Patents

Literature

56results about How to "Facilitate follow-up process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

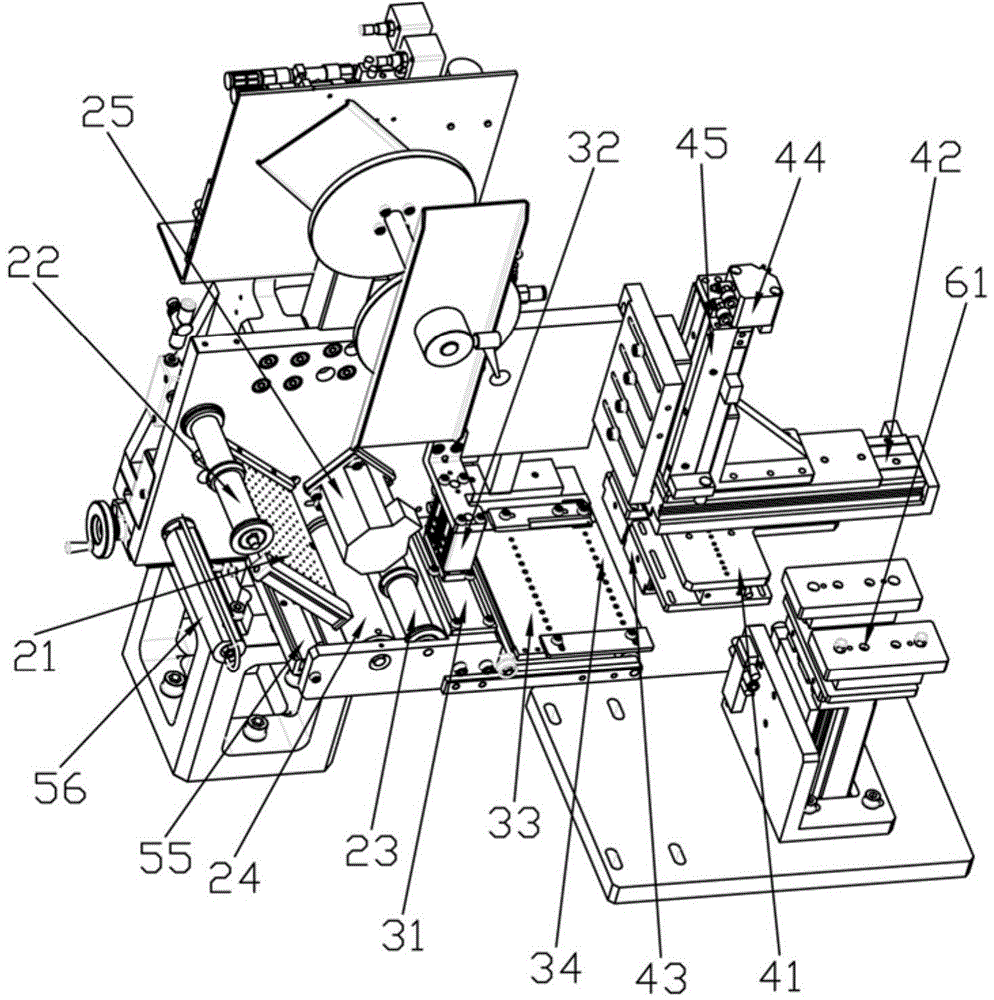

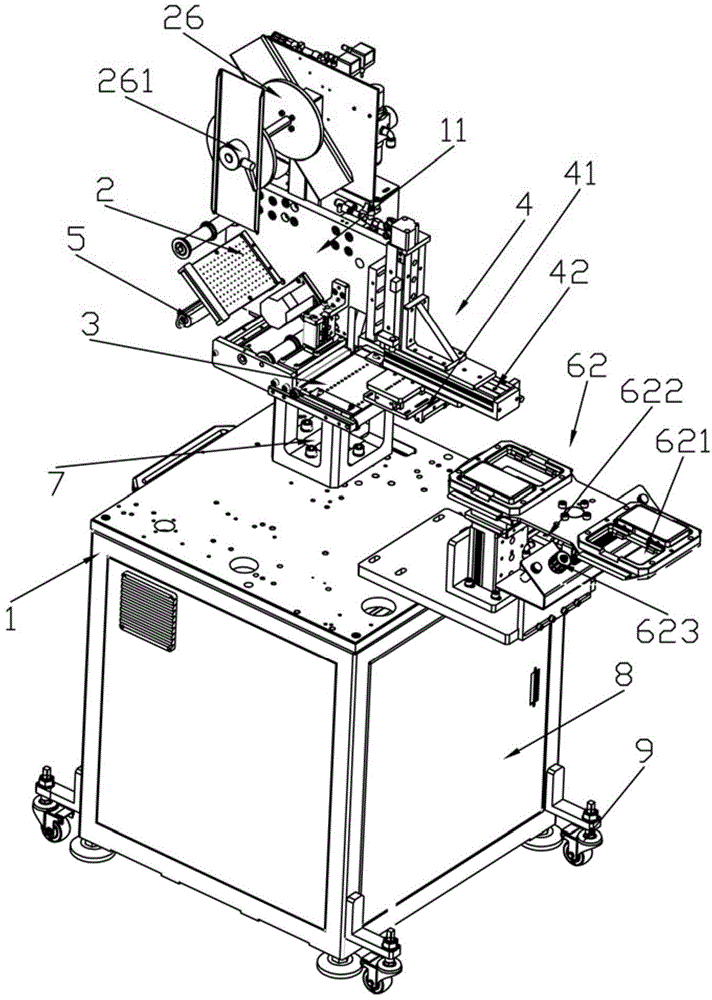

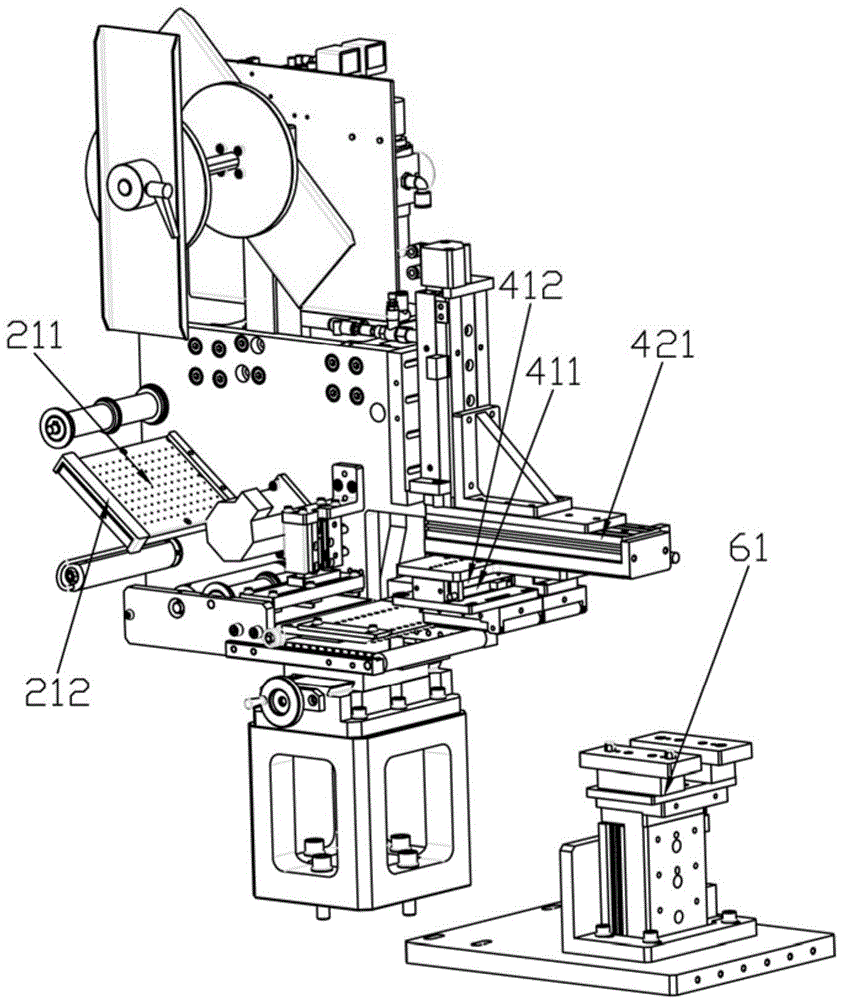

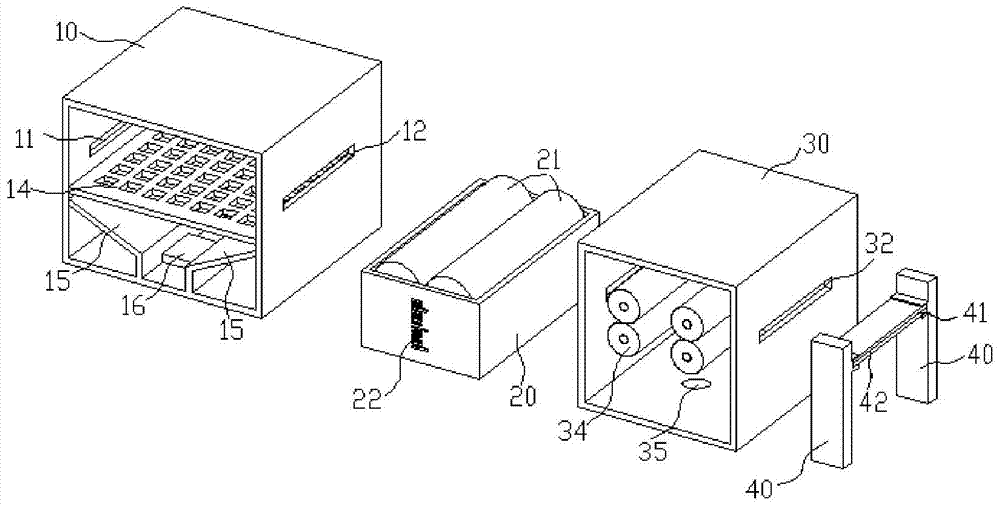

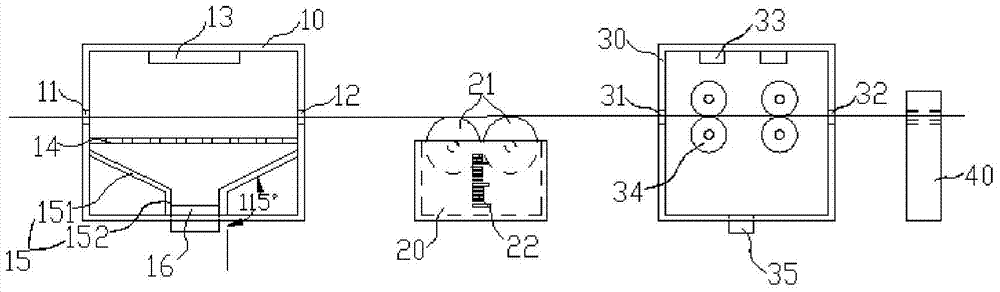

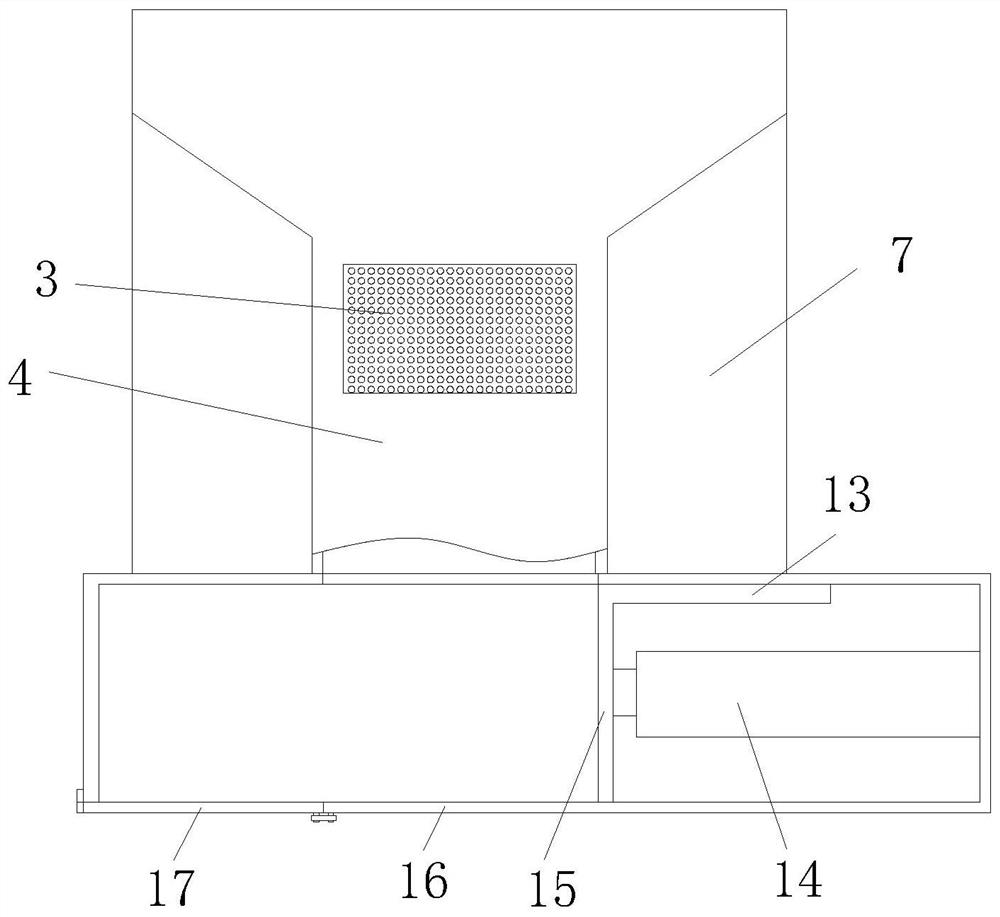

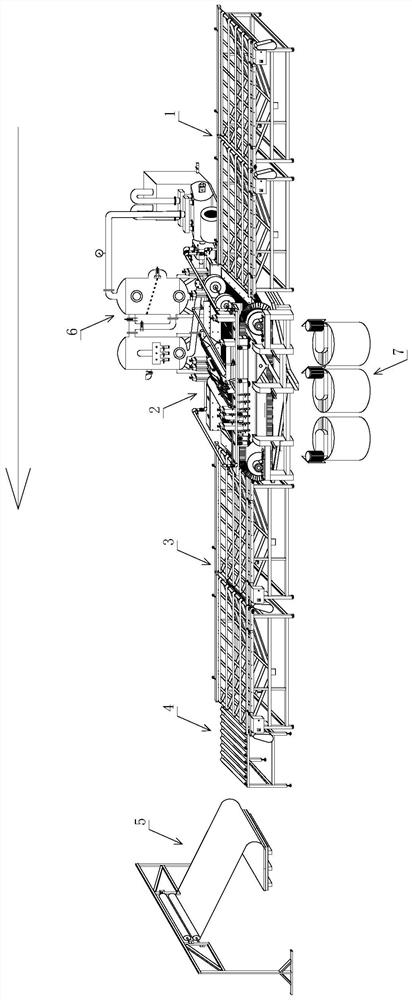

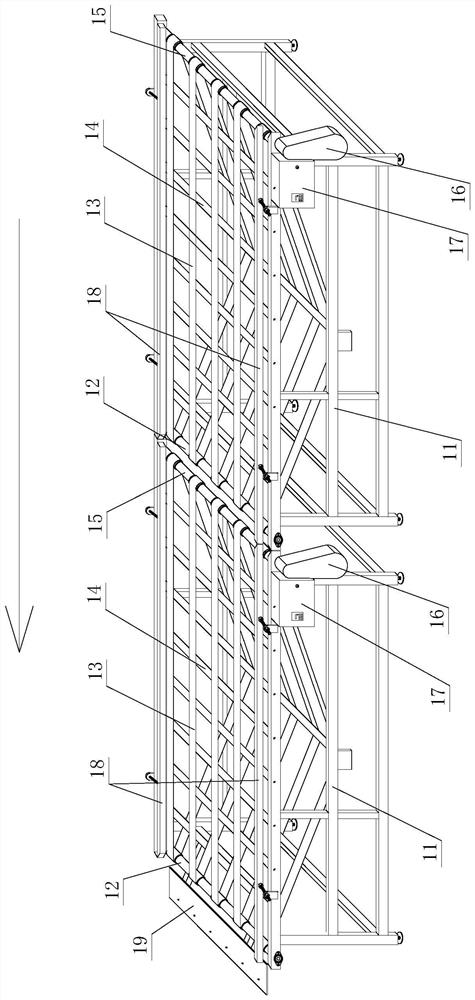

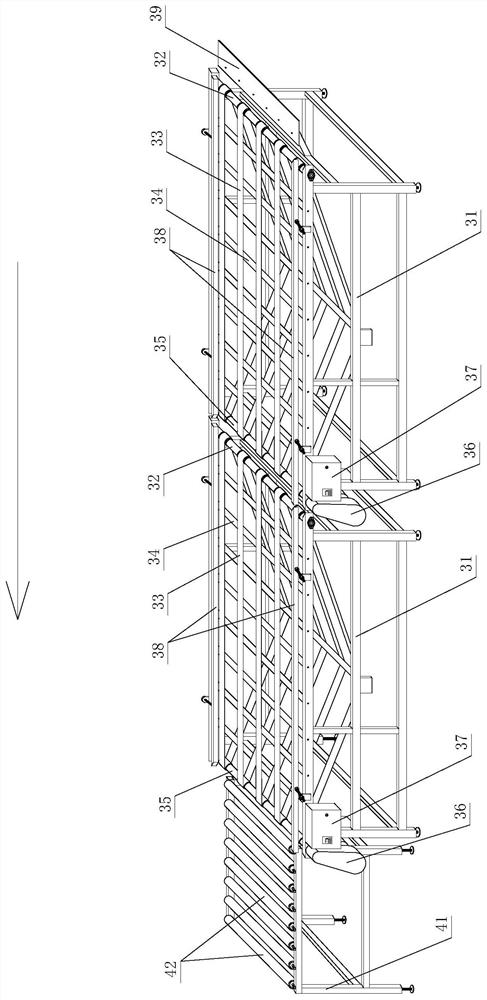

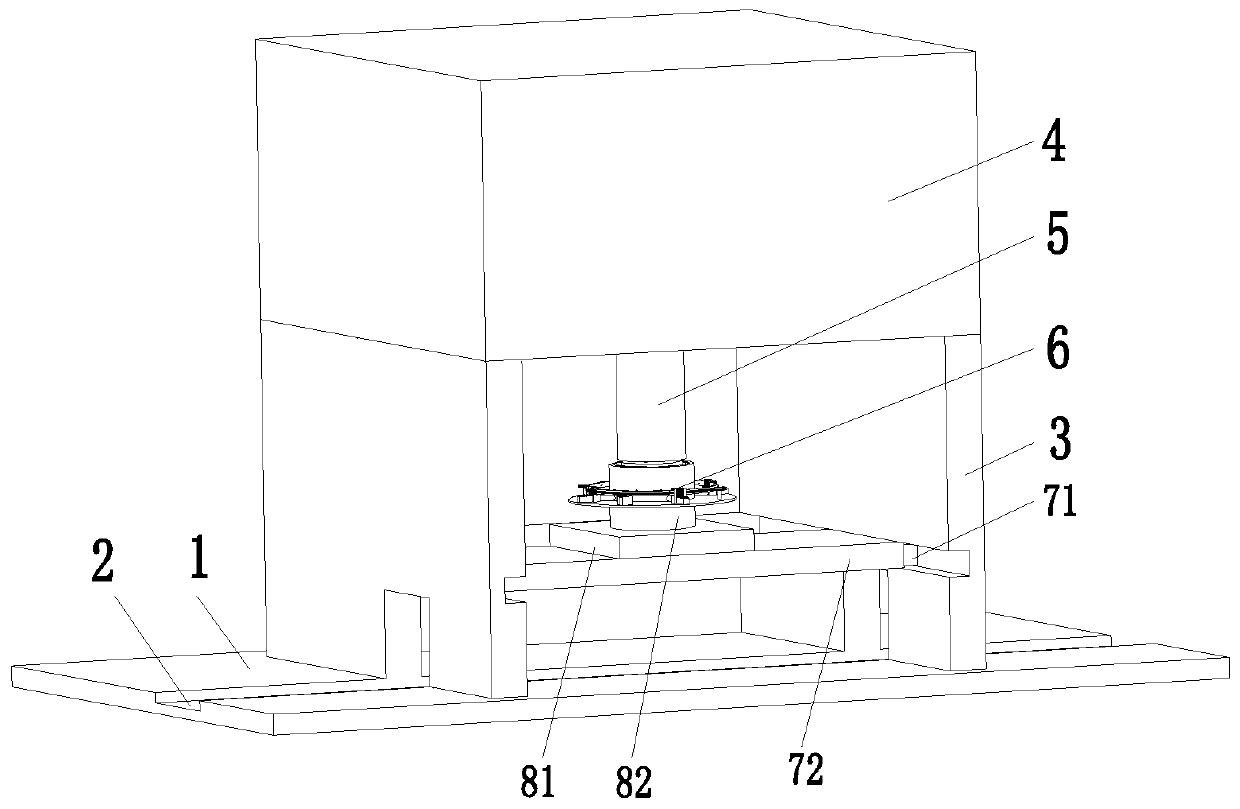

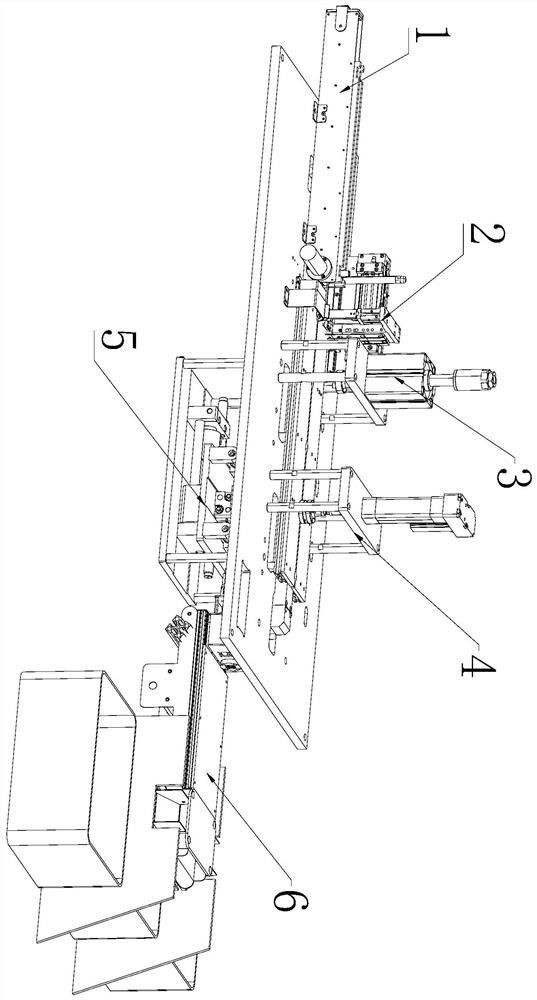

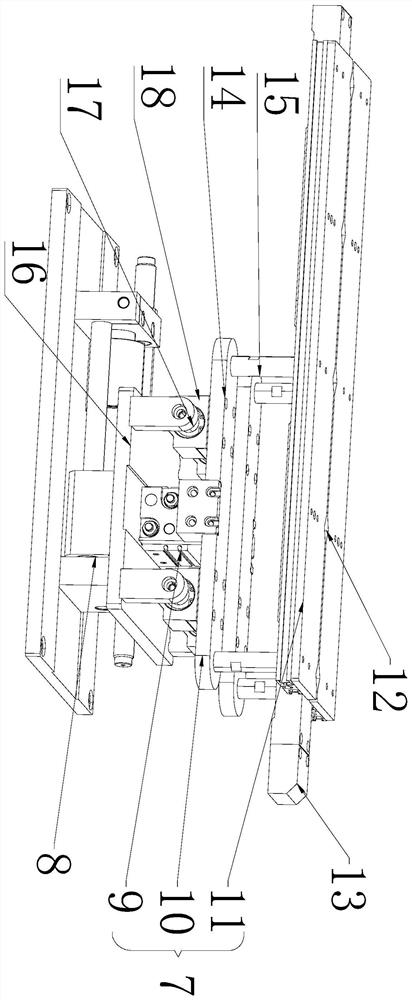

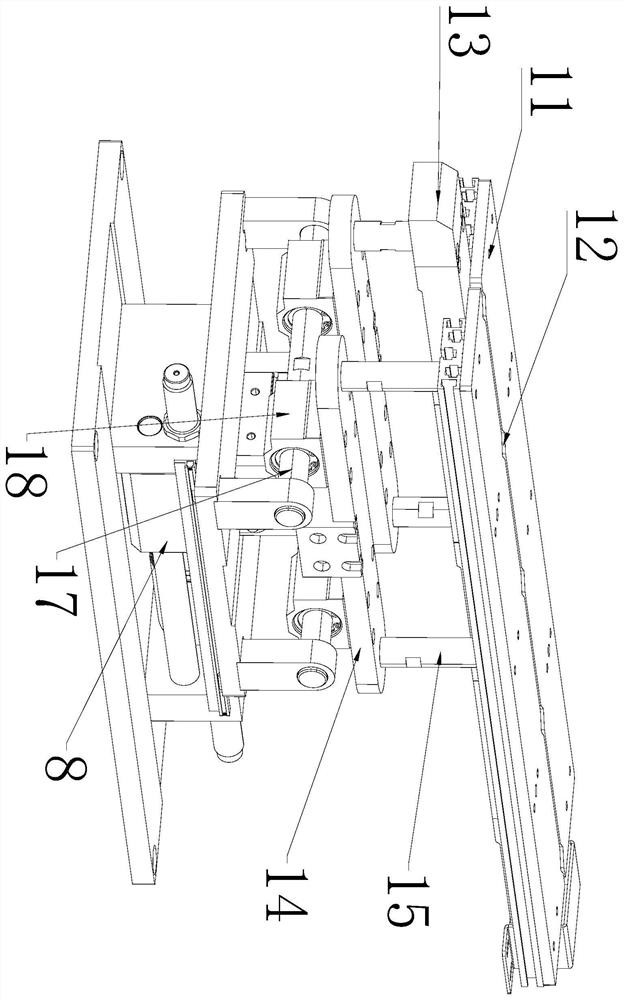

Semi-automatic pad pasting machine

InactiveCN104828283AReduce labor costsImprove film quality and film precisionPackagingManipulatorOne-time pad

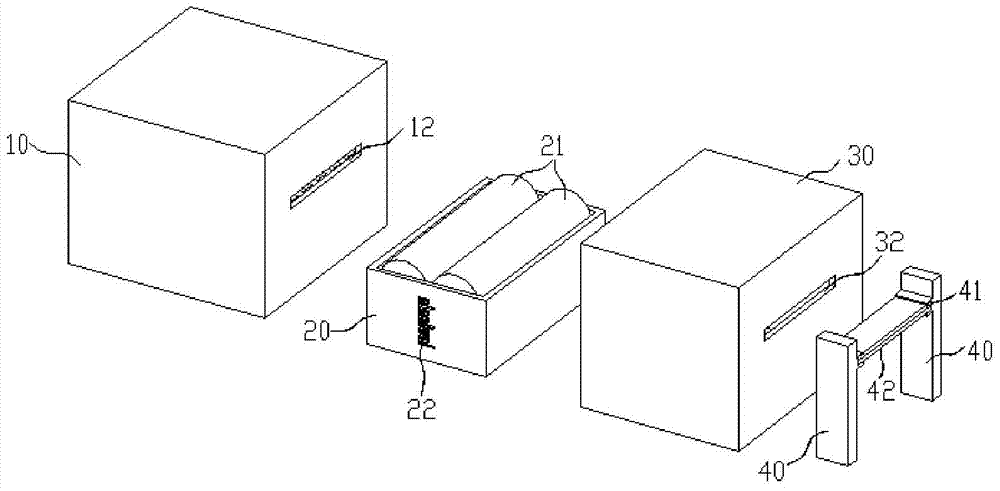

The invention relates to the field of pad pasting, in particular to a semi-automatic pad pasting machine. The semi-automatic pad pasting machine comprises a frame. A feeding mechanism is arranged on the frame. A stripping mechanism is arranged at the portion, located at the output end of the feeding mechanism, of the frame. A waste recycling mechanism is further arranged at the portion, located at the output end of the stripping mechanism, of the frame. A mechanical arm mechanism is arranged at the portion, located at the output end of the stripping mechanism, of the frame and comprises a suction cup assembly used for sucking a to-be-pasted pad, an unfolding assembly used for unfolding the to-be-pasted pad during pad pasting and a bubble removing assembly used for removing bubbles generated during pad pasting, wherein the suction cup assembly, the unfolding assembly and the bubble removing assembly are arranged at the bottom of the mechanical arm mechanism. A pad pasting station is further arranged on the frame and located on the transferring path of the mechanical arm mechanism. According to the semi-automatic pad pasting machine, as the feeding mechanism, the stripping mechanism and the mechanical arm mechanism are arranged to be matched, a user only needs to hang the pad on a hanging roller, the to-be-pasted pad is transferred and pasted through the mechanical arm mechanism, then the waste recycling mechanism carries out assisting to recycle waste, a one-time pad pasting process is completed, and the pad pasting quality and the pad pasting accuracy can be improved.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

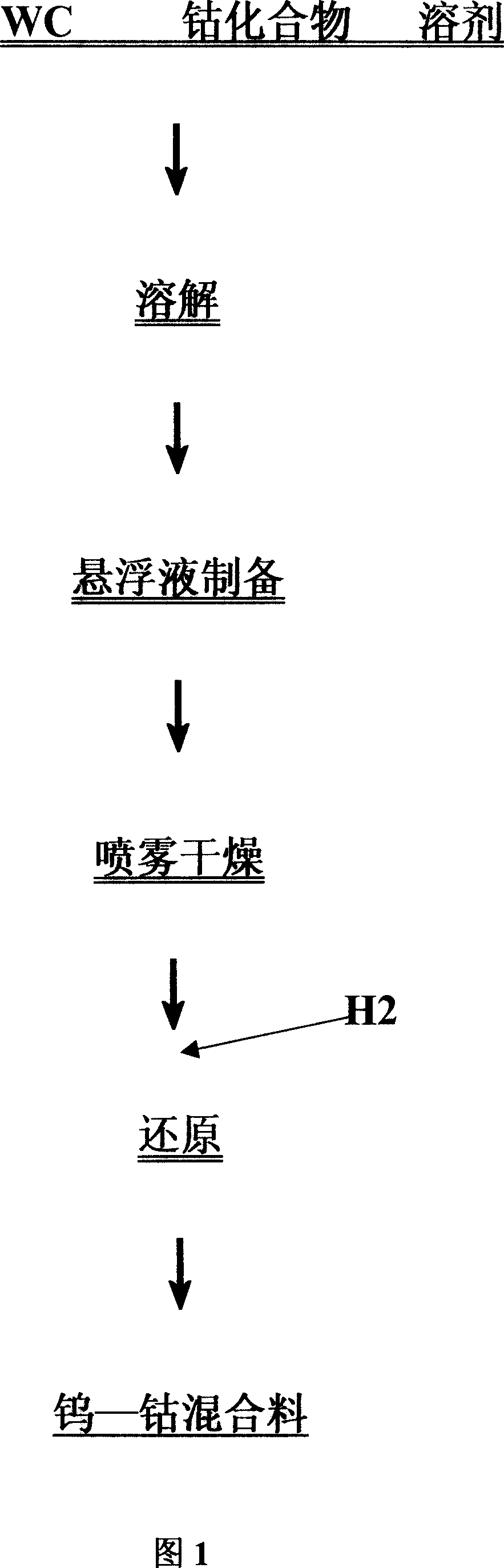

Method of preparing ultra-fine hard alloy mixture of tungsten and cobalt and product

InactiveCN1924047AThe preparation process is simple and easy to doFacilitate follow-up processAlloyUltra fine

The invention discloses a preparing method of composite material of ultrafine hard alloy tungsten and cobalt, which comprises the following steps: dissolving soluble organic cobalt compounds in the solution; fetching transparent solution; blending ultrafine tungsten carbide powder and organic cobalt compounds solution evenly; coating the organic cobalt compounds on the surface of tungsten carbide; evaporating liquid phase at spraying drying pattern; making organic cobalt compounds clad on the surface of tungsten carbide evenly; reducing; making metal cobalt clad on the external surface of each tungsten carbide particle.

