Patents

Literature

30results about How to "Fast film application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

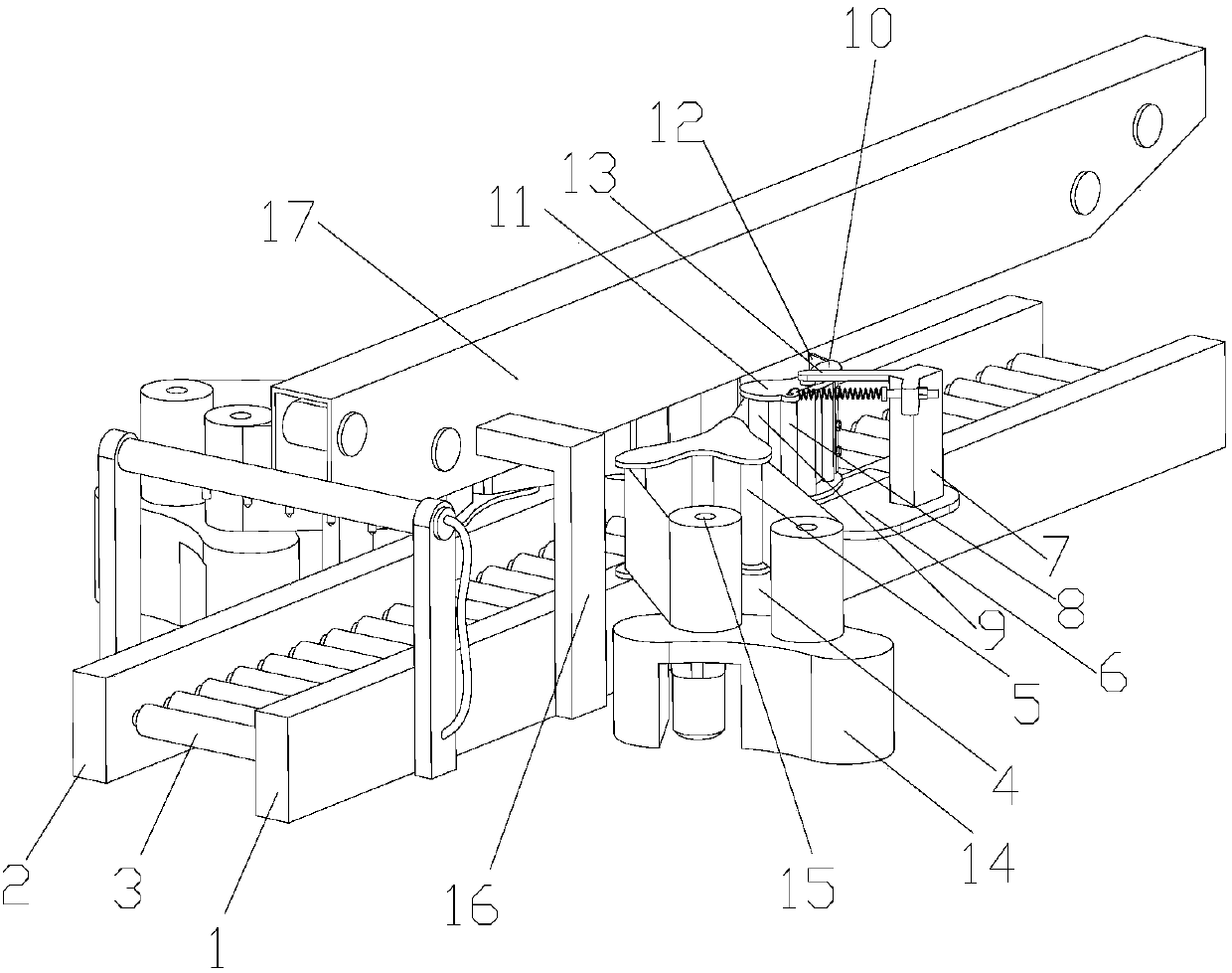

LCD panel film pasting auxiliary mechanism

InactiveCN107379720AAvoid offsetStable intervalLamination ancillary operationsLaminationEngineeringVacuum pump

