Composite embedded electric energy meter end button

An embedded, electric energy meter technology, applied in the field of end buttons, can solve the problems of non-recyclability, insufficient tension, environmental damage, etc., to improve the utilization rate and product performance, improve product quality and reliability, and improve heat-resistant temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

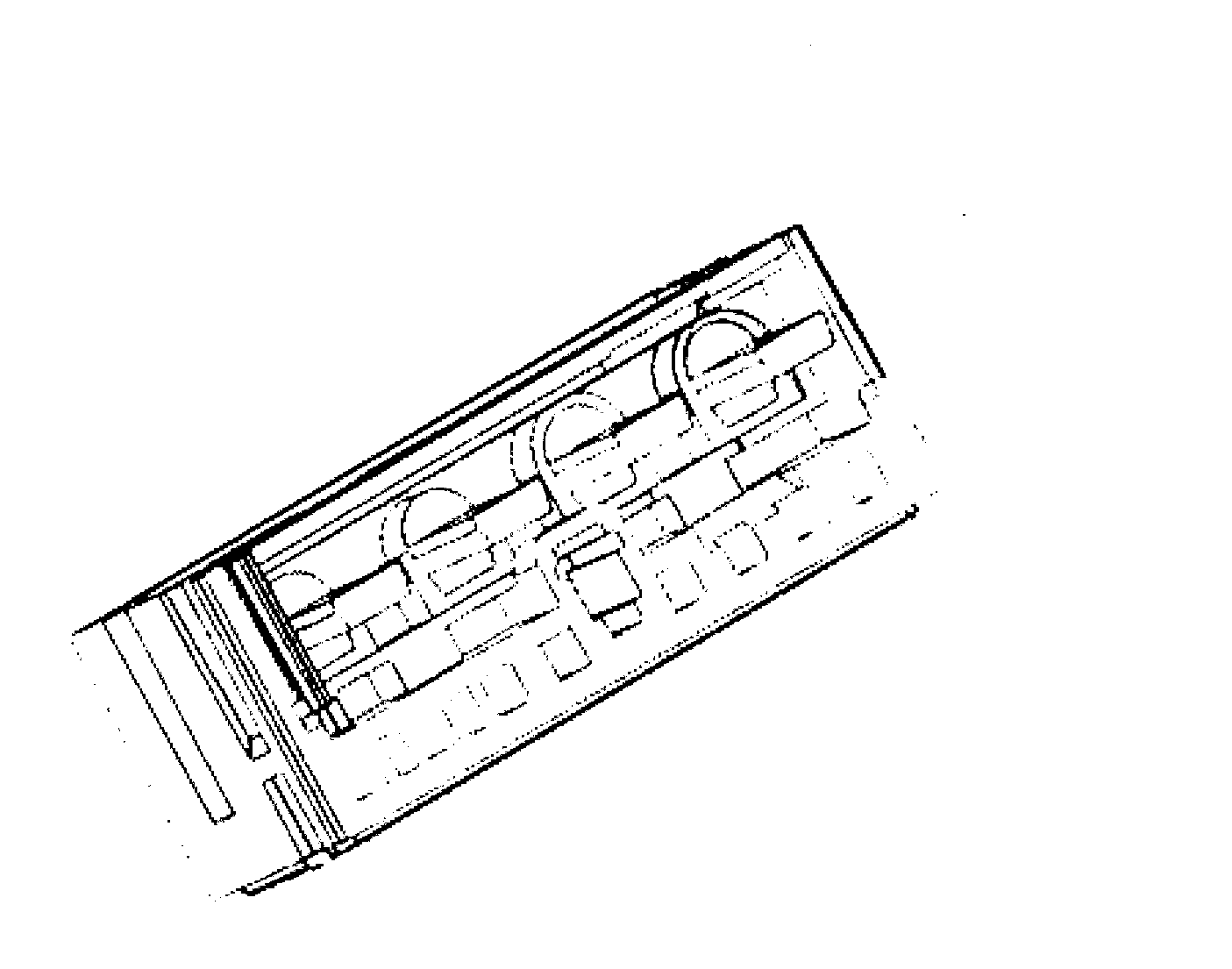

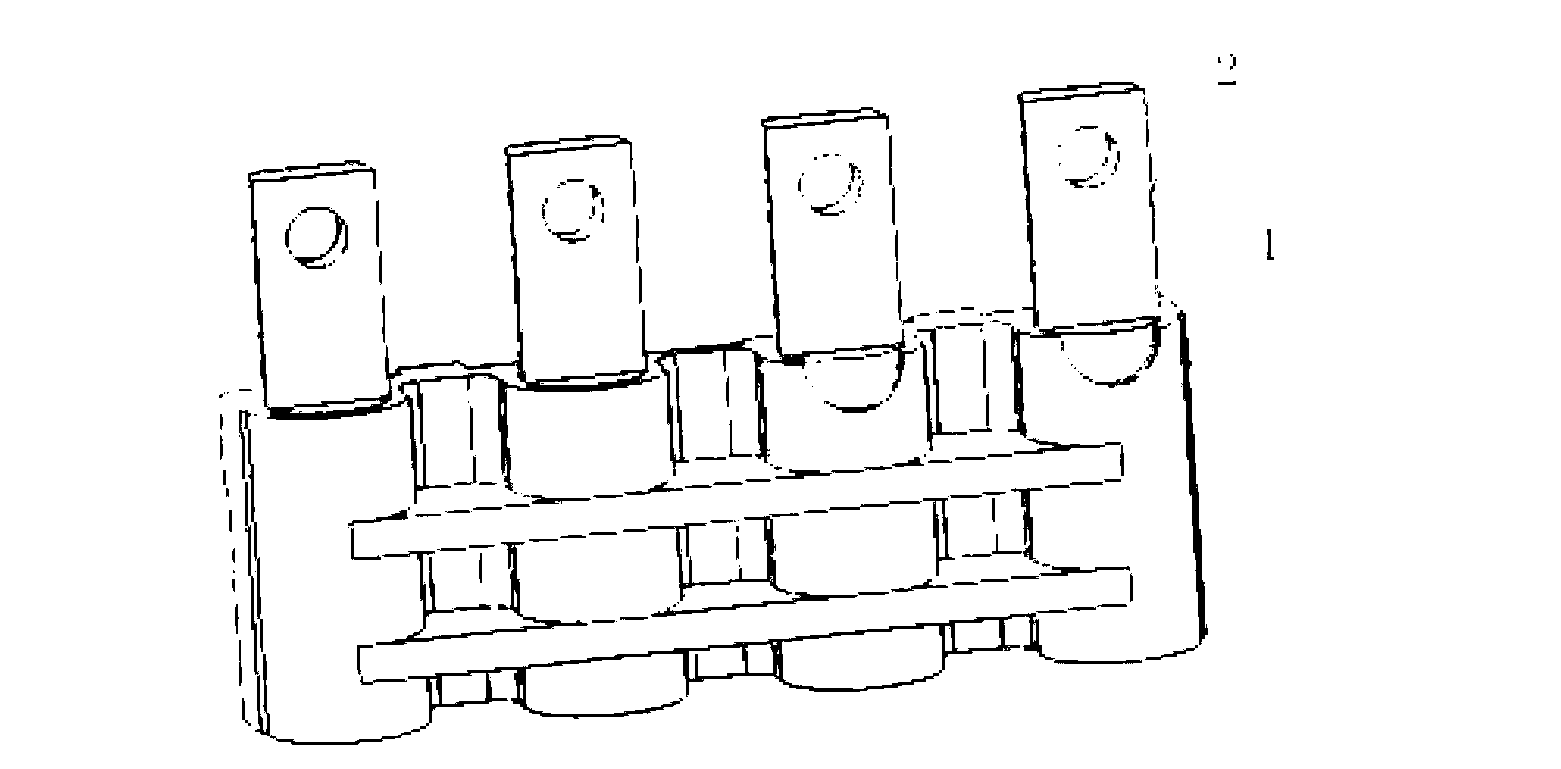

[0011] like figure 1 and figure 2 As shown, the present invention is a composite embedded electric energy meter end button, which includes an end button body and a current terminal 2 embedded in the end button body. The end button body includes bakelite 1 and plastic 3, and the current terminal 2 The bakelite 1 is thermoset formed into a bakelite terminal core row, and the bakelite terminal core row and the plastic 3 are secondary injection molded.

[0012] Now the current terminal 2 and bakelite 1 are thermoset and then poly PC + GF plastic 3 is used for secondary injection molding. The advantages of the two materials are combined, the materials are used reasonably, and the product quality and reliability are greatly improved; the original terminal button Structure Each product needs to use 70g of Bakelite, while each product only needs 18g of Bakelite in the way of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com