Owner:谭日善 +1

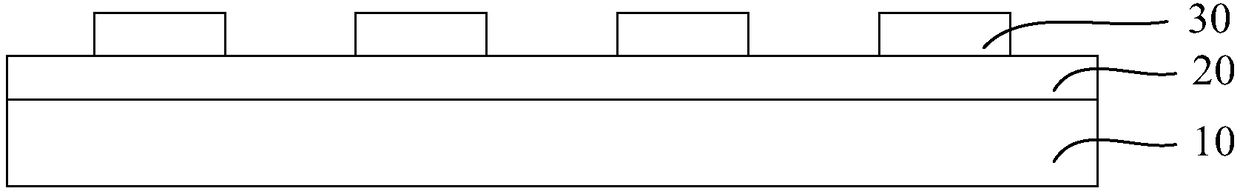

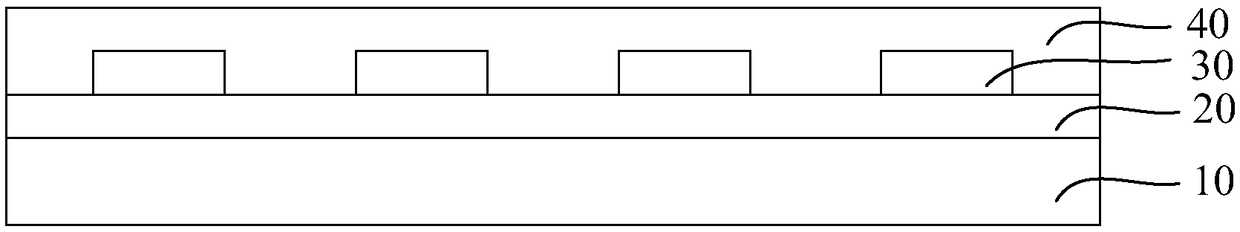

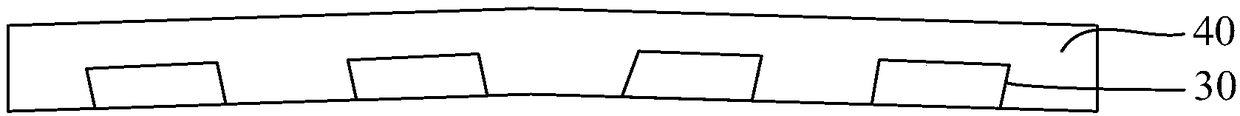

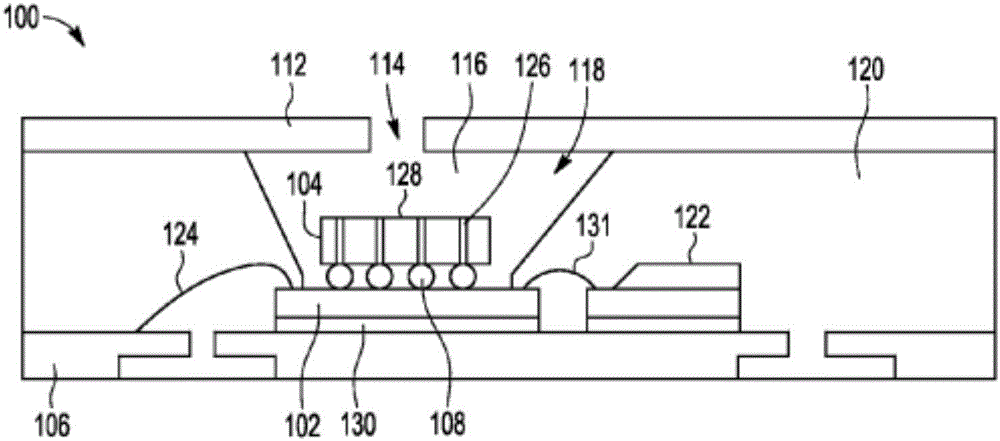

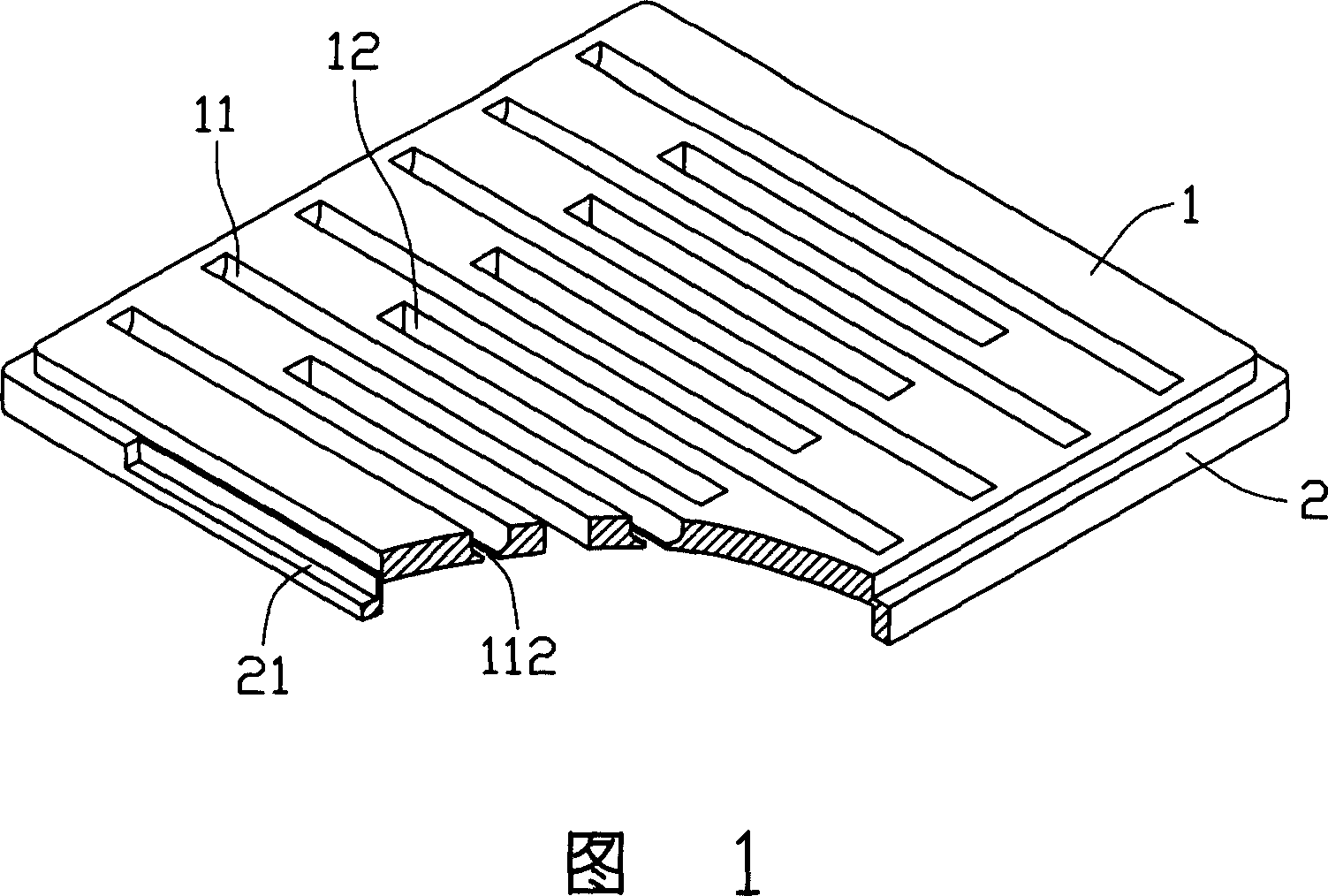

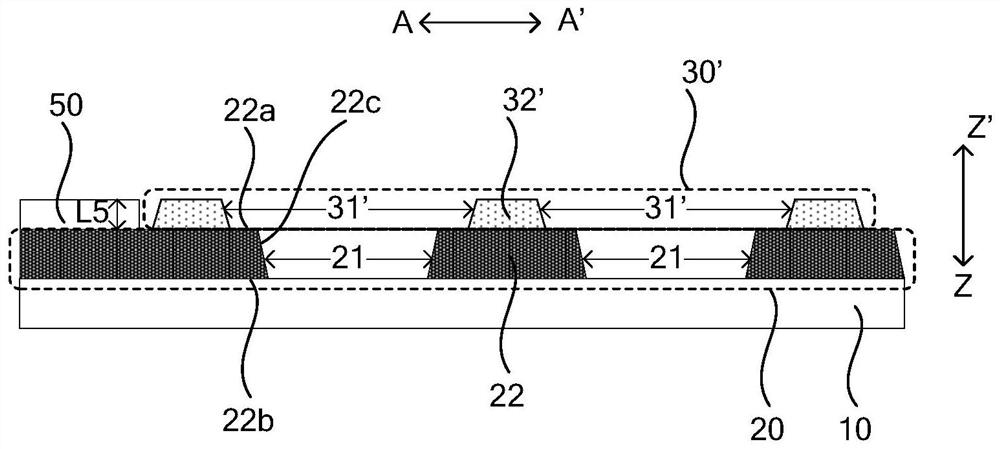

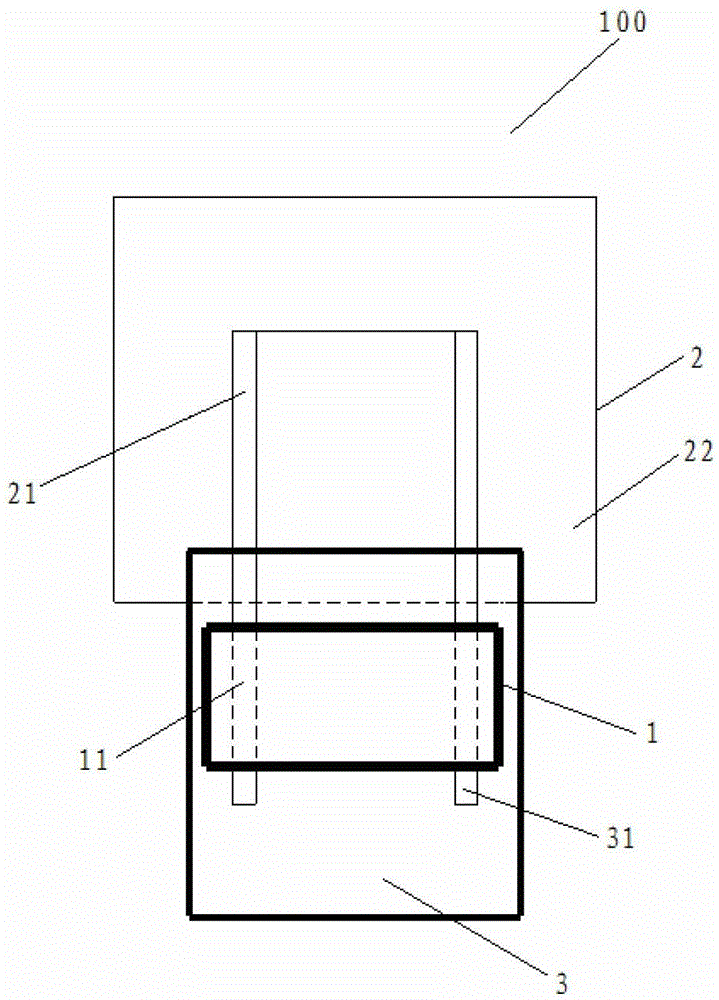

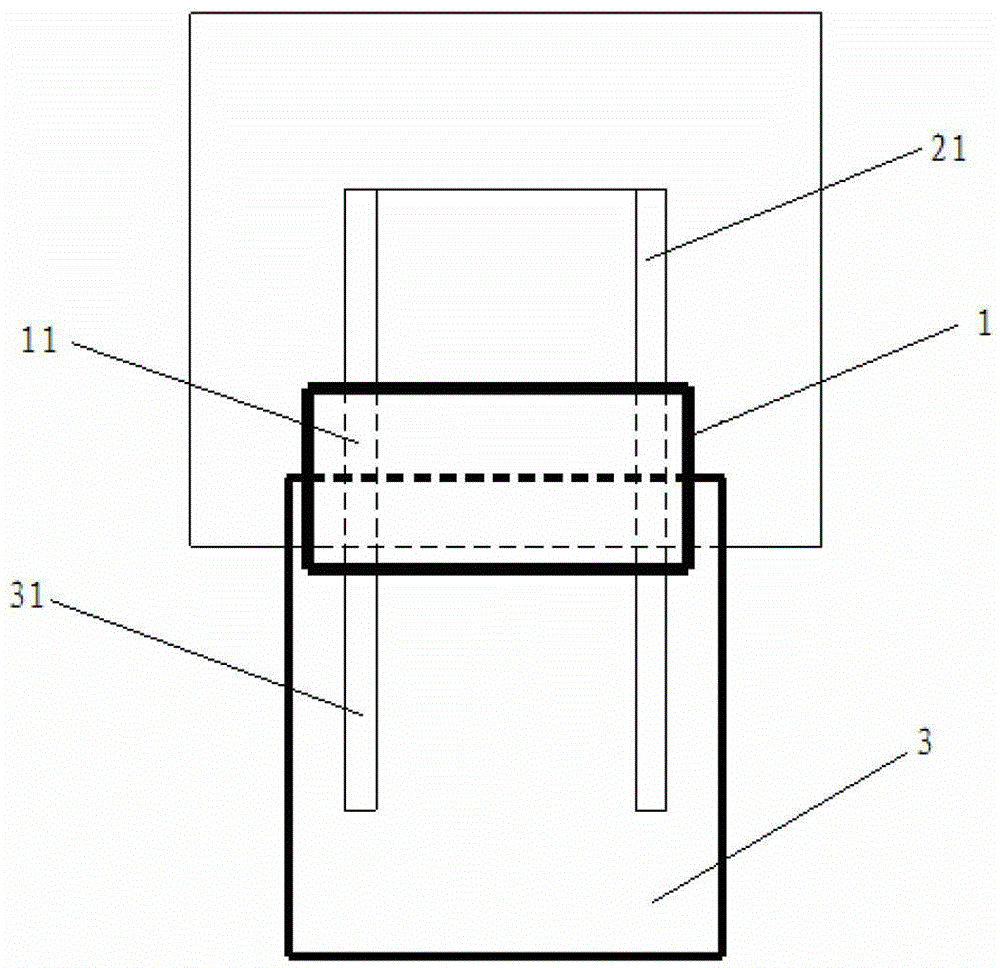

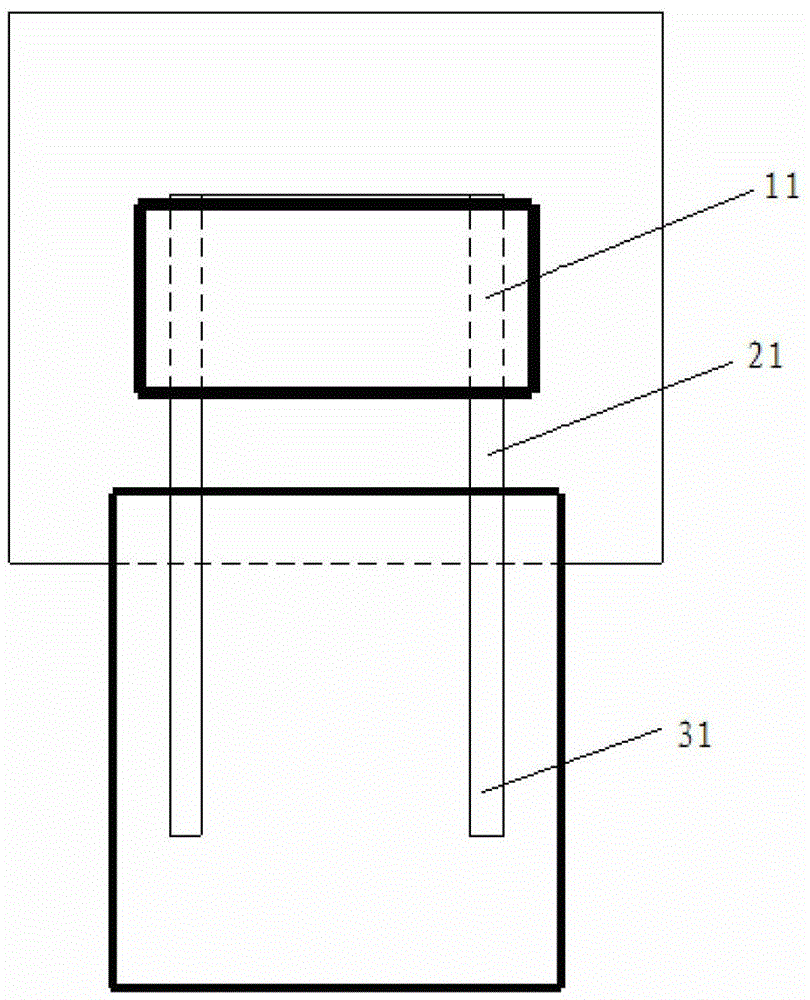

Device package structure and method for stress release in packaging process

InactiveCN108257882AQuality improvementImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringEngineering

The present invention provides a device package structure and a method for stress release in a packaging process. The method includes the following steps that: a carrying component is provided, a plurality of units to be packaged are fixed onto the carrying component at intervals; a plastic package layer is formed on the carrying component, wherein the plastic package layer covers the carrying component and the units to be packaged; and a plurality of stress release openings are formed in the plastic package layer. Since the stress release openings are capable of releasing stress inside the plastic package layer, so that the warpage of the units to be packaged which have been subjected to plastic package can be decreased, and therefore, subsequent process manufacture can be facilitated. The method is suitable for mass production and can improve the quality and performance of the device package structure.

Owner:NINGBO SEMICON INT CORP

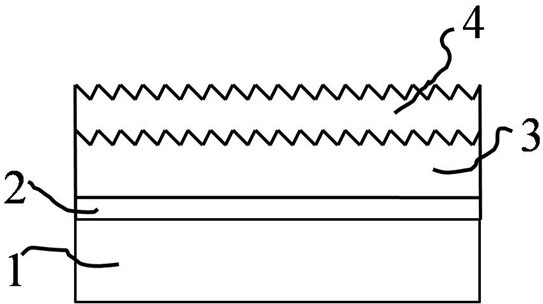

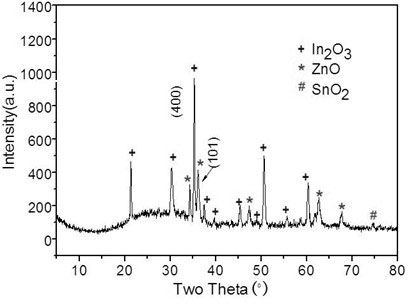

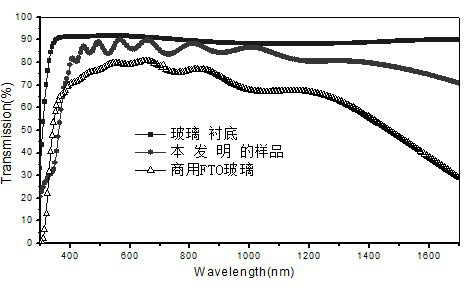

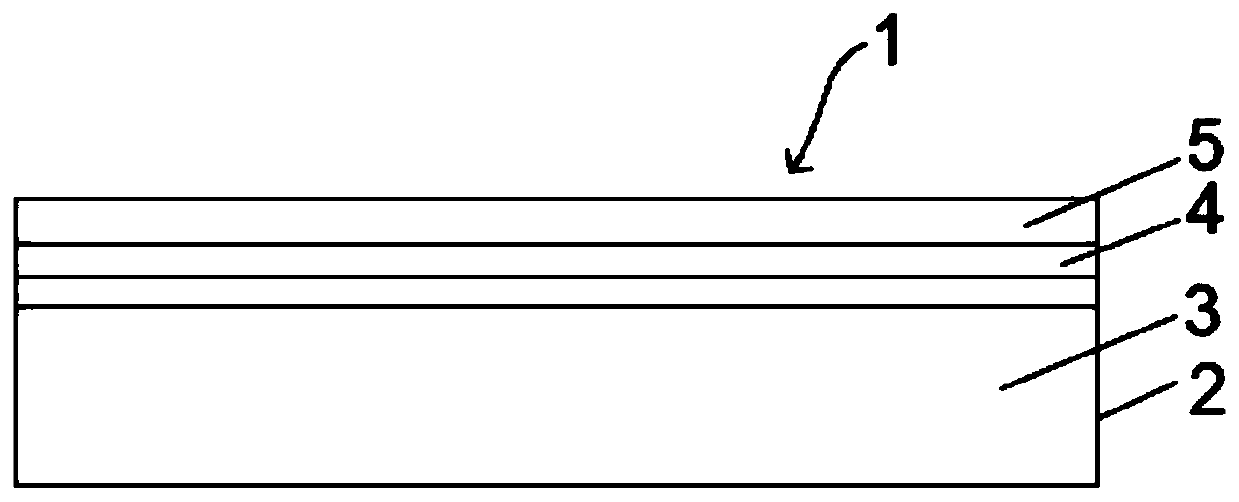

