Patents

Literature

34results about How to "Improve grinding and polishing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

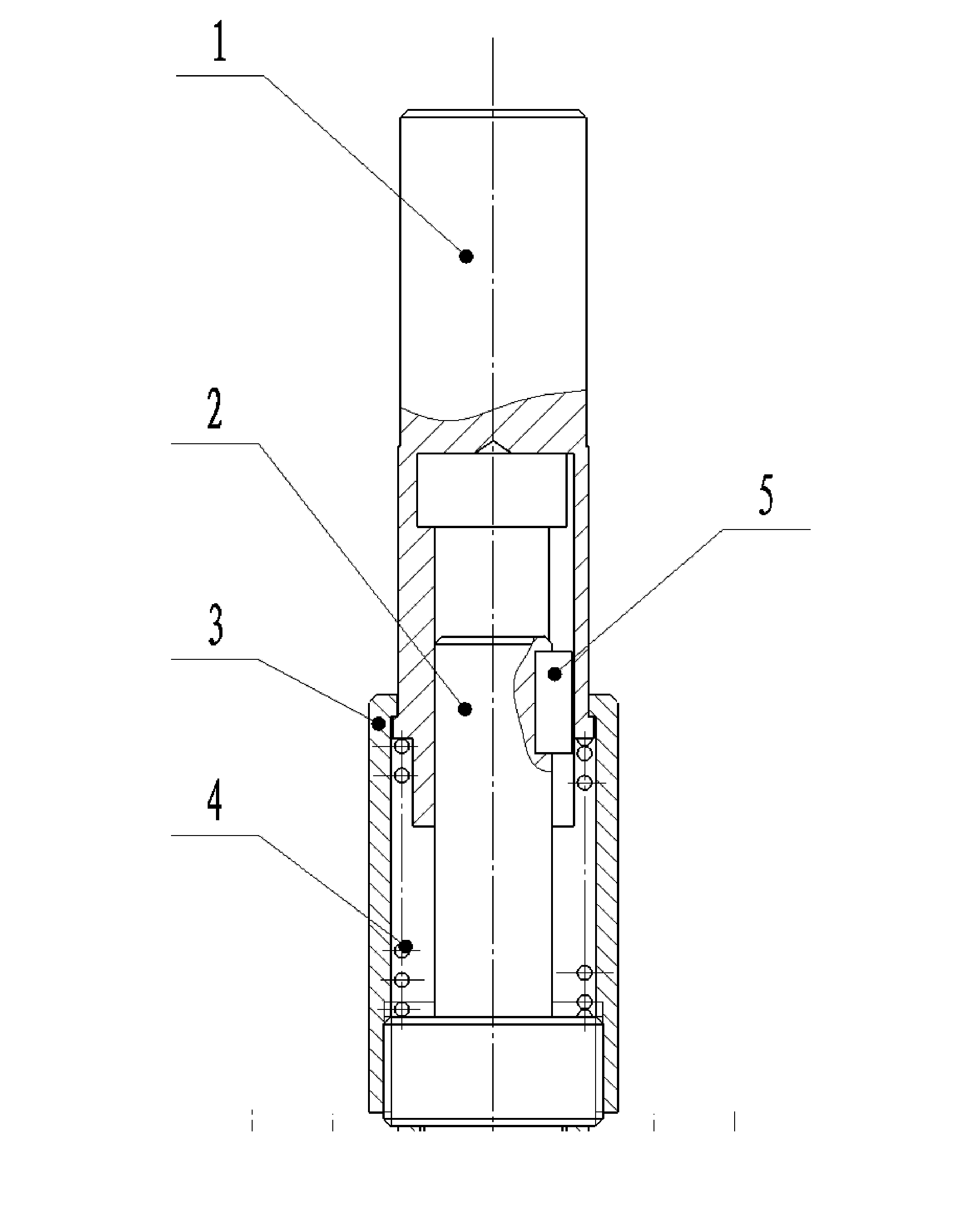

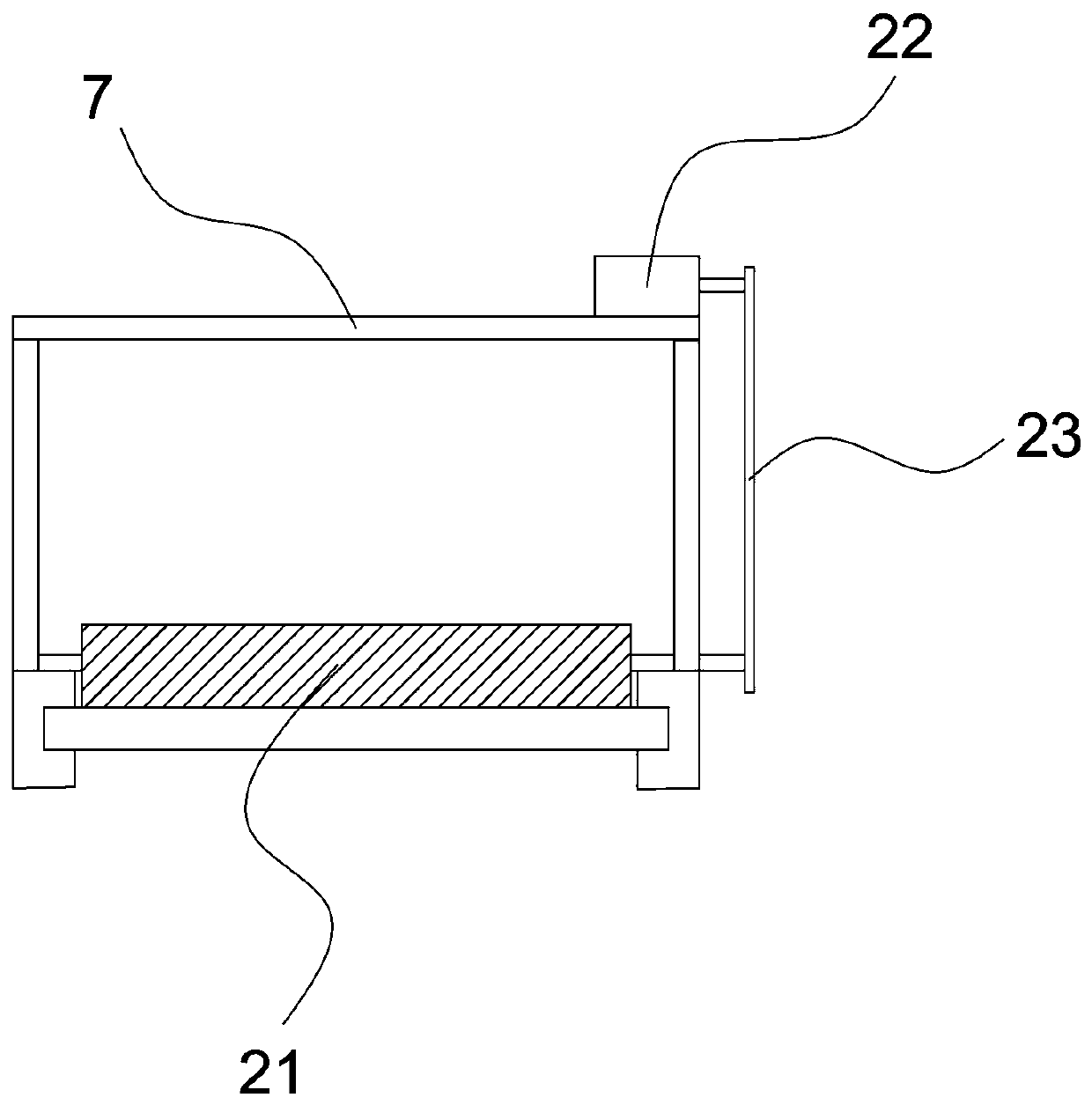

Abrasive belt grinding and polishing device

ActiveCN104084866AMeet the process requirementsAutomatic roll inBelt grinding machinesElectromagnetic clutchGear wheel

