Self-service film sticking machine and self-service film sticking method

A film sticking machine and film sticking technology, which is applied in the field of film sticking of electronic equipment, can solve the problems of poor film sticking effect and unfavorable wide application of film sticking, and achieve the effects of guaranteed film sticking effect, convenient management, and not easy to waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

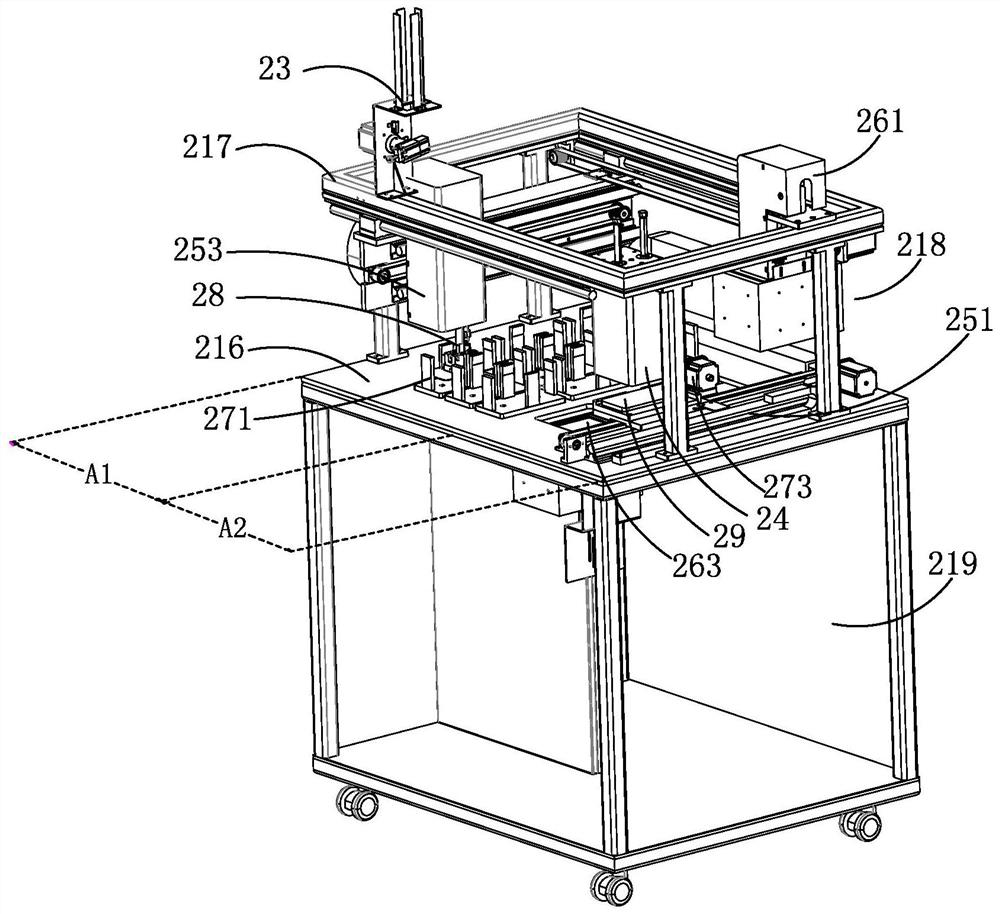

[0068] see Figure 6 The film tearing mechanism 273 includes a control member 2731 and a film tearing clip 2733. The control member 2731 controls the clamping and loosening of the film tearing clip 2733, and controls the rotation of the film tearing clip 2733. As a specific embodiment, the control member 2731 includes a second motor 2732 that controls the rotation of the tearing film clip 2733, and it further includes one or more of the cylinder 2734 or the motor and the screw or other mechanical structures to control the tearing film clip Clamping and unclamping of 2733. The pick-up assembly 28 moves the protective film to the tearing film mechanism 273, the tearing film mechanism 273 clamps the peeling film, the control member 2731 controls the tearing film clip 2733 to rotate, the first moving mechanism 251 drives the tearing film mechanism 273 to move, and the peeling film is torn off . Preferably, a recycling area 2736 is provided under the film tearing mechanism 273 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com