Patents

Literature

156results about How to "Enough tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

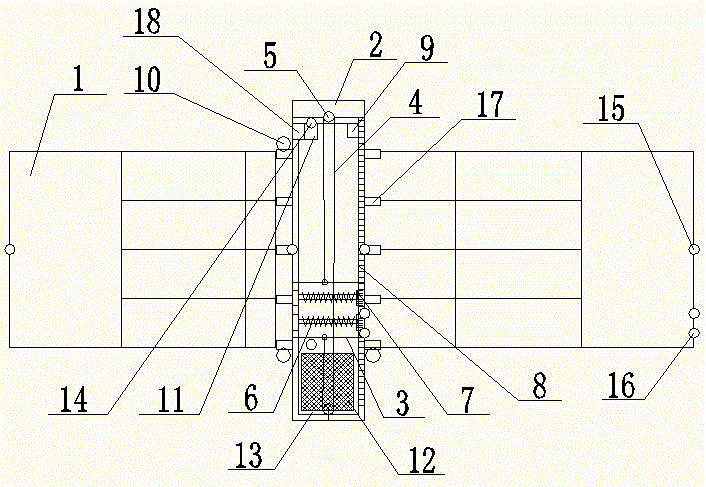

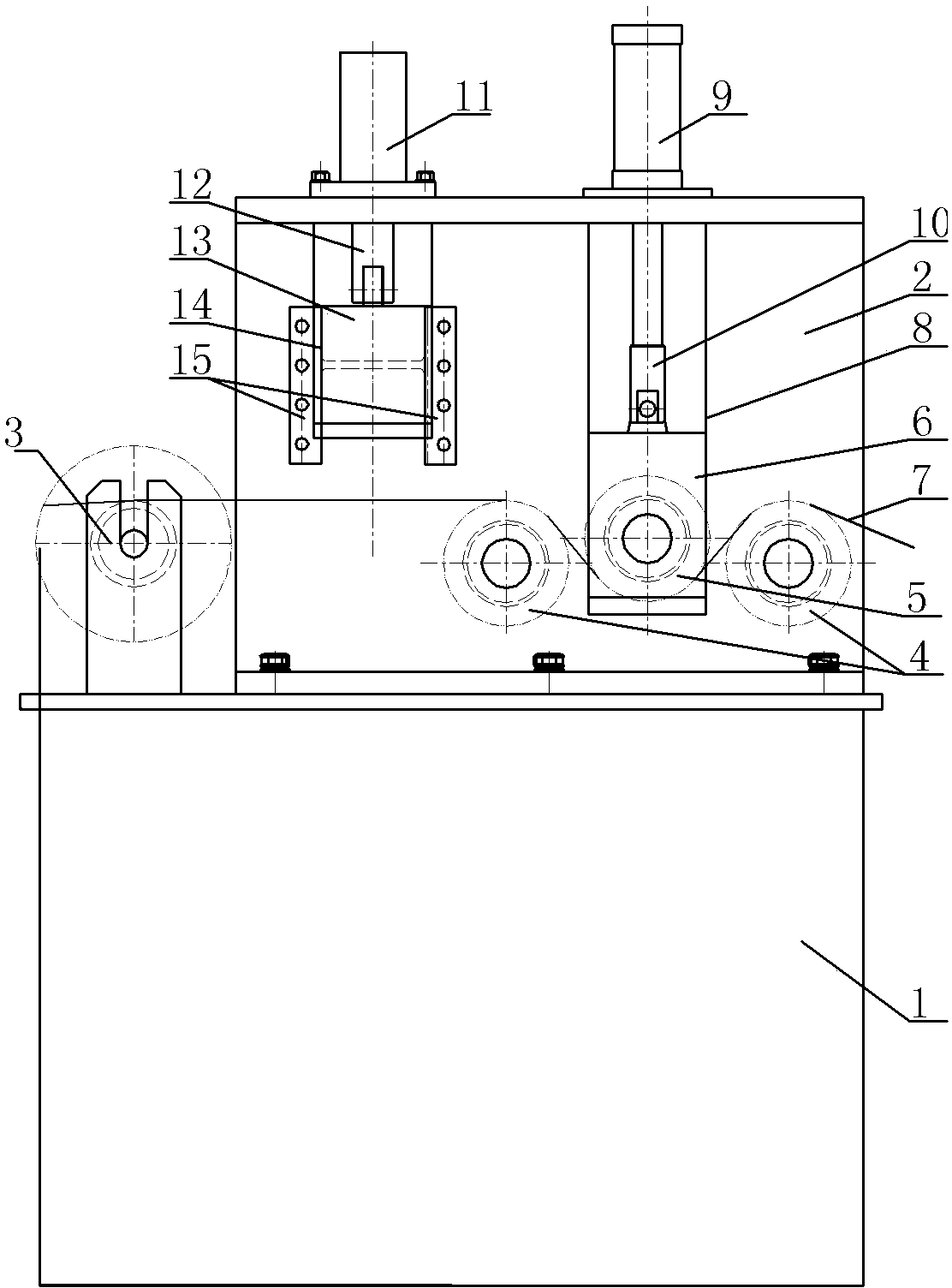

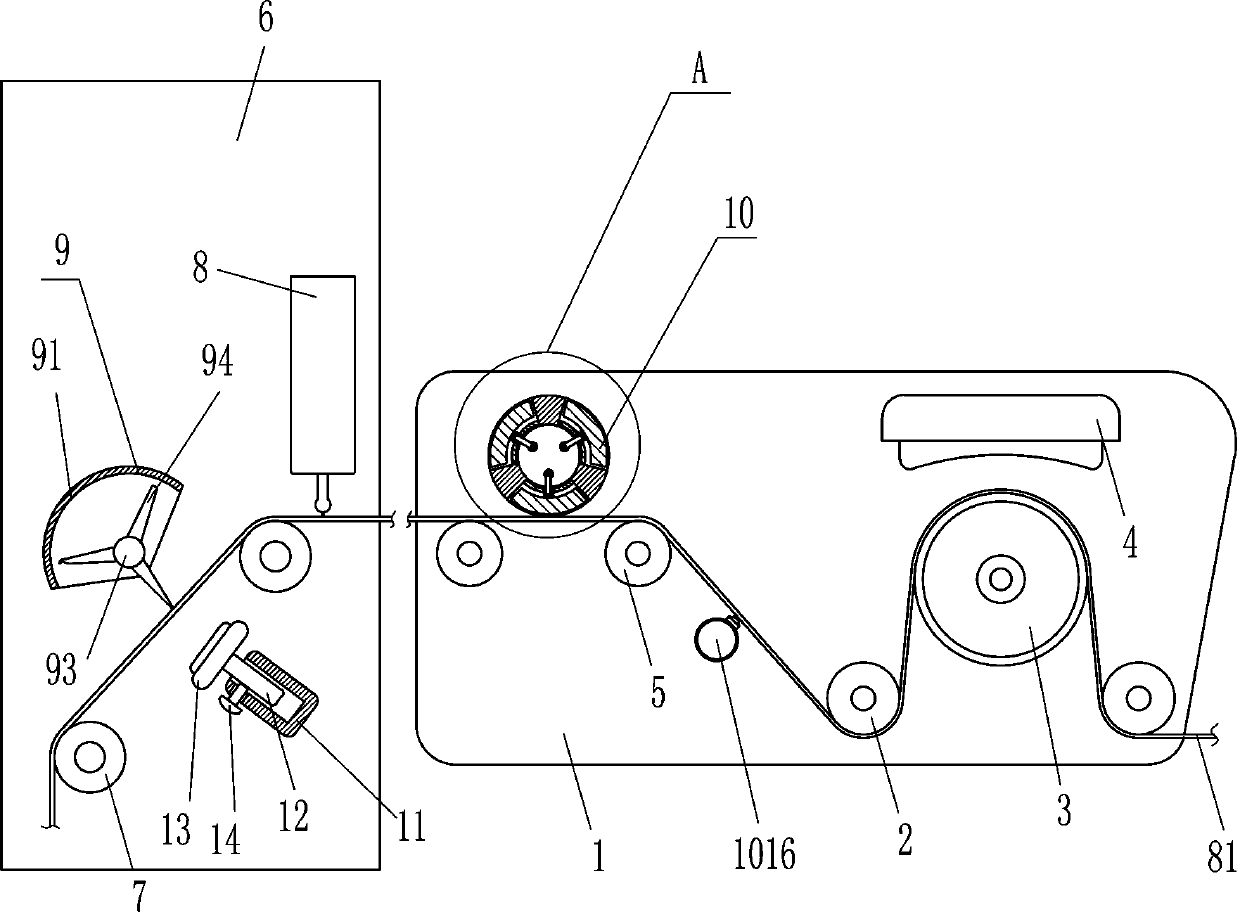

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

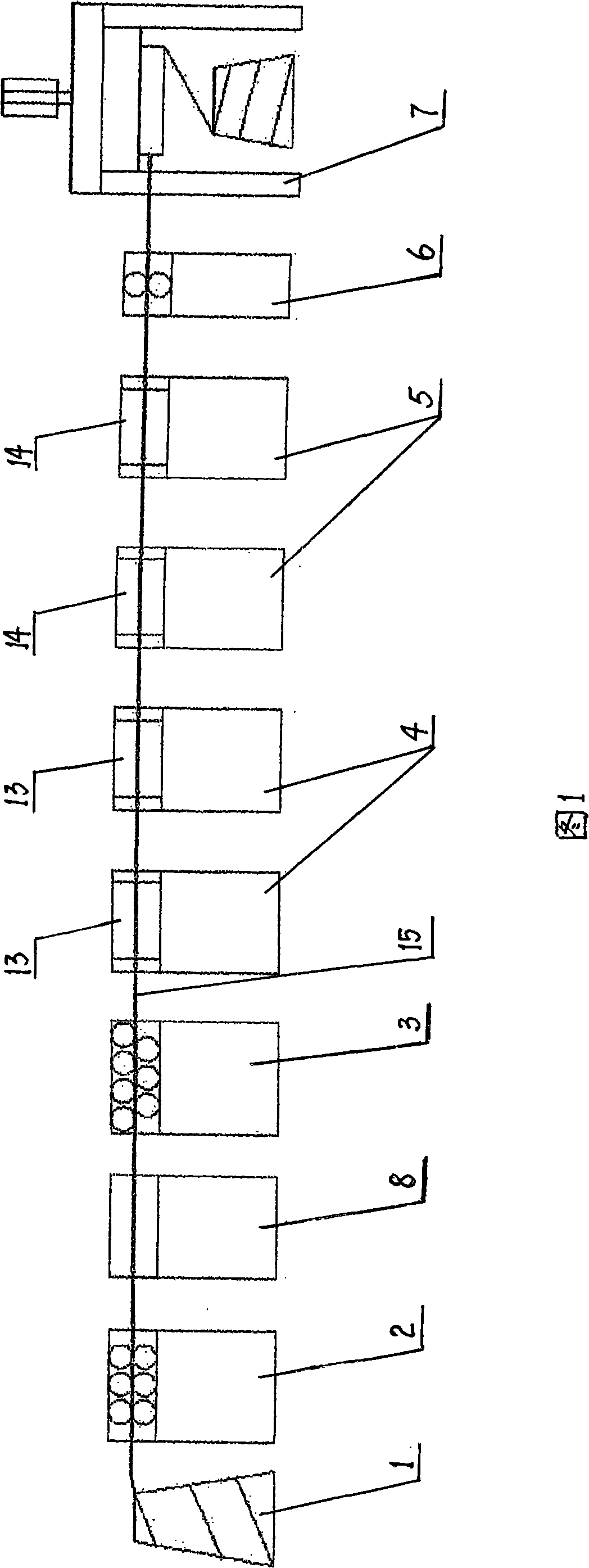

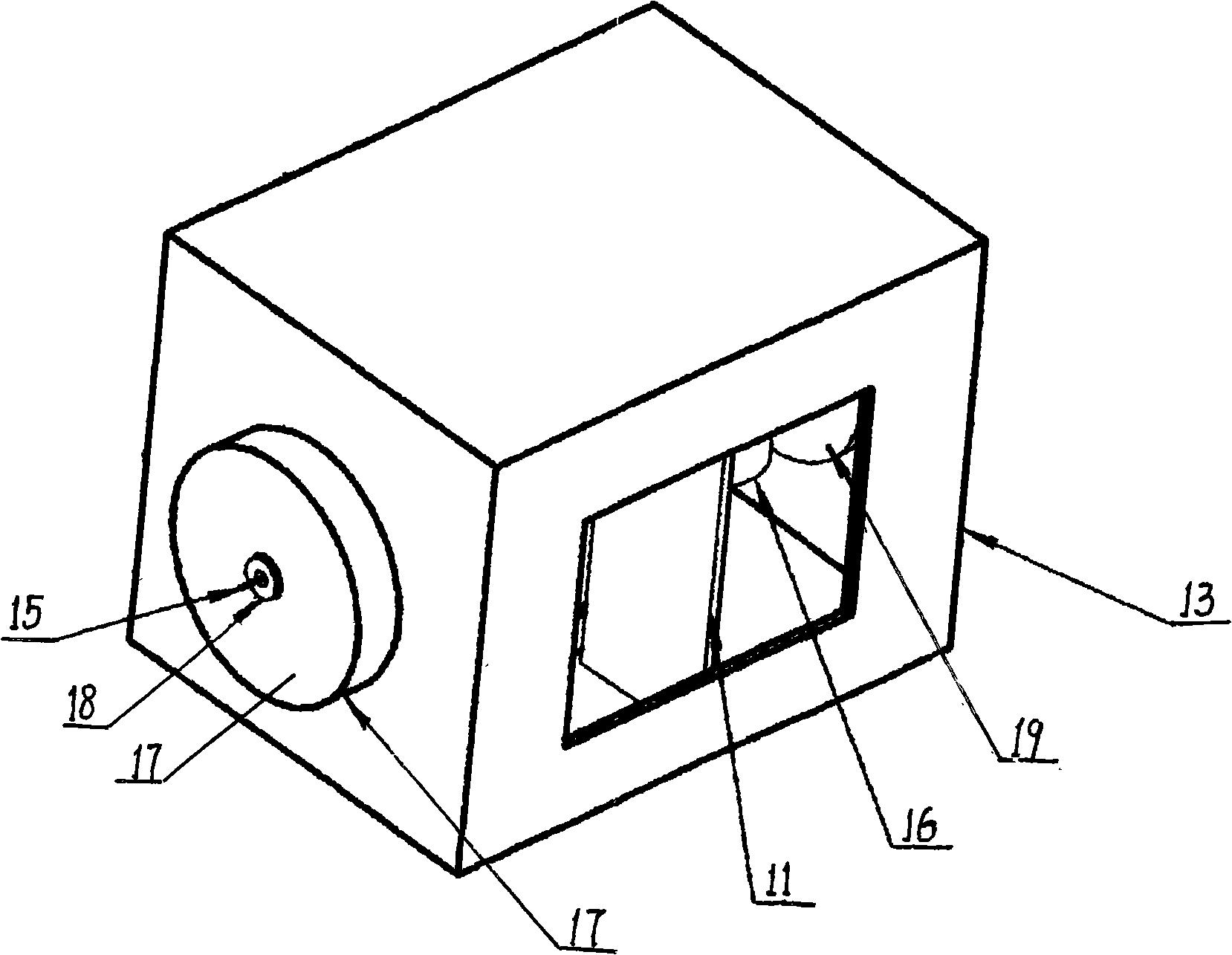

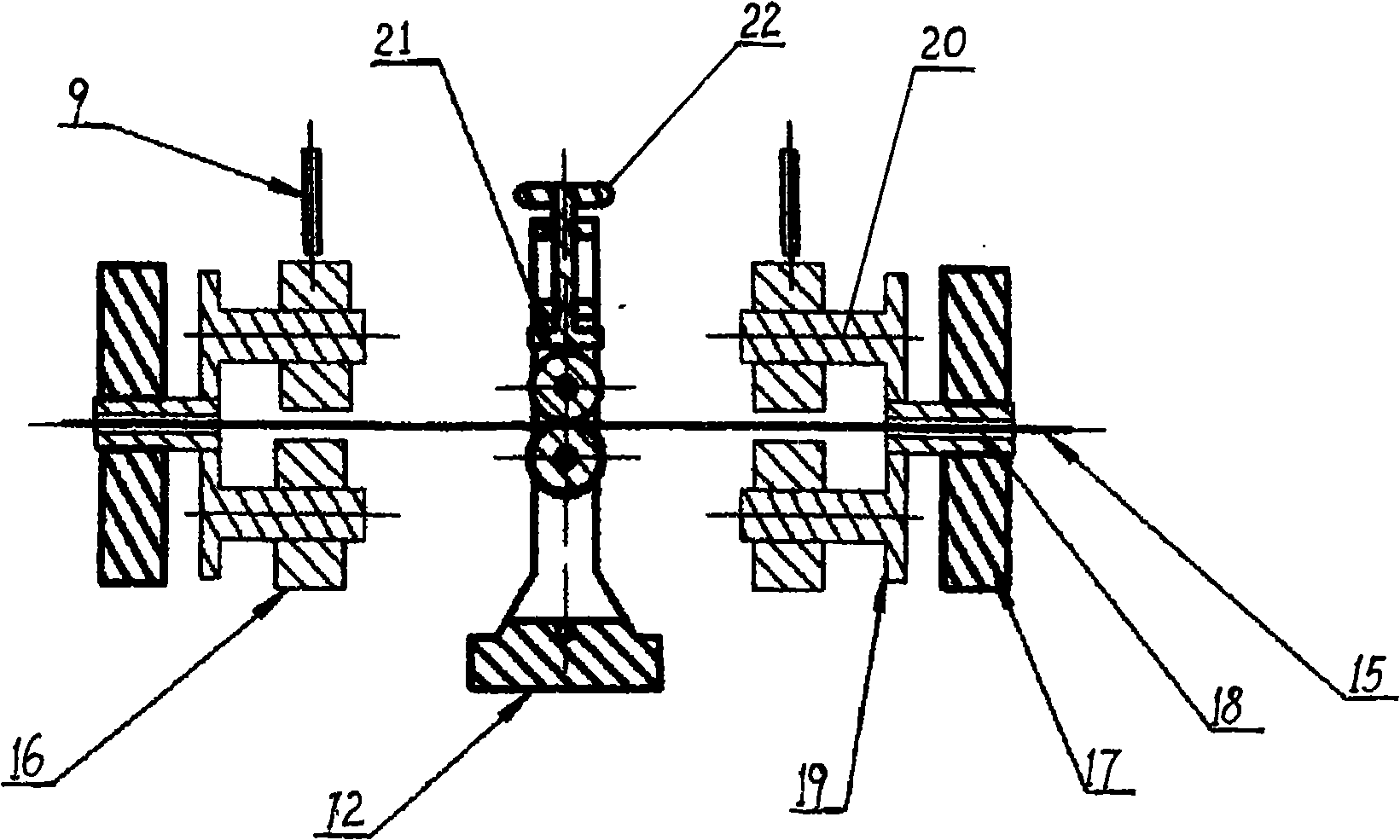

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

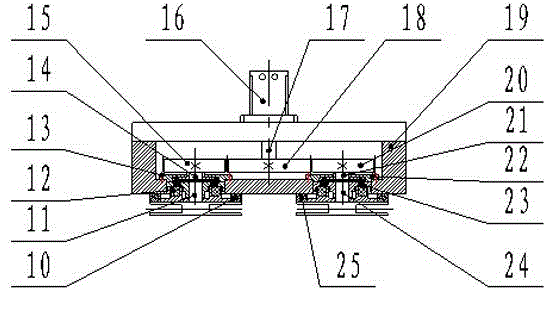

Abrasive belt grinding and polishing device

ActiveCN104084866AMeet the process requirementsAutomatic roll inBelt grinding machinesElectromagnetic clutchGear wheel

The invention discloses an abrasive belt grinding and polishing device. The abrasive belt grinding and polishing device comprises a mounting plate, an unwinding roller, a winding roller, a tensioning mechanism and a driving mechanism. The driving mechanism comprises a servo motor, a driving gear, driven gears, driven gear transmission shafts and roller shafts. The driving gear is mounted on an output shaft of the servo motor. The driven gears are mounted at one end of the driven gear transmission shaft on one side of the driving gear and one end of the driven gear transmission shaft on the other side of the driving gear respectively and are meshed with the driving gear. The unwinding roller is mounted at one end of the corresponding roller shaft. The winding roller is mounted at one end of the corresponding roller shaft. The other ends of the roller shafts are connected with the other ends of the corresponding driven gear transmission shafts through electromagnetic clutches. The tensioning mechanism is composed of friction disks, transition wheels and the like. The rollers are controlled through engagement and disengagement of the electromagnetic clutches arranged between the roller shafts of the rollers and a driving shaft, so that active belt winding or passive belt unwinding is achieved; the friction disks on the end faces of the rollers can apply friction force to the rollers subjected to passive unwinding so as to ensure that a grinding and polishing belt has enough tensile force in the machining process and improve the grinding and polishing quality.

Owner:CHONGQING UNIV +1

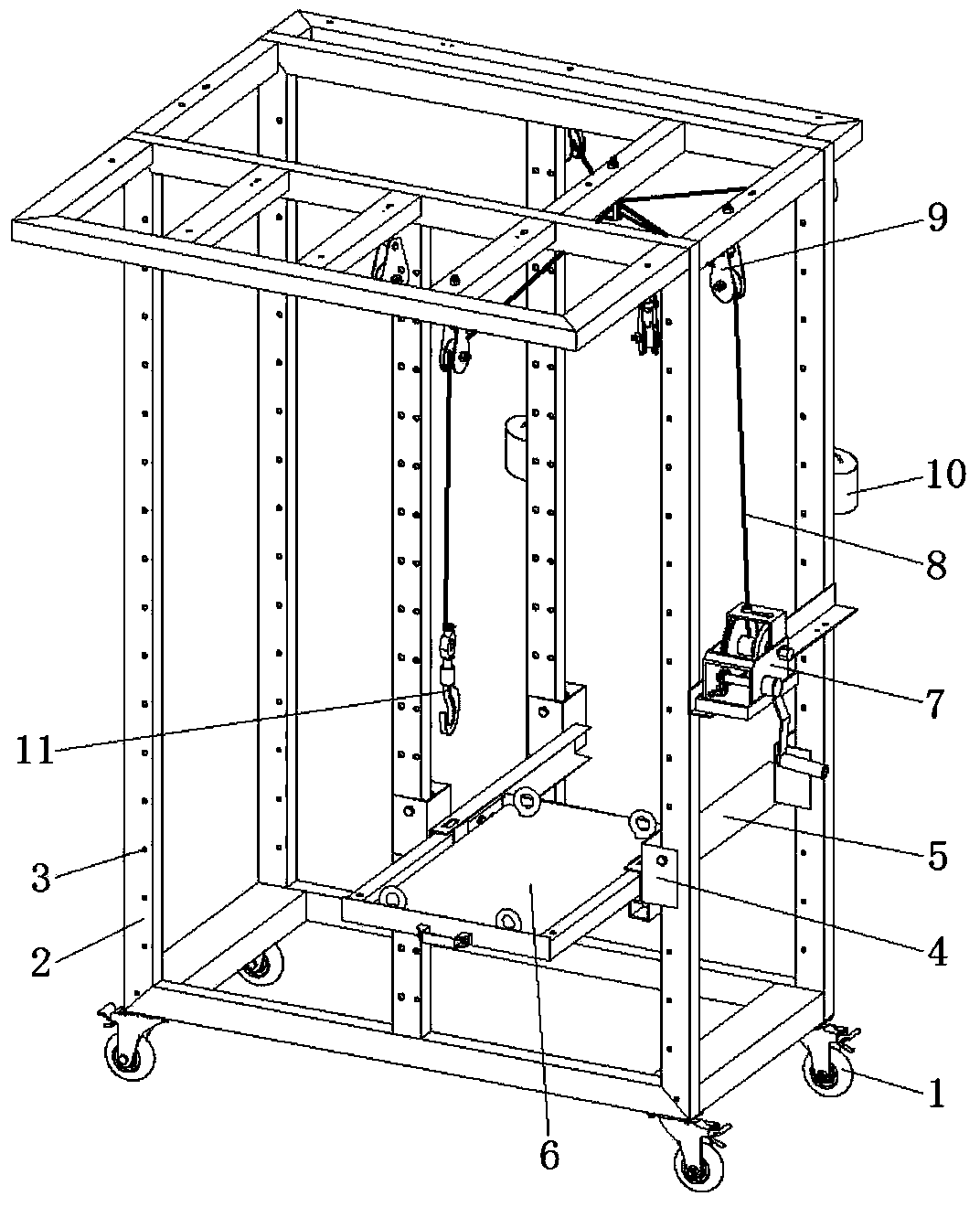

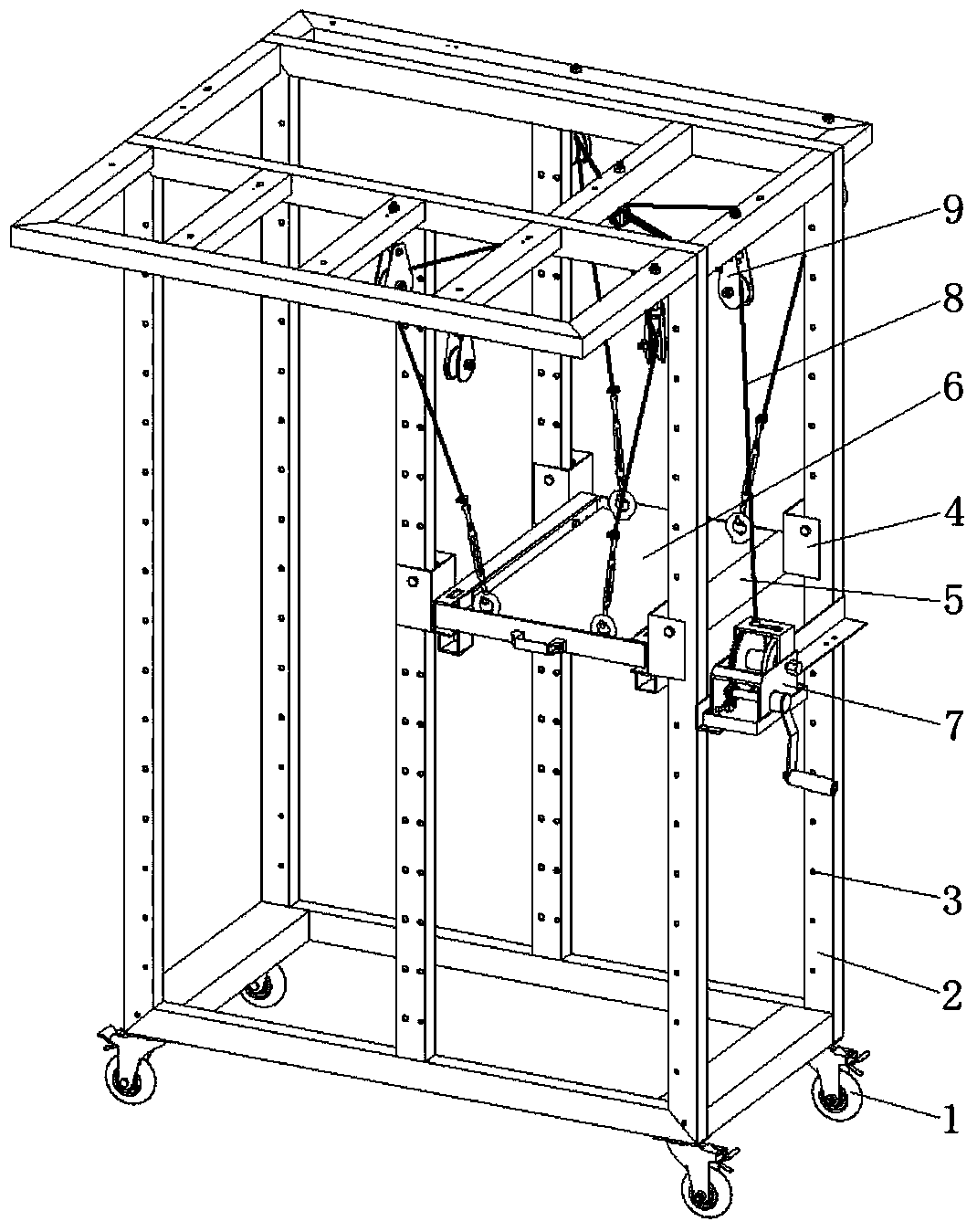

Self-loading and unloading heavy-load shelf with adjustable layer interval

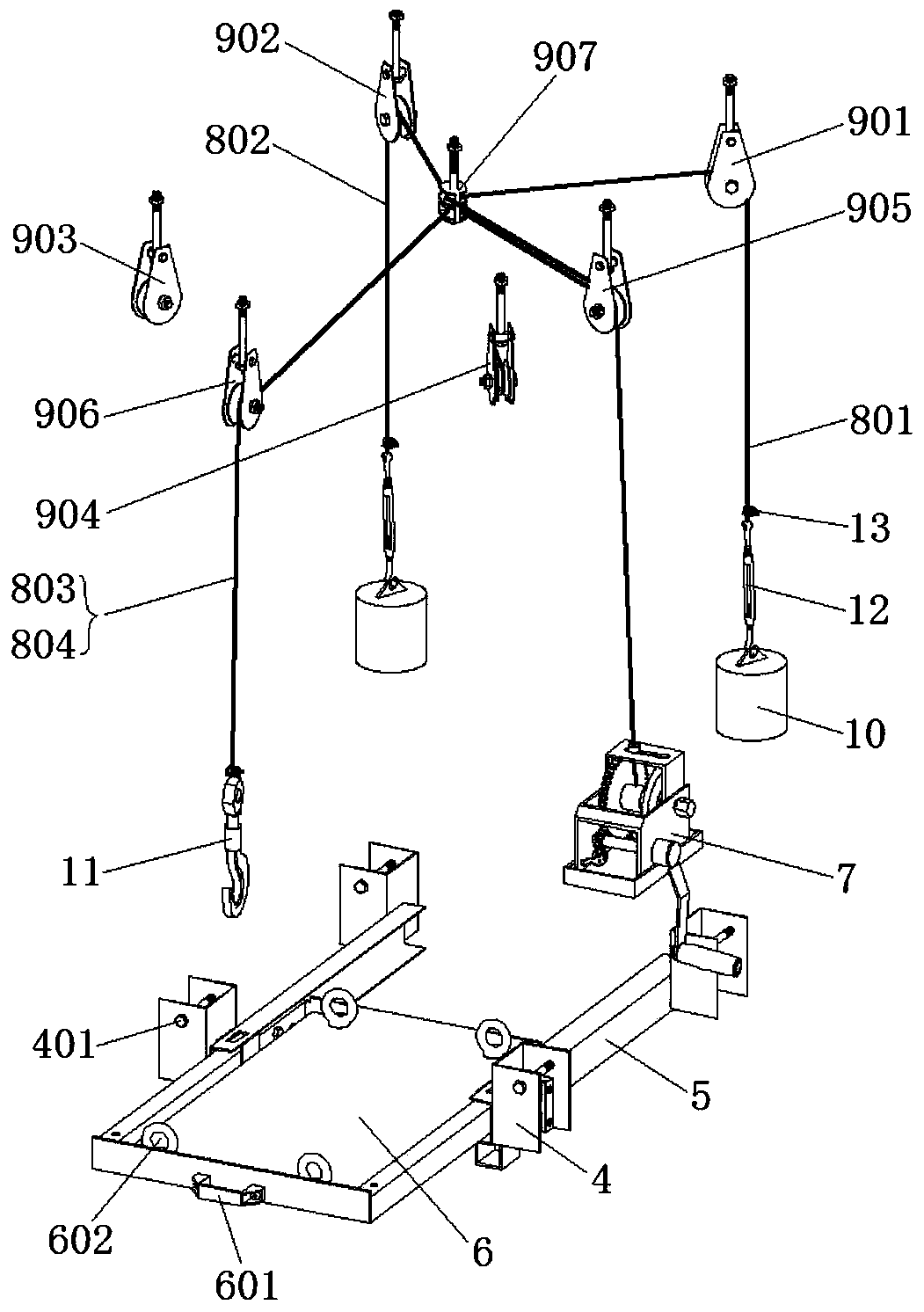

ActiveCN104210796ARealize spacing adjustmentAchieve mechanical propertiesWinding mechanismsStorage devicesBlock and tackleWinch

The invention discloses a self-loading and unloading heavy-load shelf with an adjustable layer interval, and belongs to the field of shelves. The self-loading and unloading heavy-load shelf comprises a main framework, a layered frame, a manual winch, steel wire ropes, a pulley block, a heavy object and a lifting hook, wherein the layered frame comprises rolling lifting sliding sleeves, heavy-load slide rails and a tray; the heavy-load slide rails are arranged on both sides of the tray, and are arranged on vertical columns of the main framework through the rolling lifting sliding sleeves arranged at the two ends of the heavy-load slide rails; the manual winch is fixed on one side of the main framework, and four steel wire ropes are led out of the manual winch; after the steel wire ropes pass through the pulley block on the top of the main framework, two of the steel wire ropes are combined together and are connected with the hoisting hook, and the other two steel wire ropes are connected with the heavy object; hoisting rings are arranged on the four corners of the tray respectively and are correspondingly connected with the four steel wire ropes, and the tray is lifted or lowered through the manual winch. By adopting the self-loading and unloading heavy-load shelf, the height of a laminate can be adjusted under the condition that the laminate is under load; moreover, loading and unloading of heavy goods can be realized, and the self-loading and unloading heavy-load shelf is particularly suitable for storing heavy goods.

