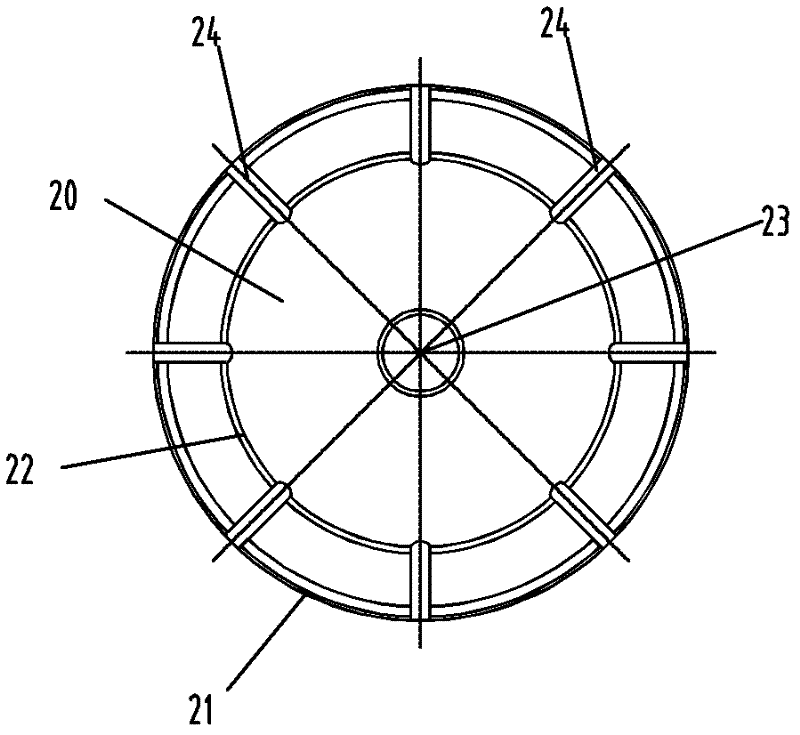

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

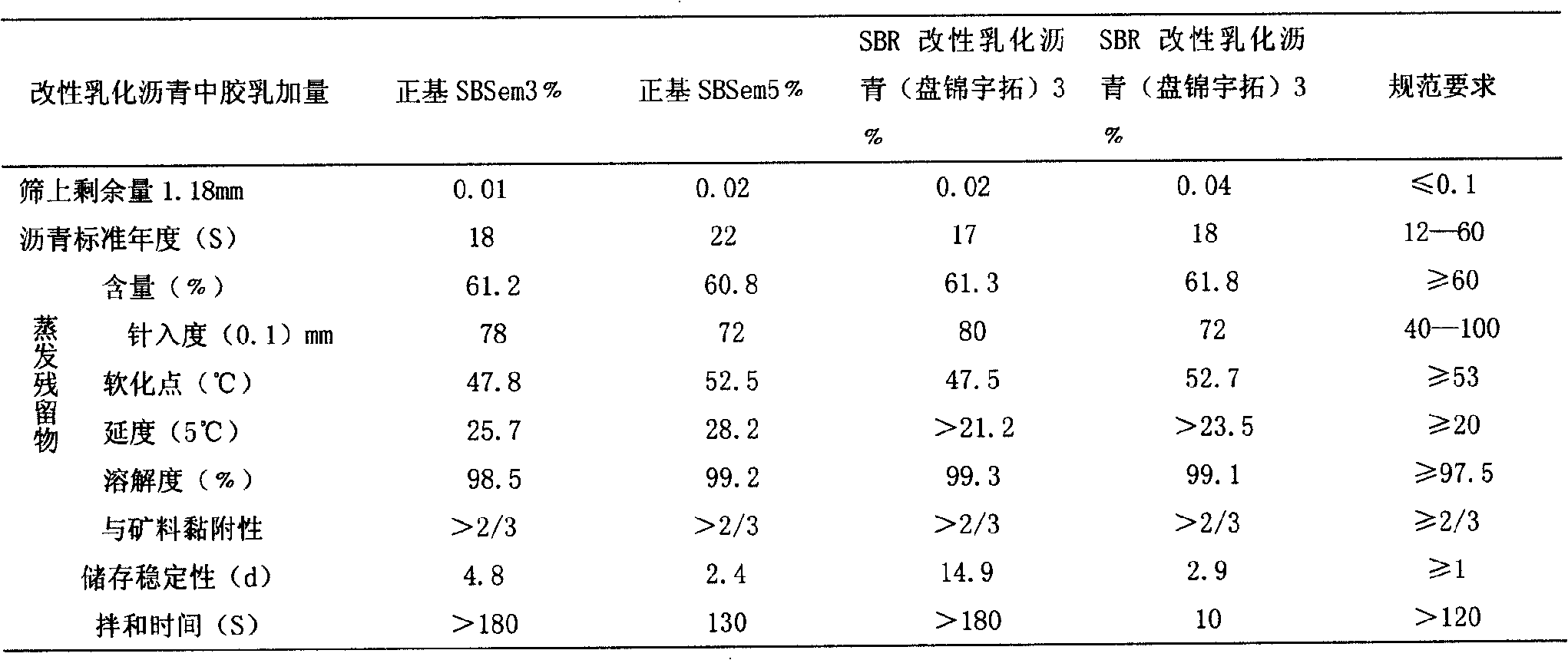

Thermoplastic butadiene styrene rubber aqueous rubber latex asphalt modifying agent and preparation thereof

InactiveCN101348598ASuperiorSimple production processBuilding insulationsThermoplasticPolymer science

The invention relates to a thermoplastic styrene-butadiene rubber water latex asphalt modifier and a preparation method thereof, belonging to the chemical engineering field. The modifier is made from the following raw materials in weight percentage: 10 to 70 percent of rubber, 0.1 to 30 percent of surfactant, 20 to 80 percent of water, 0.1 to 20 percent of natural polysaccharide polymer matter and 0.1 to 10 percent of electrolyte. The preparation method has the advantages of simplifying the production process of thermoplastic styrene-butadiene rubber SBS modified asphalt, saving equipment investment and simultaneously avoiding the material ageing phenomena caused when the thermoplastic styrene-butadiene rubber SBS modified asphalt is processed at a high temperature. Modified asphalt obtained by use of the modifier is stable in performance and difficult to segregate. The modifier can also be used in other aspects of the thermoplastic styrene-butadiene rubber SBS modified asphalt or modified emulsified asphalt.

Owner:JILIN ZHENGJI TECH DEV

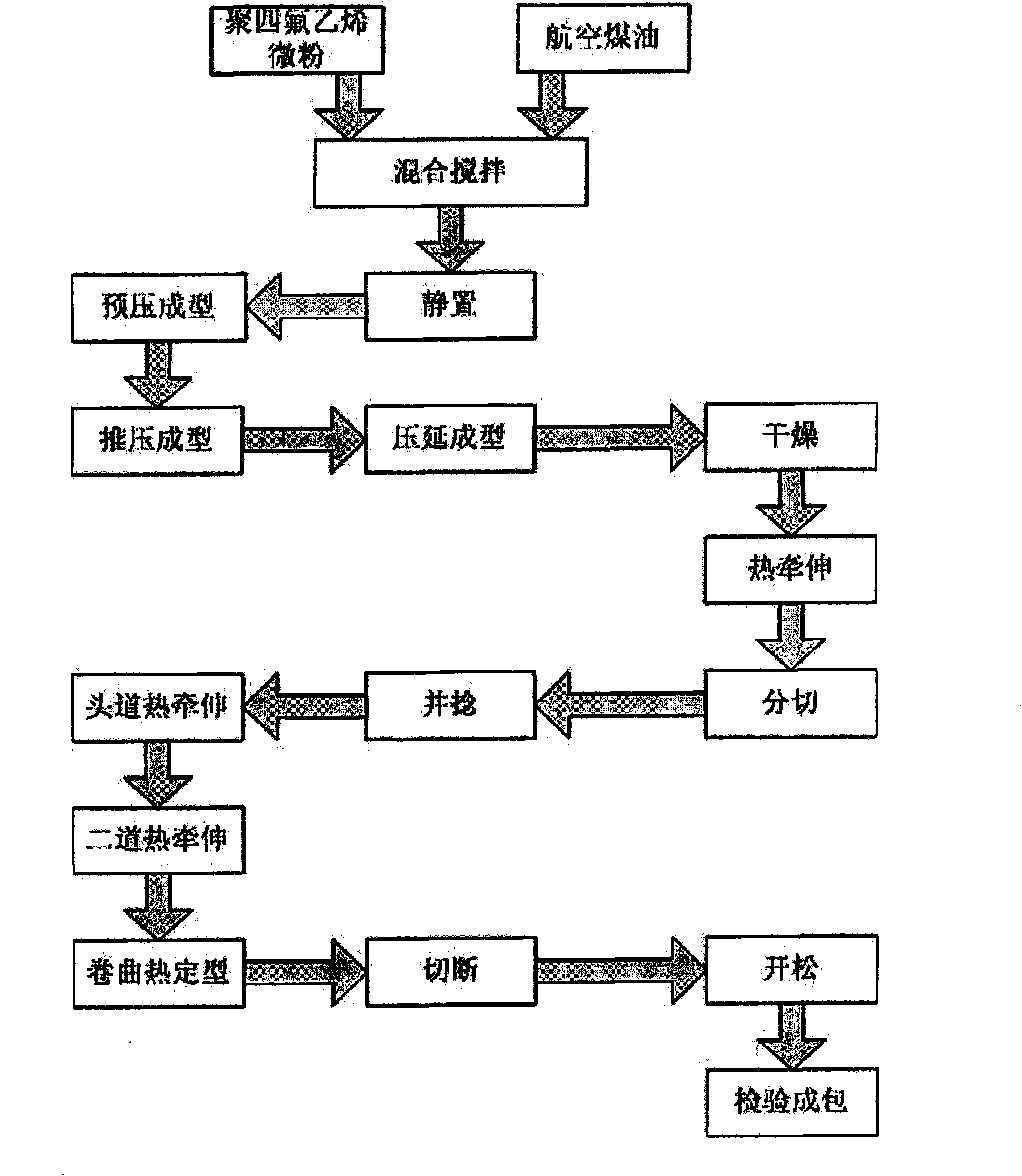

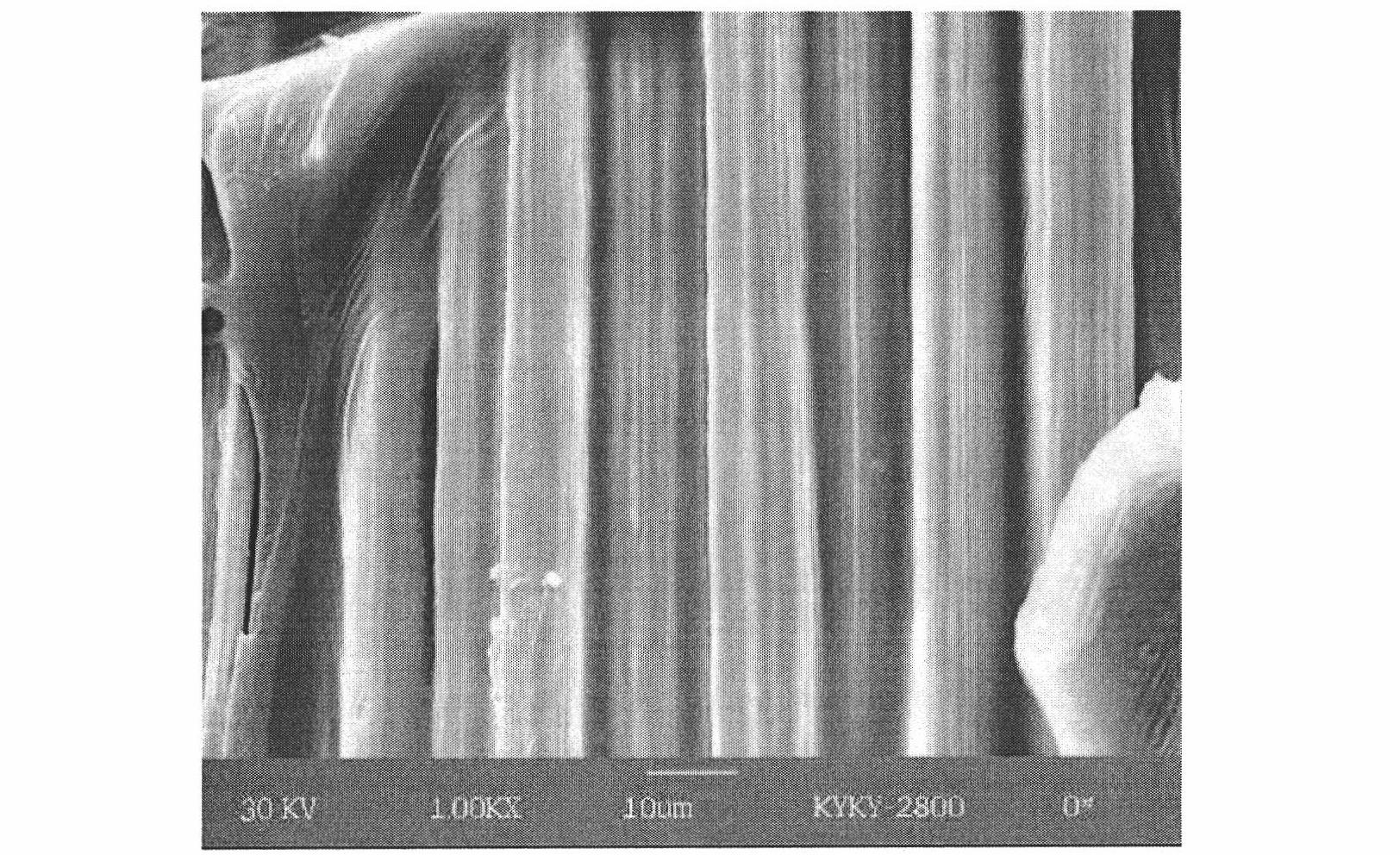

Preparation method of polytetrafluoroethylene chopped fiber

InactiveCN102071483ASimple processing equipmentEasy to operateFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentFiberPre compression

The invention aims to provide polytetrafluoroethylene chopped fiber with high intensity, high uniformity and low production cost and preparation technology thereof. A process flow comprises the following steps of: mixing polytetrafluoroethylene micro powder and a lubricating agent; stirring; standing; performing pre-compression molding; performing push molding; performing rolling molding; drying; performing hot stretching; parting off; twisting; performing primary hot drawing; performing secondary hot drawing; curling and thermally forming; cutting off; loosening; and inspecting and packaging so as to obtain high-intensity polytetrafluoroethylene chopped fiber. In a manufacturing process, the temperature rises gradually from the primary hot stretching to the secondary hot stretching to the curling and thermally forming.