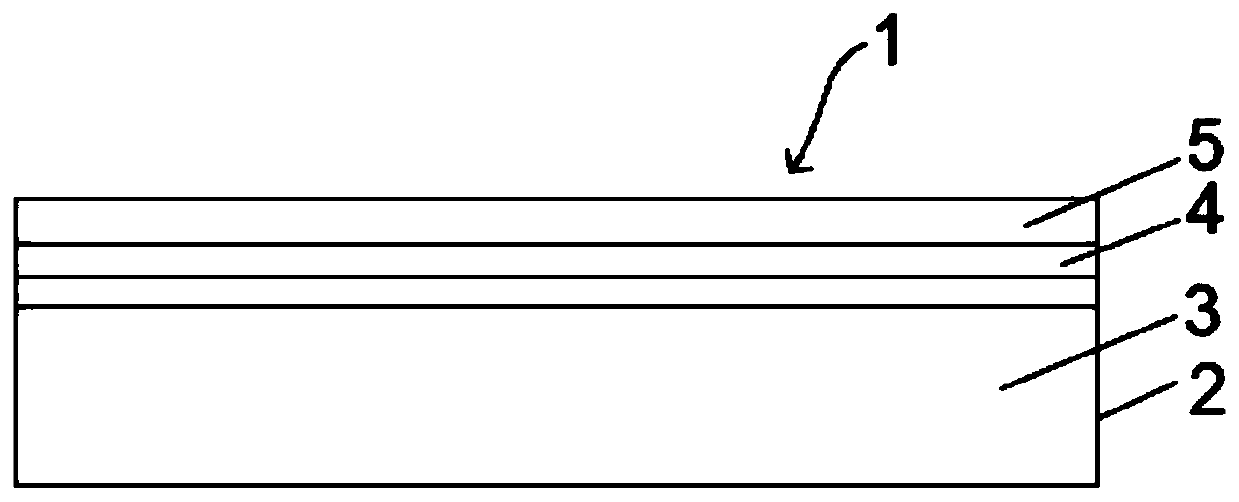

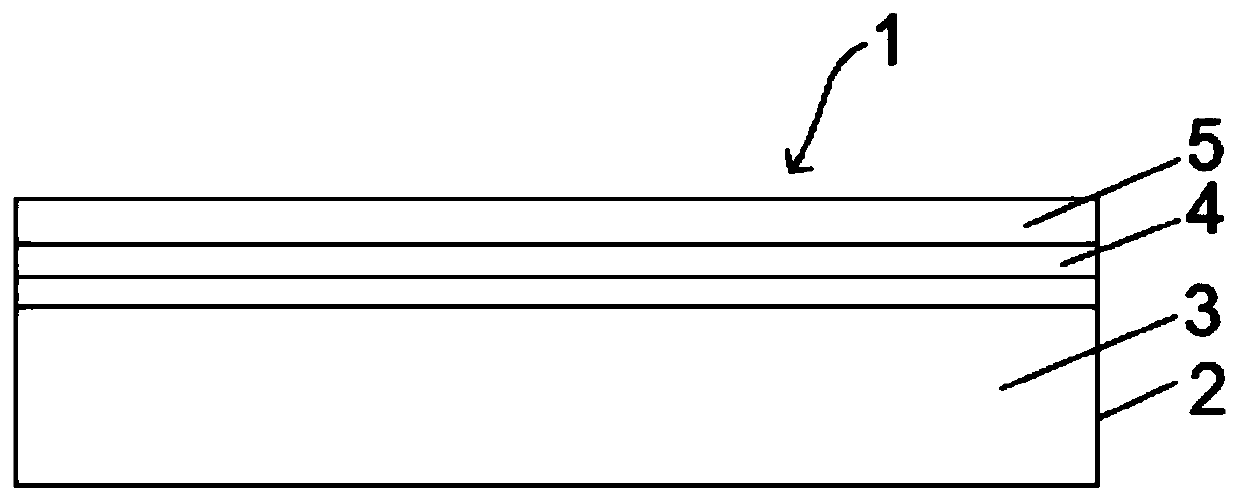

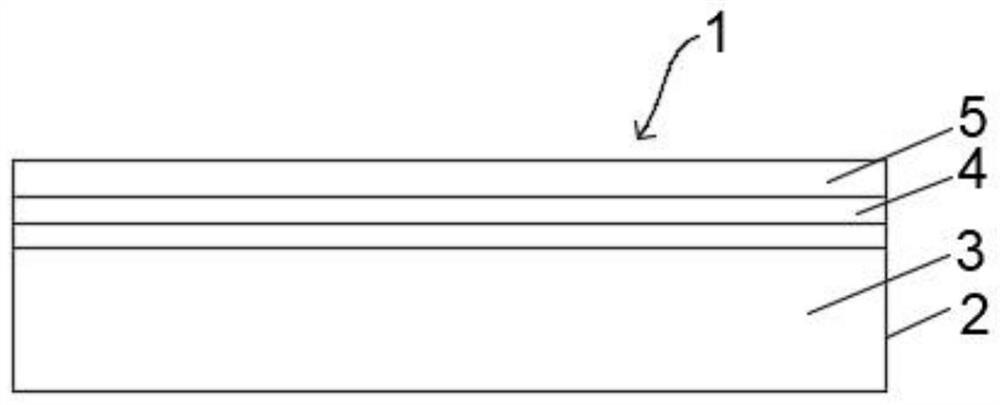

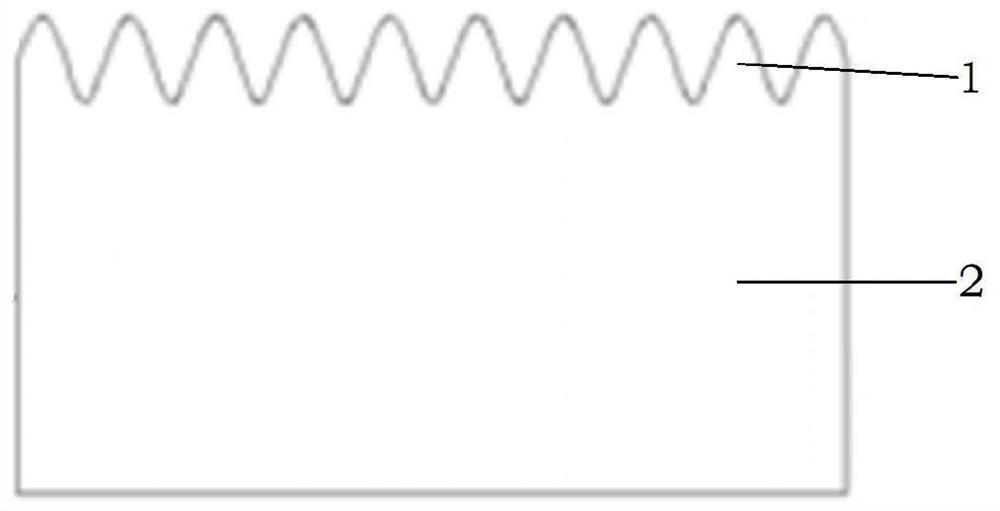

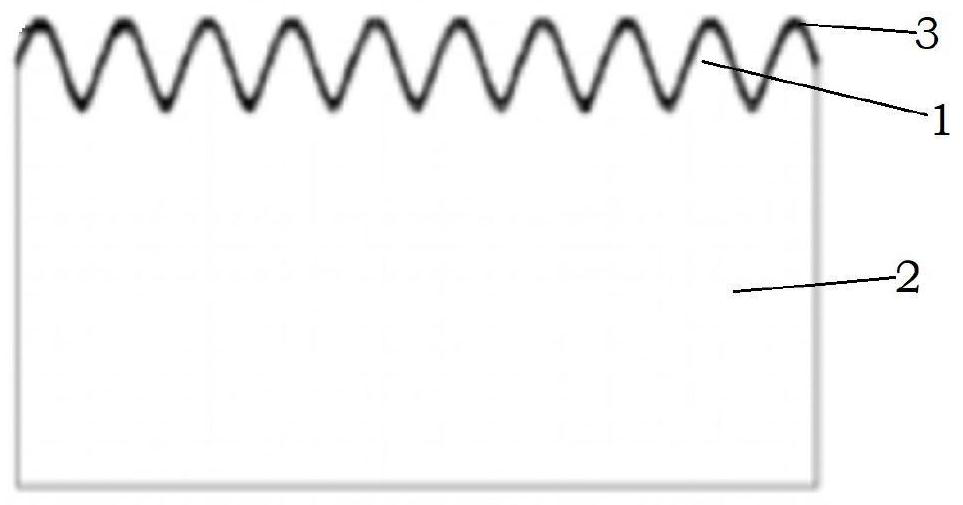

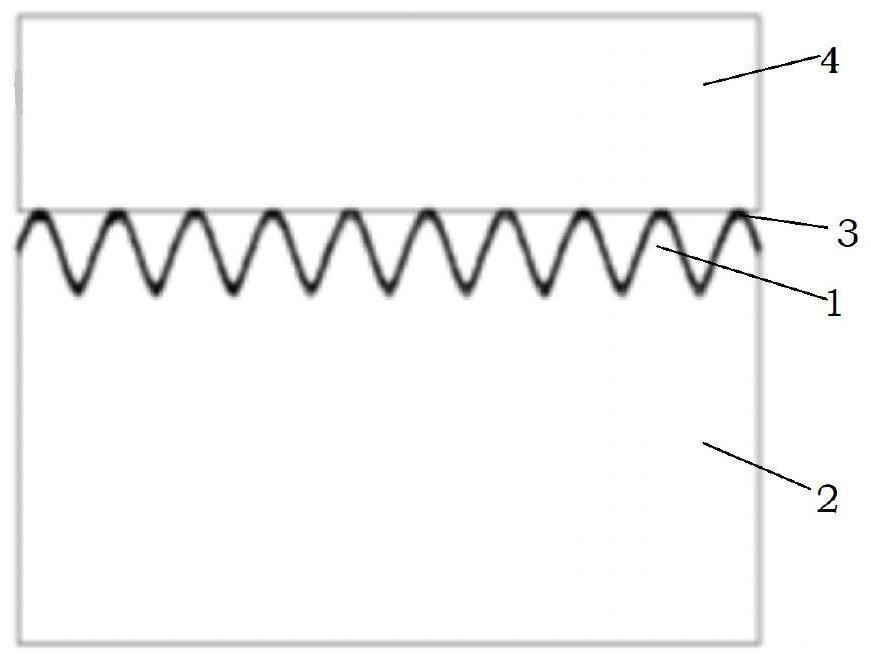

Novel transparent conducting oxide thin film with multi-layer film structure and manufacturing method thereof

InactiveCN102157575AImprove photoelectric performanceImprove adhesionFinal product manufactureVacuum evaporation coatingHydrogenIndium tin oxide

The invention discloses a novel transparent conducting oxide thin film with a multi-layer film structure, wherein the thin film provided by the invention is composed of a base plate, a transition layer, an ITO (indium tin oxide) layer and a ZnO-based thin film layer; the base plate is made of super white glass; the transition layer is made from SiO2 or SiNx; the ITO layer is a Sn-doped In2O3 thin film; and the doped elements of the ZnO-based thin film layer is one or more of the elements consisting of Al, Ga or Zr. As doped ZnO-based thin film layer is deposited on the ITO thin film, the transparent conducting oxide thin film of the multi-layer film structure has better photoelectric properties, lower material cost, is more stable under the hydrogen plasma environment, and is very suitable for the field of thin film solar cells; and the invention simultaneously discloses a novel manufacturing method for manufacturing the novel transparent conducting oxide thin film with the multi-layer film structure, a wet-method process in the manufacturing method is utilized, and a suede structure is formed on the surface of the thin film finally.