Owner:常州东吉路国际贸易有限公司

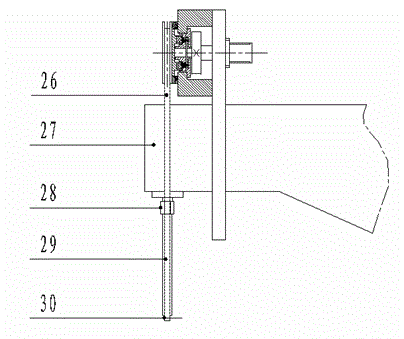

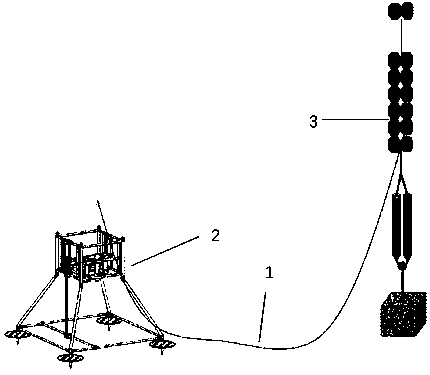

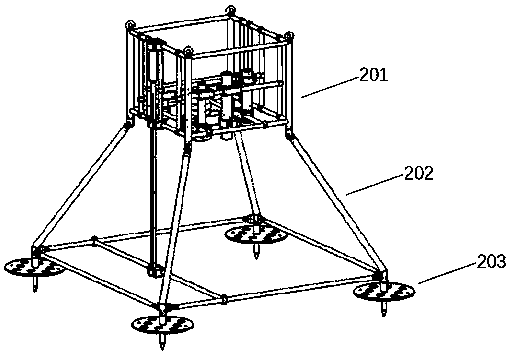

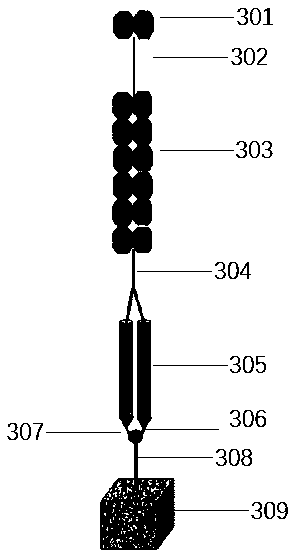

Seabed boundary layer observation device and laying and recovering method thereof

ActiveCN111351528AImprove accuracyGood for recyclingMeasurement apparatus componentsVessel partsObservation dataGeotechnical engineering

The invention relates to the technical field of ocean survey, and especially relates to a seabed boundary layer observation device and a laying and recovering method thereof. The split design of an observation platform and a recovery device is adopted, and a floating body material with a huge size is separated from observation equipment, so that the influence of the floating body material on key parameters such as ocean current is avoided, and the accuracy of observation data is greatly improved; the observation platform on the seabed is recovered by using a connecting cable, so enough tensioncan be provided, and the situation that the observation platform sinks into sediments and cannot be smoothly separated from the seabed is avoided; due to the chained design of the recovery device, after the recovery device floats up to the water surface, recycling of a large scientific investigation ship is better facilitated; and the laying and recovering method is set according to the characteristics of the device, is stable and reliable, is suitable for various ships, and has a good popularization prospect.

Owner:OCEAN UNIV OF CHINA

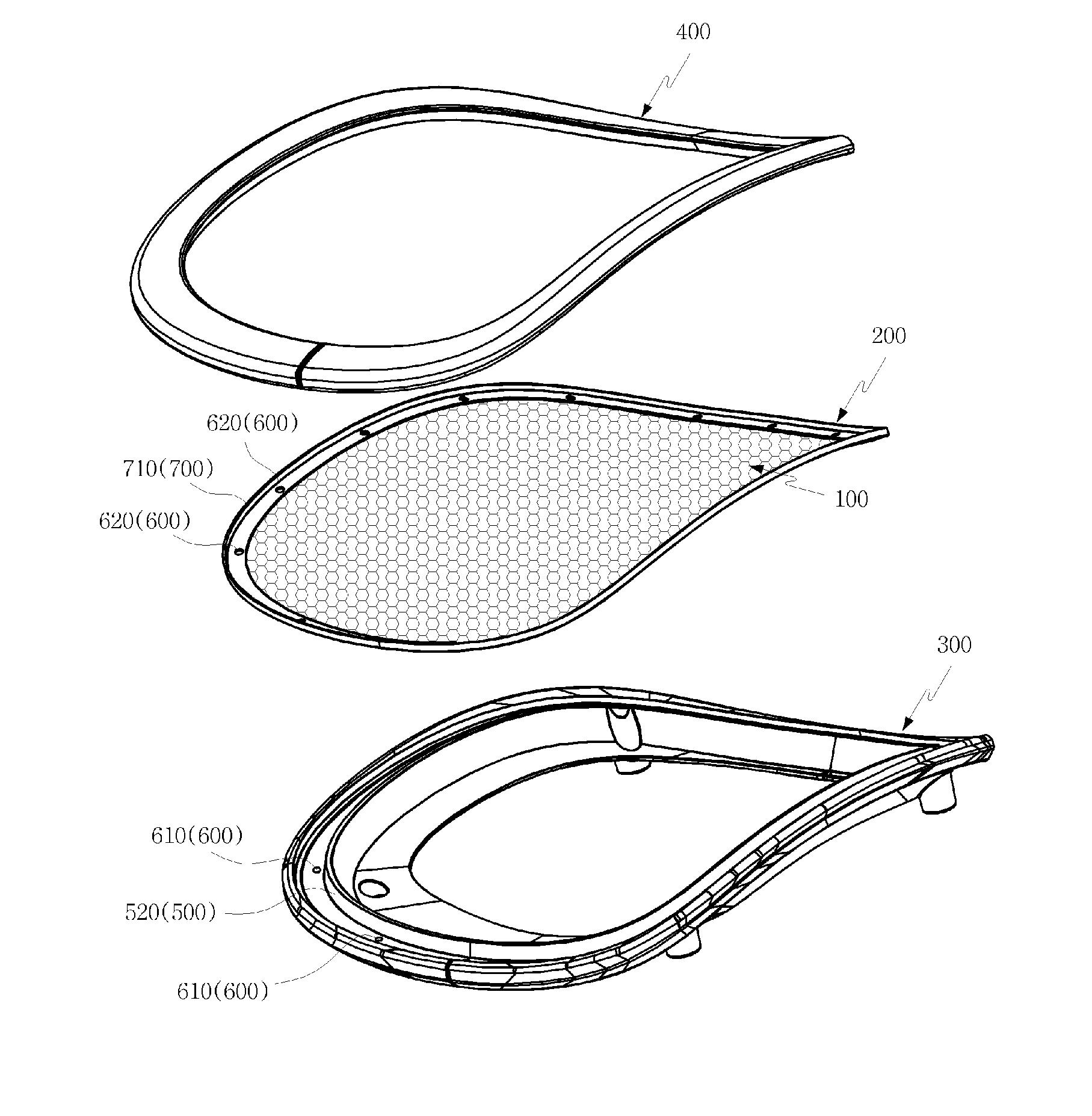

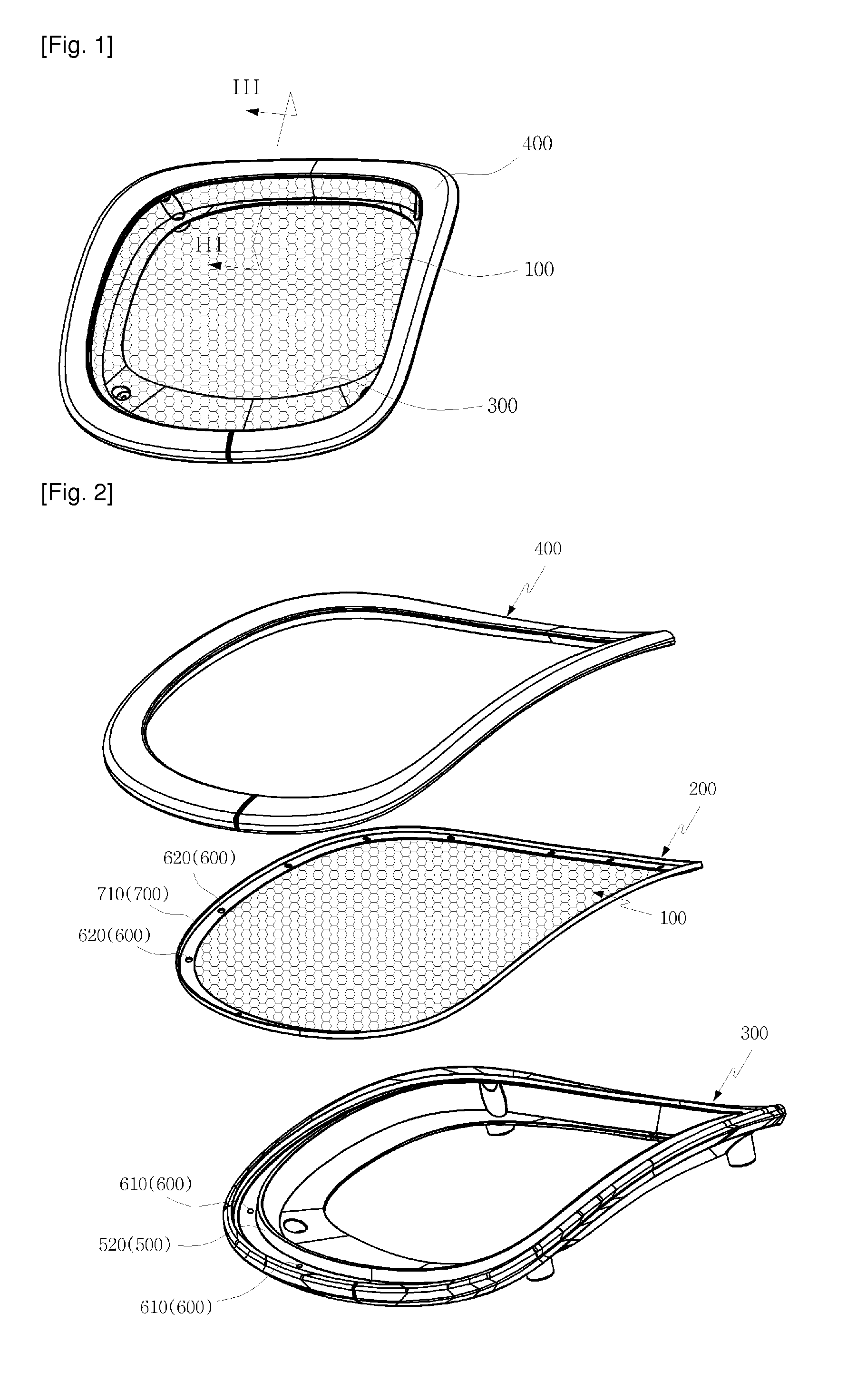

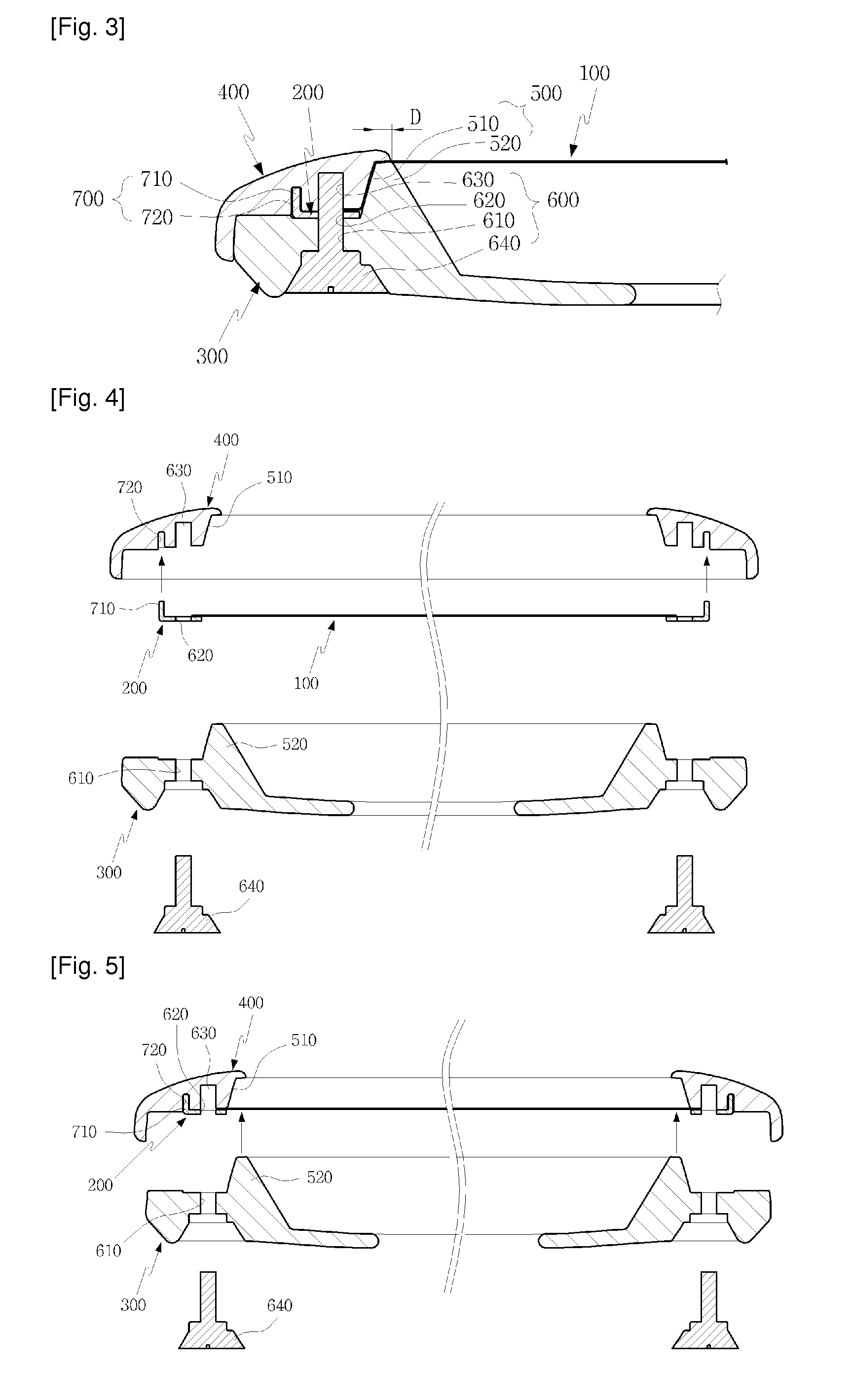

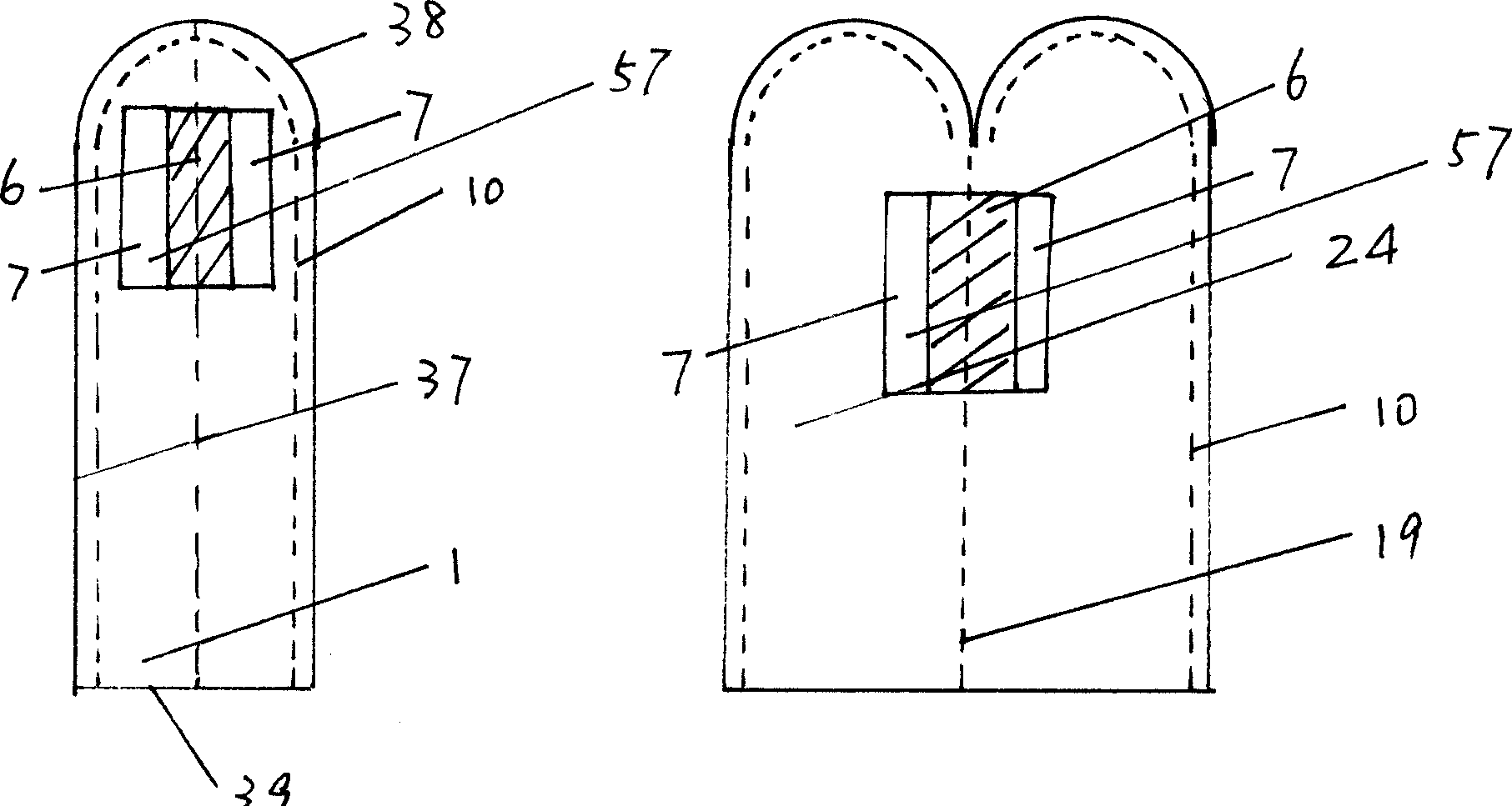

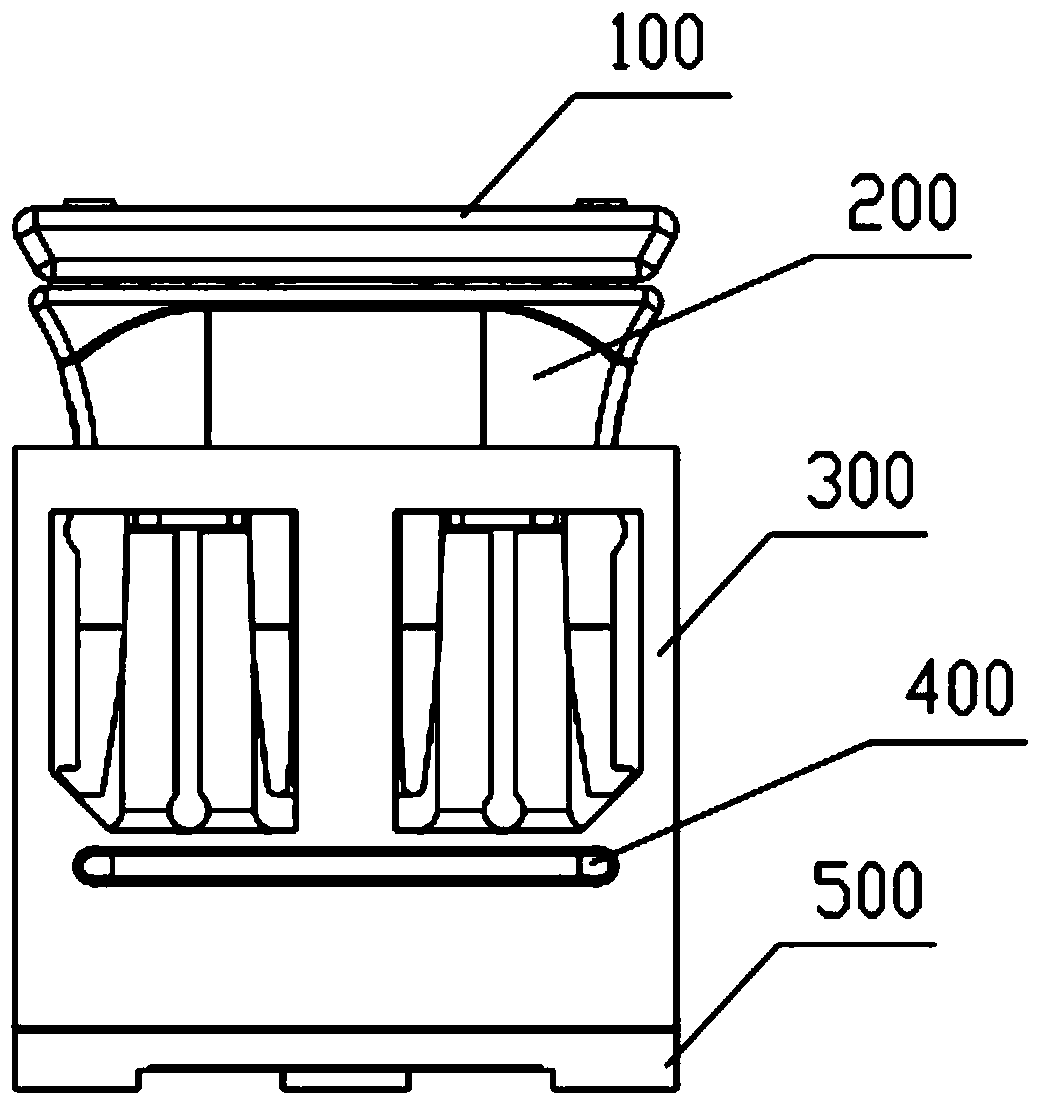

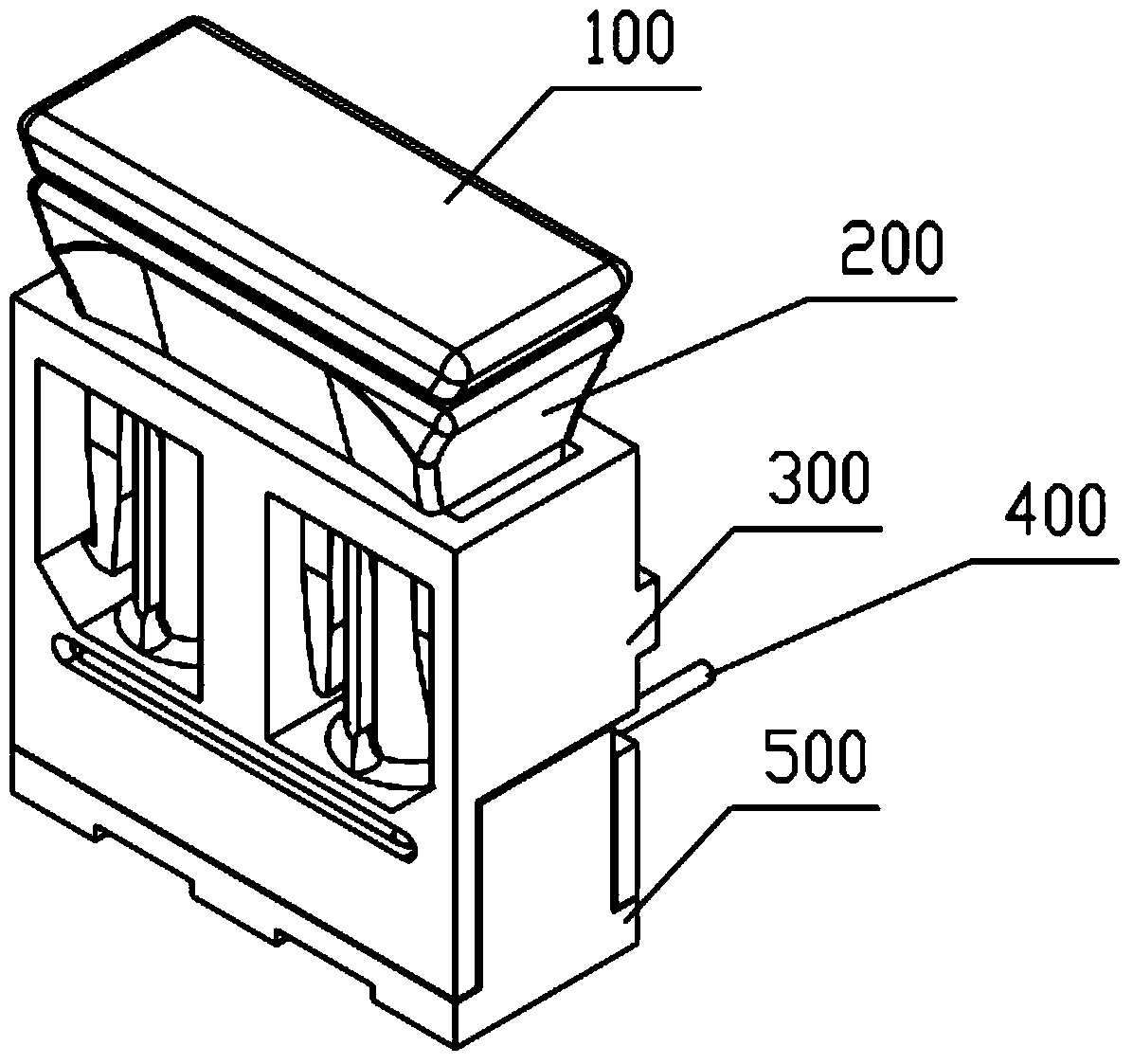

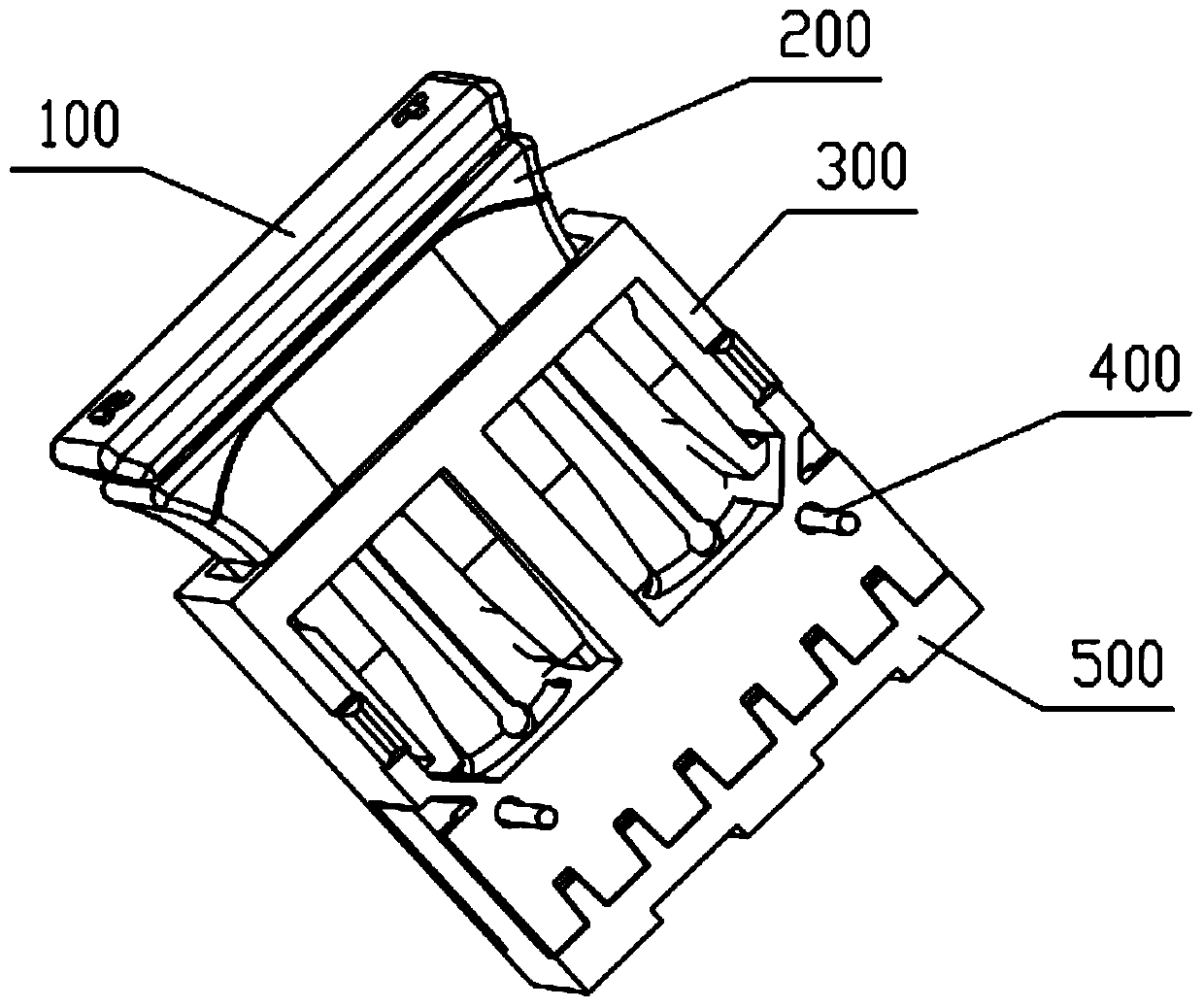

Assembly of mesh cushion in a mesh chair and assembling method thereof

ActiveUS20110169321A1Enough tensionPrevent from out frictionStoolsMetal working apparatusEngineeringMechanical engineering

In an assembly of a mesh cushion in a mesh chair and an assembling method thereof, a mesh member can be strongly fixed to a frame, enough tension can be provided to the mesh member with a simple scheme, and the edge of the mesh member can be prevented from being worn away, since the mesh type cushion assembly of a chair includes: a mesh member; a middle member fixing the edge of the mesh member; a frame and a cover that are assembled with each other so as to fix the middle member to between the frame and the cover; a tension part disposed between the frame and the cover so as to provide the mesh member with tension when the frame and the cover are assembled with each other; and a coupling unit coupling the frame and the cover to each other, and wherein, the mesh member is positioned between the frame and the cover.