Owner:宋朋泽

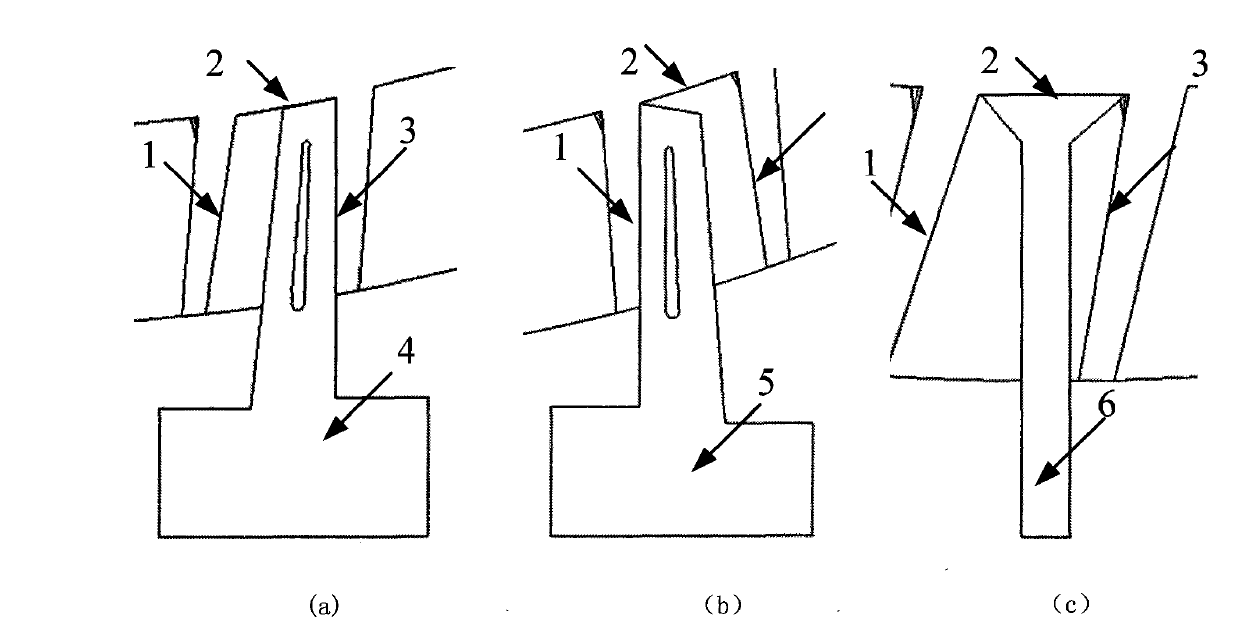

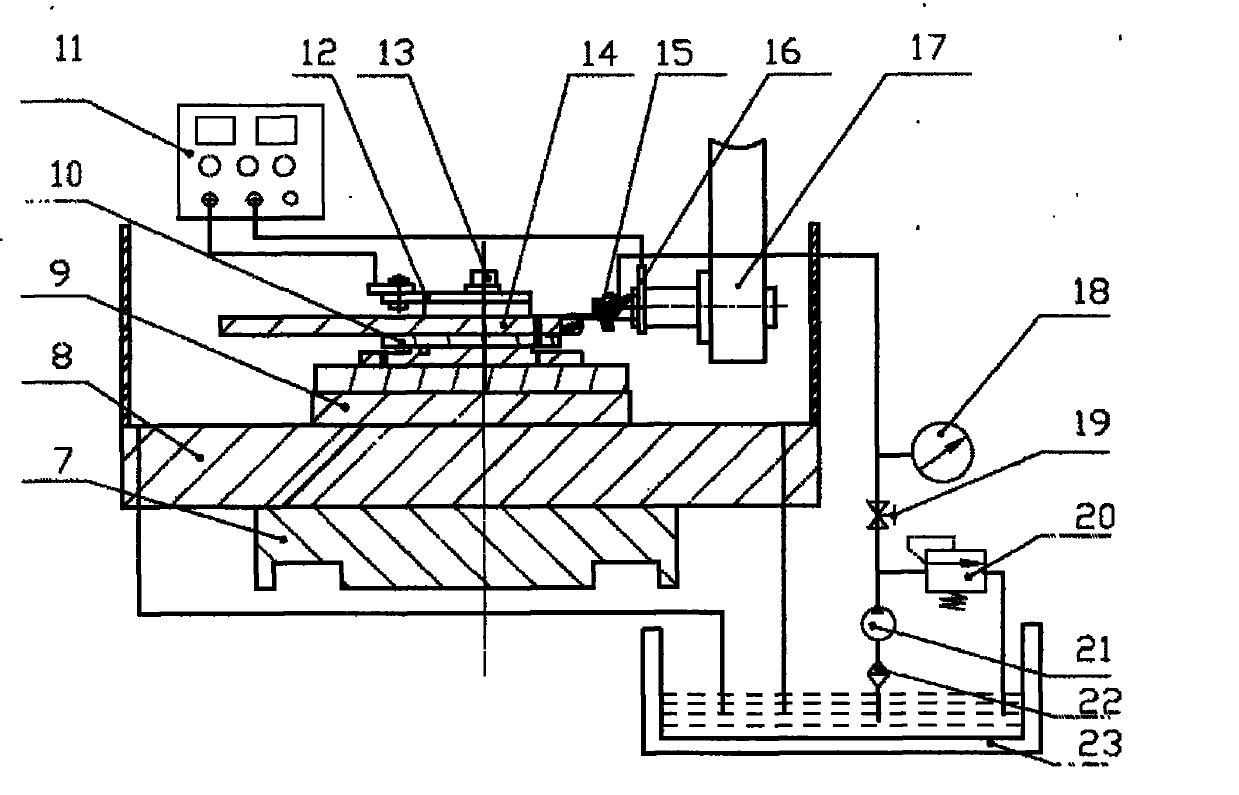

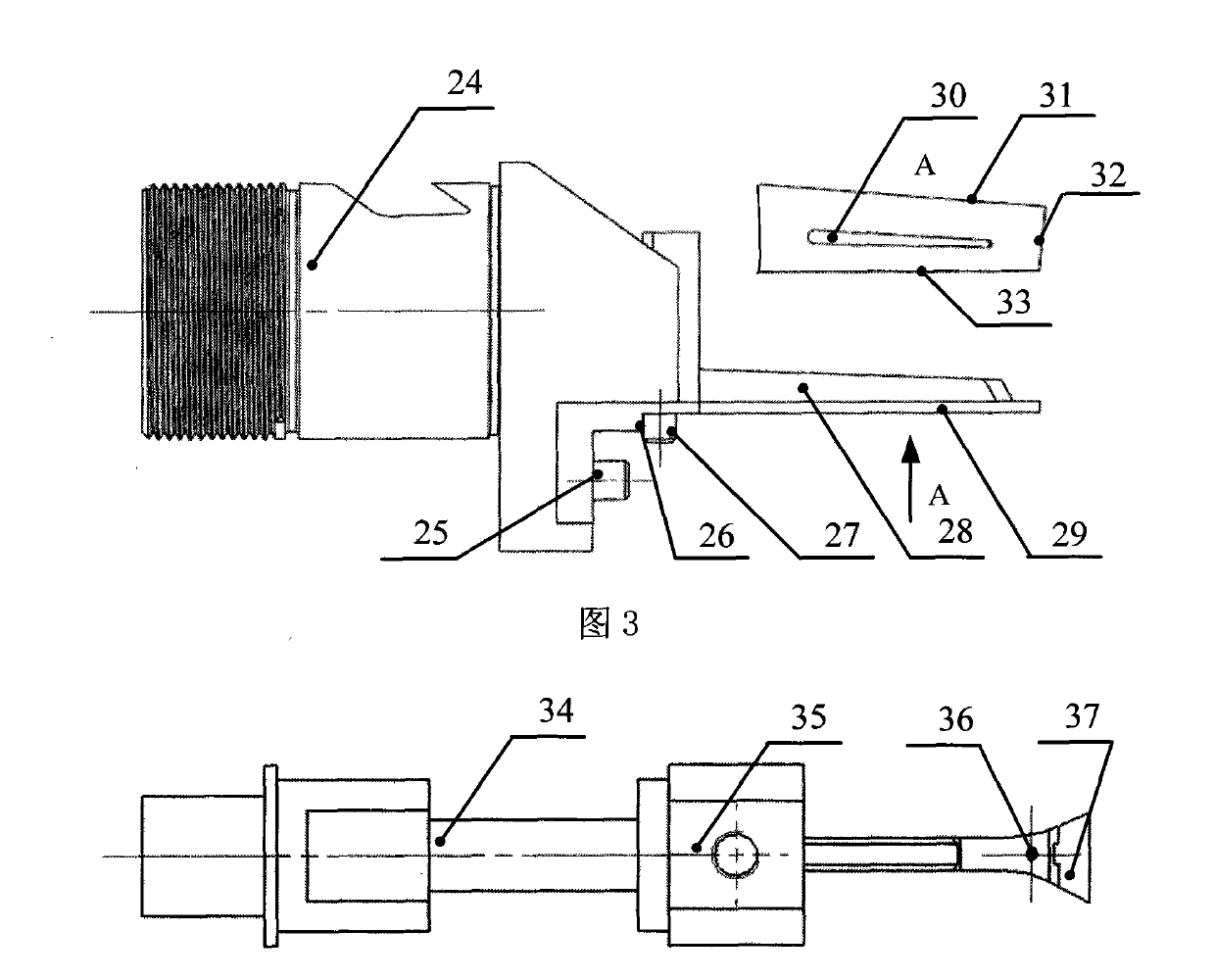

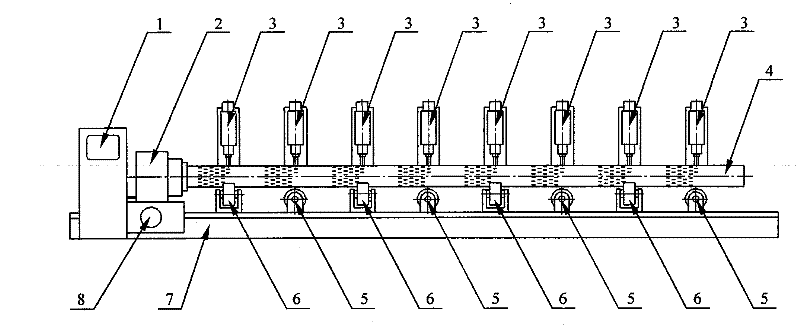

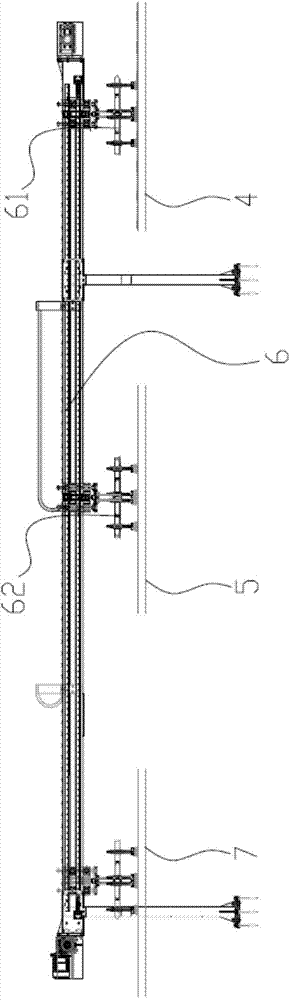

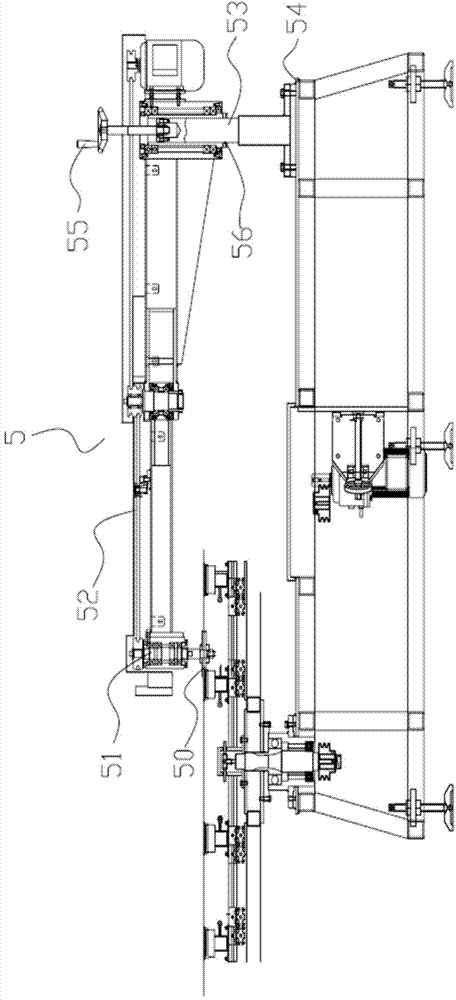

Plasma machining production line of dual-trapezoid slotted sieve tube

The invention relates to a plasma machining production line of a dual-trapezoid slotted sieve tube, belonging to the field of machining. The production line comprises a main control table, a digital control rotary work table, a plasma machining machine tool, an axial feed driving device, a radial rotary supporting device, an axial guiding and transmission device and a tool body. When processing is performed, the main control table is used for controlling the machining and moving states of the plasma machine tool, the digital control rotary work table, the axial feed driving device, the axial guiding and transmission device and the radial rotary supporting device, the plasma machining machine tool is used for machining slots of the dual-trapezoid slotted sieve tube, the digital control rotary work table drives the slotted sieve tube to perform a rotary indexing movement; when a circle of slots are completely machined, the axial feed driving device drives the slotted sieve tube to move to a designated position axially, the next circle of slots are machined, and the steps are repeated to machine a whole slotted sieve tube. In the invention, modification of a slotted surface material can be realized in the machining process, and the phenomenon of 'match head' does not exist at two ends of the machined slot.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for utilizing and disposing micro-electrolyzed waste residue of organic waste water and method for immobilizing arsenic and heavy metal in soil

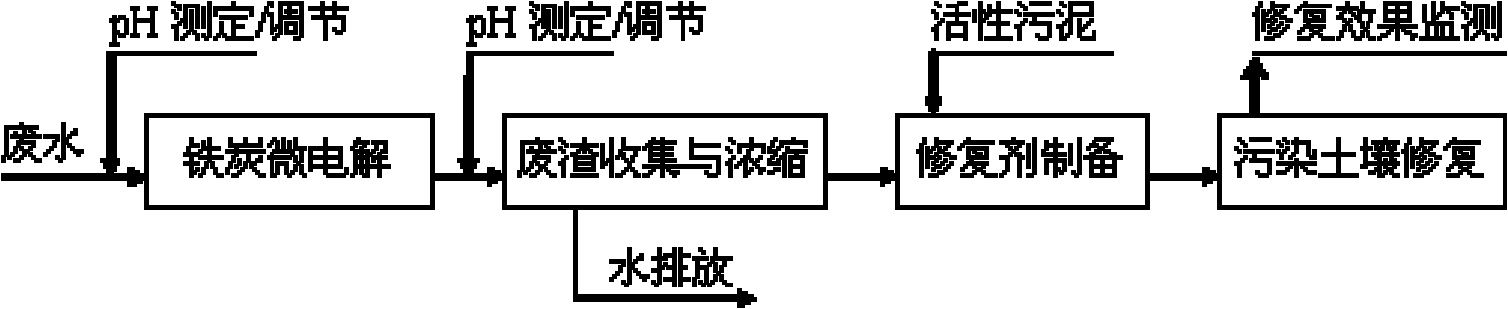

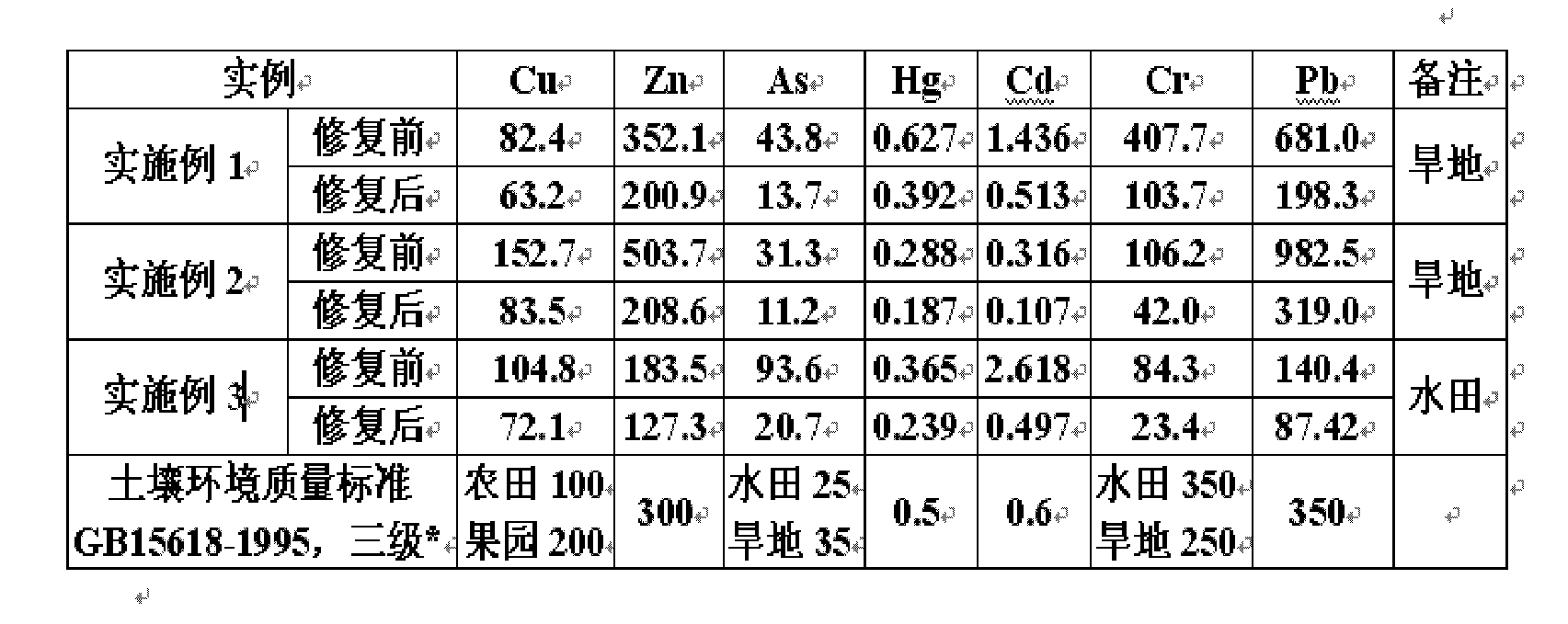

InactiveCN101791624AEfficient disposalEnhance agricultural securityContaminated soil reclamationWater/sewage treatmentActivated sludgeElectrolysis

The invention relates to a method for utilizing and disposing micro-electrolyzed waste residue of organic waste water, a method for immobilizing arsenic and heavy metal in soil and a method for utilizing and disposing micro-electrolyzed waste residue and activated sludge of organic waste water. The invention is characterized in that iron carbon is used as main filler for the micro electrolysis of the organic waste water, the waste residue (solids) produced after the micro electrolysis of the iron carbon is collected, concentrated and mixed with the activated sludge, inorganic / organic mixed restoration agent is prepared after 10-50 days of composting treatment are conducted, the weight of the iron in the restoration agent accounts for (0.5-20) percent of the total weight of the solids, finally deep tillage is conducted to restore the pollution soil after the restoration agent is evenly dispersed in soil, and the weight ratio of the restoration agent to the polluted soil is (0.1-5.0):100.

