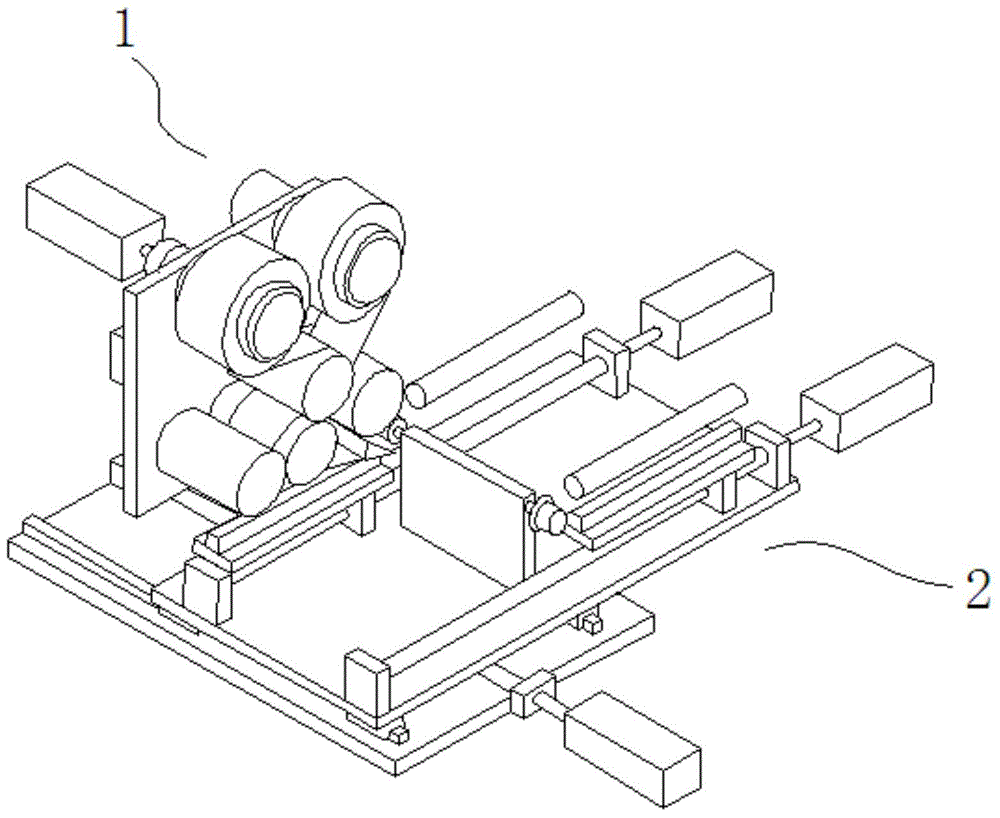

Automatic film sticking machine

A film laminating machine, automatic technology, applied in the direction of packaging, etc., can solve the problems of low lamination precision between film and workpiece, insufficient utilization of film lamination stations, and unsmooth film peeling, so as to reduce the defective rate of film lamination and reduce the risk of paper breakage , The effect of smooth recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