Owner:DUOBACK KOREA

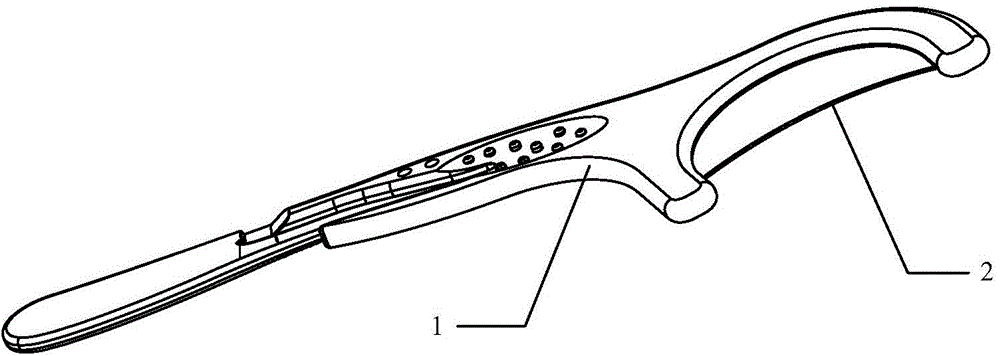

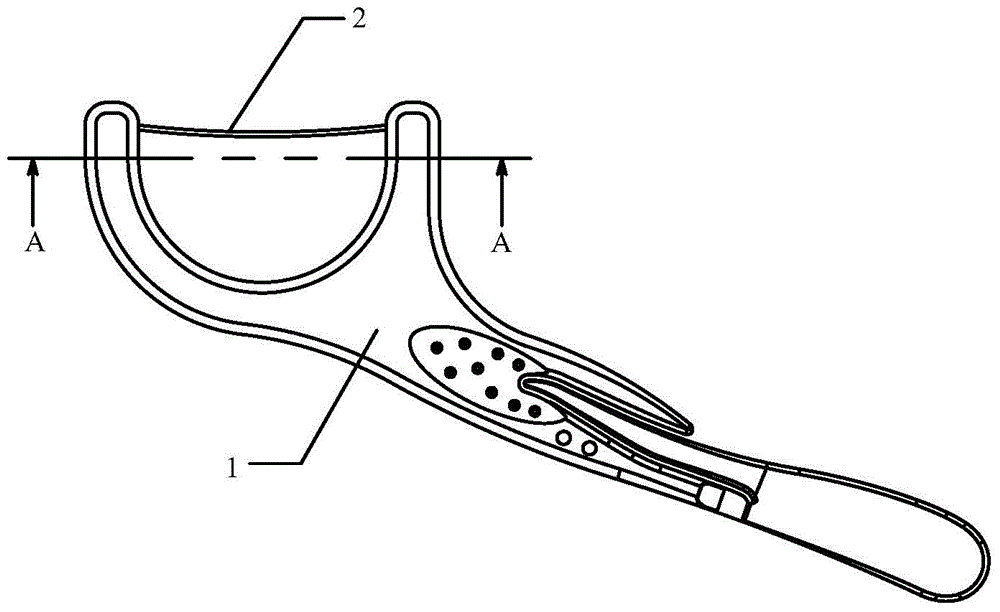

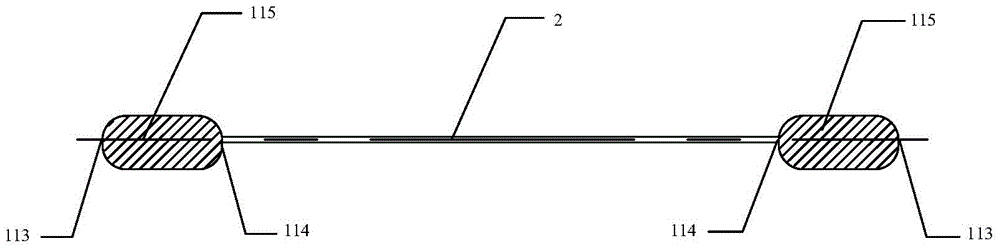

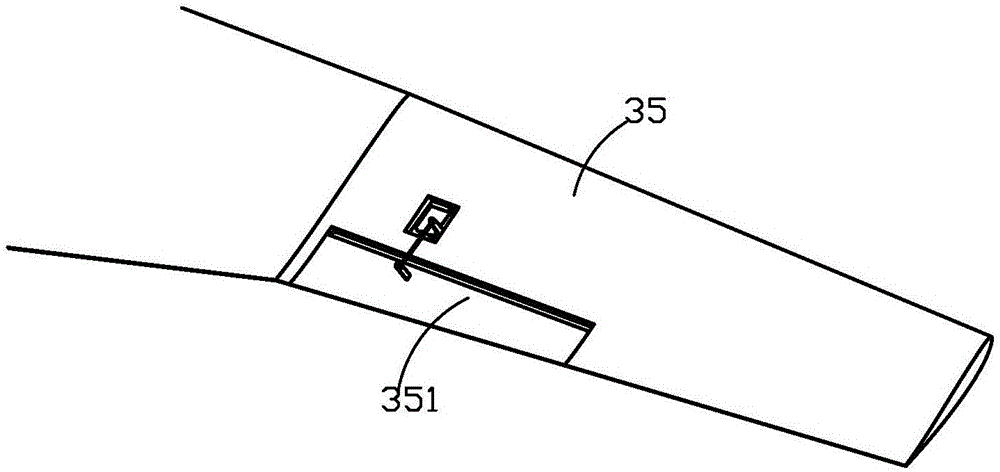

Dental floss stick with tight and straight dental floss as well as manufacturing equipment and manufacturing method for dental floss stick

The invention provides a dental floss stick with a tight and straight dental floss as well as manufacturing equipment and a manufacturing method for the dental floss stick. The dental floss stick comprises a handle and a dental floss bracket, wherein the dental floss bracket comprises a first bracket and a second bracket which are integrally molded; a dental floss which is tightened to be a straight line is arranged between the first bracket and the second bracket. Along the dental floss length direction, opposite sides of the first and the second brackets are inner sides, and the far-away sides of the first and the second brackets are outer sides; thicknesses of the first and the second brackets are gradually reduced from the outer sides to the inner sides. The manufacturing equipment is a special mould, depth of a part, corresponding to the dental floss bracket, of a mould cavity of the special mould is gradually shrunk and reduced from the outer side of the dental floss bracket to the inner side of the dental floss bracket. The dental floss stick is integrally injection-molded in the special mould; in the injection-molding process, the shrinking percentage of the part, closer to the outer side, of the material of the dental floss bracket part is relatively large, and the dental floss is tightened and straightened by tensile force produced by large shrinkage percentage of the outer side to form the dental floss stick with tight and straight dental floss. The obtained dental floss stick is suitable for various dental flosses, so that the dental floss has enough tension to meet oral-cavity cleaning needs.

Owner:赵瑞乐

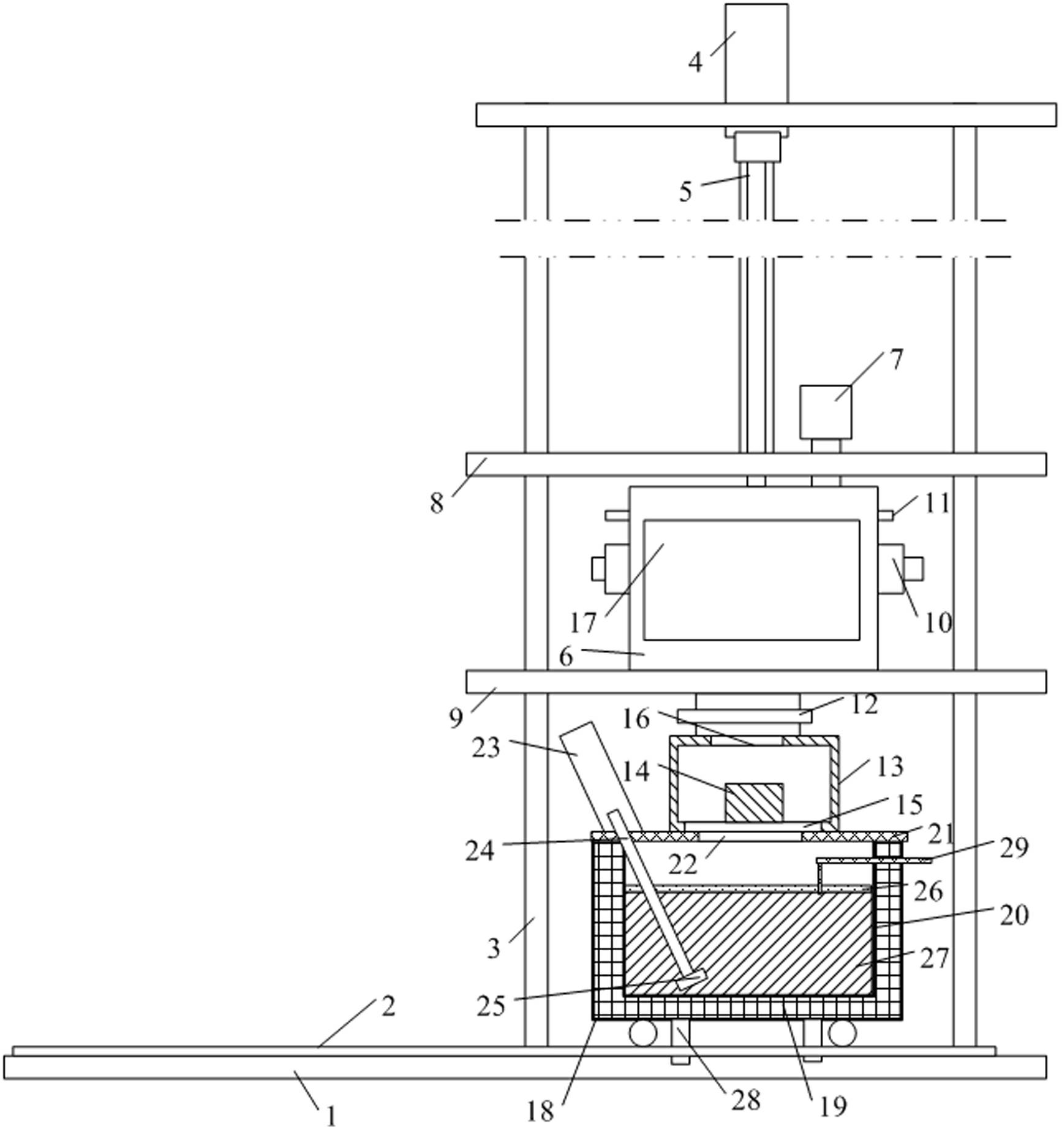

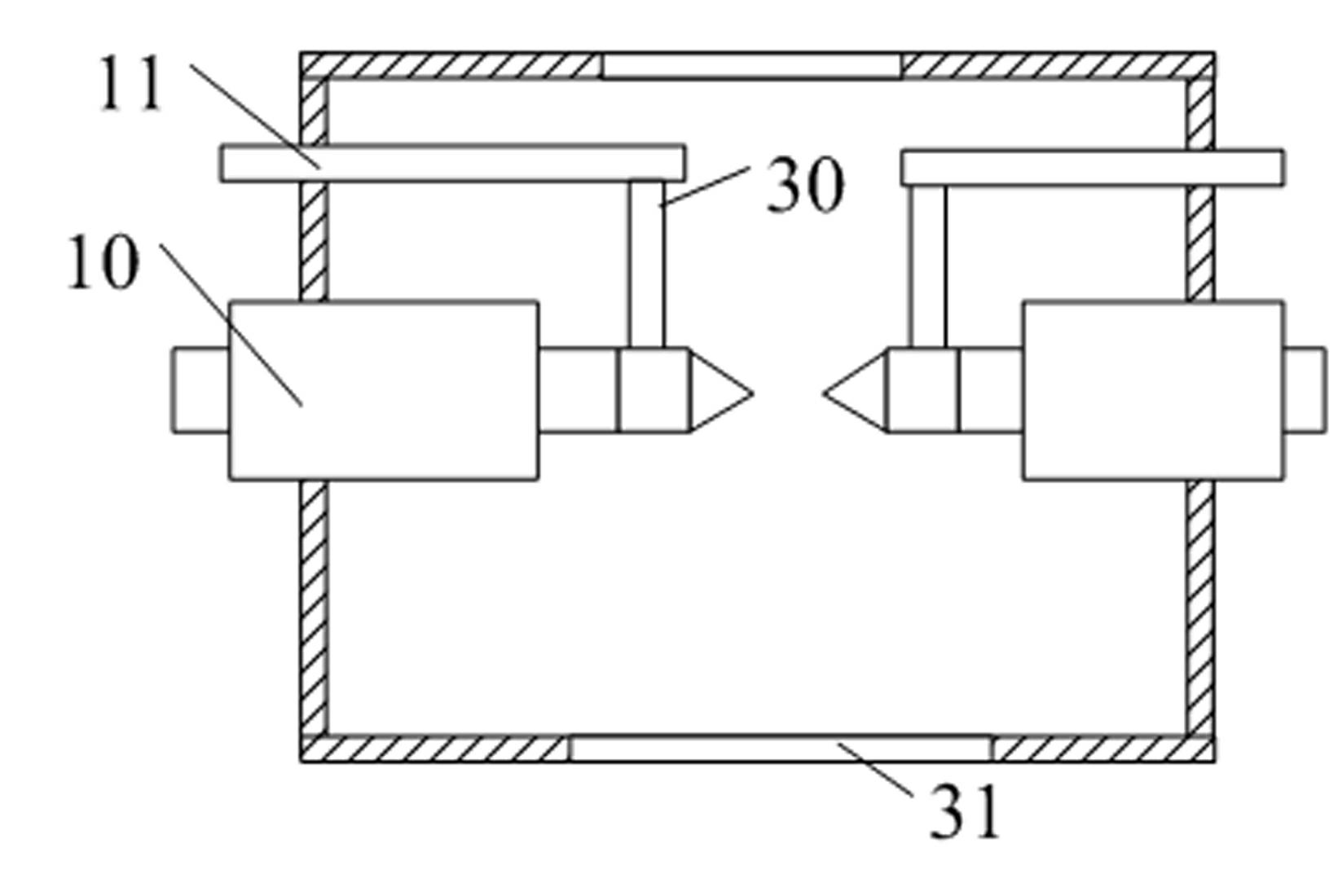

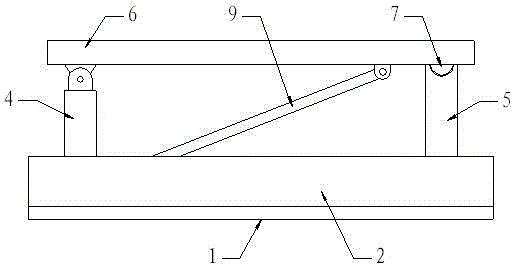

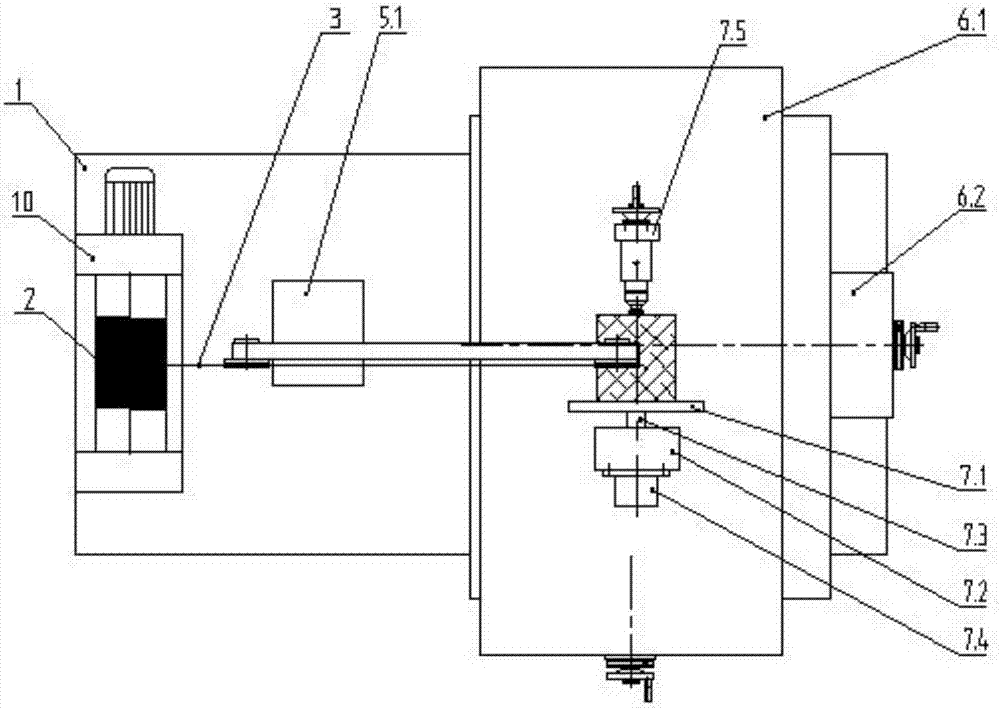

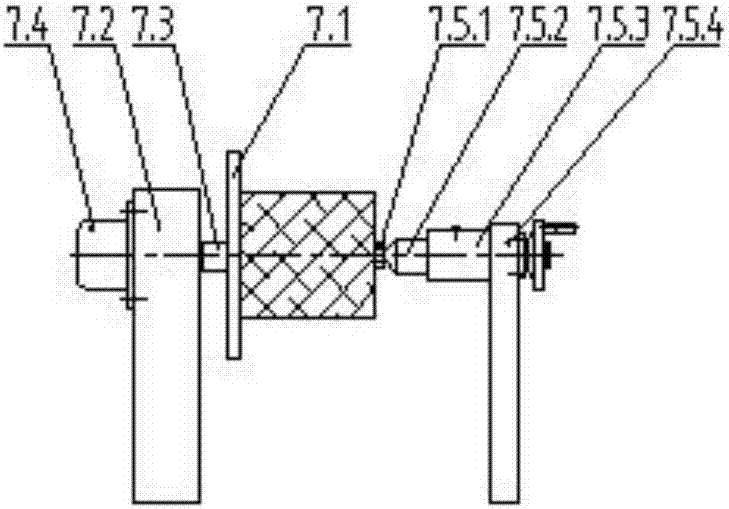

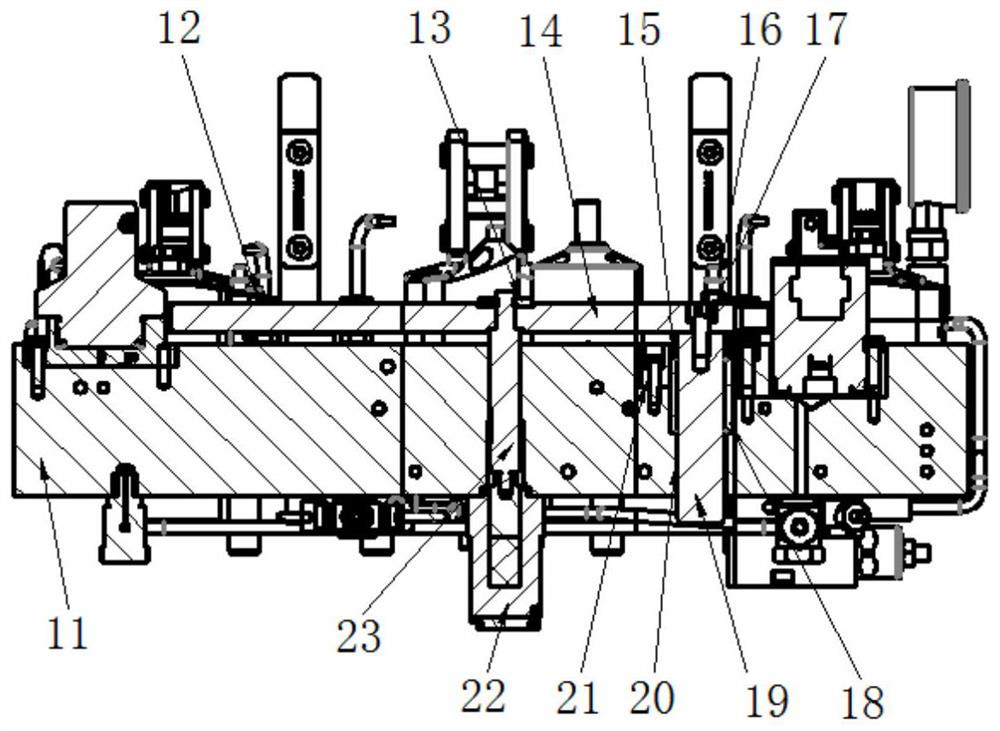

Test machine for simulating hot galvanizing of slat

ActiveCN102175709AQuick conversionQuick stretchHot-dipping/immersion processesMaterial thermal analysisEngineeringZinc

The invention relates to a test machine for simulating the hot galvanizing of a slat, wherein a rack is fixed on a base; an upper connecting plate and a lower connecting plate are arranged on the rack; a lifting device is fixed on the upper connecting plate; an operation box is fixed on the upper surface of the lower connecting plate; a hydraulic chuck device and a heating electrode are fixed in the operation box; a gate valve is fixed on the lower surface of the lower connecting plate; the lower surface of the gate valve is fixedly connected with an air knife chamber; an air knife device is arranged in the air knife chamber; a rail is arranged on the base; a trolley is arranged on the rail; a zinc pot is arranged in the trolley; a cover plate is arranged on the zinc pot; and a jack bolt is arranged at the bottom of the trolley. The device provided by the invention has the advantages of convenience in operatio, high simulation accuracy, safety, reliability, capability of repeatedly feeding through the trolley, convenience in repeated test and the like.