Owner:TIANJIN NORMAL UNIVERSITY

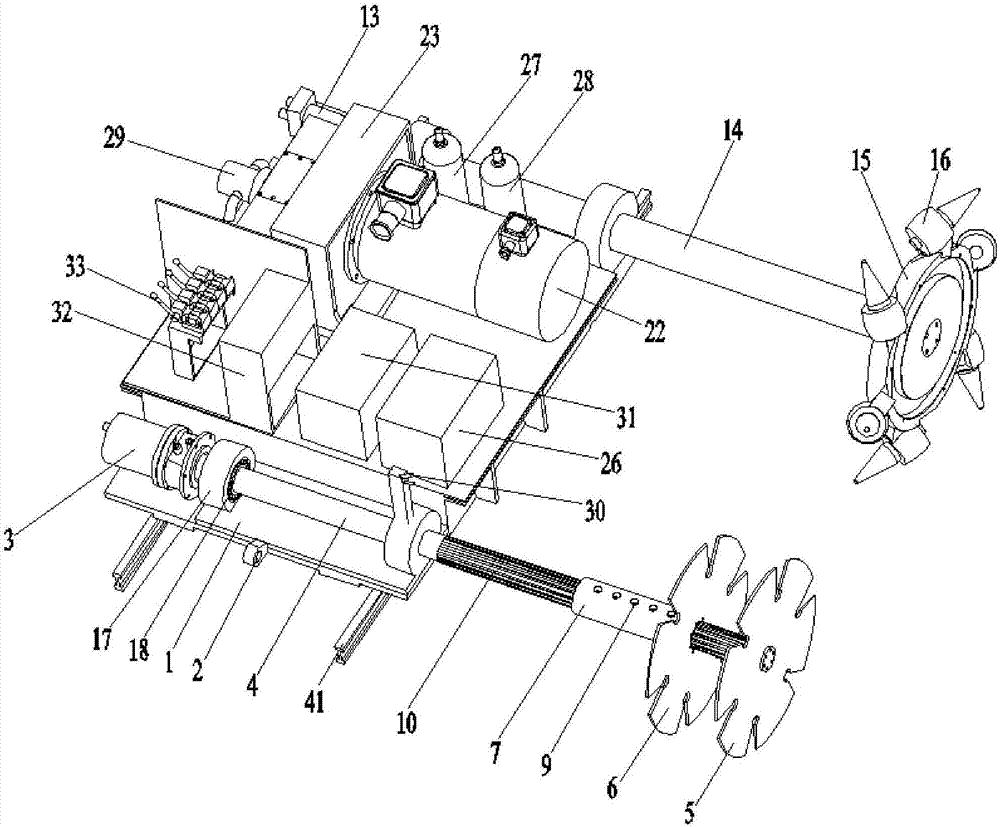

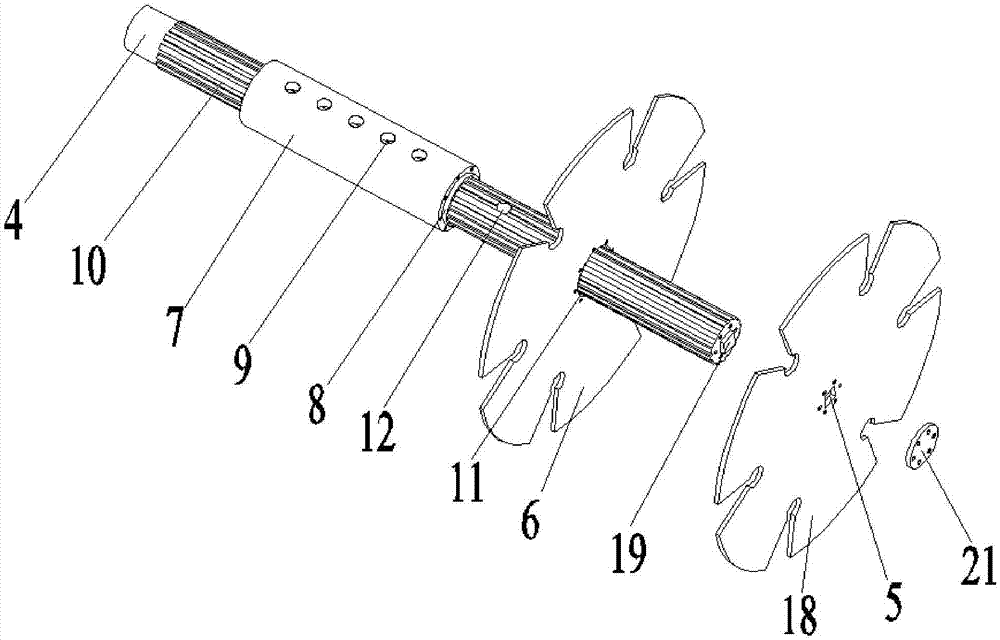

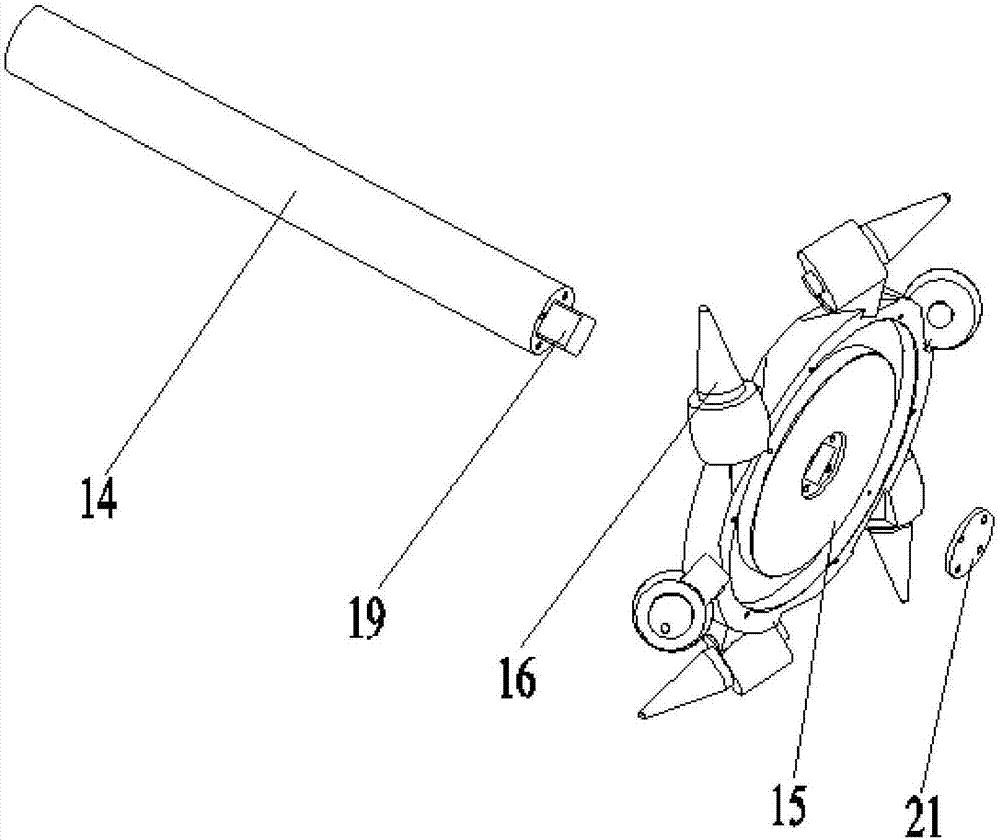

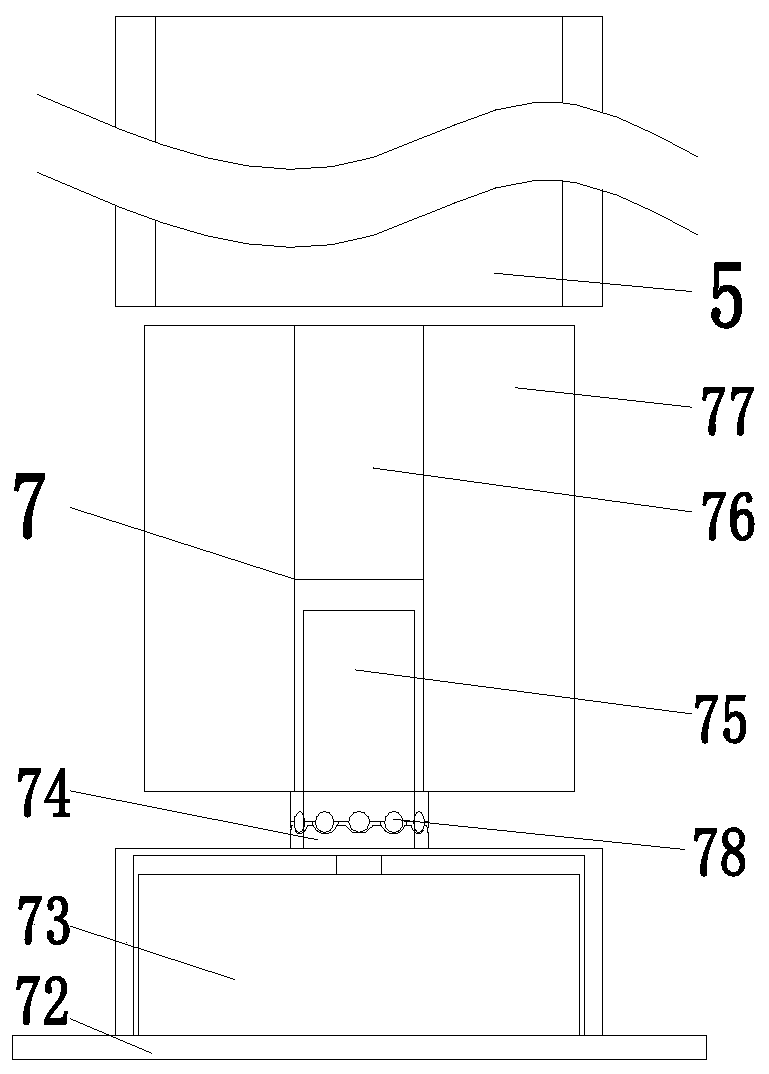

Traction type hydraulic driving water tank cutting machine and using method thereof

ActiveCN107355256ASimplify subsequent processesSpeed up the progress of the projectDrainageStone-like material working toolsVehicle framePiston pump

The invention discloses a traction type hydraulic driving water tank cutting machine and a using method thereof. The cutting machine comprises a frame; a first hydraulic motor and a second hydraulic motor are arranged on the frame; the output end of the first hydraulic motor is connected with a first drive shaft; a first cutting piece and a second cutting piece which are arranged in a spaced mode are fixed to the first drive shaft; and the output end of the second hydraulic motor is connected with a second drive shaft, a rotating disc is fixed to the second drive shaft, and a plurality of cutting teeth which are arranged by certain angles are arranged on the rotating disc. An electric motor is arranged on the frame; the output end of the electric motor is connected with a crank piston pump; the two sides of the crank piston pump are connected to an oil tank through a first double-valve body and a second double-valve body correspondingly; and an oil outlet of the crank piston pump is connected to oil inlets of the first hydraulic motor and the second hydraulic motor; and a travelling part is arranged at the bottom of the frame. Machines are adopted to replace manual work, the time and labor are saved, convenience and high efficiency are achieved, a water tank with the two level sides can be opened, the subsequent process is facilitated, the situation that accumulation water in a roadway is discharged in time is facilitated, the project progress is accelerated, and the work efficiency is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for extracting ganglioside from animal tissue

InactiveCN1400216AIncrease productionHigh puritySugar derivativesSugar derivatives preparationCholesterolSolvent

The present invention discloses a method for extracting ganglioside from animal tissue. Said method adopts one kind of several kinds of polar solvents matched with polarity of ganglioside to greatly raise extraction efficiency of ganglioside, and adopts inversed phase extraction method to remove impurity from the extract to raise product grade and reduce production cost. The purity of the ganglioside prepared by using said invented method can be up to 81%, and its cholesterol and neutral lipide contents are low. Said invention is simple in production process, suitable for scale production, its product purity is high, and can meet the food and medicinal requirements.

Owner:上海宝智生物制品有限公司

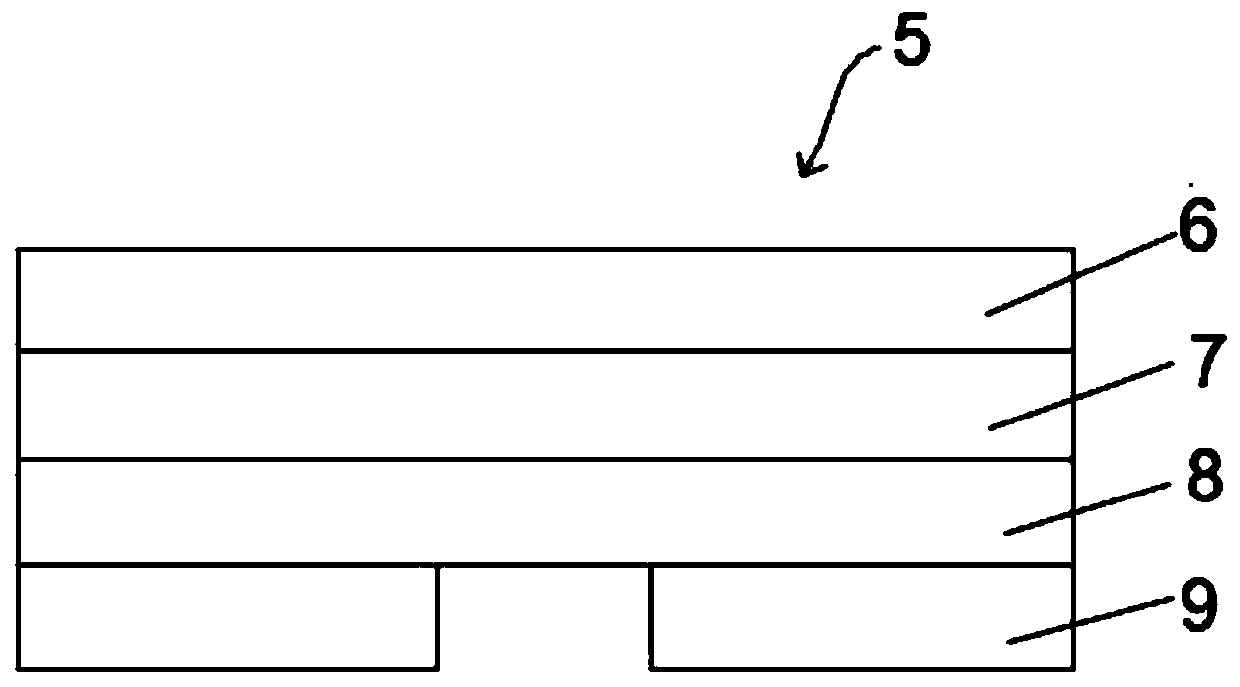

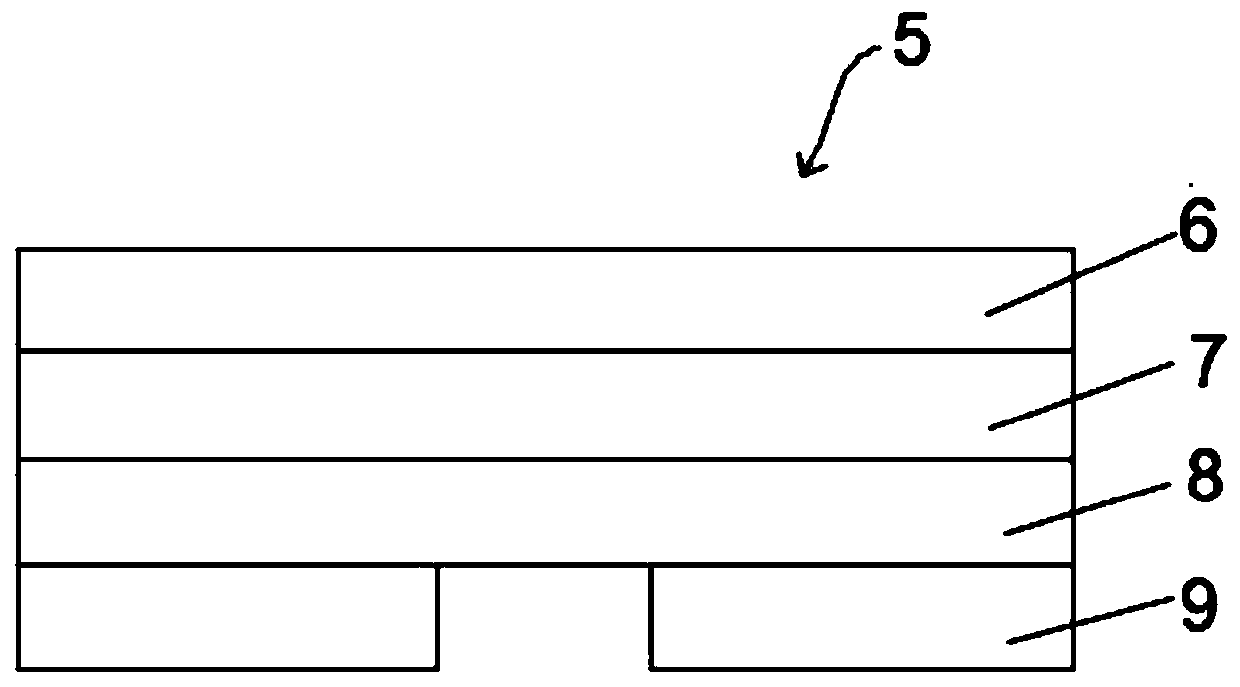

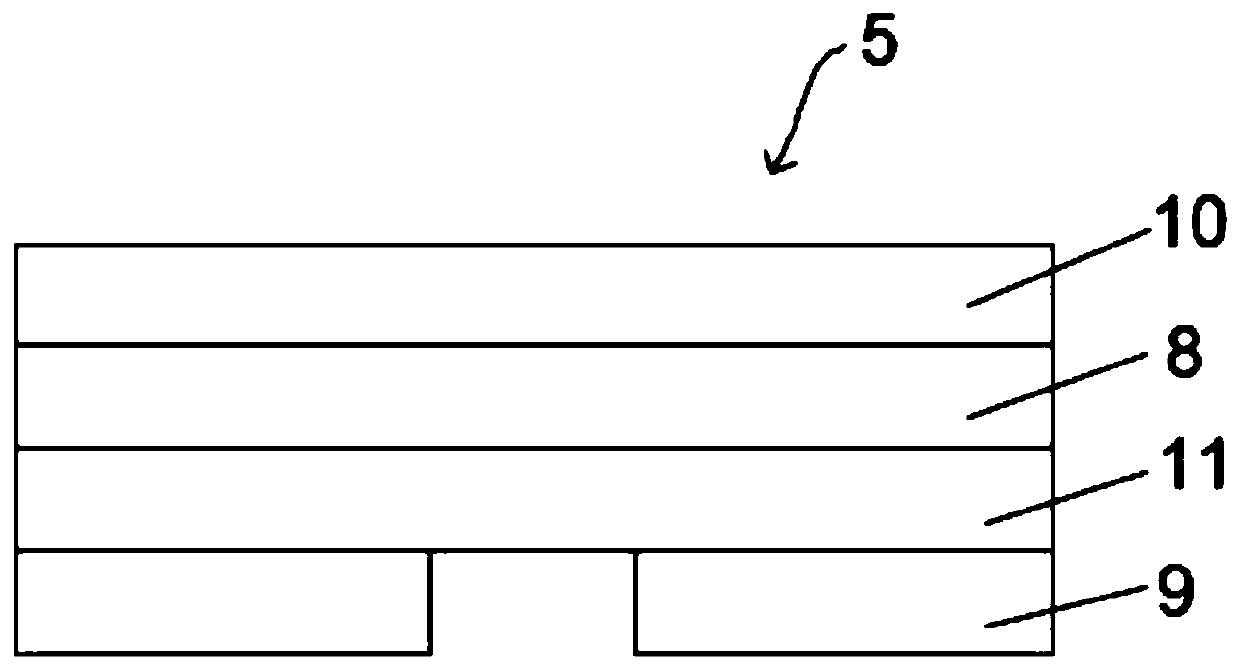

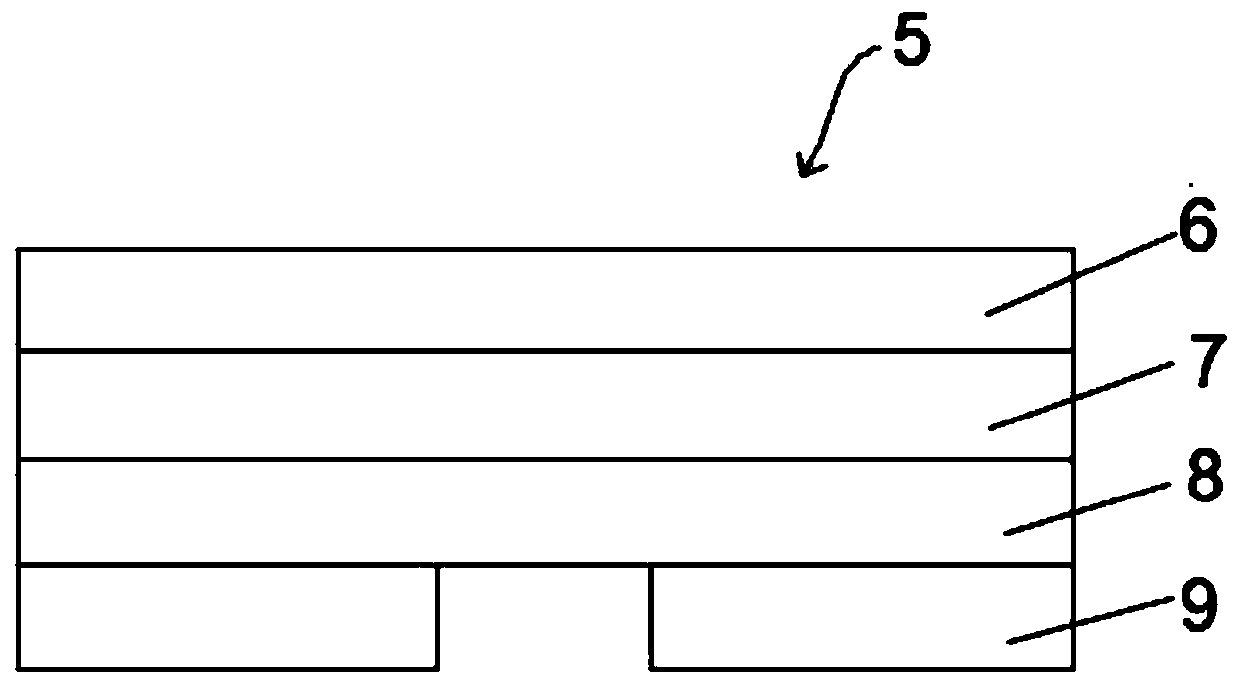

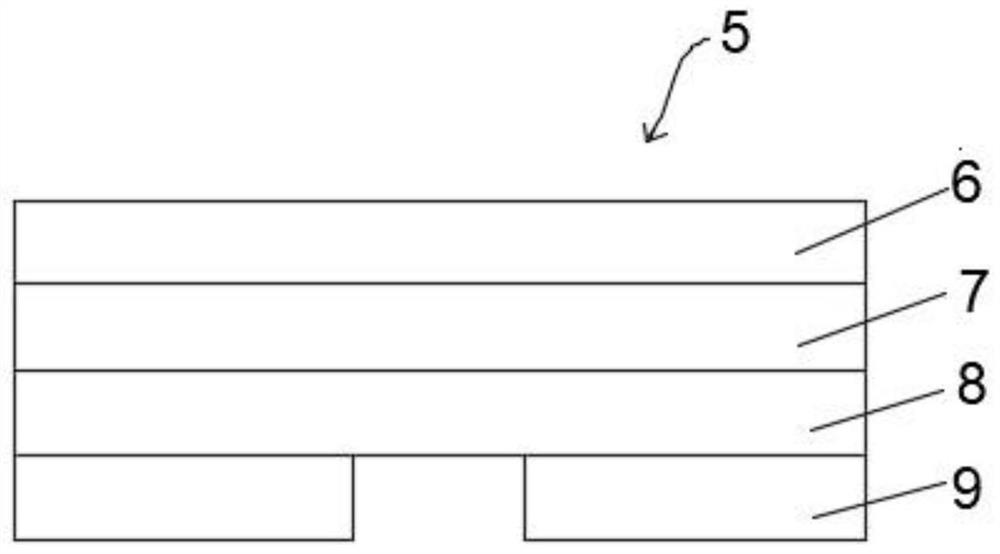

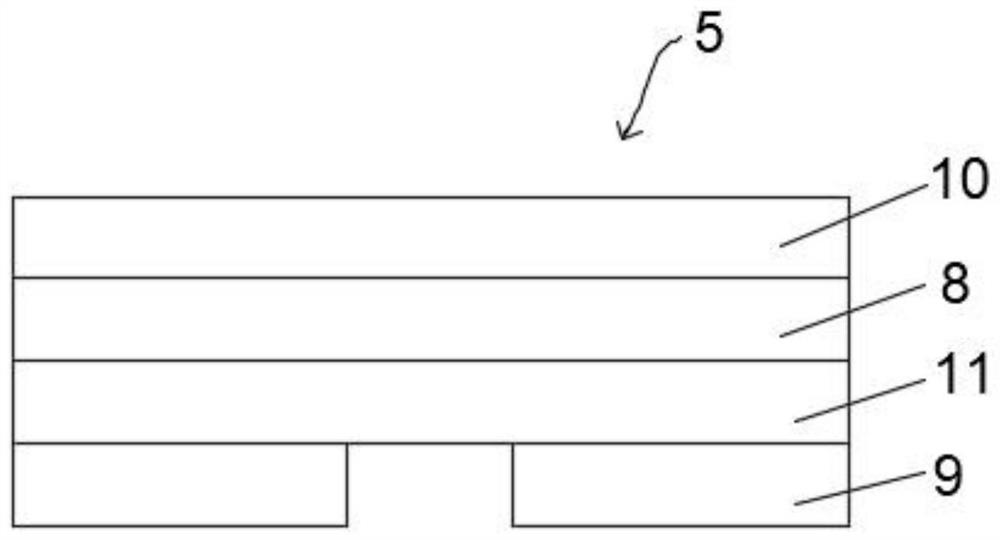

Flexible display screen cover plate

InactiveCN110576664AThe overall thickness is thinReduce thicknessSynthetic resin layered productsElectrical equipmentPolysilazanePolyamide