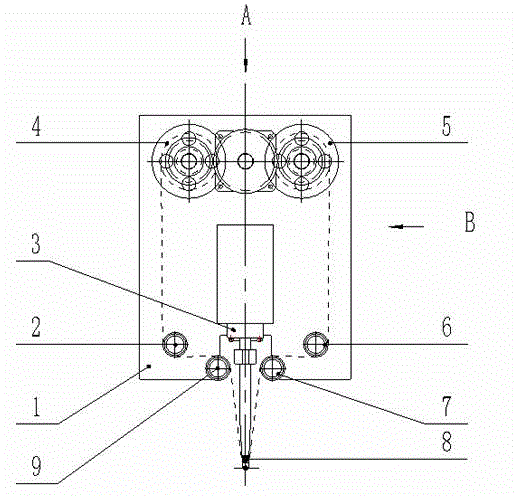

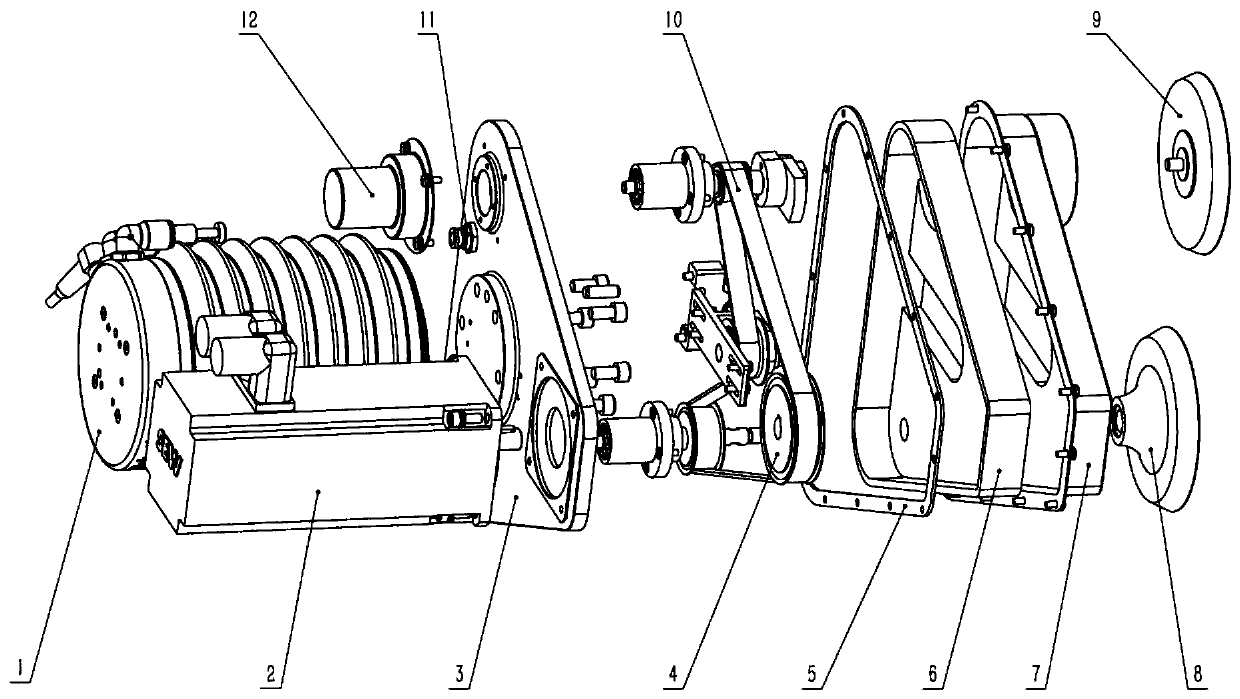

The invention discloses an abrasive belt grinding and polishing device. The abrasive belt grinding and polishing device comprises a mounting plate, an unwinding roller, a winding roller, a tensioning mechanism and a driving mechanism. The driving mechanism comprises a servo motor, a driving gear, driven gears, driven gear transmission shafts and roller shafts. The driving gear is mounted on an output shaft of the servo motor. The driven gears are mounted at one end of the driven gear transmission shaft on one side of the driving gear and one end of the driven gear transmission shaft on the other side of the driving gear respectively and are meshed with the driving gear. The unwinding roller is mounted at one end of the corresponding roller shaft. The winding roller is mounted at one end of the corresponding roller shaft. The other ends of the roller shafts are connected with the other ends of the corresponding driven gear transmission shafts through electromagnetic clutches. The tensioning mechanism is composed of friction disks, transition wheels and the like. The rollers are controlled through engagement and disengagement of the electromagnetic clutches arranged between the roller shafts of the rollers and a driving shaft, so that active belt winding or passive belt unwinding is achieved; the friction disks on the end faces of the rollers can apply friction force to the rollers subjected to passive unwinding so as to ensure that a grinding and polishing belt has enough tensile force in the machining process and improve the grinding and polishing quality.

Owner:CHONGQING UNIV +1

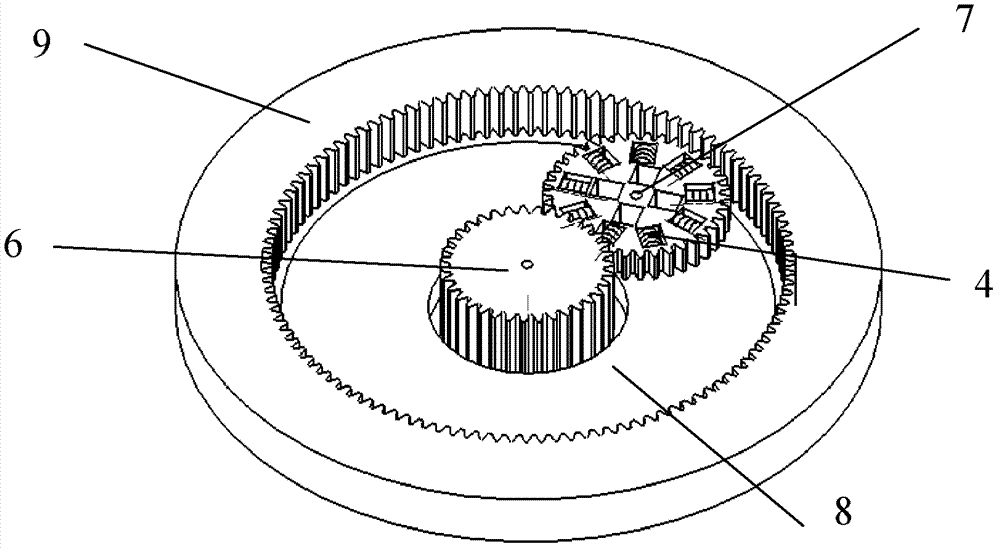

Laser gyro lens excircle grinding and polishing method

ActiveCN102049728AImprove grinding and polishing efficiencyImprove grinding and polishing qualityLapping machinesAdhesiveEngineering