Owner:沈阳科安捷材料技术有限公司

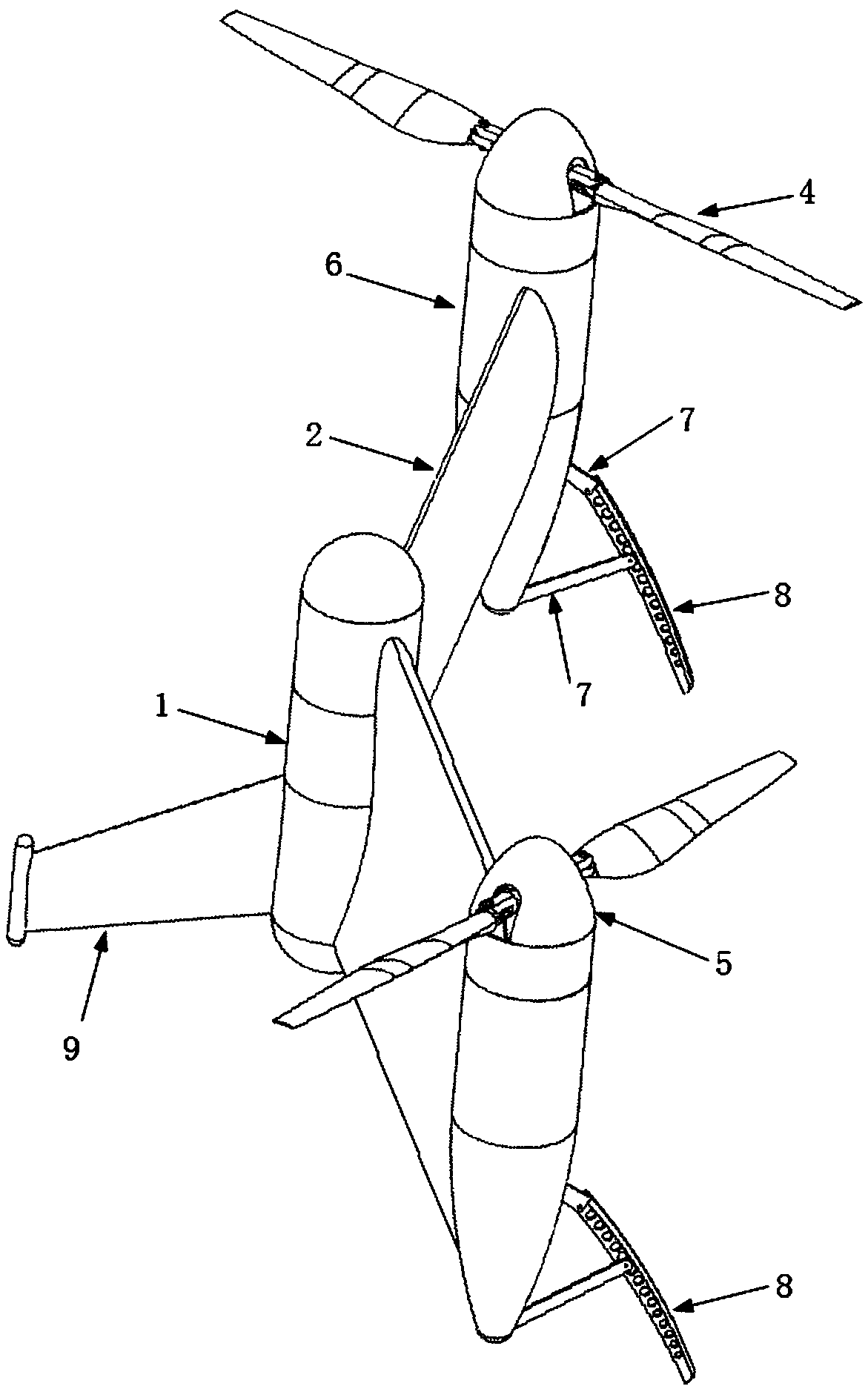

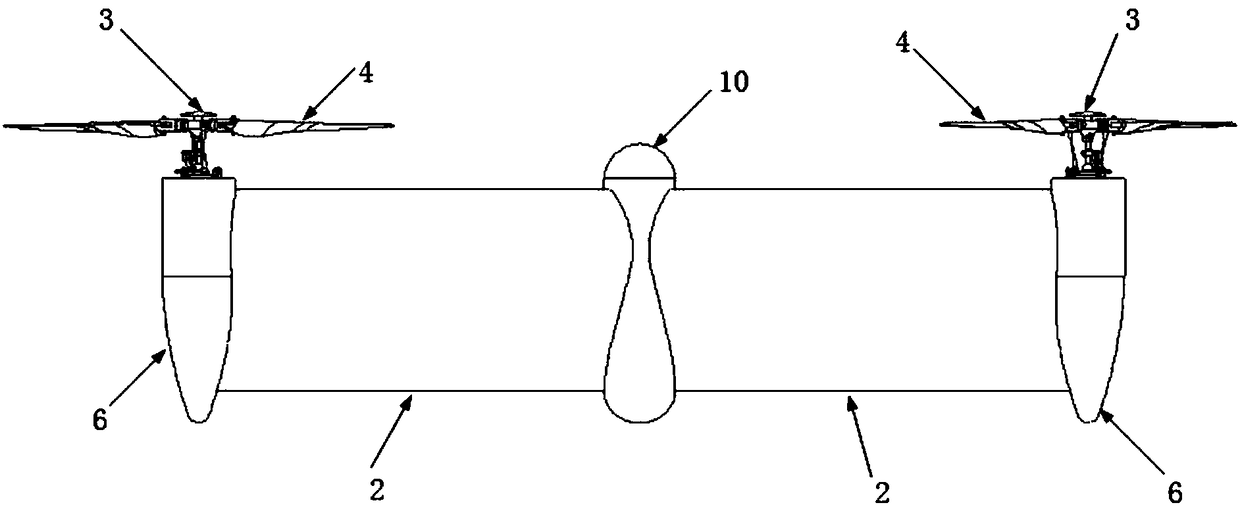

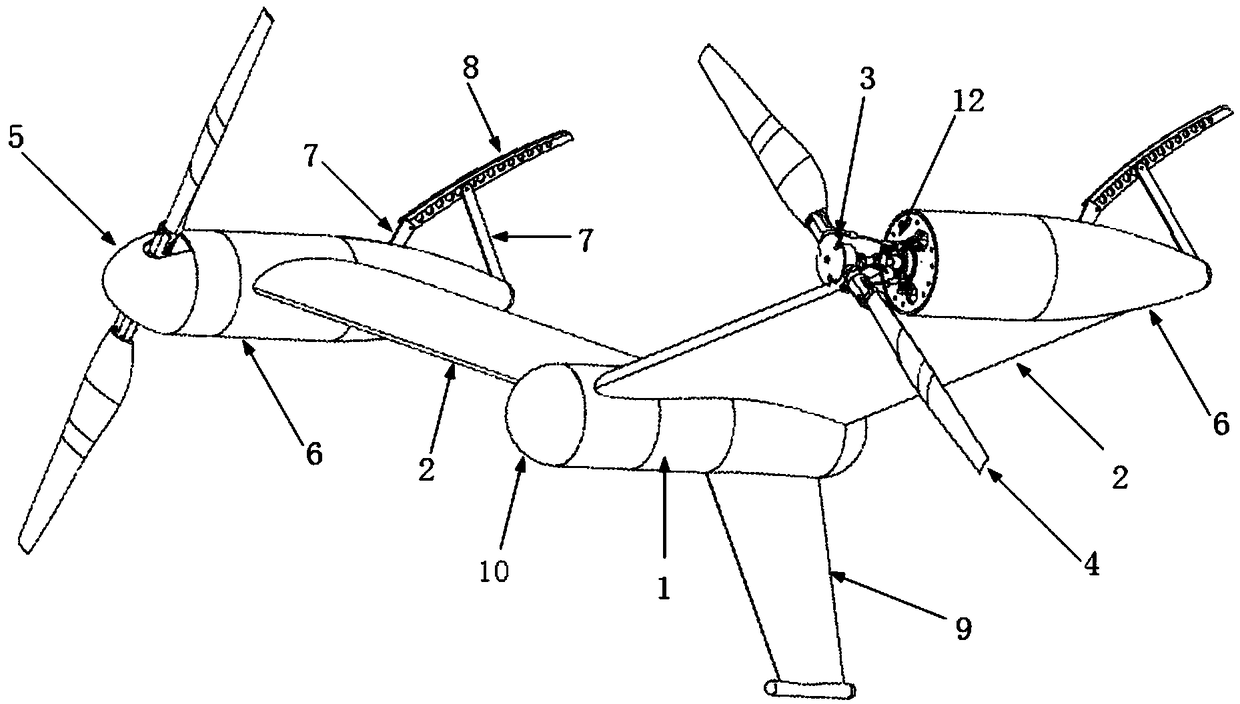

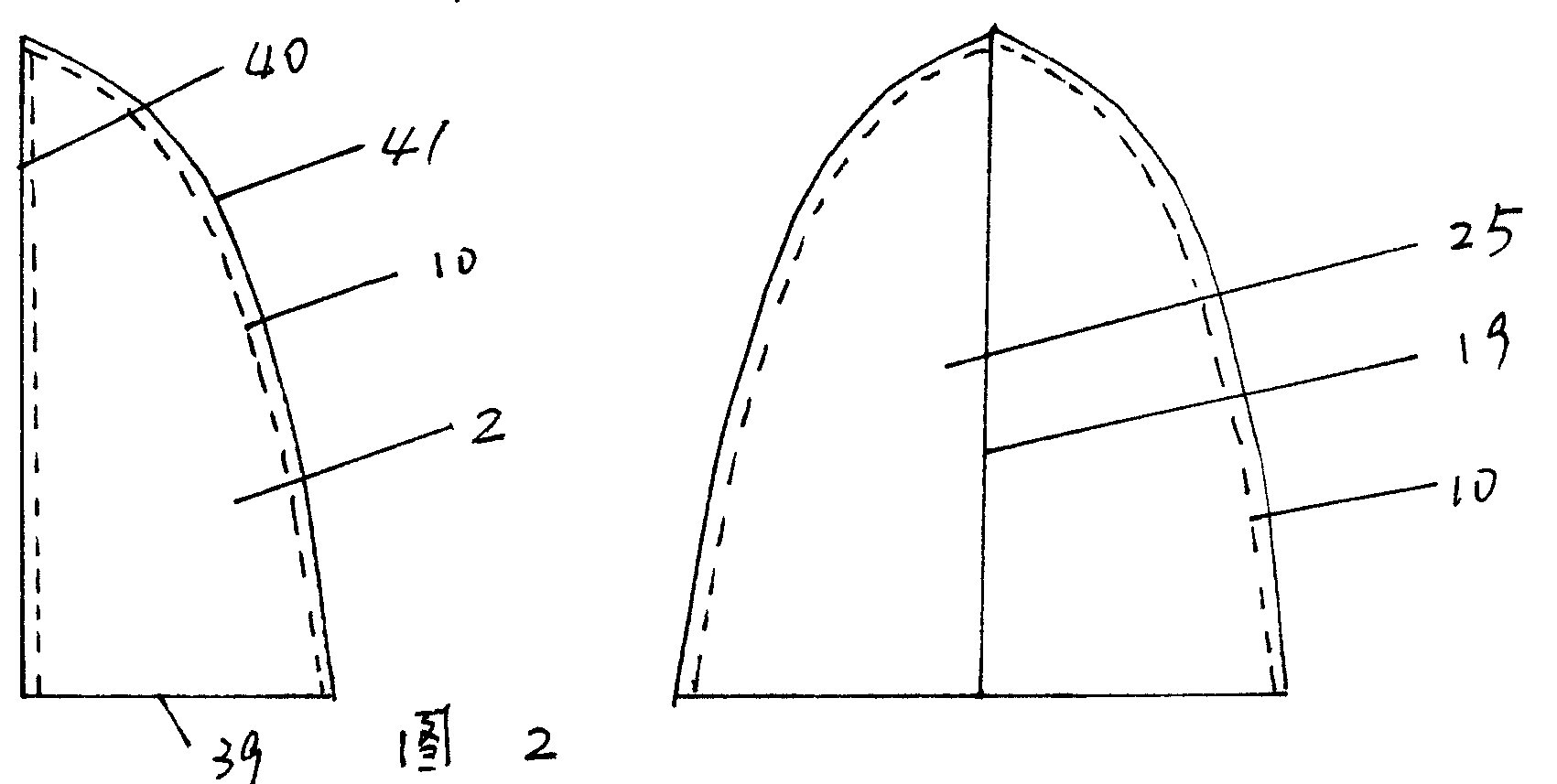

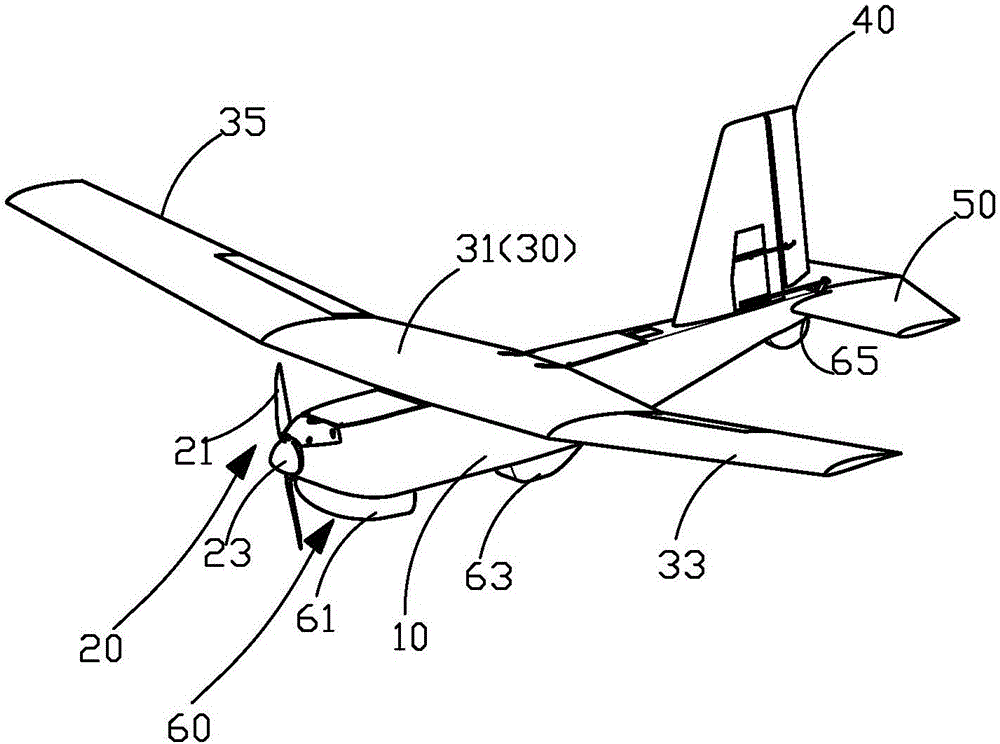

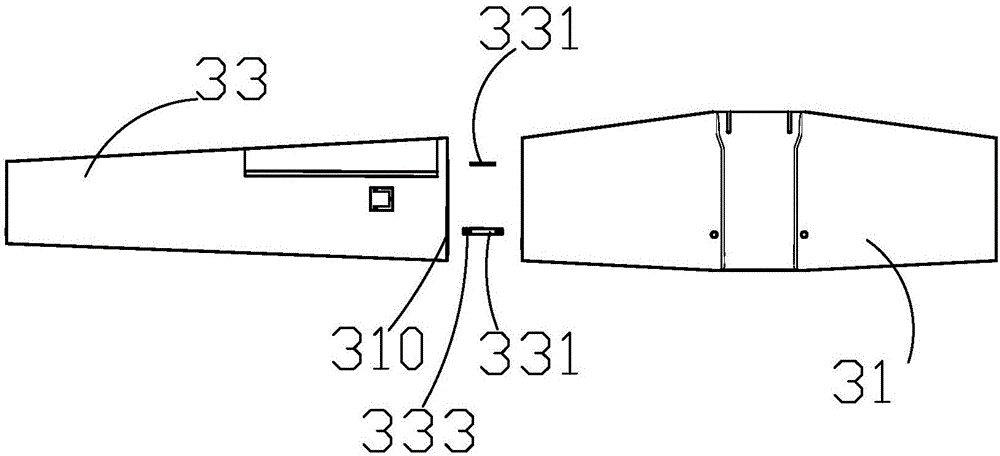

Double-rotor aircraft with folding wings, and control method of double-rotor aircraft

ActiveCN108528692AReduce your weightSimple structureFuselagesAir-flow influencersFlight vehicleAerial photography

The invention discloses a double-rotor aircraft with folding wings, and a control method of the double-rotor aircraft, and relates to the field of aircrafts. The double-rotor aircraft comprises a fuselage, and the two wings respectively positioned at the two sides of the fuselage, wherein the two wings are hinged with the fuselage and can rotate around the longitudinal axis of the fuselage; rotorsystems are respectively arranged at the ends, far away from the fuselage, of the two wings; the rotor systems use the periodic variable pitch generated by a built-in automatic tilter to change the aerodynamic forces and aerodynamic moments of rotors, thus realizing the control of the pitch, yaw and rolling motions of the aircraft. The aircraft uses the same set of operating system when operatingin a helicopter mode and an aircraft mode. Compared with the existing vertical take-off and landing aircraft applying two sets of operating systems, the double-rotor aircraft provided by the inventionis simpler and more reliable in design, and does not need a redundant operating mechanism no matter during vertical take-off and landing or flat flight; the utilization rate of the structural components of the aircraft is improved, and the excessive structural weight is reduced. The double-rotor aircraft with the folding wings is applicable to aerial photography and can also be used for individual military investigation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

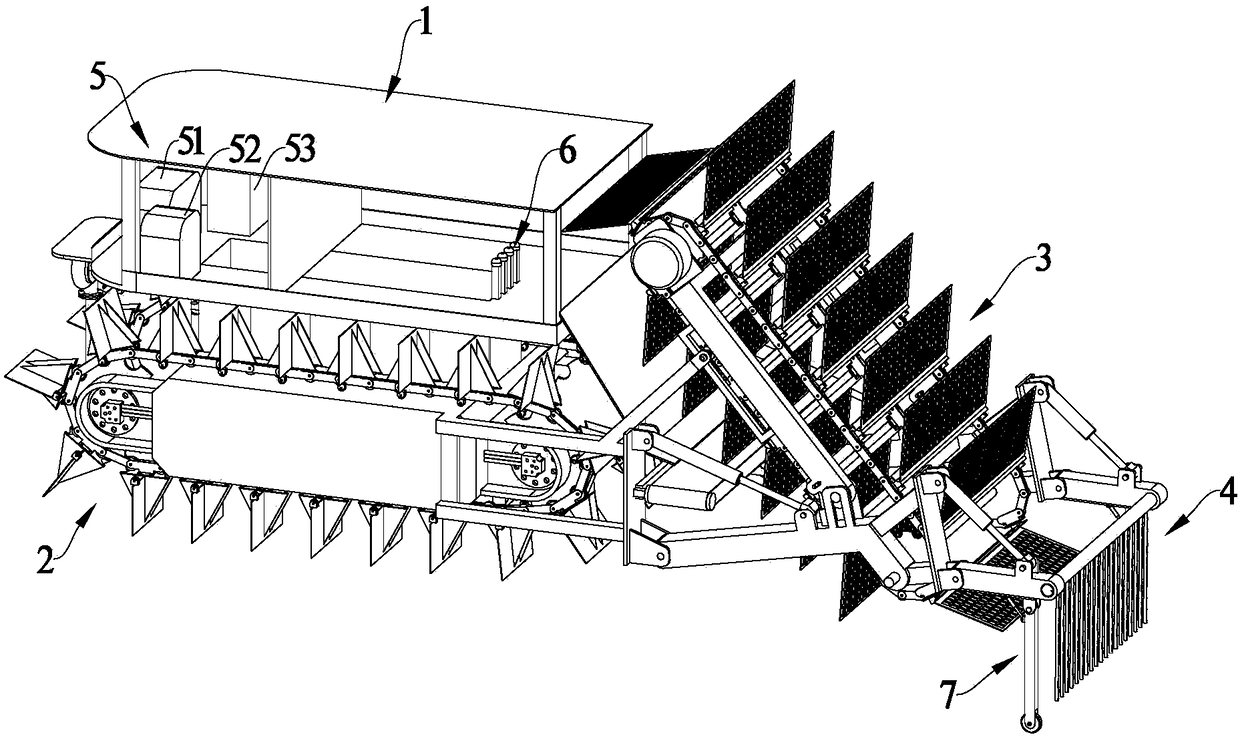

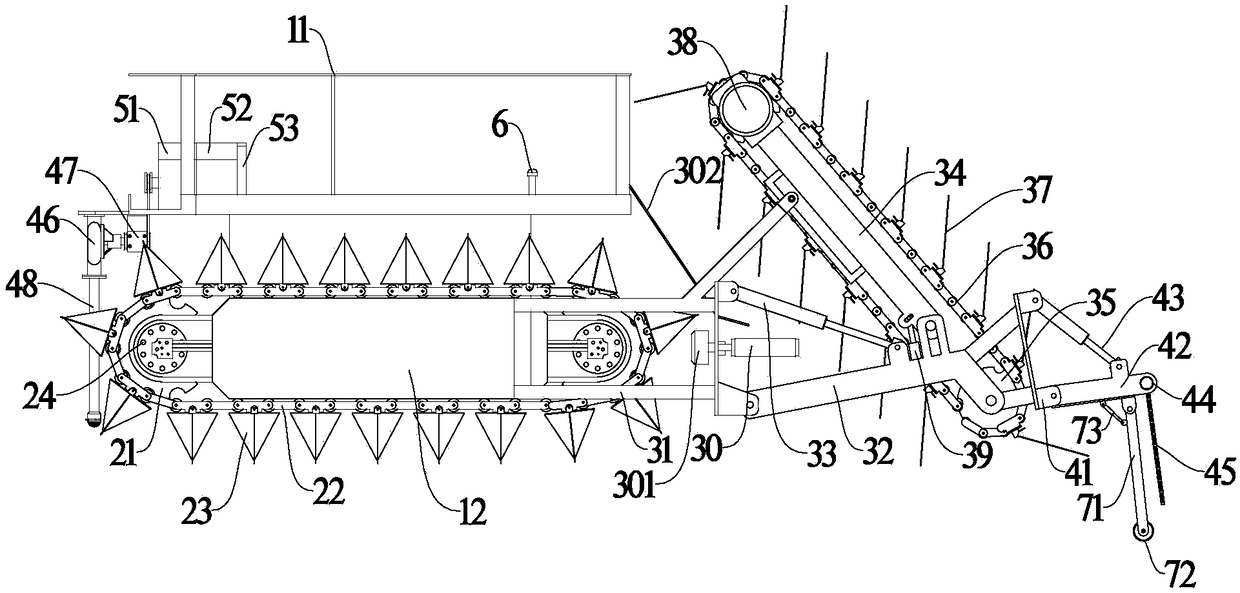

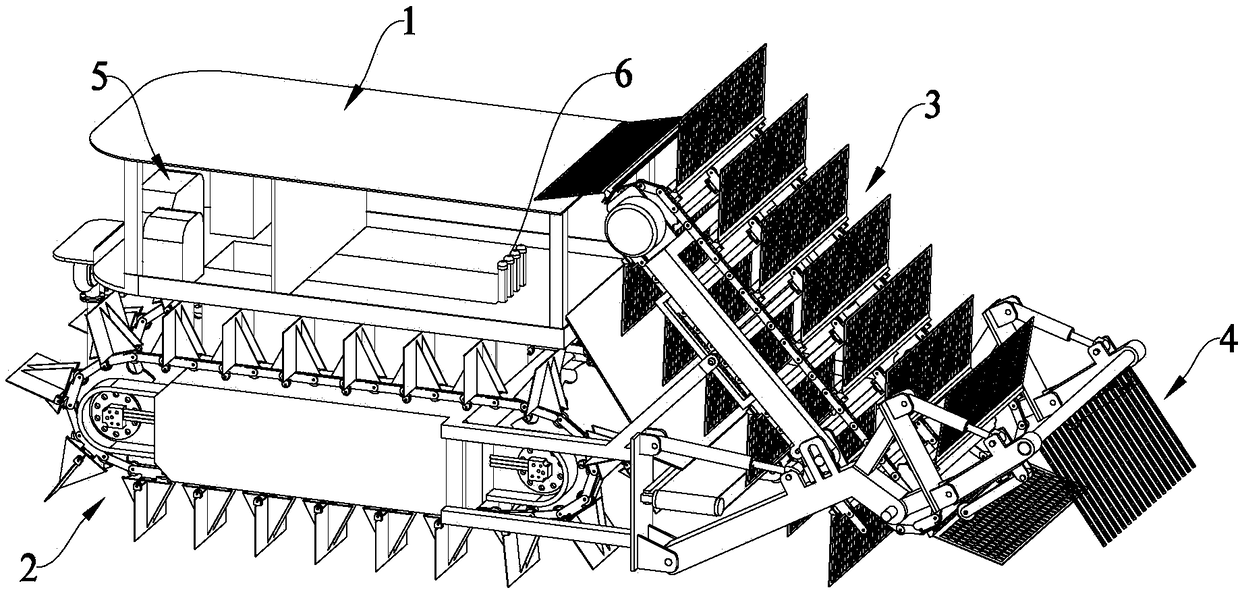

Shellfish collecting equipment

PendingCN108684620ASmooth travelImprove applicabilityPisciculture and aquariaClimate change adaptationEngineeringWater spray

The invention provides shellfish collecting equipment. The shellfish collecting equipment comprises a vehicle body part, walking parts, a collecting part, a water spraying part, a power part and a control part. The vehicle body part comprises a floating box and a cab arranged on the floating box. The two sets of walking parts are arranged on the two sides of the floating box respectively, and comprise walking gears, walking chains, walking feet and walking motors. The collecting part comprises a supporting base, a lower movable base, a first telescopic rod part, an upper movable base, a collecting gear, a collecting chain, a turning shovel net, a collecting motor and a conveying belt. The water spraying part comprises an installing base, a water pipe base, a second telescopic rod part, a main water pipe, an auxiliary water pipe, a water pump, an engagement and disengagement assembly and a water drawing pipe. The power part provides power and provides telescopic power of the first telescopic rod part and the second telescopic rod part. The control part carries out operation. The shellfish collecting equipment has the advantages of collecting razor clams, clams, baby clams and othershellfishes on mud flat.

Owner:易小兵

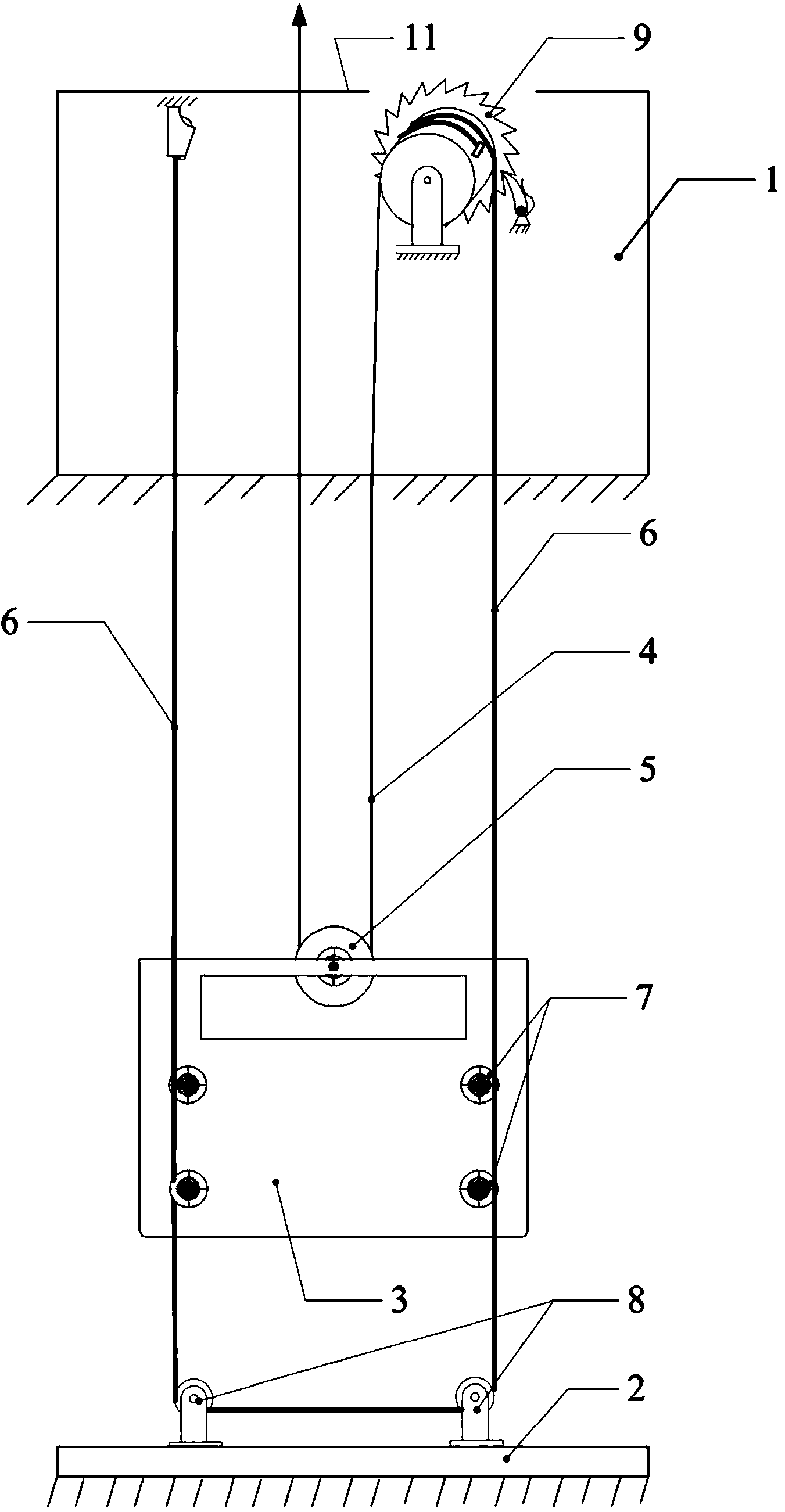

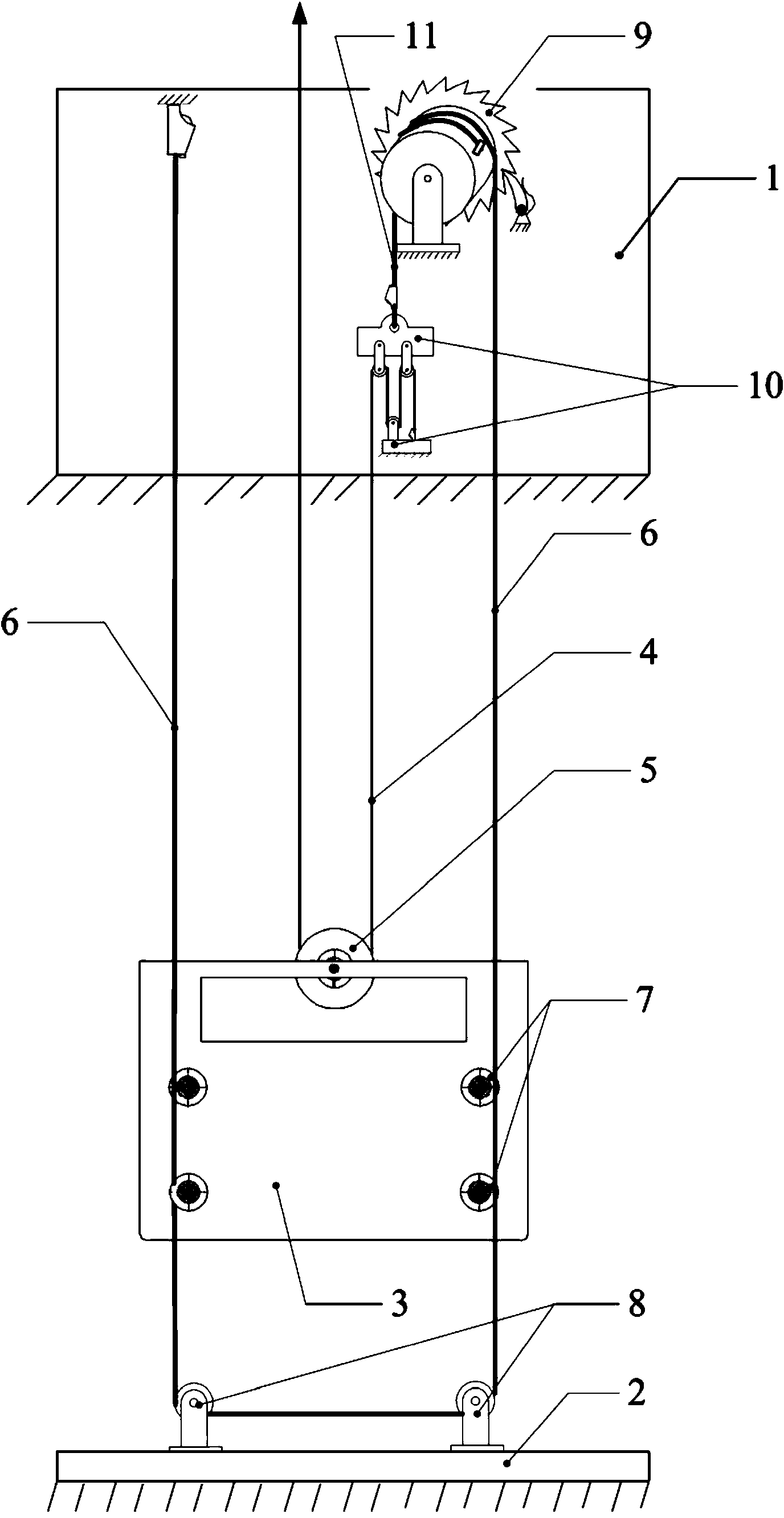

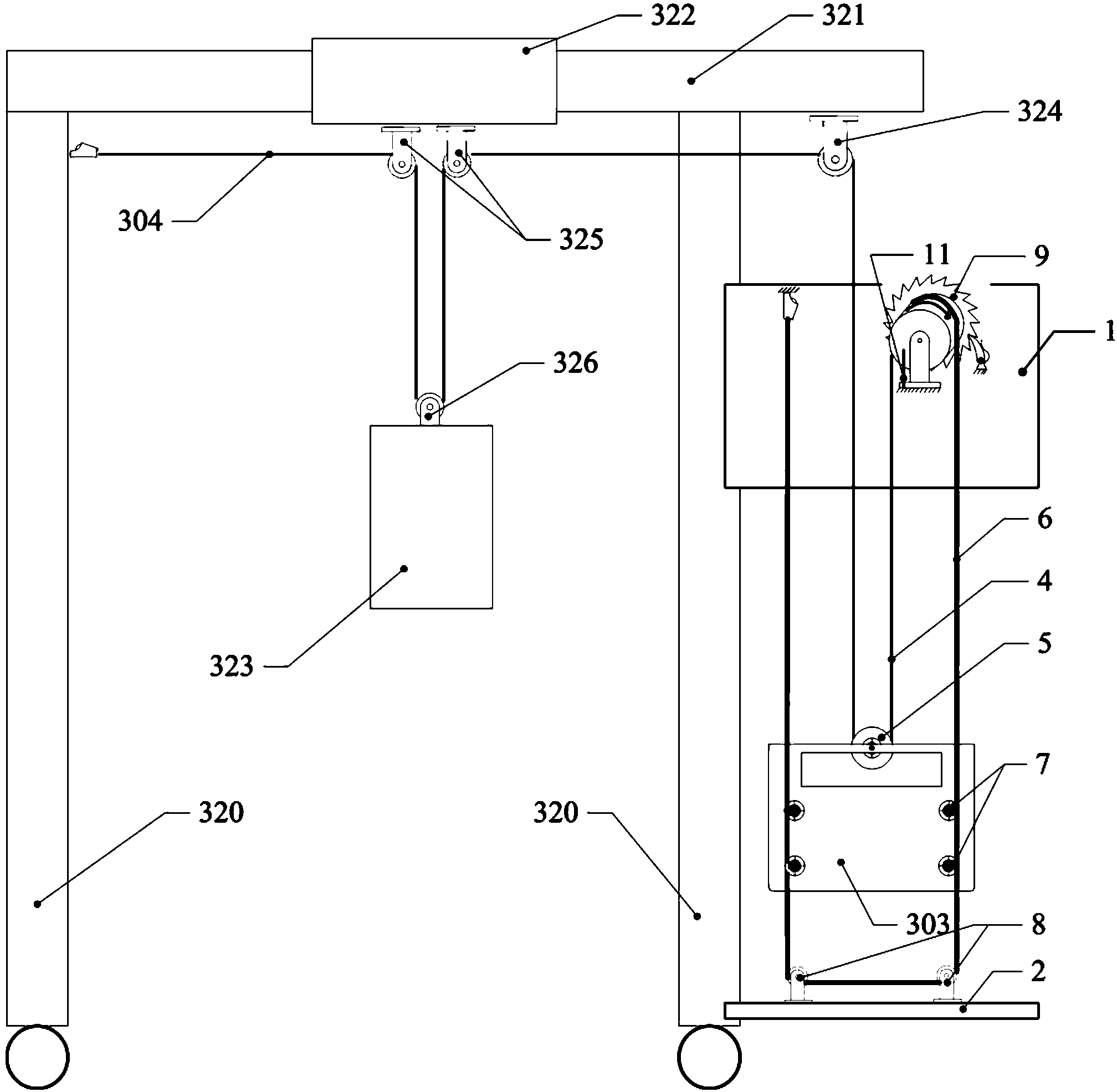

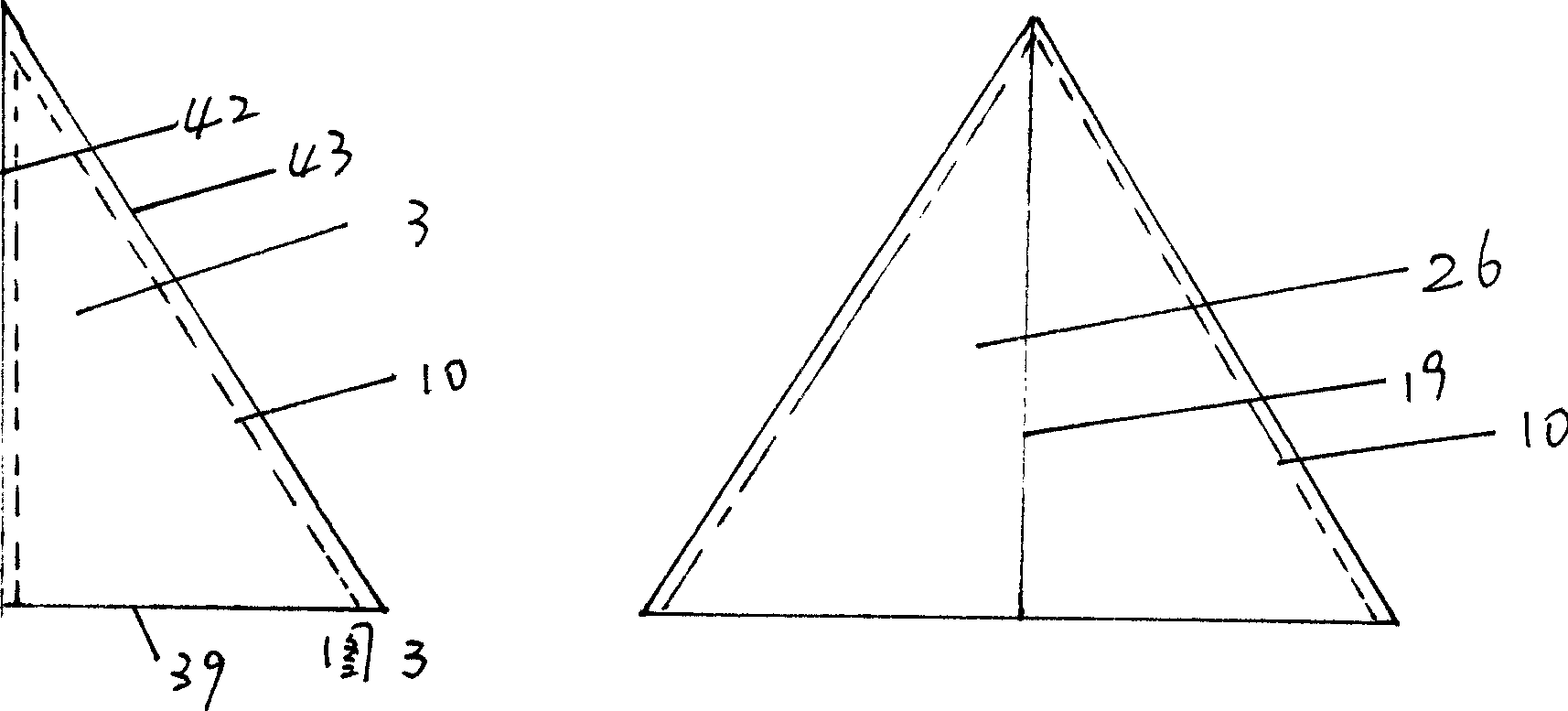

Entire flexible guide rail based on pulling force tension of lifting body and realization method thereof

InactiveCN103950808ARealize the rail function of counterweightSolve the flatnessElevatorsPull forceIndustrial engineering

The invention discloses an entire flexible guide rail based on the pulling force tension of a lifting body and a realization method thereof. The entire flexible guide rail comprises an entire guide rail steel wire rope; the entire guide rail steel wire rope forms flexible guide rails distributed in the lifting direction of the lifting body on the two sides of the lifting body through steering mechanisms; one end of the entire guide rail steel wire rope is fixed, the other end of the entire guide rail steel wire rope is pulled by the pulling force of the lifting body, and the entire guide rail steel wire rope is synchronously tensioned by the pulling force of the lifting body in the lifting process of the lifting body, so that the tensioning forces of the flexible guide rails on the two sides of the lifting body are the same. With the adoption of the technical scheme, the entire flexible guide rail can effectively solve the problem existing in an existing lifting body guide rail.