Owner:CENT SOUTH UNIV

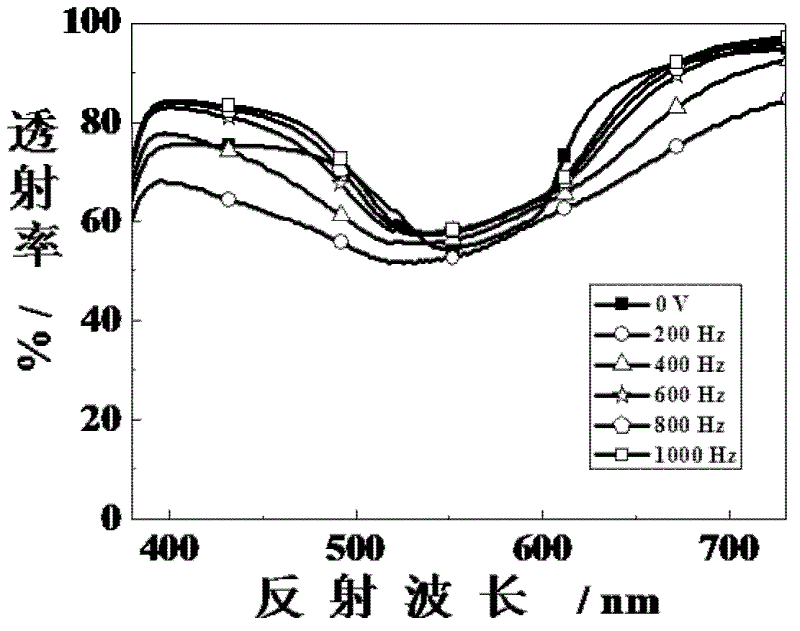

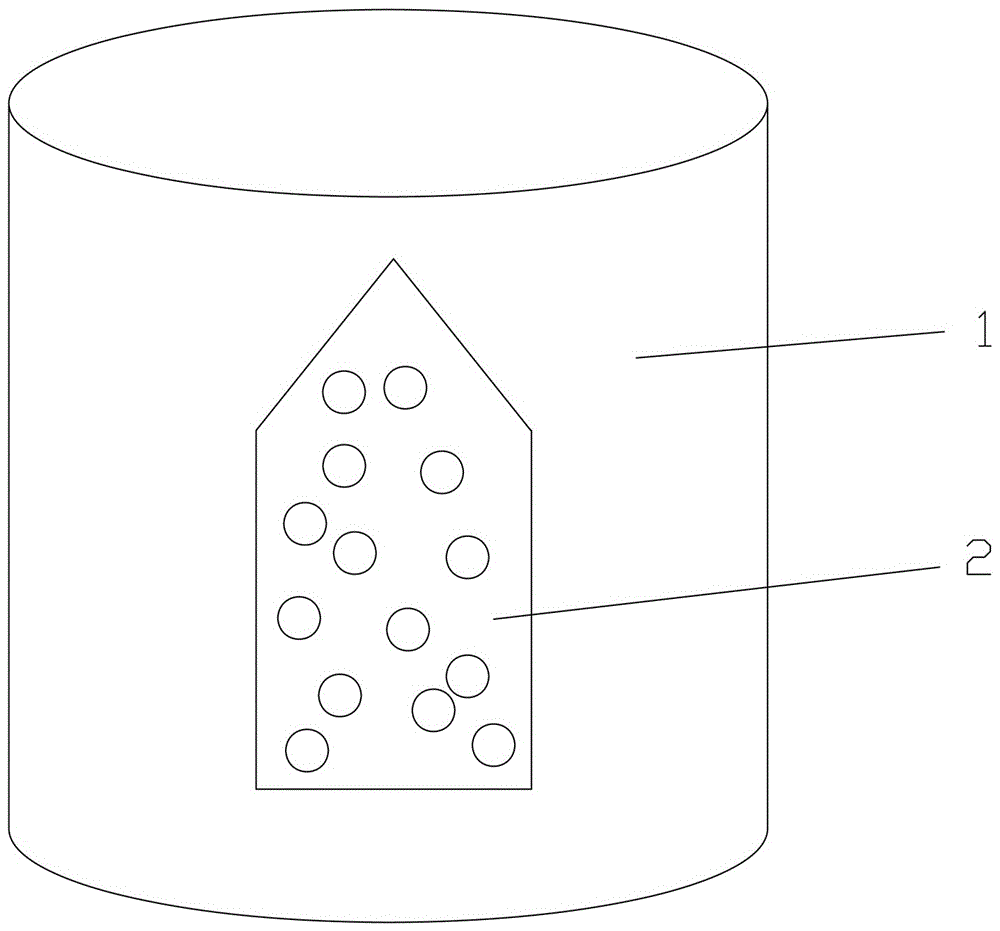

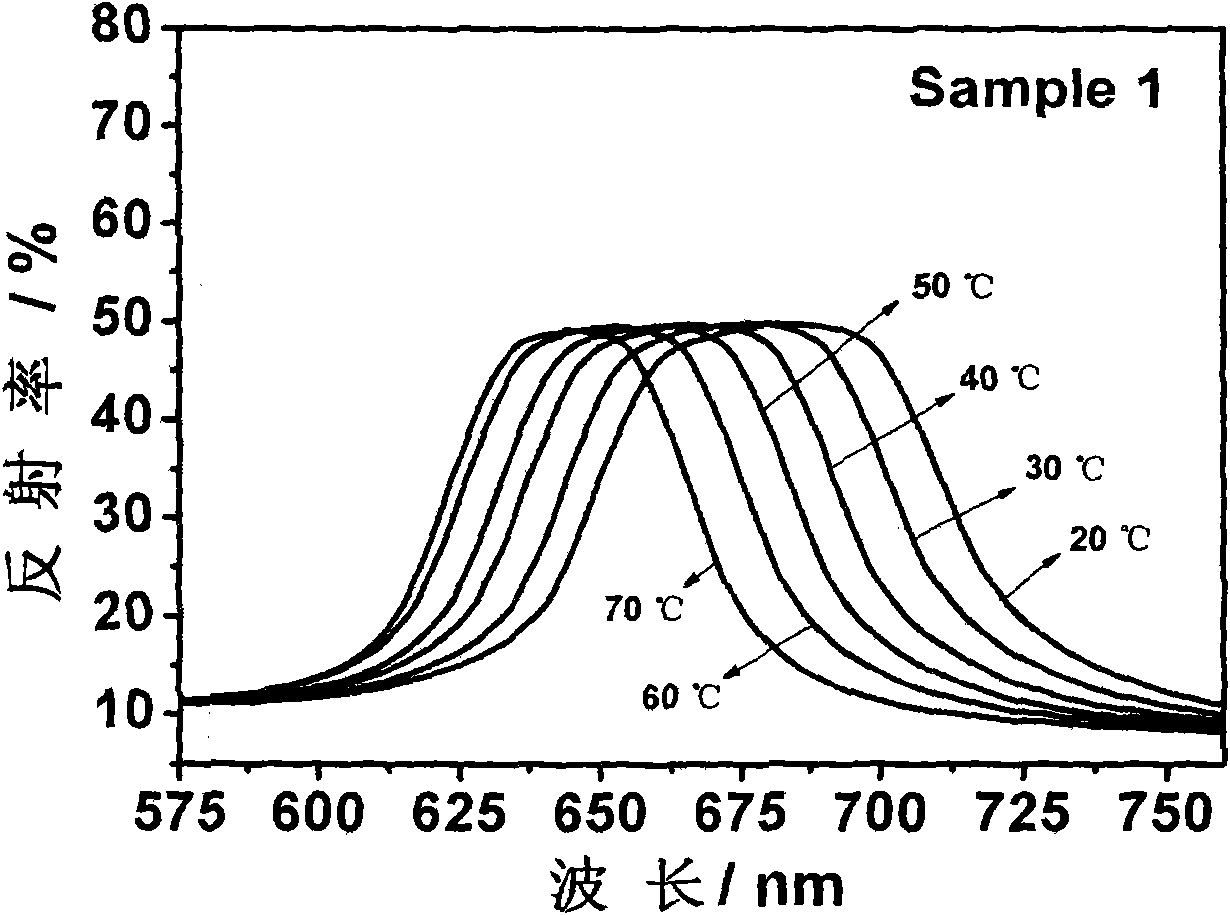

Production method for nano-doped electric field controlled liquid crystal round polaroid

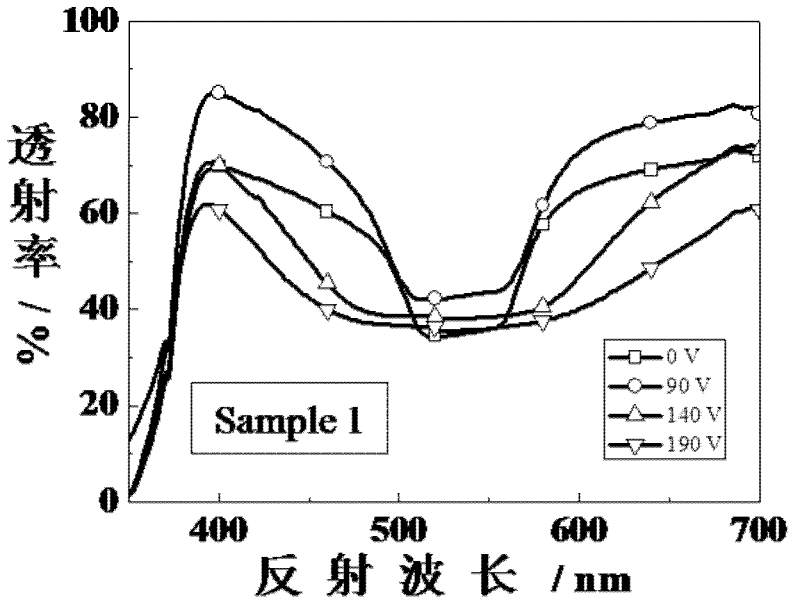

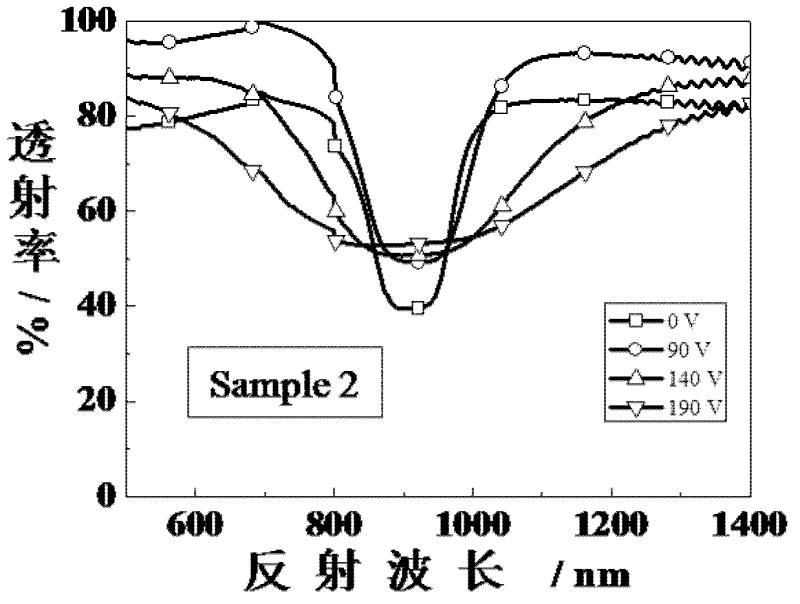

InactiveCN102621617ARealize reversible regulationSimple ingredientsPolarising elementsNon-linear opticsLiquid-crystal displaySmart glass

The invention provides a production method for an electric field controlled wide wave reflection liquid crystal round polaroid, which belongs to the technical field of functional material liquid crystal display. By enabling one-dimensional nano materials and cholesteric liquid crystal to be mixed and poured into a liquid crystal box or a thin membrane, the method exerts different electric fields to control reflection wave width. The method has the advantages of being simple in composition and process, reflection wave width of the polaroid can be controlled through electric fields according to actual needs, and reversible control also can be achieved. The method can be applied to functional thin membranes and devices such as intelligent glass, electronic paper, liquid crystal display light incremental membranes and the like.

Owner:UNIV OF SCI & TECH BEIJING

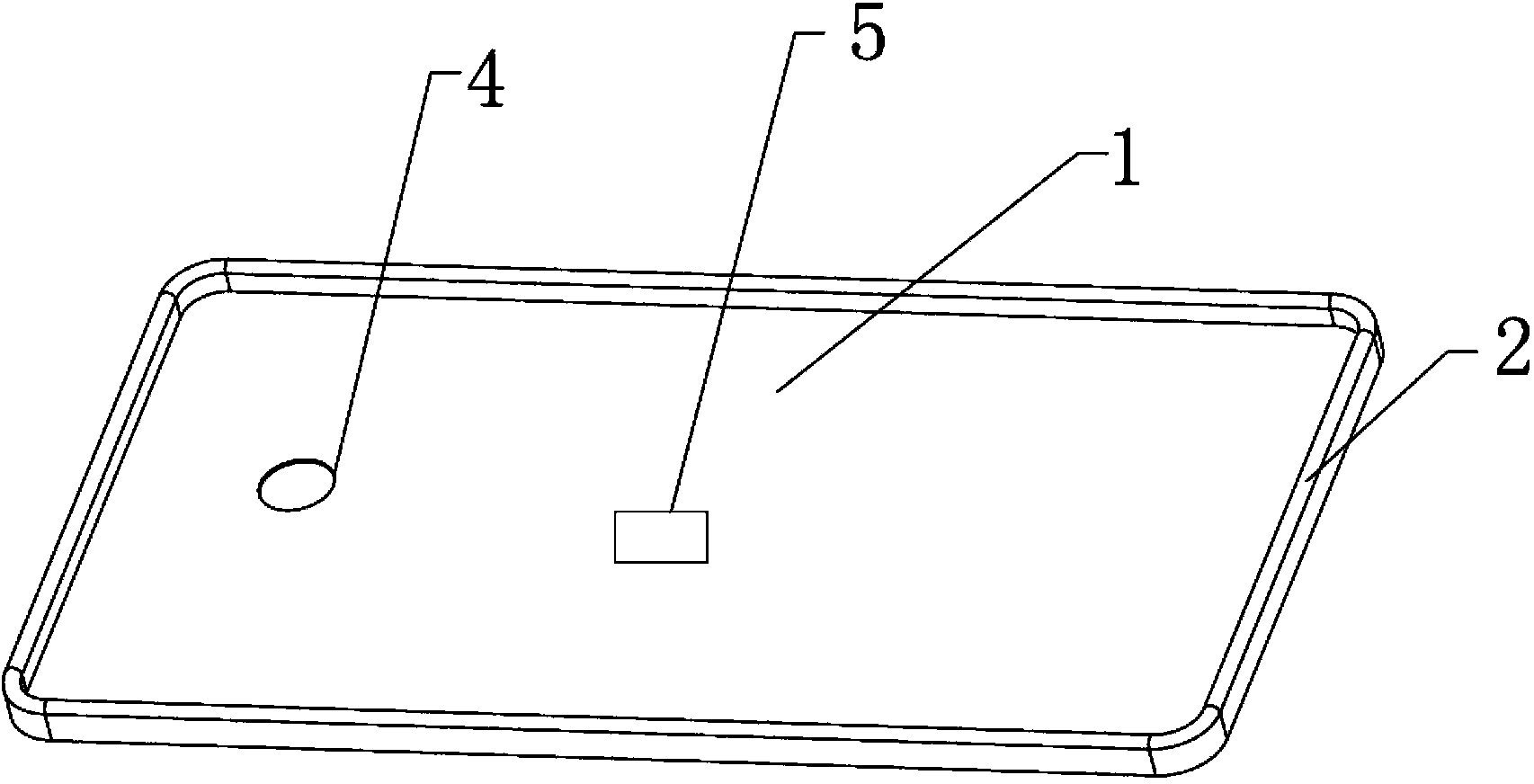

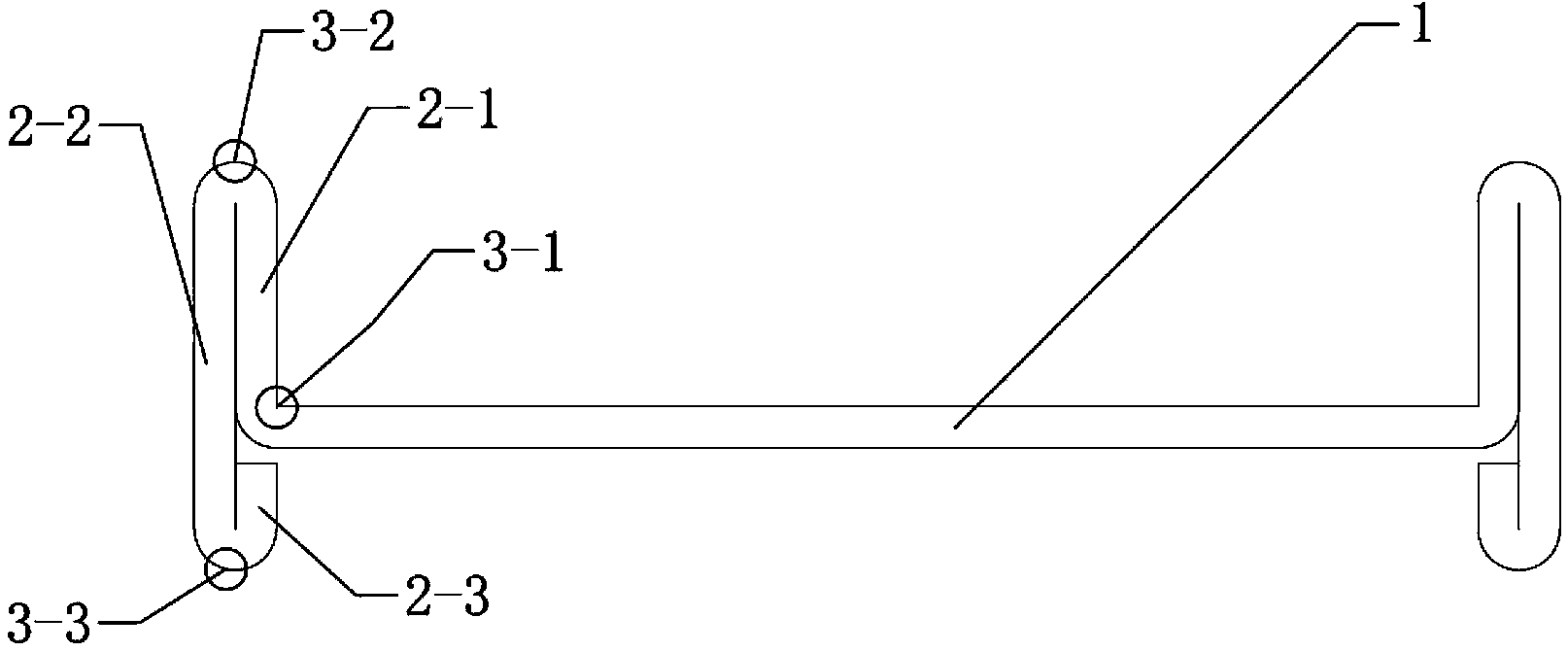

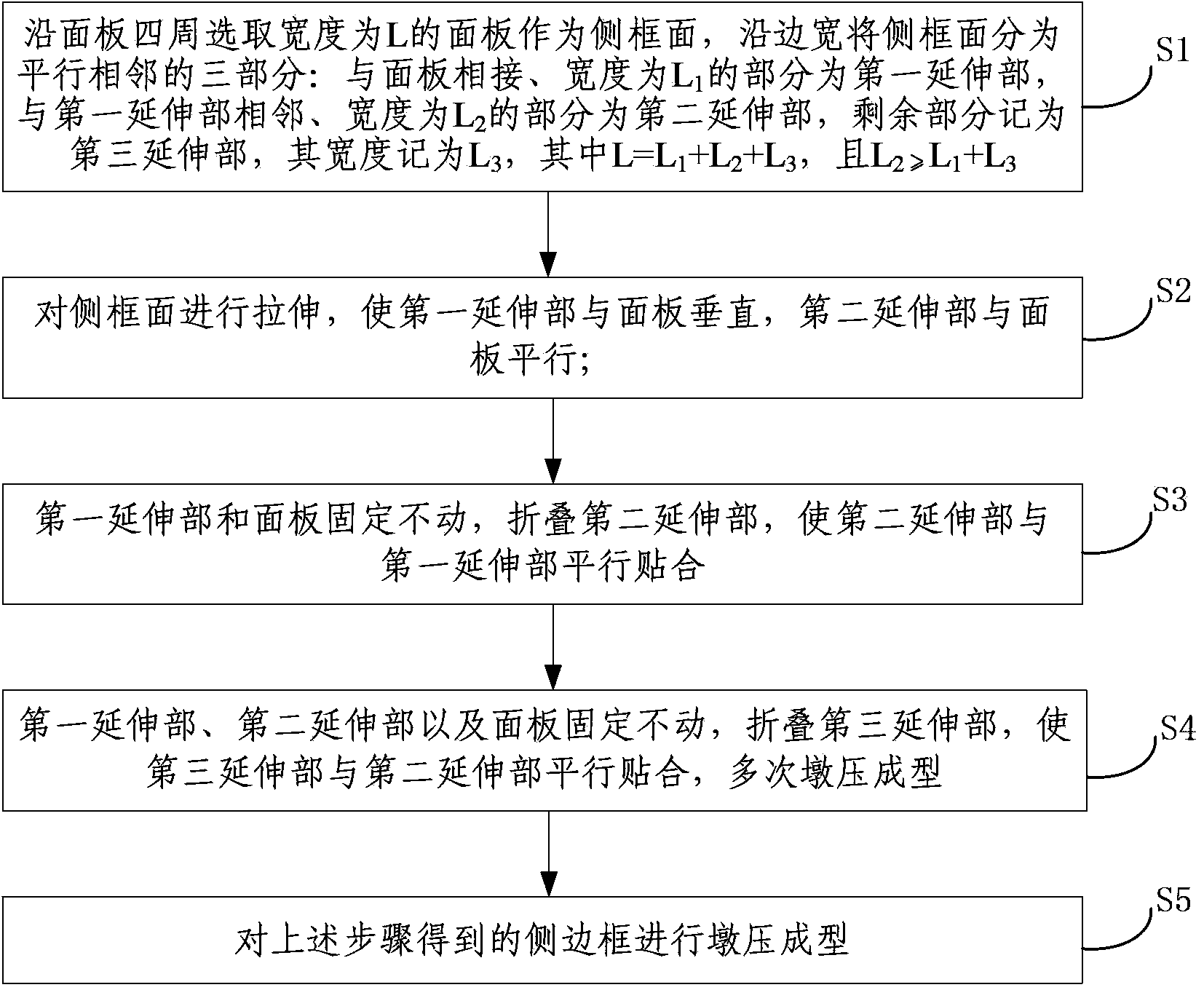

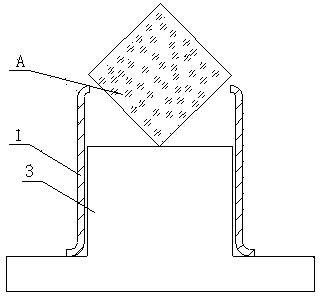

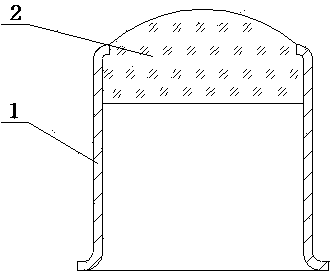

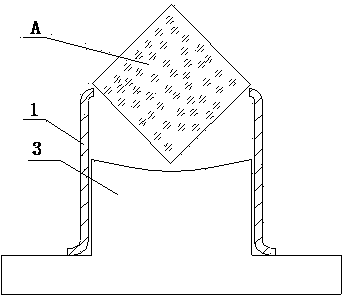

Electronic product middle frame and processing method thereof

InactiveCN103402340AHigh strengthLow utilizationDigital data processing detailsSubstation equipmentBiochemical engineeringUltimate tensile strength

The invention discloses an electronic product middle frame and a processing method thereof, and belongs to the technical field of electronic product components. The electronic product middle frame comprises a panel and a side frame which are integrally connected with each other, wherein the side frame comprises three extending parts; the first extending part is connected with the panel and is perpendicular to the panel; the second extending part is in tight fit with the first extending part and is parallel to the first extending part; the third extending part is in tight fit with the second extending part and is parallel to the second extending part; the third extending part and the first extending part are positioned on the same side of the second extending part. The electronic product middle frame adopts an integrated structure; the side frame is formed by bending and stamping the edge of the panel for many times, so that the structural strength is high; the electronic product middle frame is processed by a continuous die or an engineering die, the working procedure is simple, and the yield is high; processing equipment is simple; the utilization rate of raw materials is high; the production cost is low; the raw materials which are as thin as 0.3-0.8 mm can be used for processing the electronic product middle frame; therefore the finished product is light in weight and convenient to use and carry.