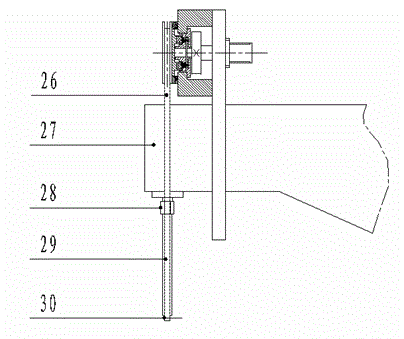

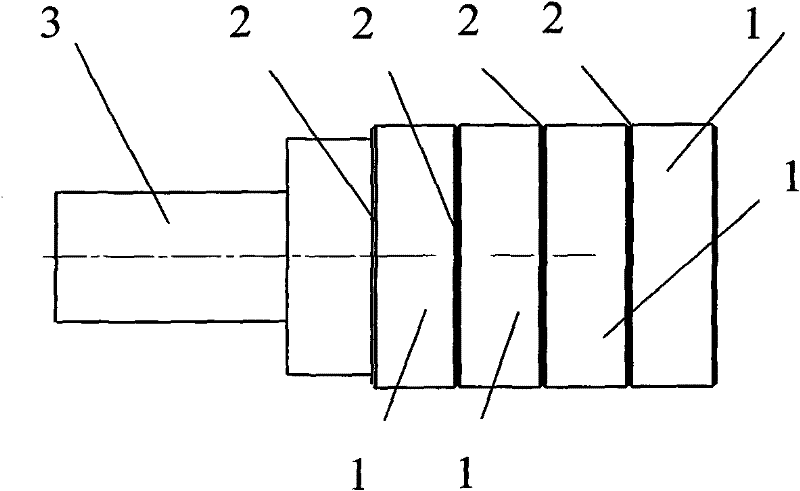

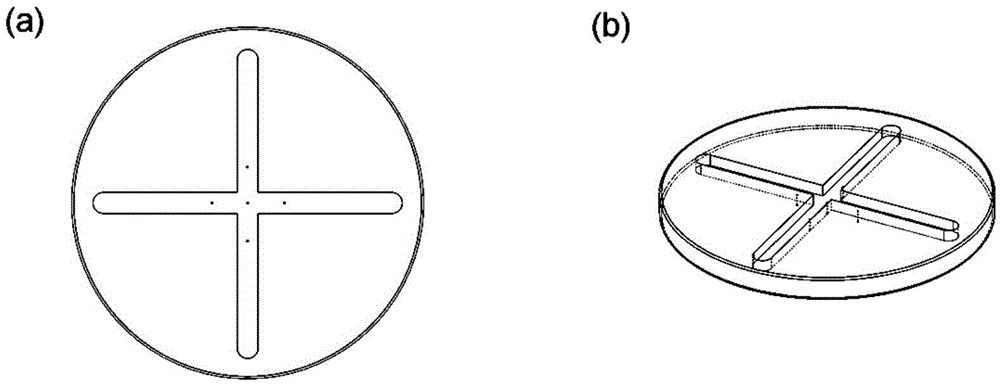

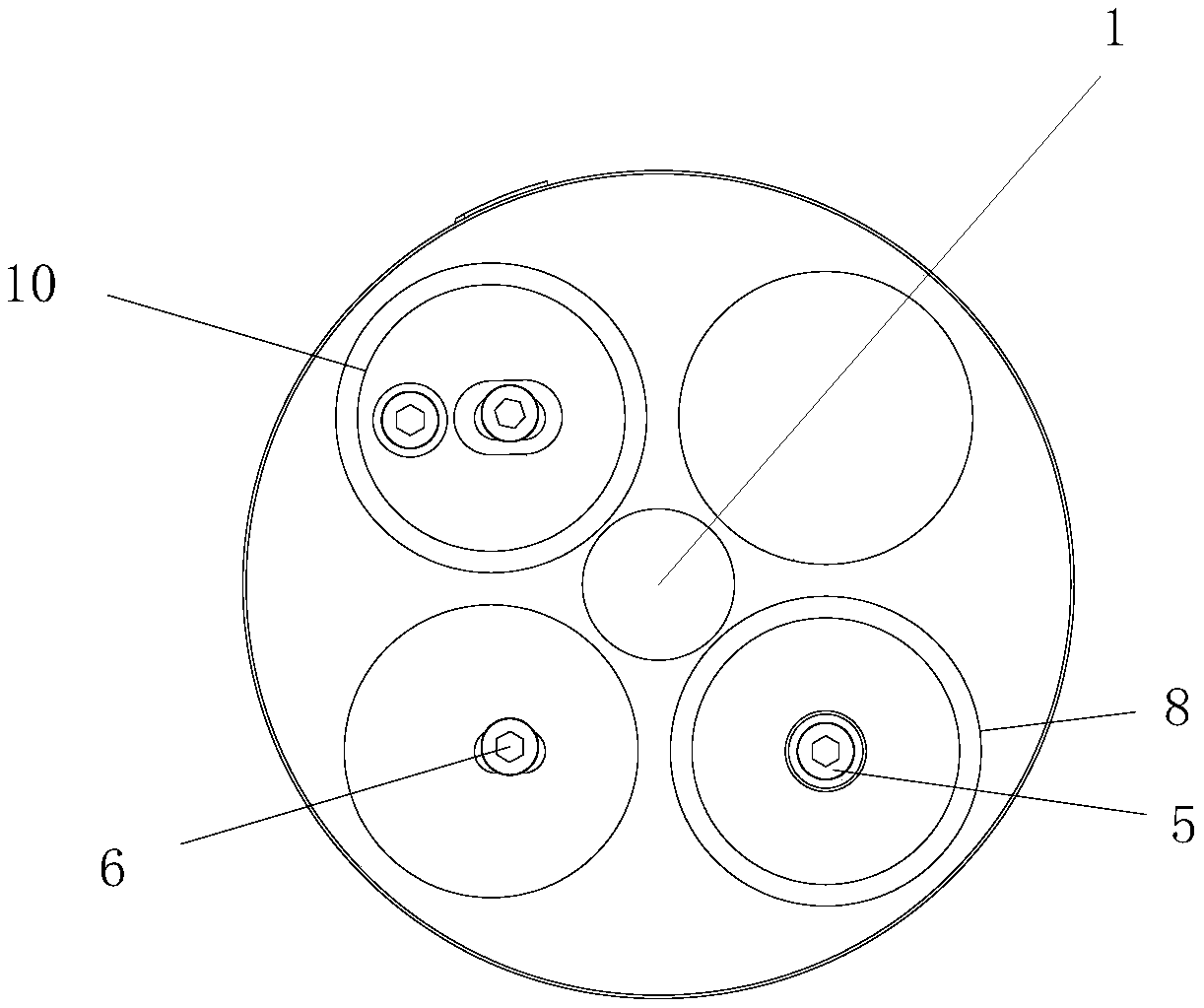

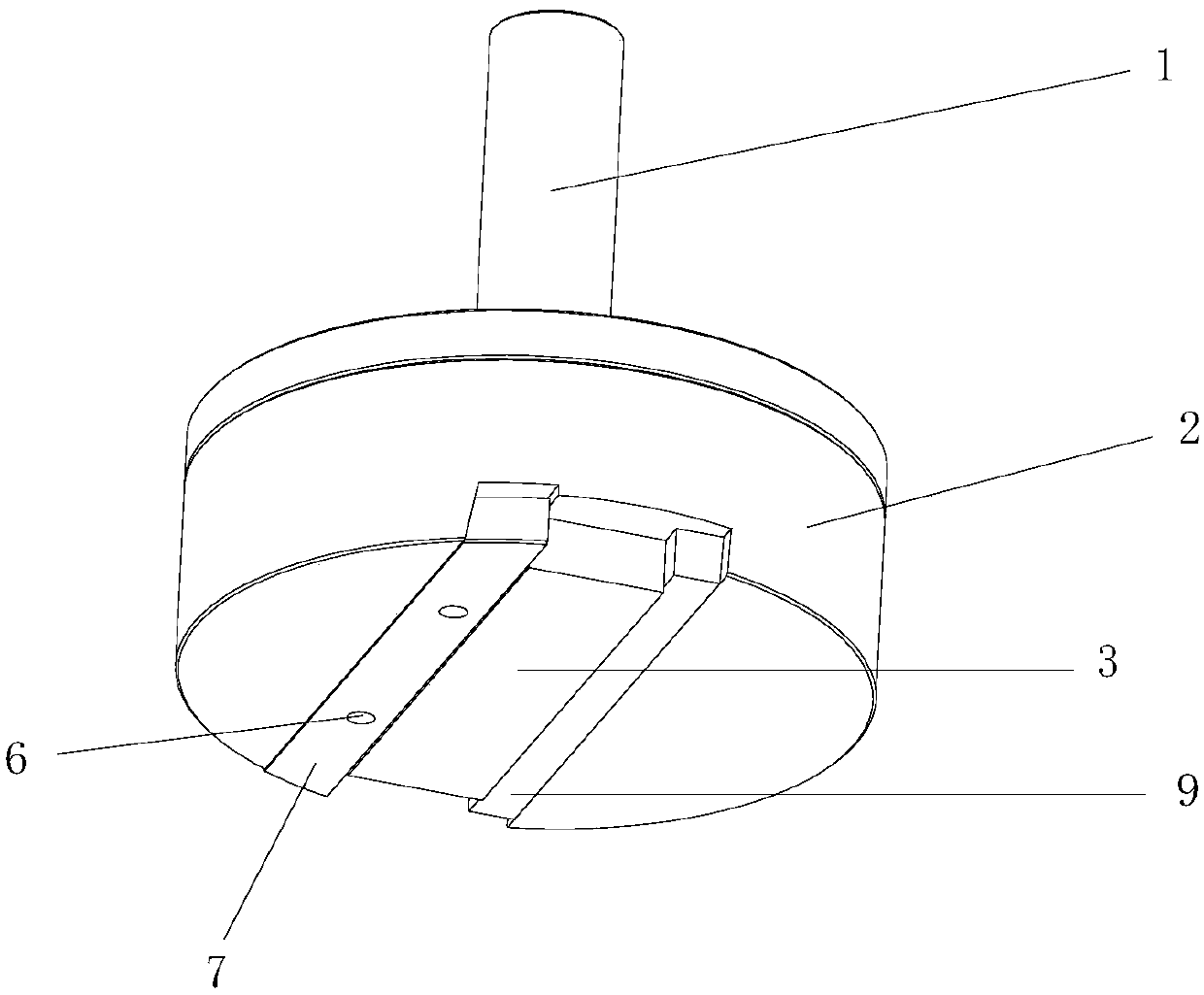

The invention relates to a laser gyro lens excircle grinding and polishing method which comprises the following steps of: bonding a lens and a bonded joint into a pillar with the bonded joint (see the figure 1) by using a bonding adhesive, and fixing the bonded joint by using a three-jaw clamp of a grinding machine to ensure that the runout of the excircle of the lens pillar is less than 0.3 mm; disconnecting the adhesive to remove the bonded joint after the excircle of the lens pillar is ground to grinding size, and chamfering the sharp edges of both end faces of the lens pillar; placing a wandering star wheel carrier on a double-face grinding machine or polishing machine, and placing the lens pillar in the wandering star wheel carrier; starting the machine, introducing a liquid (a grinding powder liquid or a polishing powder liquid), and driving the wandering star wheel carrier to rotate through the rotation of an inner gear ring and an outer gear ring; and suspending an upper disc of the equipment to ensure that the lens pillar rotates around central axis per se on a lower disk to achieve the effect of grinding and polishing the excircle. The laser gyro lens excircle grinding and polishing method provided by the invention is convenient to operate and has the advantages of high grinding and polishing efficiency, good machining consistency and high quality.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