Owner:上海港研实业有限公司

Disposable finger stall toothbrush using pure natural plant fiber sponge as materials and its package

The present invention is a disposable finger stall toothbrush using pure natural plant fiber sponge as materials and its package. The public known superior characteristic pure natural plant fiber sponge is selected as material and is made to finger stall toothbrush by a sewing machine; the front end of the stall is disposed with bristles so that the teeth can be cleaned thoroughly and will not be damaged, and the machining work procedure is simple and the toothbrush can be produced easily. In order to take conveniently, the toothpaste bags with certain disposable using amount are used to pack paste shape, powder or slice shape toothpaste, and the toothpaste bags are parallel with the toothbrush and separated from it, that is the toothbrush and the toothpaste are respectively sealed by heat bonding mode and are made parallel to form an unique disposable package.

Owner:李韶华

Adjustable motor base

Owner:张振堂

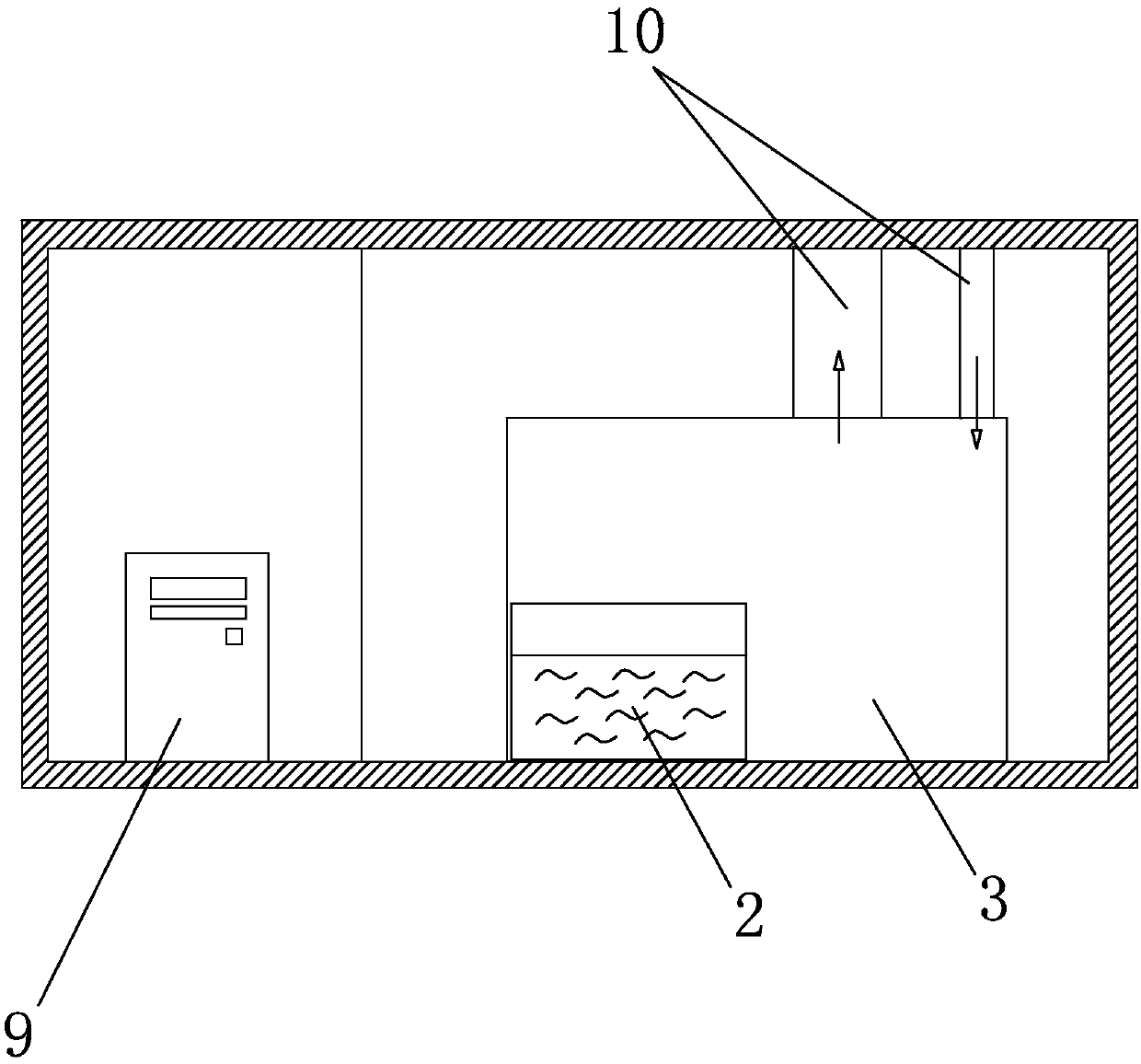

Car body repair device and method

ActiveCN109647935AImprove repair efficiencyImprove maintenance efficiencyMetal working apparatusRestoration deviceFuel tank

The invention discloses a car body repair device which comprises a tank, an oil tank arranged in the tank, a hydraulic control device, and a repair plate arranged on the tank. A repair pull rod is arranged in the repair plate; a sucking disc is arranged at the front end of the repair pull rod and can be tightly adsorbed onto the surface of a car body; the hydraulic control device is connected withthe oil tank through an oil conveying pipe; the hydraulic control device drives the repair pull rod to move in the repair plate; and the repair pull rod can pull out a concave surface of the car body. According to the car body repair device provided by the invention, the car body is repaired through a sucking disc adsorption principle, and the big concave surface on the car body can be pulled outand repaired, so that compared with manual repair, the efficiency is higher, and the maintained efficiency is improved.

Owner:GUANGDONG INST OF SCI & TECH

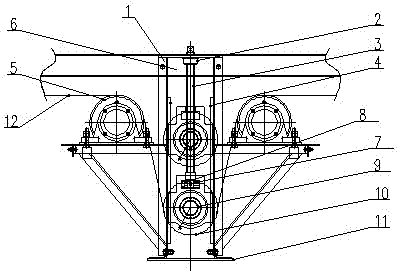

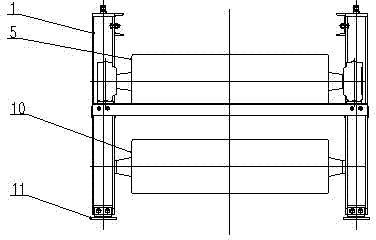

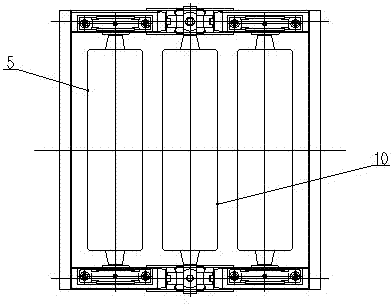

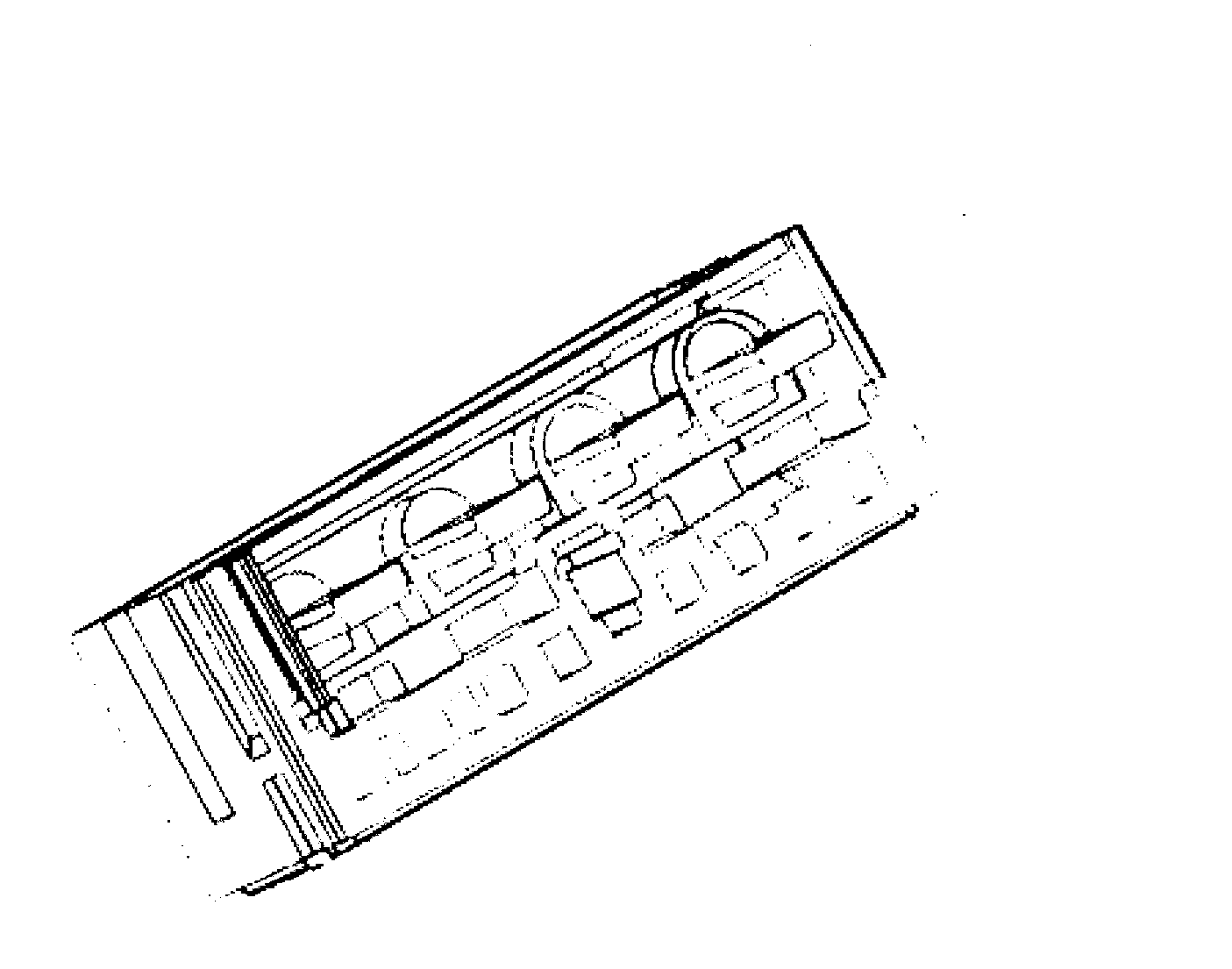

Roller line storage type sand line cutting machine tool

InactiveCN106881772AImprove flatnessSolve problems with visible streaksWorking accessoriesGrinding machinesEngineeringStorage type

The invention discloses a drum wire storage type sand wire cutting machine tool, which comprises a base, a wire storage drum, moving parts of the wire storage drum, a sand wire, a workbench assembly, a guide wheel assembly, a guide wheel support frame; a workbench assembly, a wire storage The moving parts of the barrel are arranged on the base at intervals; the workbench assembly includes a workbench, a vertical and horizontal movement mechanism; The moving parts of the wire barrel are driven to move horizontally left and right; the guide wheel assembly includes an upper front guide wheel, a lower front guide wheel, a tensioning wheel, and a lower rear guide wheel. On the front guide wheel and the lower rear guide wheel, a reciprocating wire routing structure is formed in the up and down direction; the worktable is equipped with a turntable clamp; the further improvement lies in: the tensioning wheel is equipped with a tensioning mechanism; the outer surface of the wire storage barrel is equipped with nylon or resin layer. The invention can realize streak-free cutting, has high cutting precision and long service life.

Owner:泰州市江洲数控机床制造有限公司

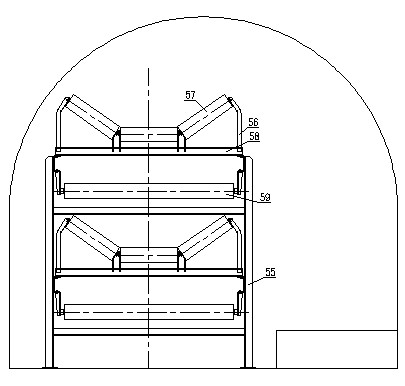

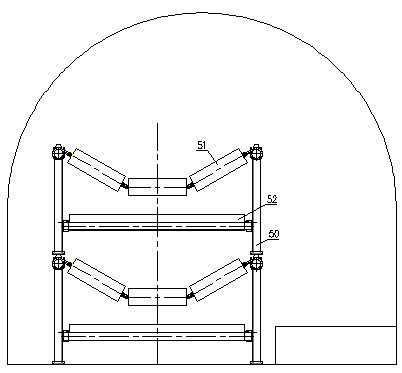

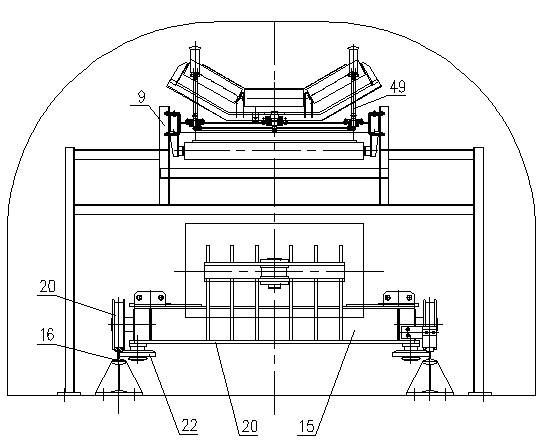

Double-layer double-conveying belt type conveyer for mine

InactiveCN102602659AHighly consistentShorten the lengthConveyorsEarth drilling and miningBelt conveyorFlange

The invention discloses a double-layer double-conveying belt type conveyer for a mine. Racks and adhesive tapes of two sets of belt conveyers are overlapped longitudinally; a tensioning direction-changing mechanism of the belt conveyer on the upper layer is located in front of a drive mechanism on the lower layer; a tensioning direction-changing mechanism of the belt conveyer on the lower layer is arranged in a trench below a mounting basal surface and is adjacent to the drive mechanism on the lower layer; each of wheels at two ends of a tensioning car is provided with a double-wheel flange; anti-derail wheels in contact with the side faces of a guide rail are arranged at two sides below a car body; a plurality of supporting legs of rectangular frames in the middle parts of the two sets of belt conveyers are all double-layer composite supporting legs; the double-layer composite supporting legs are provided with a plurality of adjustable hoops; the rectangular frames on the upper layerand the lower layer are arranged in the corresponding hoops respectively; and each of the rectangular frames on the upper layer and the lower layer is connected with a lower supporting roller by a mounting frame, a groove-shaped supporting roller and a concave arc-shaped supporting frame. The double-layer double-conveying belt type conveyer for the mine guarantees stable, safe and high-efficiencyrunning of equipment, is convenient to mount and wide in the range of application, and has high application value for small and medium mines, in particular for the improvement of old conveying roadways.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

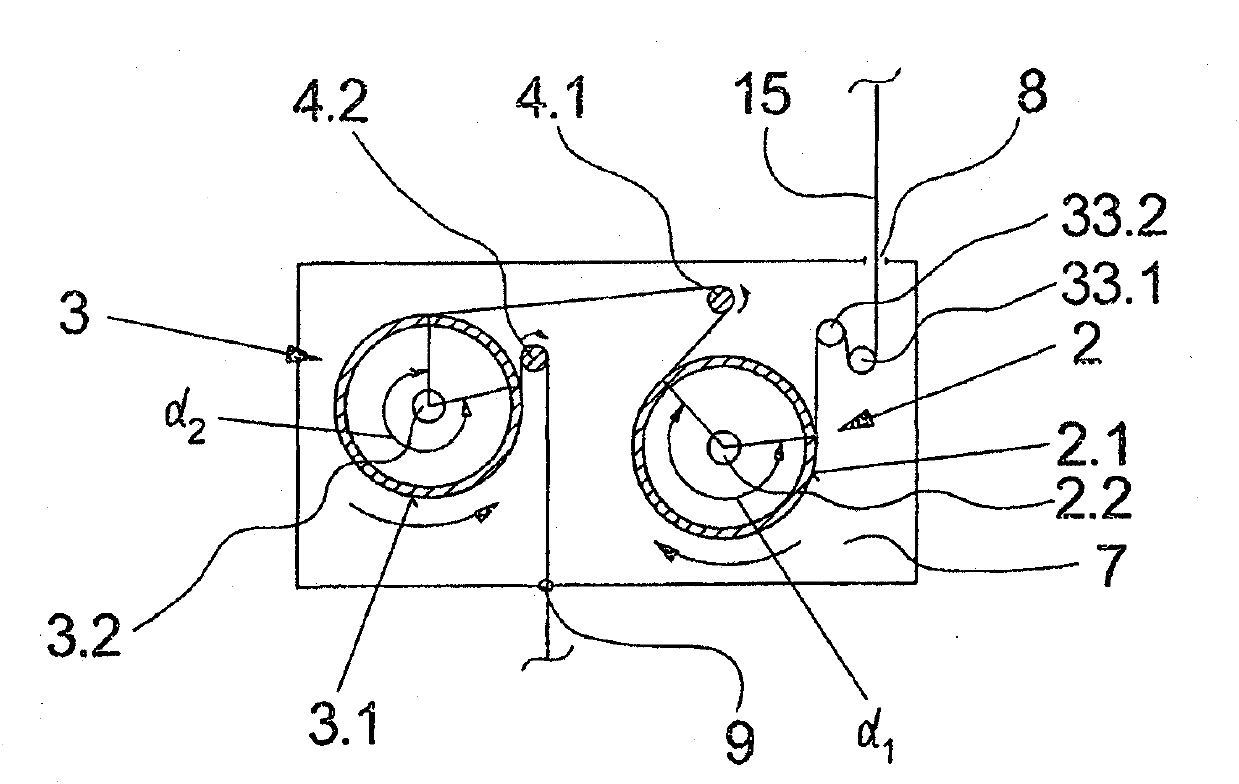

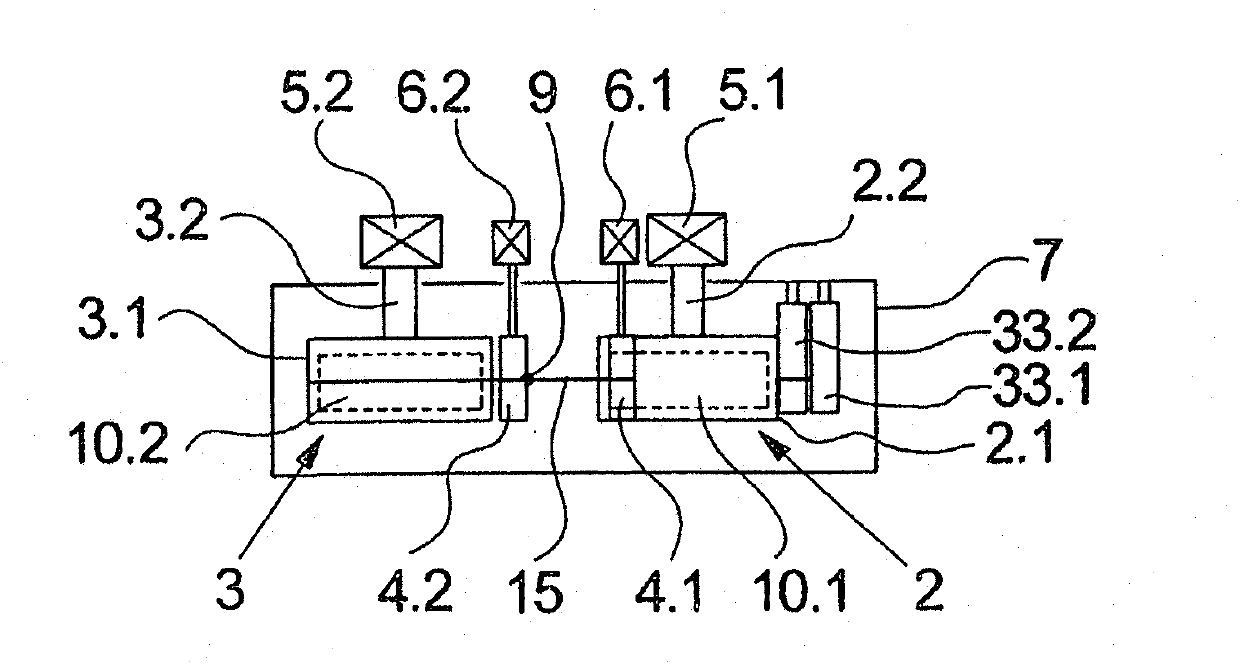

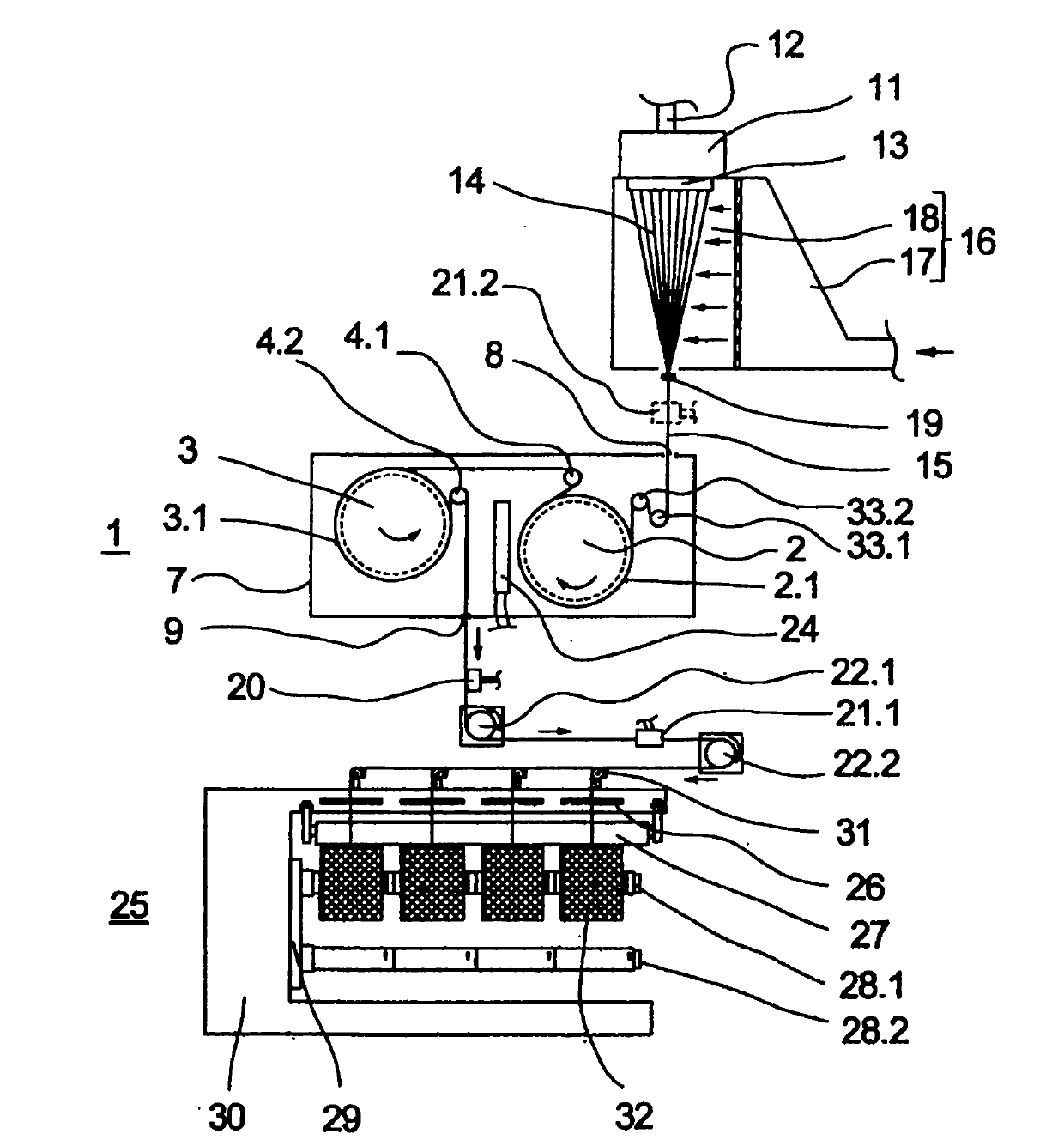

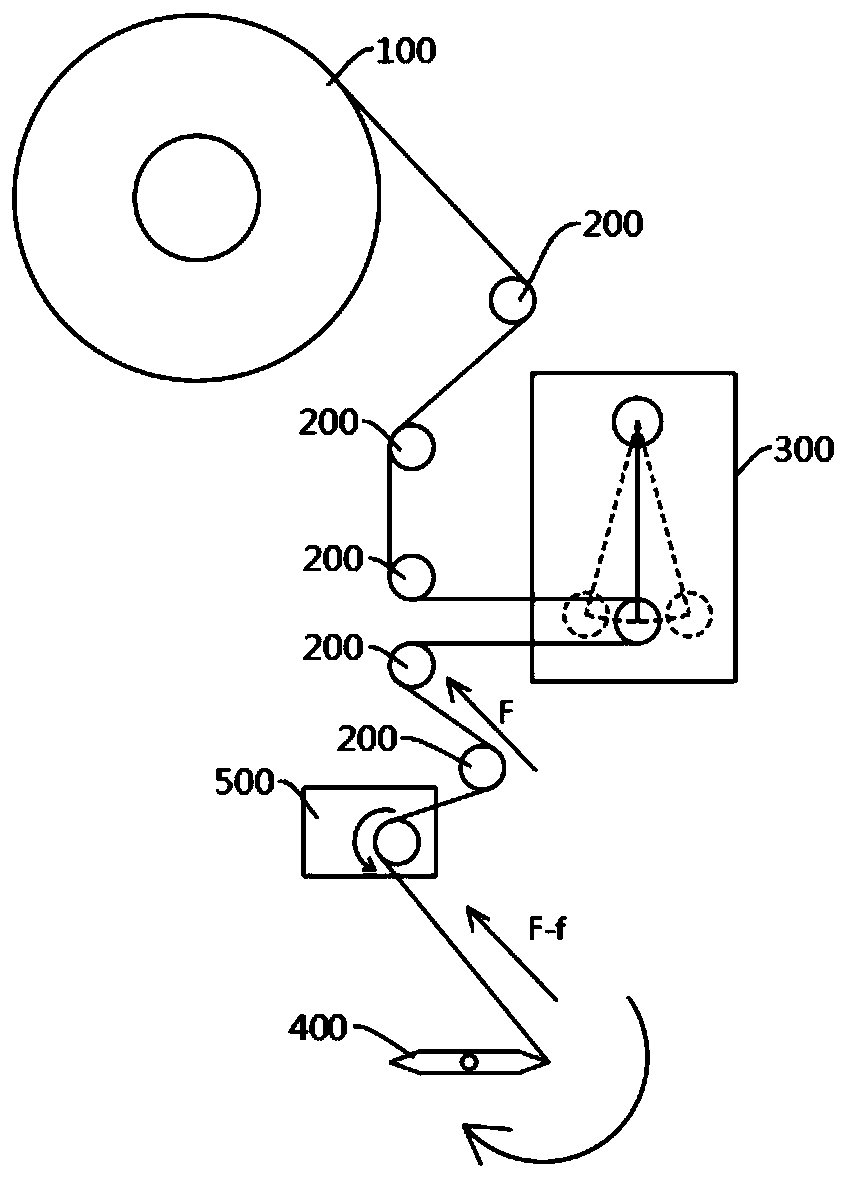

Method for taking up and drawing a multifilament during melt-spinning, and apparatus for carrying out said method

InactiveCN102016139AFull stressEnough tensionArtificial thread manufacturing machinesFilament manufacturePolymer scienceMelt spinning

The invention relates to a method and an apparatus for taking up and drawing a multifilament during melt-spinning. In said method and apparatus, the multifilament is guided on driven guiding sleeves of several godets, at least partially going therearound. Several guiding sleeves are heated. One of the guiding sleeves is driven at a circumferential speed exceeding 1,500 m / min so as to take up the multifilament, while at least one guiding sleeve located downstream is driven at least at twice said circumferential speed so as to draw the multifilament. In order to sufficiently heat the multifilament as the same goes around the guiding sleeves once and generate a sufficient tensile force on the multifilament, the multifilament is guided on the guiding sleeve that is driven for taking up the multifilament such that the multifilament and the guiding sleeve are in uninterrupted contact for a minimum length of 650 mm, the guiding sleeve being heated to a surface temperature ranging from 80 DEG C to 200 DEG C.