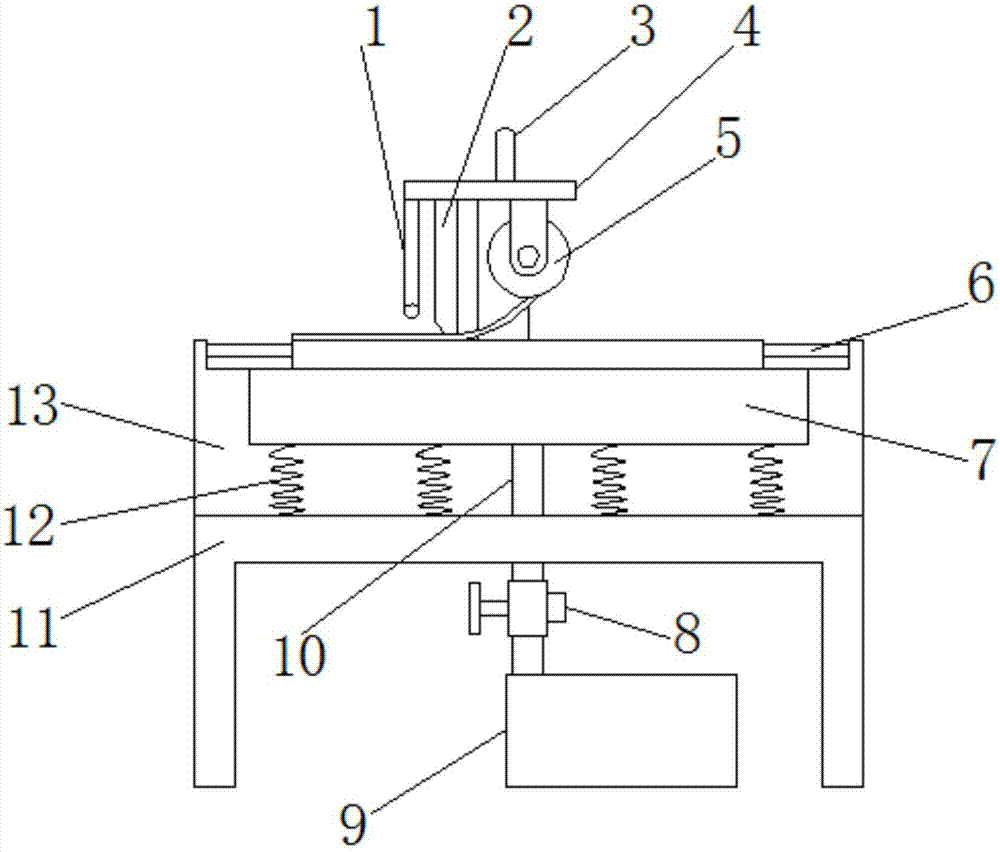

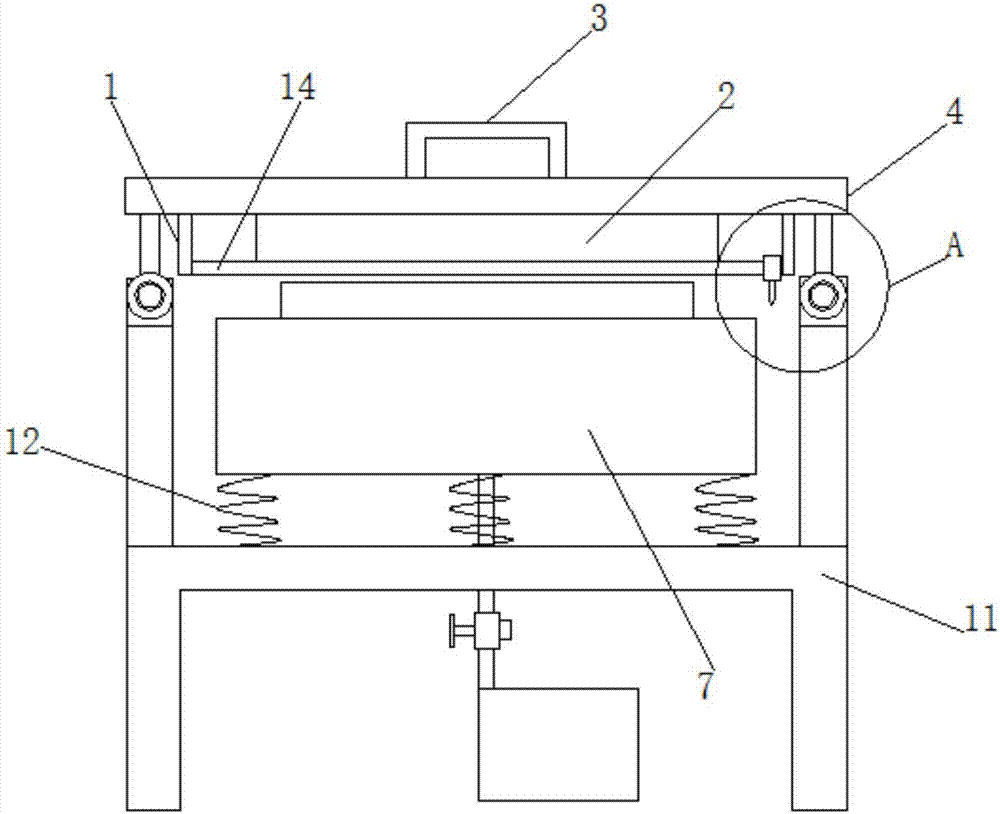

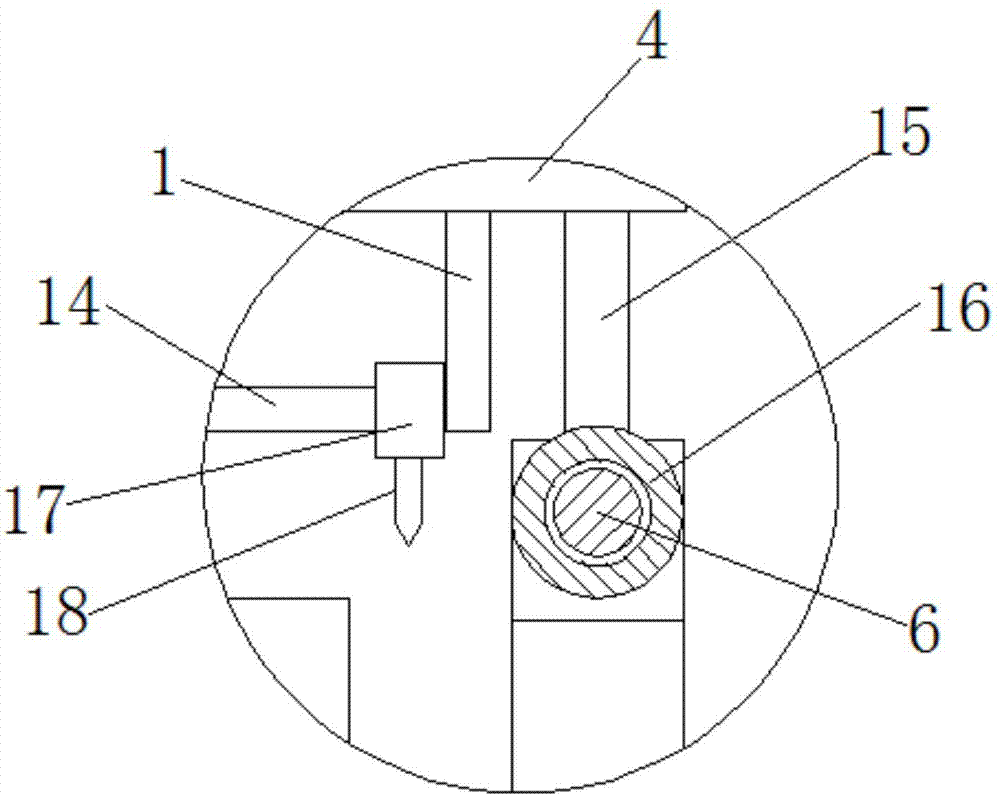

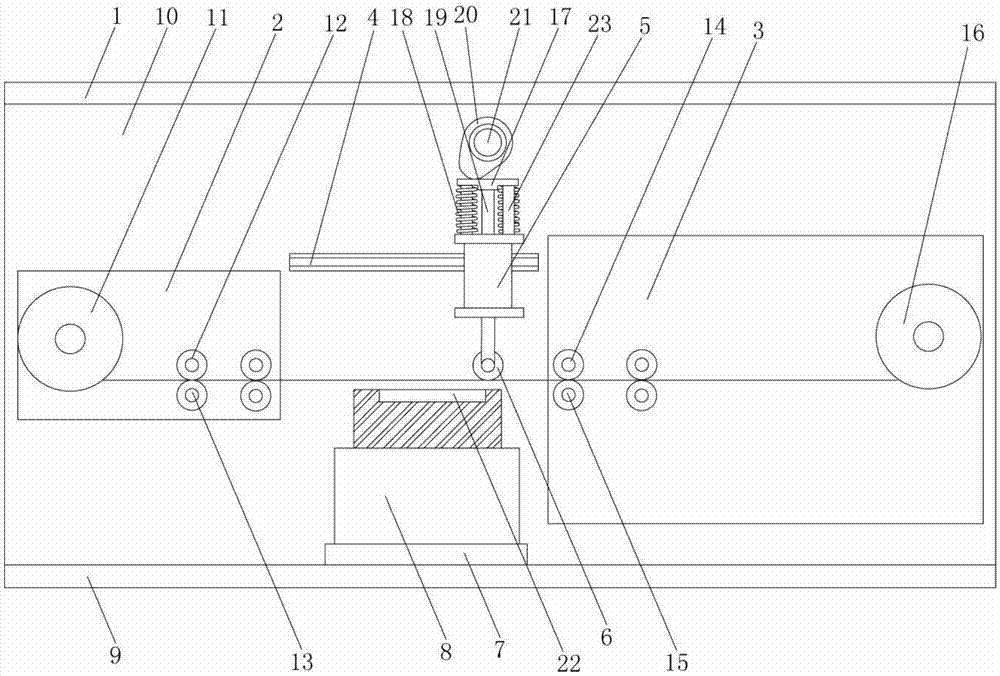

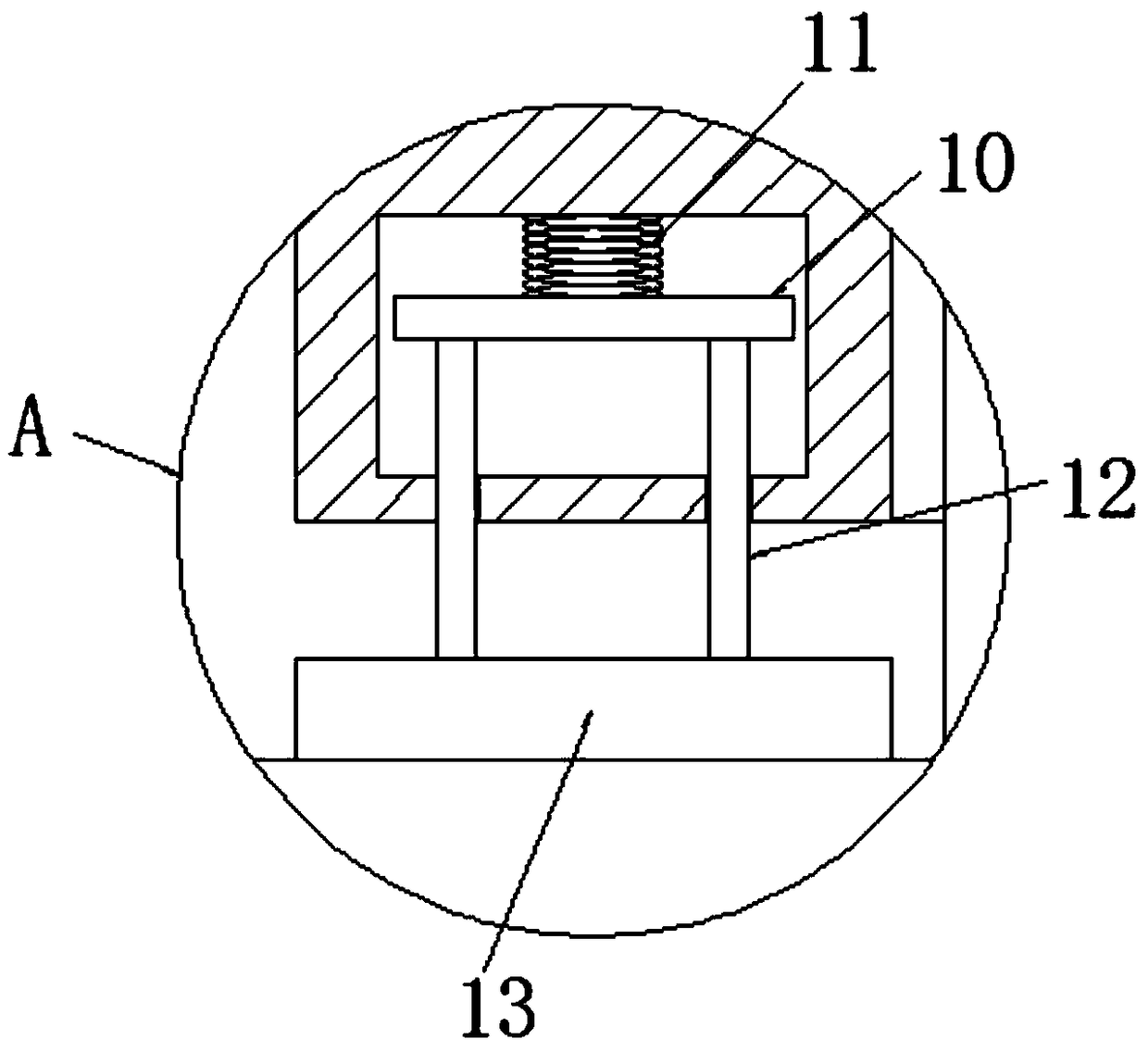

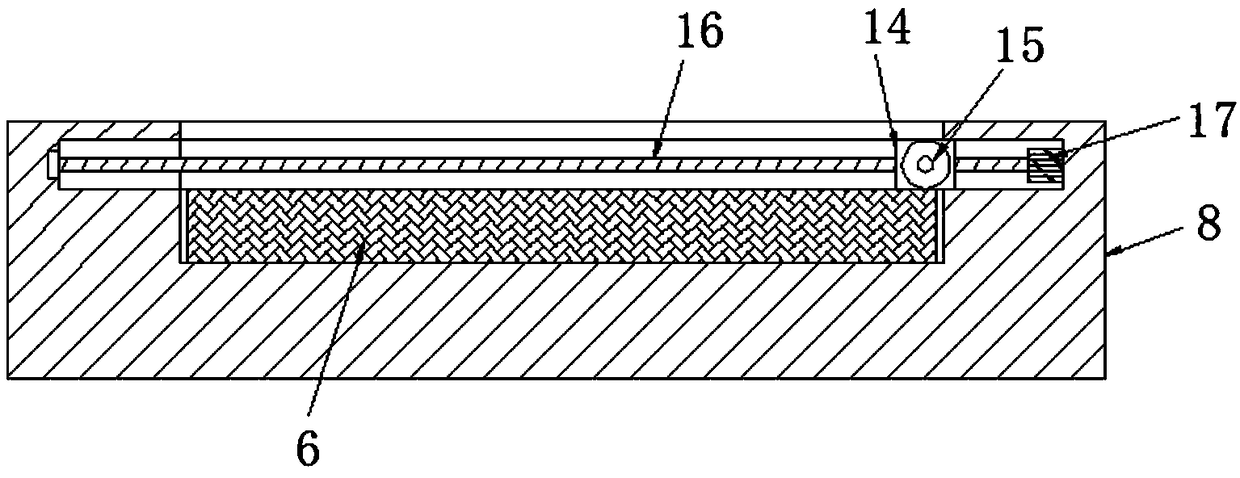

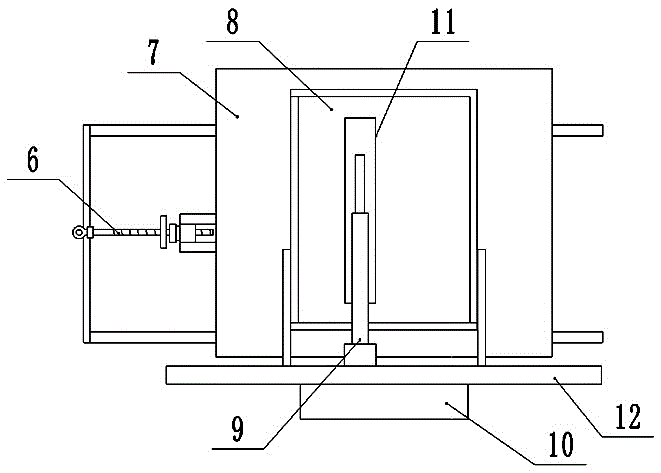

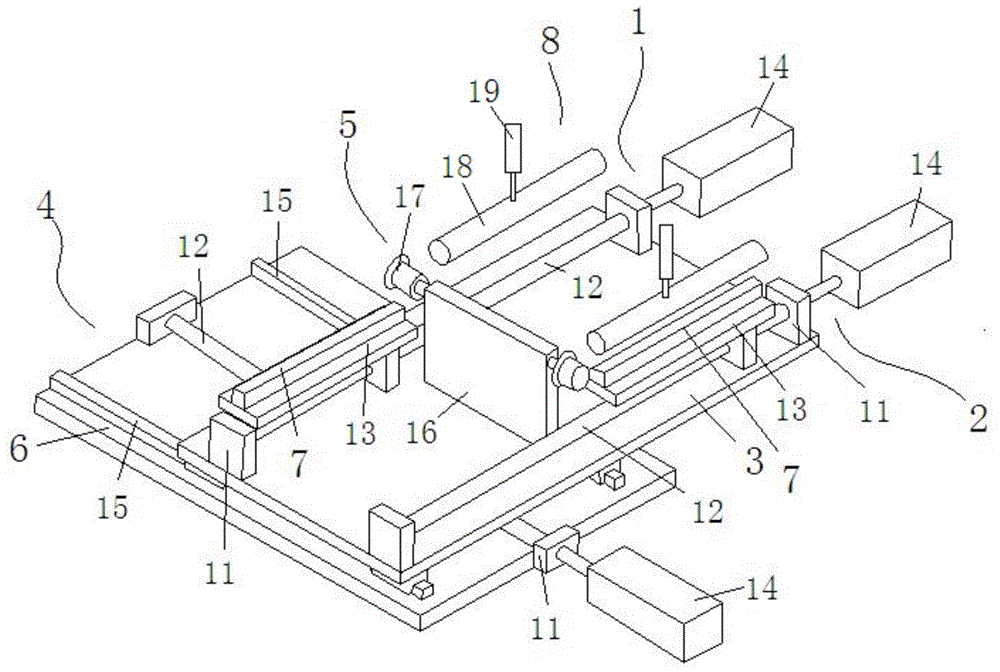

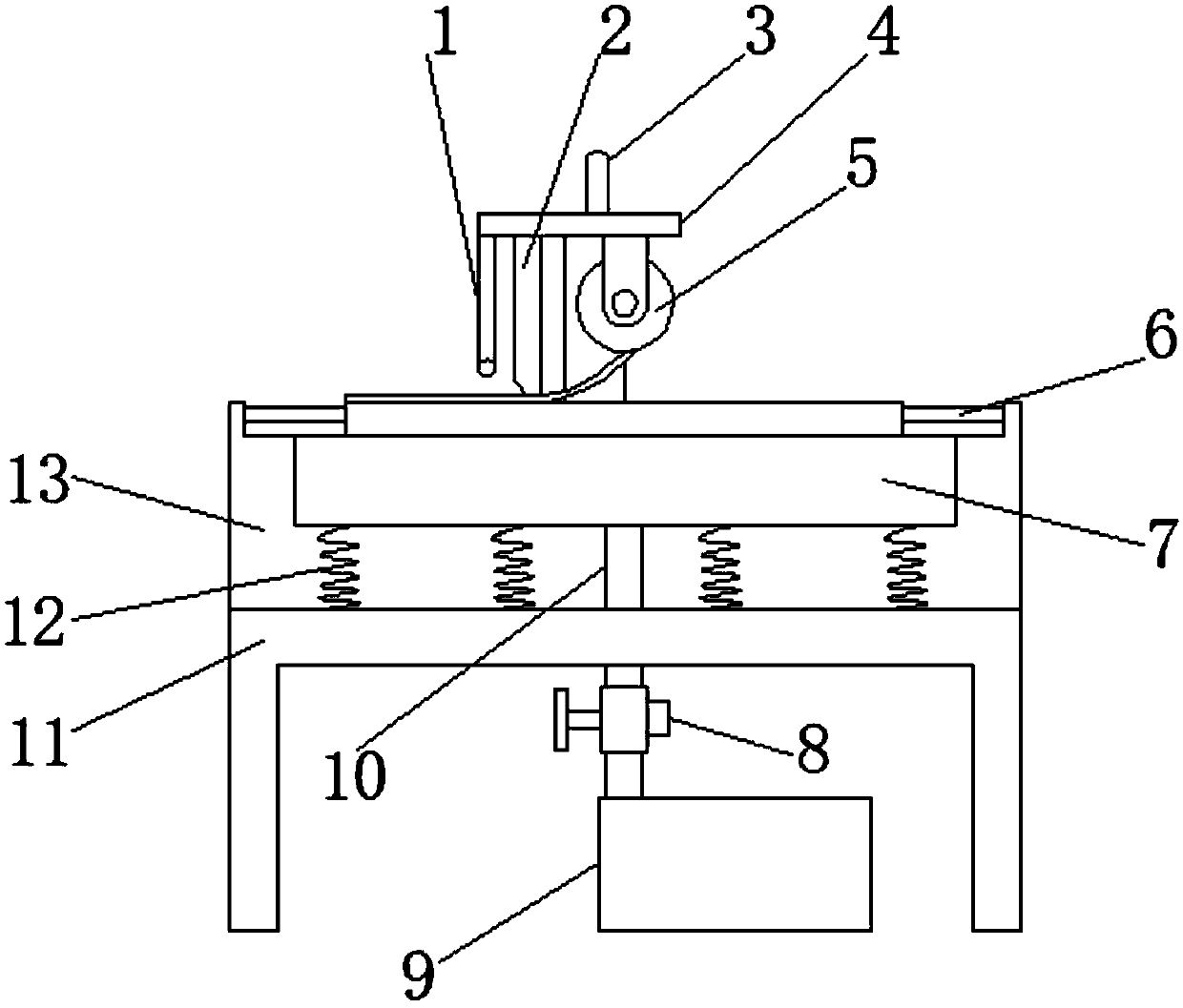

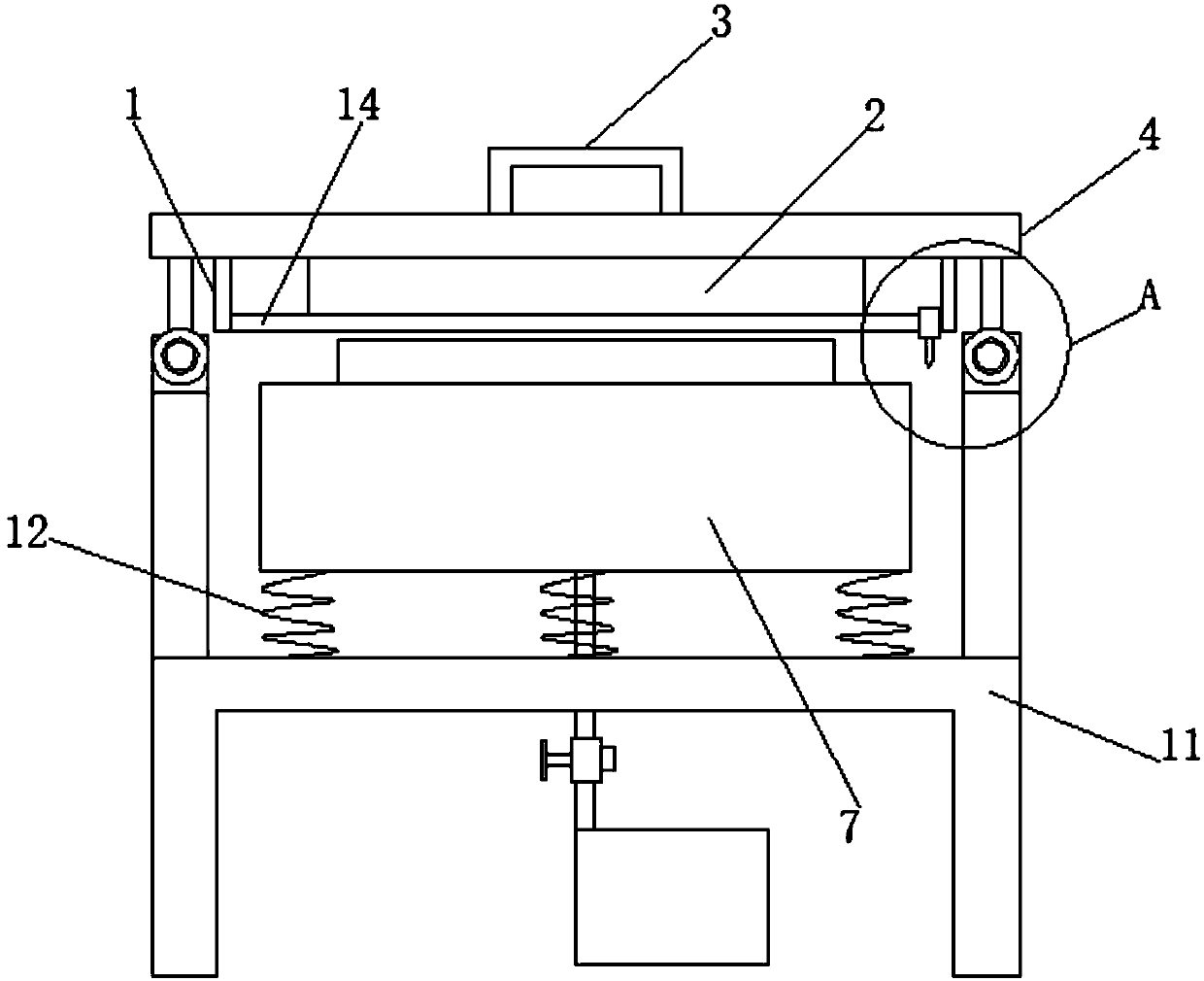

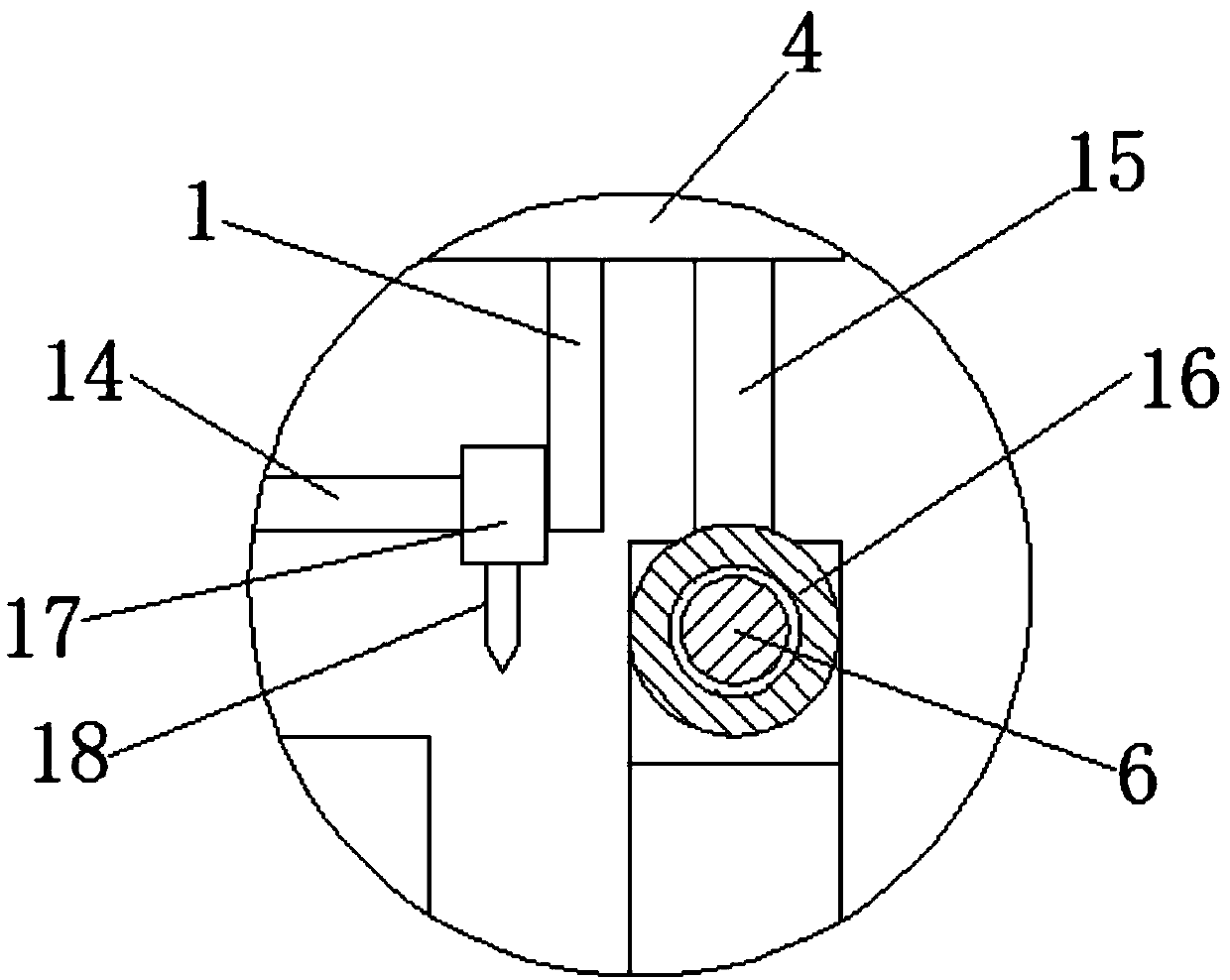

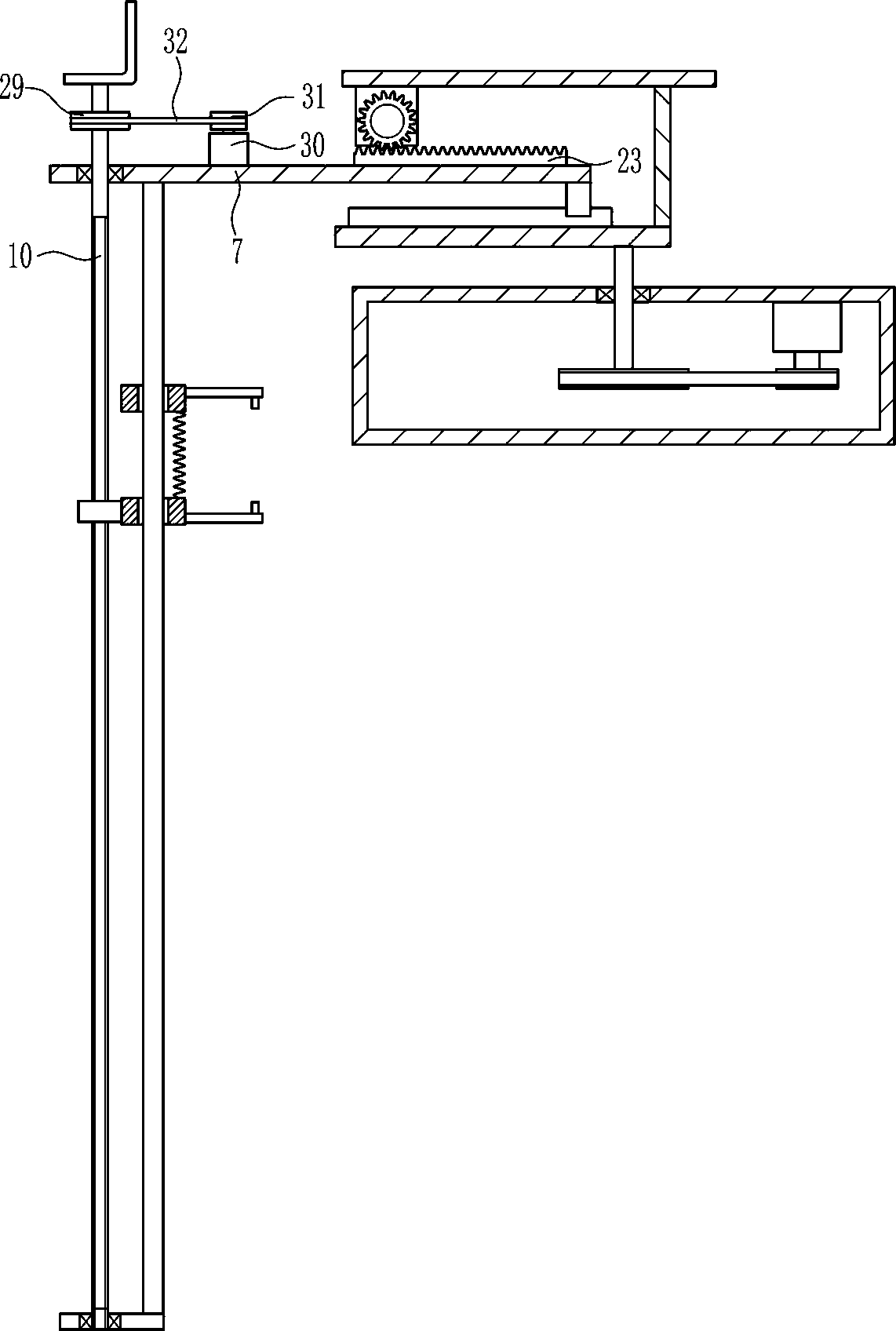

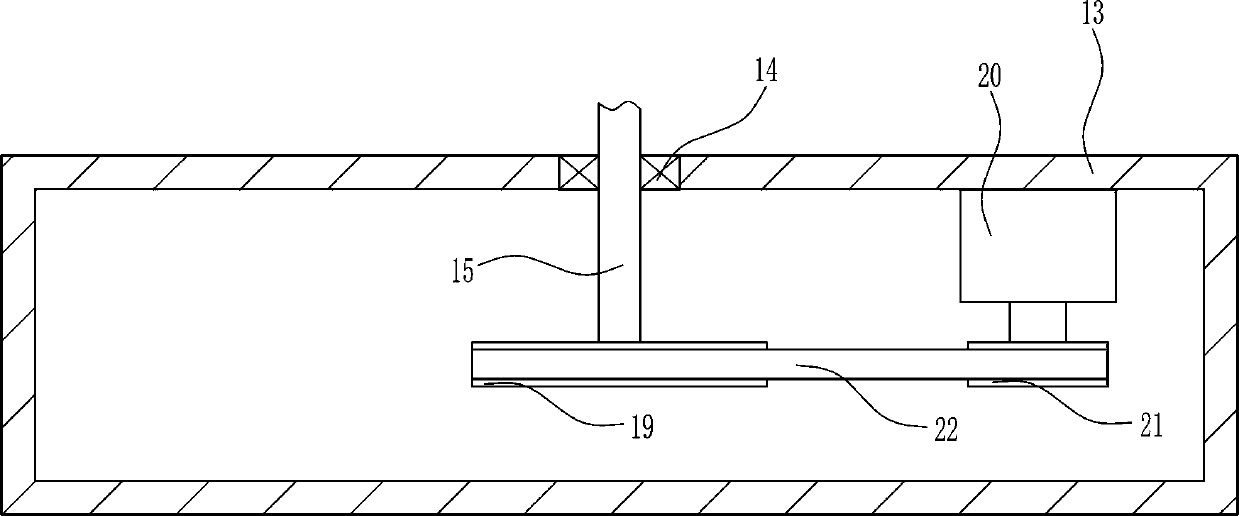

The invention discloses an LCD panel film pasting auxiliary mechanism. The LCD panel film pasting auxiliary mechanism comprises a fixing platform and a frame. The frame is fixedly connected to the lower surface of the fixing platform through a spring. The bottom of the fixing platform is connected to a vacuum pump through a pipe. Two sides of the frame are respectively welded and fixed to the bottoms of side plates. First sliding rods are slidingly connected to first sliding sleeves. The tops of the first sliding sleeves are welded and fixed at the bottoms of ejector rods. The top ends of the ejector rods are welded and fixed on the two ends of an ejector plate. The lower surface of the ejector plate is orderly provided with a fixing rod, a scraper plate and a discharge roller. A LCD suction plate is adsorbed and fixed by negative pressure so that LCD plate shift in film pasting is prevented. The ejector plate is pushed manually to drive the scraper plate so that the film is automatically pasted. The LCD panel film pasting auxiliary mechanism has a fast film pasting rate. The spring can ensure load balance of the LCD plate so that film pasting effects are improved and bubbles are effectively avoided. The mechanism can fast cut a film, is easy to operate and improves film pasting quality and efficiency.

Owner:成都预细科技有限公司

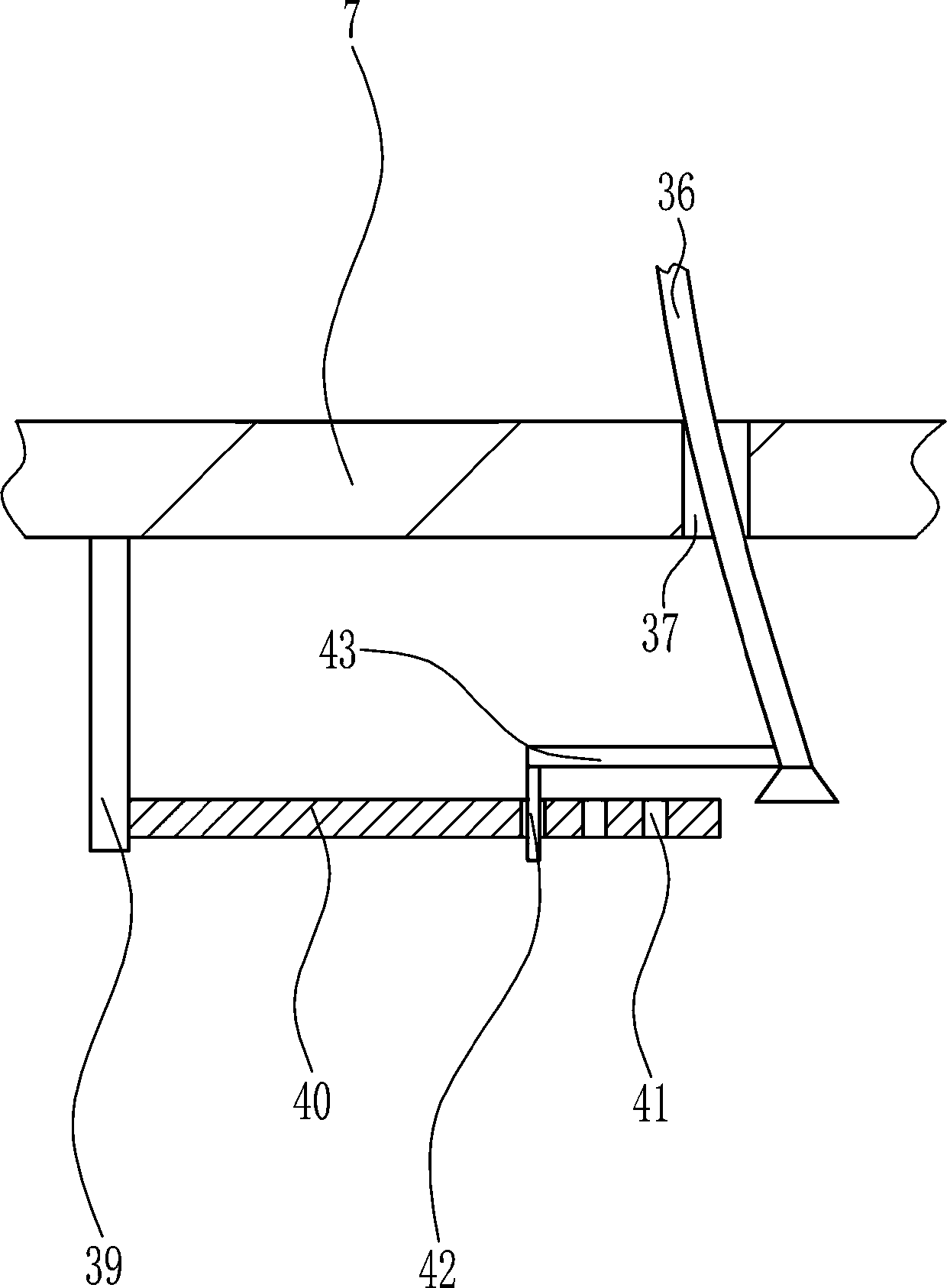

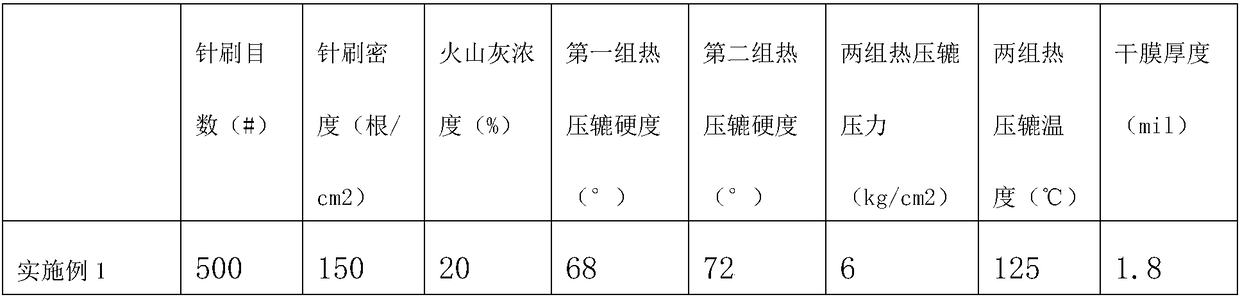

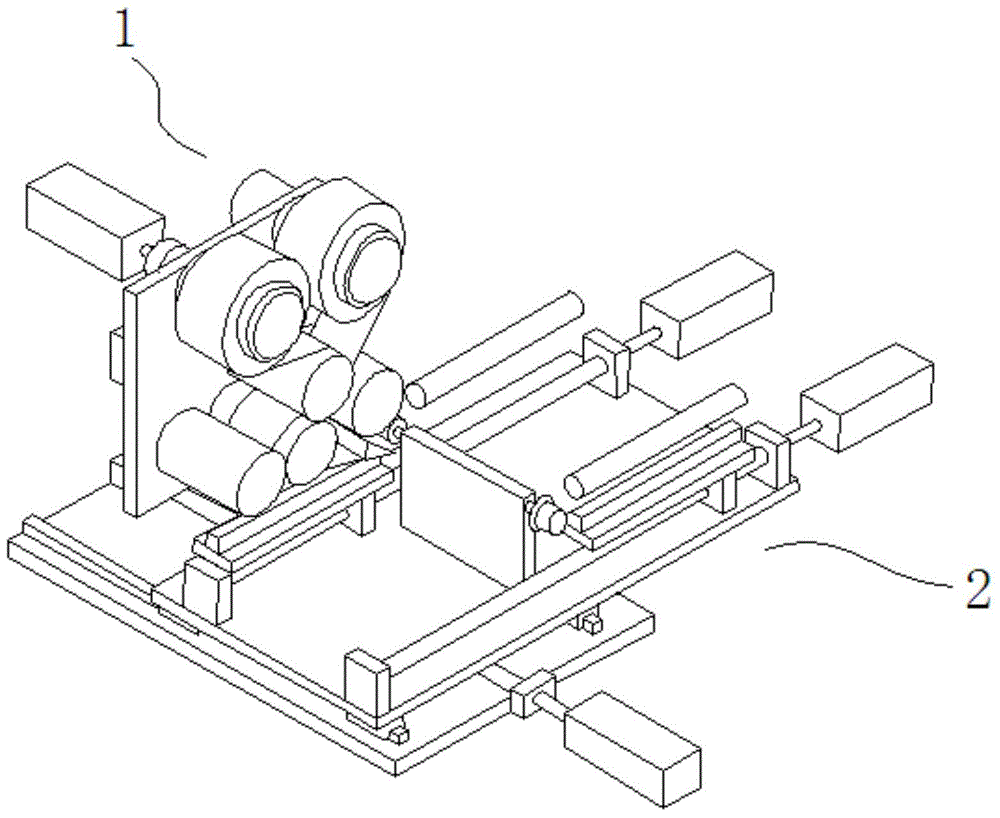

Rapid board-grinding and film-pasting method for outer layer circuit board

ActiveCN106028655AIncrease surface roughnessImprove adhesionConductive material chemical/electrolytical removalEngineeringHardness

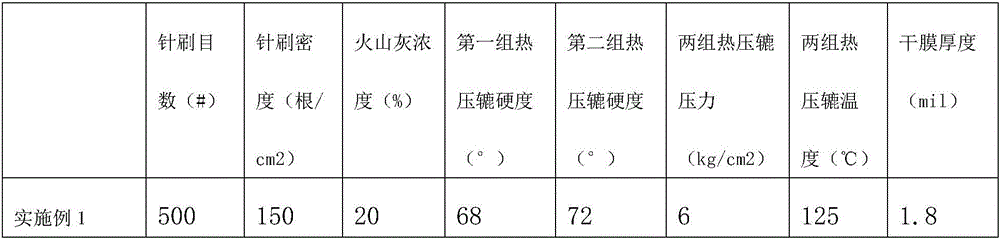

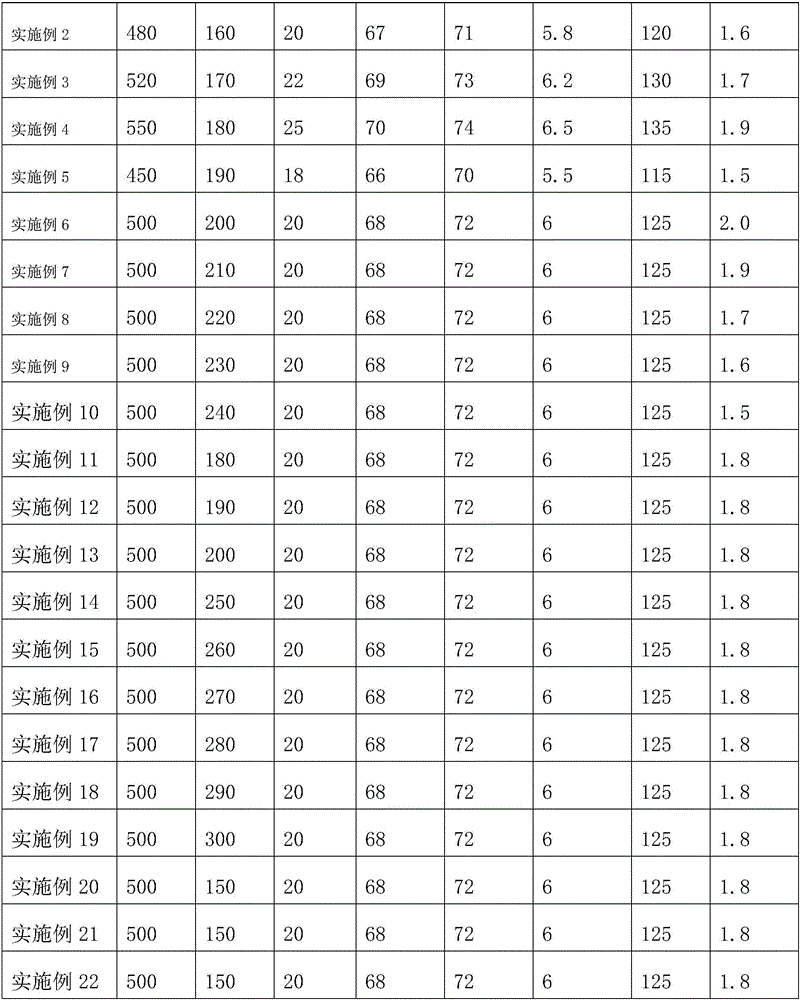

The invention discloses a rapid board-grinding and film-pasting method for an outer layer circuit board. The rapid board-grinding and film-pasting method comprises the following steps of putting a circuit board; performing acid washing; performing water washing for the first time; grinding the board by a needle brush; grinding the board by volcanic ash; removing the volcanic ash; drying by hot air; preheating the board surface; pasting a film; and collecting the board, wherein the grinding brush used in the step of grinding the board by the needle brush is 450#-550# needle brush; the volcanic ash used in the step of grinding the board by the volcanic ash is 18-25% in concentration; the first group of hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 68 plus or minus 2 degrees in hardness; the second group of hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 72 plus or minus 2 degrees in hardness; the two groups of the hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 5.5-6.5kg / cm<2> in pressure; and the two groups of the hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 115-135 DEG C in temperatures. By adoption of the rapid board-grinding and film-pasting method, the film-pasting speed can reach 3.8-4.0m / min; and meanwhile, the quality of the product can be ensured.