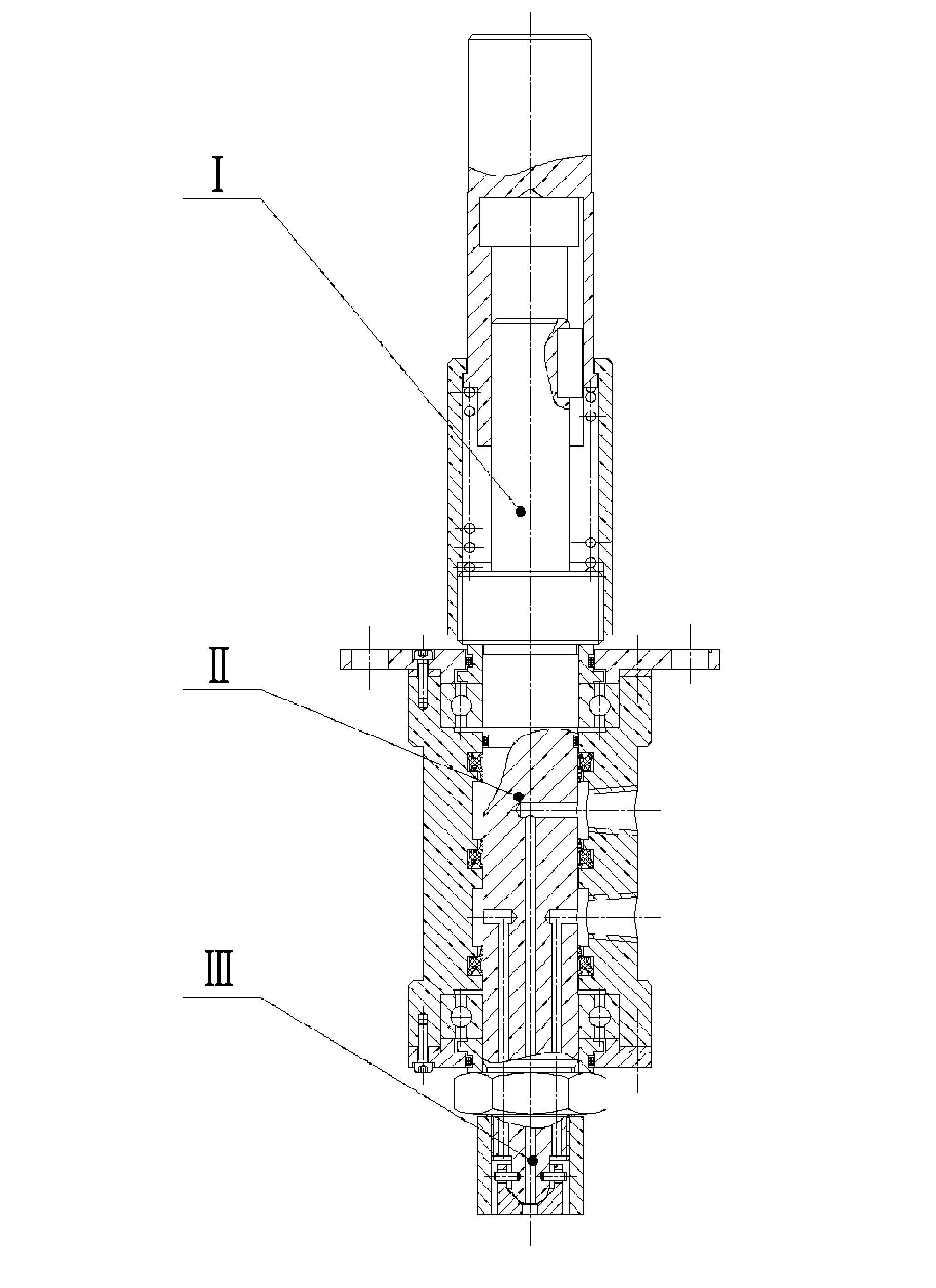

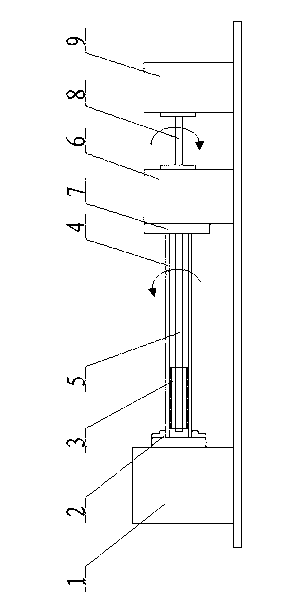

Self-cleaning grinding and polishing tool

ActiveCN102615576AAvoid wastingFully contactedPolishing machinesGrinding/polishing safety devicesEngineeringScrap