Owner:OERLIKON TEXTILE GMBH & CO KG

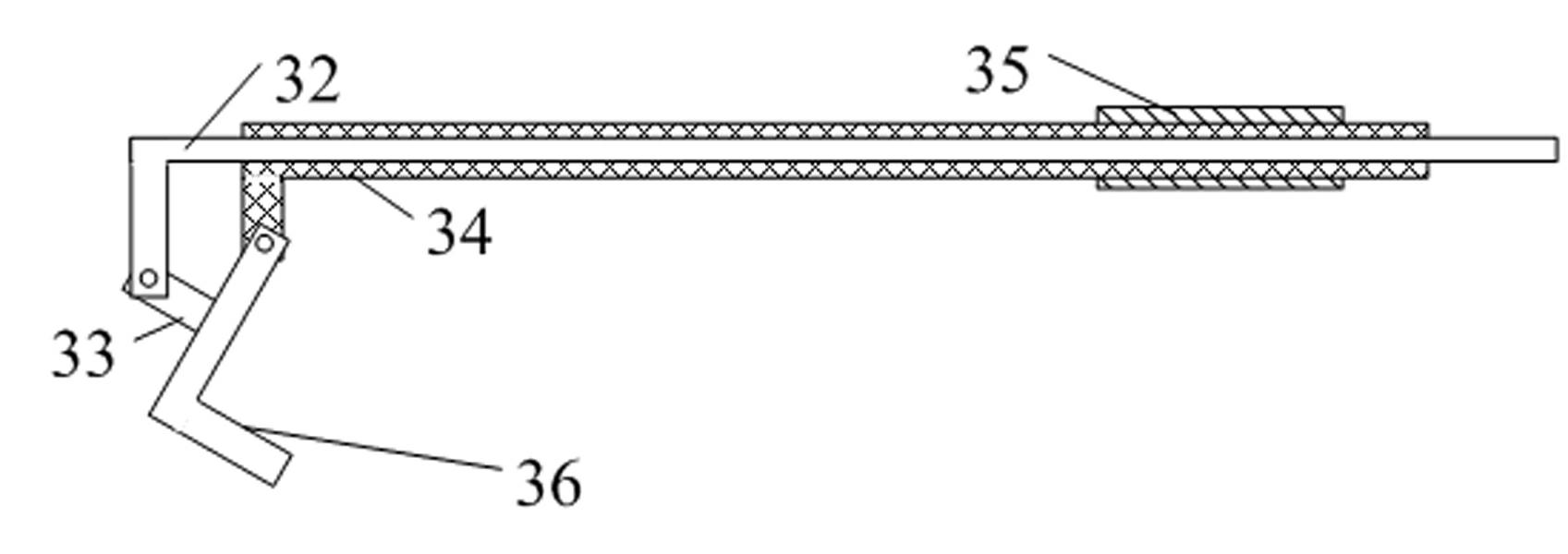

Solar panel cleaning device capable of cleaning up and down without power thereof

PendingCN105964587ASolve the fragileAvoid damagePhotovoltaicsCleaning using toolsEngineeringEnergy consumption

The invention relates to a solar panel cleaning device capable of cleaning up and down without power thereof. The solar panel cleaning device capable of cleaning up and down without power thereof comprises a solar panel, wherein a framework trolley is arranged on the solar panel; a cleaning trolley is arranged on the framework trolley; the upper end and the lower end of the cleaning trolley are separately connected to the two ends of a mooring rope; the mooring rope is wound on slide wheels at the upper end and the lower end of the framework trolley; a plurality of rows of cleaning hairbrushes are mounted on the cleaning trolley; and one side of each row of cleaning hairbrushes is separately provided with a gear which is arranged on a toothed bar. The solar panel cleaning device has the beneficial effects: when an inclination angle of the solar panel is relatively great, the trolley is not provided with a motor and is not needed to be provided with a power supply thereof, so that weight is small, energy consumption is reduced, and the problem that a power line is easily damaged due to long-term operation is avoided; the mooring rope is closed by the double slide wheels to pull the trolley in dual directions, so that the closed mooring rope is guaranteed to have enough tension for pulling the cleaning trolley to operate up and down in dual directions, the solar panel is not rubbed, and the solar panel can be effectively cleaned without being modified.

Owner:SHANDONG HAOWO ELECTRICAL CO LTD

Optical fiber connector

InactiveCN103869427AEnough connectionStrong enough connectionCoupling light guidesTransceiverEngineering

The invention discloses an optical fiber connector which comprises a clamp, a main body and a rear cover, wherein the main body is provided with a cavity which is used for containing an external optical transceiver pair; the rear cover is fixed to a buckle of the main body and is used for fixing the optical transceiver pair; the clamp is movably mounted on the main body; two guide pipes are arranged in the main body; the clamp is correspondingly provided with two mounting openings; a group of clamping sheets are arranged beside each mounting openings and comprise outer clamping parts and inner clamping parts; first ends of the outer clamping parts and the inner clamping parts are respectively and fixedly arranged on the clamp; the guide pipes are hollowly arranged and are used for penetrating through an external optical fiber; each guide pipe comprises at least two clamping parts which are arranged annularly to form the guide pipe; at least one convex part is arranged on the inner wall of each clamping part; a first end of each clamping part is fixedly arranged on the main body and is used for matching with the outer clamping parts and the inner clamping parts; when the clamping is mounted, the gaps between the outer clamping parts and the inner clamping parts are shrunk, each clamping part is clamped, the gap between adjacent clamping parts is shrunk, and optical fibers in the middle of the guide pipes are clamped by matching with each convex part.

Owner:SHENZHEN HAOTONGJIA IND

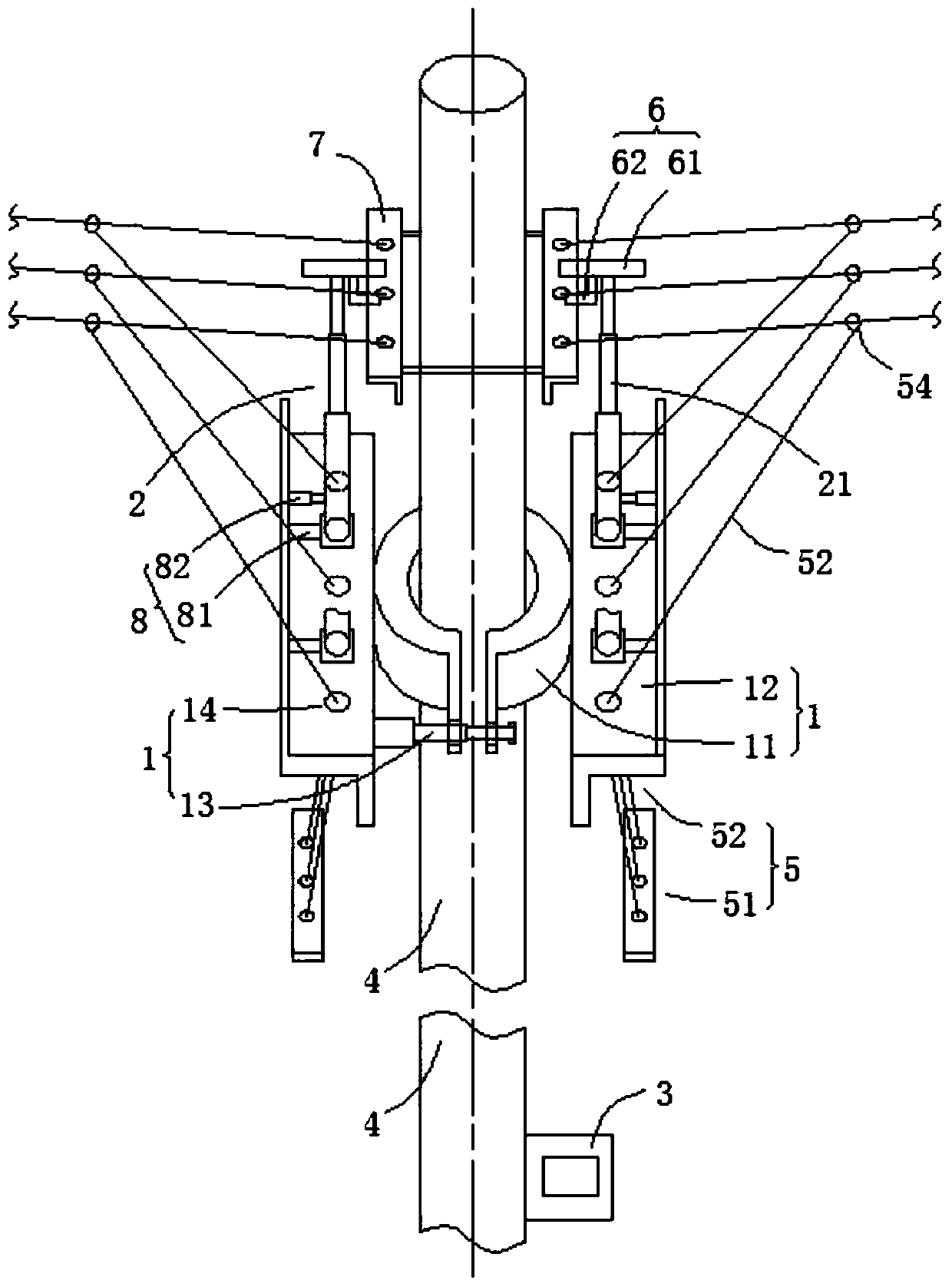

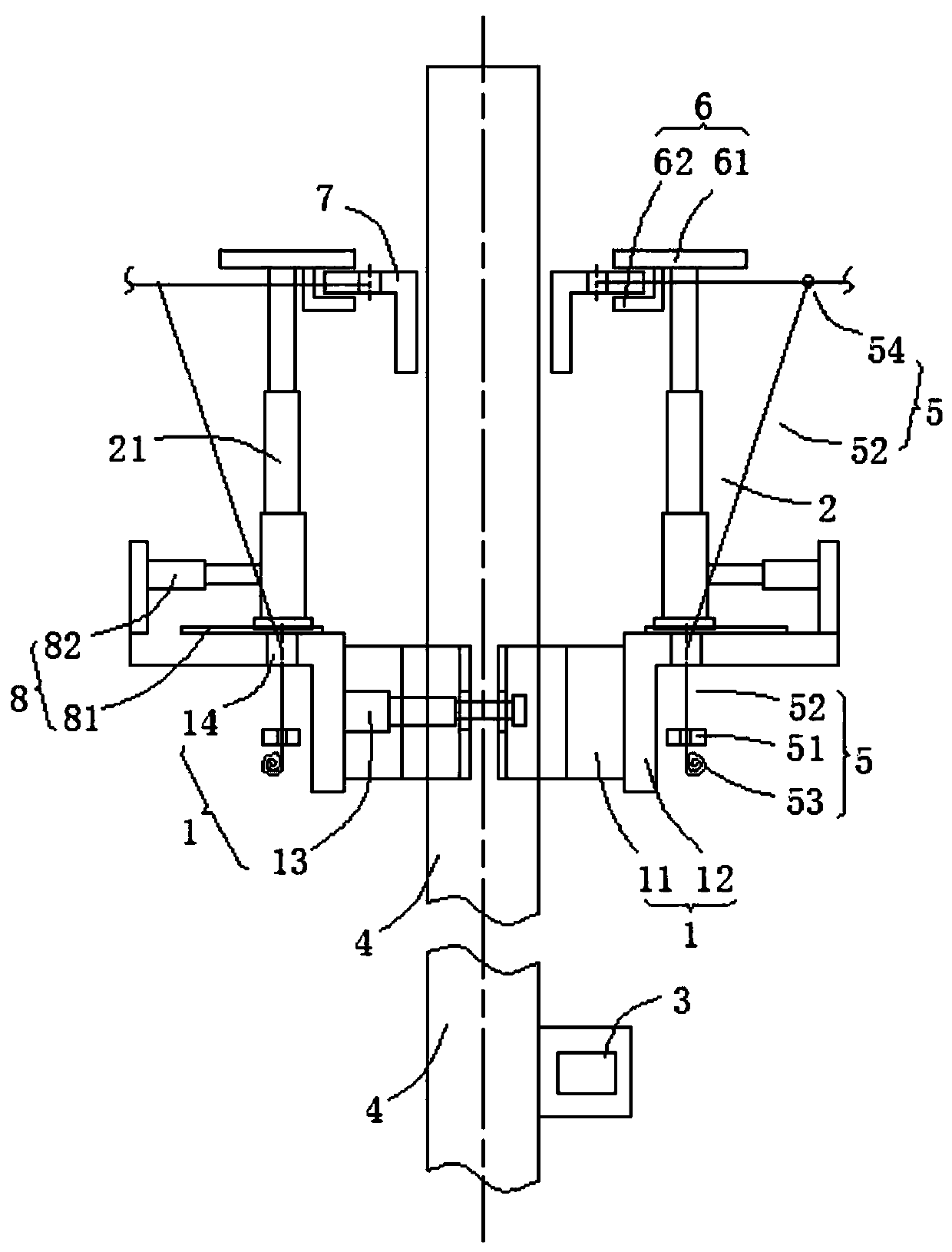

Strain power pole live replacement device

ActiveCN110364964AEnough tensionReduce manual workApparatus for overhead lines/cablesLocking mechanismEngineering

The invention provides a strain power pole live replacement device, which belongs to the technical field of power auxiliary tools. The strain power pole live replacement device comprises a support assembly, a push assembly and a control assembly, wherein the support assembly and the strain power pole are detachably connected; the support assembly is provided with a locking mechanism for fixing a wire; the push assembly is arranged on the support assembly and is provided with a clamping mechanism, a beam is clamped by the clamping mechanism and is pushed by the push assembly and moves along theheight direction of the strain power pole until the beam is separated from the strain power pole; and the control assembly can control actions of the push assembly and the locking mechanism. According to the strain power pole live replacement device provided in the invention, the locking mechanism fixes the beam, the push assembly enables the beam to be separated from the strain power pole, and the operation can be completed through operation of the control assembly. The strain power pole live replacement device has the technical effects that the operation process is optimized, the working efficiency is improved, the construction fee is reduced, and the operation is smooth.

Owner:STATE GRID CORP OF CHINA +2

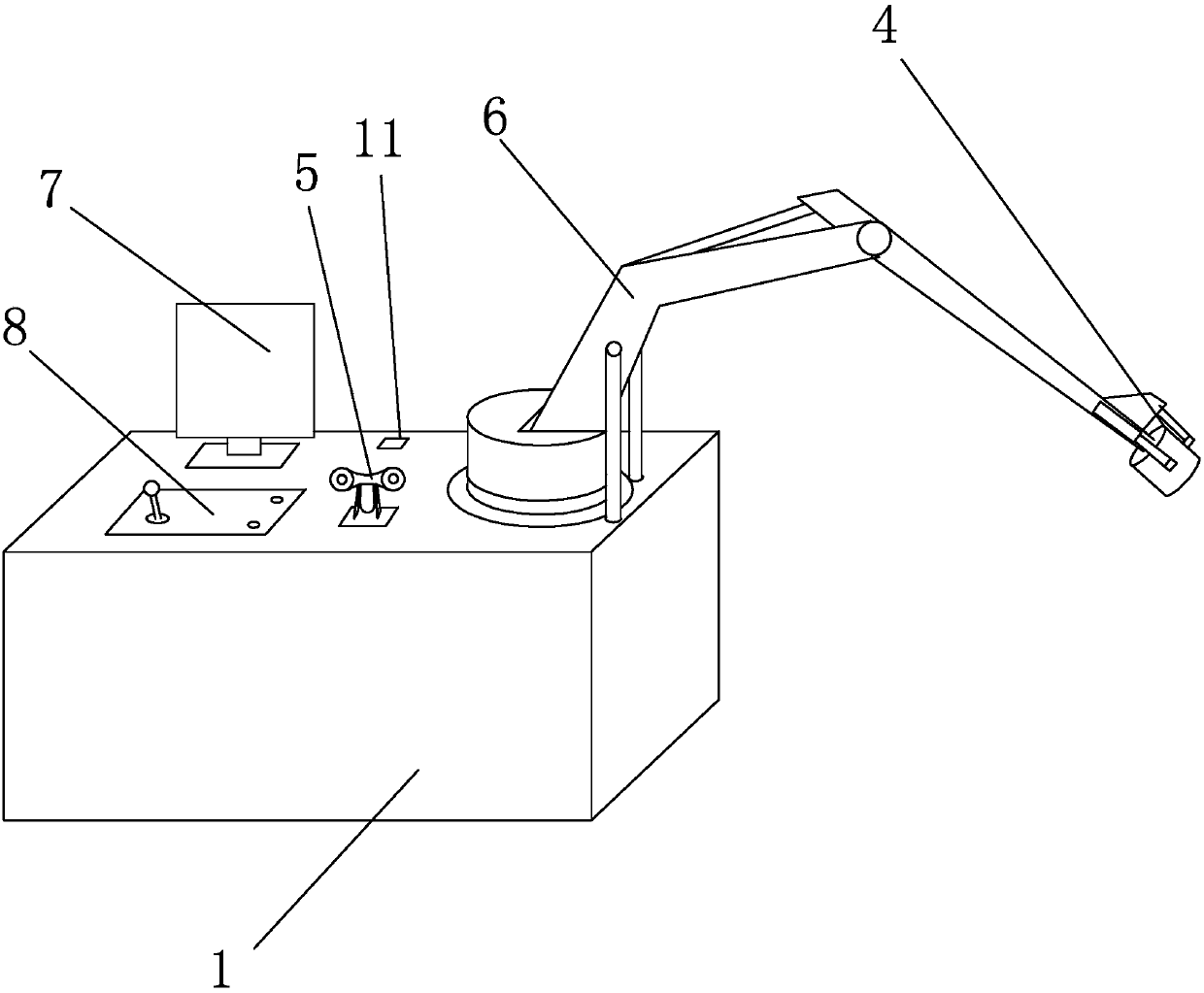

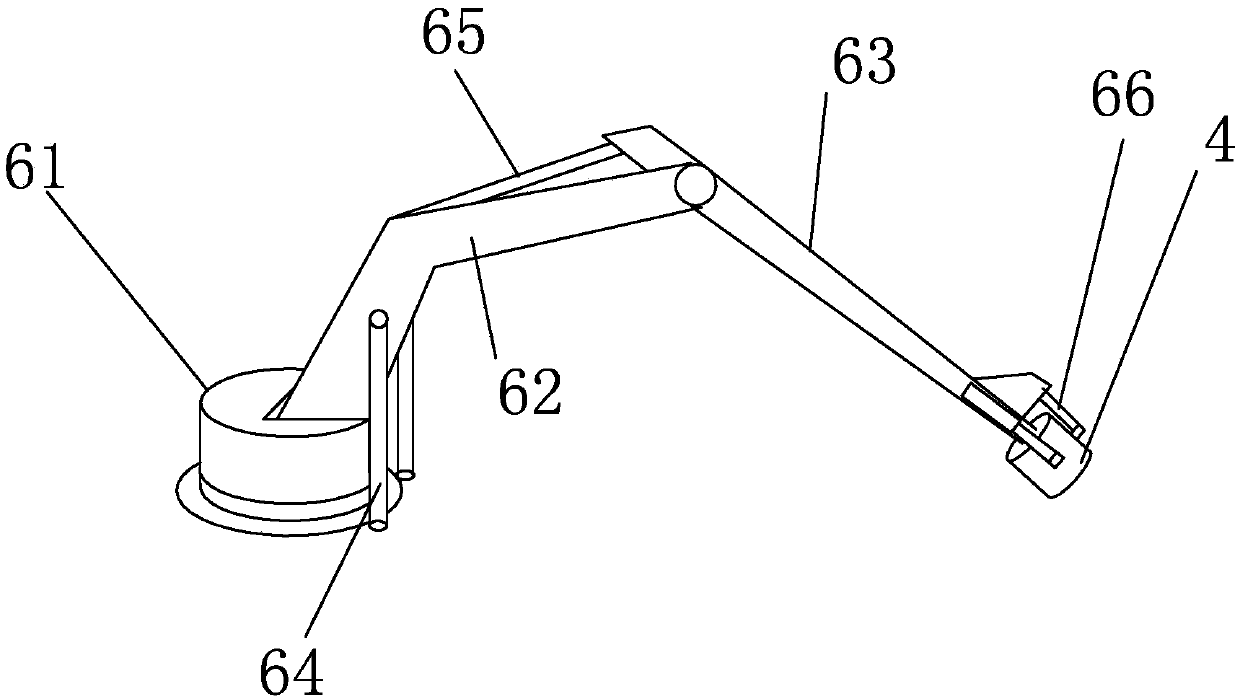

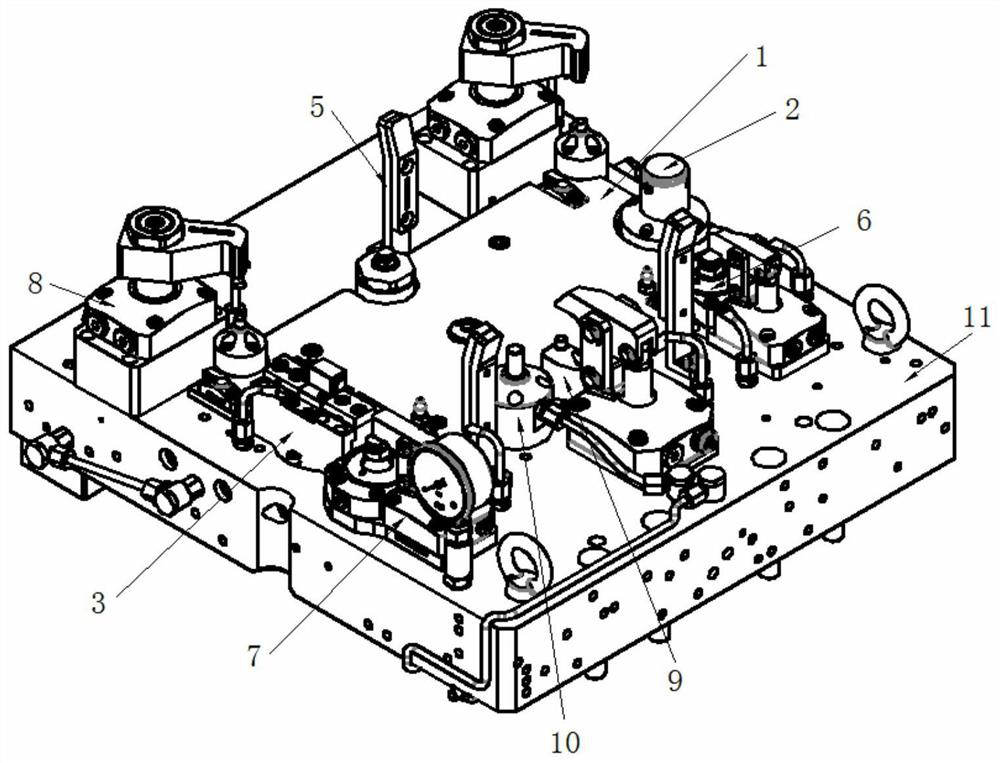

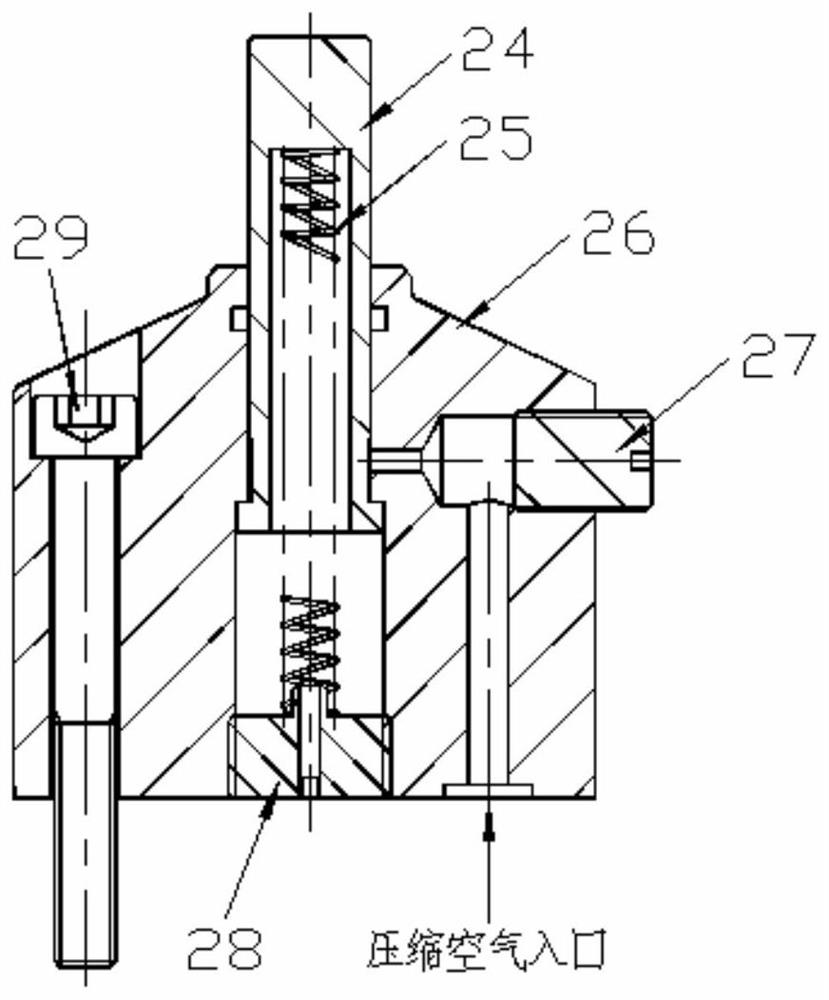

Machining clamp of cylinder cover blank adopting robot feeding and discharging mode

ActiveCN112025365AResists rough cutting forcesAvoid workpiece shiftingMeasurement/indication equipmentsPositioning apparatusEngineeringRoboty

The invention discloses a machining clamp of a cylinder cover blank adopting a robot feeding and discharging mode, and relates to the technical field of tool clamps. The machining clamp comprises a clamp body, a positioning assembly, a clamping element and an equipment control system, and a lifting supporting plate assembly is arranged at the upper end of the clamp body; and the lifting supportingplate assembly comprises a supporting plate, a supporting mounting base, a cushion block, a thick guide nail, a guide rod and a linear air cylinder, a connecting rod is arranged between the supporting plate and the linear air cylinder, and a nut is arranged between the supporting plate and the connecting rod. According to the machining clamp of the cylinder cover blank adopting the robot feedingand discharging mode, the equipment control system can judge whether a workpiece exists on the clamp body or not through a workpiece existence detection device and keep communication with a robot, sothat machine collision caused by repeated feeding can be prevented, and the problems that because a traditional hydraulic clamp cannot conduct timely information interaction, the workpiece is possiblyclamped, and a collision accident occurs between the hydraulic clamp and the workpiece are solved.