Owner:江西景旺精密电路有限公司

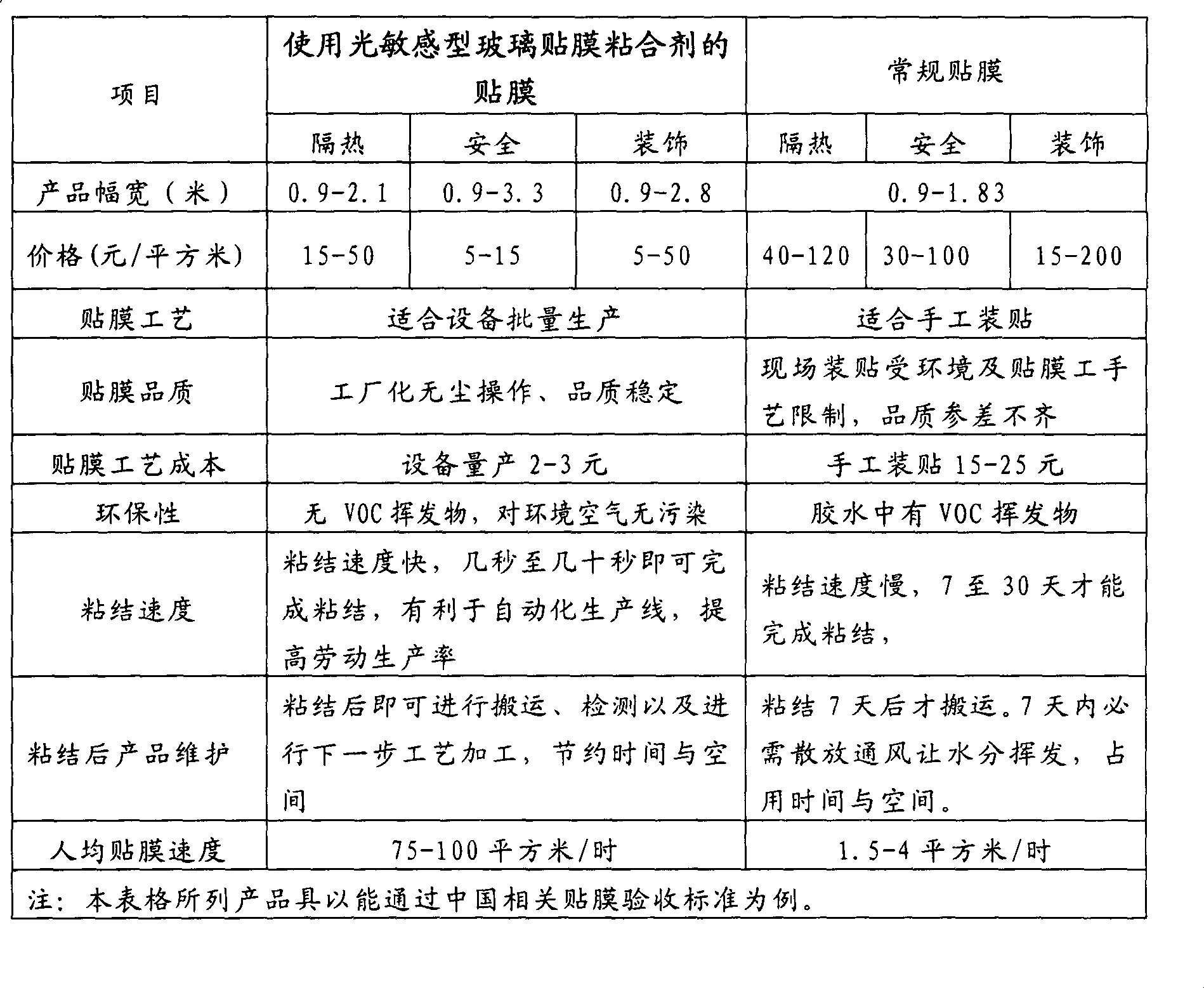

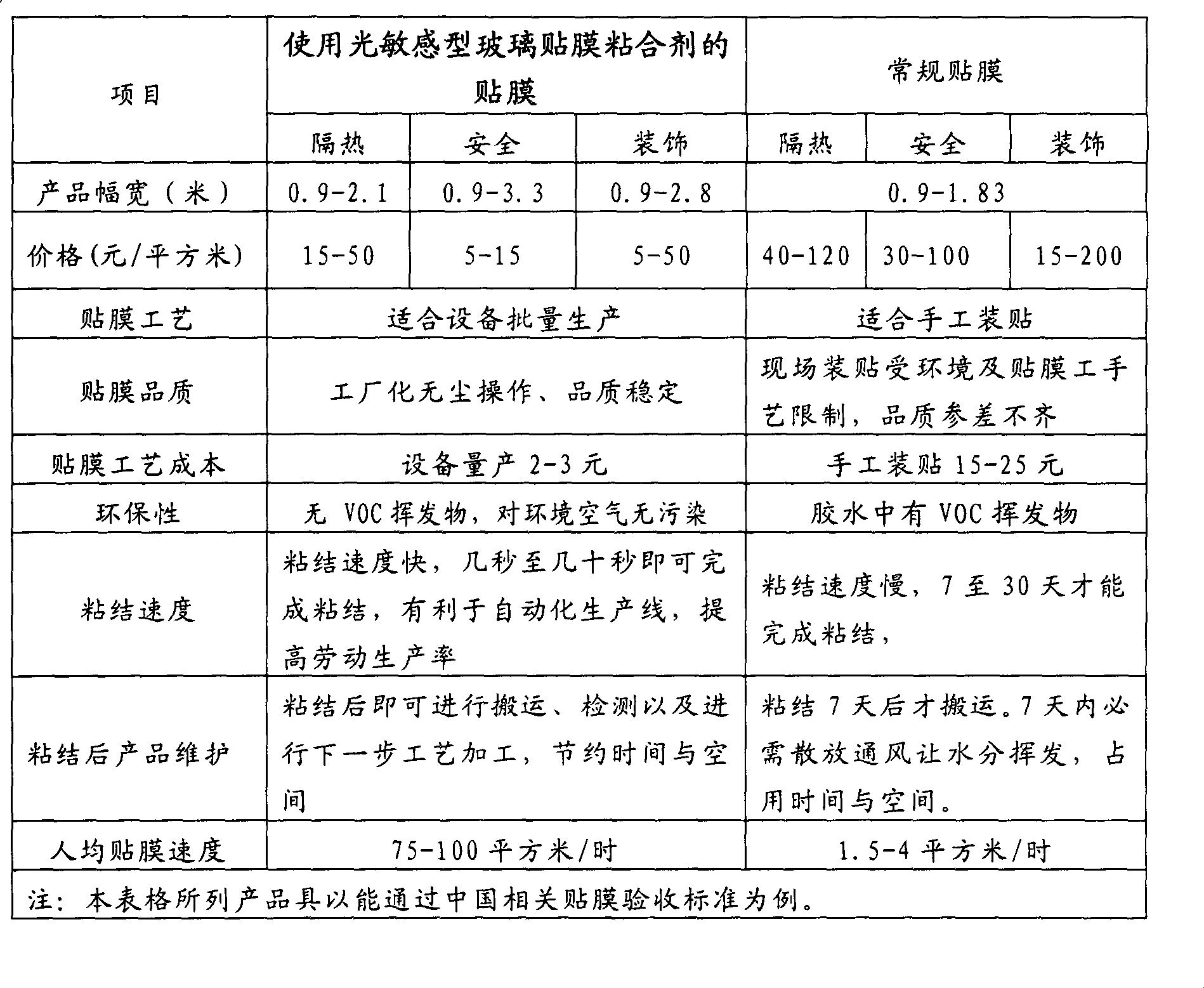

Light sensitive glass film binding agent

InactiveCN103013416AFast film applicationStable qualityPolyureas/polyurethane adhesivesSynthetic resin layered productsSolventPhotoinitiator

The invention discloses a light sensitive glass film binding agent, and provides a binding formula and a film prime coat formula, wherein the binding formula comprises components in percentage by mass as follows: 30-50% of base resin, 40-60% of an active monomer, 1-8% of a photoinitiator, 0.01-1% of a flatting agent, 0.01-1% of an antifoaming agent and 0.01-1% of coupling reagent; and the film prime coat formula comprises components in percentage by mass as follows: 25-45% of base resin, 15-35% of an active monomer, 1-8% of a photoinitiator, 0.05-1% of a flatting agent, 0.01-1% of an antifoaming agent, 0.01-1% of coupling reagent and 20-40% of a solvent. The invention further discloses a method for preparing the binding agent, the process is simple, and the preparation cost is low. The glass films produced by using the binding agent is high in curing speed, high in peel strength and good in safety performance.

Owner:苏州威仕薄膜科技有限公司

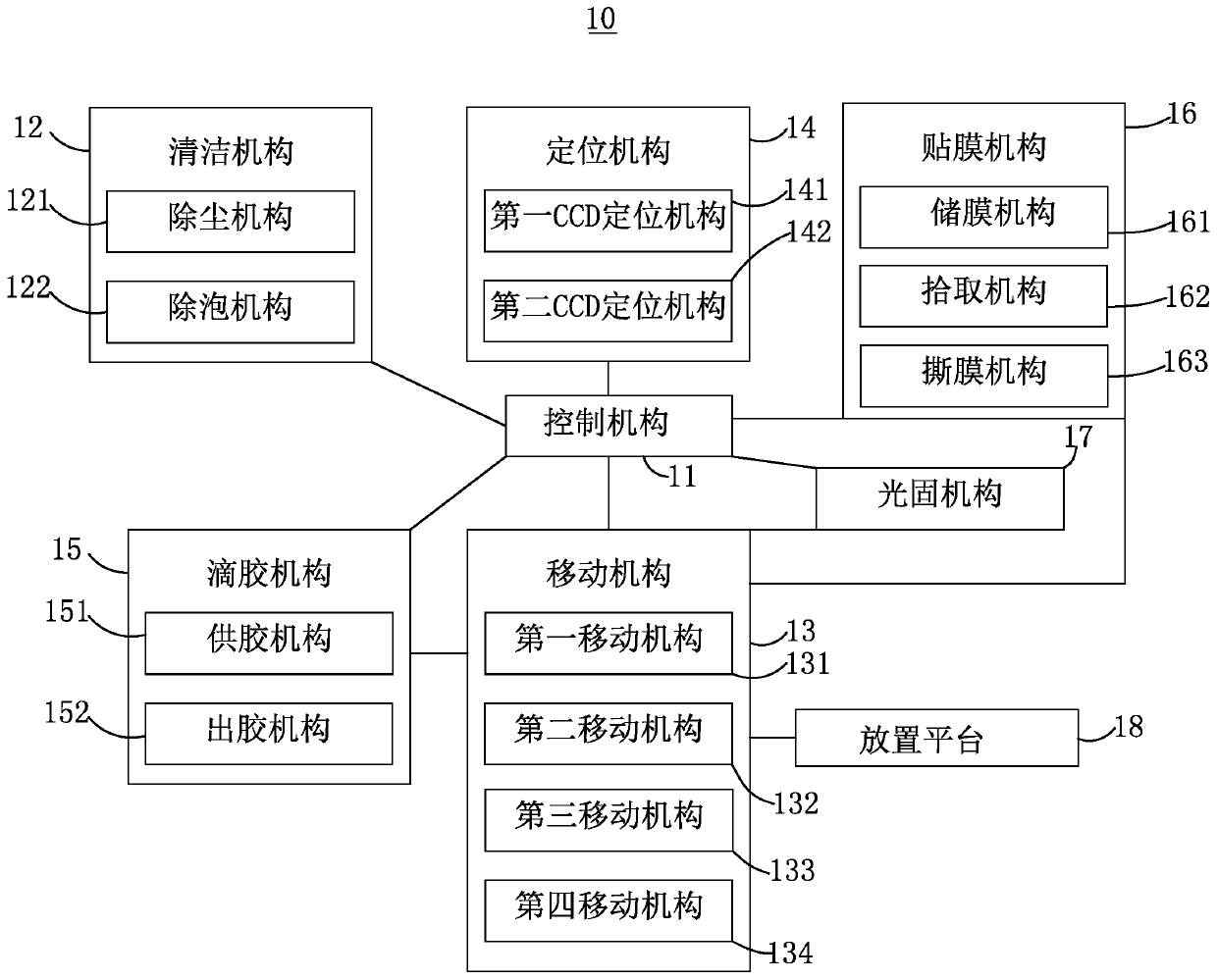

Film pasting machine and film pasting method

The invention provides a film pasting machine. The film pasting machine comprises a control mechanism, a moving mechanism, a glue dripping mechanism, a film pasting mechanism and a light curing mechanism; the control mechanism is electrically connected with the moving mechanism, the glue dripping mechanism, the film pasting mechanism and the light curing mechanism; the moving mechanism is connected with the glue dripping mechanism, the film pasting mechanism and the light curing mechanism and is used for driving the glue dripping mechanism, the film pasting mechanism and the light curing mechanism to move; the glue dripping mechanism is used for dripping at least one drop of photosensitive glue on an area to be pasted with a film; the film pasting mechanism is used for pasting a curved film on the area to be pasted with the film; the light curing mechanism is used for emitting and irradiating ultraviolet rays to the area to be pasted with the curved film so as to cure the photosensitive glue; and the control mechanism is at least used for controlling the glue dripping mechanism, the film pasting mechanism and the light curing mechanism to work in sequence when receiving a film pasting signal. The invention further provides a film pasting method adopting the film pasting machine. The film pasting machine has the advantages of being good in curved screen film pasting effect, lowin film pasting time consumption and reasonable in charging.