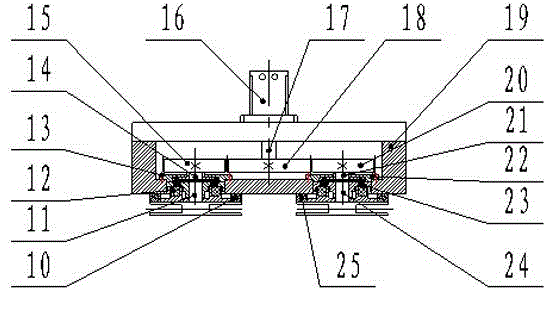

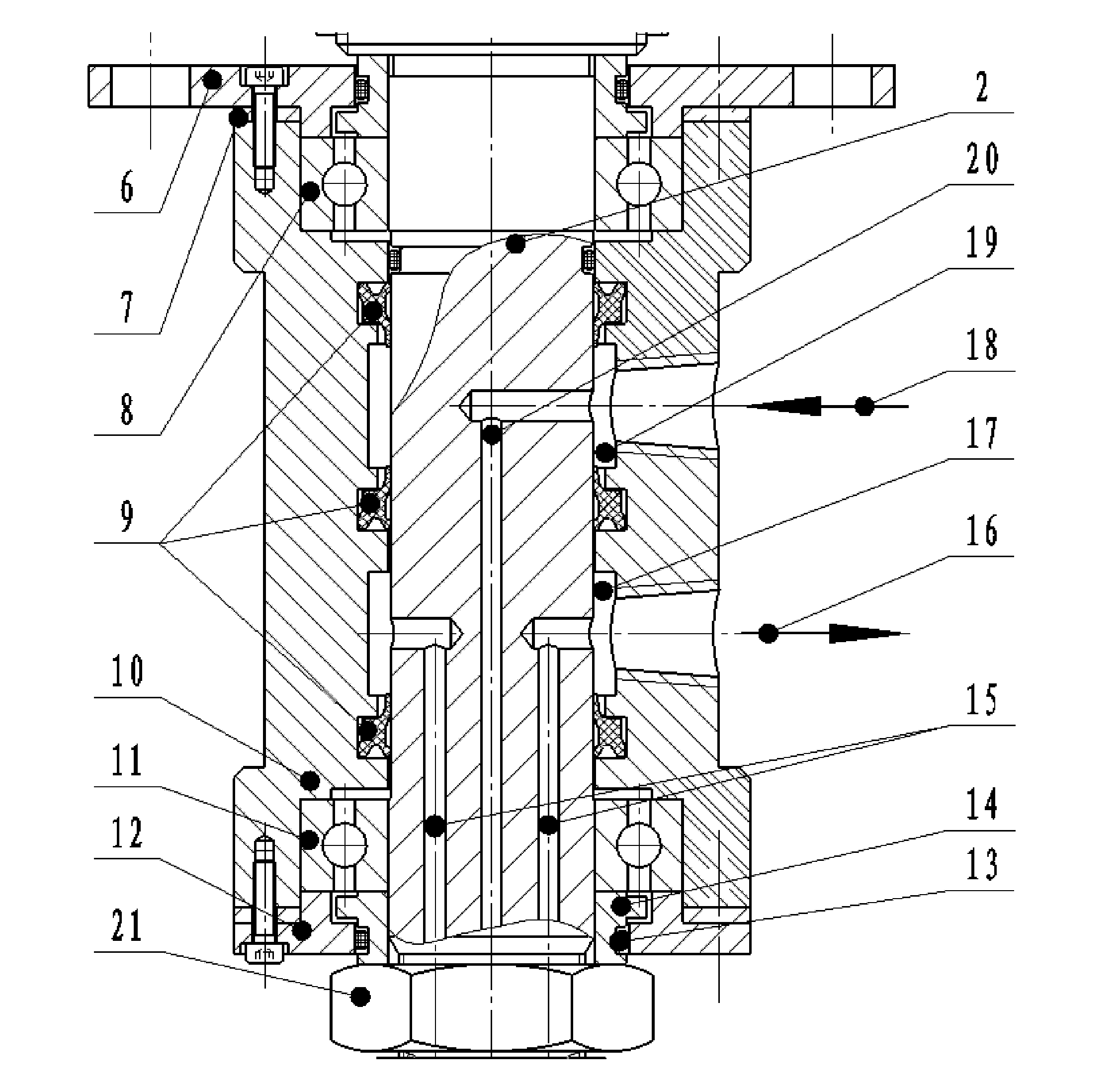

The invention relates to a self-cleaning grinding and polishing tool, which relates to a grinding and polishing tool for self-cleaning overflow grinding and polishing liquid and grinding and polishing scraps through vacuum absorption while grinding and polishing a surface in the central liquid supplying process. The tool consists of a pressurization unit, a liquid supplying and cleaning unit and a grinding and polishing operation unit, wherein the pressurization unit is used for adjusting grinding and polishing pressure; the liquid supplying and cleaning unit is used for introducing grinding and polishing media and vacuumizing and absorbing the grinding and polishing media; and a grinding and polishing effect is achieved by the grinding and polishing operation unit. The grinding and polishing tool moves in a certain track under the control of a computer, so that a large plane can be totally flattened. The tool has the advantages that the grinding and polishing media are introduced into the center of a grinding and polishing head, so that the grinding and polishing media can be fully contacted with grinding and polishing materials, and the grinding and polishing quality and the grinding and polishing efficiency are improved; and by a vacuumized pore passage of an outer ring of the grinding and polishing tool, the grinding and polishing media which are subjected to a grinding and polishing process is sucked away in time, so that the ground and polished surface is prevented from being polluted, the effect of self-cleaning the surface of a workpiece in the grinding and polishing process is achieved, subsequent cleaning processes are eliminated, and processing efficiency is improved.