The invention discloses a flexible display screen cover plate and relates to the field of optical film technology. The flexible display screen cover plate comprises a transparent aromatic polyamide substrate; a polysilazane layer disposed on one side surface of the transparent aromatic polyamide substrate; a polarizing layer disposed on the aromatic polyamide substrate and on the other side, relative to the polysilazane layer, the aromatic polyamide substrate; and a hardened layer arranged on the polarizing layer and on the other side, relative to the transparent aromatic polyamide substrate,of the polarizing layer. According to the invention, the polarizing layer is directly prepared on the transparent aromatic polyamide substrate, so that the overall thickness of the flexible display screen cover plate is reduced, and meanwhile, the overall hardness of the flexible display screen cover plate is greatly improved.

Owner:新纶电子材料(常州)有限公司

Stress-responsive polymethyl-methacrylate-modified silicon-boron polymer microgel and preparation method thereof

The invention provides stress-responsive polymethyl-methacrylate-modified silicon-boron polymer microgel and a preparation method thereof; the modified silicon-boron polymer microgel is prepared by stirring and reacting pre-polymerization liquid at 80-130 DEG C for 6-8 hours, adding a bifunctional chain extender, continuously stirring and reacting for 6-8 hours at 60-90 DEG C, adding a surfactant, stirring and reacting at 80 DEG C for 1-2 hours, introducing polymethyl methacrylate monomer solution containing a catalyst, reacting at 60-80 DEG C for 4-6 hours, and drying the solvent; the pre-polymerization liquid comprises, by weight, 75.0-95.0% of low-molecular-weight polydiorganosiloxane, and 5.0-25.0% of a boron-containing compound. The preparation method of the invention has low reaction temperature, is simple to perform and facilitates large-scale production, and the microgel prepared has good flexibility and good impact resistance.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

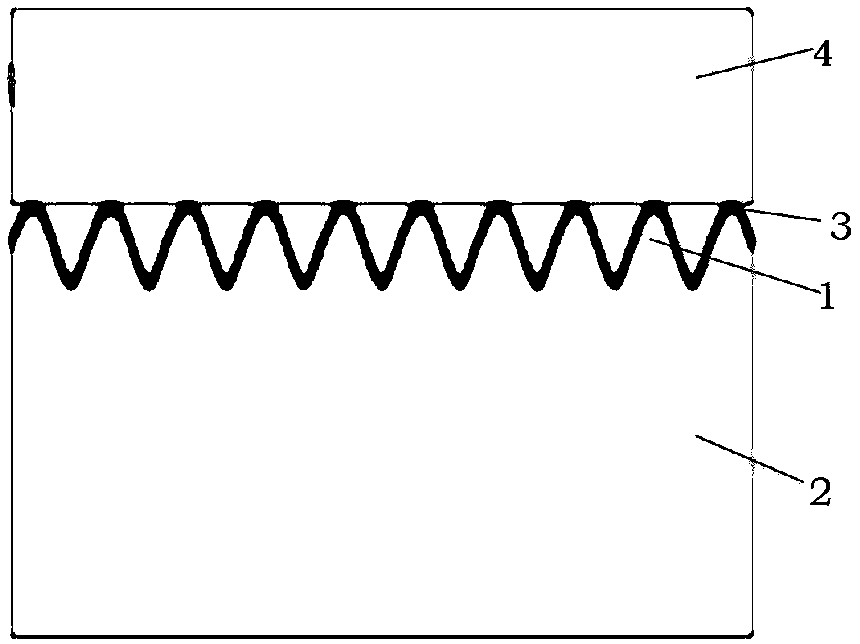

Piezoresistive pressure sensor applicable to surface mounting process and manufacturing method thereof

ActiveCN107176585AImprove the selectivity of subsequent processing technologyIncrease flexibilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricitySemiconductor materials

The invention relates to a piezoresistive pressure sensor applicable to a surface mounting process and a manufacturing method thereof. A utilized wafer structure comprises a substrate semiconductor material, a top-layer semiconductor material and an insulating layer, wherein a cavity is formed in an interface position of the insulating layer in the substrate semiconductor material; the top-layer semiconductor material and the substrate semiconductor material are formed by inverse-phase doping; the substrate semiconductor material is provided with an electric isolation groove; an electric contact hole is formed in the substrate semiconductor material surrounded by the electric isolation groove; metal is re-doped and deposited into the electric contact hole to form an electric channel and a metal pin; a piezoresistive strip, an electric lead wire region and an electric connection hole of the pressure sensor are formed in the top-layer semiconductor material; the electric lead wire region is overlapped with the substrate semiconductor material surrounded by one part of the piezoresistive strip and the electric isolation groove; the electric connection hole is located in an overlapped region of the electric lead wire region and the substrate semiconductor material; and an electric connection channel is formed by depositing a conductive layer in the electric connection hole. By adopting the piezoresistive pressure sensor provided by the invention, three dimension (3D) packaging with a corresponding control circuit (IC) is conveniently and subsequently realized, and the cost is low.

Owner:GUANGDONG HEWEI INTEGRATED CIRCUIT TECH

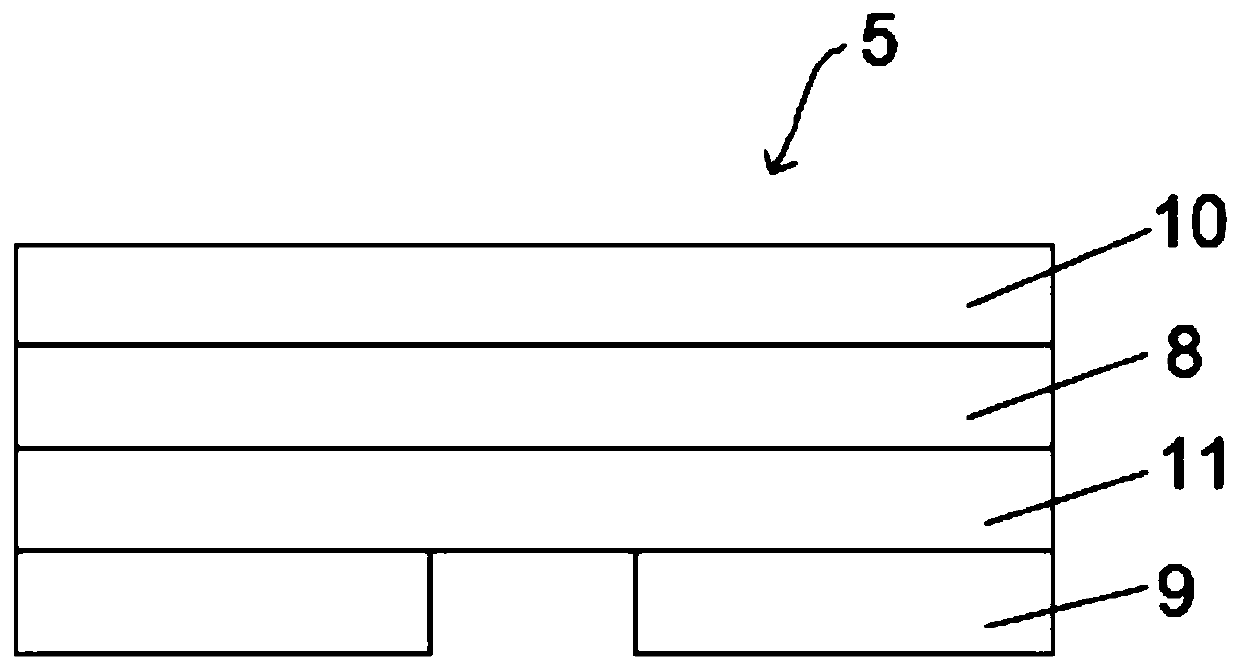

Flexible display screen cover plate

ActiveCN110602274AHigh hardnessThe overall thickness is thinDigital data processing detailsTelephone set constructionsPolyamidePolysilazane

The invention discloses a flexible display screen cover plate, and relates to the technical field of optical films. The flexible display screen cover plate of the present invention comprises: a transparent aromatic polyamide substrate; a polysilazane layer provided on one side surface of the transparent aromatic polyamide substrate; and a protective layer provided on one side surface of the polysilazane layer opposite to the transparent aromatic polyamide substrate. The aromatic polyamide is used as the substrate, so that the hardness and the bending resistance of the traditional flexible display screen cover plate are improved.

Owner:新纶电子材料(常州)有限公司

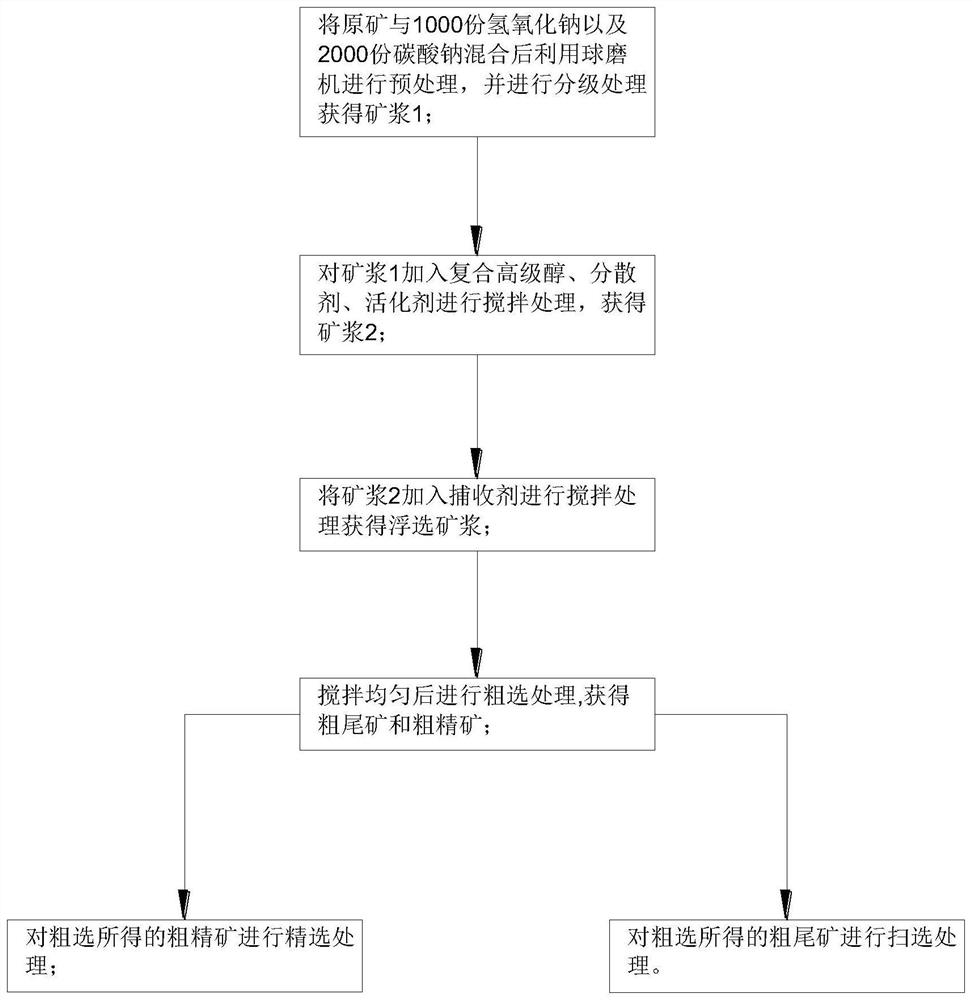

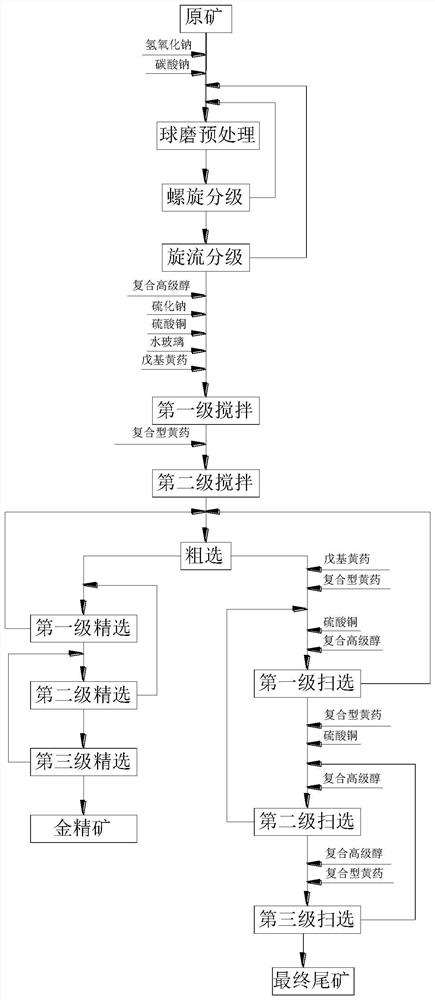

Beneficiation process of high-carbon high-oxidation micro-fine particle gold ore

ActiveCN112844859AEasy to separateAvoid adsorption effectsFlotationGrain treatmentsEngineeringGold ore

The invention provides a beneficiation process for high-carbon high-oxidation micro-fine particle gold ore, and relates to the technical field of ore beneficiation. The process comprises the following steps: mixing raw ore with 1000 parts of sodium hydroxide and 2000 parts of sodium carbonate, and conducting crushing by using a ball mill to obtain ore pulp 1; subjecting the ore pulp 1 to grading treatment, and returning coarse materials obtained through separation treatment for smashing treatment; carrying out stirring treatment on fine materials obtained through separation treatment; after uniform stirring, carrying out roughing treatment to obtain rough tailings and rough concentrates; carrying out concentration treatment on rough concentrate obtained by roughing; and conducting scavenging treatment on rough tailings obtained through roughing. The technological process is simple, the cost is low, the grade of the gold concentrate is improved, and the recovery rate of beneficiation is increased.

Owner:刘学军

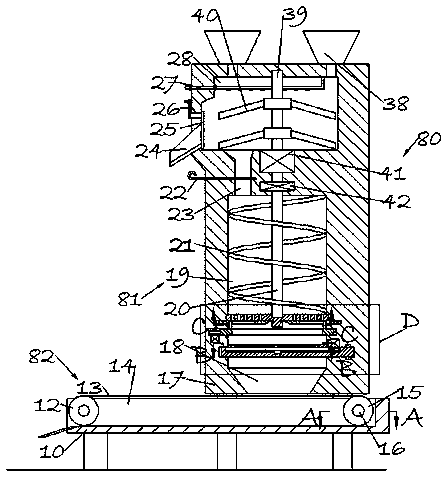

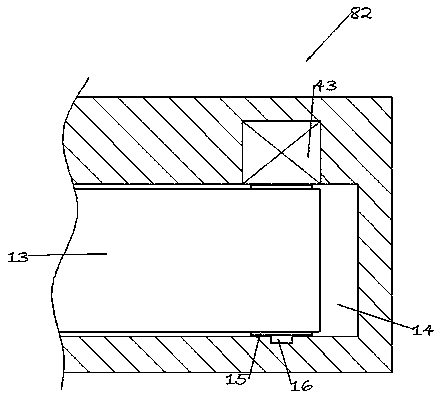

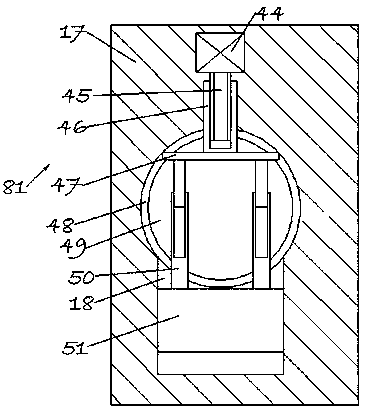

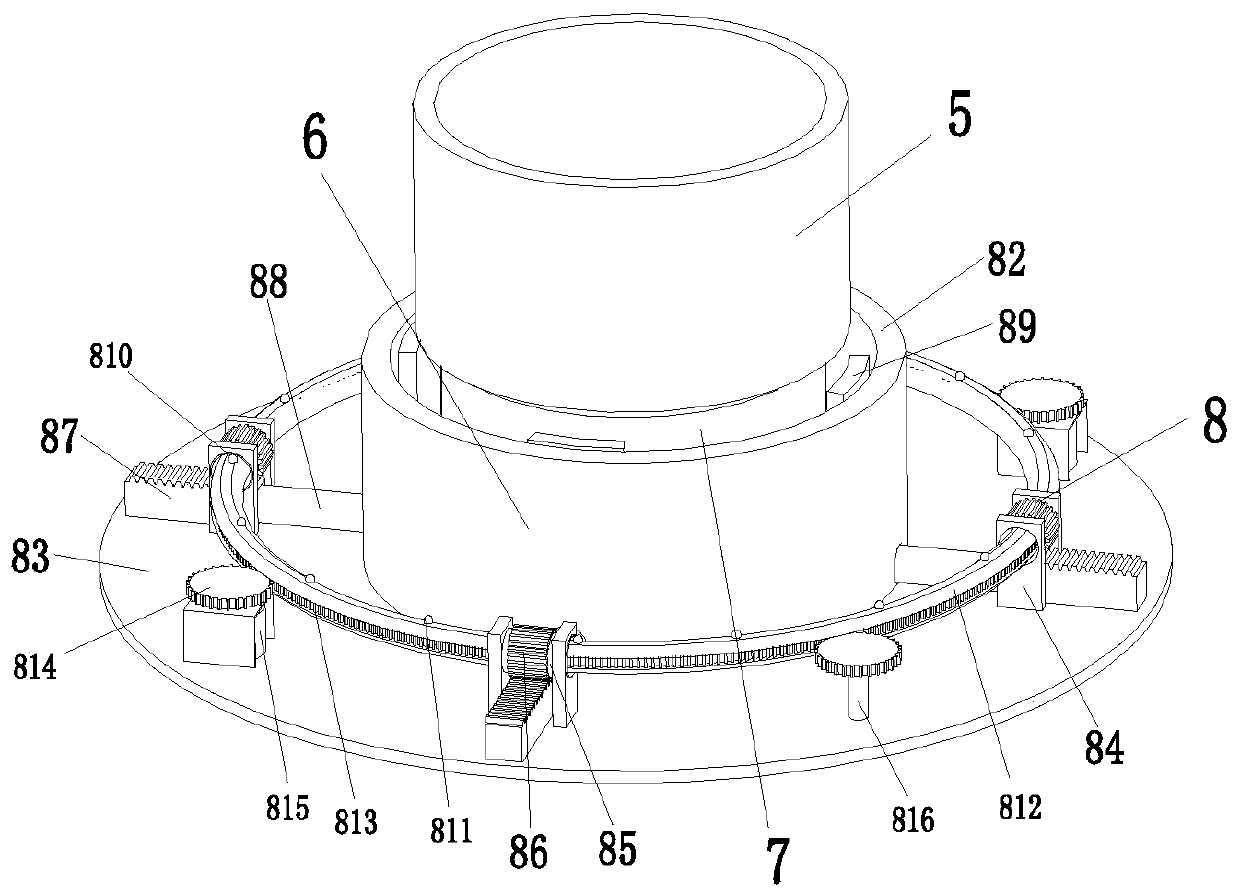

Granulator for producing ceramsites by using municipal sludge

The invention discloses a granulator for producing ceramsites by using municipal sludge. The granulator comprises a production box body; a stirring chamber is arranged in the production box body; thelower side of the stirring chamber is provided with an extrusion chamber; a stirring blade capable of stirring and mixing sludge and other additives is arranged in the stirring chamber; a closed platecan be opened by rotating a rotating rod, so that raw materials in the stirring chamber are sampled; when the raw materials in the stirring chamber is relatively dried, water is introduced to a waterinjection pipe to humidify the raw materials in the stirring chamber, so that the sludge and other raw materials can be mixed, and a great deal of working time can be saved; the mixed raw materials can be subjected to sampling inspection during mixing treatment, and the water can be sprayed into the stirring chamber, so that the viscosity of the raw materials is increased; when the ceramsites areproduced by using the granulator, the sizes of particles are regulated, in this way, the ceramsites can be directly delivered after being produced so as to be prevented from being adhered to each other.

