Evening primrose oil microcapsule and pulverization method

A technology of microcapsules and powdering, applied in microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of high energy consumption of evening primrose oil microcapsules, high requirements on wall material specifications, poor capsule shell compactness, etc. Antioxidant performance, good dispersibility, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for powdering evening primrose oil microcapsules. The method uses a solvent-non-solvent method to coat evening primrose oil into microcapsules. The solvent-non-solvent method includes the following steps:

[0028] 1) Mix acrylic resin No. II or acrylic resin No. III or a mixture of acrylic resin No. II and acrylic resin No. III in a certain proportion, dissolve in ethanol, and use it as a wall material solution.

[0029] ) by adding evening primrose oil and polyoxyethylene hydrogenated castor oil RH40, high-shear emulsification and dispersion to form a stable O / W emulsion.

[0030] ) Stirring and adding sodium lauryl sulfate solution to the core material, wall material and medium at the same time, with the continuous increase of water content in the system, the concentration of ethanol is reduced, resulting in a decrease in the solubility of the wall material, and the core material is precipitated from the system Evening primrose oil is coated to form microcaps...

Embodiment 2

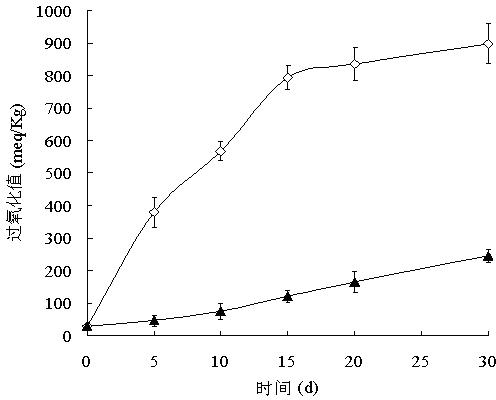

[0033] An evening primrose oil microcapsule, which consists of: evening primrose oil core material, acrylic resin II or acrylic resin III or acrylic resin II and acrylic resin III, polyoxyethylene hydrogenated castor oil RH40, characterized in that: The parts by weight of the evening primrose oil core material is 1, and the parts by weight of the acrylic resin II or acrylic resin III or acrylic resin II and acrylic resin III are 0.6 to 8.5 parts by weight; the polyoxyethylene hydrogenated castor oil The parts by weight of RH40 are 0.05-0.5. attached image 3 Middle (?) is evening primrose oil; (▲) is evening primrose oil microcapsules.

Embodiment 3

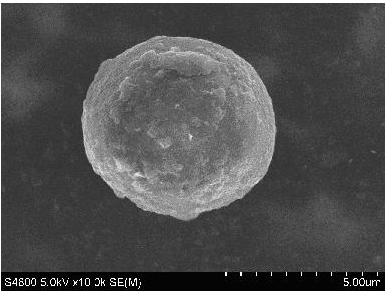

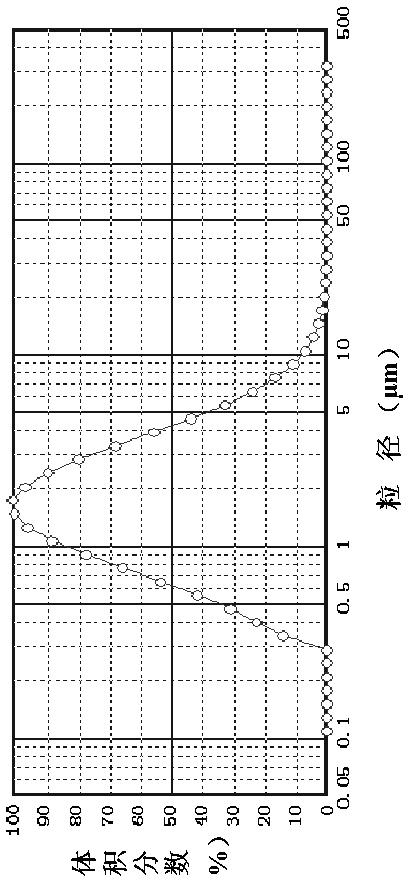

[0035] For the evening primrose oil microcapsules and powdering method described in the above examples, weigh 8 g of acrylic resin No. II and No. III (1:1) and dissolve them in 95% ethanol, then add 2 g of evening primrose oil, Polyoxyethylene hydrogenated castor oil RH40 0.2 g, 10000 rpm homogeneous emulsification for 2 min, 0.2% sodium lauryl sulfate solution was added dropwise with a 50 ml acidic burette, while stirring continuously at 1000 rpm until a large number of microcapsule solids were precipitated in the solution , filtered and then washed twice with 0.2% sodium lauryl sulfate solution, filtered and dried under reduced pressure to obtain evening primrose oil microcapsule powder. The final evening primrose oil microcapsules were white powder with good fluidity and good anti-oxidation ability. The average particle size of the microcapsules was determined by laser particle size analyzer to be 7.66 μm, and the encapsulation efficiency was 95.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com