Owner:DALIAN UNIV OF TECH

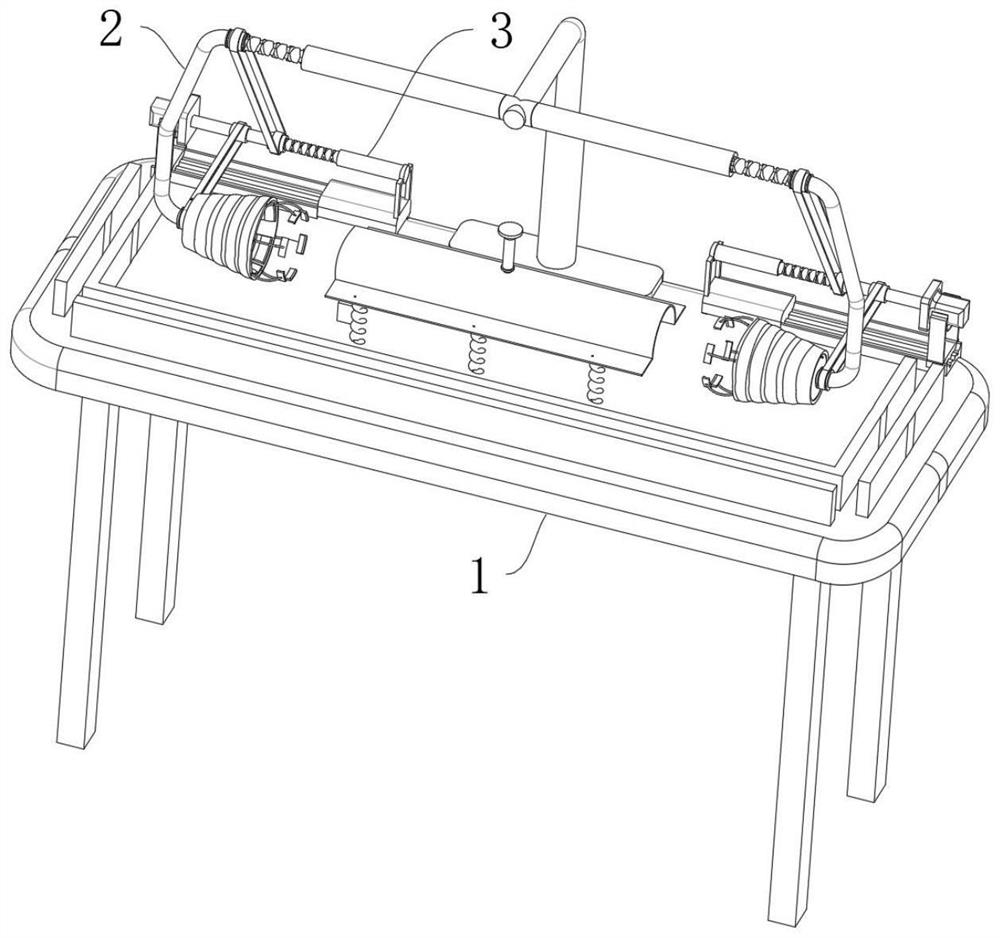

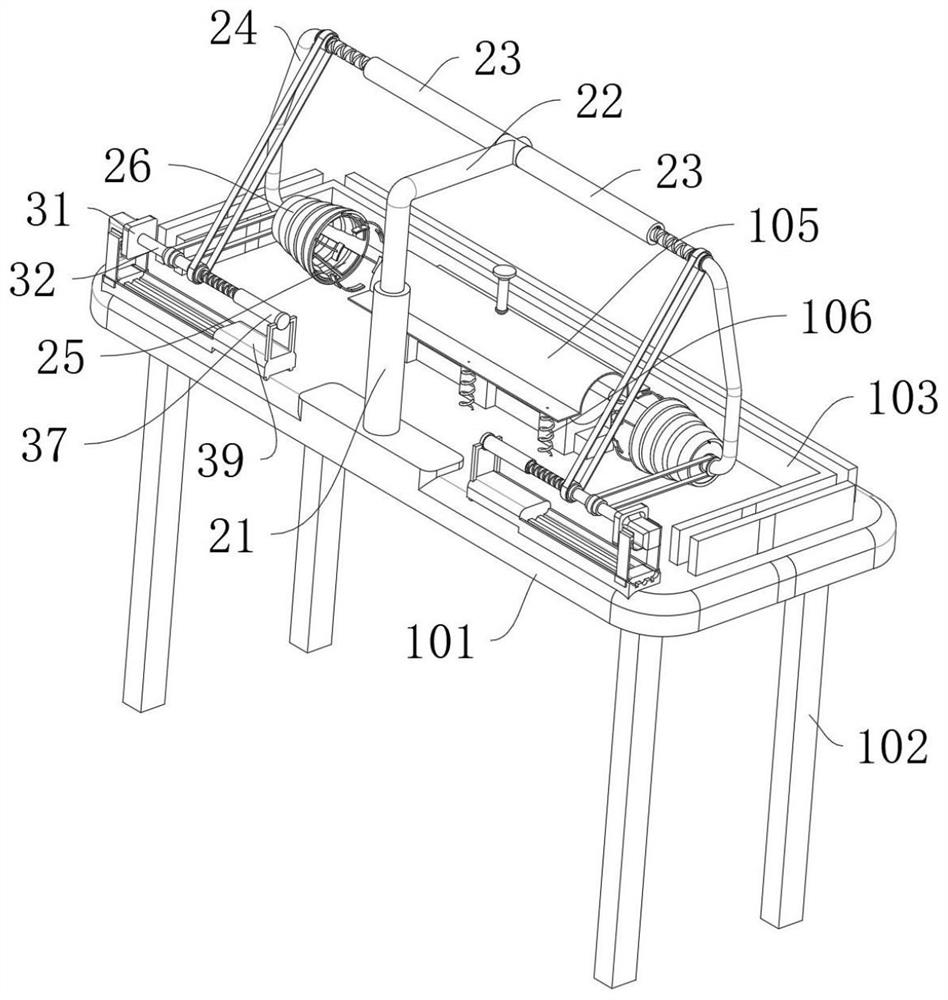

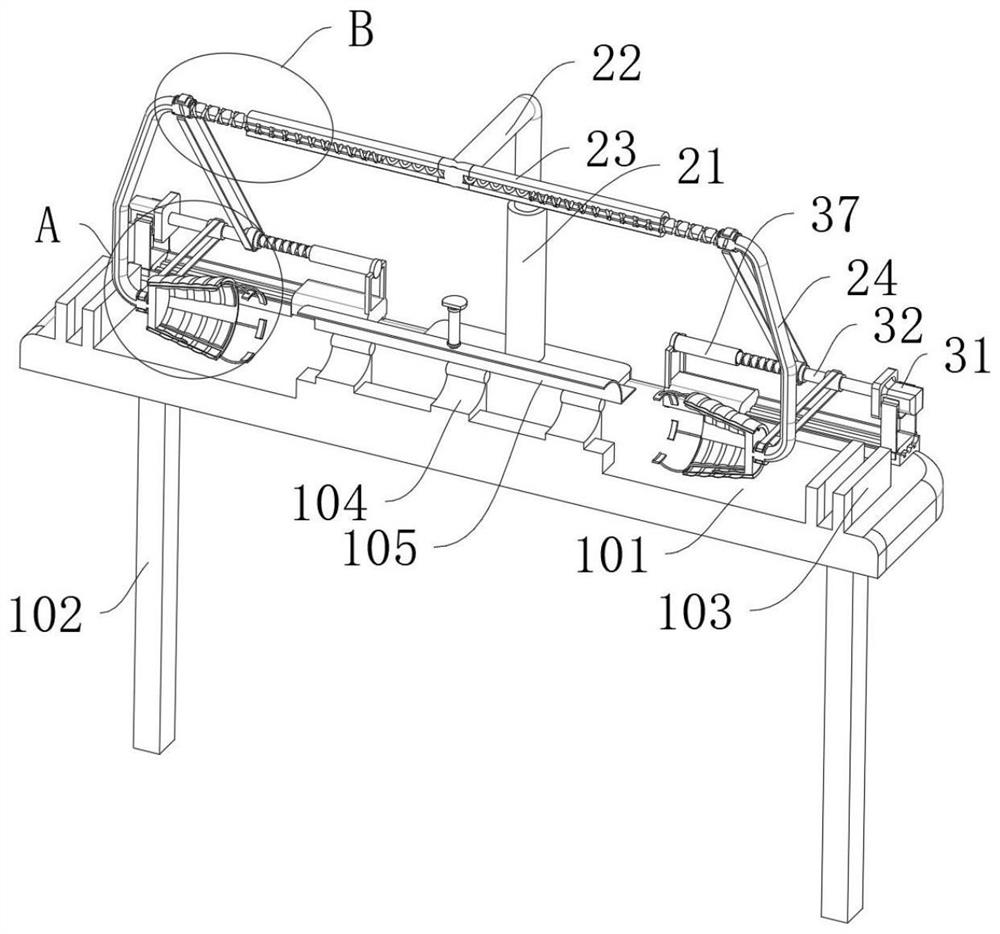

Grinding and polishing equipment for post-treatment of wood carving

ActiveCN110834247AEasy to installAdjustable distanceGrinding carriagesGrinding drivesShape changePolishing

The invention discloses grinding and polishing equipment for post-treatment of wood carving. The grinding and polishing equipment comprises a base, wherein two left-right symmetrical fixing plates arefixedly connected to the upper side end face of the base; a transverse moving box is fixedly connected to the fixing plates; the fixing plates are each provided with a clamp, and the two clamps are symmetrical left and right and are used for clamping and fixing the wood carving; a transverse moving device used for providing transverse moving motion for grinding and polishing is arranged in the transverse moving box; a power device is arranged between the transverse moving device and the left clamp and is used for providing power for the clamps and the transverse moving device; and a polishingdevice is arranged on the transverse moving device. A grinding and polishing mechanism utilizes the shape change of the wood carving to change the acting force between a polishing flower-like head and the wood carving, so that an air path switching mechanism switches the air path, then an air cylinder mechanism correspondingly moves up and down to adapt to the shape change of the wood carving, and thus the automatic grinding and polishing of the wood carving is realized.