Owner:SHENZHEN BNT INTELLIGENT TECH CO LTD

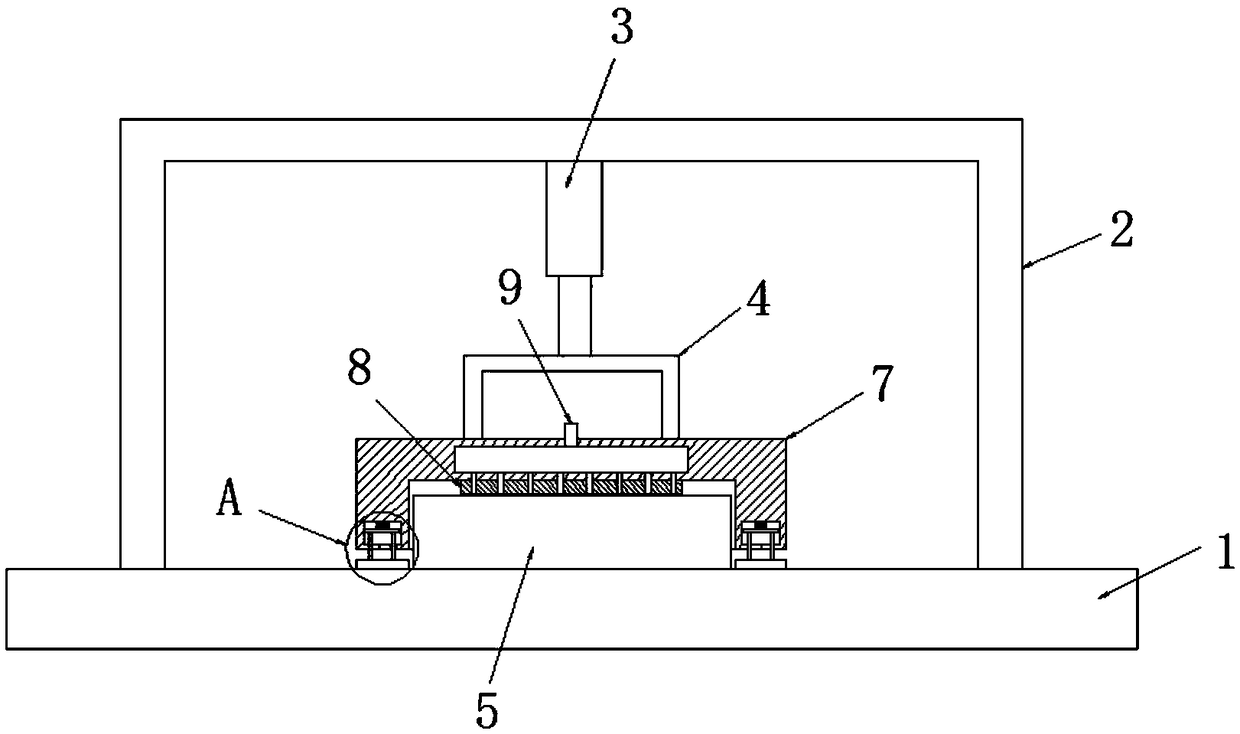

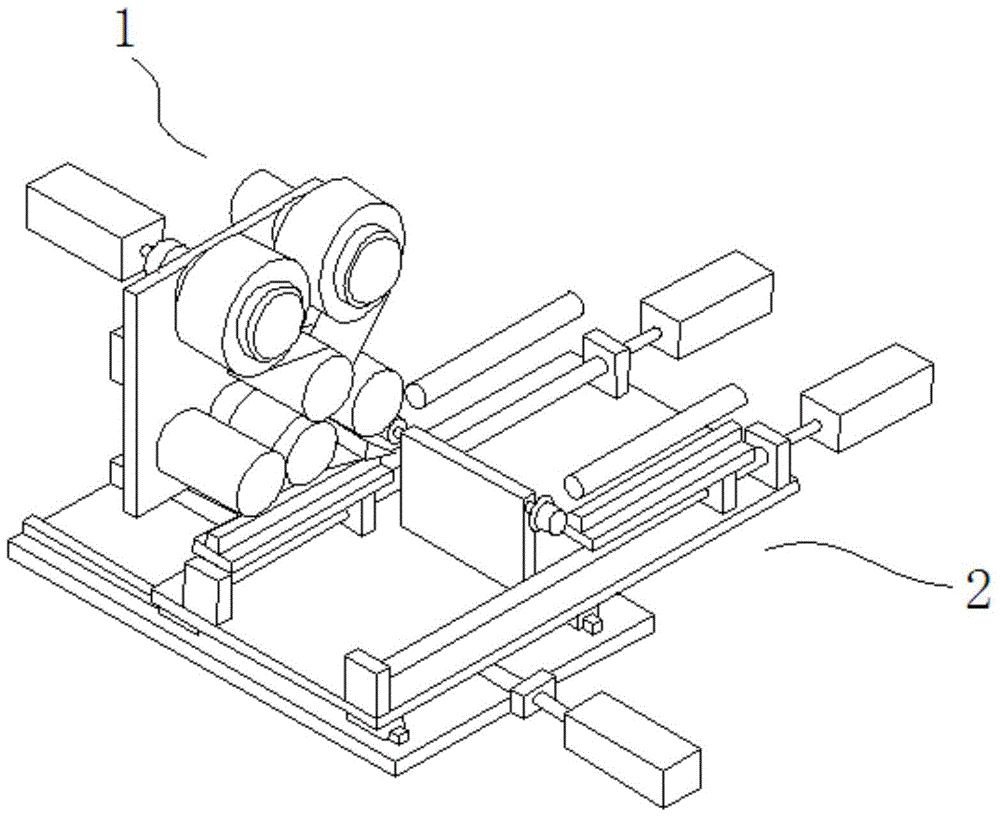

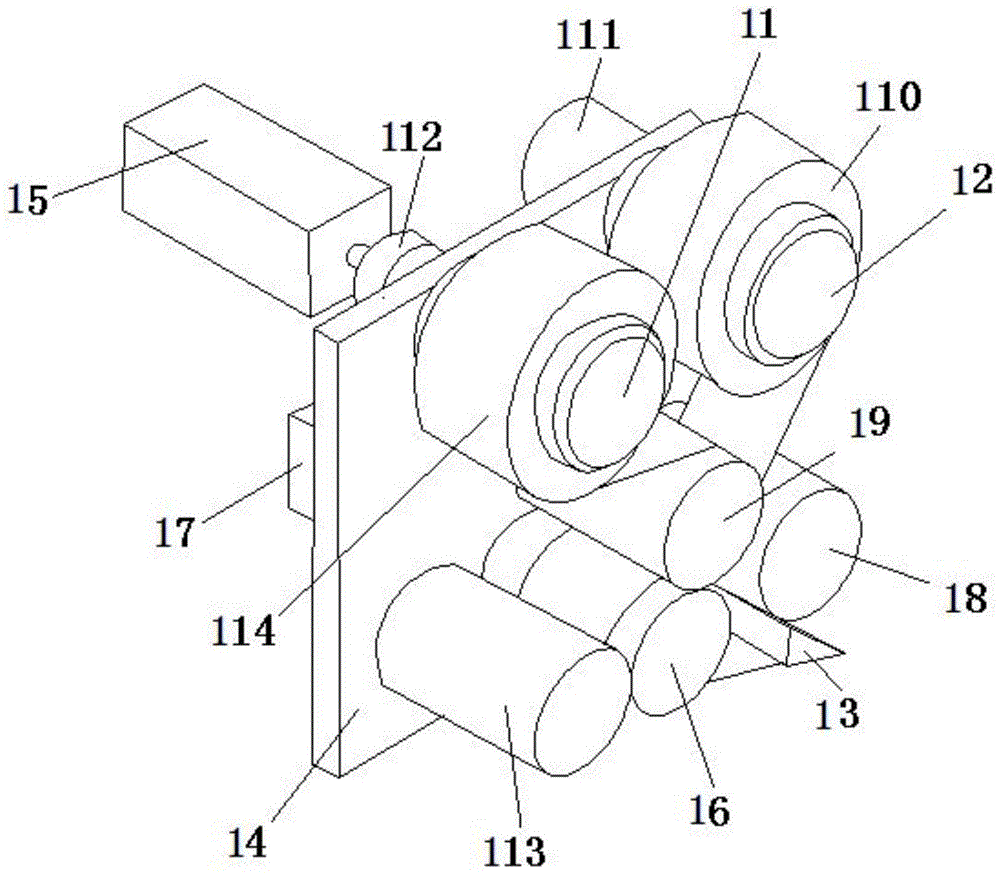

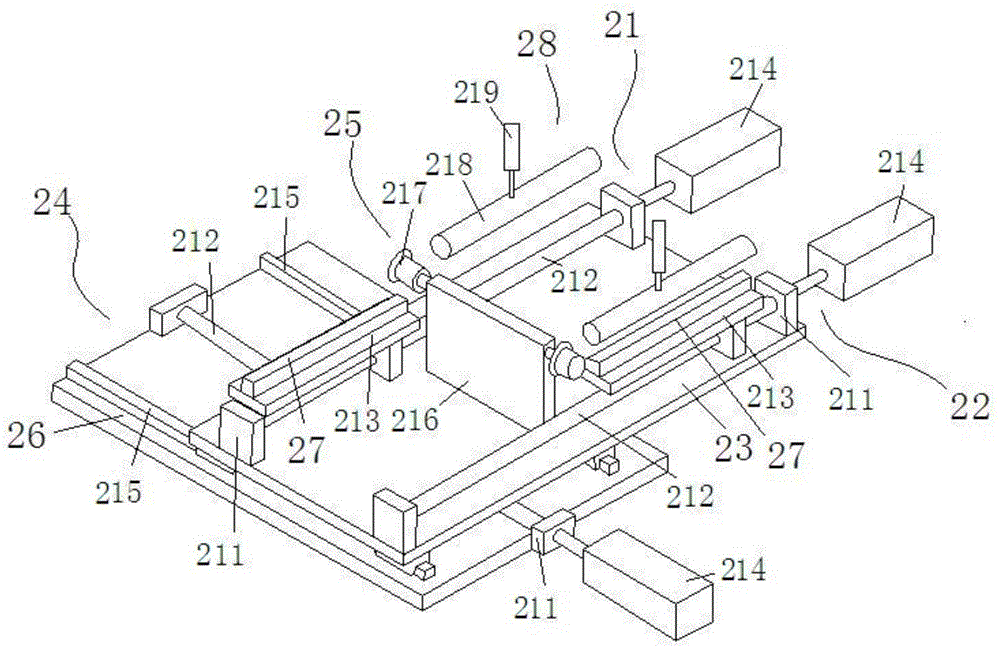

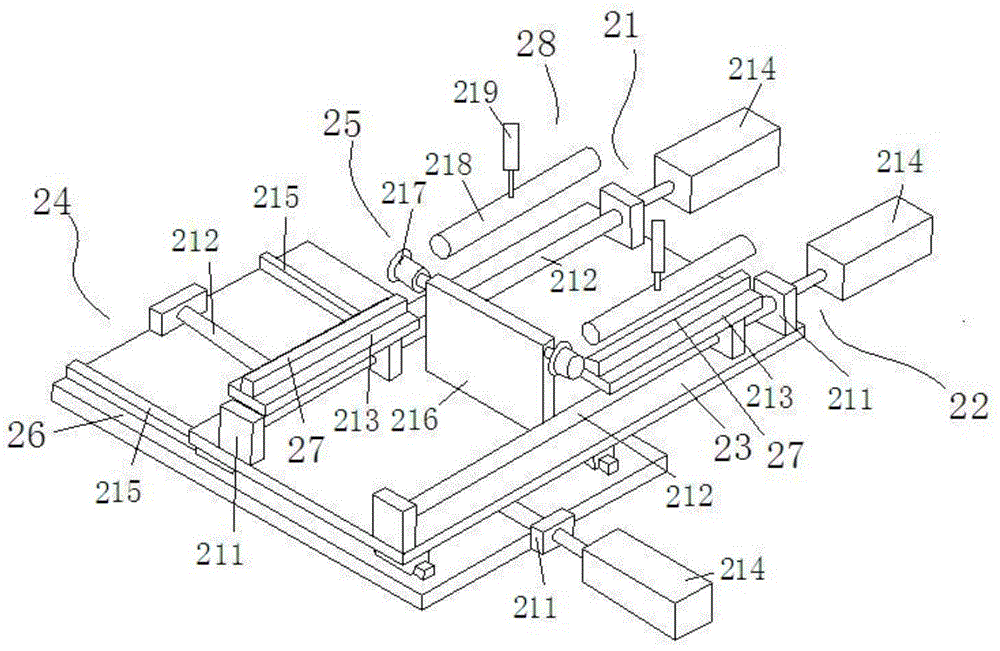

Automatic film sticking machine for touch panel of mobile phone

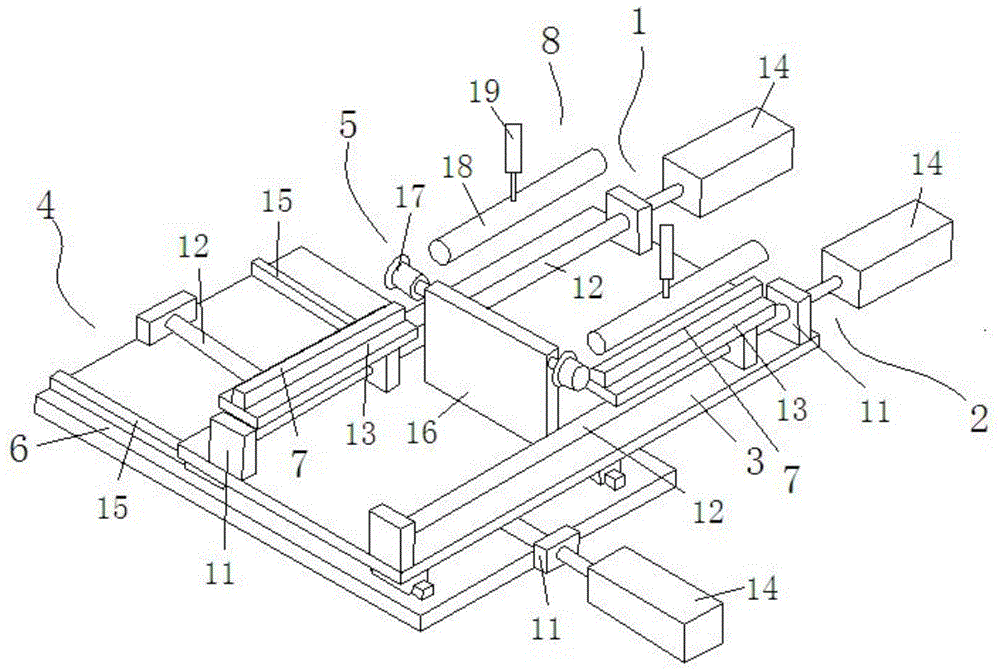

The invention provides an automatic film sticking machine for a touch panel of a mobile phone, and belongs to the technical field of film sticking equipment for touch panels of mobile phones. The automatic film sticking machine for the touch panel of the mobile phone solves the technical problem that an existing film sticking device is low in film sticking efficiency. The automatic film sticking machine for the touch panel of the mobile phone comprises a base. A lower film sticking plate is fixed to the upper surface of the base, and a first film sticking surface is arranged on the upper surface of the lower film sticking plate. A first sliding groove and a second sliding groove are formed in the upper surface of the base, a first sliding base is connected to the first sliding groove in a sliding mode, and a second sliding base is connected to the second sliding groove in a sliding mode. A rotating shaft is connected between the first sliding base and the second sliding base, can rotate around the axis of the rotating shaft relative to the first sliding base and the second sliding base, and enables the first sliding base and the second sliding base to be linked in the horizontal direction. An upper film sticking plate is arranged on the rotating shaft, and one side of the upper film sticking plate is fixed to the rotating shaft. A first driving mechanism and a second driving mechanism are arranged on the base. A second film sticking surface is arranged on the upper surface of the upper film sticking plate, and the second film sticking surface and the first film sticking surface can be stuck together through horizontal movement and rotation of the upper film sticking plate. The automatic film sticking machine is high in film sticking speed and working efficiency.

Owner:江门市威瑞电子科技有限公司

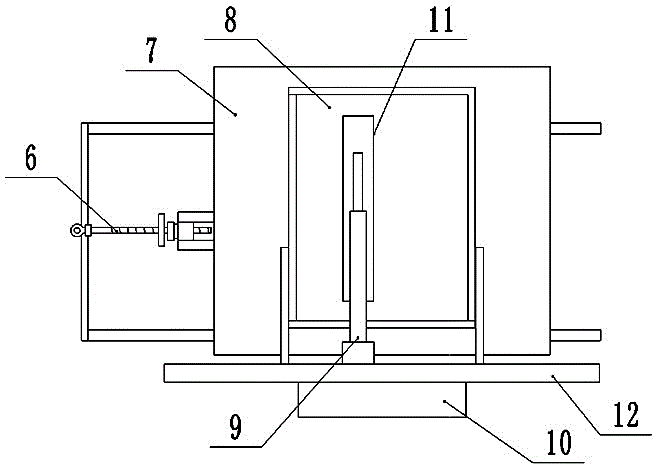

Film pasting equipment for computer liquid crystal display screen

InactiveCN106915494AFast film applicationNice appearanceWrapping material feeding apparatusWebs handlingLiquid-crystal displayCam

The invention belongs to the field of computer production equipment, and particularly relates to film pasting equipment for a computer liquid crystal display screen. The film pasting equipment is characterized in that film releasing upper guide wheels and film releasing lower guide wheels are arranged in pairs and located on one side of a film releasing wheel; film rolling upper guide wheels and film rolling lower guide wheels are arranged in pairs and located on one side of a film rolling wheel; a motion device is arranged on a motion device sliding guide rail; one end of an extensible spring is connected with a movable plate, and the other end of the extensible spring is connected with the motion device; one end of a telescopic shaft is connected with the movable plate, and the other end of the telescopic shaft penetrates through the motion device to be connected with the film pressing wheel; a cam is mounted above the movable plate, and a center shaft of the cam is connected with a cam rotating shaft; the film pressing wheel is located between the film releasing upper guide wheels and the film rolling upper guide wheels; a liquid crystal display screen lifting base is mounted on a liquid crystal display screen lifting base sliding guide rail and located below the film pressing wheel; and a liquid crystal display screen placing groove is formed in the liquid crystal display screen lifting base.

Owner:天津奥凯康科技有限公司

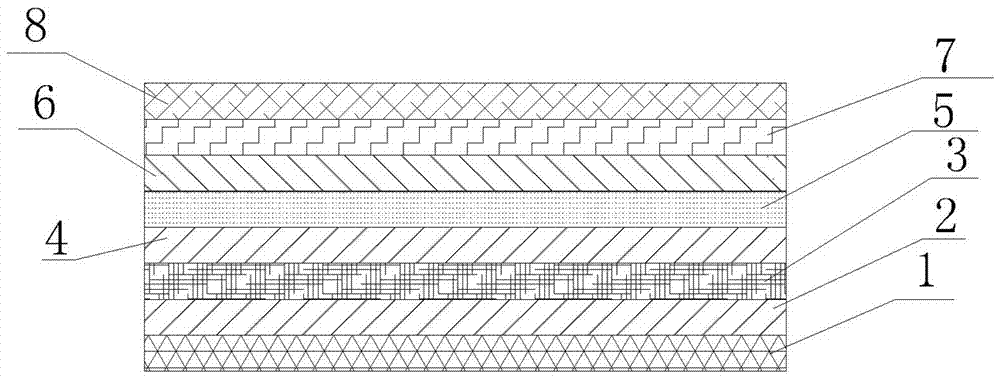

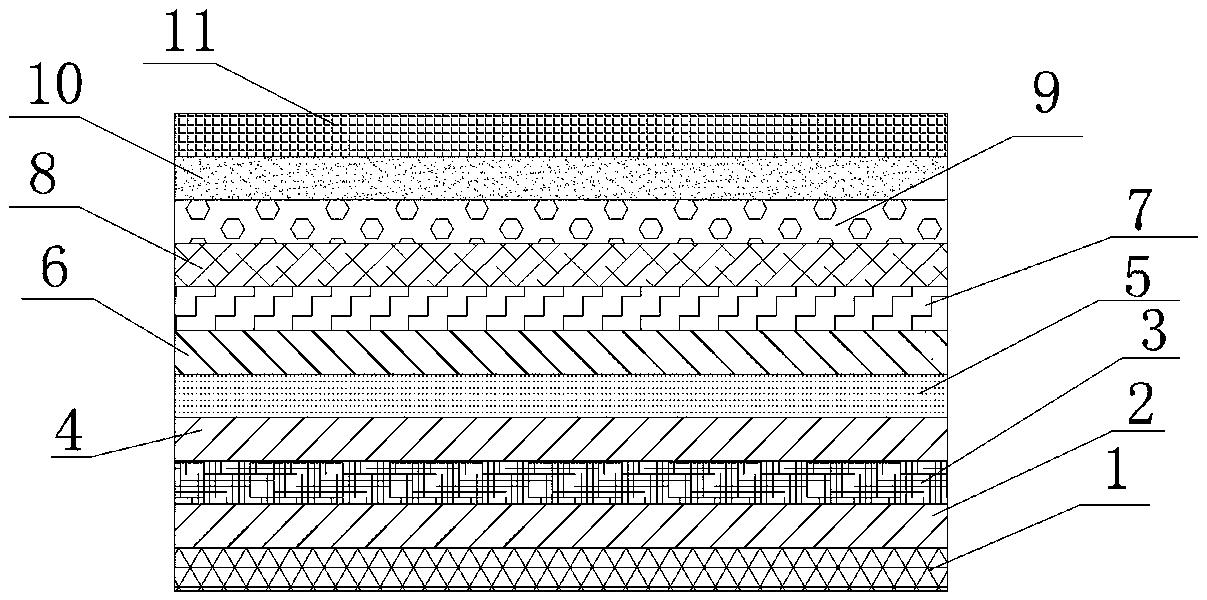

Film provided with self-adhesion protective film and capable of being jointed with ceiling at low temperature and preparation method thereof

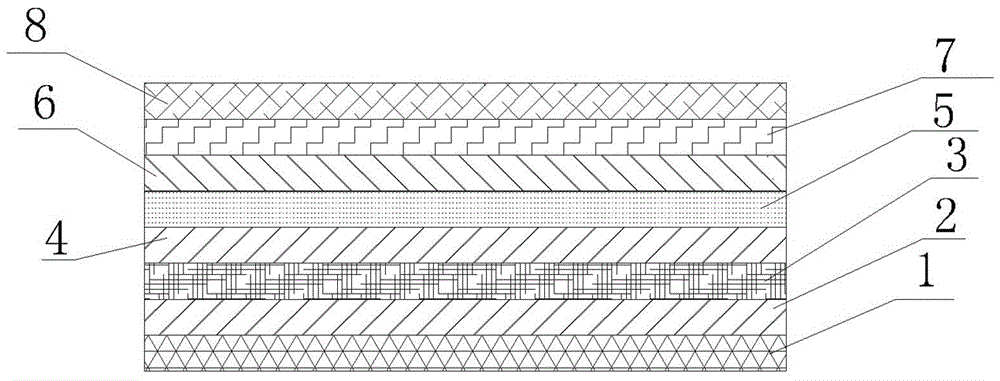

ActiveCN106273816APromote environmental protectionReduce the cost of protectionCovering/liningsSynthetic resin layered productsAdhesiveEngineering

The invention discloses a film provided with a self-adhesion protective film and capable of being jointed with a ceiling at low temperature. The film comprises an outer layer, a middle layer, an inner layer, a printed layer, a film protection layer, a self-adhesion material layer and a self-adhesion material protection layer, wherein the inner side of the self-adhesion material layer adheres to the outer side of the film protection layer; the inner side of the self-adhesion material protection layer adheres to the outer side of the self-adhesion material layer via an adhesive; the inner side of the film protection layer adheres to the outer side of the printed layer via the adhesive; the inner side of the printed layer adheres to the outer side of the outer layer via a glue layer; the outer side of the middle layer adheres to the inner side of the outer layer via the adhesive; the outer side of the inner layer adheres to the inner side of the middle layer via the adhesive; the inner side of the inner layer adheres to a ceiling inner board. The film has the beneficial effects that the self-adhesion protective film is compounded on the film of the common ceiling to replace traditional gluing processes, so that the film has good environment friendliness and is low in protection cost; meanwhile, a polymer material capable of adhering at low temperature is adopted as the base layer, so that the film can be directly jointed on the ceiling at a lower temperature, thus increasing the film adhering speed and improving the use efficiency.

Owner:浙江华清包装材料有限公司

Mobile phone screen film pasting machine

The invention discloses a mobile phone screen film pasting machine which comprises a base, a portal frame is fixedly arranged at the upper end of the base, and an electric push rod is fixedly arrangedat the center of the lower end of the cross beam of the portal frame, the movable end of the electric push rod is fixedly connected with a U-shaped rod, the two ends of the vertical part of the U-shaped rod are together fixedly connected with a film loading mechanism, a fixing block is fixedly arranged at the position, corresponding to the position of the film loading mechanism, of the upper endof the base, a containing groove is formed in the upper end of the fixing block, a mobile phone is arranged at the bottom of the containing groove, strip-shaped grooves which are communicated with each other are formed in the peripheral side walls of the containing groove, and roller pressing mechanisms are arranged inside the strip-shaped grooves. According to the invention, the quality of the mobile phone film pasting is improved, and the film pasting speed of the mobile phone is increased.

Owner:安顺云首创科技开发有限公司

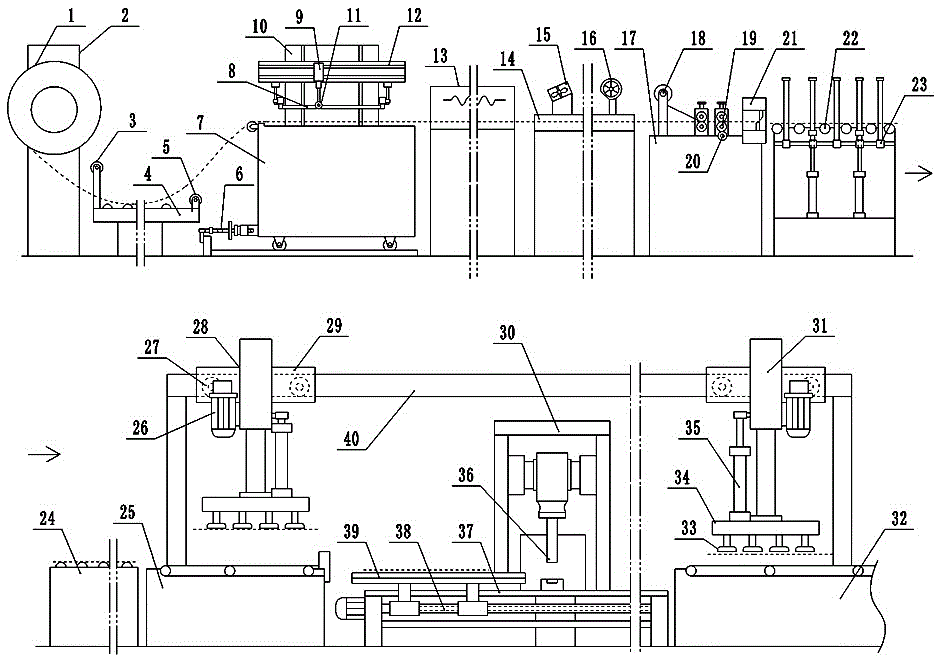

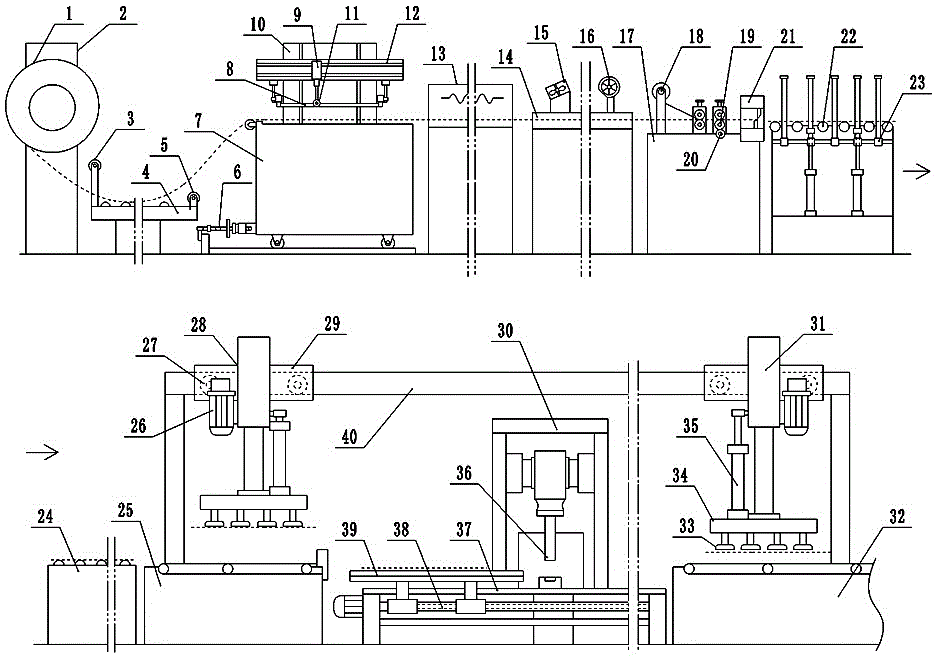

Printing and punching production line for solar water tank shells

ActiveCN105414385APrinting alignment is accurateImprove printing qualityHollow articlesProduction linePunching

The invention provides a printing and punching production line for solar water tank shells. The rear end of an unrolling frame for metal strip rolls of the production line is sequentially provided with an unrolling speed buffer platform, a flat-bed printing machine, a drying oven, a cooling table, a film pasting frame, a plate overturning frame, a plate connection frame and a single-plate conveying frame. A start inductive switch and a stop inductive switch of an unrolling motor are arranged on the unrolling speed buffer platform. A film containing frame, a film pressing roller and a length-fixed cutter are arranged on the film pasting frame. A length encoder of the length-fixed cutter is arranged beside the film pressing roller. Suction disc plate conveying devices are arranged on the single-plate conveying frame. A lead screw plate conveying table and a punching machine are arranged below the single-plate conveying frame. By the adoption of the technical scheme, rolled plates are unrolled from the unrolling frame and punched automatically, small manual operation is needed in the whole process, the quality of printing, film pasting and punching is better, and production efficiency is higher.

Owner:YUNNAN YUXI TAIBIAO SOLAR ENERGY EQUIP

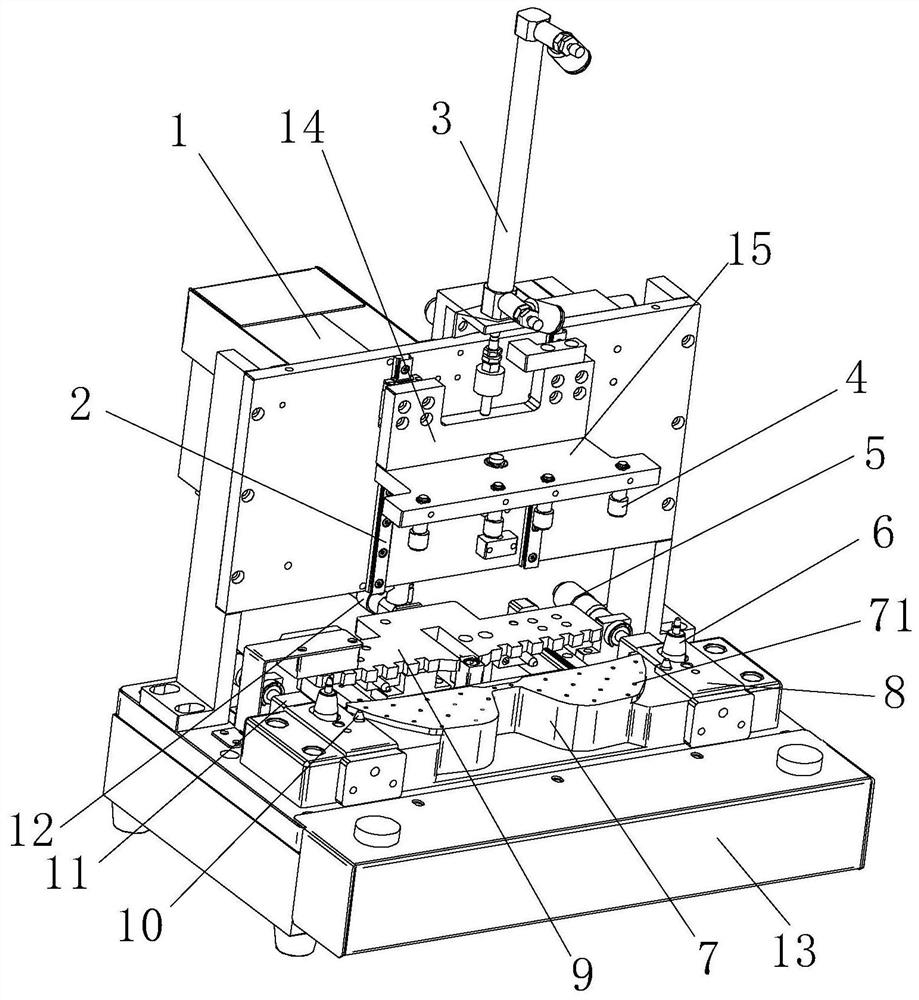

Special-shaped part film pasting device and method

ActiveCN110902000AEliminate Positional TolerancesEliminate Tolerance ChainsPackagingEngineeringMechanical engineering

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

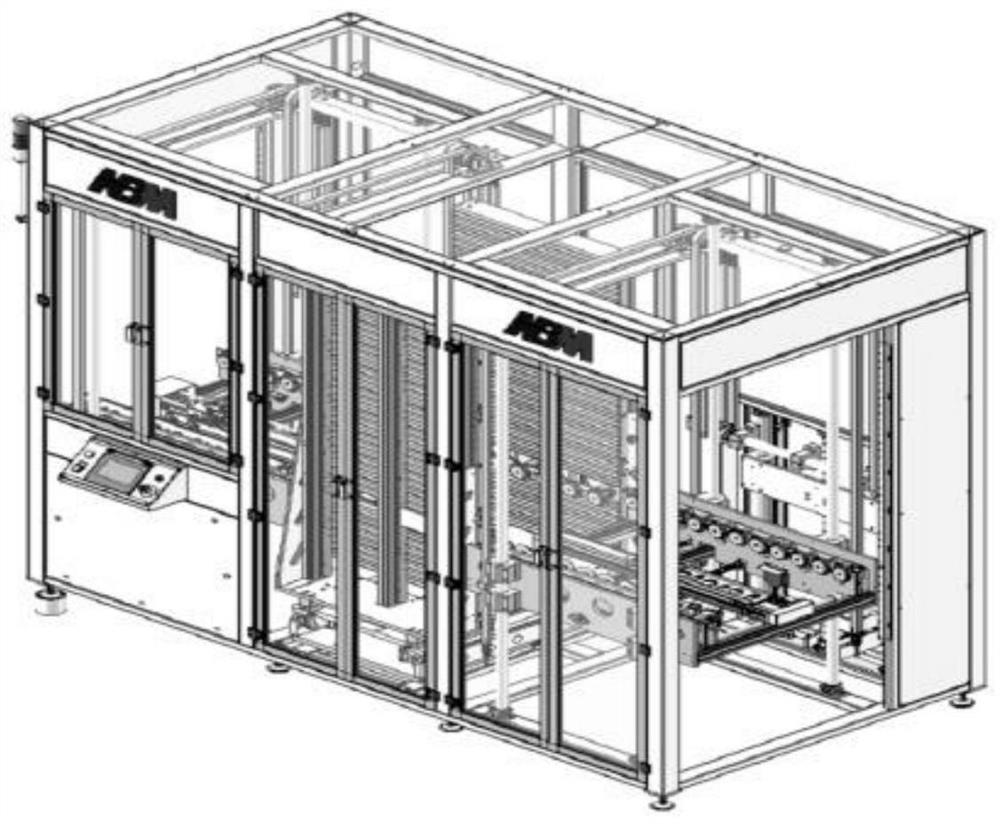

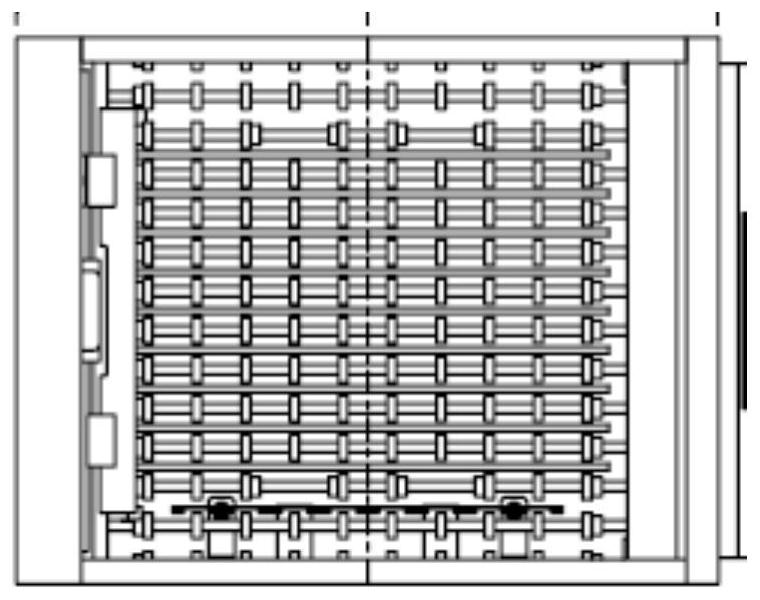

Pad pasting apparatus

ActiveCN104890933AAchieve uninterrupted continuous film applicationFast film applicationPackagingEngineeringUltimate tensile strength

Owner:JIANGSU BVM INTELLIGENT TECH

LCD plate film-attaching assisting mechanism

The invention discloses an LCD plate film-attaching assisting mechanism which comprises a fixing table and a rack. The upper portion of the rack is fixedly connected to the lower surface of the fixingtable through springs. The bottom of the fixing table is connected to a vacuum pump through a pipeline. The two sides of the rack are welded and fixed to the bottoms of side plates correspondingly. First sliding bars are in sliding connection with first sliding sleeves correspondingly. The tops of the first sliding sleeves are welded and fixed to the bottom ends of top rods correspondingly. The top ends of the top rods are welded and fixed to the two ends of a top plate correspondingly. A fixed rod, a scraping plate and a discharging roller are mounted on the lower surface of the top plate insequence. According to the LCD plate film-attaching assisting mechanism provided by the invention, LCD plates are adsorbed and fixed through negative pressure, shifting of the LCD plates during film-attaching is prevented, the scraping plate can be driven to perform film-attaching automatically by pushing the top plate through a handle, the film-attaching speed is high, it can be guaranteed thatthe LCD plates are balanced in stressing through the springs, the film-attaching effect is improved, air bubbles are effectively prevented from being generated, attaching film can be fast cut, operation is convenient, and the film-attaching quality and efficiency are improved.

