Oil-resistant and low-temperature lamination polymer film with self-adhesive protective film and its manufacturing method

A technology of self-adhesive protective film and polymer film, applied in the direction of polymer adhesive additives, adhesive types, chemical instruments and methods, etc., can solve problems such as film cracking and degumming, affecting film speed, and blackening of ceiling boards , to achieve the effect of preventing blackening and yellowing, speeding up the speed of film application, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

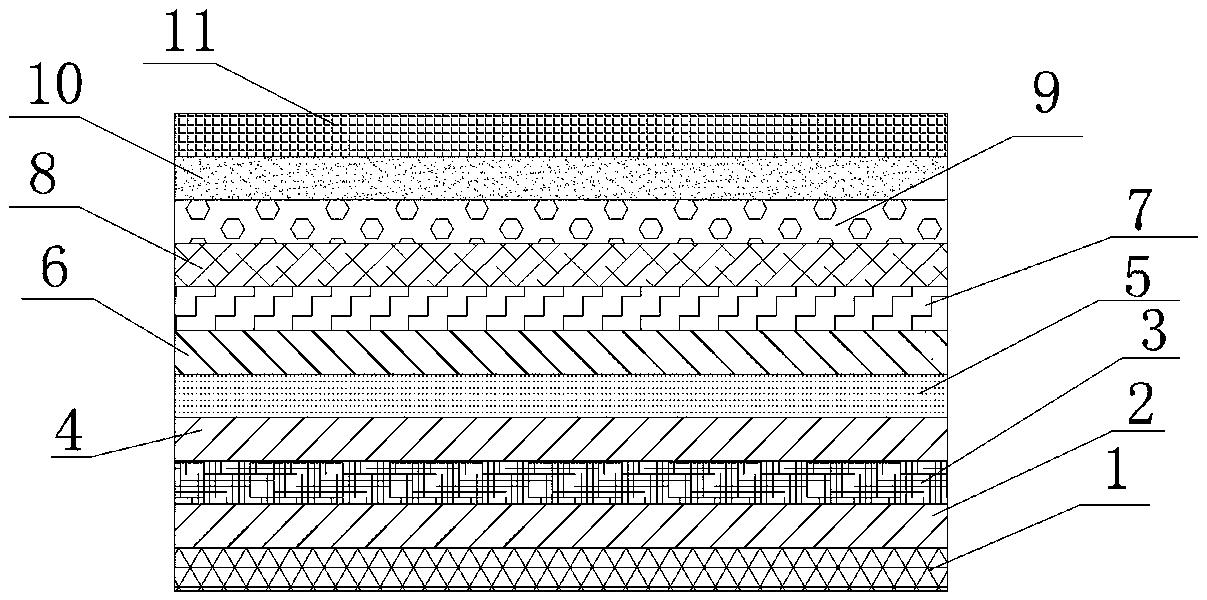

[0037] The inner layer 1 is composed of the following components in parts by mass: 30 parts of polymer resin, 60 parts of low-temperature adhesive, 0.3 parts of brightener, and 3 parts of anti-sticking agent. The self-adhesive material layer 10 is composed of the following components in mass fractions: 80 parts of epoxy resin, 10 parts of tackifying resin, and 1 part of elastomer.

Embodiment 2

[0039] The inner layer 1 is composed of the following components in parts by mass: 40 parts of polymer resin, 70 parts of low-temperature adhesive, 0.5 parts of brightener, and 5 parts of anti-sticking agent. The self-adhesive material layer 10 is composed of the following components in mass fractions: 90 parts of epoxy resin, 15 parts of tackifying resin, and 2 parts of elastomer.

Embodiment 3

[0041] The inner layer 1 is composed of the following components in parts by mass: 35 parts of polymer resin, 65 parts of low-temperature adhesive, 0.4 parts of brightener, and 4 parts of release agent. The self-adhesive material layer 10 is composed of the following components in mass fractions: 85 parts of epoxy resin, 12 parts of tackifying resin, and 1.5 parts of elastomer.

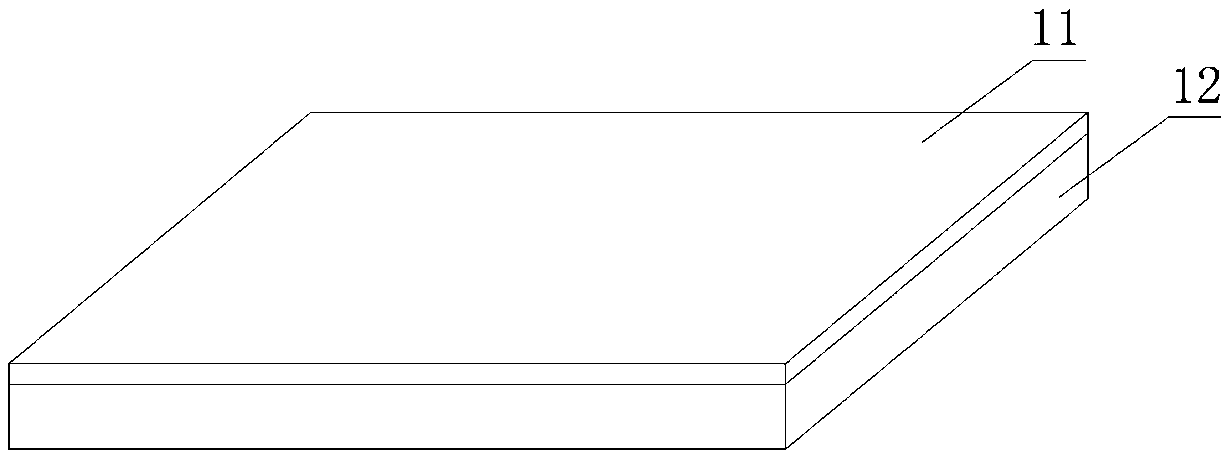

[0042] The self-adhesive protective film of the present invention is compounded on the outermost layer of the oil-resistant low-temperature lamination polymer film while being attached to the ceiling board with the oil-resistant low-temperature lamination polymer film, and is used for the transportation and storage of the ceiling board. The ceiling board and the polymer film play a protective role; when the ceiling board is used, only the self-adhesive protective film needs to be removed; it changes the protection of the ceiling board by applying glue in the past, and it can not only protect the ceiling b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com