Owner:阜南县中泰工艺品有限公司

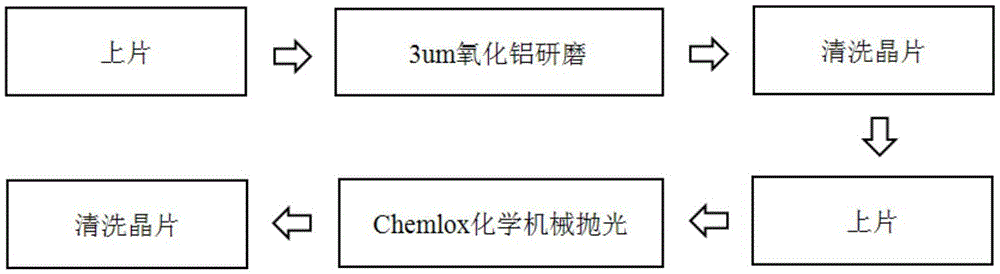

Method for grinding and polishing CdZnTe wafer without wax

The invention discloses a method for grinding and polishing a CdZnTe wafer without wax. The method includes the steps that firstly, a grinding and polishing clamp joint plate is designed and manufactured and horizontally placed on an adsorption plane of a grinding and polishing clamp; the wafer is placed in the center of the joint plate to cover all small vacuum flow guide holes in the joint plate; a grinding clamp is connected with a vacuum generator, and the wafer is adsorbed and fixed; and the wafer is ground through a 3-micron aluminum oxide water solution, 30-50 microns of the wafer is removed, and then a Chemlox polishing liquid chemical machine produced by the Logitech enterprise in England is used for polishing for 2-5 min, and the high-flatness CdZnTe wafer is obtained after cleaning. The method has the beneficial effects that a heating wafer sticking and wax melting wafer taking are not needed, the thickness of the wafer is controlled more accurately, and flatness is higher; the method is suitable for wafers of different sizes, shapes and thicknesses, and practicability is high; cleaning is easy after grinding and polishing, and secondary contamination cannot be caused on the wafer; and cracks and scratches can be reduced, and the grinding and polishing quality is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Vehicle rotor machining method