Owner:成都预细科技有限公司

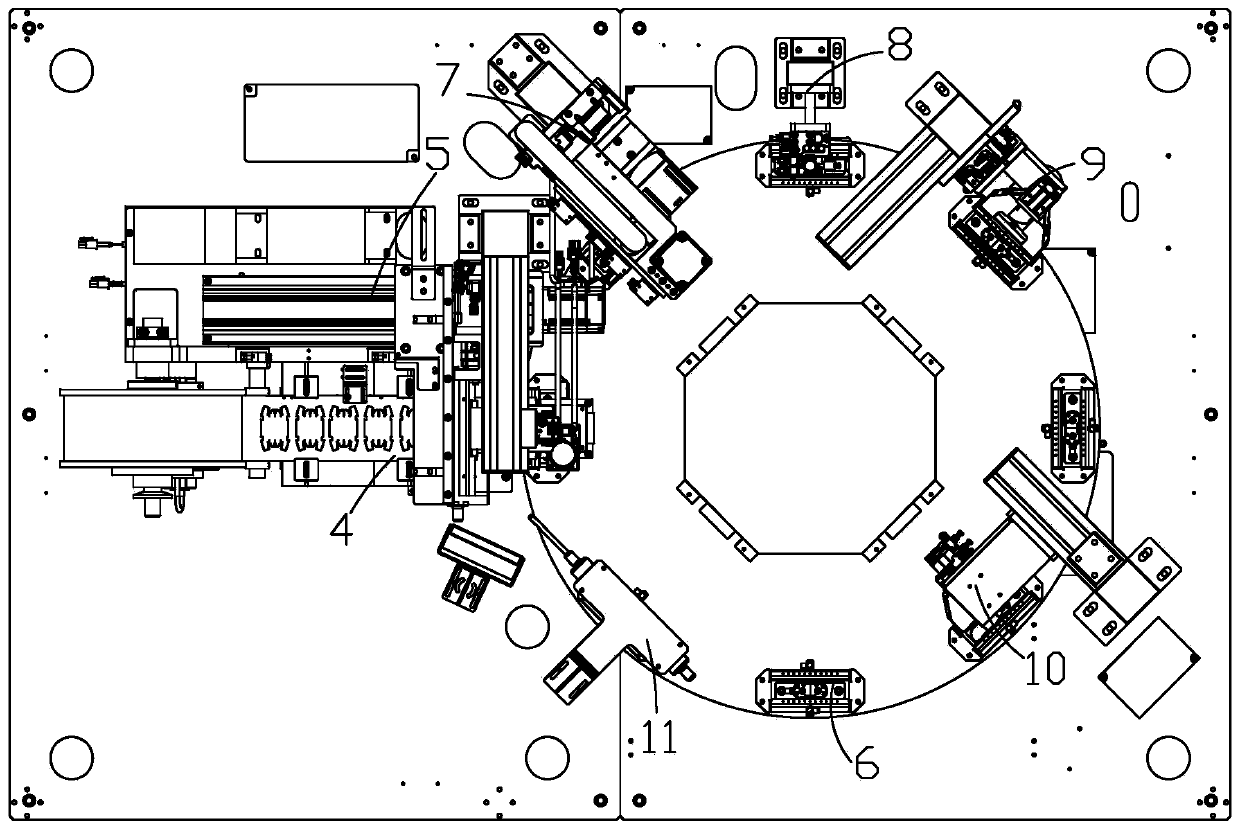

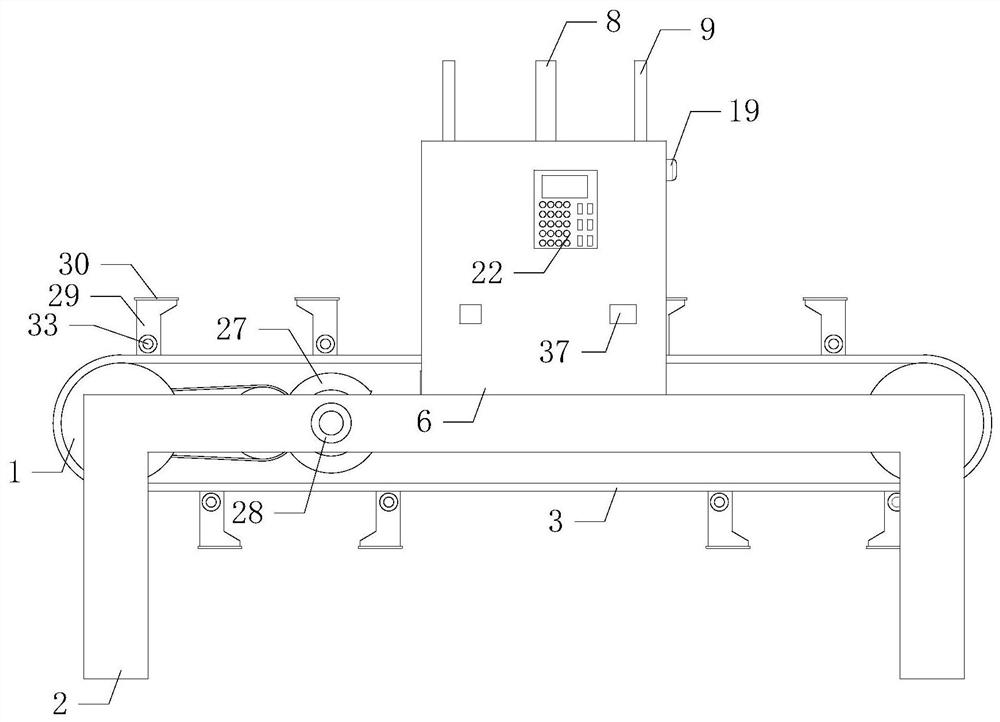

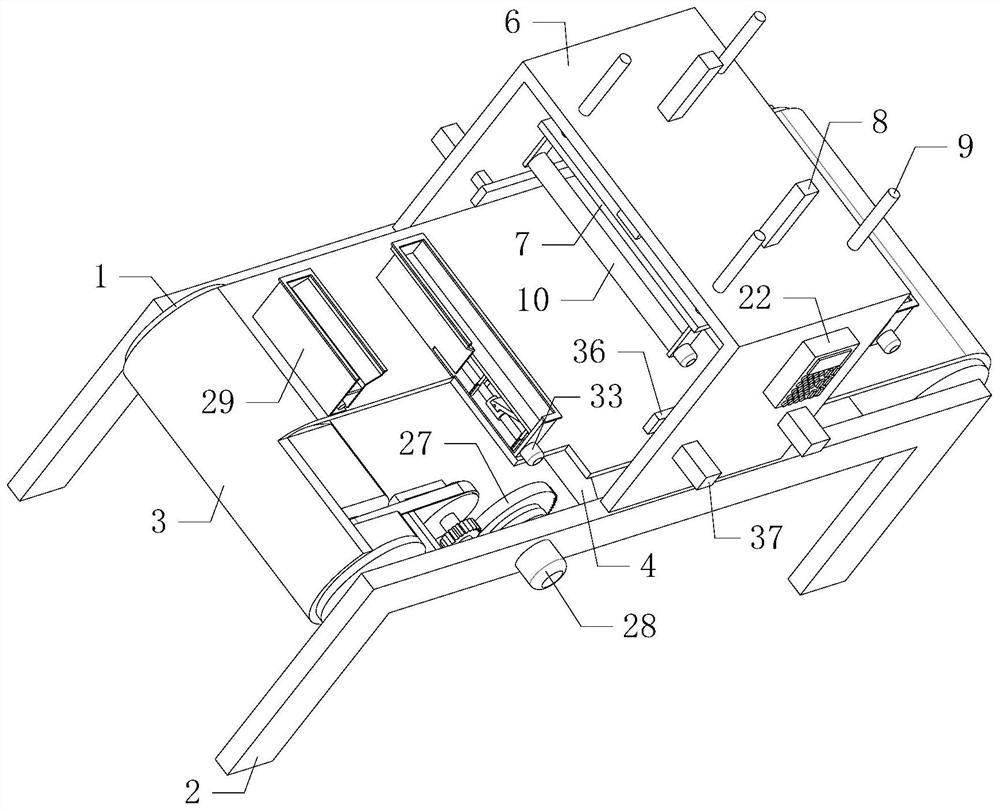

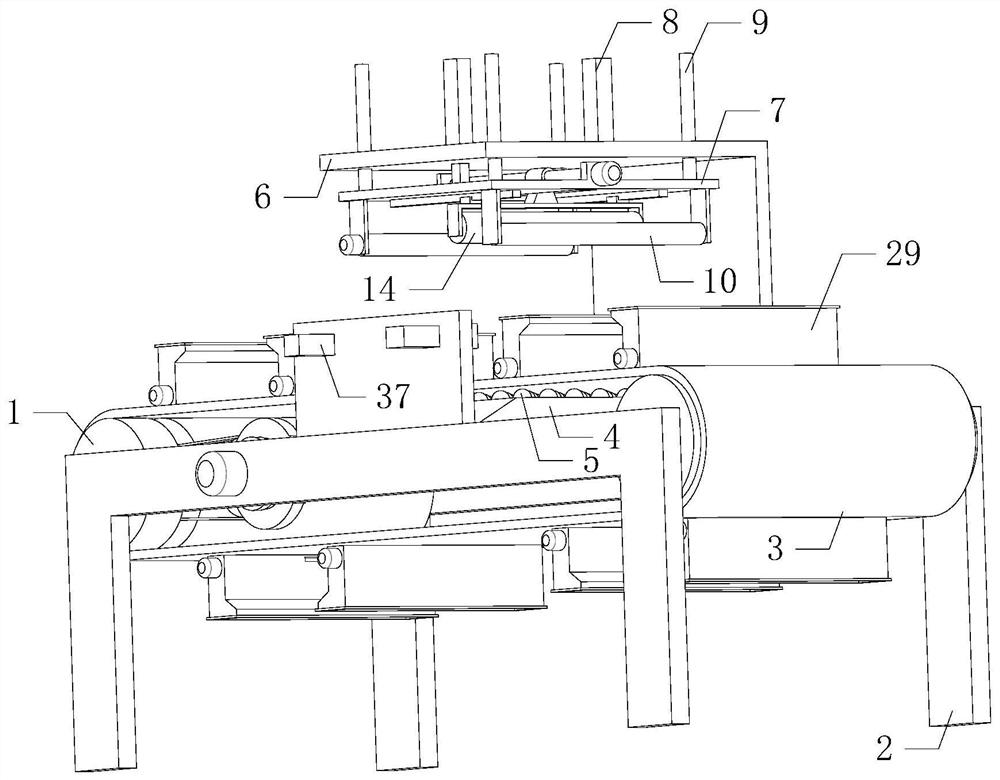

Semi-automatic film sticking equipment

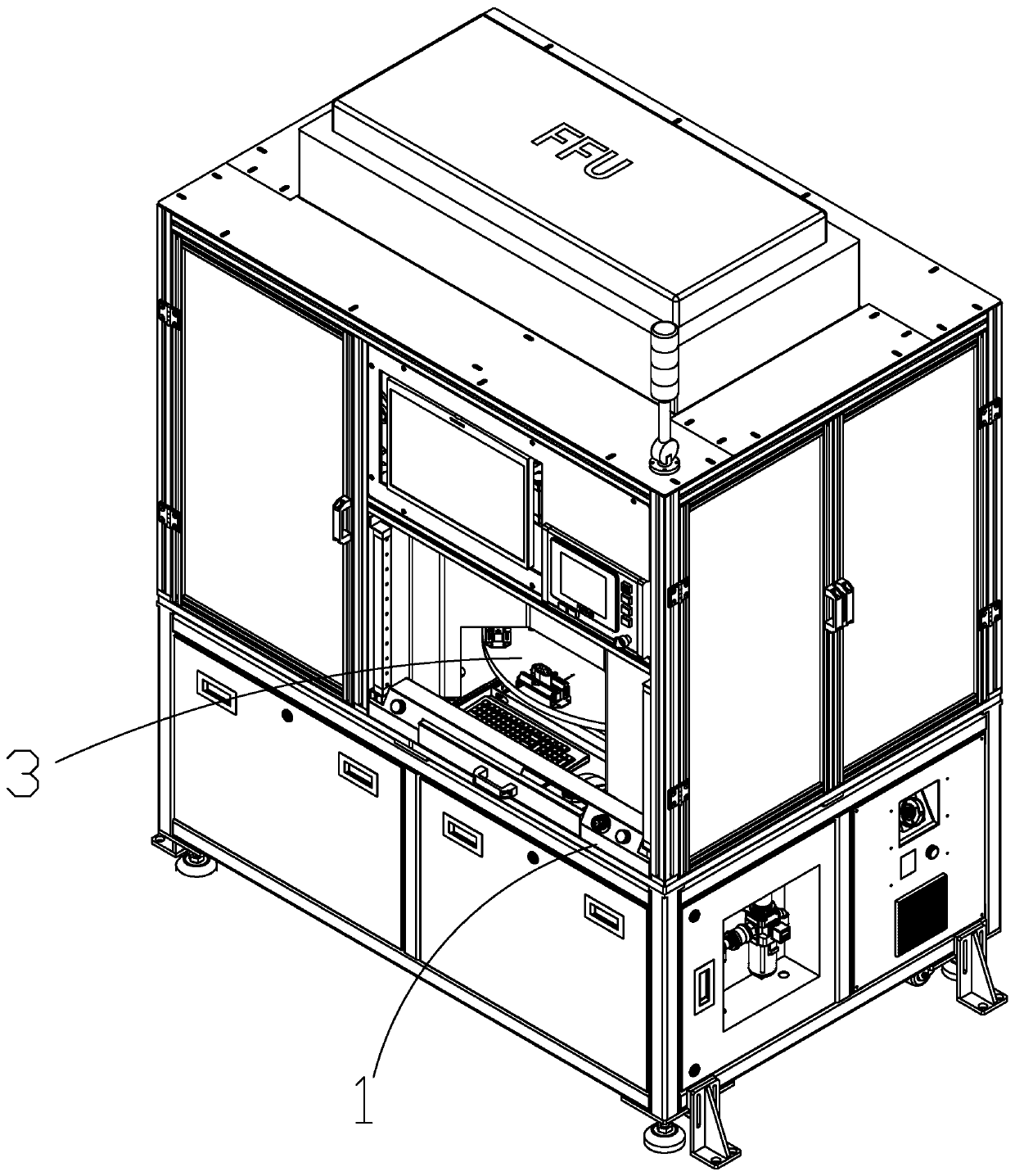

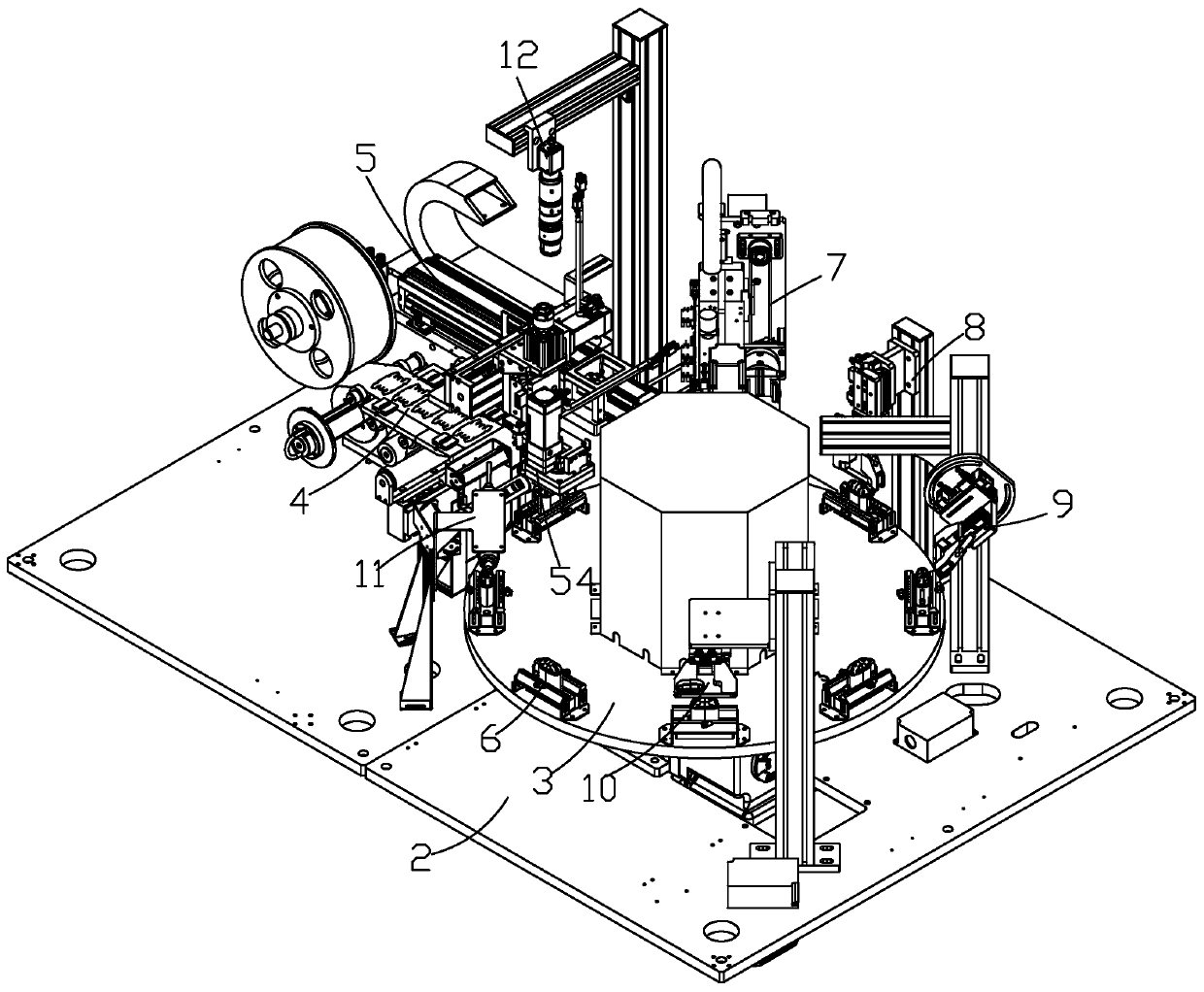

The invention discloses semi-automatic film sticking equipment. The semi-automatic film sticking equipment comprises a lower rack and a rotating bearing platform, a film supplying mechanism, a film sticking mechanism and a pressure maintaining mechanism which are arranged on a workbench face of the lower rack; multiple rotating disc fixtures used for containing products are evenly distributed on the rotating bearing platform along the same circumference, and the rotating bearing platform is used for rotating to drive the rotating disc fixtures to sequentially pass through the film supplying mechanism, the film sticking mechanism and the pressure maintaining mechanism; the film supplying mechanism is used for supplying protective films stuck to the product surfaces; the film sticking mechanism is used for sticking the protective films to the upper surfaces of the products; and the pressure maintaining mechanism is used for pressing the protective films stuck to the upper surfaces of theproducts to be fit and comprises a short-side two-end pressure maintaining mechanism, a long-side two-end pressure maintaining mechanism, an outer arc face pressure maintaining mechanism and an innerarc face pressure maintaining mechanism. According to the semi-automatic film sticking equipment, the irregular protective films can be stuck to the products, the film sticking speed is high, the efficiency is high, the quality is stable, and the danger coefficient is low.

Owner:苏州德机自动化科技有限公司

Solar panel surface automatic film pasting forming equipment

InactiveCN112571781AEasy to limitAvoid extrusion damageFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to solar panel surface automatic film pasting forming equipment. Through automatic film pasting treatment on a solarpanel, the equipment can effectively save the physical strength and time during manual film pasting, improve the film pasting speed, improve the working efficiency, meanwhile improve the surface flatness of a solar panel, prevent wrinkles during film pasting, improve the film pasting effect, and improve practicability and reliability; the equipment comprises two sets of conveying rollers, two sets of first arch-shaped frames, a conveying belt, a supporting table and a second arch-shaped frame, the two sets of conveying rollers are longitudinally located at the left side and the right side between the two sets of first arch-shaped frames correspondingly, and the front sides and the rear sides of the two sets of conveying rollers are rotationally installed at the inner sides of the two setsof first arch-shaped frames correspondingly; and the conveying belt is laid on the two sets of conveying rollers and drives the two sets of conveying rollers to rotate synchronously.