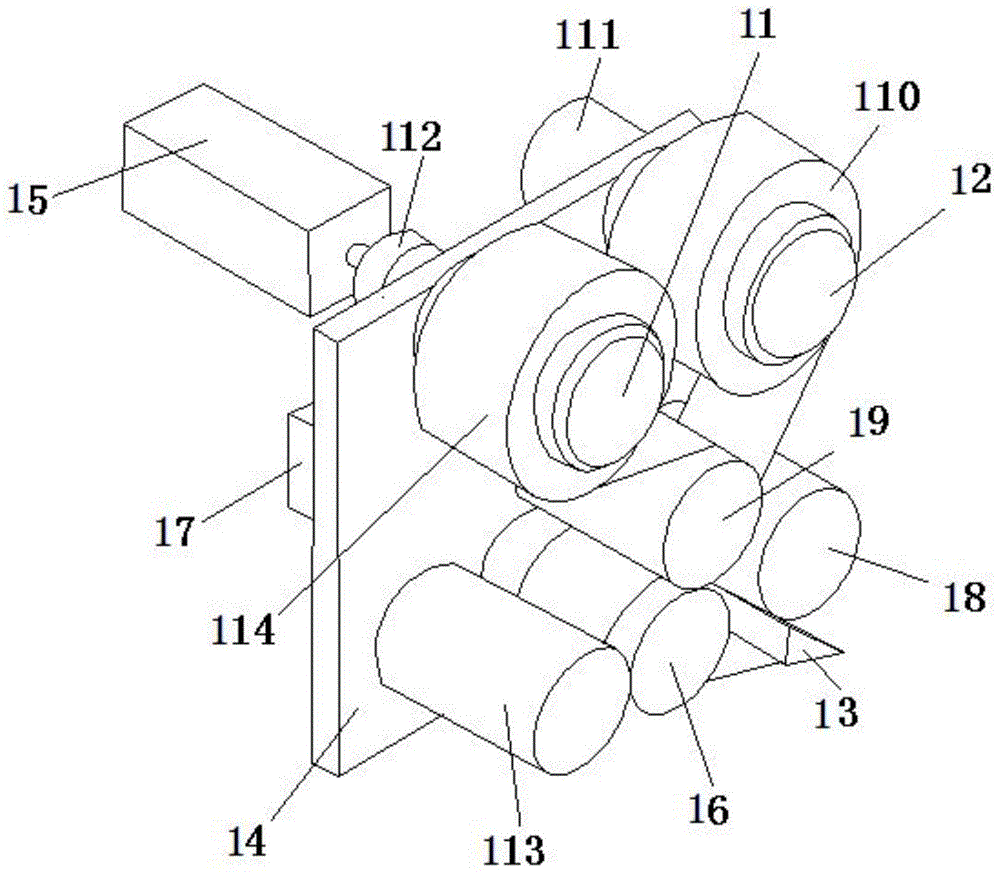

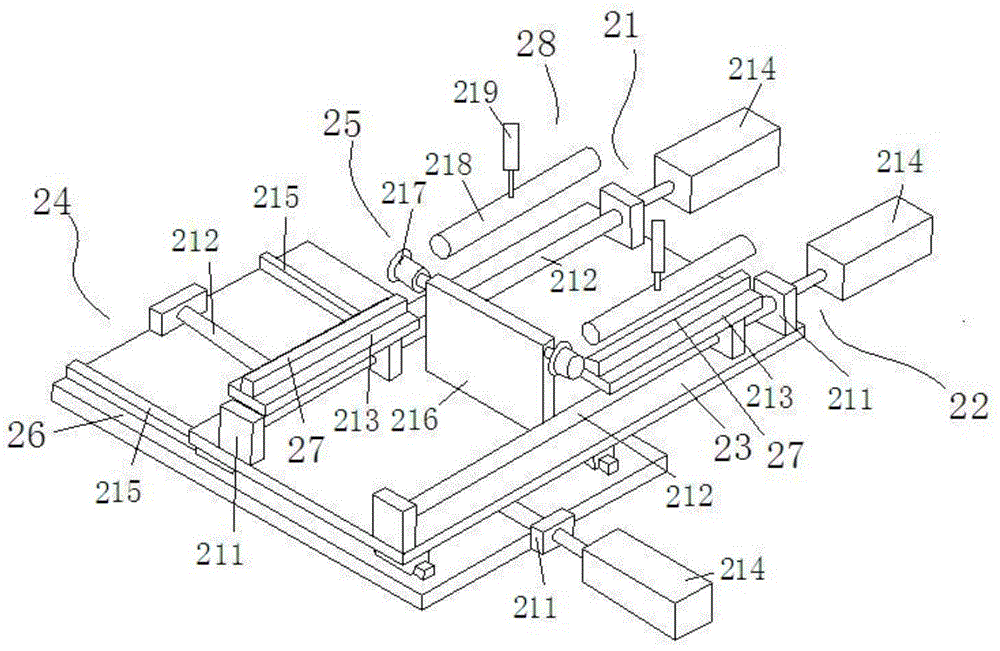

[0025] Specific embodiment: the active material frame motor of the film stripping device turns on the active material frame to rotate, and the coil material is drawn out from the driven material frame to bypass the first tensioning wheel and the film stripping knife in turn. The first film sticking station and the second film sticking station are placed on the workpiece to be processed, and under the action of the transposition mechanism, they alternately move to the stripping knife and move to the right together with the peeled film; at this time, the workpiece top The surface and sides are covered with a film, which is initially pressed by the film-pressing roller, and then the side is further pressed by the side pressing roller to complete the film-attaching process of the workpiece, so that the reciprocating and uninterrupted processing. The stripped backing paper continues to pass through the fixed speed wheel and the second tensioning wheel to be wound on the active mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com