Owner:祁东县鑫丰建材有限公司

Bare wire washing device for enameled wires

InactiveCN104841669AEasy to cleanFacilitate follow-up processCleaning using gasesCleaning using liquidsMetal powderMechanical engineering

The invention discloses a bare wire washing device for enameled wires and relates to the technical field of the enameled wires. The bare wire washing device comprises a dust suction unit, a cleaning fluid unit fixedly arranged at one side of the dust suction unit, a washing unit fixedly arranged at one side of the cleaning fluid unit, and a drying unit arranged at one side of the washing unit. The bare wire washing device can wash bare wires of the enameled wires step by step, at first, a dust suction box is used for attaching metal powder to the bare wires away, a cleaning fluid roller is used for attaching cleaning fluid in a cleaning fluid tank to the surfaces of the bare wires, then the bare wires enter a washing box to be washed with water, finally a water absorbing towel is used for wiping the washed bare wires dry, the washing effect is good, and the follow-up process can be carried out conveniently.

Owner:启动鹏隆投资管理有限公司

Microfiltration film separation technology for straw pulp balck liquor

InactiveCN1486937AReduce investmentReduce energy consumptionPulp liquor regenerationWater/sewage treatment bu osmosis/dialysisBlack liquorSeparation technology

The microfiltration film separation technology for straw pulp black liquor features the technological process includes five relatively independent steps: treating black liquor, reusing effective matters from the black liquor, steaming, blowing and extracting. The specific technological process includes: leading black liquor into storage tank and mixing homogeneously; pumping black liquor to microfiltration film separation with microfiltration film of alumina or zirconia material and of pore size 0.1-100 microns to obtain permeated liquid, with the flow rate, pressure and temperature being controlled in 5-15 m / s, 0.1-0.8 MPa and 30-120 deg.c separately; and returning the permeated liquid to steaming step for feuse. The present invention has the advantages of low equipment investment, simple technological process, no 'silicon interference' problem, and high COD and lignin eliminating rate.

Owner:TSINGHUA UNIV

Temporary bound/de-bound material and preparation method and application thereof

ActiveCN108511384AAbundant resourcesIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceGraphite

The invention belongs to the technical field of the semiconductor, and especially relates to a temporary bound / de-bound material and a preparation method and application thereof. The temporary bound / de-bound material provided by the invention comprises roughened slide glass and a graphite material, and the graphite material is attached to a rough surface of the roughened slide glass. The inventionfurther provides a preparation method of the temporary bound / de-bound material, and the preparation method comprises the following steps: performing roughening treatment on the surface of the slide glass to obtain the roughened slide glass; and attaching the graphite material to the rough surface of the roughened slide glass to obtain the temporary bound / de-bound material. Through the material disclosed by the invention, the technical defect that the temporary bonding glue is incomplete in de-binding, free from reuse and high in cost can be solved.

Owner:GUANGDONG UNIV OF TECH

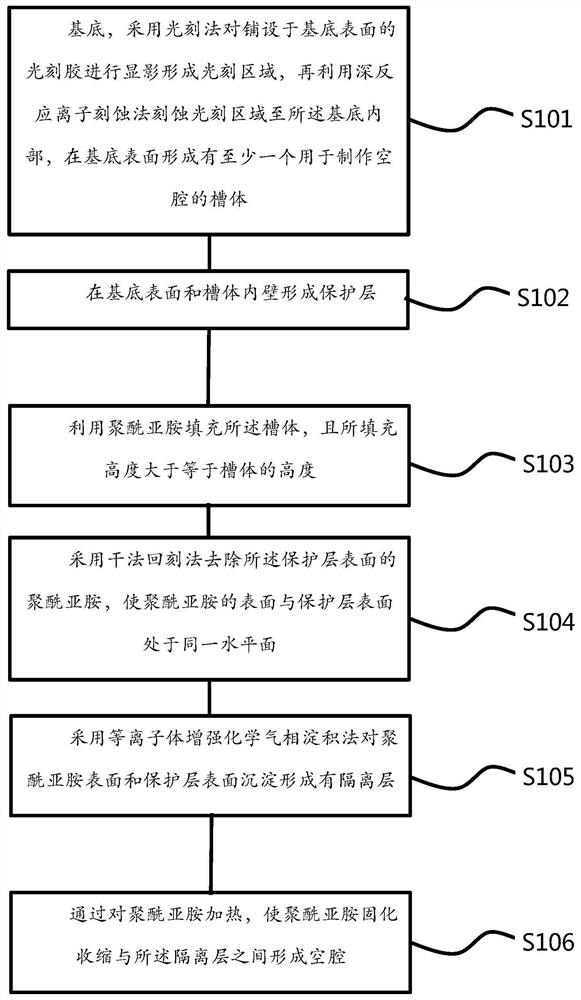

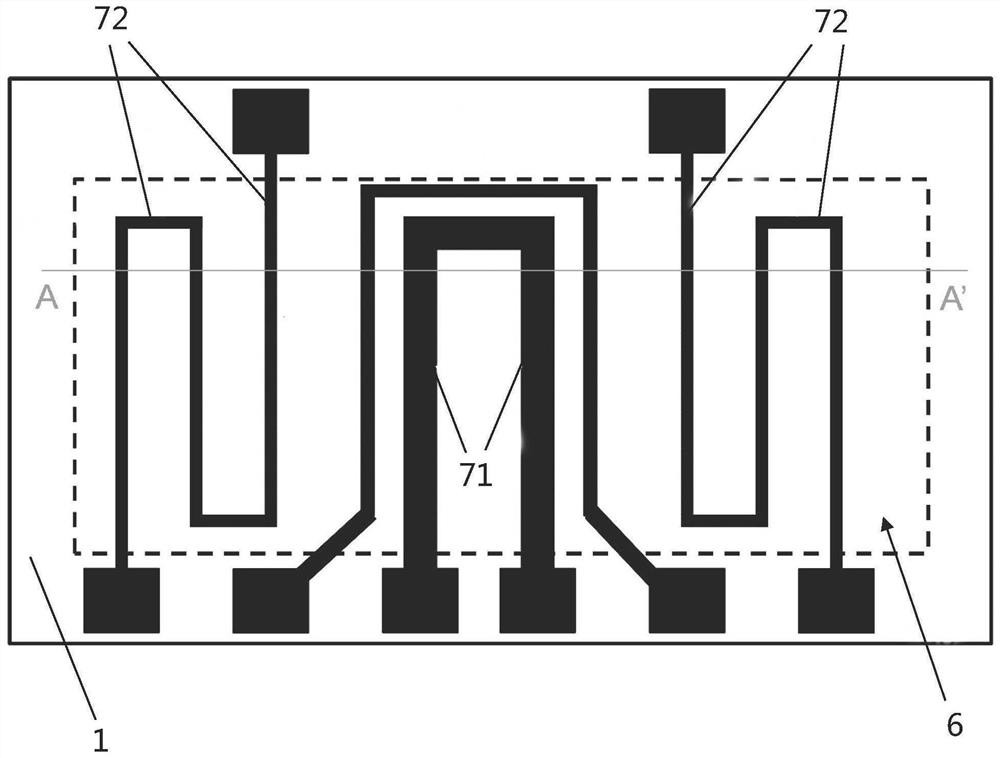

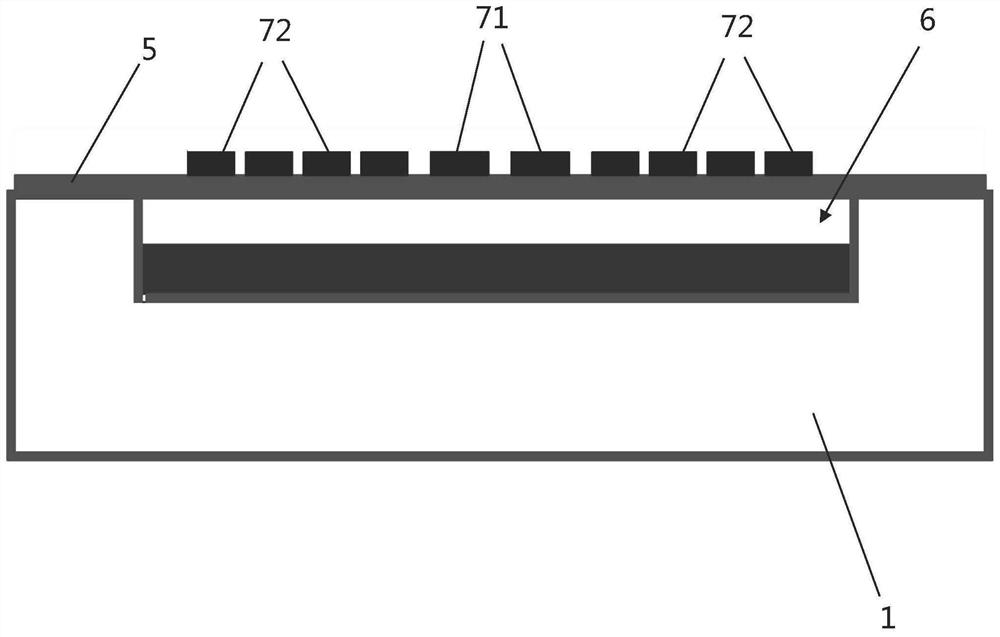

Method for manufacturing flow sensor chip

ActiveCN112501593ARepair damageImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusHigh volume manufacturingIsolation layer

The invention provides a method for manufacturing a flow sensor chip. The method comprises the following steps that regarding a base, photoresist paved on the surface of the base is developed througha photoetching method to form a photoetching region, the photoetching region is etched to reach the interior of the base through a deep reactive ion etching method, and at least one groove body for manufacturing a cavity is formed in the surface of the base; a protective layer is formed on the surface of the base and the inner wall of the groove body; the groove body is filled with polyimide, wherein a filling height is greater than or equal to a height of the groove body; the polyimide on the surface of the protective layer is removed through a dry back-etching method, so that the surface ofthe polyimide and the surface of the protective layer are positioned on the same horizontal plane; the polyimide surface and the protective layer surface are precipitated through a plasma enhanced chemical vapor deposition method to form an isolation layer; and the polyimide is heated, so that the polyimide is solidified and contracted to form a cavity with the isolation layer. The method has goodstructural stability and is suitable for mass production.

Owner:长芯科技(上海)有限公司

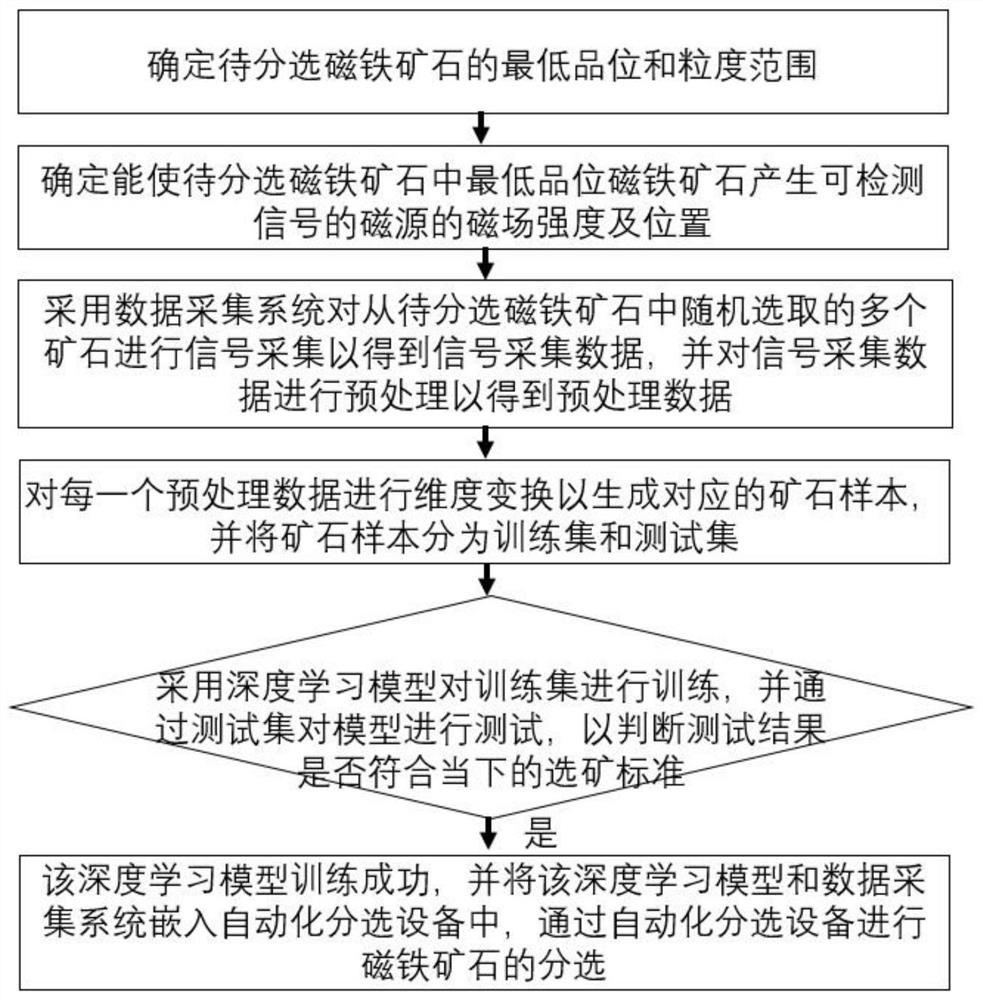

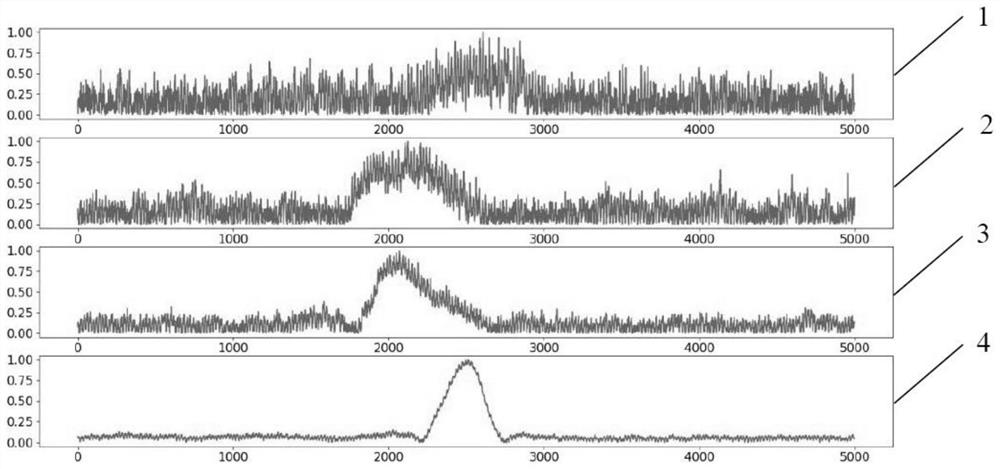

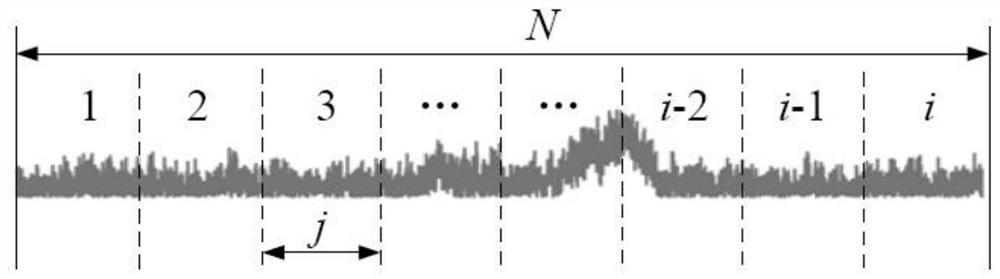

Intelligent magnetic iron ore separating method and device

ActiveCN112916432AImprove ore utilizationReduce the cost of beneficiationProcess efficiency improvementSortingMagnetic field magnitudeBeneficiation

The invention discloses an intelligent magnetic iron ore separating method and device. The method comprises the following steps that the lowest grade and the particle size range of to-be-separated magnetic iron ore are confirmed; the magnetic field intensity and position of a magnetic source capable of making the lowest-grade magnetic iron ore in the to-be-separated magnetic iron ore generate a detectable signal are determined; signal acquisition is conducted on the ore randomly selected from the to-be-separated magnetite ore to obtain signal acquisition data, and the signal acquisition data are preprocessed to obtain preprocessed data; dimension transformation is conducted on the preprocessed data to generate corresponding ore samples, and the ore samples are divided into a training set and a test set; the training set is trained, and a model is tested through the test set to judge whether the test result meets the current mineral separation standard or not; and if yes, the deep learning model is trained successfully, and the deep learning model and a data acquisition system are embedded into an automatic separation device to conduct magnetic iron ore separation. The selected grade of the to-be-separated magnetite ore is expanded, and the ore utilization rate is increased.