Owner:KUNMING YUNNEI POWER

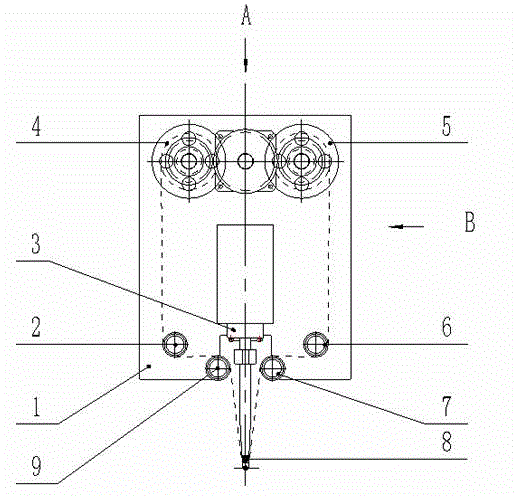

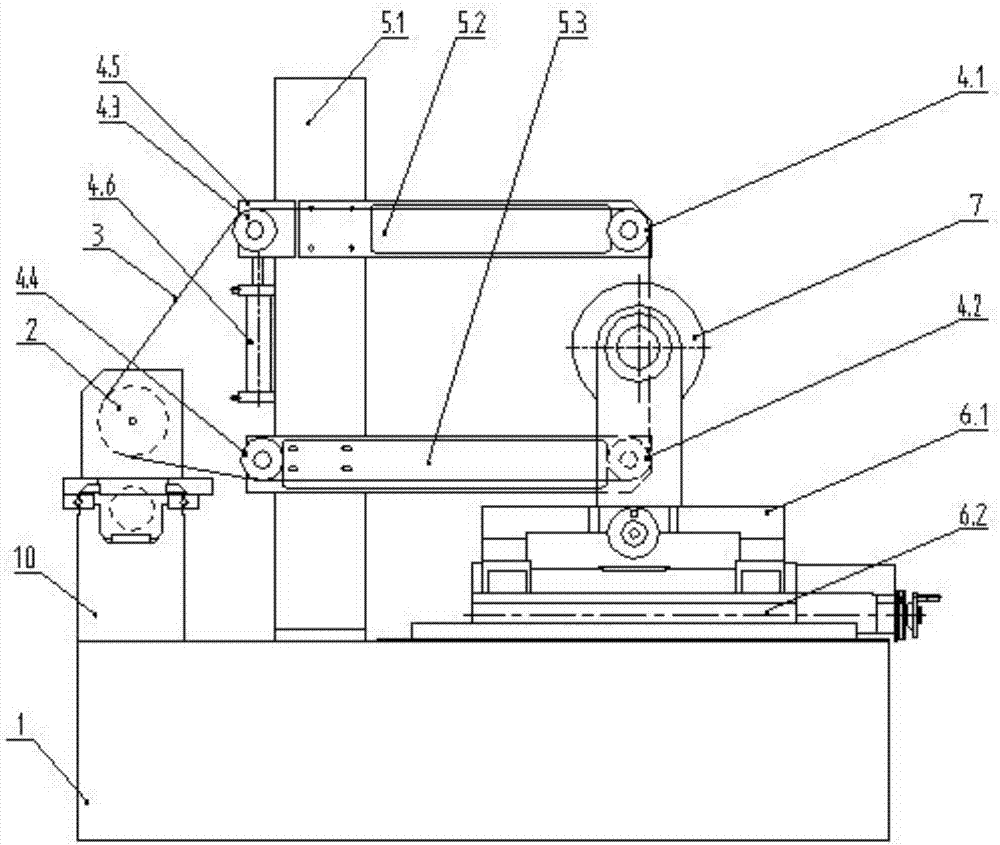

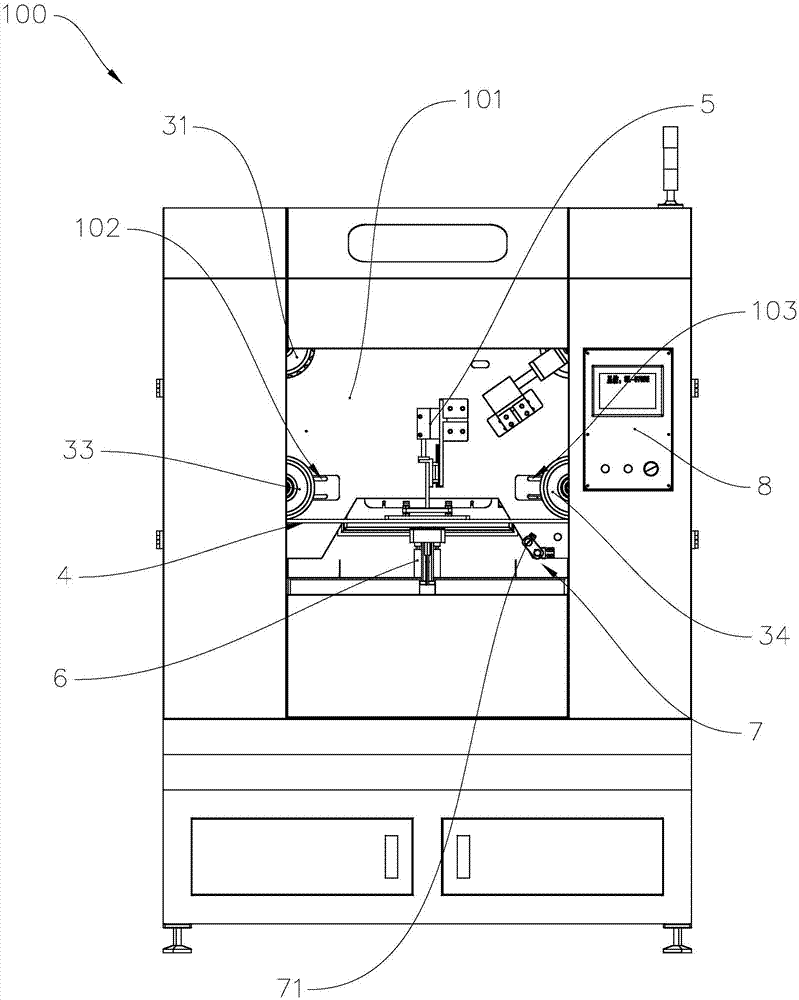

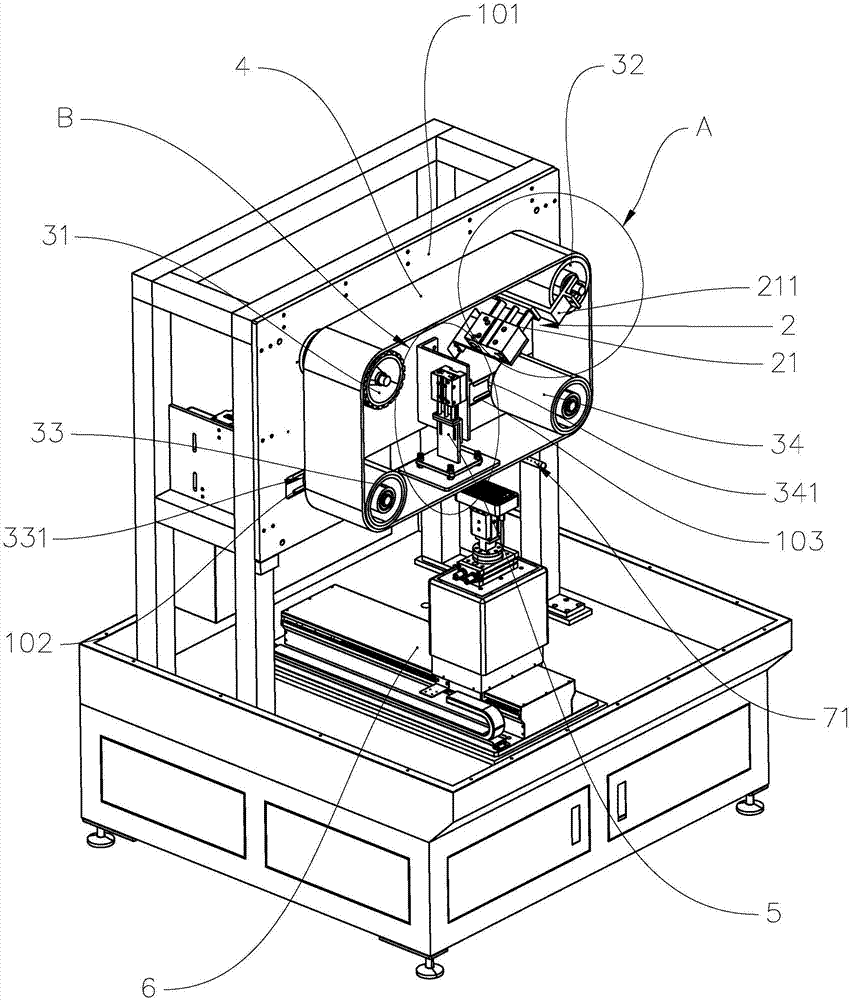

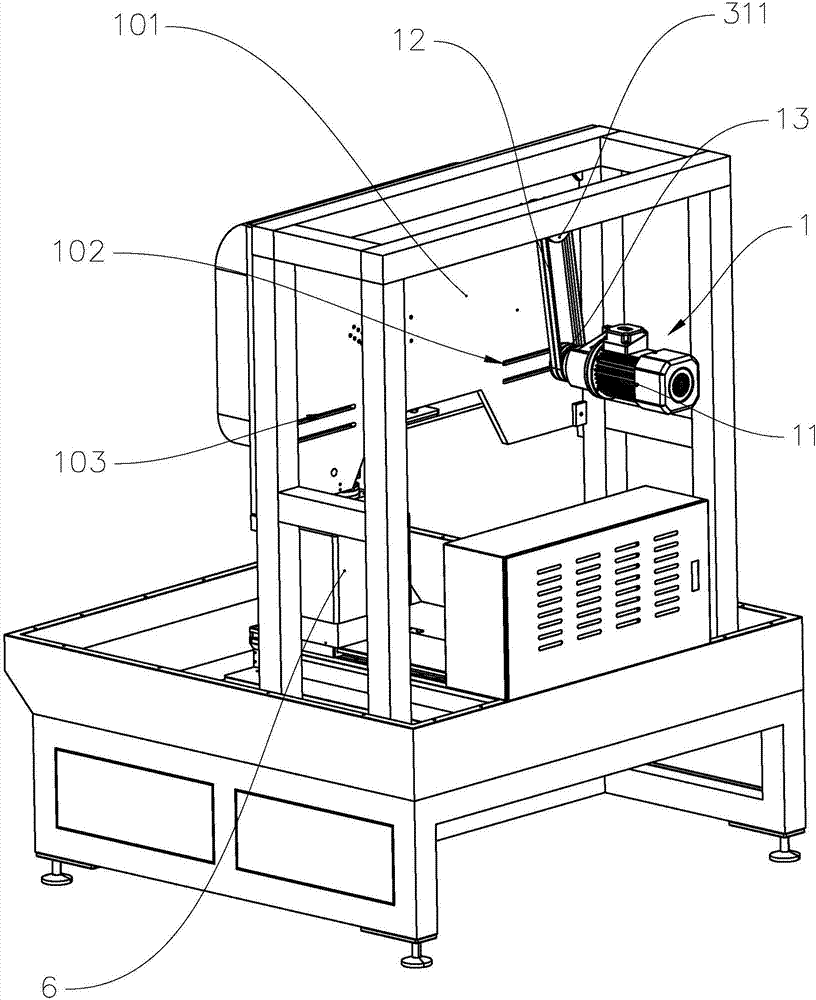

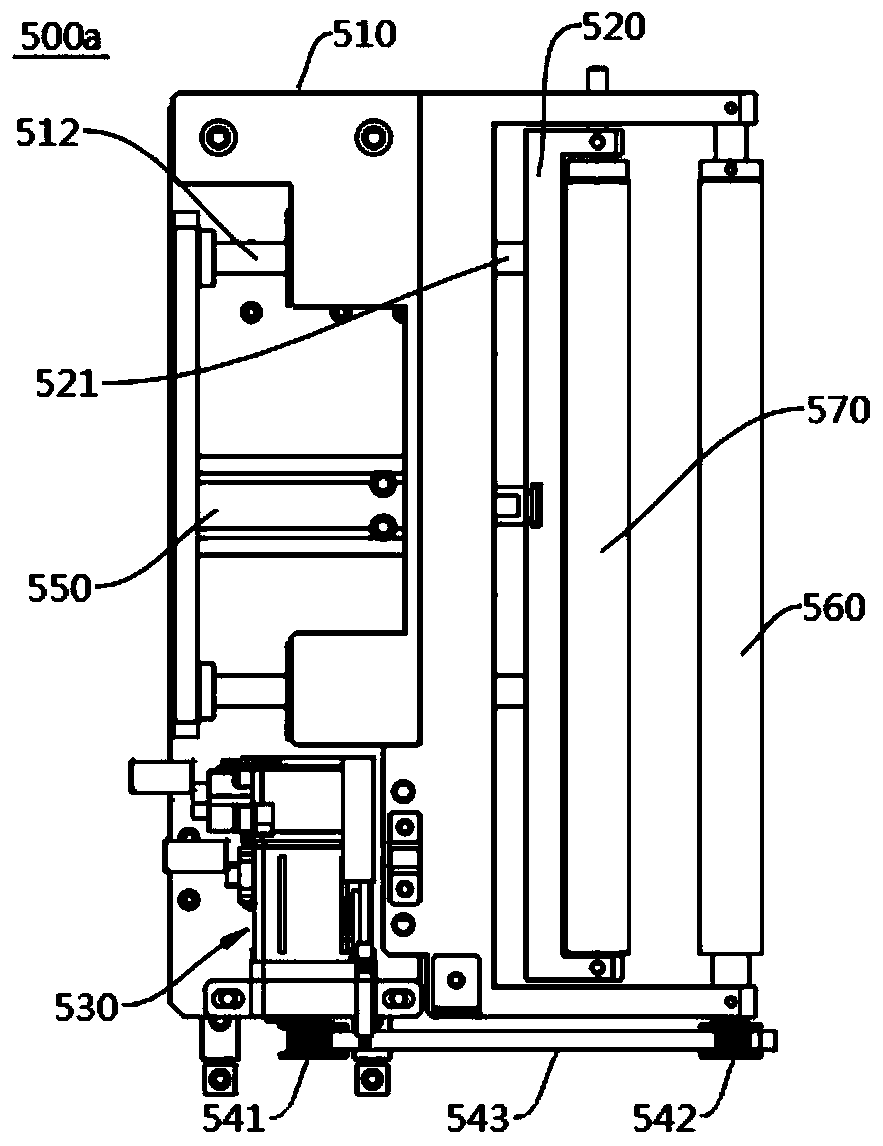

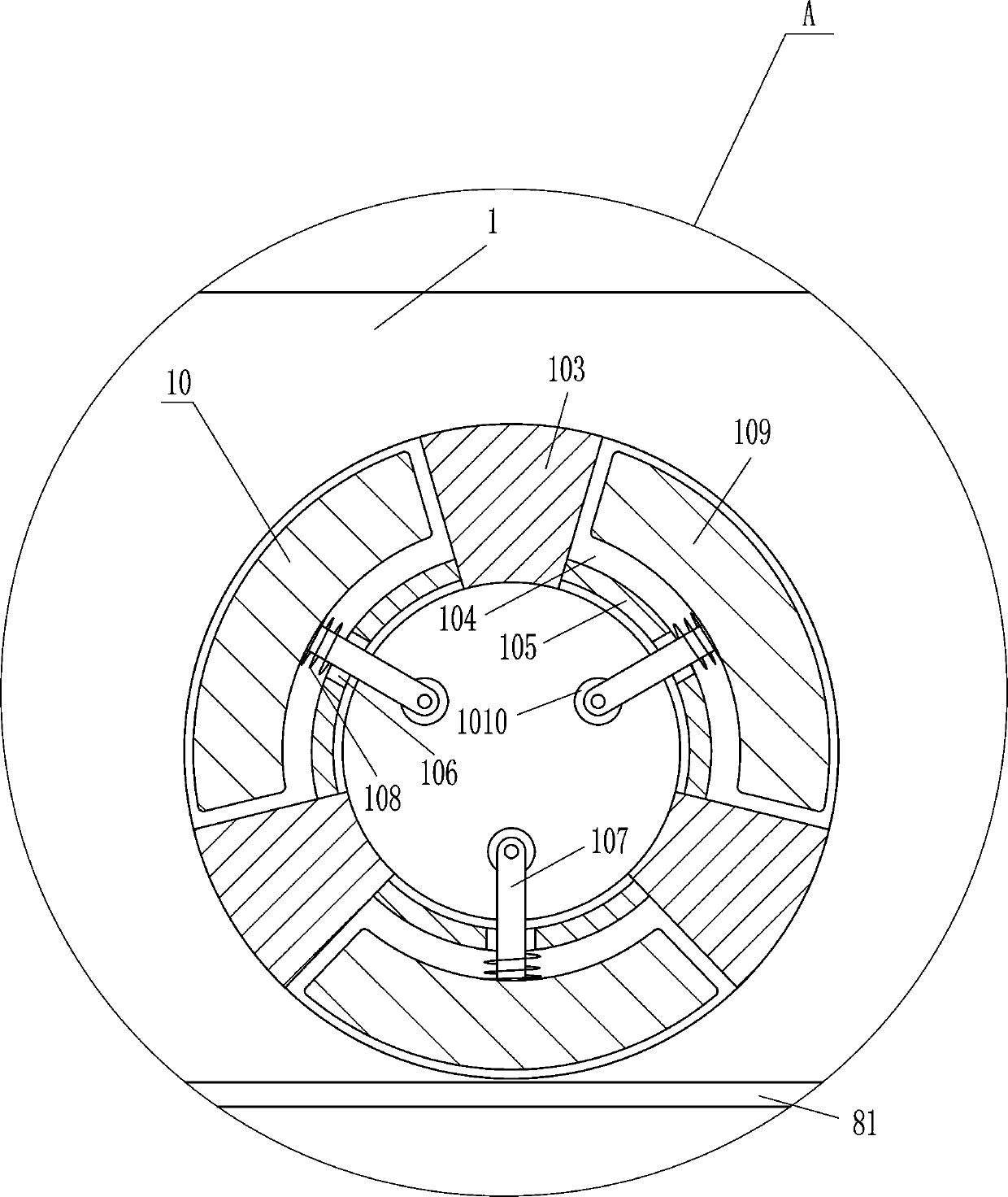

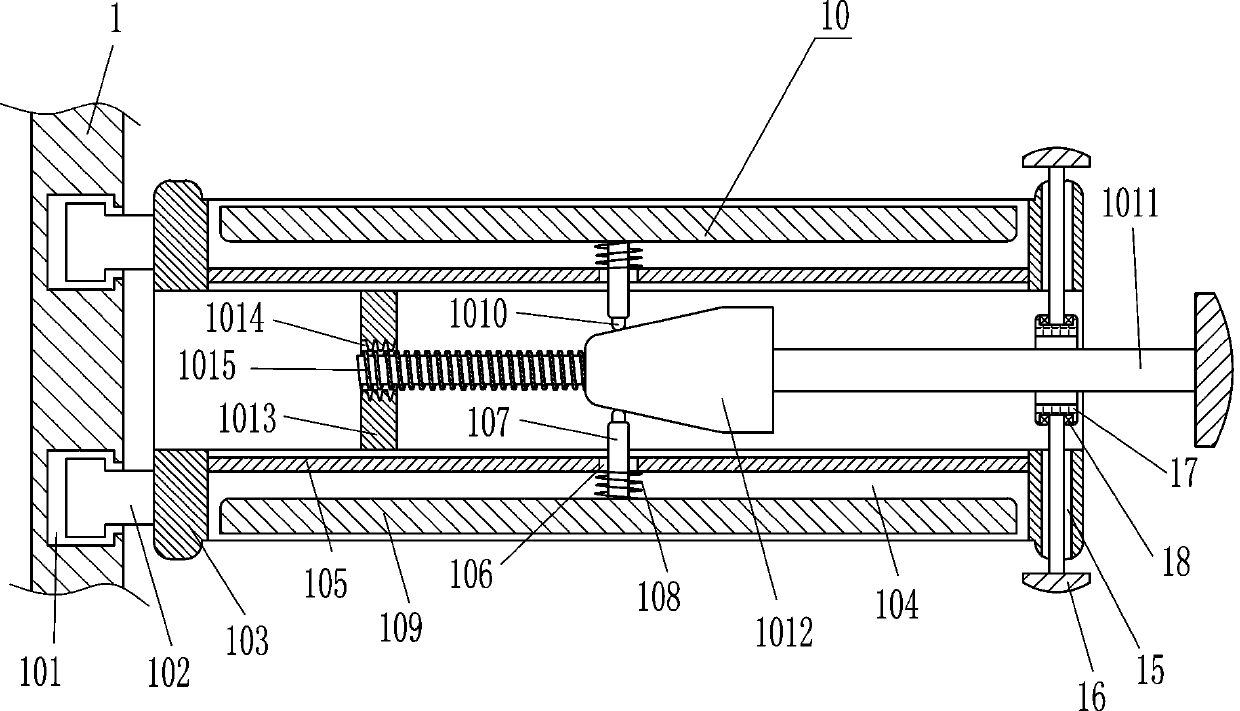

Wire drawing machine and machining method thereof

PendingCN107414640AEnough tensionGuaranteed drawing effectGrinding drivesBelt grinding machinesEngineeringMachine

The invention provides a wire drawing machine and a machining method thereof. The wire drawing machine comprises a machine frame, a first driving mechanism, a second driving mechanism, a plurality of roll shafts, a wire drawing belt, a downward pressing device and a fixture device. The first driving mechanism and the second driving mechanism are fixedly connected with the machine frame. The first roll shaft is connected with the machine frame, and the first driving mechanism drives the first roll shaft to rotate. The second roll shaft is rotationally connected with the second driving mechanism, and the second driving mechanism drives the second roll shaft to move in the axial direction of the second driving mechanism. The third roll shaft is connected with the machine frame. The wire drawing belt is wound on the multiple roll shafts. The downward pressing device comprises a third driving mechanism and a downward pressing assembly. The fixture device comprises a tool fixture, the tool fixture and the downward pressing assembly are located on the two sides of the wire drawing belt correspondingly, the tool fixture is opposite to the downward pressing assembly, and the third driving mechanism drives the downward pressing assembly to push the wire drawing belt towards the tool fixture. The invention further provides the machining method of the wire drawing machine. The wire drawing machine and the machining method thereof have the advantages of being good in wire drawing effect and high in wire drawing quality and wire drawing efficiency.

Owner:珠海桑贝思精密科技有限公司

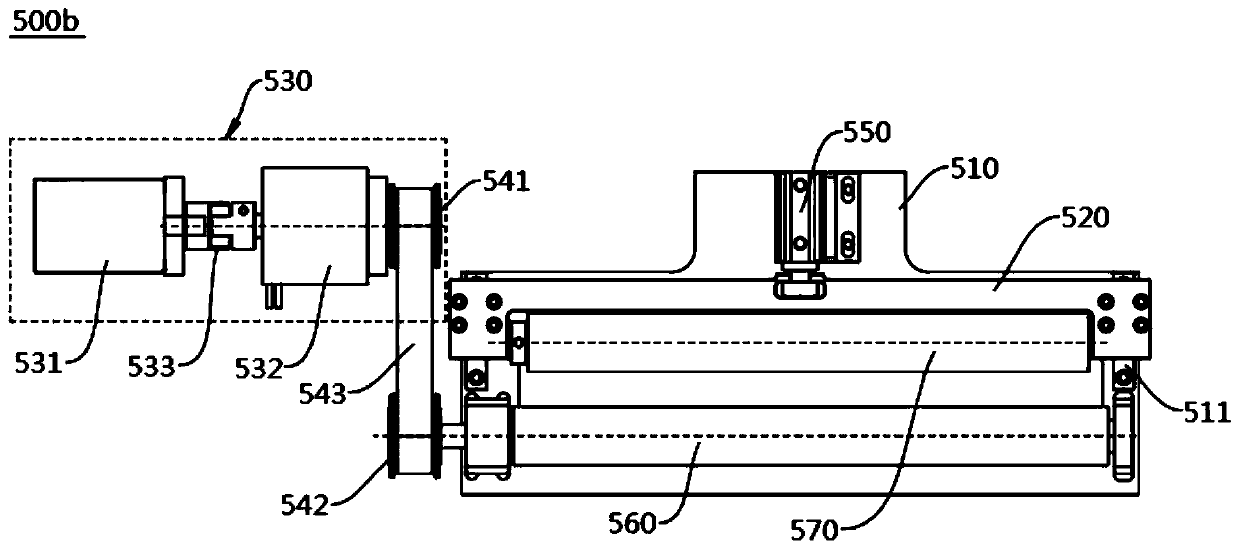

Winding tension reducing device and winding equipment

InactiveCN111170056AReduce winding tensionReduce tensionWebs handlingLithium-ion batteryMechanical engineering

The invention relates to the technical field of lithium ion battery manufacturing, in particular to a winding tension reducing device and winding equipment. The winding equipment comprises an unwinding device, a tension mechanism and a winding device which are sequentially arranged, the winding tension reducing device is arranged between the tension mechanism and the winding device, and comprisesa driving roller, a pressing roller and a torque driving mechanism, wherein the torque driving mechanism is used for driving the driving roller to rotate, and the pressing roller is used for clampinga coil by cooperating with the driving roller. The winding tension reducing device enables the coil to have tendency to be dragged by the driving roller in winding direction in a clamped state, so that the coil is enabled to maintain large tension transmission before passing through the driving roller, obtain relative acting force for counteracting tension after passing through the driving roller, and be wound after the tension is reduced to small tension, and the purpose of taking into account the internal uniformity and the product deformation of a battery product is achieved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

