Automatic film sticking machine for touch panel of mobile phone

A touch screen and laminating machine technology, applied in packaging and other directions, can solve the problems of inability to meet large-scale production, low lamination speed and efficiency, and no automation equipment, and achieve fast lamination speed, high work efficiency, and good positioning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

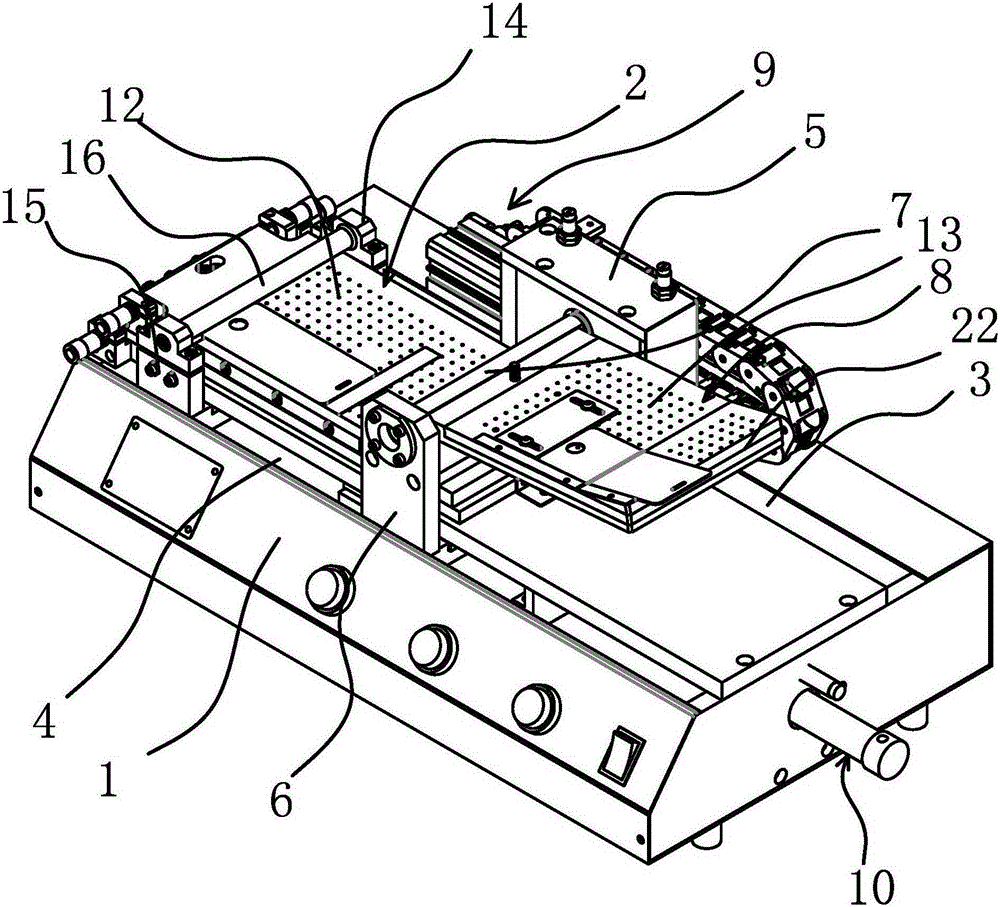

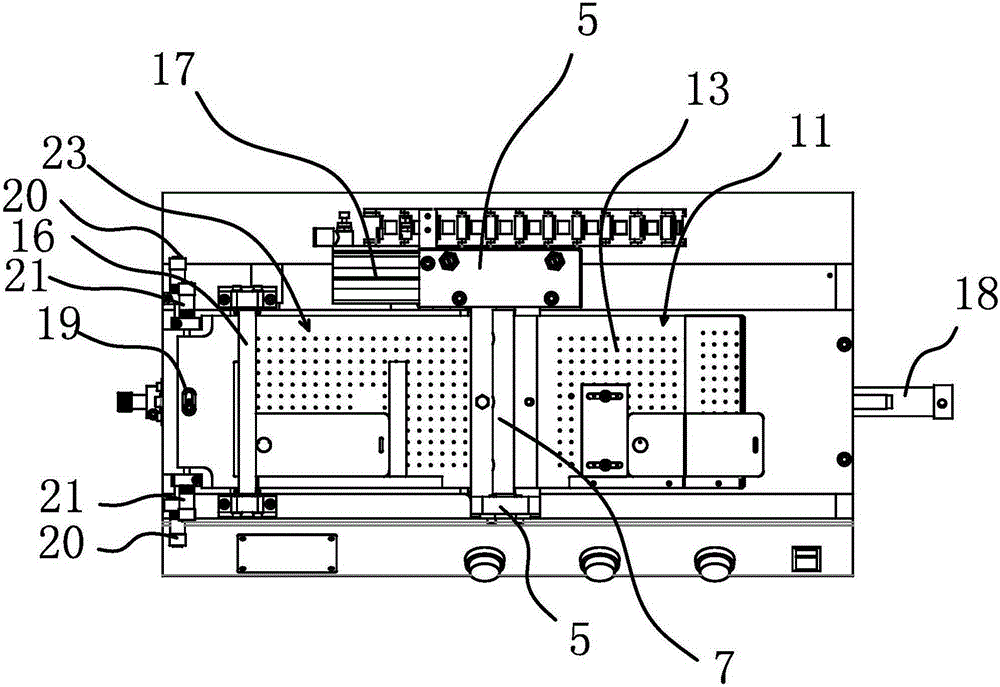

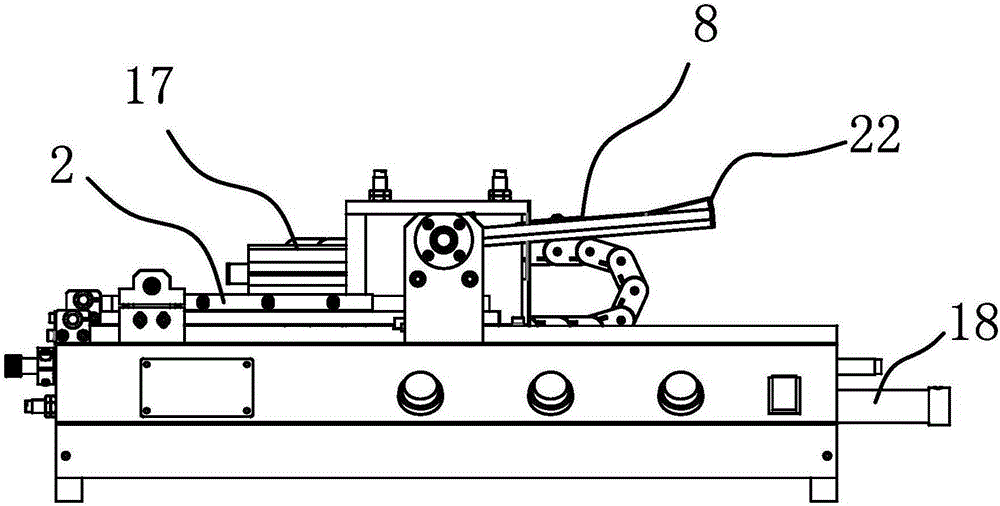

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0028] Such as figure 1 and figure 2As shown, the film laminating machine includes a base 1, the upper surface of the base 1 is fixed with a lower film sticking plate 2 arranged in the horizontal direction, the upper surface of the lower film sticking plate 2 has a film sticking surface 23 for fixing the touch screen, the base 1 The upper surface of the upper surface is also provided with a chute 3 and a chute 4 arranged in the horizontal direction. The chute 3 and the chute 4 are respectively located on both sides of the lower film plate 2 and are parallel to each other. Sliding connection has sliding seat one 5, sliding connection has sliding seat two 6 on the chute two 4, also slidingly connecting with sliding seat th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com