Owner:太仓治誓机械设备科技有限公司

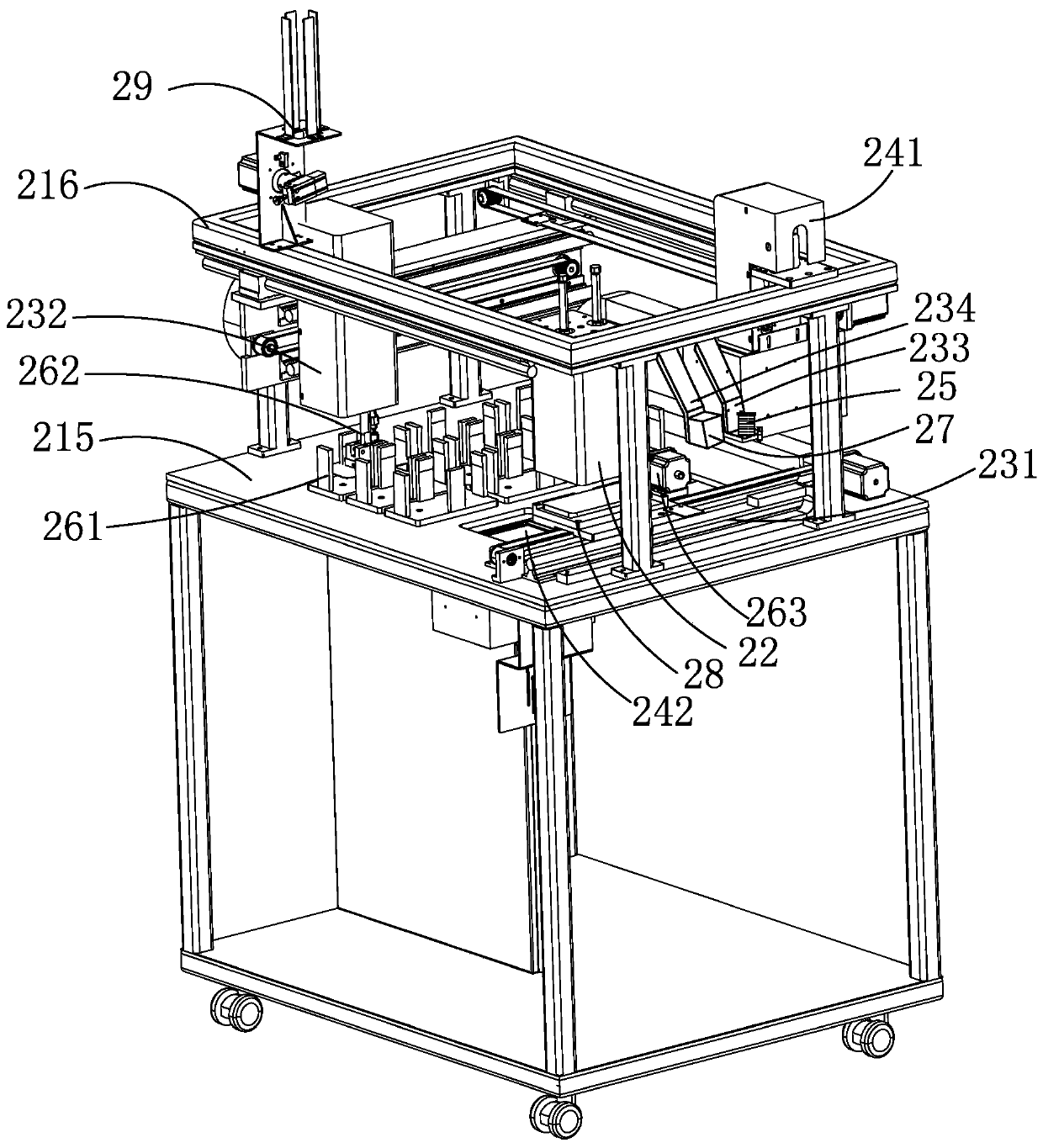

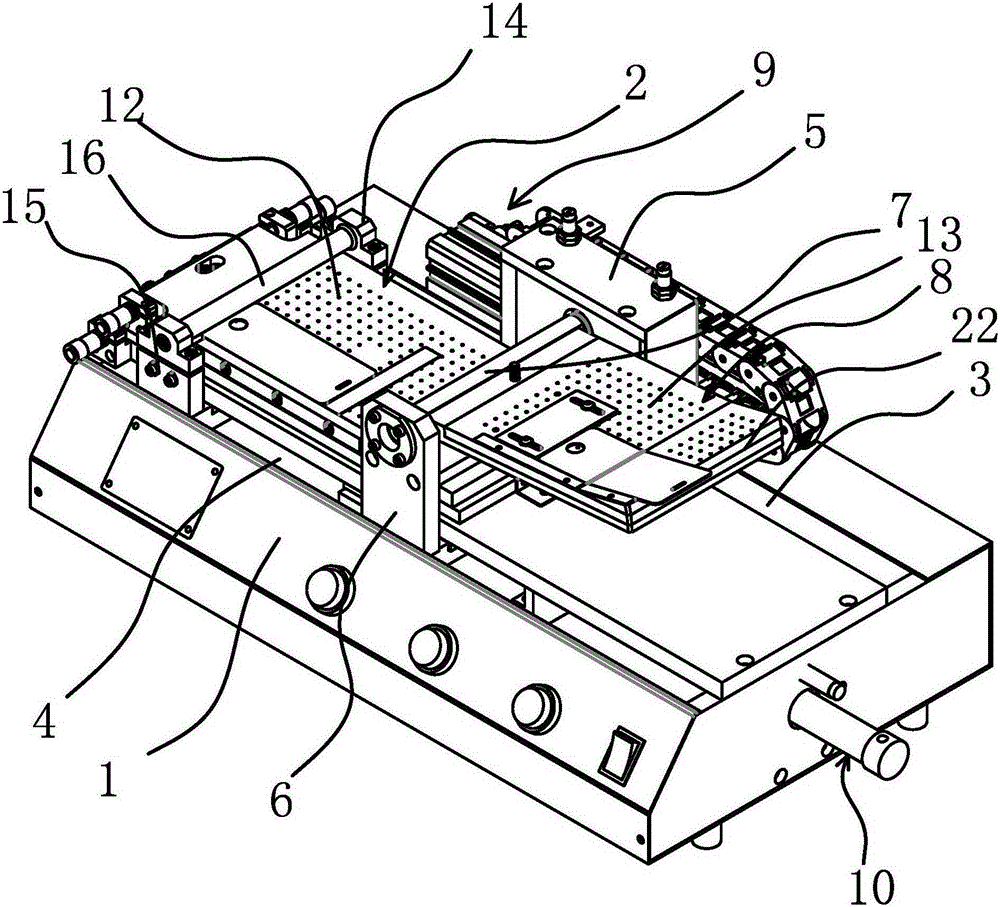

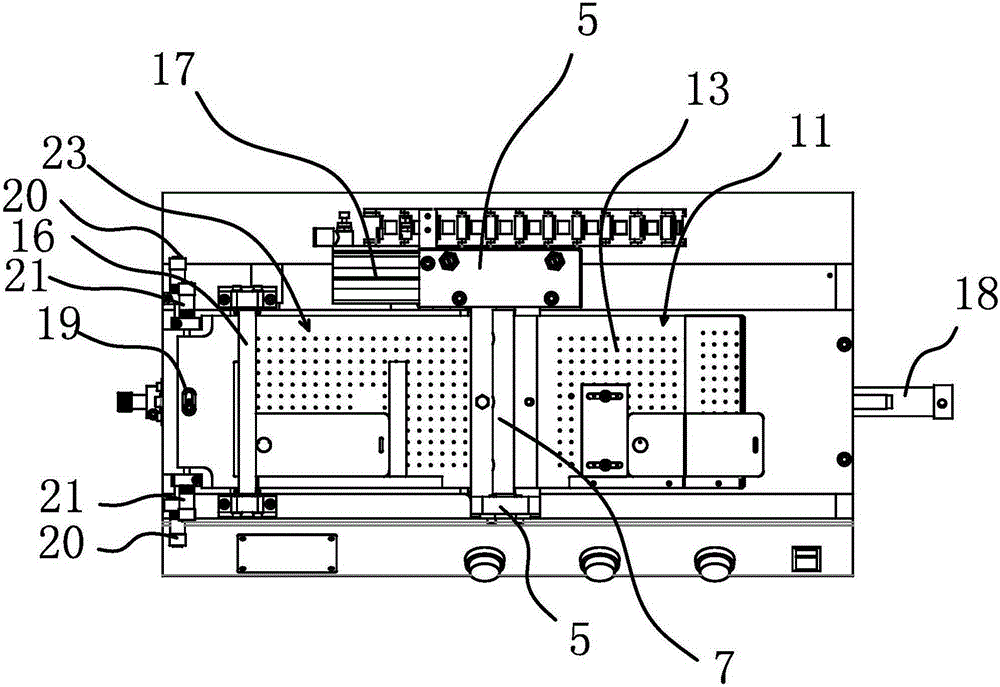

An automatic film laminating machine for a mobile phone touch screen

ActiveCN105173188BFast film applicationImprove work efficiencyPackagingEngineeringMechanical engineering

The invention provides an automatic film sticking machine for a mobile phone touch screen, which belongs to the technical field of film sticking equipment for a mobile phone touch screen. It solves the technical problem of low film sticking efficiency of existing film sticking equipment. The film laminating machine includes a base, the upper surface of the base is fixed with a lower film sticking plate, the upper surface of the lower film sticking plate has a film sticking surface 1, the upper surface of the base is provided with a chute 1 and a chute 2, and the chute 1 is slidably connected with a sliding seat 1. Sliding seat 2 is connected to the chute 2. A rotating shaft is connected between sliding seat 1 and sliding seat 2. The rotating shaft can rotate around its own axis relative to sliding seat 1 and sliding seat 2. The rotating shaft makes sliding seat 1 and sliding seat 2 The two are interlocked along the horizontal direction. The upper film plate is provided on the rotating shaft, and one side of the upper film plate is fixed on the rotating shaft. The drive mechanism 1 and the drive mechanism 2 are arranged on the base. The upper surface of the upper film plate has a film surface 2. The second film-sticking surface and the first film-sticking surface can be fitted together by horizontally moving and rotating the upper film sticking plate. The film laminating machine has fast film laminating speed and high work efficiency.

Owner:江门市威瑞电子科技有限公司

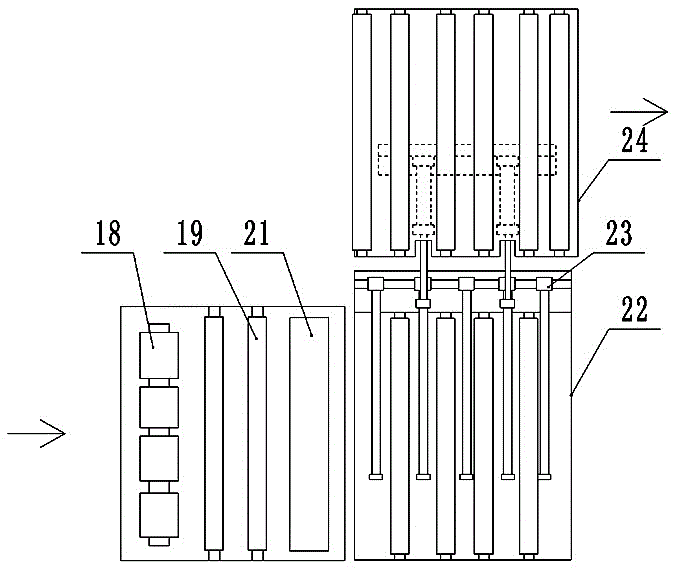

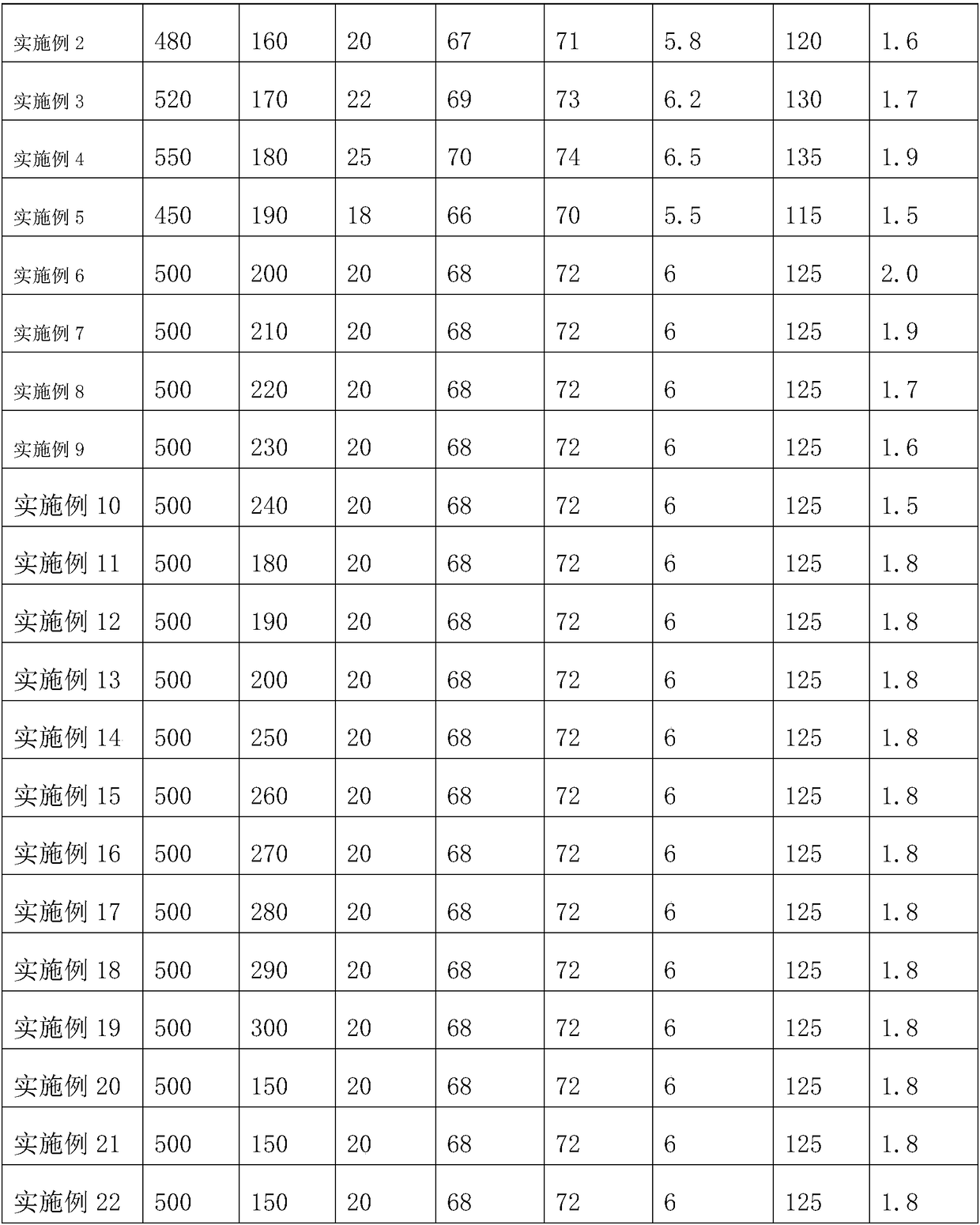

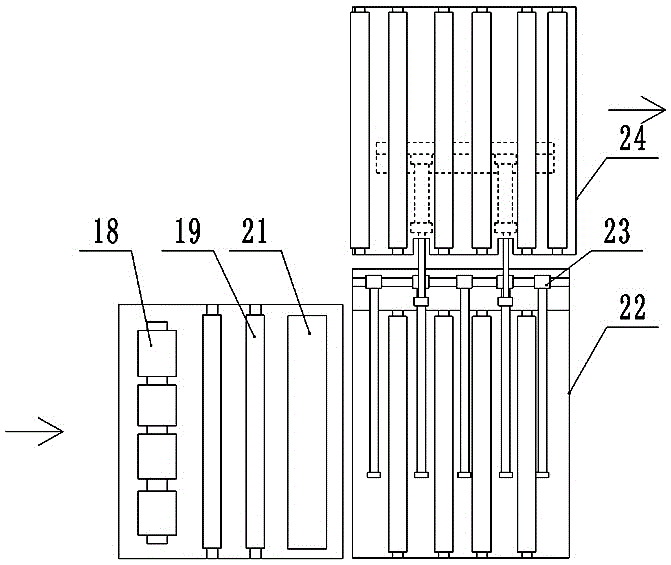

Production method and device for solving pre-treatment film pasting exposure line connection and application of production method and device for solving pre-treatment film pasting exposure line connection

ActiveCN114348337ASolve pain pointsFast film applicationPrinted circuit manufacturePackagingMechanical engineeringPrinted circuit board

The invention belongs to the technical field of PCB (Printed Circuit Board) manufacturing, and discloses a production method and device for solving pre-treatment film pasting exposure line connection and an application of the production method and device. The problem of direct overexposure after PCB film pasting is innovatively solved. 100 towbar type temporary storage machines are matched with the front capacity and the rear capacity, 5 towbar type temporary storage machines can be used for temporarily storing for 20 minutes per minute, the dry film is required to be temporarily stored for at least 15 minutes, and the technical requirements are met. The pressure and temperature of film pasting are improved, the film pasting speed is increased, the film pasting speed is increased to 5 pieces per minute, and the matching capacity is maximized. Compared with the prior art, connection production is achieved, and efficiency is improved. And on-line production reduces carrying and improves quality. And connection automatic production control is simple.

Owner:ZHUHAI CHINA EAGLE ELECTRONIC CIRCTCUIS CO LTD

Film application methods for packaging tubes

ActiveCN106586080BFast film applicationImprove film application efficiencyPackagingEngineeringFilm-coated tablet

The invention discloses a film sticking method for a packaging barrel. The film sticking method comprises the following steps: (1) enabling a film to pass through a film separation unit of a film sticking device for the packaging barrel to ensure that an inner film is separated from an outer film; (2) enabling the outer film to sequentially pass through a tightening column, a film sticking column and a film sticking block to ensure film sticking of the packaging barrel which passes through the film sticking block; and (3) pressing the packaging barrel subjected to film sticking with a rubber plate. The film sticking method is high in film sticking speed, the packaging barrel subjected to film sticking does not need to be processed later, and the film sticking efficiency is improved further.

Owner:WUHU HUIYU TRADING CO LTD

Low-temperature lamination ceiling film with self-adhesive protective film and method for producing the same

ActiveCN106273816BAdjustable widthAdjustable thicknessCovering/liningsSynthetic resin layered productsPolymer scienceAdhesive glue

Owner:浙江华清包装材料有限公司

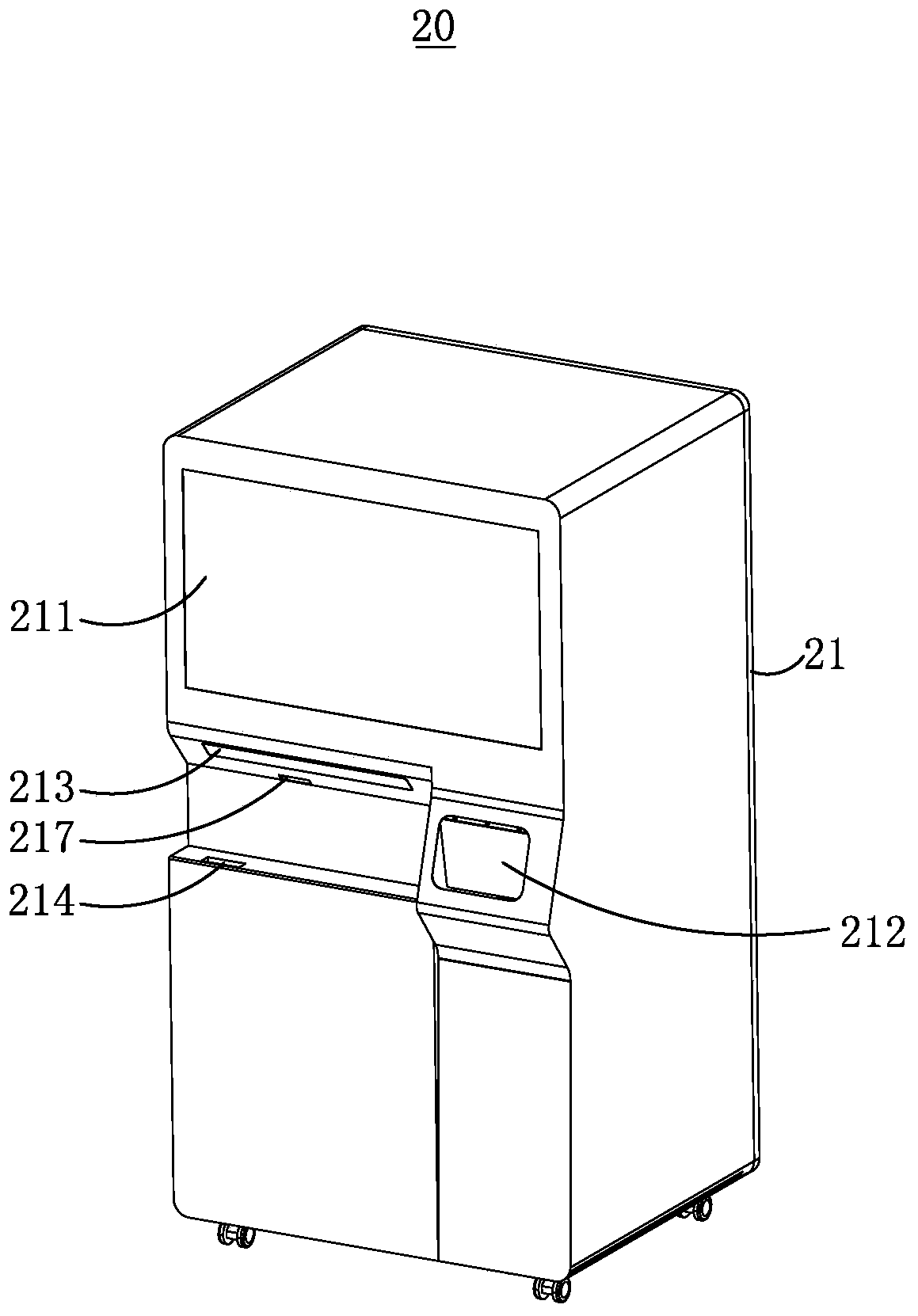

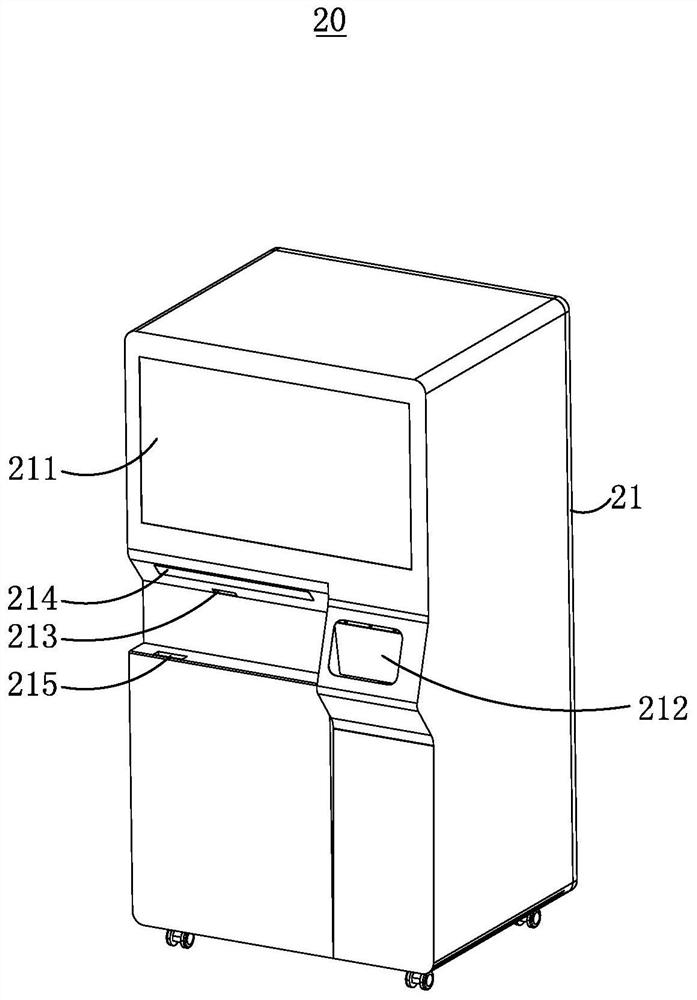

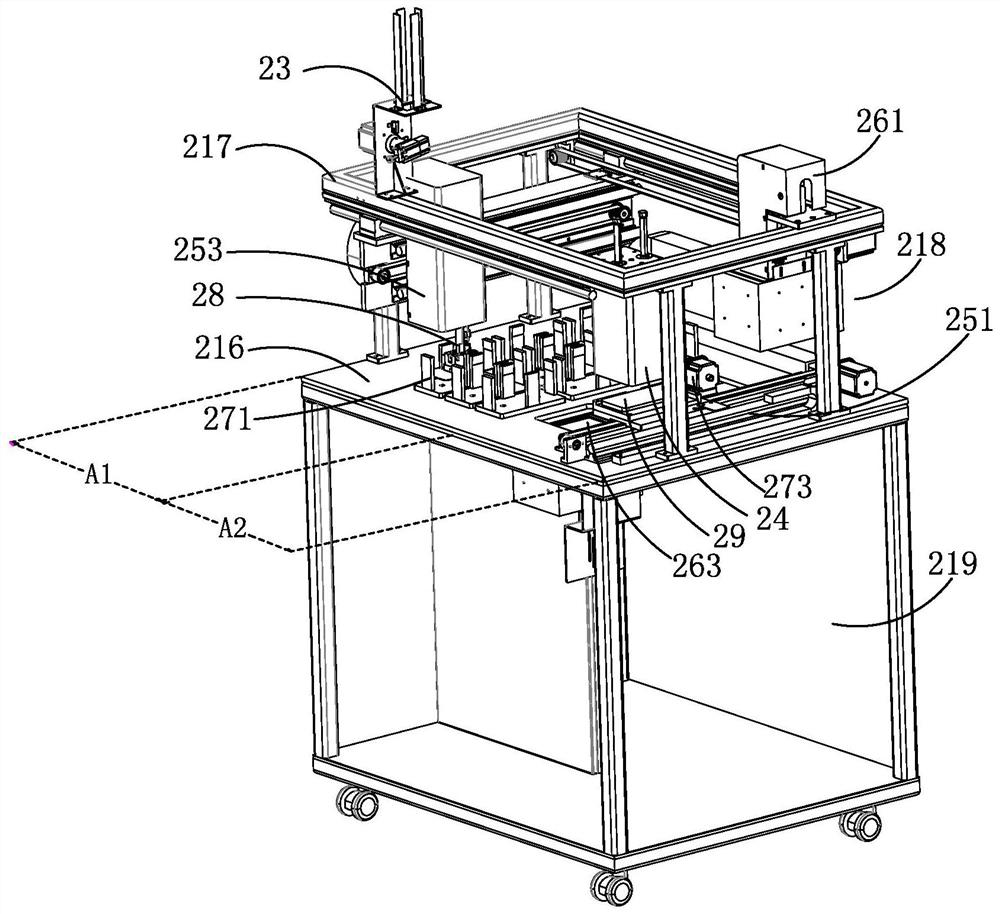

Self-service film sticking machine and self-service film sticking method

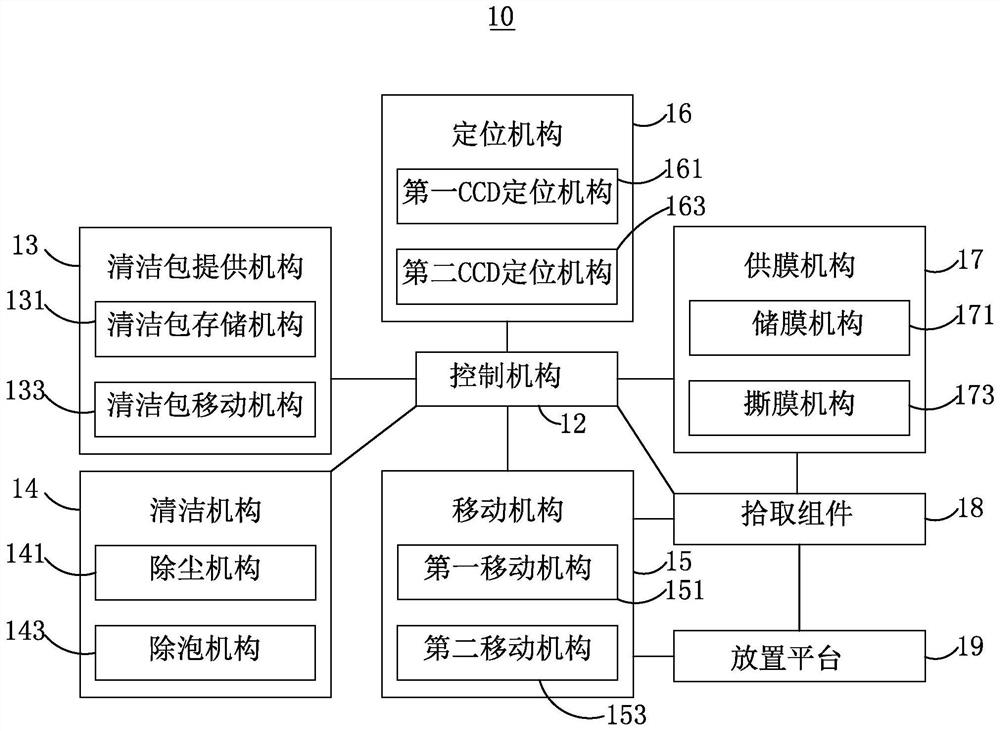

The present invention provides a self-service film laminating machine. The self-service film laminating machine includes a control mechanism and a cleaning package providing mechanism, the control mechanism and the cleaning package providing mechanism are electrically connected, and the cleaning package providing mechanism is used to provide cleaning packages for users to clean electronic equipment , the control mechanism is at least used to control the cleaning package providing mechanism to provide the cleaning package when receiving the film sticking trigger signal. The present invention also provides a self-service film application method, which includes: step S1: receiving a film application trigger signal generated by a user operation; step S2: providing a cleaning package for the user to clean the electronic device for the first time; And step S3: the self-service film sticking machine provides a protective film and attaches the protective film to the area to be filmed of the electronic device. The self-service film sticking machine and the self-service film sticking method provided by the present invention have the advantages of fast film sticking and good film sticking effect.

