Thermosetting peelable blue gum

A technology of thermal curing and blue glue, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of manual cleaning, cutting size, glue residue pollution, etc., to improve production efficiency and yield rate, good toughness and softness, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

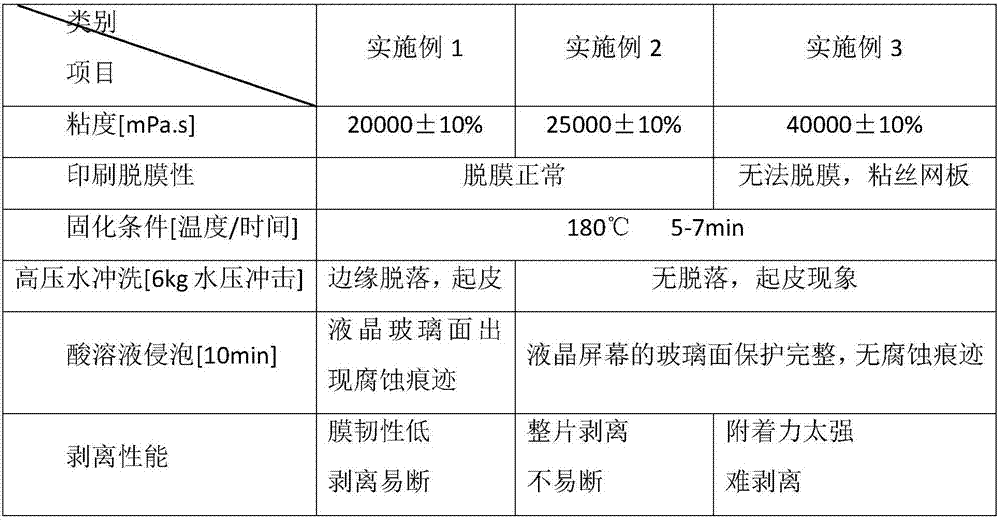

Embodiment 1

[0034] The raw material composition and content of heat-curing peelable blue glue are as follows: 40 parts of paste resin, 10 parts of filler, 20 parts of dioctyl phthalate, [KH-570]γ-(methacryloxy)propyl trimethoxy 0.2 part of base silane, 0.4 part of polymethylphenylsiloxane, 0.2 part of fumed silica, 0.5 part of Airex900 and 0.2 part of phthalocyanine blue PB15:3. The above-mentioned raw materials are dispersed, stirred and mixed to prepare a heat-curable peelable blue glue for temporary protection of liquid crystal screen processing and manufacturing.

[0035] In this embodiment, the paste resin is a mixture of polyvinyl chloride paste resin P450 and binary vinyl acetate paste resin, and the mass ratio is 1:1.5.

Embodiment 2

[0037] The raw material composition and content of heat-curable peelable blue glue are as follows: paste resin 50 parts, filler 15 parts, dioctyl phthalate 28 parts, [KH-570]γ-(methacryloxy)propyl trimethoxy 0.5 part of base silane, 0.4 part of polymethylphenylsiloxane, 0.5 part of fumed silica, 0.5 part of Airex900, and 0.4 part of phthalocyanine blue PB15:3. The above-mentioned raw materials are dispersed, stirred and mixed to prepare a heat-curable peelable blue glue for temporary protection of liquid crystal screen processing and manufacturing.

[0038] In this embodiment, the paste resin is a mixture of polyvinyl chloride paste resin P450 and binary vinyl acetate paste resin, and the mass ratio is 1:1.5.

Embodiment 3

[0040] The raw material composition and content of the heat-curable peelable blue glue are as follows: 60 parts of paste resin, 20 parts of filler, 28 parts of dioctyl phthalate, [KH-570]γ-(methacryloxy)propyl trimethoxy 1 part of base silane, 0.4 part of polymethylphenylsiloxane, 0.5 part of fumed silica, 0.5 part of Airex900, and 0.4 part of phthalocyanine blue PB15:3. The above-mentioned raw materials are dispersed, stirred and mixed to prepare a heat-curable peelable blue glue for temporary protection of liquid crystal screen processing and manufacturing.

[0041] In this embodiment, the paste resin is a mixture of polyvinyl chloride paste resin P450 and binary vinyl acetate paste resin, and the mass ratio is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com