Owner:AOJIE HARDWARE JIANGSU

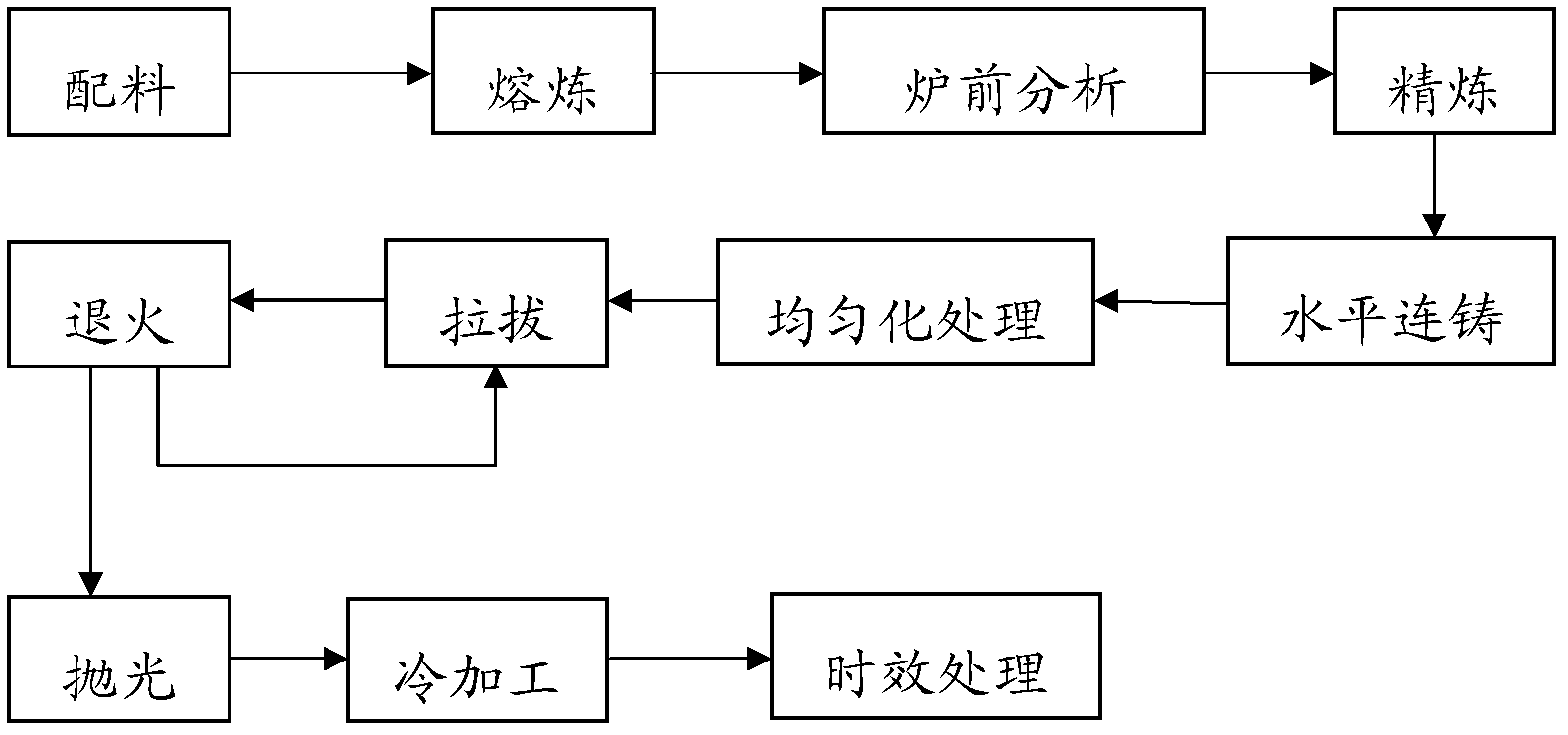

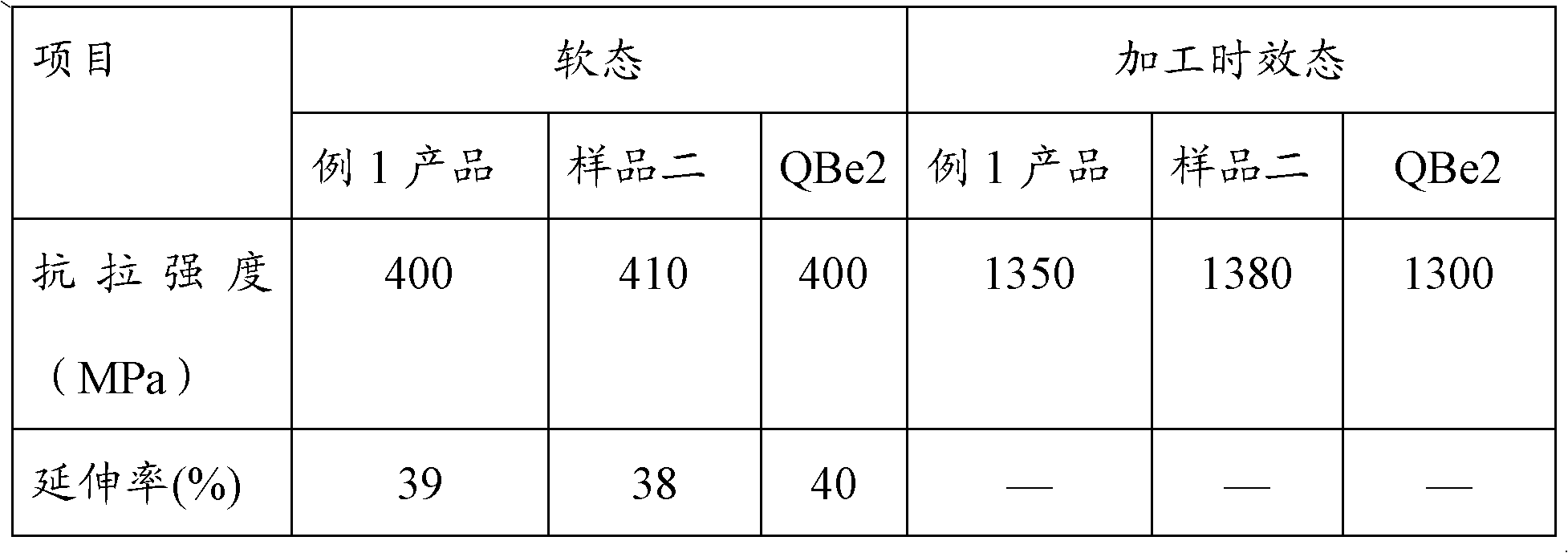

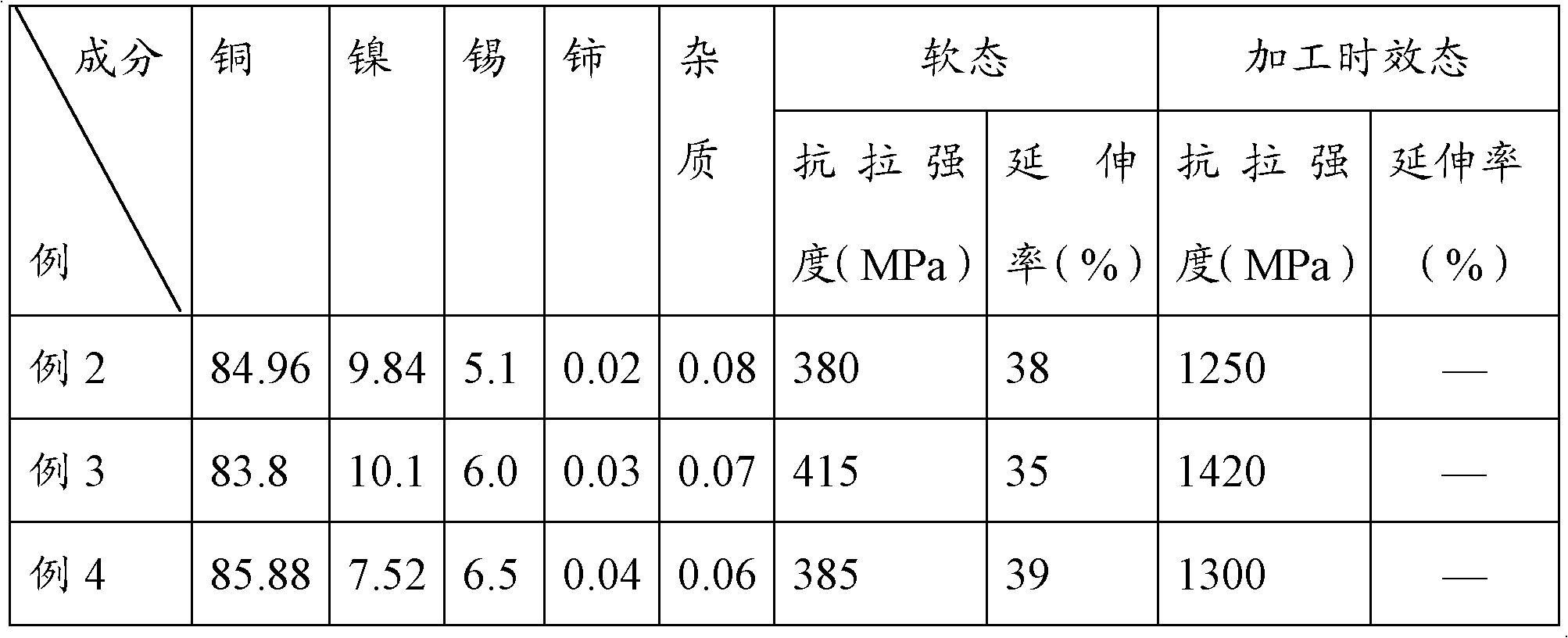

Copper-nickel-tin alloy and preparation method for wires thereof

The invention discloses copper-nickel-tin alloy and a preparation method for wires thereof. The copper-nickel-tin alloy comprises, by weight, 7 to 11% of nickel, 4 to 8% of tin and 0.02 to 0.04% of cerium, with the balance being copper and unavoidable impurities; the alloy has same performance as beryllium-copper alloy does. Horizontal continuous casting is used in the preparation method for wires of the copper-nickel-tin alloy; compared to vacuum melting commonly used at home and abroad, the method provided in the invention has the advantages of high rolling yield, simple processing equipment, small investment, short process flow and capacity of obtaining wire products with same excellent performance.

Owner:厦门火炬特种金属材料有限公司

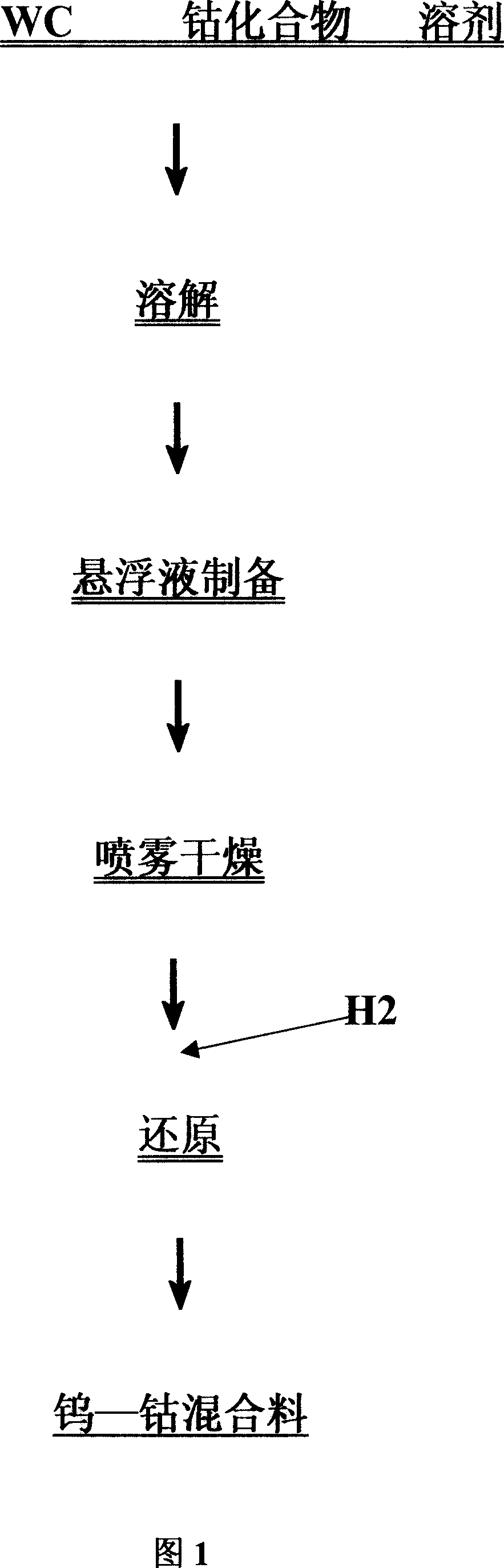

Method of preparing ultra-fine hard alloy mixture of tungsten and cobalt and product

InactiveCN1924047AThe preparation process is simple and easy to doFacilitate follow-up processAlloyUltra fine

The invention discloses a preparing method of composite material of ultrafine hard alloy tungsten and cobalt, which comprises the following steps: dissolving soluble organic cobalt compounds in the solution; fetching transparent solution; blending ultrafine tungsten carbide powder and organic cobalt compounds solution evenly; coating the organic cobalt compounds on the surface of tungsten carbide; evaporating liquid phase at spraying drying pattern; making organic cobalt compounds clad on the surface of tungsten carbide evenly; reducing; making metal cobalt clad on the external surface of each tungsten carbide particle.

Owner:谭日善 +1

Aging method and device for mineralizing green wine with glaze

InactiveCN106047623ALarge specific surface areaImprove adsorption capacityAlcoholic beverage preparationAge methodManganese

The invention discloses an aging method and a device for mineralizing green wine with glaze. Green wine which needs to undergo aging is stored when being contacted with glaze particles. The glaze particles are micropores contained by a traditional container made from glaze. The glaze particles are rich in metal ions for promoting aging of wine liquid, wherein metal ions mainly contain iron, manganese, copper, chromium and cadmium ions. During storage of green wine, low-boiling-point micromolecules and other foreign flavor can be adsorbed. The trace amount of metal ions contained by the glaze can accelerate reactions, such as an esterification reaction. Thus, aging of the wine is promoted. Contact area of the wine liquid and the glaze particles is increased to the maximum. The method and the device are economical and practical. In addition, investment is low, and equipment and energy are not required.