Owner:SHENZHEN BNT INTELLIGENT TECH CO LTD

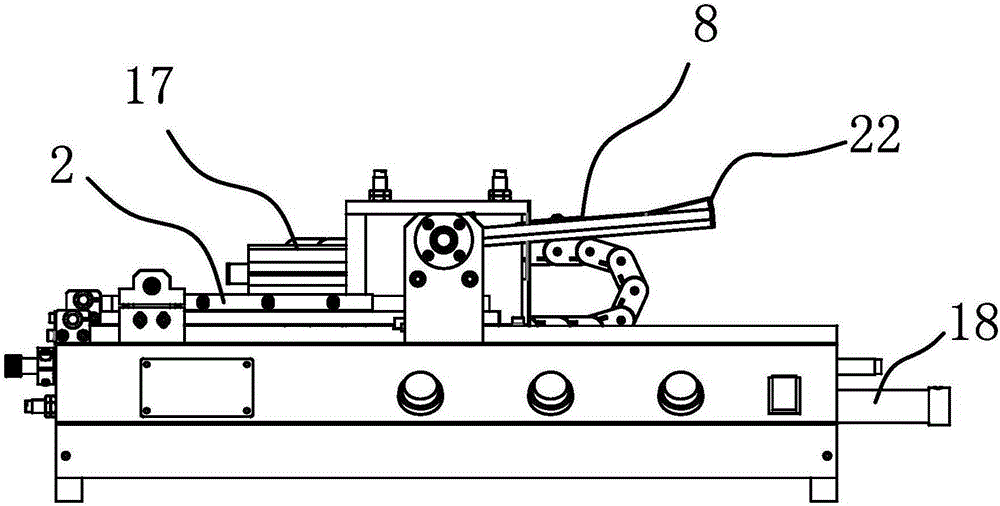

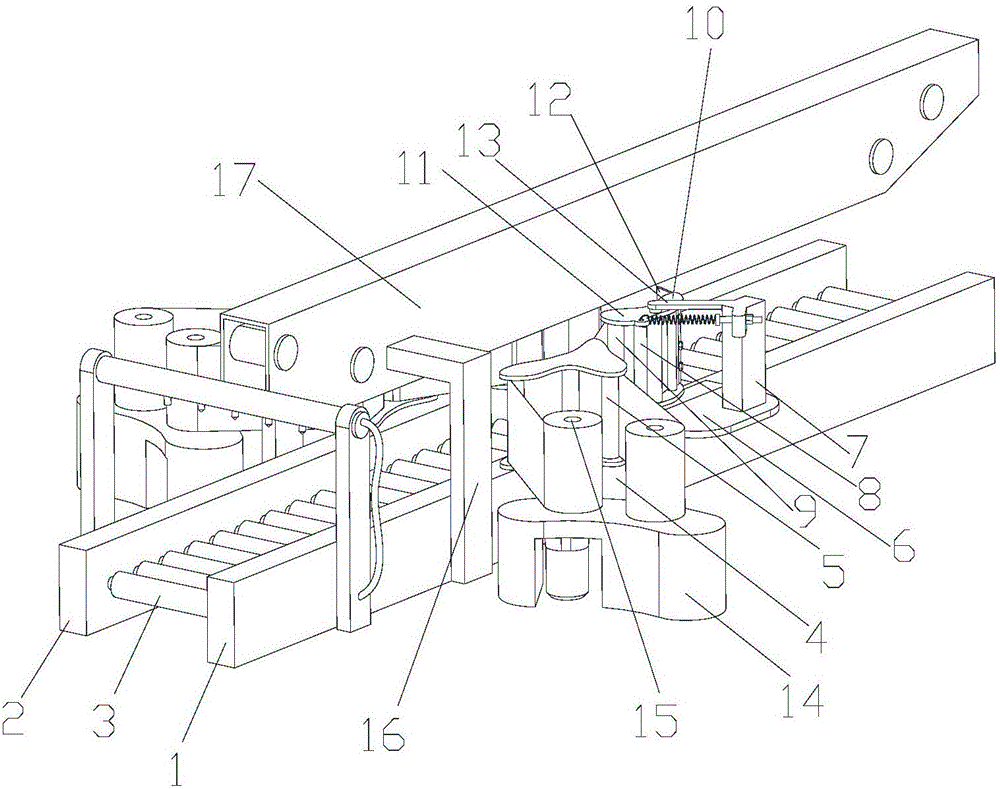

An automatic film sticking machine

ActiveCN104828281BSmooth recyclingEasy to peelPackagingUltimate tensile strengthElectrical and Electronics engineering

The invention discloses an automatic film sticking machine comprising a film stripping device and a film sticking device. The film stripping device comprises a driving material frame, a driven material frame, a tensioning wheel, a film stripping knife, a backboard, a driving material frame motor, a constant speed wheel and a constant speed motor. The film sticking device comprises a first film sticking position, a second film sticking position, a first bottom plate, a transposition mechanism and a film pressing mechanism. The film stripping device is fixed above the first bottom plate of the film sticking device. The film stripping knife of the film stripping device is arranged above the workboard of the film sticking device. According to the automatic film sticking machine, stable and smooth film stripping can be realized; and smooth recovery of backing paper can be guaranteed by the overall design of constant material receiving speed. Besides, uninterrupted continuous film sticking is realized by the two film sticking position alternating contraposition film stripping mechanisms so that film sticking speed is effectively enhanced; and film sticking strength is enhanced by the design of a film pressing roller and a lateral pressing roller so that film sticking defective ratio is reduced.

Owner:JIANGSU BVM INTELLIGENT TECH

Film sticking method for packaging barrel

ActiveCN106586080AFast film applicationImprove film application efficiencyPackagingEngineeringRubberized sheet

The invention discloses a film sticking method for a packaging barrel. The film sticking method comprises the following steps: (1) enabling a film to pass through a film separation unit of a film sticking device for the packaging barrel to ensure that an inner film is separated from an outer film; (2) enabling the outer film to sequentially pass through a tightening column, a film sticking column and a film sticking block to ensure film sticking of the packaging barrel which passes through the film sticking block; and (3) pressing the packaging barrel subjected to film sticking with a rubber plate. The film sticking method is high in film sticking speed, the packaging barrel subjected to film sticking does not need to be processed later, and the film sticking efficiency is improved further.

Owner:WUHU HUIYU TRADING CO LTD

A film sticking device

ActiveCN104890933BAchieve uninterrupted continuous film applicationFast film applicationPackagingMechanical engineeringFilm-coated tablet

Owner:JIANGSU BVM INTELLIGENT TECH

A plastic film sticking equipment for bridge piers

ActiveCN108755417BFast film applicationImprove the film effectBridge erection/assemblyArchitectural engineeringStructural engineering

The invention relates to special equipment for bridge construction, in particular to special equipment for pasting a plastic film on a bridge pier of bridge construction. The special equipment for pasting plastic film on the bridge pier of bridge construction can improve the film pasting efficiency, relieves aches of arms, and easy to operate operation. According to the technical scheme, the special equipment for pasting the plastic film on the bridge pier of bridge construction comprises a bottom plate, a sliding rod, sliding sleeves, a first spring, a first connecting plate, a supporting rod, a top plate and so on; the sliding rod is connected to the right side of the bottom plate; the two sliding sleeves are arranged on the sliding rod; and the first spring is connected between the internal side surfaces of the two sliding sleeves. According to the special equipment for pasting the plastic film on the bridge pier of bridge construction, the plastic film can be pasted on the bridge pier by being rotated, the plastic film can be pasted on the bridge pier in an omnibearing manner by being moved downwards, the surface of the bridge pier can be made wet by using a nozzle to spray water to the bridge pier so that the plastic film sticks to the bridge pier; and therefore effects that the film pasting efficiency can be enhanced, the aches of the arms can be relieved and the operation is simple can be achieved.

Owner:乾元建设集团(延吉)有限公司

A method for quickly grinding and pasting films on outer circuit boards

ActiveCN106028655BIncrease concentrationImprove adhesionConductive material chemical/electrolytical removalAcid washingHardness

The invention discloses a rapid board-grinding and film-pasting method for an outer layer circuit board. The rapid board-grinding and film-pasting method comprises the following steps of putting a circuit board; performing acid washing; performing water washing for the first time; grinding the board by a needle brush; grinding the board by volcanic ash; removing the volcanic ash; drying by hot air; preheating the board surface; pasting a film; and collecting the board, wherein the grinding brush used in the step of grinding the board by the needle brush is 450#-550# needle brush; the volcanic ash used in the step of grinding the board by the volcanic ash is 18-25% in concentration; the first group of hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 68 plus or minus 2 degrees in hardness; the second group of hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 72 plus or minus 2 degrees in hardness; the two groups of the hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 5.5-6.5kg / cm<2> in pressure; and the two groups of the hot pressing rolling wheels of the film-pasting machine used in the film-pasting step are 115-135 DEG C in temperatures. By adoption of the rapid board-grinding and film-pasting method, the film-pasting speed can reach 3.8-4.0m / min; and meanwhile, the quality of the product can be ensured.

