Honeycomb-structure sheet material having fiber-reinforced thermoplastic skin and preparation method thereof

A fiber-reinforced, honeycomb structure technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve problems such as difficult to find defects in advance, inconvenient direct detection of interlayer quality, low mechanical properties of skin, etc. To achieve the effect that product quality can be controlled, product quality is easy to control, and the internal quality of the skin is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

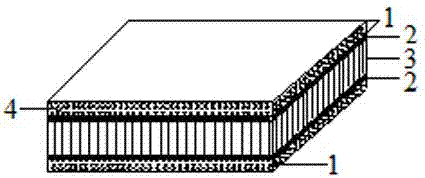

[0031] ① Lay 4 layers of continuous glass fiber reinforced polypropylene prepreg tape criss-cross, put it into the mold, wait until the temperature reaches 180°C, put it into a hot press, press 0.2MPa, and hold for 20min. After the heat preservation is over, it is sent to a cold press with a pressure of 2 MPa and a pressure hold of 20 minutes. The mold is released to produce a continuous glass fiber reinforced polypropylene skin.

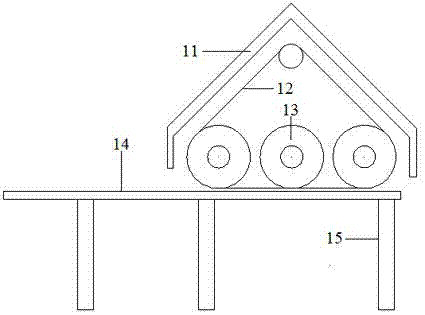

[0032] ② Lay the above-mentioned continuous glass fiber reinforced polypropylene skin, epoxy film, PP honeycomb core, epoxy film, and continuous glass fiber reinforced polypropylene skin of the same area on the front end of the hot pressing roller in sequence, and wait until the temperature reaches 40°C , according to the thickness of the plate, adjust the height of the transfer table and the hot pressing roller, the speed of the transfer table is 2m / min, and send it into the hot pressing roller. After 60s, the sheet comes out from the other side of...

Embodiment 2

[0034] ① Lay 3 layers of continuous carbon fiber reinforced polyvinyl chloride prepreg tape in a crosswise and criss-cross pattern, put it into the mold, wait for the temperature to reach 160°C, and put it into a hot press with a pressure of 0.3 MPa and a holding time of 24 minutes. After the heat preservation is over, it is sent to a cold press with a pressure of 3 MPa and a pressure hold of 30 minutes. The mold is released to produce a continuous carbon fiber reinforced PVC skin.

[0035] ② Lay the above-mentioned continuous carbon fiber reinforced PVC skin, epoxy film, PE honeycomb core, epoxy film, and continuous carbon fiber reinforced PVC skin of the same area on the front end of the hot pressing roller in turn, and wait until the temperature reaches 40°C. Adjust the height of the transfer table and the hot press roller, the speed of the transfer table is 3m / min, and send it into the hot press roller. After 50s, the plate comes out from the other side of the hot press ro...

Embodiment 3

[0037] ① Lay 2 layers of continuous aramid fiber-reinforced PBT prepreg tape criss-cross, put it into the mold, wait for the temperature to reach 228°C, put it into a hot press with a pressure of 0.4MPa, and hold for 30 minutes. After the heat preservation is over, it is sent to a cold press with a pressure of 4 MPa and a pressure hold of 35 minutes. The mold is released to make continuous aramid fiber reinforced PBT skin.

[0038]② Lay the above-mentioned continuous aramid fiber reinforced PBT skin, acrylic film, PVC honeycomb core, acrylic film, and continuous aramid fiber reinforced PBT skin of the same area on the front of the hot pressing roller in sequence. Adjust the height of the transfer table and the heat press roller for the thickness of the plate. The speed of the transfer table is 4m / min, and it is sent into the heat press roller. After 40s, the plate comes out from the other side of the heat press roller, and the two-way continuous aramid fiber reinforced PBT ski...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com