Owner:郭波

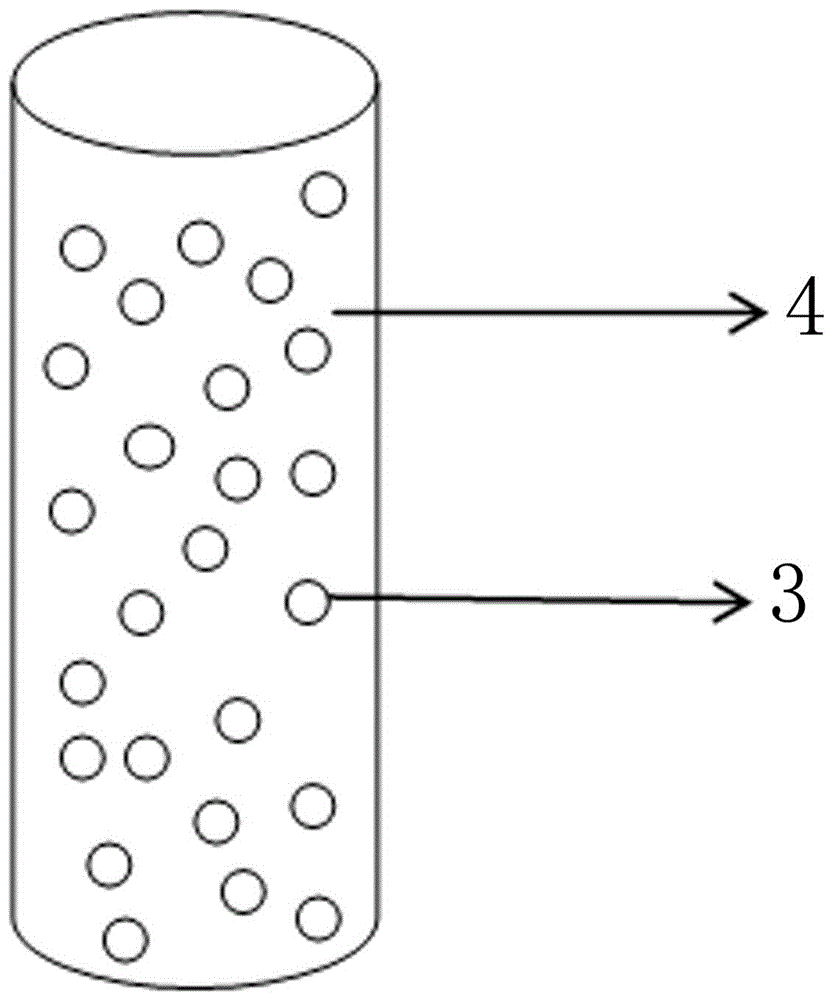

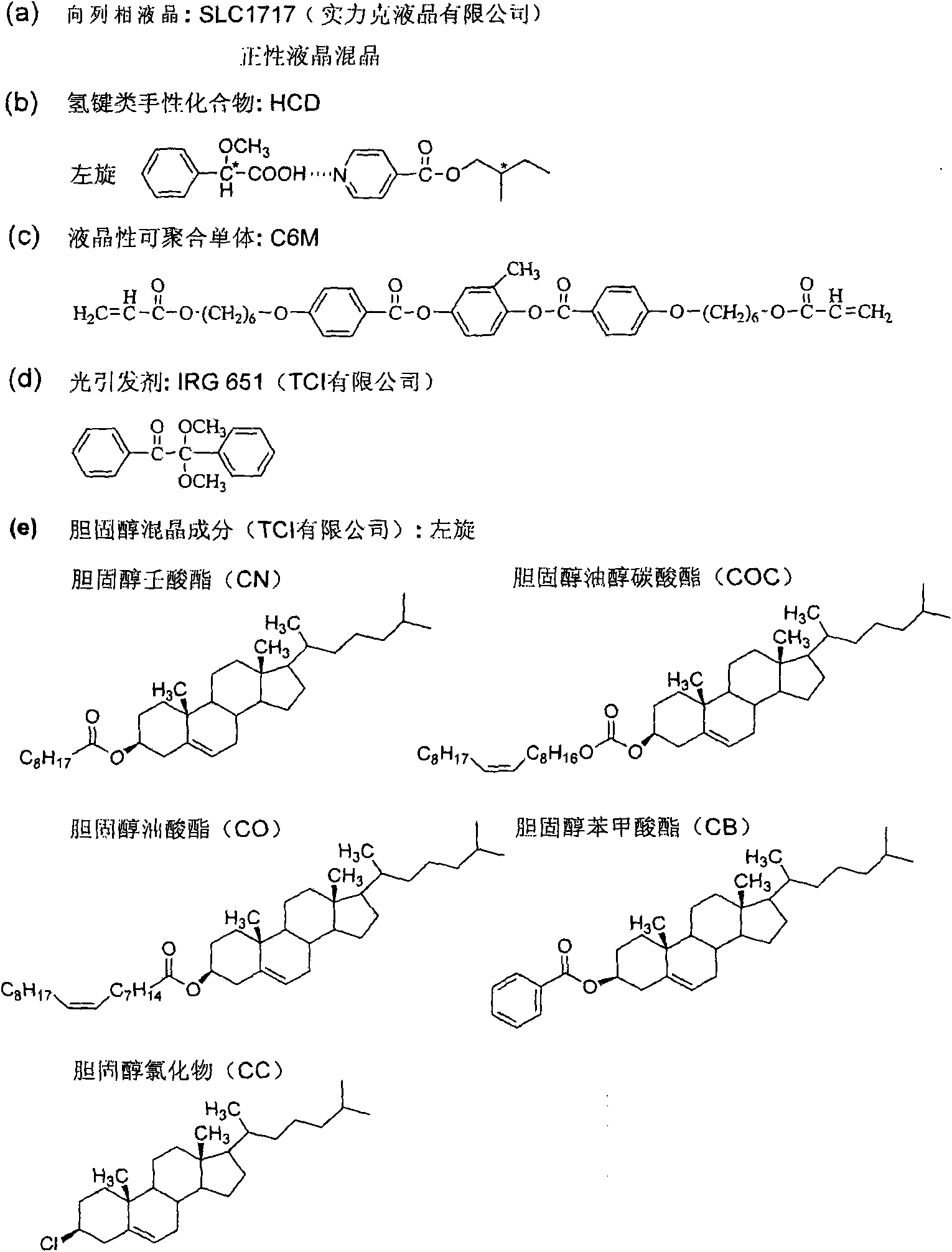

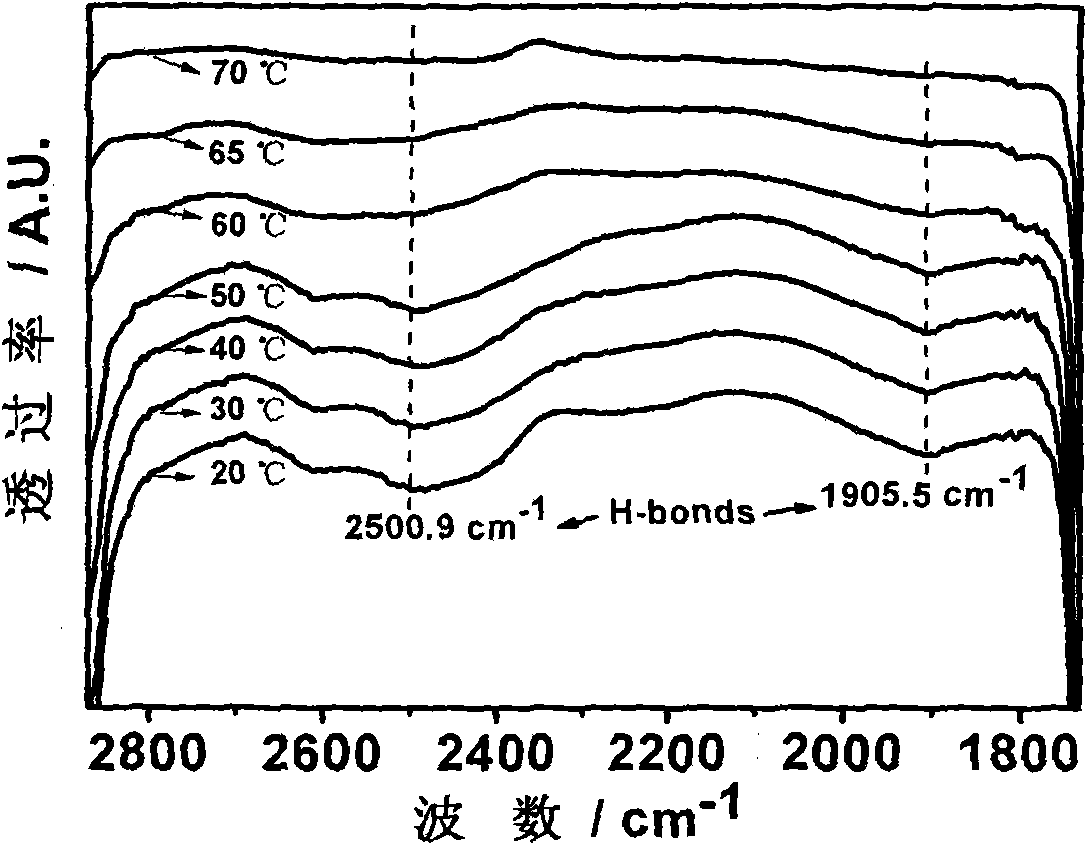

Preparation method for liquid crystal material of electronic paper material

InactiveCN101671565AHave memory effectSimple processing equipmentLiquid crystal compositionsNon-linear opticsDisplay deviceElectron

The invention relates to a preparation method for liquid crystal material of electronic paper material, belonging to the functional polymer liquid crystal display field. The manufacturing process is that a series of choiesl-like compounds are mixed, so that the indoor temperature is in the liquid crystal state; nematic liquid crystal and hydrogenbond-like chirality compounds are fed in the mixture; when the temperature is raised to a certain degree, the hydrogenbond-like chirality compounds are decomposed, and the liquid-system thread pitch is changed, so that the reflecting color is changed;after the temperature is reduced to the room temperature, the changed color can keep a period of time, namely, the changed color has memory; then, along with the completion of the self-assembling of chirality compounds in the system, the reflecting color is recovered to the initial state; polymerizable monomer and light photoinitiator are added in the system, and a polymer wall is formed by ultraviolet polymerization under a photomask, thereby obtaining a reflecting colorful display electronic paper driven by a thermal field. The preparation method has the advantages that the background colorof the liquid crystal material can be regulated as required, the color is brilliant without the background source, the energy is saved, and the method can be applied in a display device, a thermal sensitivity temperature sensor and the like.

Owner:UNIV OF SCI & TECH BEIJING

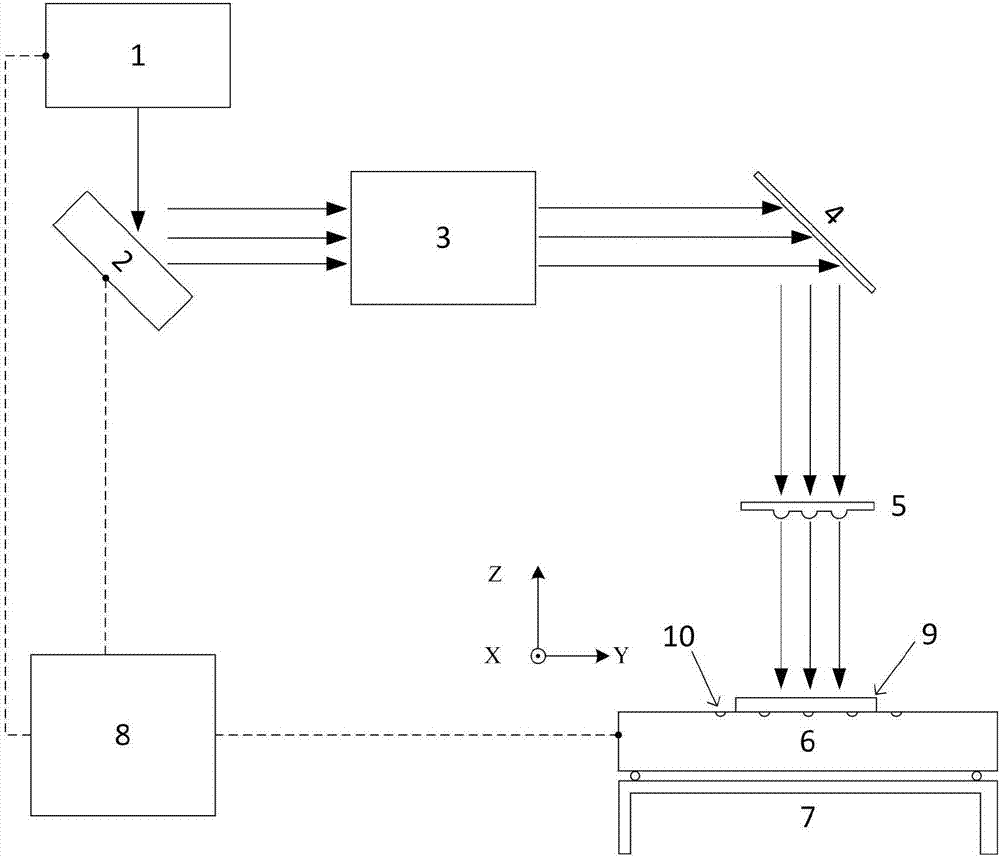

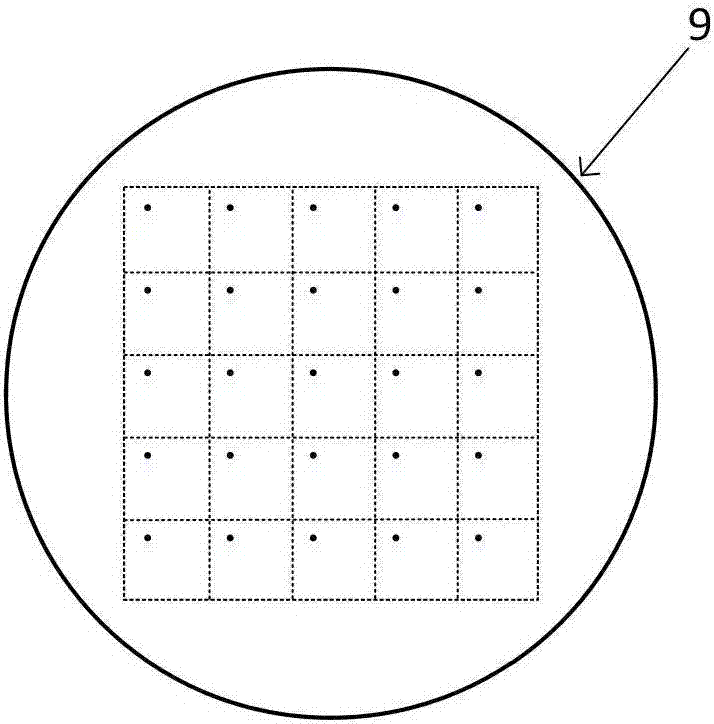

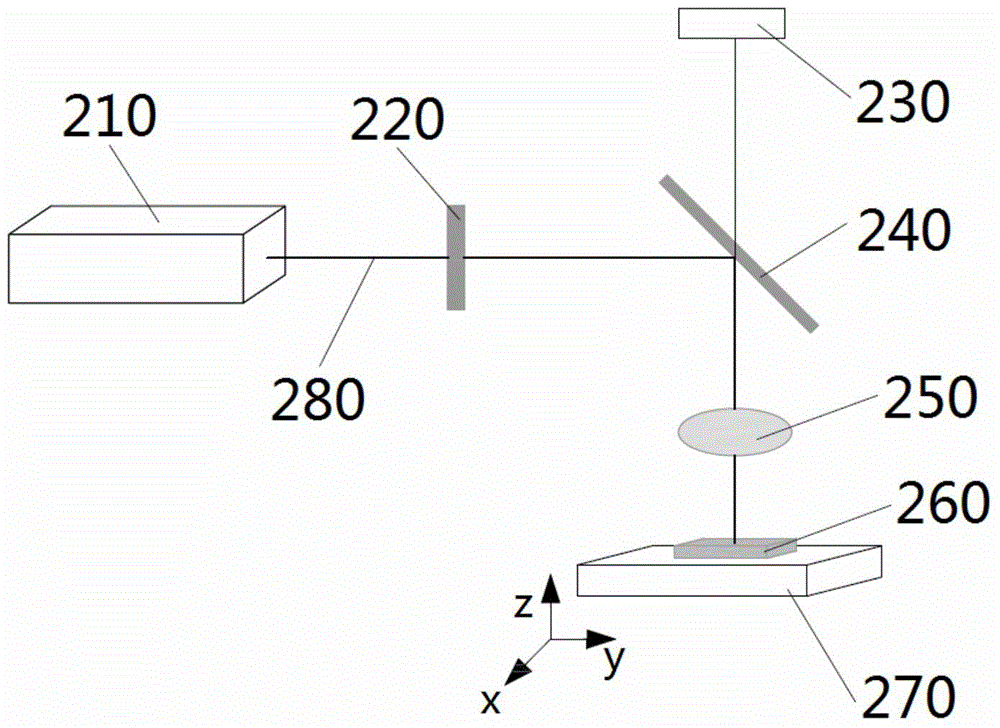

Ultrafast-laser optical chip array processing system and method

InactiveCN107199404AImprove processing efficiencyImprove quality consistencyLaser beam welding apparatusMicro nanoBeam expander

The invention discloses an ultrafast-laser optical chip array processing system and method, and belongs to the technical field of micro-nano processing of optical chips. The system comprises a laser light source, a spatial light modulator, a beam expander, a reflector, a micro-lens array and a six-dimensional working platform, and the system further comprises an air-floating platform and a central-control computer, wherein the central-control computer is connected with the laser light source, the spatial light modulator and the six-dimensional working platform and used for control of the whole system, and the air-floating platform is arranged under the six-dimensional working platform and used for bearing the six-dimensional working platform. According to the ultrafast-laser optical chip array processing system and method, a laser array processing method is adopted, dozens of optical chips can be obtained in one-time processing process, the processing efficiency is high, and quality consistency is good; in addition, the laser processing method is adopted, processing equipment is simple, the requirement on the processing environment is low, and therefore the production cost is greatly reduced.

Owner:HUBEI UNIV OF TECH

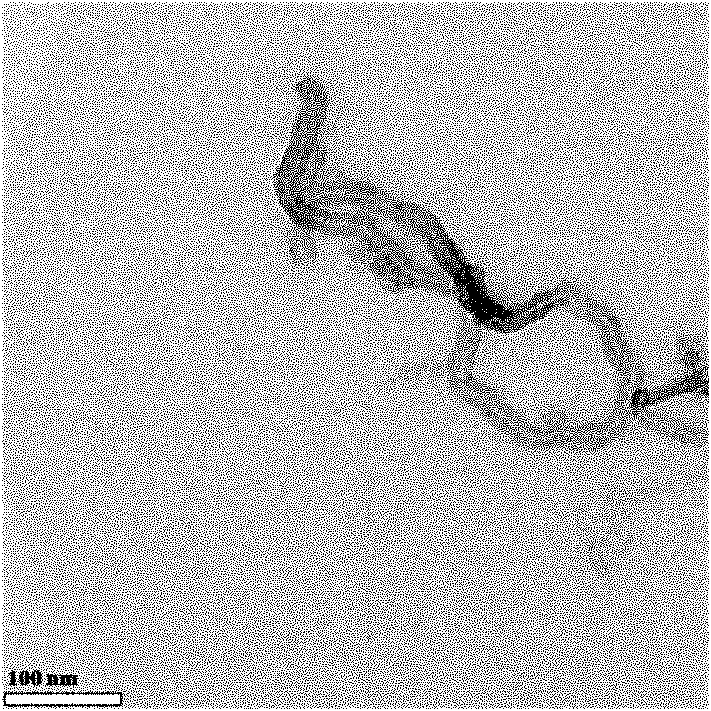

Method for preparing carbon nanotube by use of biodegradable plastic

InactiveCN102115076AReduce consumptionAvoid issues such as emissionsSolid waste disposalPolymer scienceCarbon nanotube

The invention discloses a method for preparing carbon nanotubes by use of biodegradable plastics. The method is characterized in that a biodegradable composite is prepared from the following materials by melt-bending method using an internal mixer or double-screw extrusion method or solution reaction method: (by mass) 85% to 99% of a biodegradable plastic, 0.6% to 10% of an organically modified layered compound and 0.4% to 5% of a catalyst; then a mixture containing carbon nanotubes is prepared by Muffle furnace method or tube furnace method; and finally the carbon nanotubes are produced by purification treatment. Based on the barrier effect of the layers of the organically modified layered compound on the pyrolysis product of the biodegradable plastic, the volatile components of the biodegradable plastic are transformed to the carbon nanotubes under the action of the catalyst. The method for preparing the carbon nanotubes simplifies the process and the equipment, reduces the requirements for reaction conditions, and adopts the easily-accessible and recyclable biodegradable plastic as carbon source, so as to not only reduce the energy consumption but also solve the problem of greenhouse gas emissions during the degradation process of the biodegradable plastic.

Owner:UNIV OF SCI & TECH OF CHINA

Vegetable fermenting method

The present invention relates to a method for making fermented vegetable by using pure natural lactic acid. Said method includes the following steps: (1) preparing fermenting liquor; placing the pure culture of Lactobacillus bulgaricus and streptococcus thermophilus into fermentation container, and adding the water whose hardness is greater than 16 deg. and temp. is 40 deg.C-50 deg.C to 2 / 3 place of volume of fermentation container to make them into fermenting liquor; (2) sealing vegetable: placing the drained vegetable into the fermentation container, making the distance of fermenting liquor level from the mouth of said container be 1-2 cm, capping and sealing said container; and (3). fermentation; moving the fermentation container into fermentation chamber, fermenting for 6-12 days at 20-30 deg.C, after the pH value of fermenting liquor is 3-5, taking out the ferromented vegetable which is patatable, unique in flavor and has health-care weight-reducing effect.