Owner:JIANGXI UNIV OF SCI & TECH

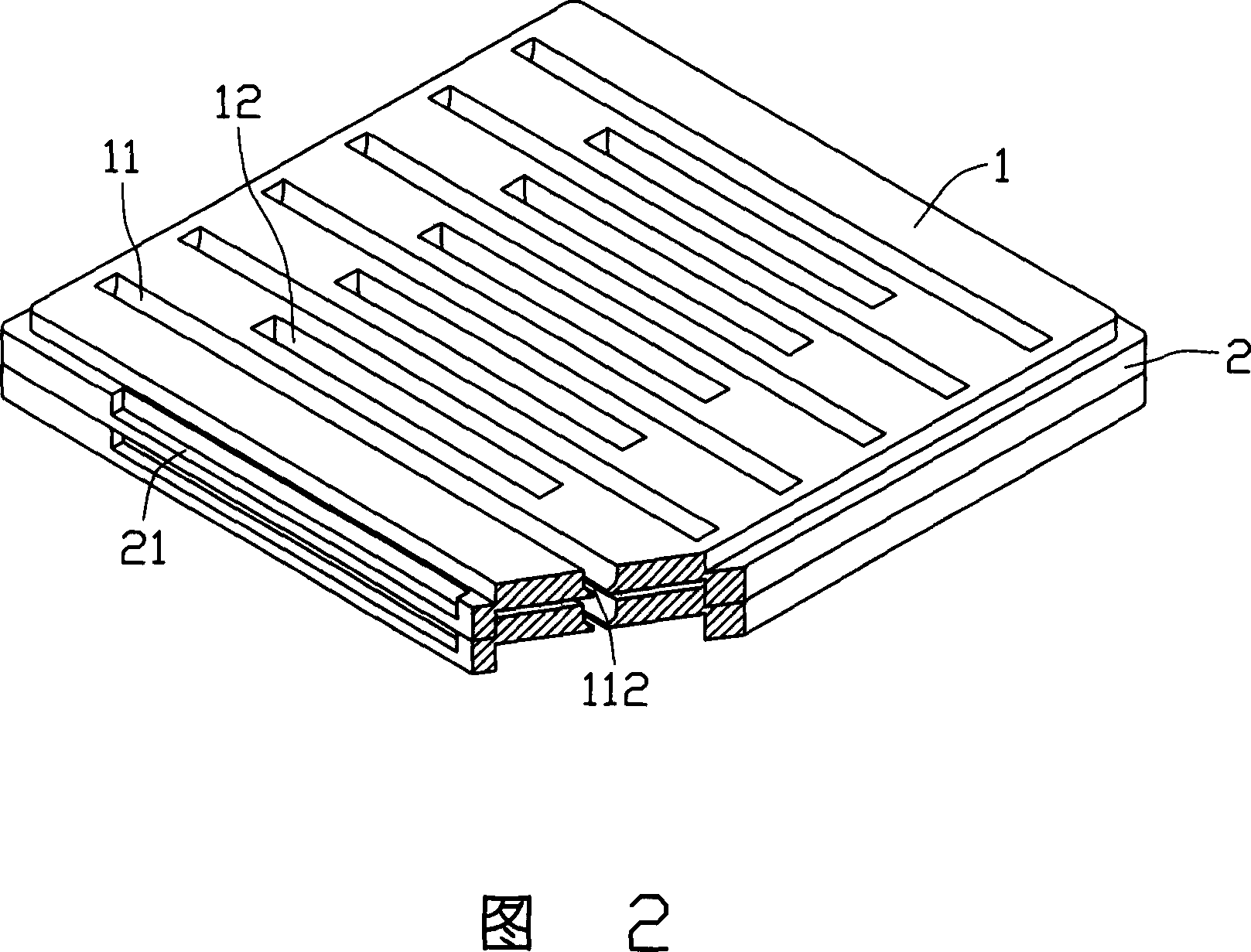

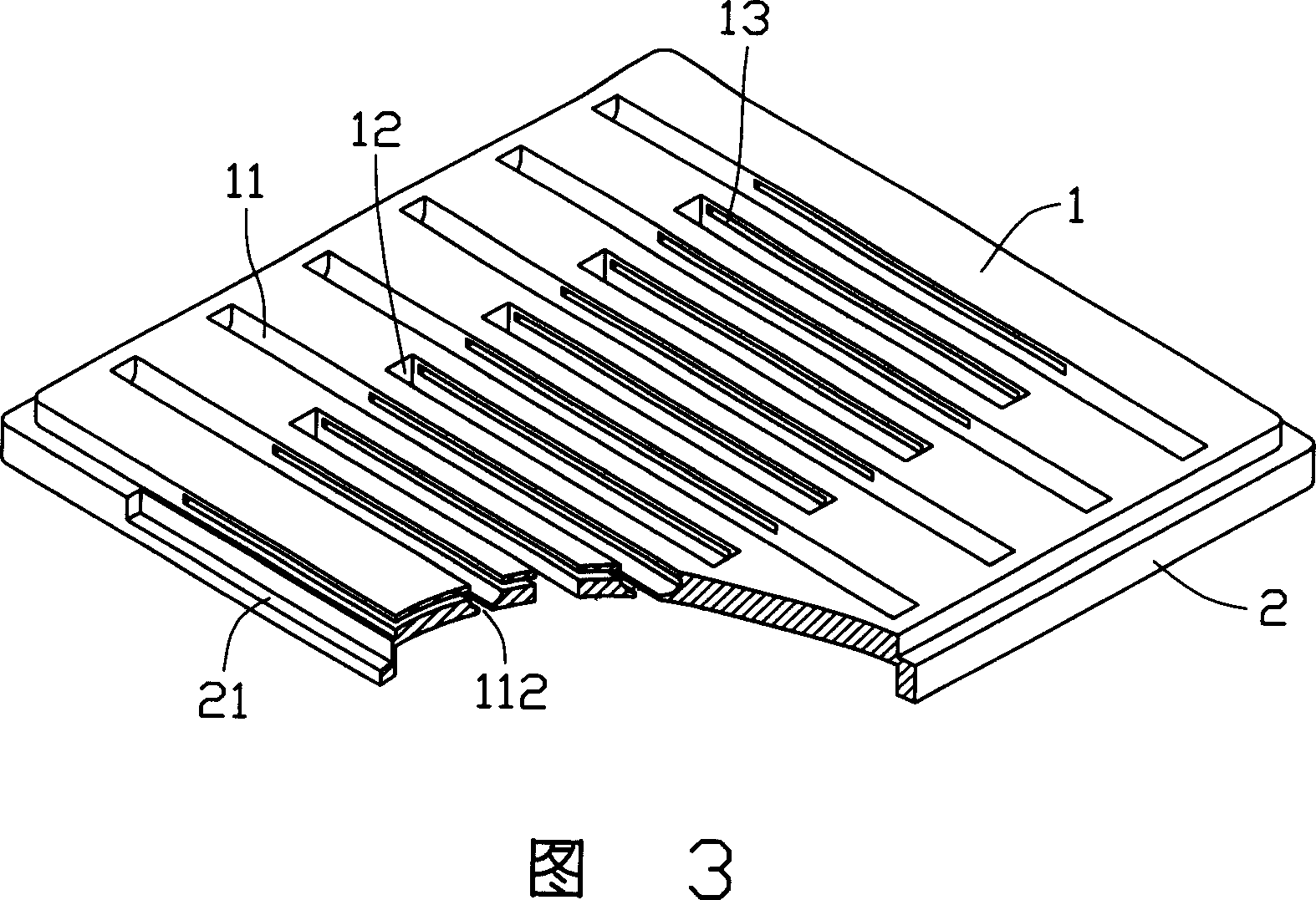

Lens cleaning equipment

InactiveCN1990128AHigh glue removal efficiencyOrderly rowsWork holdersFlexible article cleaningLens plateEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

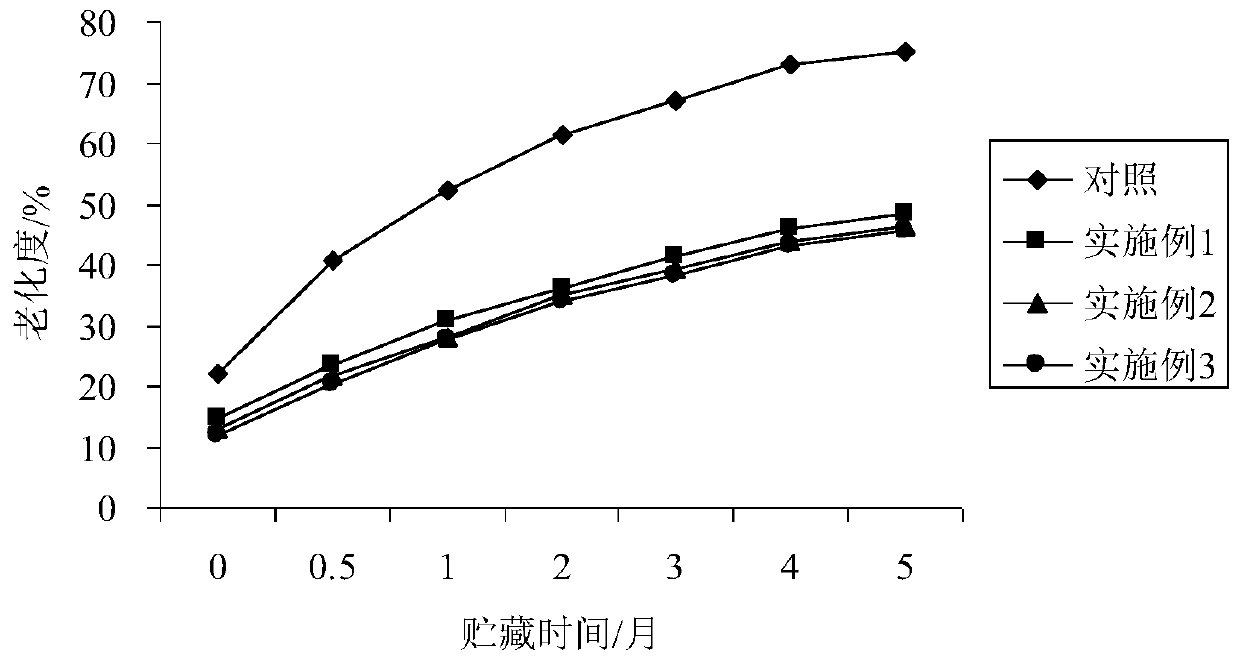

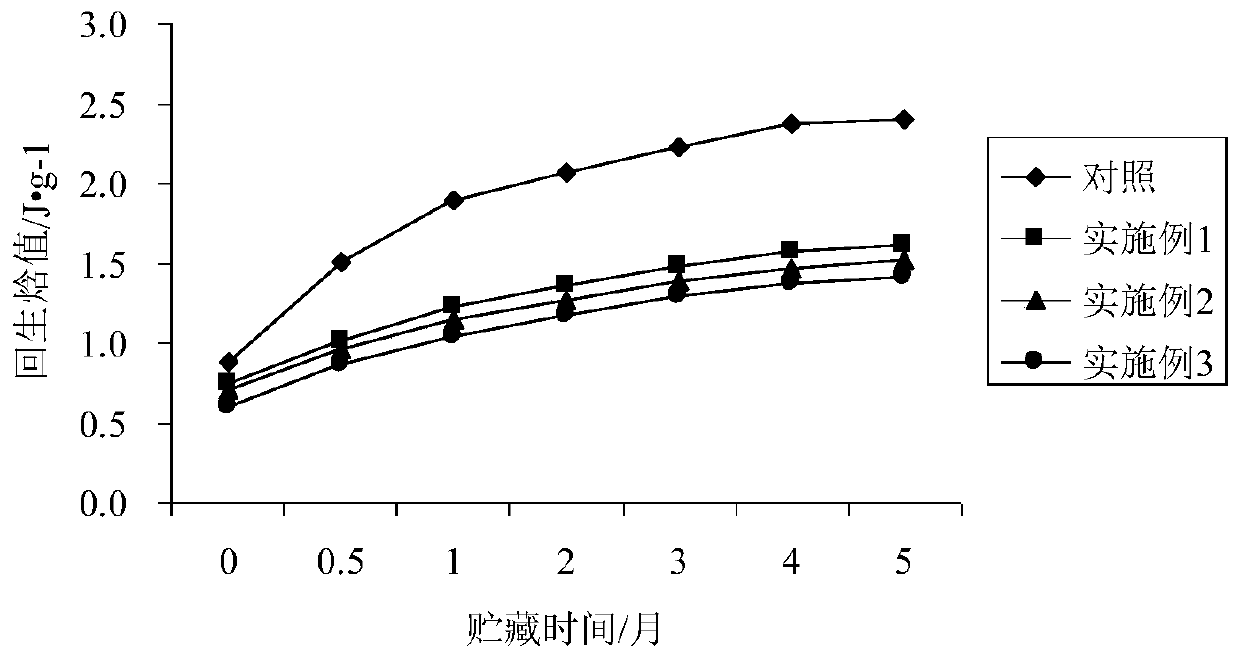

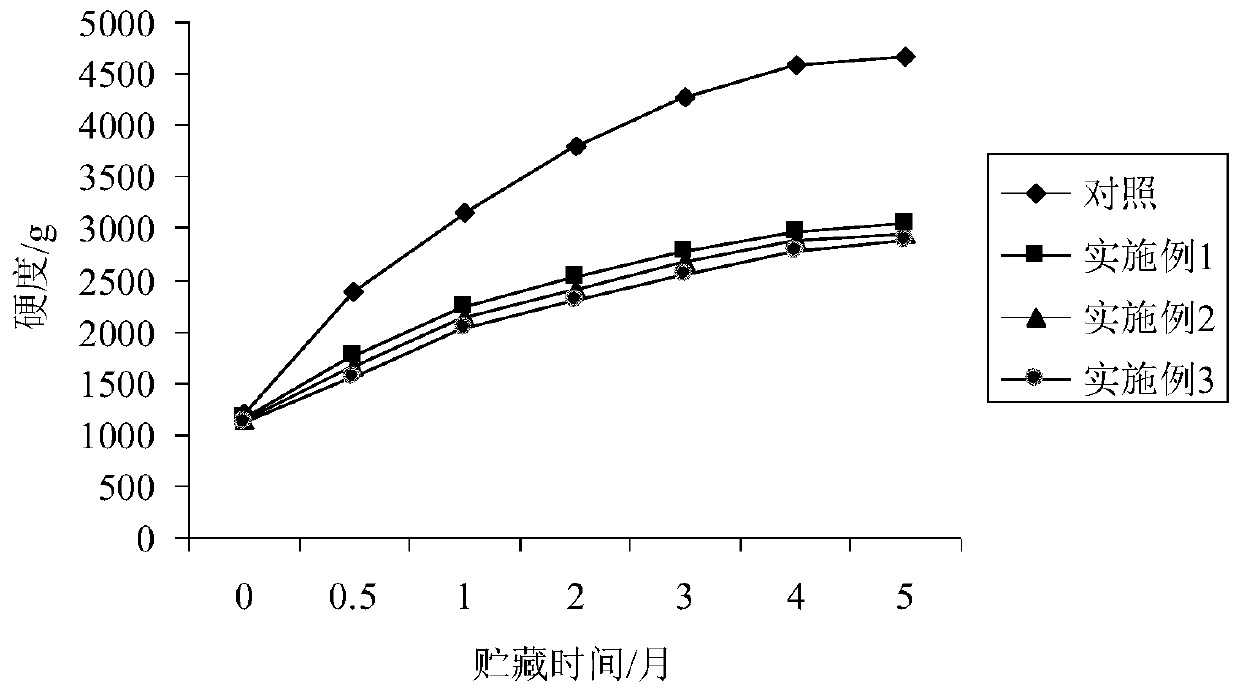

Production process of compound soybean polysaccharide-based conditioning food anti-ageing instant rice

PendingCN110786462AHelp with attachmentFacilitate follow-up processGrain huskingGrain polishingBiotechnologyCarrageenan

A production process of compound soybean polysaccharide-based conditioning food anti-ageing instant rice particularly comprises the following steps: polishing rice by a baking soda solution to serve as a raw material rice; and compounding water-soluble soybean polysaccharide, guar gum, fructo-oligosaccharide and carrageenan to obtain an anti-ageing agent, taking the anti-ageing agent and sorbitolas water for cooking rice, putting the anti-ageing agent, the sorbitol and the raw material rice jointly into a packaging box and sealing, and cooking the rice by high-temperature steam to obtain non-dehydrated instant rice. The production process has the following advantages: the baking soda is used in the polishing process of the rice, so that impurities on the surfaces of the rice are eliminated and the adhesive rate of the anti-ageing agent on rice grains is increased; the sorbitol is added in the compound anti-ageing solution, so that the anti-ageing agent can be adsorbed on the surfacesof the rice grains well, permeation of the anti-ageing agent into the rice grains is accelerated, the surfaces of the rice grains are prevented from being dried and cracked and the rice is maintainedfresh and soft; and the composite anti-ageing agent is added in the instant rice, so that starch ageing can be inhibited, the edible quality of starch-based staple food can be improved and the shelf life can be prolonged.

Owner:BOHAI UNIV

Processing method of granular green tea

The invention discloses a processing method of granular green tea. The method sequentially comprises the following steps: first-time spreading and airing, steam enzyme deactivation, dehydration, standing, primary rolling, heating, hot rolling, second-time spreading and airing, stoving, third-time spreading and airing, aroma strengthening and fourth-time spreading and airing. The method breaks thetradition that green tea can only be made into strips or rolls, produces the granular green tea, can fix an aroma in tea while prolonging the aroma of the tea so as to leave tea down in the tea and toeffectively prevent the tea down from scattering around and polluting the environment, and can also increase the purity of tea, reduce the bitter and astringent taste of tea, and guarantee the palatability of tea.

Owner:四川金璋府茶业有限公司

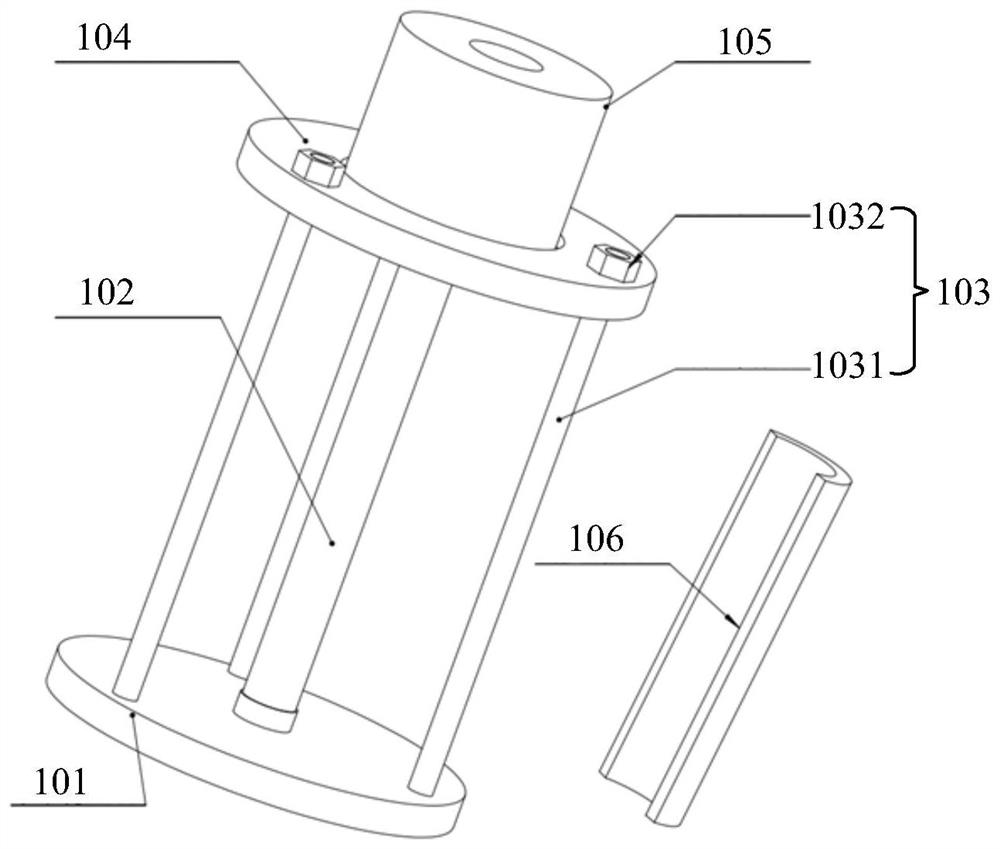

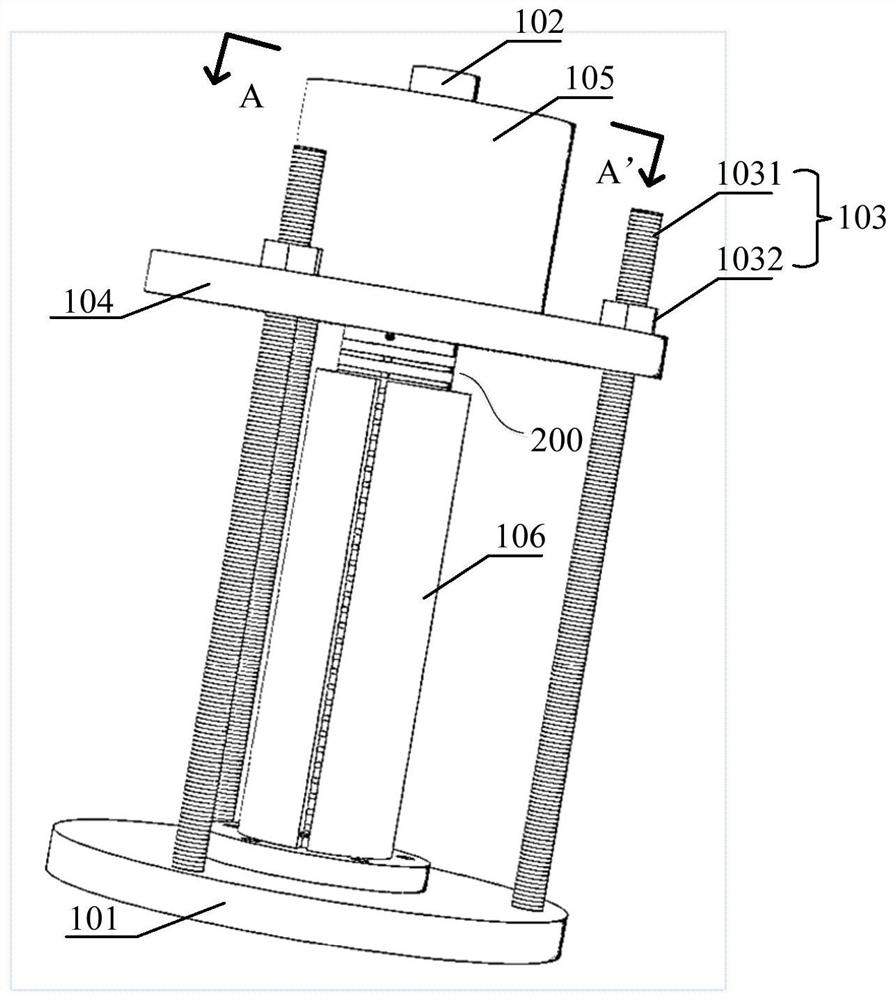

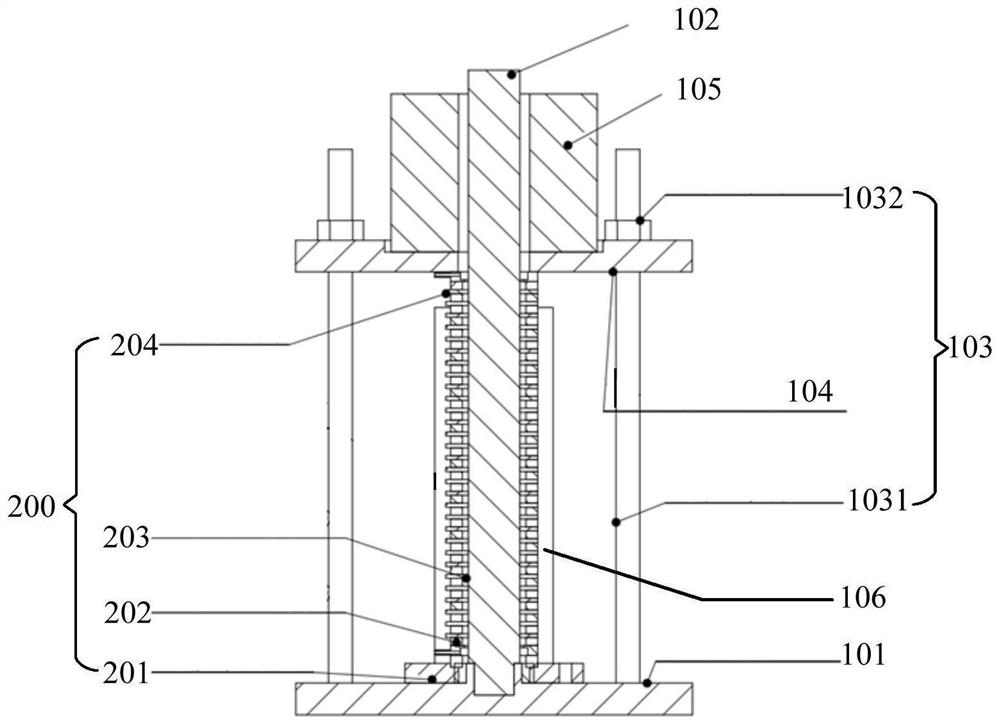

Brazing welding frame tool and sealing method

PendingCN113145976AEasy to assemble and disassembleFacilitate follow-up processSoldering auxillary devicesThermal dilatationEngineering

The invention provides a brazing welding frame tool and a sealing method. The brazing welding frame tool comprises a horizontal base, a concentric column, a positioning adjusting assembly, a horizontal pressing disc, a pressing block and an adjusting die, wherein the concentric column and the adjusting die serve as centering dies of a workpiece, and fins of the workpiece can be fixed to the same straight line position through the adjusting die so as to facilitate the follow-up process. The horizontal base, the positioning adjusting assembly and the horizontal pressing disc can fix the workpiece in the vertical direction. The pressing block with a through hole can force the horizontal pressing disc to uniformly slide down under the action of gravity, so that a welding seam of the workpiece is sealed. Furthermore, due to the characteristics of self-lubrication, low expansion and moderate hardness of the graphite concentric column, a certain gap can be kept between the graphite concentric column and the workpiece in the high-temperature brazing and welding flux melting process, and due to the fact that the horizontal base, the positioning adjusting assembly and the horizontal pressing disc are made of materials with the same thermal expansion, the brazing welding frame tool does not clamp a film and is convenient to disassemble and assemble.