Owner:江西景旺精密电路有限公司

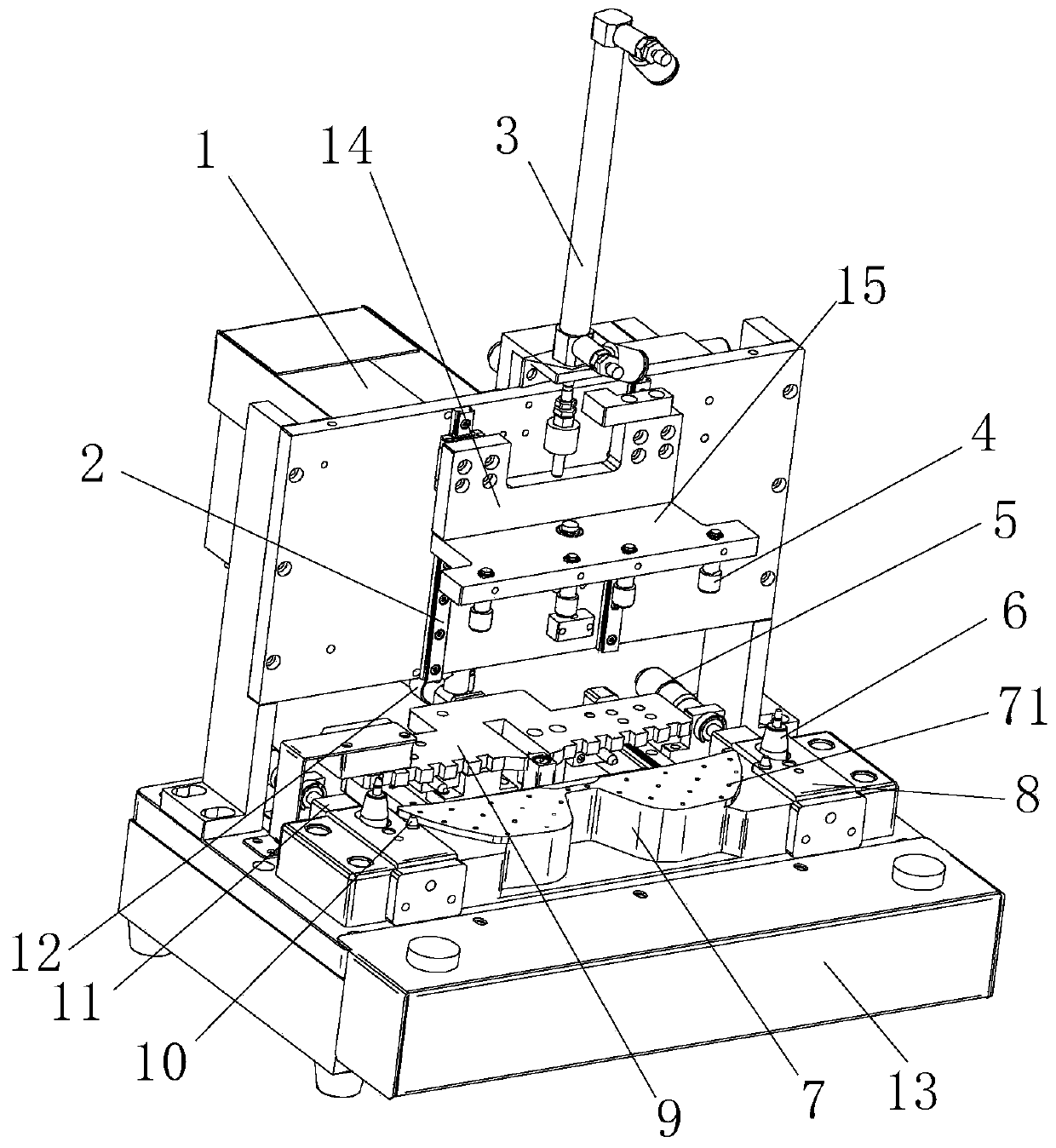

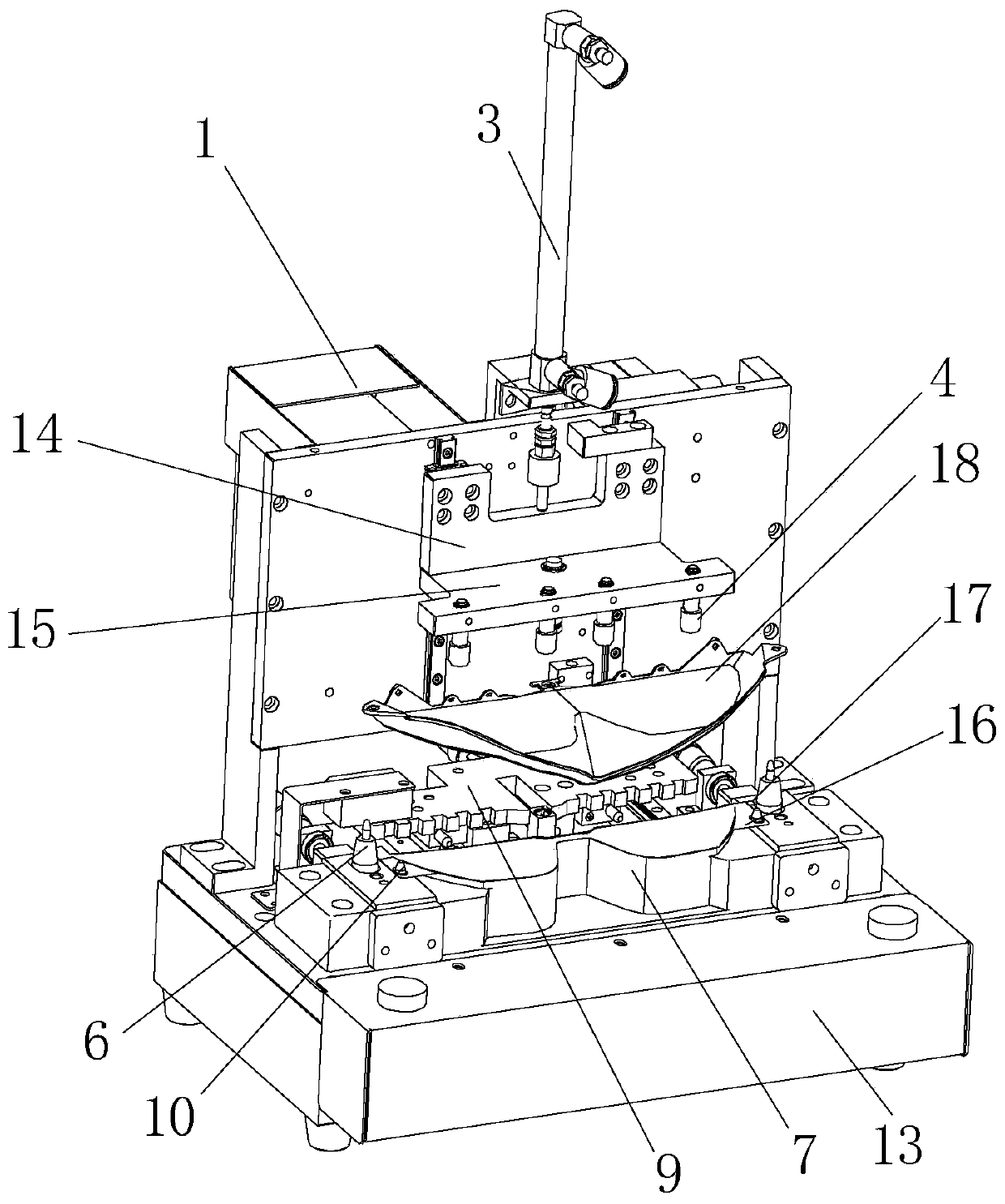

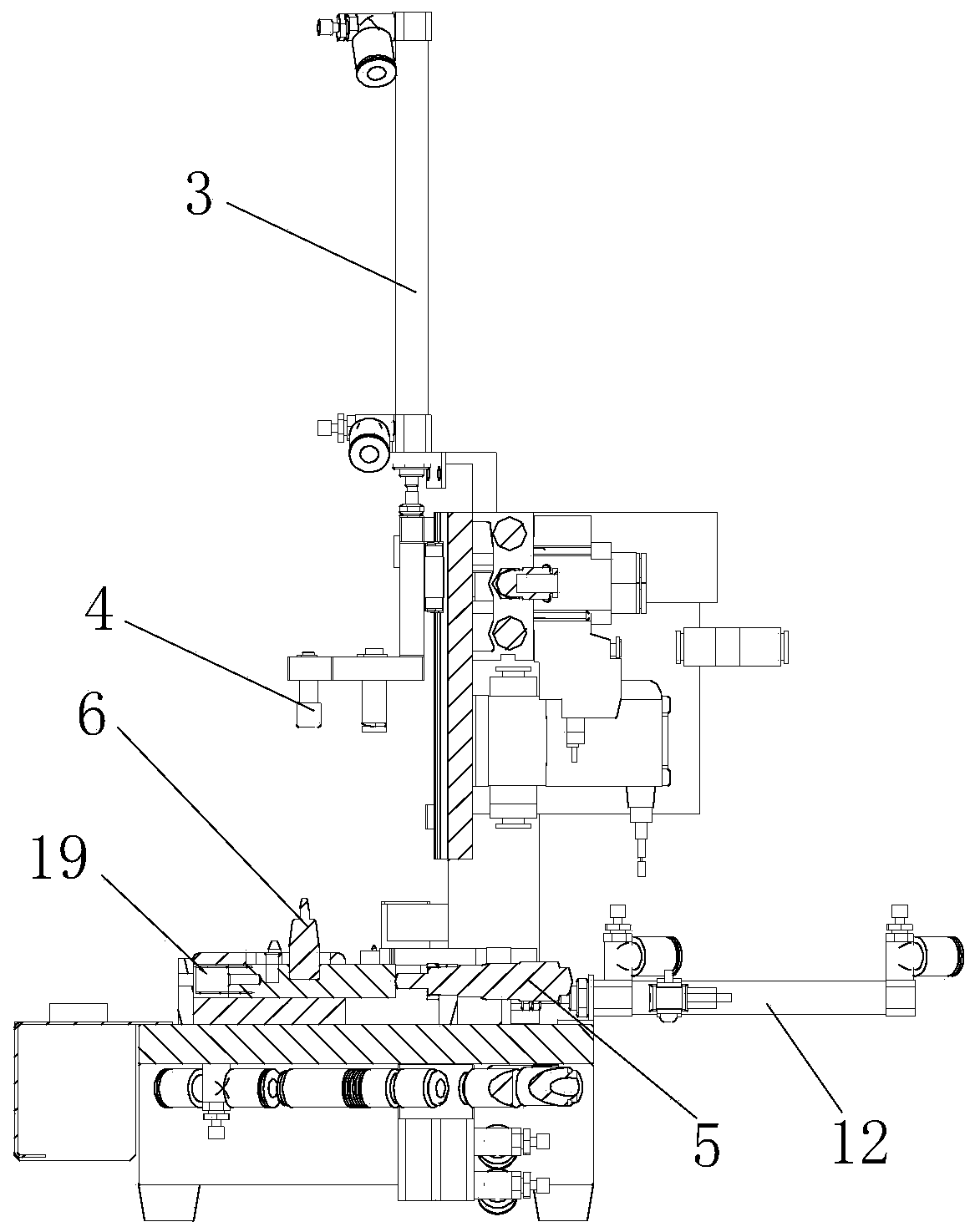

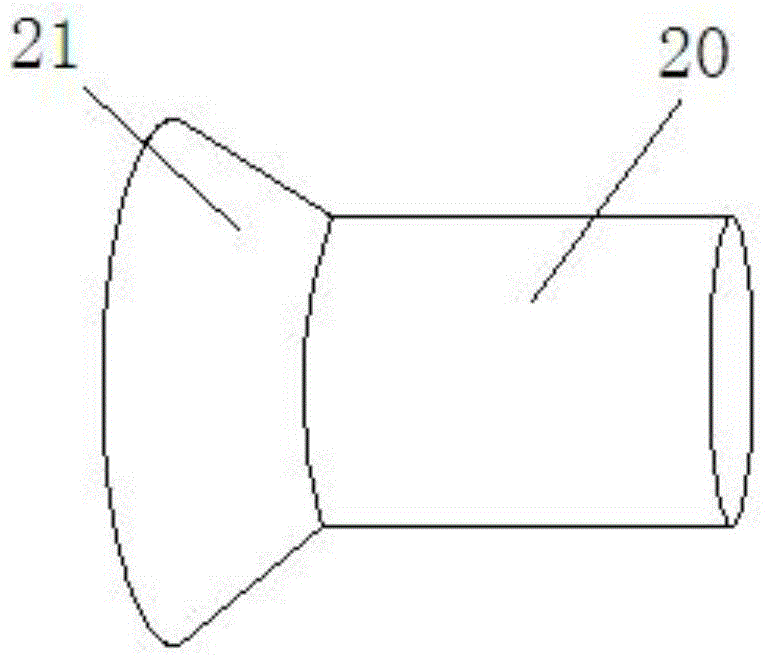

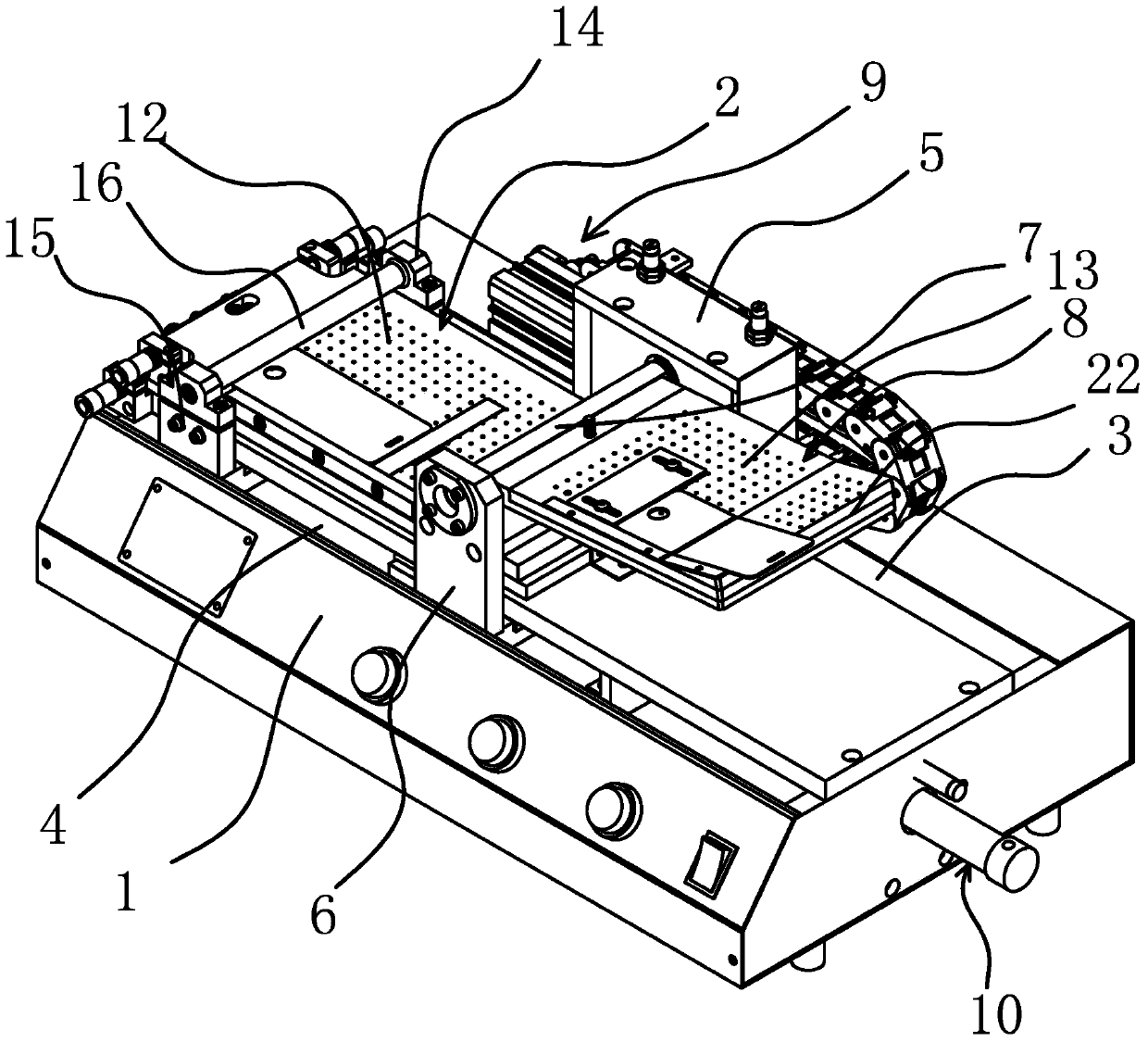

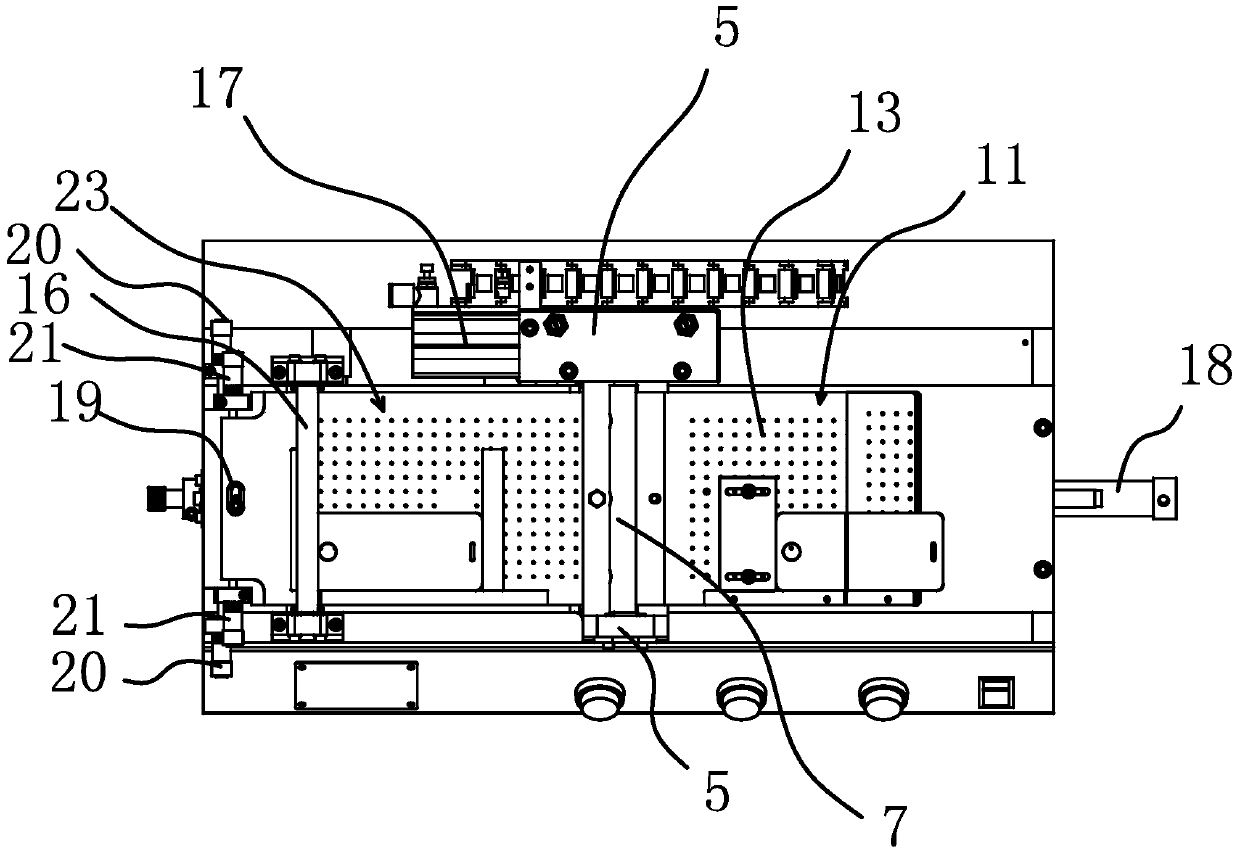

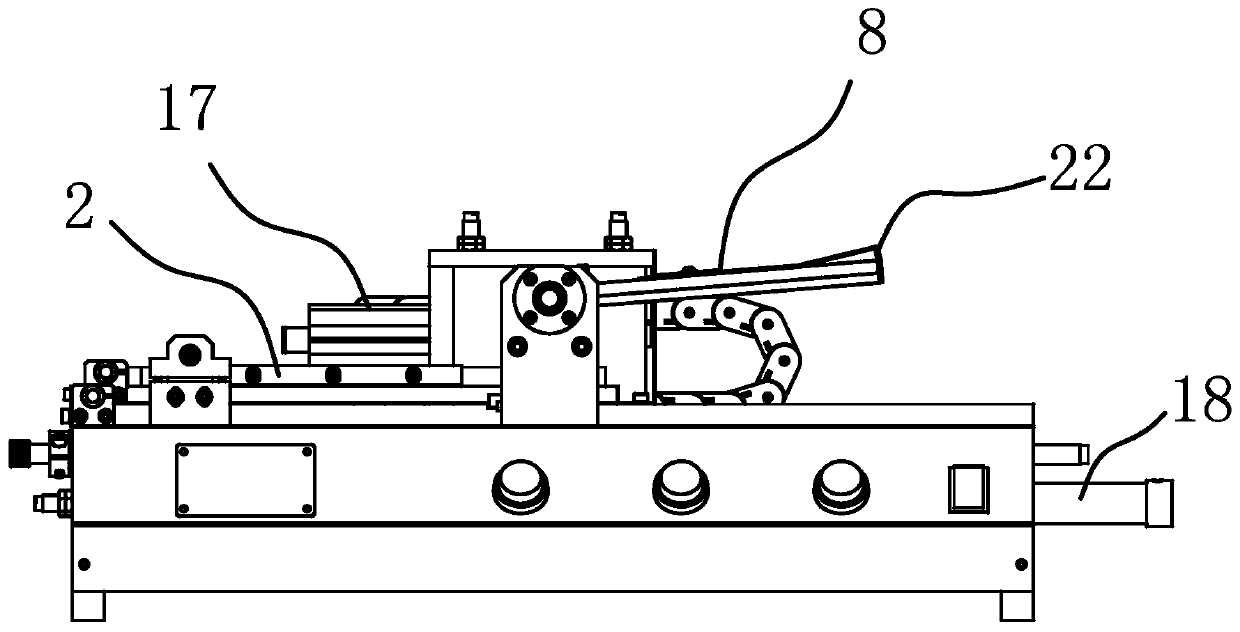

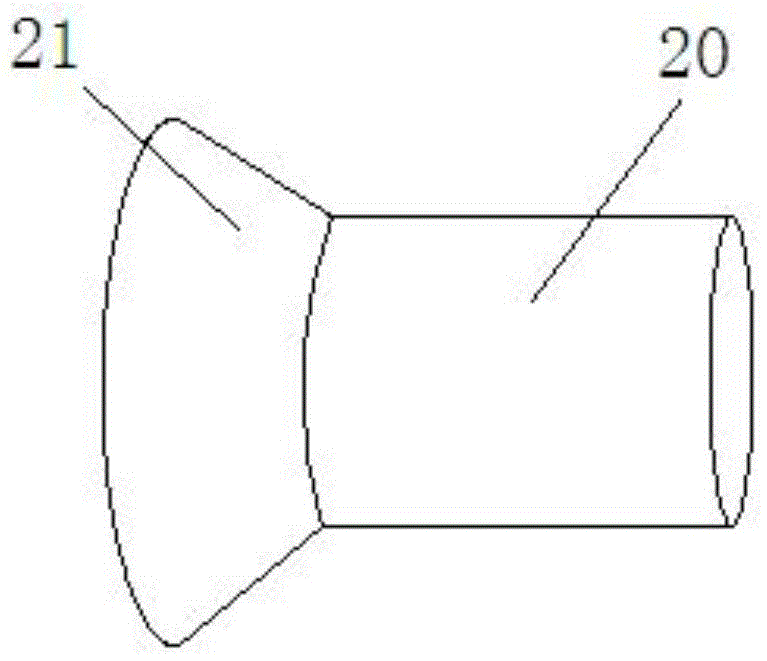

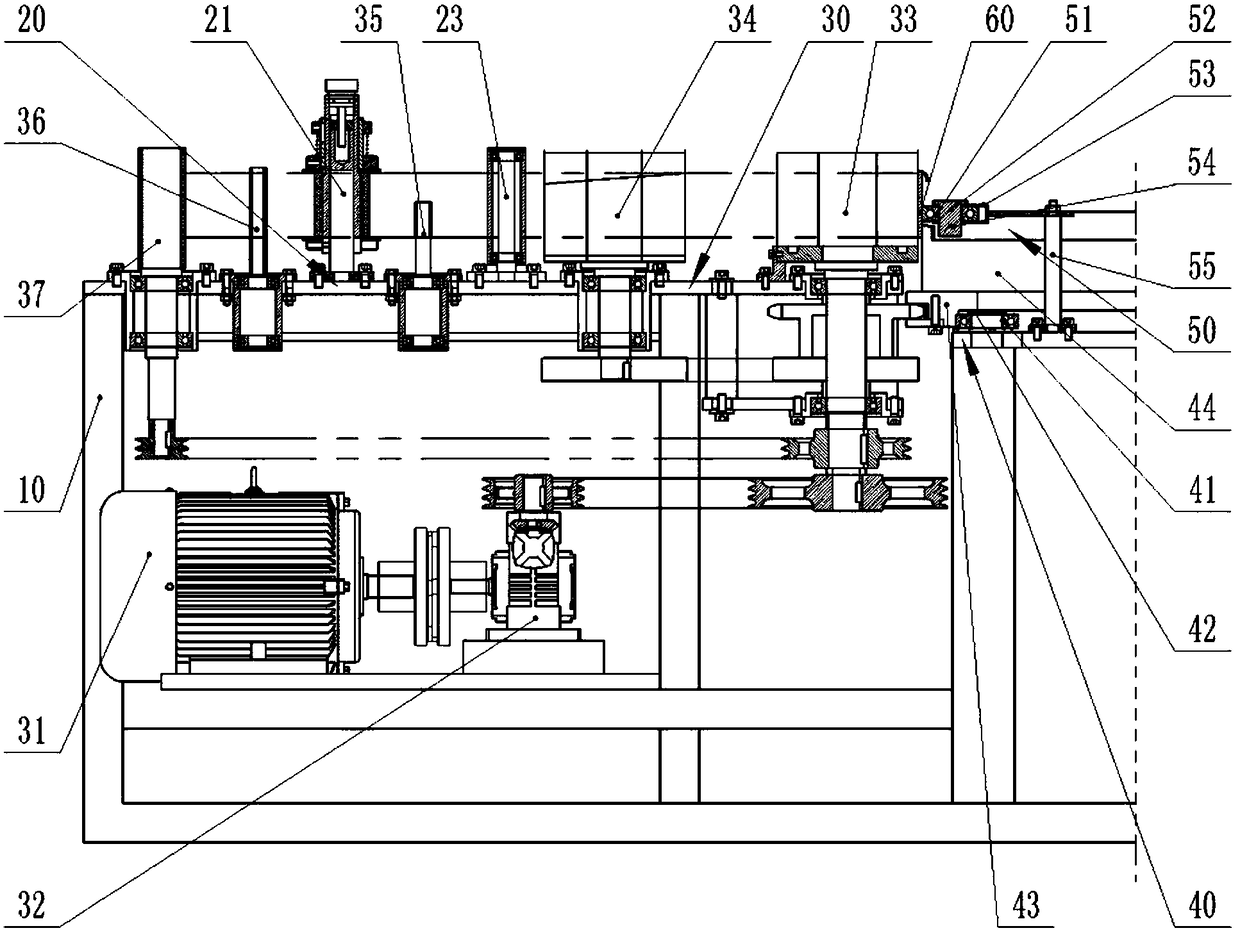

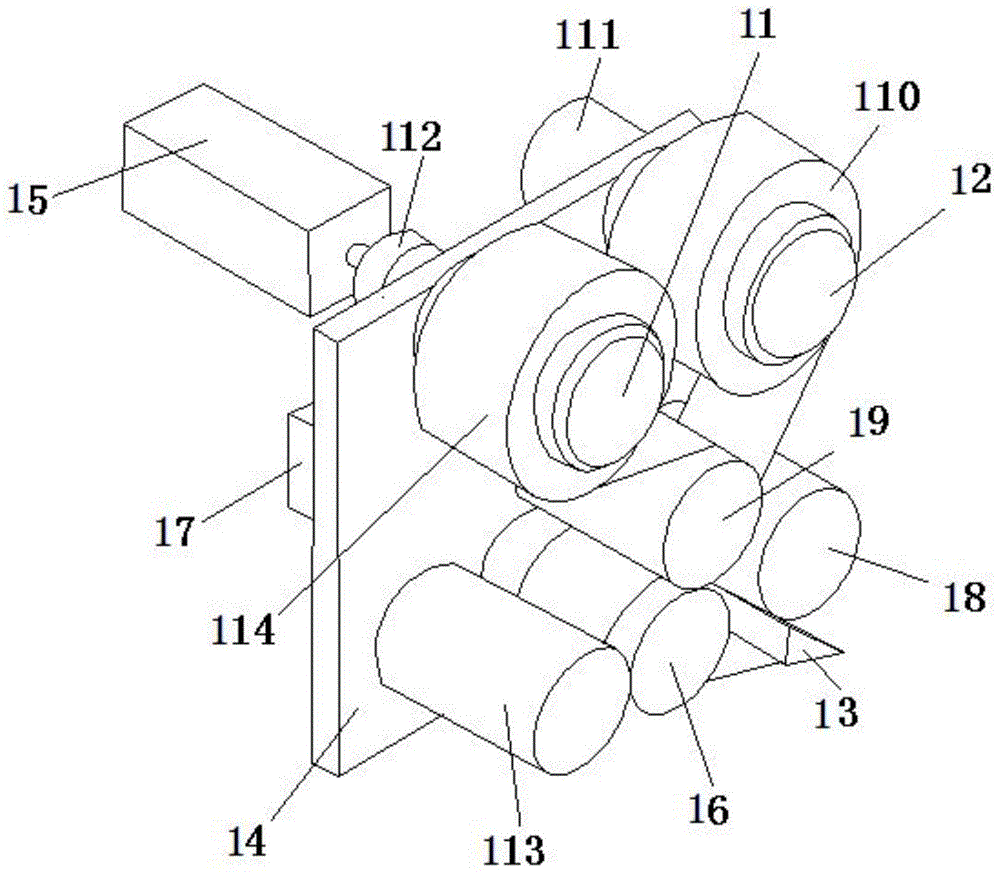

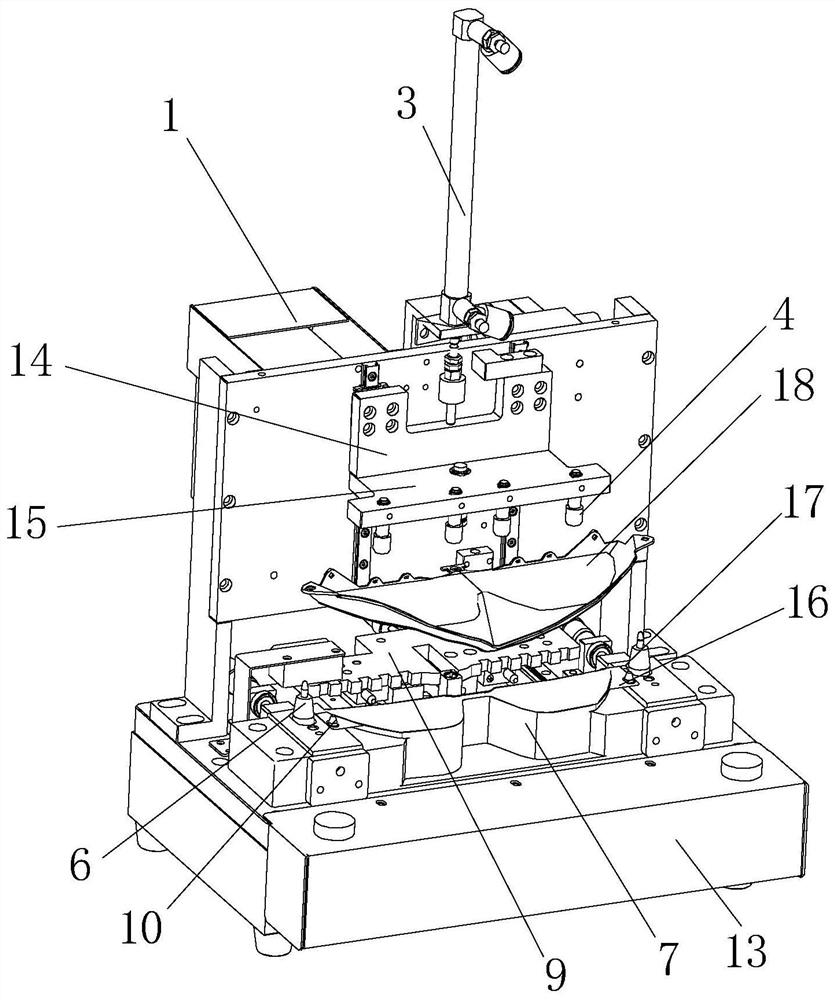

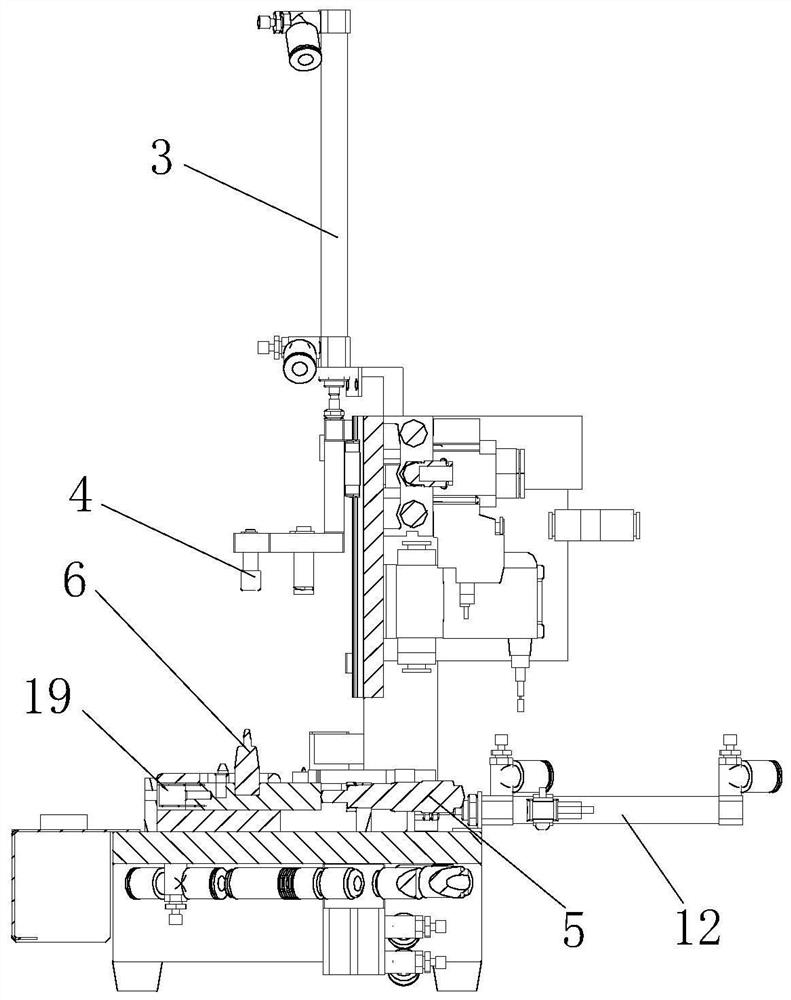

Car B-pillar exterior trim panel surface laminating machine

The invention relates to an automobile B column exterior decoration plate surface filming machine. The filming machine comprises a machine frame, a material feeding module installed on the machine frame, a film absorbing and adhesion module, a work piece conveying device and a filming pressure balance device. The material feeding device, film absorbing and adhesion module, work piece conveying device and the filming pressure balance device are all installed on the machine frame. The film absorbing and adhesion module is located at the right side of the material feeding module. The work piece conveying device is located at the right side of the film absorbing and adhesion module, and is driven by a motor of the film absorbing and adhesion module. An automobile B column exterior decoration plate which is to be filmed is placed on the work piece conveying device. The rotation plane of the work piece conveying device is tangent to the positive-negative-pressure filming roller. The tangent point is the filming work position. The filming pressure balance device is located at the tangent position of the back position side of the automobile B column exterior decoration plate which is to be filmed, and is fixed to the machine frame.

Owner:HEBEI UNIV OF TECH

Printing and punching production line for solar water tank shell

ActiveCN105414385BPrinting alignment is accurateImprove printing qualityHollow articlesProduction linePunching

The invention provides a printing and punching production line for solar water tank shells. The rear end of an unrolling frame for metal strip rolls of the production line is sequentially provided with an unrolling speed buffer platform, a flat-bed printing machine, a drying oven, a cooling table, a film pasting frame, a plate overturning frame, a plate connection frame and a single-plate conveying frame. A start inductive switch and a stop inductive switch of an unrolling motor are arranged on the unrolling speed buffer platform. A film containing frame, a film pressing roller and a length-fixed cutter are arranged on the film pasting frame. A length encoder of the length-fixed cutter is arranged beside the film pressing roller. Suction disc plate conveying devices are arranged on the single-plate conveying frame. A lead screw plate conveying table and a punching machine are arranged below the single-plate conveying frame. By the adoption of the technical scheme, rolled plates are unrolled from the unrolling frame and punched automatically, small manual operation is needed in the whole process, the quality of printing, film pasting and punching is better, and production efficiency is higher.

Owner:YUNNAN YUXI TAIBIAO SOLAR ENERGY EQUIP

Automatic film sticking machine

ActiveCN104828281ASmooth recyclingEasy to peelPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine comprising a film stripping device and a film sticking device. The film stripping device comprises a driving material frame, a driven material frame, a tensioning wheel, a film stripping knife, a backboard, a driving material frame motor, a constant speed wheel and a constant speed motor. The film sticking device comprises a first film sticking position, a second film sticking position, a first bottom plate, a transposition mechanism and a film pressing mechanism. The film stripping device is fixed above the first bottom plate of the film sticking device. The film stripping knife of the film stripping device is arranged above the workboard of the film sticking device. According to the automatic film sticking machine, stable and smooth film stripping can be realized; and smooth recovery of backing paper can be guaranteed by the overall design of constant material receiving speed. Besides, uninterrupted continuous film sticking is realized by the two film sticking position alternating contraposition film stripping mechanisms so that film sticking speed is effectively enhanced; and film sticking strength is enhanced by the design of a film pressing roller and a lateral pressing roller so that film sticking defective ratio is reduced.

Owner:JIANGSU BVM INTELLIGENT TECH

Oil-resistant and low-temperature lamination polymer film with self-adhesive protective film and its manufacturing method

ActiveCN106113842BAvoid erosionPrevent blackening and yellowingSynthetic resin layered productsLaminationPolymer scienceAdhesive glue

The invention discloses an anti-fouling low-temperature laminated polymer film with a self-adhesive protective film. The polymer film comprises a low-temperature polymer base layer, a printing layer, an anti-fouling layer, a film protection layer, a self-adhesive layer and a self-adhesive protective layer, wherein the outer side of the low-temperature polymer base layer is adhered to the inner side of the printing layer; the inner side of the anti-fouling layer is adhered to the outer side of the printing layer; the inner side of the film protection layer is adhered with the outer layer of the anti-fouling layer together by virtue of a first glue layer; the low-temperature polymer base layer comprises an outer layer, an intermediate layer and an inner layer; the inner side of the self-adhesive layer is adhered to the outer side of the film protection layer; the inner side of the self-adhesive protective layer is adhered to the outer side of the self-adhesive layer; the inner side of the inner layer is used for being adhered to a kitchen ceiling board. The anti-fouling low-temperature laminated polymer film disclosed by the invention is good in environment friendliness and low in protection cost, the ceiling board can be prevented from being eroded by oil dirt and prevented from blackening and yellowing, and the service life of the ceiling board and the adhered film can be prolonged; and moreover, the film can be directly adhered to the kitchen ceiling board at a low temperature, so that the film adhering speed is increased, and the service efficiency is improved.

Owner:浙江华清包装材料有限公司

Film sticking device and method for special-shaped parts

ActiveCN110902000BEliminate Positional TolerancesEliminate Tolerance ChainsPackagingEngineeringMechanical engineering

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

Light sensitive glass film binding agent

InactiveCN103013416BFast film applicationImprove qualityPolyureas/polyurethane adhesivesSynthetic resin layered productsSolventUltimate tensile strength

The invention discloses a light sensitive glass film binding agent, and provides a binding formula and a film prime coat formula, wherein the binding formula comprises components in percentage by mass as follows: 30-50% of base resin, 40-60% of an active monomer, 1-8% of a photoinitiator, 0.01-1% of a flatting agent, 0.01-1% of an antifoaming agent and 0.01-1% of coupling reagent; and the film prime coat formula comprises components in percentage by mass as follows: 25-45% of base resin, 15-35% of an active monomer, 1-8% of a photoinitiator, 0.05-1% of a flatting agent, 0.01-1% of an antifoaming agent, 0.01-1% of coupling reagent and 20-40% of a solvent. The invention further discloses a method for preparing the binding agent, the process is simple, and the preparation cost is low. The glass films produced by using the binding agent is high in curing speed, high in peel strength and good in safety performance.

Owner:苏州威仕薄膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com