Owner:GUANGZHOU UNIVERSITY

Method for producing whole wheat flour by performing air flash explosion technology on bran and product thereof

PendingCN108402392AEfficient killingGreat tasteFood thermal treatmentFood preservationPre treatmentHigh pressure

The invention discloses a method for producing whole wheat flour by performing air flash explosion technology on bran and a product thereof. The method for producing whole wheat flour by performing air flash explosion technology on bran comprises the following steps of carrying out pretreatment, namely adjusting water content of bran, performing air flash explosion treatment, and carrying out drying so as to obtain dried bran; and then, carrying out flour blending, namely crushing the dried bran, carrying out sieving, and carrying out mixing with flour so as to obtain the whole wheat flour. The technology for producing whole wheat flour by performing air flash explosion technology on bran aims to solve the problems of existing whole wheat flour, namely liable damages on gluten protein andstarch, difficult powder preparation, short storage time and the like. According to the method for producing whole wheat flour, bran is treated by utilizing air flash explosion technology, wherein airexplosion pressure is provided by an external air compressor and temperature is provided by saturated steam so that pressure and time become two independent controllable parameters; and thus, the temperature can be controlled within a relatively low range. In addition, a relatively high pressure can be simultaneously maintained and instantaneously released so as to reduce activities of lipase andlipoxygenase, and thus, shelf life of the whole wheat flour is prolonged.

Owner:JIANGNAN UNIV

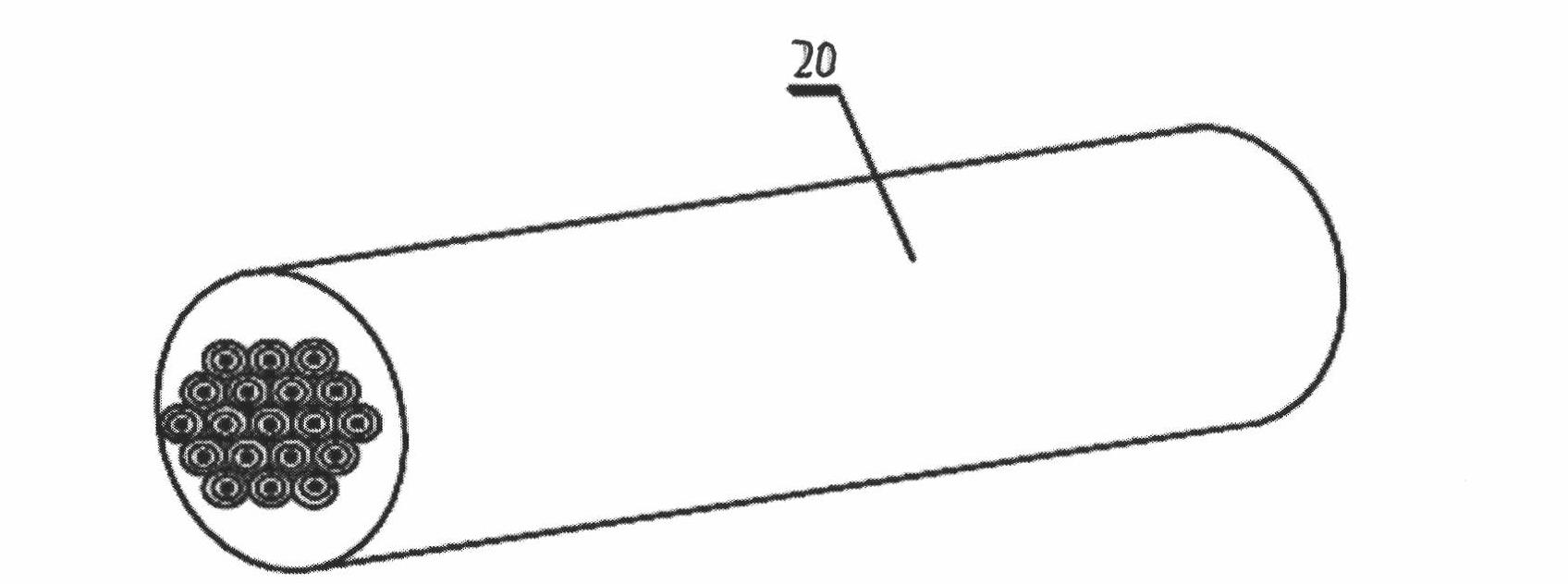

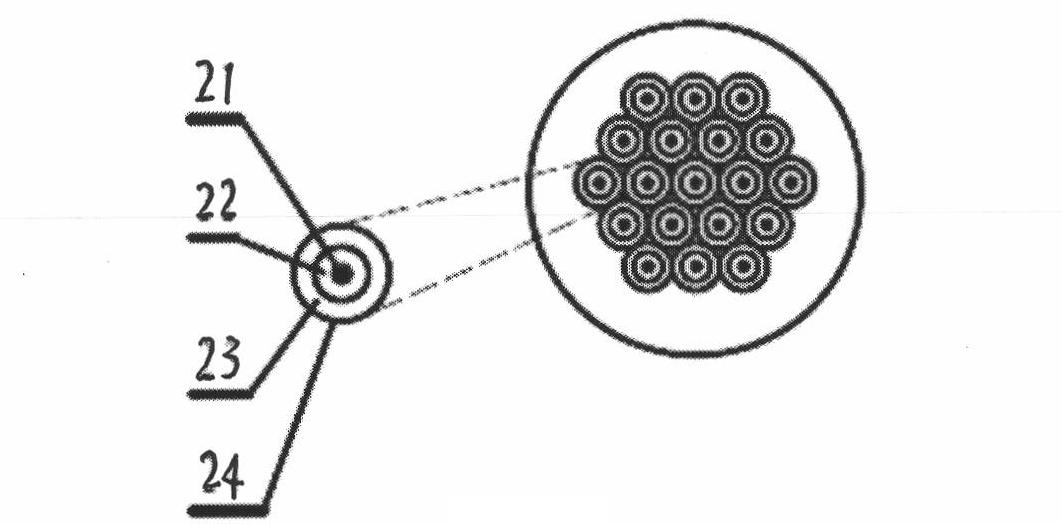

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

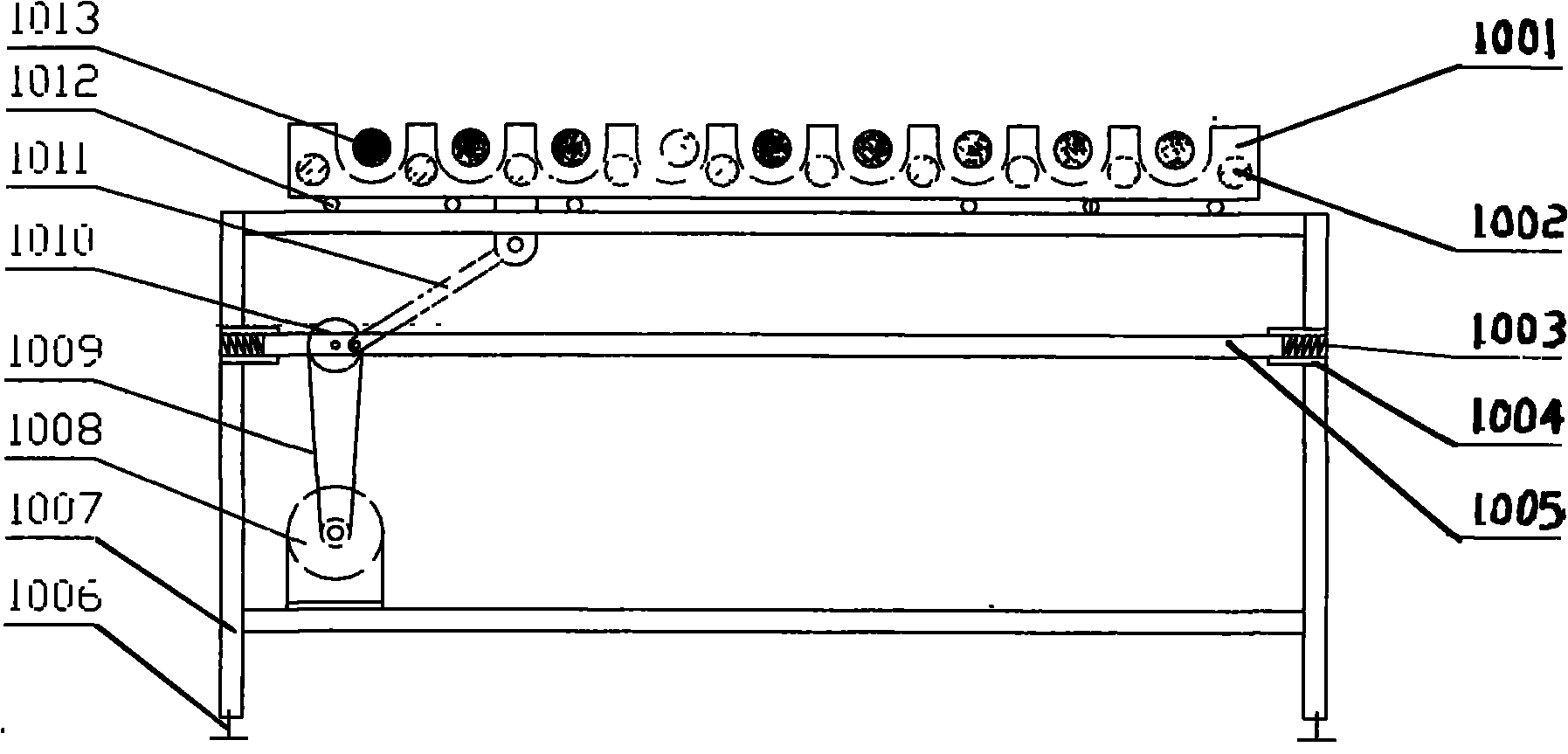

Pre-processing production system for deep-processing of automotive glass

ActiveCN104511819ARealize in-line productionReduce operating costsEdge grinding machinesWindowsProcess qualityAir bearing

The invention relates to a pre-processing production system for deep-processing of automobile glass; the pre-processing production system comprises a sheet-taking table, a cutting machine, a sheet-breaking and air-bearing table, an edge grinding machine, a suction arm, a transition conveyor, a sheet washing machine, a power blower, a cleaning, testing, overturning and discharging conveyor, a corner conveyor, a pre-targeting machine, a silk printer, a silk-printing, testing, overturning and discharging conveyor, a drying machine, an air-cooler and a discharging machine; and the edge grinding machine comprises a wheel-grinding shaft, a rocker arm, a hand wheel, locking screws, an upright column, a table top and a grinding wheel for grinding edges. The pre-processing production system for deep-processing of the automobile glass has the following beneficial effects: manual equipment and automatic equipment and combined, so that the pipelining working of the pre-processing for deep-processing of the automobile glass is realized; the production system is simple and stable in processing quality of glass; the internal glass and the external glass of coaches and minibuses are processed on the production system, so that the production staff is reduced, the labor intensity is reduced, the production field is saved, the production efficiency is improved and the operating cost of enterprises is reduced effectively.