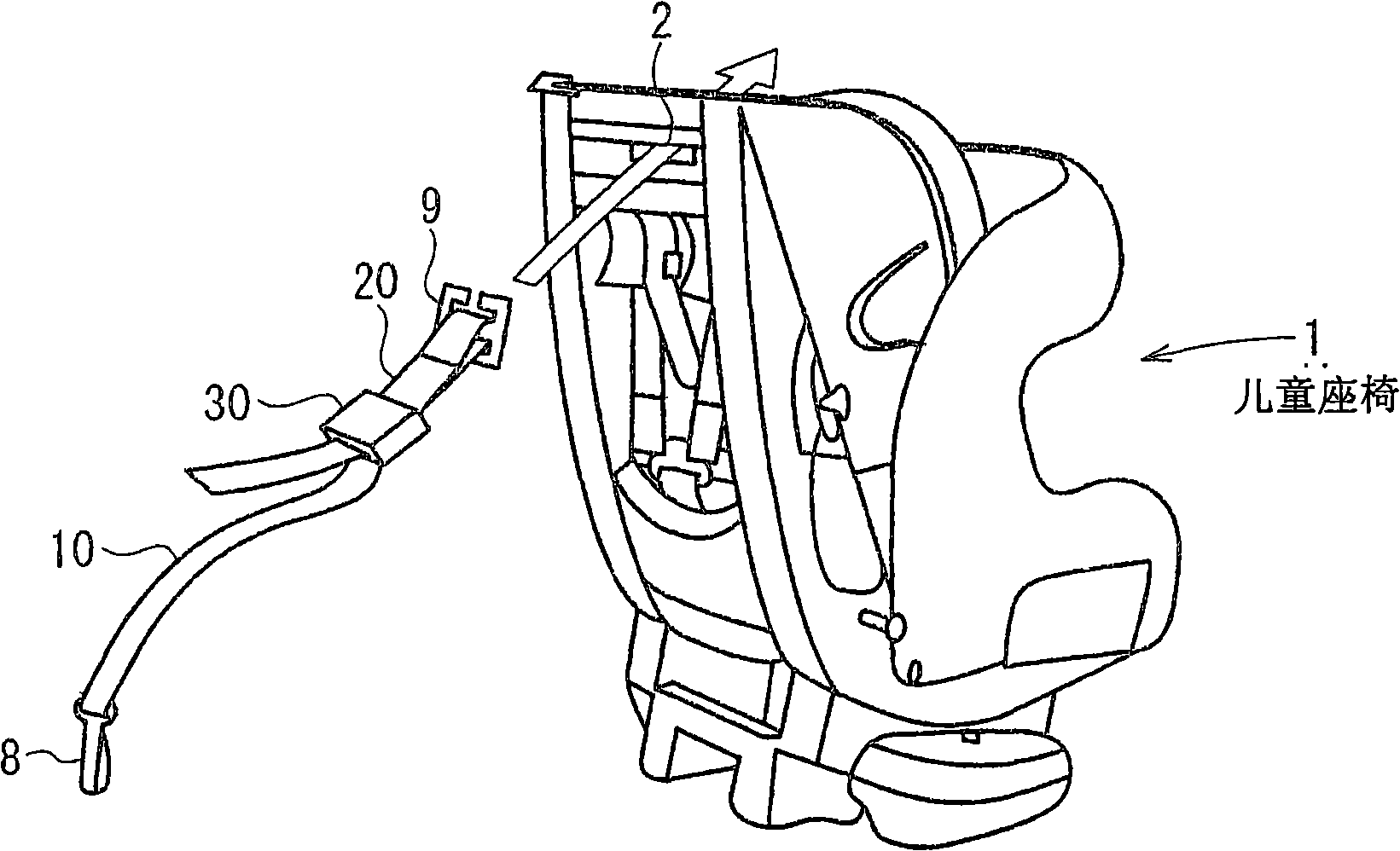

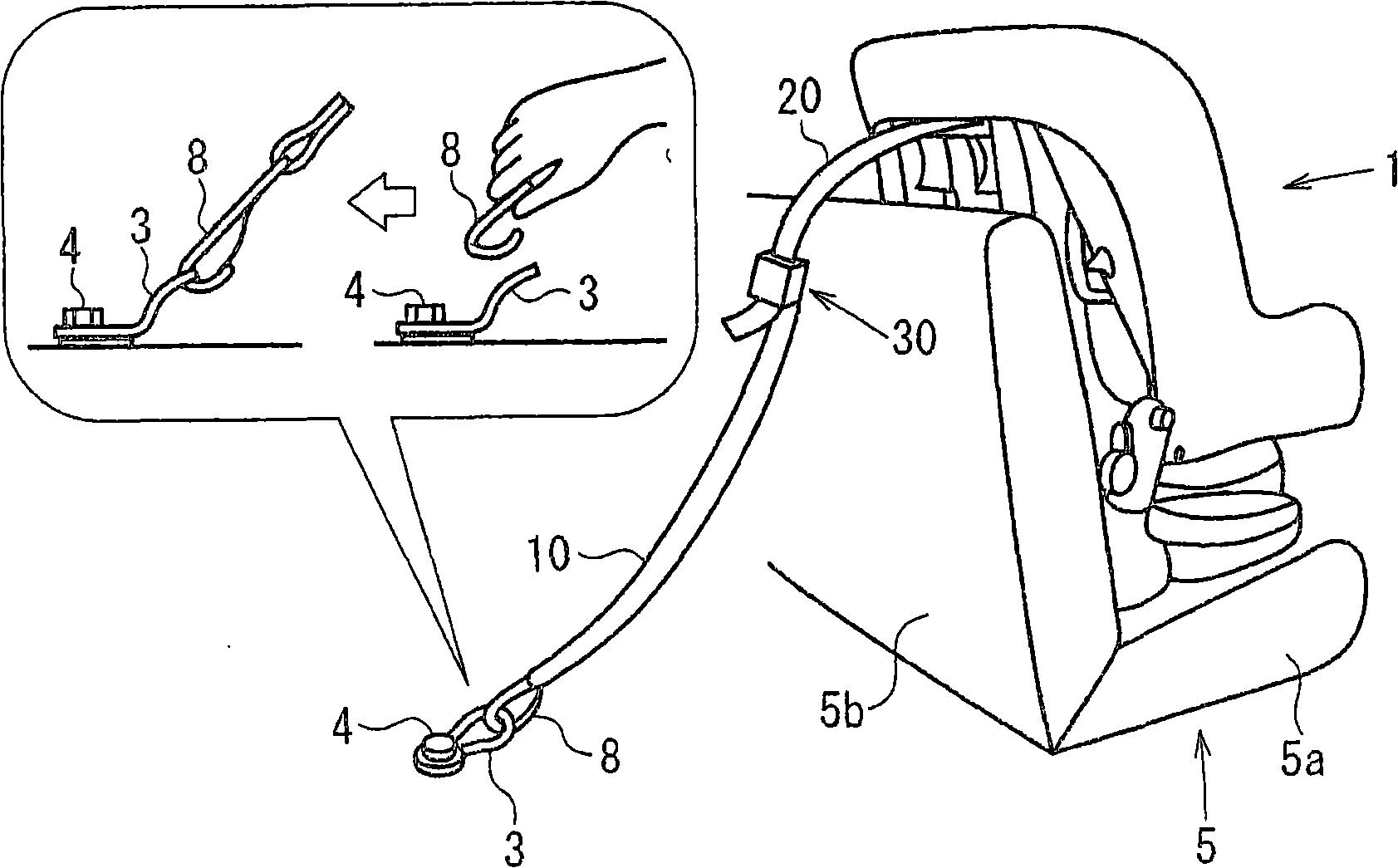

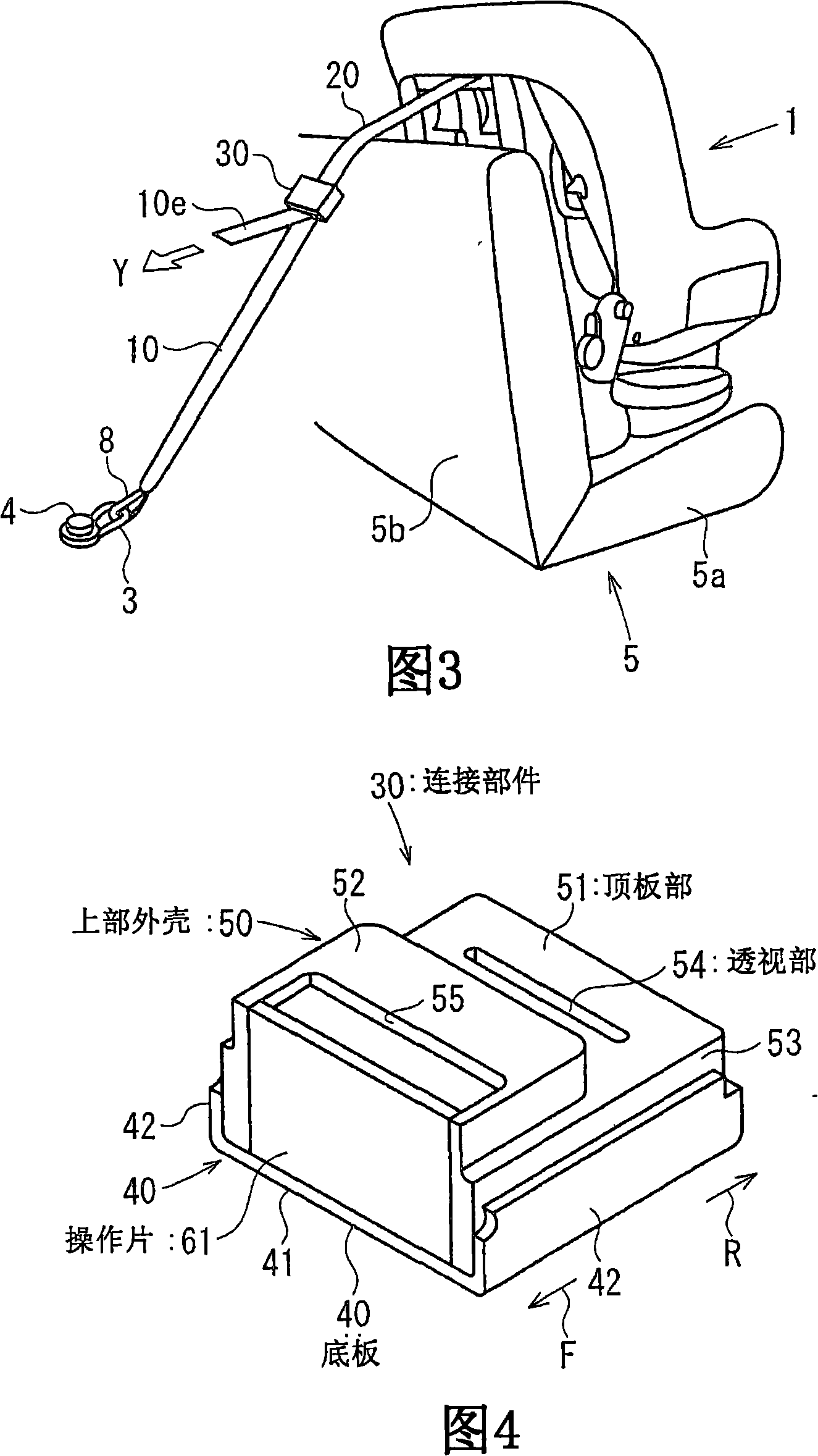

Child seat anchoring device and child seat

Owner:TAKATA CORPORATION

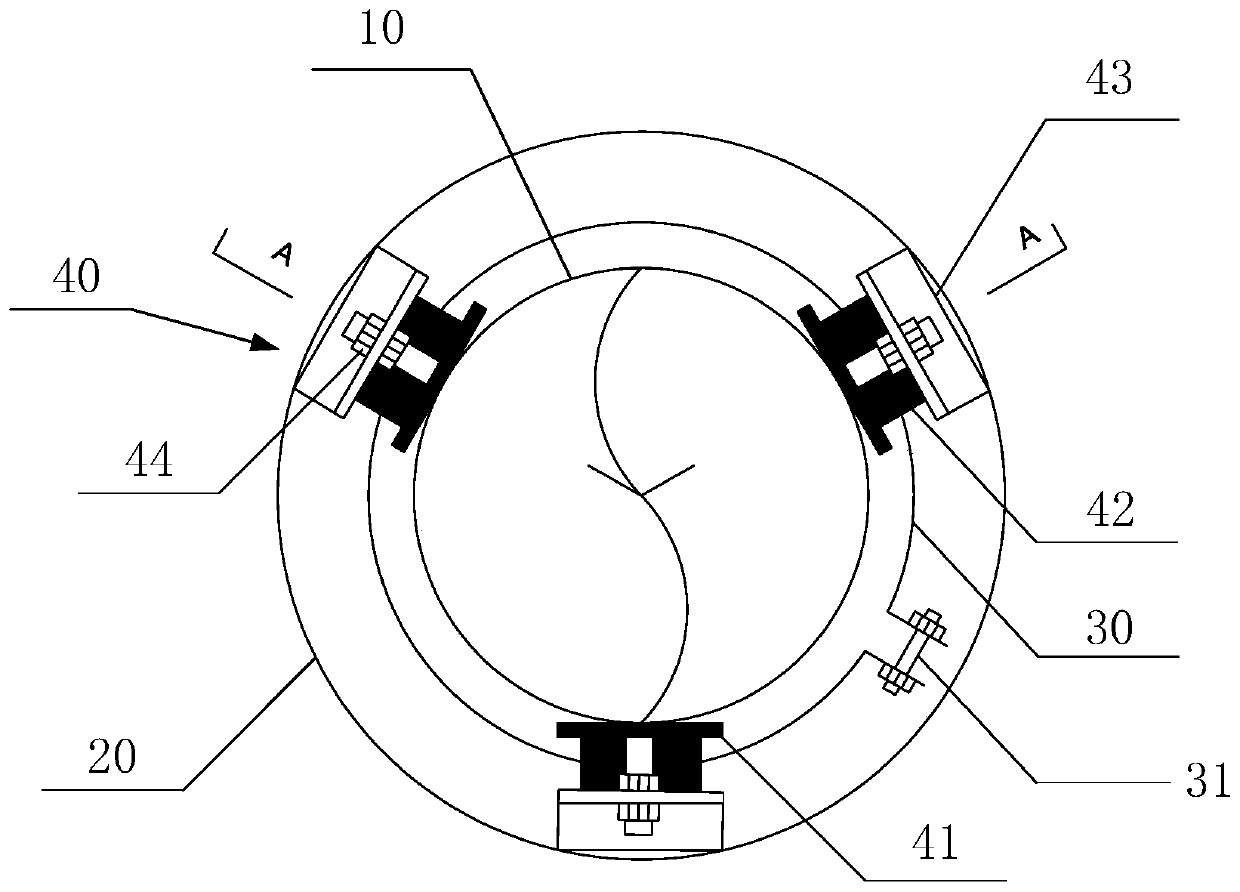

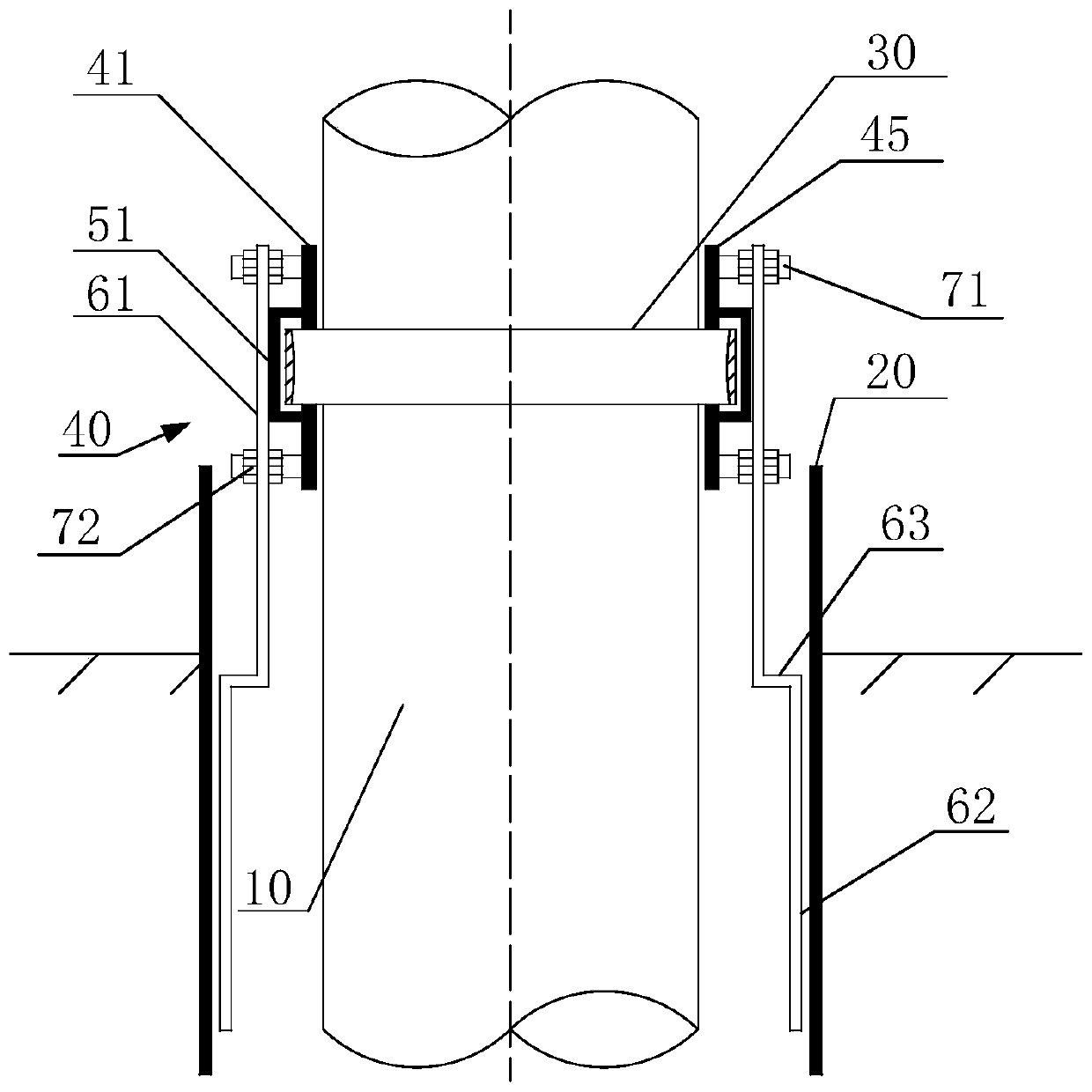

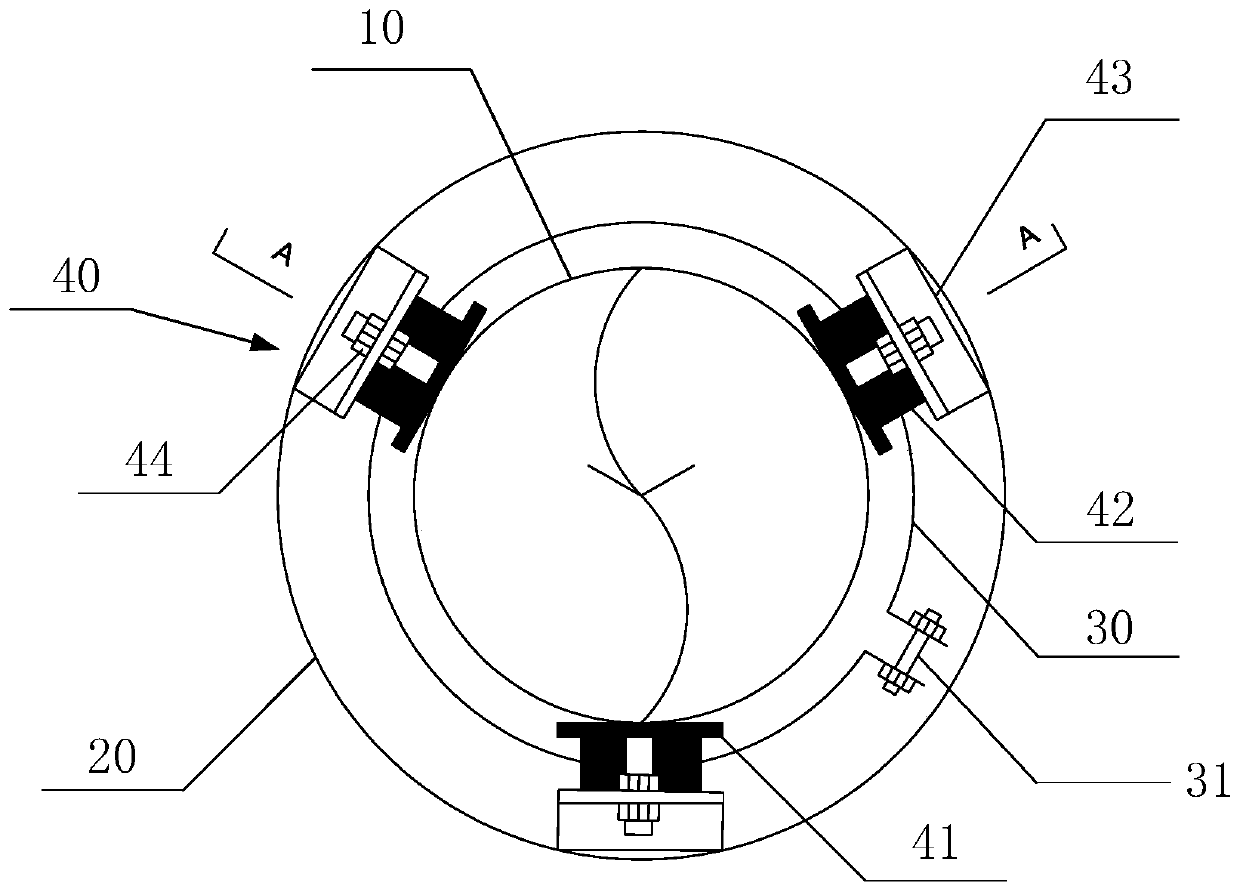

Pipeline casing pipe mounting and fixing device and application method thereof

The invention relates to a pipeline casing pipe mounting and fixing device and an application method thereof. The device comprises a clasping hoop and three or more hooks. The clasping hoop is arranged at the outer circumference of a pipeline in a sleeving manner. One end of each hook is mounted on the clasping hoop, and the other end of each hook extends in the length direction of the pipeline and can be in interference fit with the casing pipe. The three or more hooks are uniformly distributed in the outer circumference direction of the pipeline. According to the pipeline casing pipe mounting and fixing device and the application method thereof, adhesion force, on the pipeline, of all the hooks is provided by the clasping hoop; meanwhile, supporting points are provided for the hooks; thetensile force is provided for the casing pipe on the basis of the lever principle; due to the fact that the hooks are uniformly distributed in the outer circumference direction of the pipeline, it can be guaranteed that the casing pipe is stressed uniformly; and thus, consumption of materials is lowered, the casing pipe mounting efficiency is improved, and labor force is saved for site construction.

Owner:SHANGHAI CONSTR NO 1 GRP

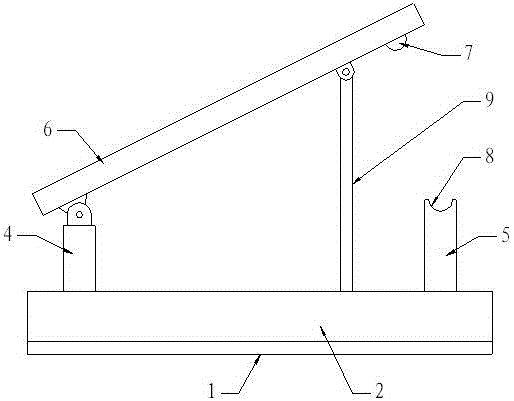

Pre-distributing tension damping device

InactiveCN103662931AEnough tensionGuarantee the quality of windingWebs handlingEngineeringConvex structure

The invention provides a pre-distributing tension damping device. By using the pre-distributing tension damping device, the tension is enough when steel strips enter a take-up machine, the take-up quality of the steel strips in the take-up machine is ensured, and the production efficiency is improved. The pre-distributing tension damping device comprises a base; and a board structure is arranged above the base. The pre-distributing tension damping device is characterized in that a guiding roll structure is arranged in front of the board structure; the guiding roll structure is fastened in front of the upper portion of the base; two positioning rolls which are arranged transversely are arranged at the rear of the board structure; a pushing roll is arranged between the two positioning rolls; a rotating shaft of the pushing roll is supported to two side walls of a base of the pushing roll; the side walls of the base of the pushing roll have outwards convex structures; outwards convex structures of side walls of the positioning rolls are clamped in perpendicular guiding grooves of the board structure; and a rear hydraulic cylinder is arranged on the rear side of the upper end of the board structure.

Owner:WUXI XINJIAYUAN METALLURGY MACHINERY MFG

Unmanned aerial vehicle

InactiveCN106516113AEnough tensionEnough steering torquePropellersAircraft stabilisationUncrewed vehicleStabilator

A fixed-wing unmanned aerial vehicle comprises a fuselage, an electric propulsion mechanism arranged at the head of the fuselage, wings arranged on the two sides of the fuselage and a horizontal tail arranged at the tail of the fuselage. Before the unmanned aerial vehicle takes off, the electric propulsion mechanism can provide larger than or equal to 5.4 kg tension for the unmanned aerial vehicle. The wings are airfoils high in lift coefficient. The horizontal tail is a stabilator. During launching of the unmanned aerial vehicle, zero-run-up hand throwing launching can be completed without providing the additional initial velocity, and the fixed-wing unmanned aerial vehicle can adapt to various area-limited environments, such as island reefs, mountain, roofs, ships and other usage environments.

Owner:深圳市易飞方达科技有限公司

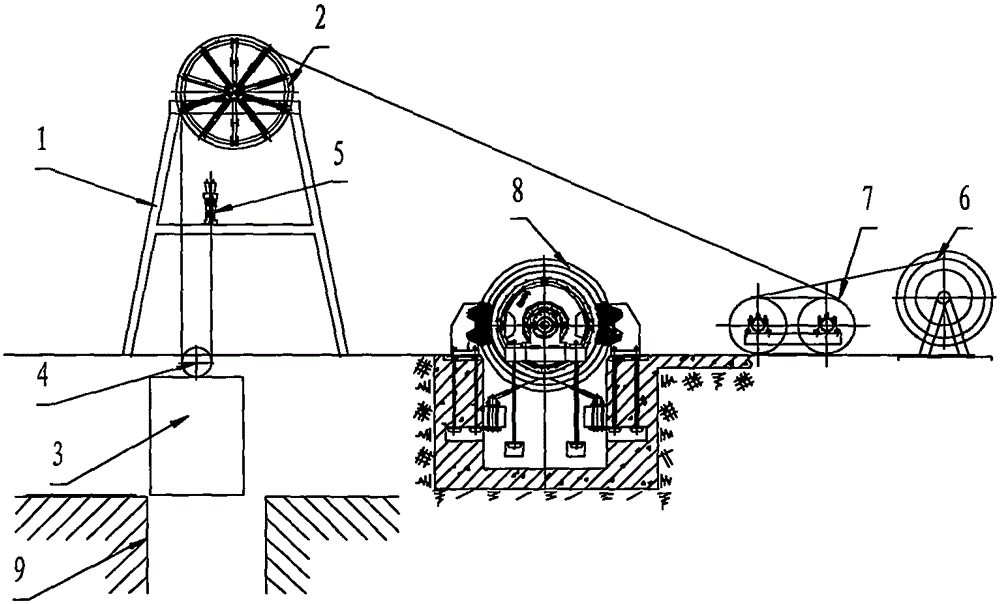

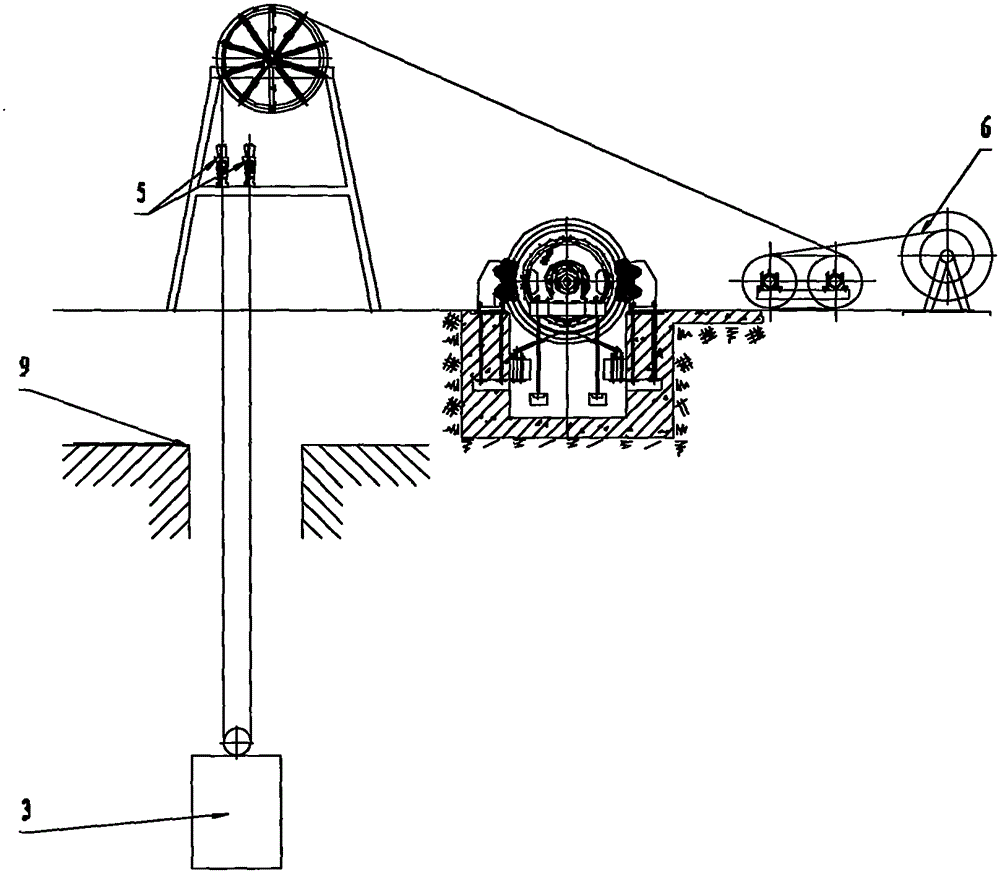

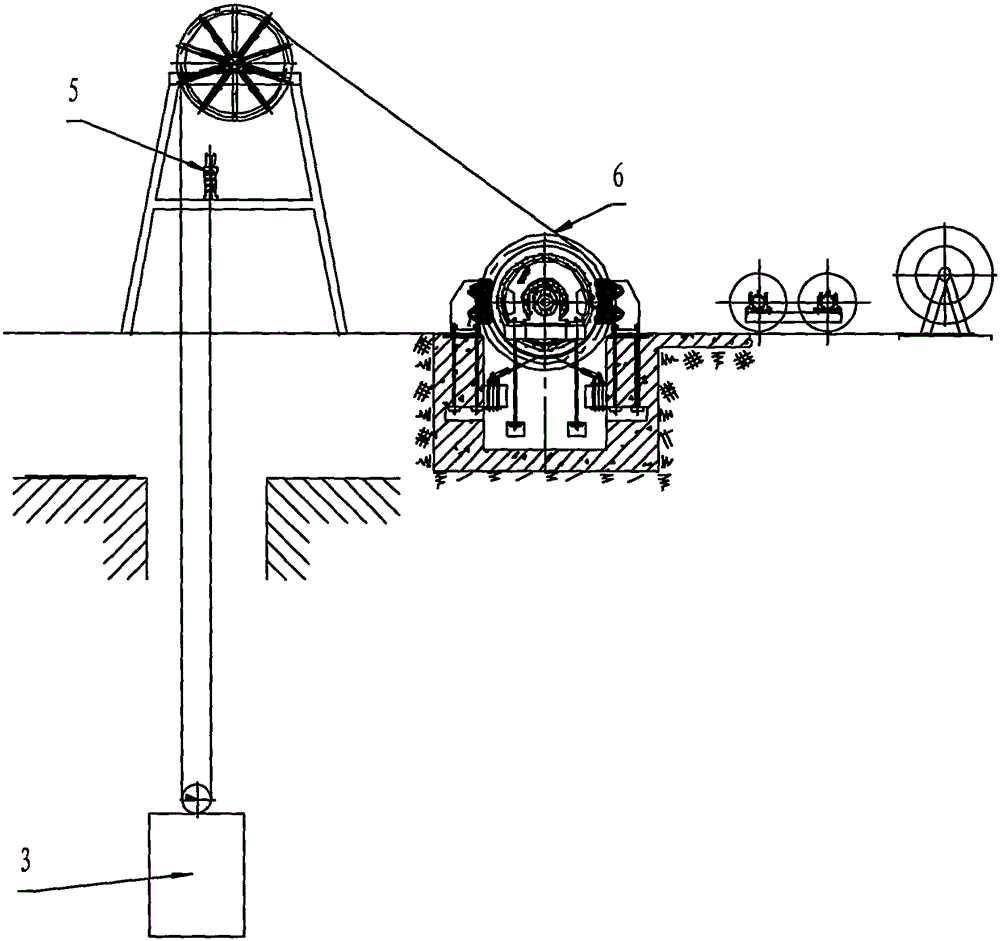

On-load installation method for small friction winch for winding of multi-layer steel wire rope of hoister

Disclosed is an on-load installation method for a small friction winch for winding of a multi-layer steel wire rope of a hoister. According to the small friction winch for winding of the multi-layer steel wire rope of the hoister, a container movable pulley is arranged above the center of a hoisting container; the steel wire rope is arranged between a steel wire rope coil and a friction trolley and between a head sheave and the hoisting container 3; the steel wire rope is installed to hoist the hoisting container, and meanwhile, the steel wire rope is wound around a winding drum of the hoister in an on-load mode; after the hoisting container is supported steady by a support plate, a rope clamping device of a steel wire rope end is released; the container movable pulley is taken down; the steel wire rope is released and pulled to be straight; and the steel wire rope end is fixedly installed on the hoisting container through a clamping buckle. According to the method, it is ensured that the multi-layer steel wire rope is wound around the winding drum in the on-load mode, so that it is ensured that steel wires of the steel wire rope are combined tightly and closely, stress is balanced and deformation is avoided; the service life of the steel wire rope can be prolonged.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

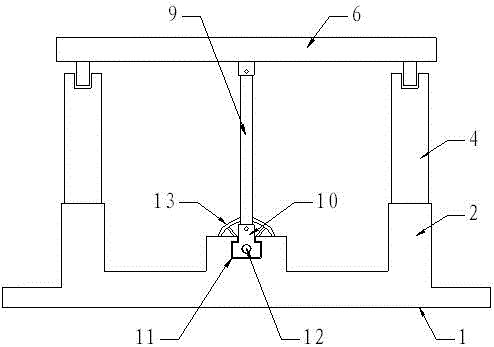

Middle screw take-up device of reversible belt conveyor

InactiveCN103538877AEnough tensionAvoid insufficient frictionConveyorsControl engineeringControl theory

The invention relates to a middle screw take-up device of a reversible belt conveyor. The middle screw take-up device comprises a support which is fixedly arranged and a threaded rod of which one end is fixed to the support. A guide rail which is fixedly installed is arranged in the middle of the support. Turnabout drums are arranged on the two sides of the support respectively. Lifting devices carrying out lifting movement vertically along the guide rail are arranged in the path of the threaded rod. Each lifting device is provided with a take-up drum. The take-up drums correspond to the turnabout drums, and the take-up drums and the turnabout drums are provided with conveyor belts in a penetrating mode. The middle screw take-up device has the advantages of being simple and compact in structure, capable of saving space and time, good in flexibility, convenient to mount, dismount and operate, low in basic requirement, safe, reliable, capable of meeting the requirement for product seriation easily, and capable of making the conveyor belts generate enough tension, limiting the sag of the conveyor belts among all carrier rollers, guaranteeing enough friction between the conveyor belts and transmission drums so as to prevent the conveyor belts from slipping, and guaranteeing normal operation of the reversible belt conveyor.

Owner:JIANGSU HENGYUAN INT ENG CO LTD

Composite embedded electric energy meter end button

InactiveCN102798742AIncrease profitImprove product performanceTime integral measurementEngineeringInjection moulding

The invention discloses a composite embedded electric energy meter end button, which comprises an end button body and a current terminal (2) embedded in the end button body, wherein the end button body comprises bakelite (1) and plastic (3); the current terminal (2) and the bakelite (1) are formed into a bakelite terminal core row through thermosetting moulding; and the bakelite terminal core row and the plastic (3) are subjected to secondary injection moulding. The composite embedded electric energy meter end button, which is made through steps of current terminal and bakelite thermosetting moulding and plastic secondary injection moulding, combines the advantages of the two materials, effectively reduces the pollution to the environment, is low-carbon and environment-friendly, has high flexibility and strength, guarantees sufficient tensile force after the current terminal and an end button box are assembled, and greatly increase the heat-resistant temperature of the product.

Owner:XUZHOU AOTAI ELECTRONICS

Optical coating composite production line of adjustable scraping structure

ActiveCN109848003AAffect qualityEnough tensionPretreated surfacesCoatingsProduction lineOptical coating

The invention relates to a composite production line, in particular to an optical coating composite production line of an adjustable scraping structure. The optical coating composite production line of the adjustable scraping structure can achieve the technical purposes that a coating solution can be uniformly scraped, the quality of an optical thin film is not influenced, the tension of the optical thin film can also be measured, and the tension of the optical thin film is sufficient without affecting coating. According to the technical scheme, the optical coating composite production line ofthe adjustable scraping structure comprises a rack, thin film leading-in rollers, a thin film cylinder, a corona processor and the like. The two thin film leading-in rollers are rotationally arrangedon the right side of the lower part of the front side face of the rack. By means of the effect of a scraper, the coating solution on the optical thin film can be uniformly scraped, so that the quality of the optical thin film is prevented from being influenced by the uneven coating solution; the tension of the optical thin film can be measured through a tension adjusting mechanism; the tension ofthe optical thin film is sufficient, and the situation that the tension of the optical thin film is insufficient and influences coating of the coating solution is avoided.

Owner:深圳市领辉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com