Owner:SHANGHAI IRAY TECH

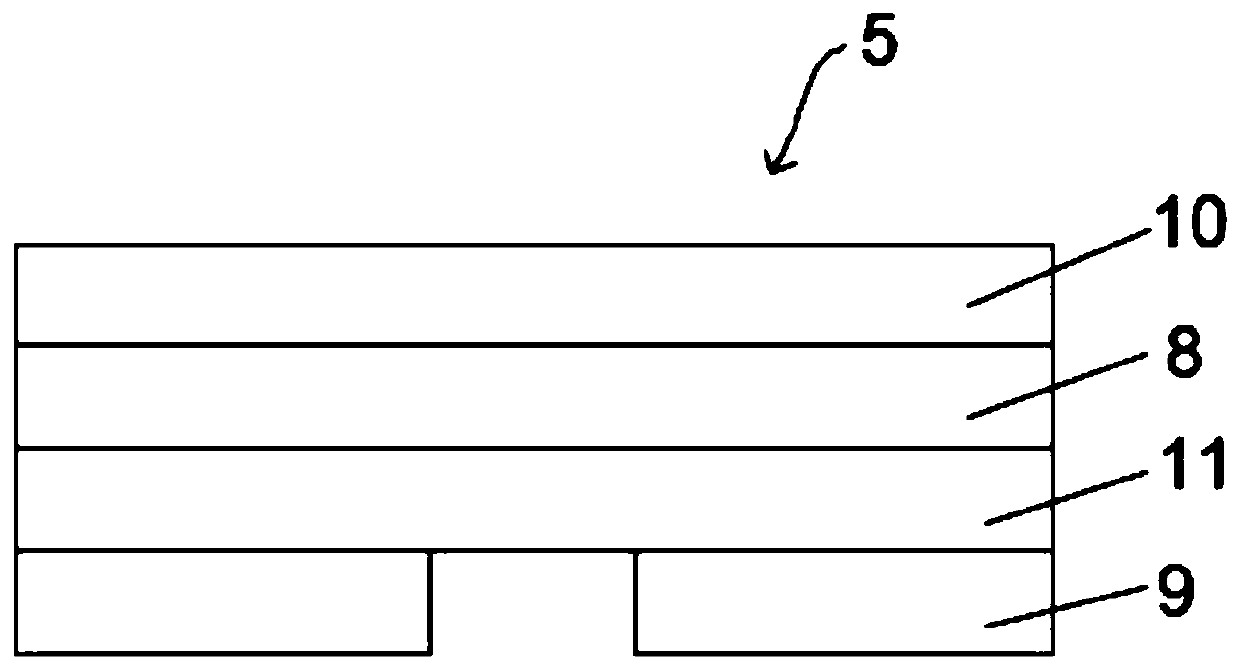

Flexible display screen cover plate

ActiveCN110491291AThe overall thickness is thinReduce thicknessPolyurea/polyurethane coatingsPolyether coatingsPolyamideHardness

The invention discloses a flexible display screen cover plate and relates to the technical field of optical films. The flexible display screen cover plate in the invention comprises a transparent aromatic polyamide substrate, an anti-fingerprint hardness layer, a polarizing layer, and a hardened layer; the anti-fingerprint hardness layer is arranged on one side surface of the transparent aromaticpolyamide substrate; the polarizing layer is arranged on the other side surface of the aromatic polyamide substrate relative to the anti-fingerprint hardness layer; and the hardened layer is arrangedon the other side surface of the polarizing layer relative to the transparent aromatic polyamide substrate. According to the flexible display screen cover plate in the invention, the polarizing layeris directly prepared on the transparent aromatic polyamide substrate, so that the overall thickness of the flexible display screen cover plate is reduced, and the overall hardness of the flexible display screen cover plate is greatly improved.

Owner:新纶电子材料(常州)有限公司

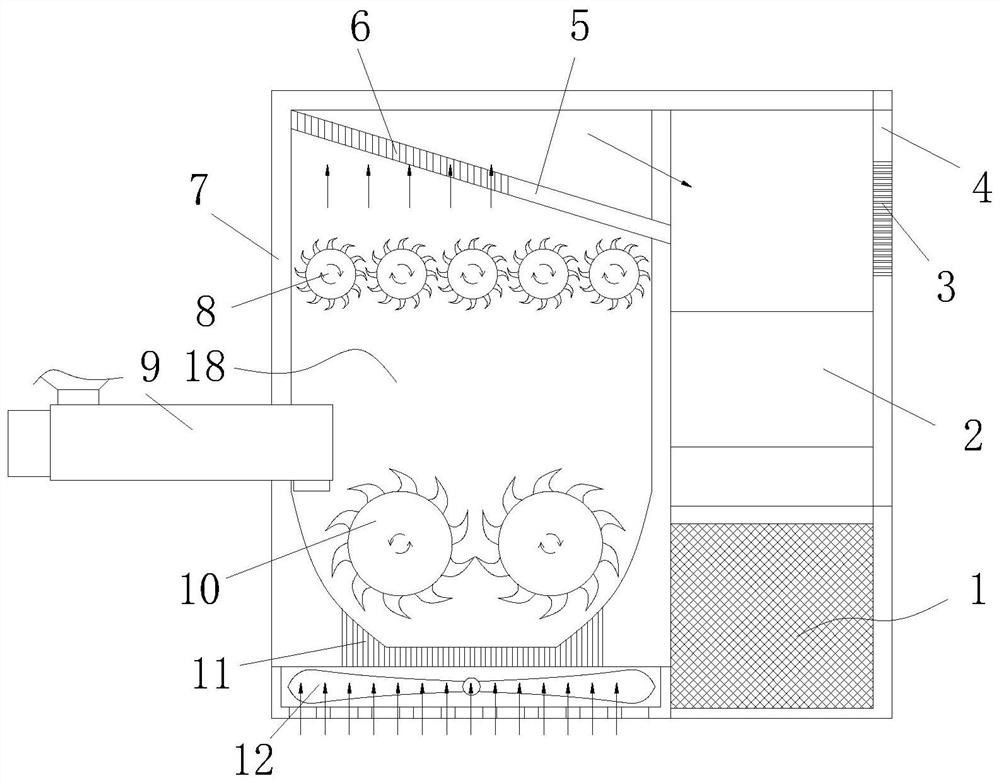

Waste recovery device for plastic woven bag production

PendingCN113083424AUniform particlesEasy accessPlastic recyclingGrain treatmentsElectric machineryProcess engineering

The invention relates to the technical field of waste recovery devices, in particular to a waste recovery device for plastic woven bag production. The waste recovery device comprises a box body, an air inlet hole is formed in a bottom plate of the box body, a fan blowing air upwards is arranged below the bottom plate of the box body, a filter plate is arranged at the top of an inner cavity of the box body, the filter plate and the box body form a discharge cavity, the filter plate and the bottom plate of the box body form a crushing chamber, a plurality of second crushing rollers are installed in the crushing chamber at the lower part of the box body, a plurality of first crushing rollers are installed in the crushing chamber at the upper part of the box body, the second crushing rollers and the first crushing rollers are connected to a power motor, and a spiral feeder for conveying materials to the crushing chamber is installed in the chamber between the second crushing rollers and the first crushing rollers. According to the waste recovery device, plastic woven bag waste is crushed step by step from bottom to top, the plastic woven bag waste with uniform particles can be better obtained, and follow-up processes are facilitated.

Owner:涡阳县利达塑料包装制品有限公司

High-pressure adsorption production line for inorganic composite polyphenyl A-grade insulation board

PendingCN112810196AImprove uniformityConsistent apparent densityCleaning using toolsFlat articlesProcess engineeringThermodynamics

The invention relates to the technical field of insulation board production equipment, in particular to a high-pressure adsorption production line for an inorganic composite polyphenyl A-grade insulation board. The high-pressure adsorption production line comprises a feeding mechanism, a high-pressure adsorption equipment main machine, a discharging mechanism, an unloading mechanism and a high-pressure adsorption recovery system. The high-pressure adsorption equipment main machine comprises a rack, a conveying belt mounted in the rack, a driving mechanism for driving the conveying belt to operate circularly, an adsorption tank mechanism, a slurry surface distribution and recovery system and a cleaning system. The adsorption tank mechanism comprises an adsorption tank, a partitioning isolation frame for equally dividing an inner cavity of the adsorption tank into a plurality of independent adsorption areas, and a plurality of vacuum high-pressure adsorption pipeline sets. The high-pressure adsorption recovery system comprises two adsorption recovery tanks, a slurry recovery pump and a vacuum adsorption pump. The inorganic composite polyphenyl A-grade insulation board produced through the high-pressure adsorption production line is good in uniformity degree and consistent in apparent density, and the product performance such as the heat conductivity coefficient, the heat value, the tensile strength and the compressive strength can all reach the standard.

Owner:山东刚磊建材科技有限公司

A flexible display cover

ActiveCN110491291BThe overall thickness is thinReduce thicknessPolyurea/polyurethane coatingsPolyether coatingsPolyamideFlexible display

The invention discloses a flexible display screen cover plate, which relates to the technical field of optical films. The flexible display screen cover plate of the present invention comprises: a transparent aromatic polyamide substrate; an anti-fingerprint hardness layer, which is arranged on one side of the transparent aromatic polyamide substrate; and a polarizing layer, which is arranged on the aromatic polyamide on the other side of the substrate opposite to the anti-fingerprint hardness layer; and a hardening layer disposed on the polarizing layer on the other side of the transparent aromatic polyamide substrate. The present invention reduces the overall thickness of the flexible display cover plate by directly preparing the polarizing layer on the transparent aromatic polyamide substrate, and simultaneously improves the overall hardness of the flexible display screen cover plate to a great extent.

Owner:新纶电子材料(常州)有限公司

An anti-dripping oil system for rapeseed oil filling machine

The invention relates to an oil dripping prevention system of a rapeseed oil filling machine. The system comprises a bottom plate, a conveyor belt, a support frame, an oil tank, an oil filling pipe and an oil wiping machinery, wherein the upper end face of the bottom plate is provided with a conveying trough, and the conveyor belt is arranged in the conveying trough; the support frame is installedin the middle of the upper end face of the bottom plate; the oil tank is arranged on the upper end face of the support frame, and the oil filling pipe is arranged on the lower end face of the oil tank and has a telescopic structure; the oil wiping machine comprises an oil wiping mechanism; the oil wiping mechanism is installed in the support frame; a collecting mechanism is installed on the oil wiping mechanism; the oil wiping mechanism comprises an oil wiping electric sliding block; oil-wiping sliding grooves are symmetrically formed in the left inner wall and the right inner wall of the support frame. The oil dripping prevention system of the rapeseed oil filling machine can solve the problems that due to the dripping of oil on the inner wall of the filling pipe during the filling, thesubsequent packaging is influenced, the cost is increased, mechanical failure and resource waste are easily caused, and the like; the system can realize a function of cleaning the oil on the inner wall of the filling pipe, and has the advantages of being cost-reducing, enabling equipment to be stable, facilitating the following process and saving resources.

Owner:安徽劲龙粮油股份有限公司

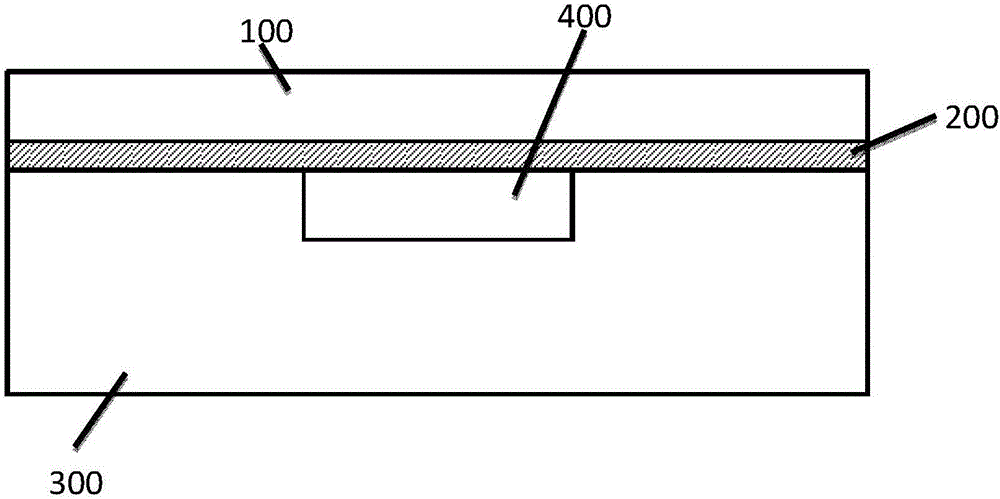

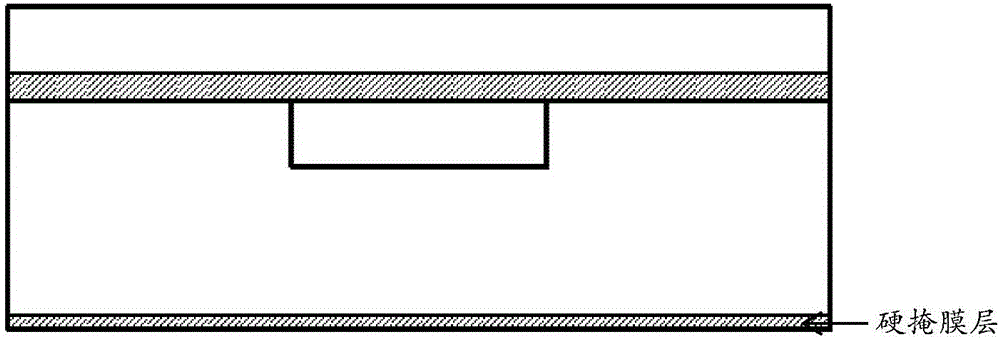

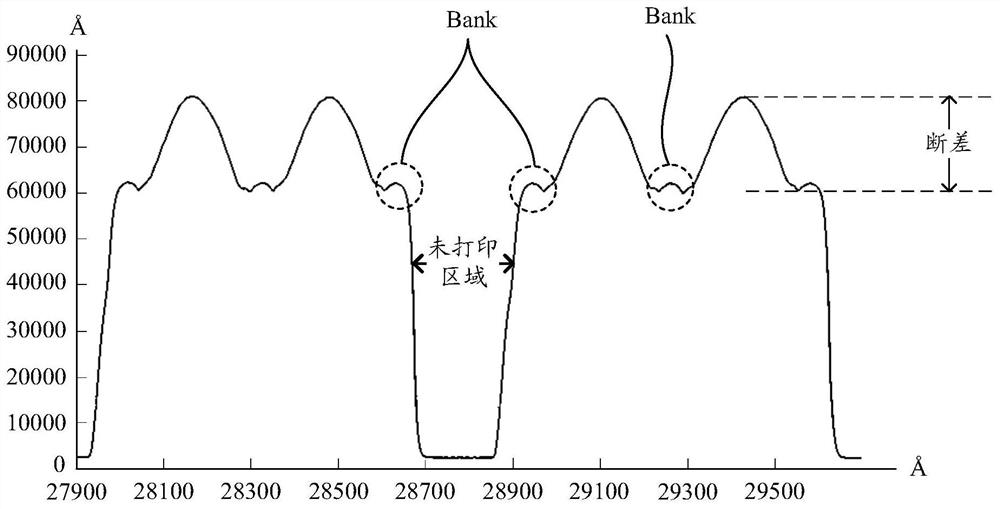

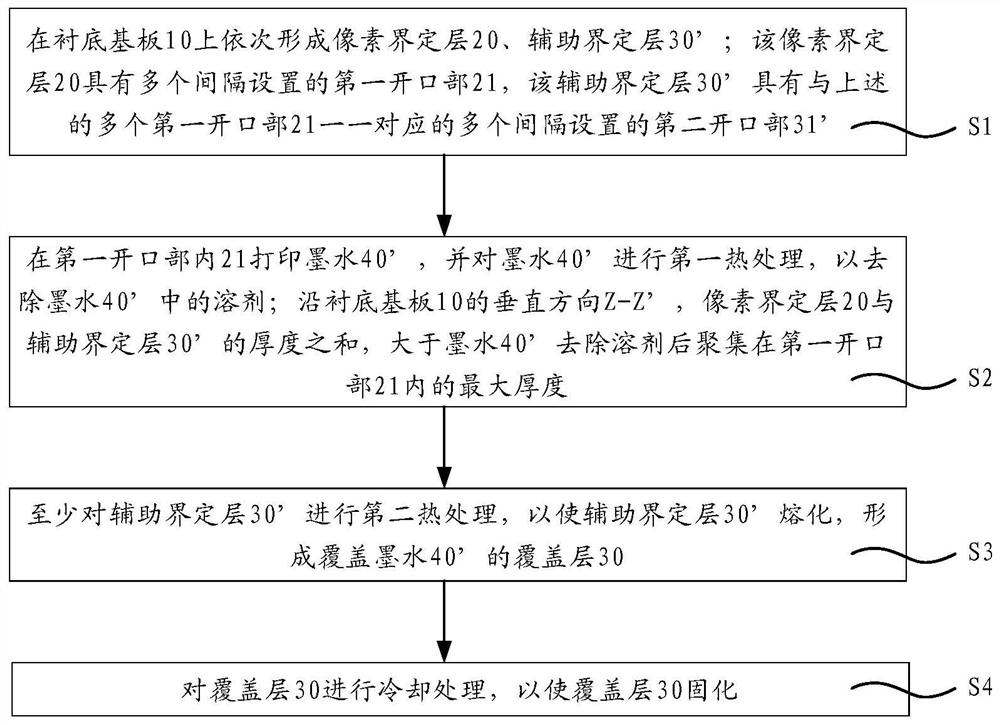

Display substrate, manufacturing method thereof, and display device

ActiveCN109830620BReduce gapFacilitate follow-up processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHeat treating

The invention provides a display substrate, a preparation method thereof, and a display device, and relates to the field of display technology. The display substrate formed by the preparation method has a relatively flat surface. The preparation method includes the following steps: S1: sequentially forming a pixel defining layer and an auxiliary defining layer on a base substrate; the pixel defining layer has a plurality of first openings arranged at intervals, and the auxiliary defining layer has a plurality of second openings arranged at intervals part; S2: print ink in the first opening, and perform the first heat treatment on the ink to remove the solvent in the ink; the sum of the thicknesses of the pixel defining layer and the auxiliary defining layer is greater than the ink that gathers in the first opening after removing the solvent S3: performing at least a second heat treatment on the auxiliary defining layer, so that the auxiliary defining layer is melted to form a cover layer covering the ink; S4: performing cooling treatment on the cover layer, so that the cover layer is solidified. It is used for the preparation of a display substrate and a display device including the display substrate.

Owner:BOE TECH GRP CO LTD

Temporarily bonded/debonded materials, methods of preparation and applications thereof

ActiveCN108511384BAbundant resourcesIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceGraphite

The invention belongs to the technical field of the semiconductor, and especially relates to a temporary bound / de-bound material and a preparation method and application thereof. The temporary bound / de-bound material provided by the invention comprises roughened slide glass and a graphite material, and the graphite material is attached to a rough surface of the roughened slide glass. The inventionfurther provides a preparation method of the temporary bound / de-bound material, and the preparation method comprises the following steps: performing roughening treatment on the surface of the slide glass to obtain the roughened slide glass; and attaching the graphite material to the rough surface of the roughened slide glass to obtain the temporary bound / de-bound material. Through the material disclosed by the invention, the technical defect that the temporary bonding glue is incomplete in de-binding, free from reuse and high in cost can be solved.

Owner:GUANGDONG UNIV OF TECH

Spring machining process equipment

PendingCN112077016ARealize the clamping effectAvoid safety hazardsSortingProcess equipmentProcess engineering

The invention provides spring machining process equipment, relates to the technical field of spring machining, and solves the technical problems of potential risks and low production efficiency causedby direct contact between workers and a press in the prior art. The spring machining process equipment comprises a conveying device, a clamping device, a standing treatment device, a load sorting device, a carrying tool and a classified putting device, wherein one end of the carrying tool is provided with the conveying device, and the other end of the carrying tool is provided with the classifiedputting device; the standing treatment device and the load sorting device are both arranged above the carrying tool, and the clamping device is arranged at the side, close to the conveying device, ofthe carrying tool; and the carrying tool comprises a clamping mechanism and a linear driving mechanism, and the clamping mechanism is connected with the linear driving mechanism. The spring machiningprocess equipment is used for completing standing treatment and load sorting of springs at a time, carrying of the springs is achieved through the carrying tool, and the problems that potential safety hazards exist in manual operation and the production efficiency is low are solved.

Owner:杭州卓易特科技有限公司

Cassette transfer device and semiconductor device having the same

ActiveCN103594403BEasy to pushAvoid inconvenienceSemiconductor/solid-state device manufacturingConveyor partsPower semiconductor deviceEngineering

The invention discloses a wafer box transmission device, which comprises a wafer box, a cavity and a mobile platform, wherein the wafer box is used for placing a tray which bears a wafer, and the outer bottom surface of the wafer box is provided with a first guide member; the cavity is internally provided with a chamber used for accommodating the wafer box, and the bottom wall of the chamber is provided with a second guide member used for being matched with the first guide member; and the upper surface of the mobile platform is provided with a third guide member, the third guide member is used for being matched with the first guide member so as to support the wafer box on the mobile platform, and the mobile platform can move to a front opening of the chamber in order that the second guide member is abutted against the third guide member and that the wafer box can move in or out of the chamber along the second guide member and the third guide member. The wafer box transmission device disclosed by the invention can place and take the wafer box conveniently and efficiently. The invention further discloses a semiconductor device.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com