Owner:XINYI AUTOMOBILE GLASS (SHENZHEN) CO LTD

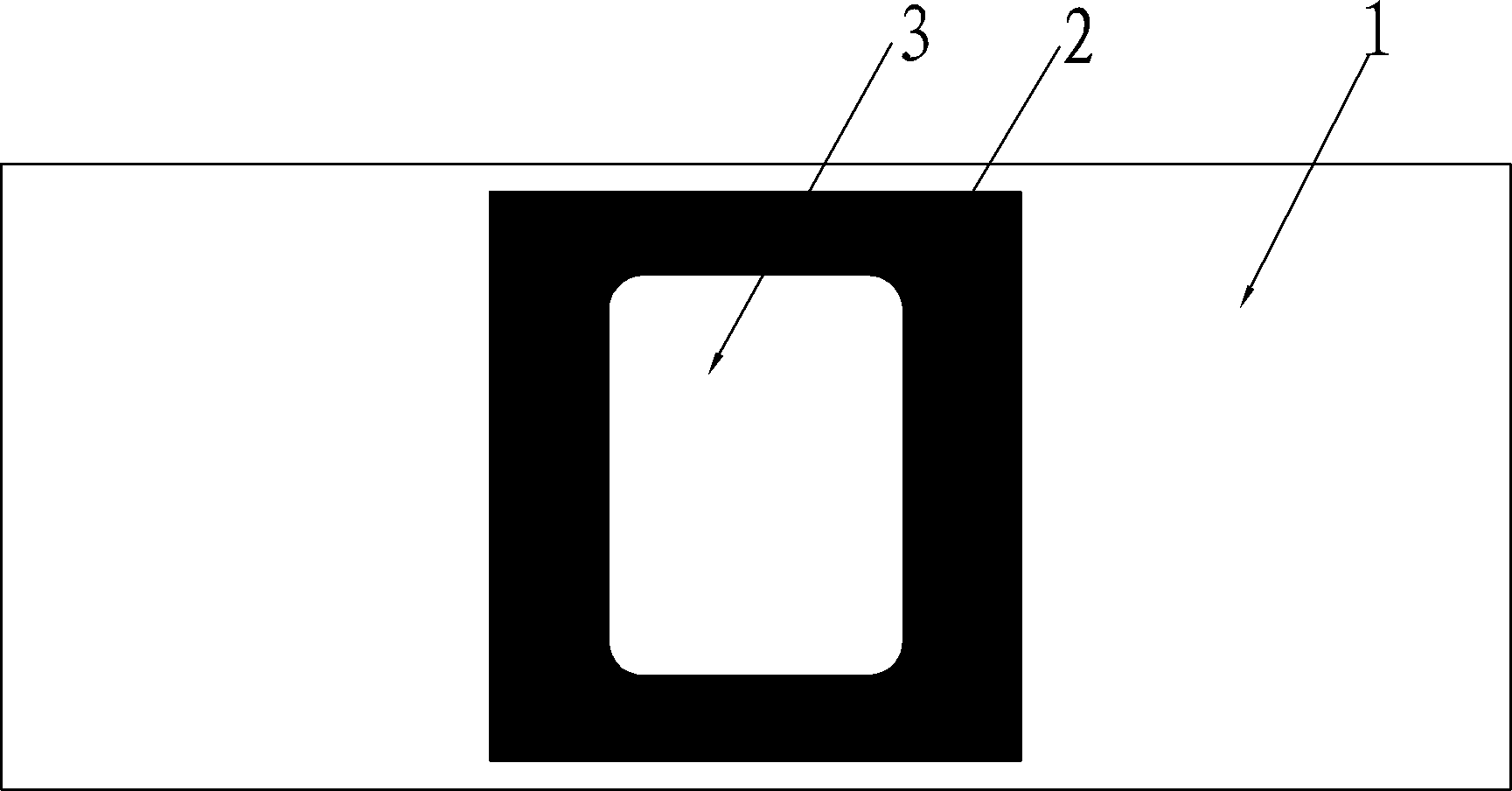

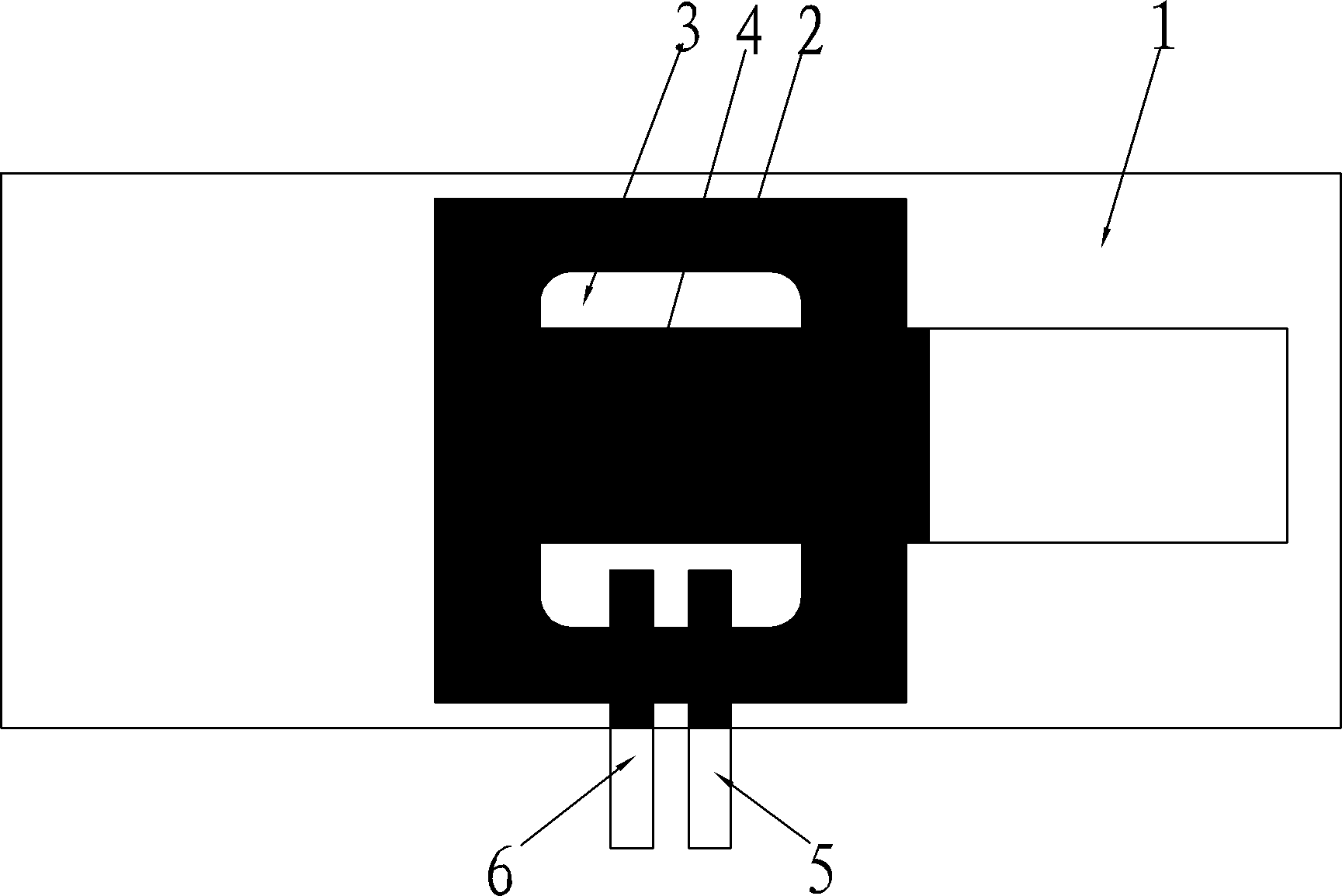

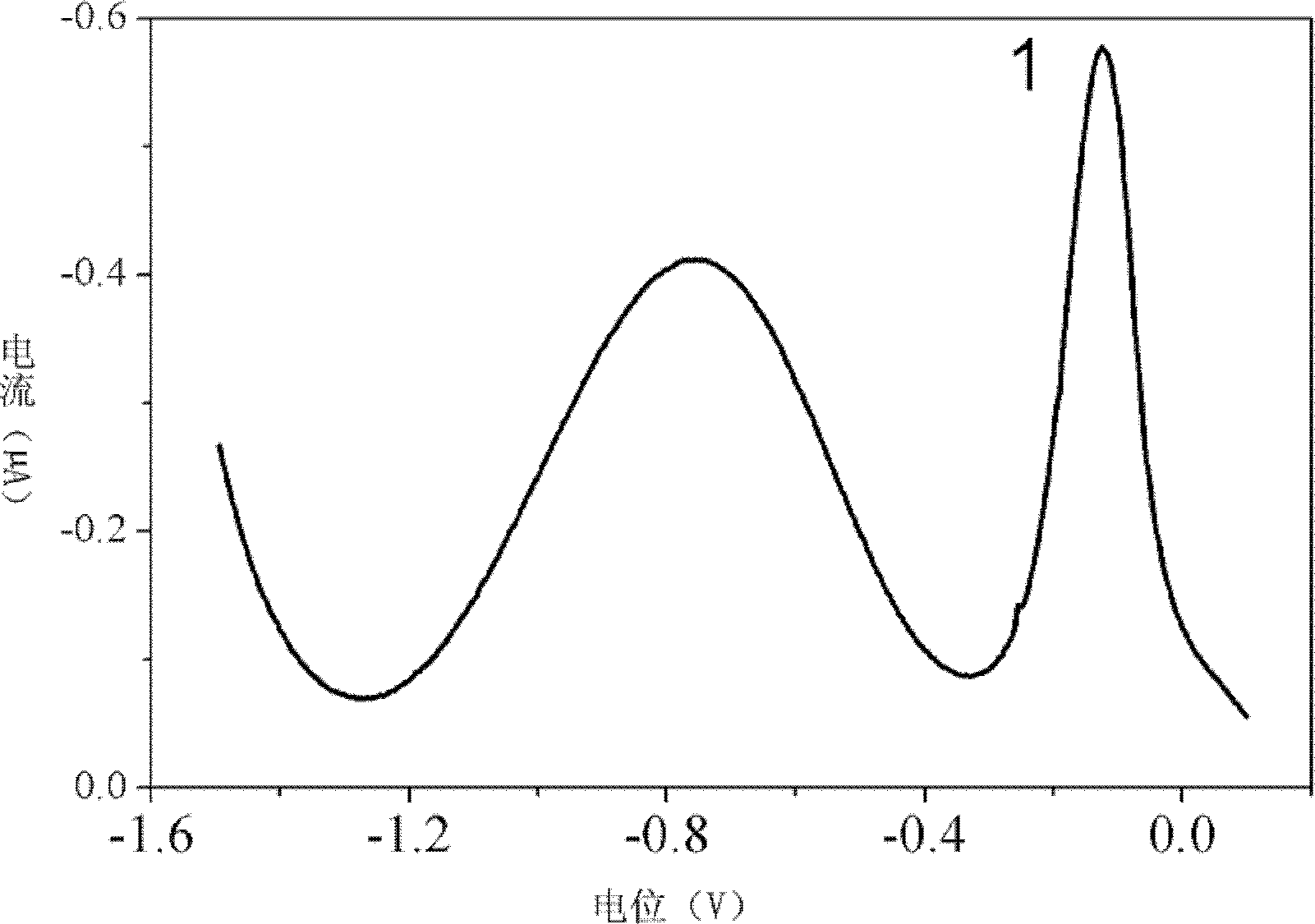

Paper-based electrolytic cell for electrochemical detection, manufacturing method thereof, and three-electrode system

InactiveCN102495123ASimple equipmentHigh precisionMaterial electrochemical variablesImage resolutionElectrolytic cell

The invention discloses a paper-based electrolytic cell for electrochemical detection. The paper-based electrolytic cell comprises filter paper, wherein a closed carbon powder region is formed on the filter paper; and a region encircled by the carbon powder region serves as an electrolytic cell region. The invention also provides a manufacturing method for the paper-based electrolytic cell. The method comprises the following steps of: making a pattern of the carbon powder region on a computer; printing the carbon powder region on the filter paper by a laser printer with resolution of more than or equal to 300 dpi; and heating the filter paper on which the pattern is printed by a heating device at the temperature of between 120 and 180 DEG C for 60 to 300 minutes, and thus obtaining the paper-based electrolytic cell. Equipment for processing the paper-based electrolytic cell for the electrochemical detection is simple, can be implemented in a common laboratory, is low in manufacturing cost, and can be manufactured easily and quickly; the volume of a required sample is only 1 to 100 microliters; and the paper-based electrolytic cell has a wide using range and a small volume, is portable, meets the requirement of portable electrochemical detection, and is discardable.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE +2

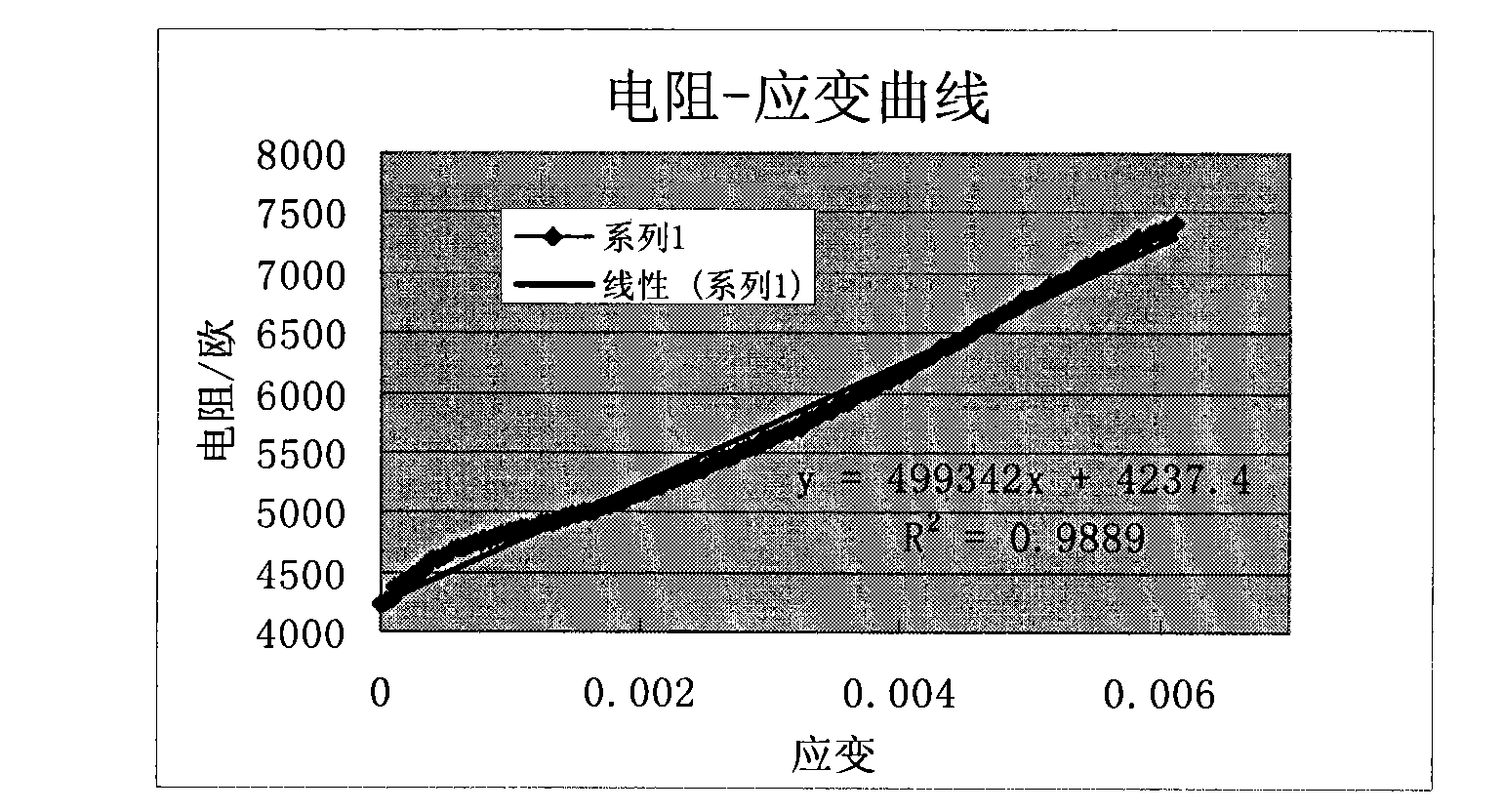

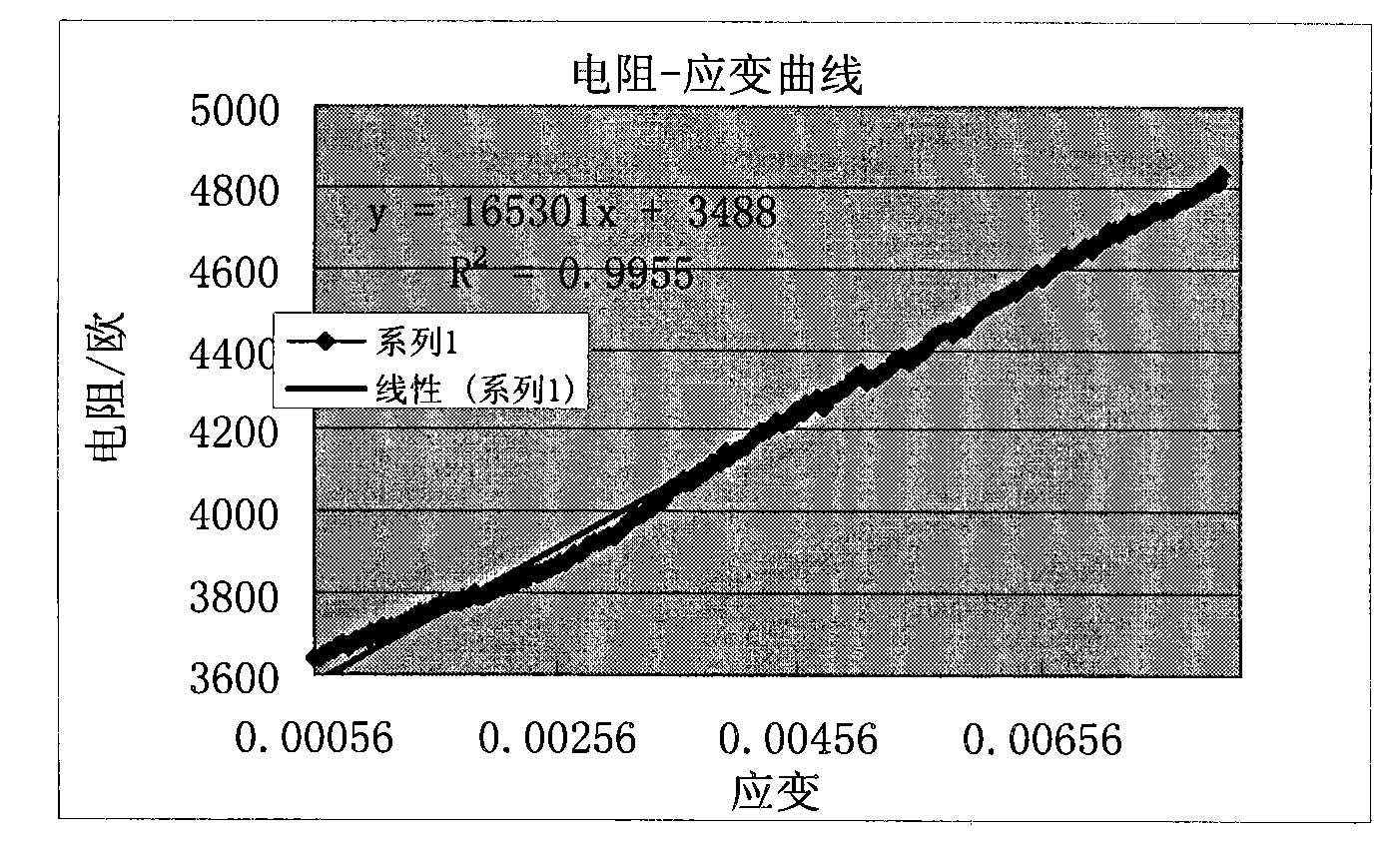

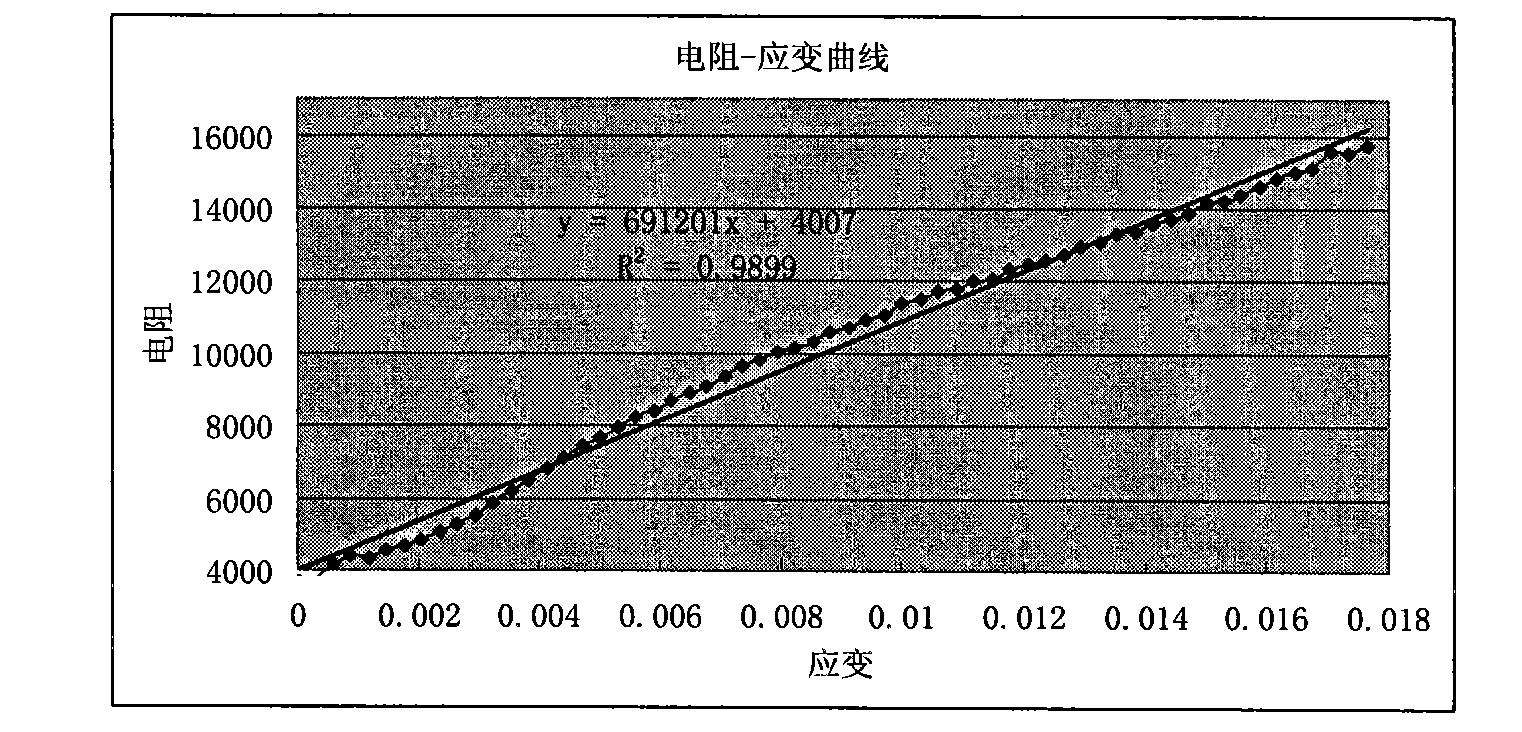

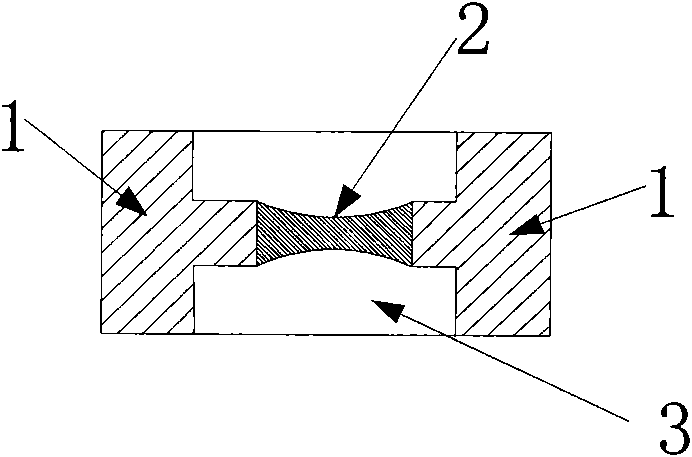

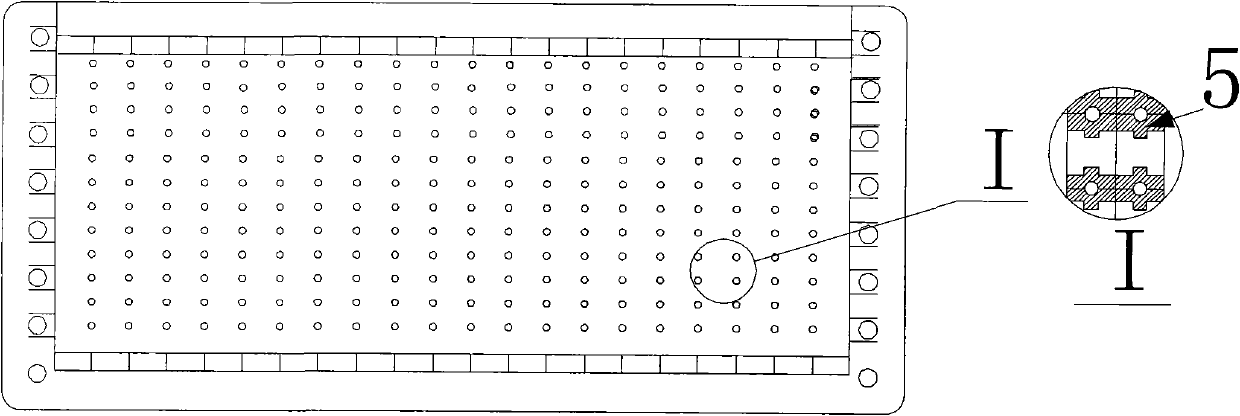

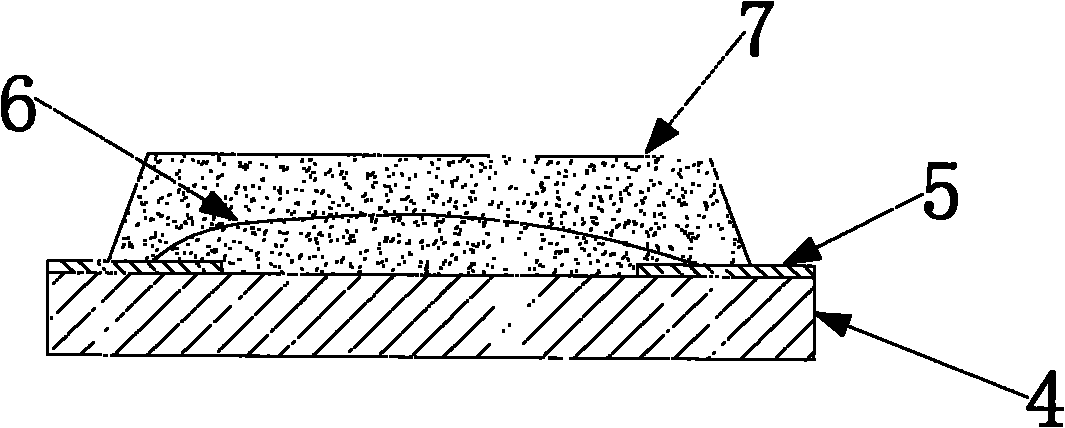

Sensitive material for tensile deformation test and preparation method thereof

InactiveCN101914290AGood flexibilityLow tensile modulusElectrical/magnetic solid deformation measurementFiberNano sio2

The invention relates to a sensitive material for a tensile deformation test and a preparation method thereof. The method comprises the following steps of: stirring and mixing liquid-state silicon rubber, chopped carbon fiber, conductive carbon black, nano-SiO2, a curing agent and a coupling agent serving as raw materials at normal temperature and under normal pressure in turn; removing air bubbles by vacuumizing; and molding. The obtained sensitive material for the tensile deformation test has high flexibility and very small tensile modulus and does not affect the deformation of a test structure or a test material in a testing process; and simultaneously, the sensitive material has the advantages of high sensitivity, performance stability, simple preparation method, wide raw material source and low manufacturing cost.

Owner:CHINA UNIV OF MINING & TECH

Patch-type filamentous fuse and manufacturing method thereof

InactiveCN101794690AHighlight substantive featuresSignificant progressFuse device manufactureBiochemical engineeringPatch type

The invention relates to a patch-type filamentous fuse and a manufacturing method thereof. The invention has the technical scheme that one or a plurality of strips of fuse materials with the same or different specification are stuck or welded at the electrode position of a base board in a certain mode, and then are encapsulated by resin or other suitable insulation materials and cut to obtain the granular fuse. Because automatic fuse feeding and fuse cutting by the machine are adopted, the lengths of the fuse body are basically consistent, so the performance of the product is ensured. The invention has the advantages of greatly improving the consistency of the performance of the patch-type fuse, effectively reducing the production cost of the patch-type fuse, ensuring the quality of the product and improving the reliability of the product. The scheme also has the advantages of simple and practical technology and the like, and has better application and popularization value.

Owner:NANJING SART SCI & TECH DEV

Instant donkey-hide glue powder and preparation method thereof

InactiveCN101912419ABeautiful colorHigh bulkinessPowder deliveryUnknown materialsEconomic benefitsProduct property

The invention relates to instant donkey-hide glue powder and a preparation method thereof. The preparation method for the instant donkey-hide glue powder comprises the following steps: heating and dissolving finished donkey-hide glue in water, adding a proper amount of tween-20, glycerin monostearate and a proper amount of sweetener according to a proportion, drying under the conditions of low temperature and vacuum, and smashing to obtain a finish product. The finished product instant donkey-hide glue powder retains original active constituents and color of the donkey-hide glue and dispersibility thereof is reduced from 154s to 15s, thereby obviously improving the instant of the donkey-hide glue powder in water and effectively removing the original fishy smell of the donkey-hide glue. The method has less equipment investment, simple and practicable technology, stable product property, convenient eating and high economic benefit, and is an ideal method for producing the instant donkey-hide glue powder.

Owner:SHAANXI UNIV OF SCI & TECH

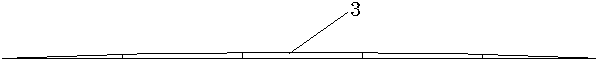

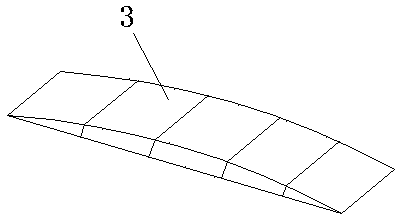

Method for machining extra large circular arc plates

A method for machining extra large circular arc plates comprises the following steps that a bed mould is manufactured, the bottom face of a plate needing to be machined is machined into a plane, the bed mould is welded to the bottom face of the plate, the bed mould is attached to the surface of a machine tool table, the radian of an upper circular arc face formed at the bottom face of the plate is detected, the upper circular arc face and an arc face of a finished circular arc plate form a conjugate surface, milling is conducted on the upper plane of the plate, the difference of a high point and a low point meets the demand of a pattern, the bed mould is dismantled, and the bed mould is separated from the circular arc plate after the bed mould is separated from the machine tool table. The method for machining and preparing the extra large circular arc plates is simple in machining device and high in machining accuracy, lowers machining difficulty, and saves machining time and machining cost.

Owner:CHINA 22MCC GROUP CORP

Completely-water-soluble organic-inorganic biological bacterial fertilizer and preparation method thereof

The invention discloses completely-water-soluble organic-inorganic biological bacterial fertilizer. The water-soluble fertilizer is composed of amino acid, yeast powder, amino acid chelated trace element fertilizer, boric acid, magnesium sulfate monohydrate and functional biological bacterial agent. The preparation method includes the steps of chelating reaction, mixing reaction, drying and smashing to obtain biological organic water-soluble fertilizer. The amino acid, the yeast powder and the amino acid chelated trace element fertilizer provide other nutrient elements and can provide sufficient carbon elements for crop growing, so that input-output ratio is higher with same input, and yield is increased by 30% averagely. The preparation method is simple in preparation process and simple in processing equipment, utilization rate of trace elements at a later stage is increased, and loss of other nutrient elements of the fertilizer during processing is avoided.

Owner:JIANGXI RUIBOTE FERTILIZER CO LTD

Multifocal lens and processing device and method thereof

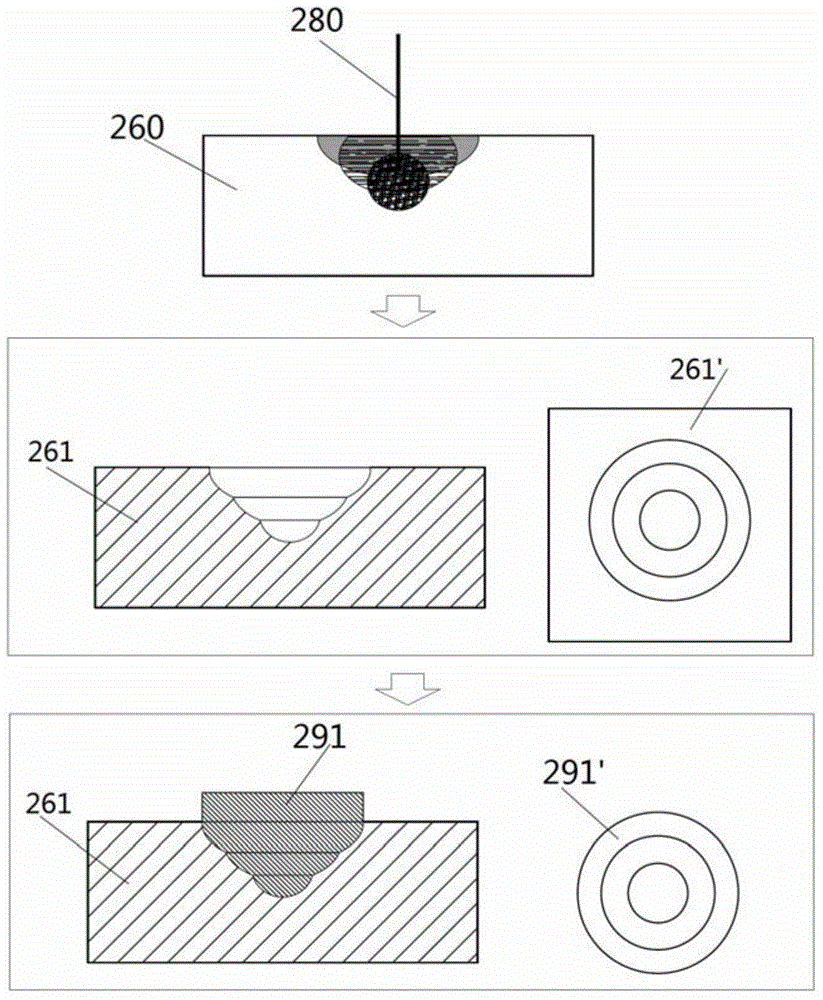

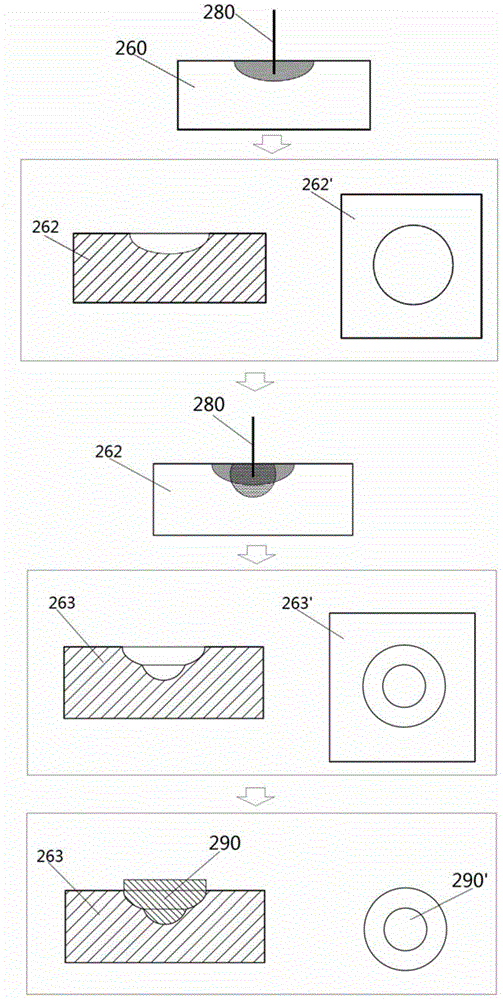

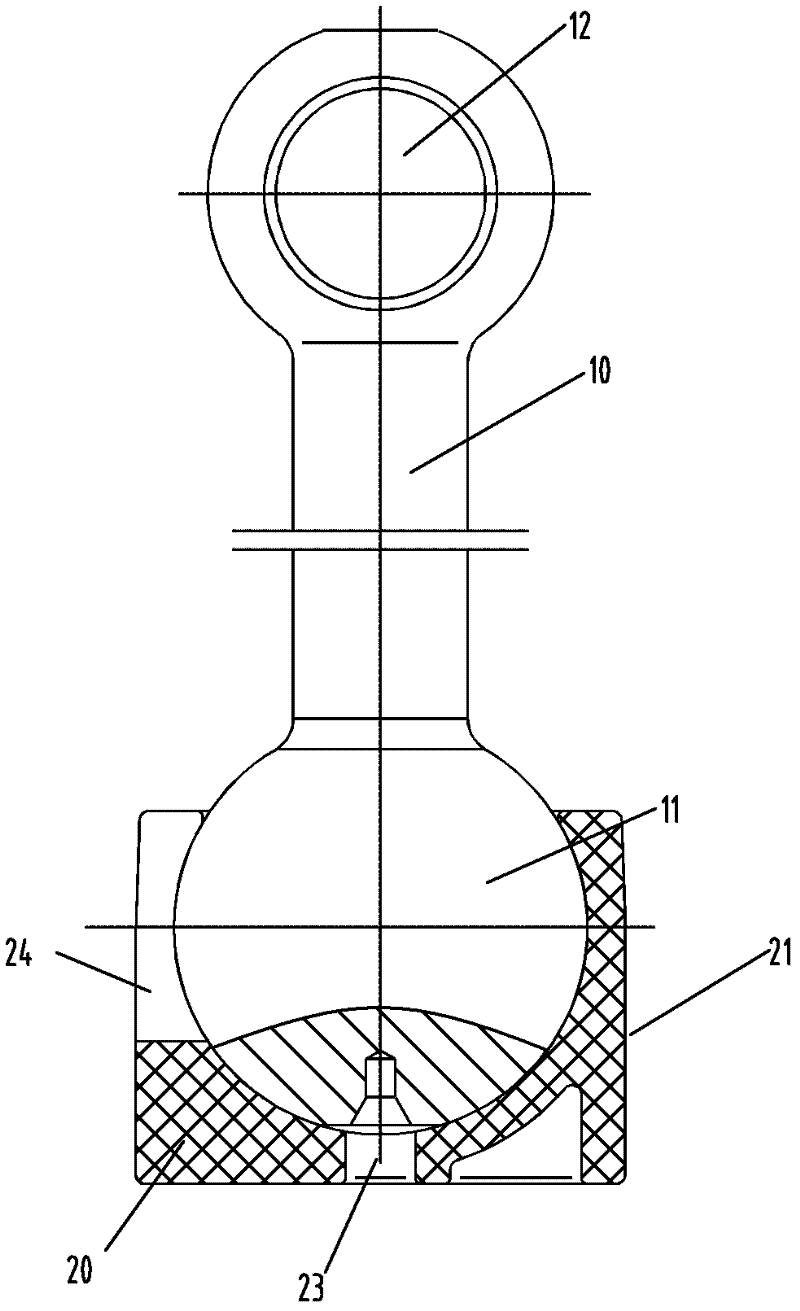

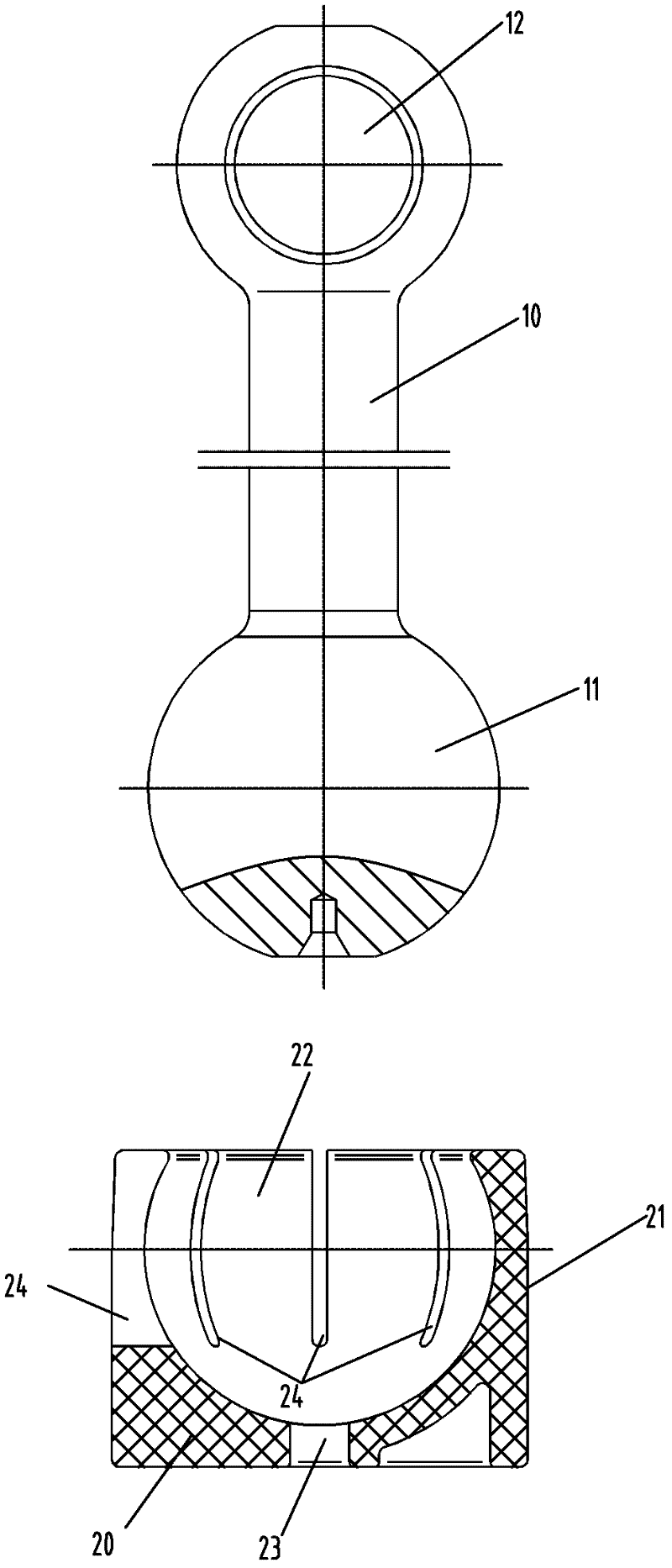

ActiveCN104808268ASimple processing equipmentFlexible processing methodMicroscopesLensOptical pathCamera lens

The invention provides a multifocal lens and a processing device and method thereof. The processing device comprises a femto second laser generator 210, a parameter modulation optical path 220, an optical CCD 230, a semitransparent and semi-reflecting lens 240, an optical focusing lens 250, a hard substrate 260 and a 3D translation platform 270, wherein the femto second laser generator 210 generates femto second laser pulses 280, the femto second laser generator 210, the parameter modulation optical path 220 and the semitransparent and semi-reflecting lens 240 are placed in the same optical path successively, the optical CCD 230, the semitransparent and semi-reflecting lens 240, the optical focusing lens 250 and the hard substrate 260 are placed in the same optical path successively, and the hard substrate 260 is arranged on the 3D translation platform 270. According to the multifocal lens and the processing device and method thereof, technology is simple, and curved surfaces are controllable.

Owner:XI AN JIAOTONG UNIV

Method for machining universal joint bearing

ActiveCN102562777AImprove pass rateEasy for mass production applicationsPivotal connectionsUniversal jointEngineering

The invention discloses a method for machining a universal joint bearing. The method comprises the following steps of: machining a spherical head rod and an outer ring, wherein the outer ring is provided with an elastic mounting groove and a splitting hole which are communicated and penetrate through the outer ring along an axial line of the mounting groove; mounting a tool in the mounting groove, wherein the tool is provided with an outer spherical surface and a through slot penetrating through an axial line of the tool, and parameters of the outer spherical surface and parameters of the mounting groove of the outer ring are matched; mounting the tool and the outer ring on a machining device in a connecting manner after a connection shaft penetrates through the through slot; carrying out finish machining on the outer side surface of the outer ring through a machining device; splitting the outer ring and the tool through the splitting hole of the outer ring; and mounting the spherical head rod and the outer ring. The method for machining the universal joint bearing, disclosed by the invention, has the following advantages that the machining precision of the outer side surface of the outer ring, which is provided with the spherical head rod, is good and the yield of the universal joint bearing can be increased.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Pipe cap with glass lens optical window and manufacturing method of pipe cap

The invention provides a manufacturing method of a pipe cap with a glass lens optical window. The pipe cap with the glass lens optical window comprises a metal pipe cap and a glass optical window, wherein a light hole is formed in the upper end of the metal pipe cap, and a glass lens is embedded in the light hole so as to form the glass optical window. The innovation of the pipe cap with the glass lens optical window lies in that after glass is liquefied, the liquefied glass is molded in the metal pipe cap by using a mold so as to form the glass lens. The pipe cap with the glass lens optical window has the beneficial effects that a packaging process of the glass optical window and the metal pipe cap and a forming process of the glass optical window are finished once, the optical property of the glass optical window and the connection firmness between the glass optical window and the metal pipe cap are very good, processing equipment is simple, and the cost is low.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com