InactiveCN111463972AAchieve supportRealize the loading workRevolution surface grinding machinesManufacturing stator/rotor bodiesHydraulic cylinderPunching

The invention discloses a vehicle rotor machining method. The vehicle rotor machining method specifically comprises steps that finish machining of a mandrel is conducted through a lathe, the mandrel and a rotor punching sheet are placed in the tool, a packaging material is put into a processing machine, after heating treatment, the packaging material is hardened, therefore, a core shaft and the rotor punching sheet are connected together, a left wire end and a welding point of the commutator are welded together after wire winding is finished, and the like, a second piston rod in a second hydraulic cylinder is controlled to move downwards through the second hydraulic cylinder, a pressing belt is in contact with a top surface of a rotor, pressure is applied to a top surface of the rotor, therotor does not slide relative to a transmission track, an output end of the second motor drives the rotating shaft to rotate, the rotating shaft drives a grinding disc to rotate, an outer surface ofthe rotor is ground and polished, a clamp does not need to be used for controlling the position of the rotor, the occupied space of the whole equipment is reduced, the processes of clamping, fixing and detaching the rotor through the clamp are reduced, and working efficiency is improved.

Owner:安徽锐锋电器有限公司

Grinding and polishing clamp for stainless steel part machining and machining technology of grinding and polishing clamp

PendingCN113305699AIncrease profitQuality improvementGrinding carriagesGrinding drivesElectric machineryDrive motor

The invention discloses a grinding and polishing clamp for stainless steel part machining and a machining technology of the grinding and polishing clamp. The grinding and polishing clamp comprises a base, a mounting seat is slidably mounted in the middle of the upper end of the base, a lifting supporting column is slidably mounted at the upper end of the mounting seat, and a grinding and polishing assembly is fixedly mounted on the upper portion of the rear end of the lifting supporting column. Two stand columns and a driving motor are fixedly installed on the left portion of the upper end of the base, the upper portions of the opposite faces of the two stand columns are jointly and rotationally connected with a shaft rod, and the right end of the shaft rod penetrates through the stand column located on the right side, extends to the right side of the stand column, and a clamping device is fixedly installed at the right end of the shaft rod. According to the grinding and polishing clamp for stainless steel part machining and the machining technology of the grinding and polishing clamp, the automation degree is high, the working efficiency is high, the utilization rate of a grinding abrasive belt and the overall grinding and polishing quality are improved, and the machining yield is improved to a certain degree; and potential safety hazards caused by the fact that stainless steel pipes are not clamped and fly out in the rotating process due to misoperation can be avoided, and safety is high.

Owner:江门市弈创科技有限公司

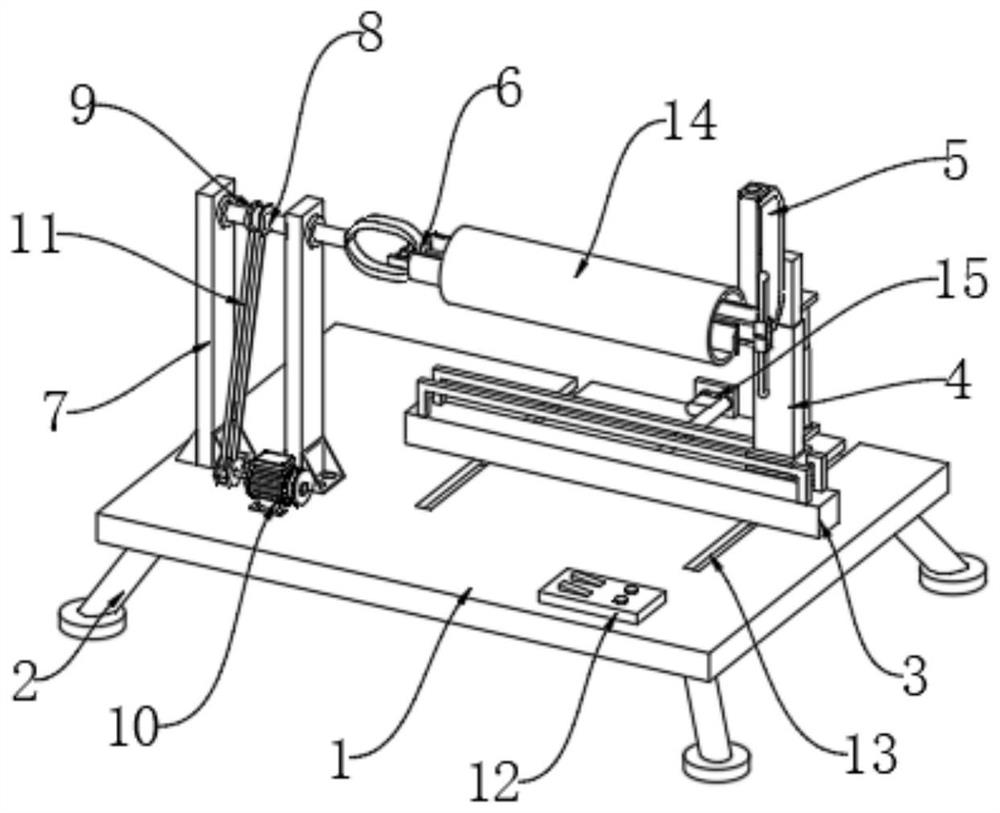

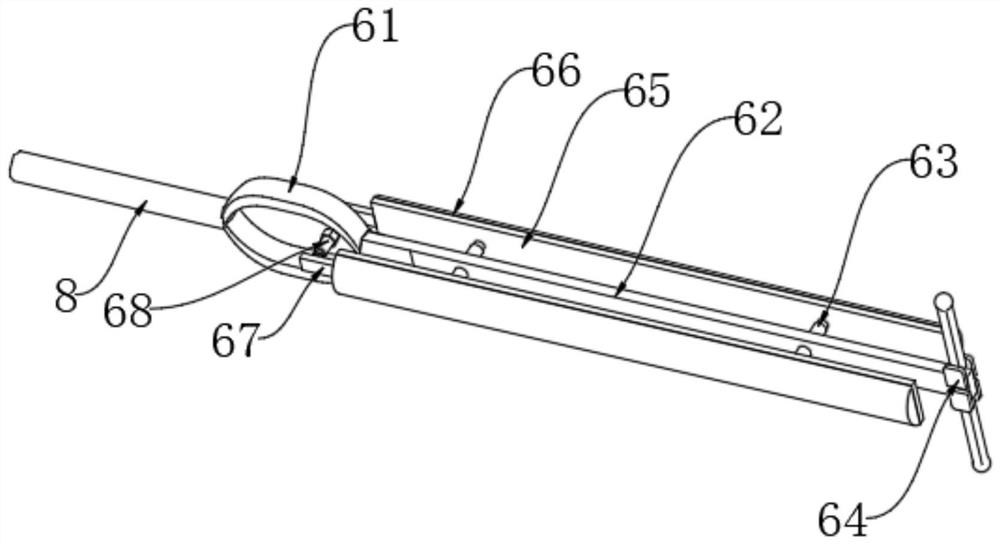

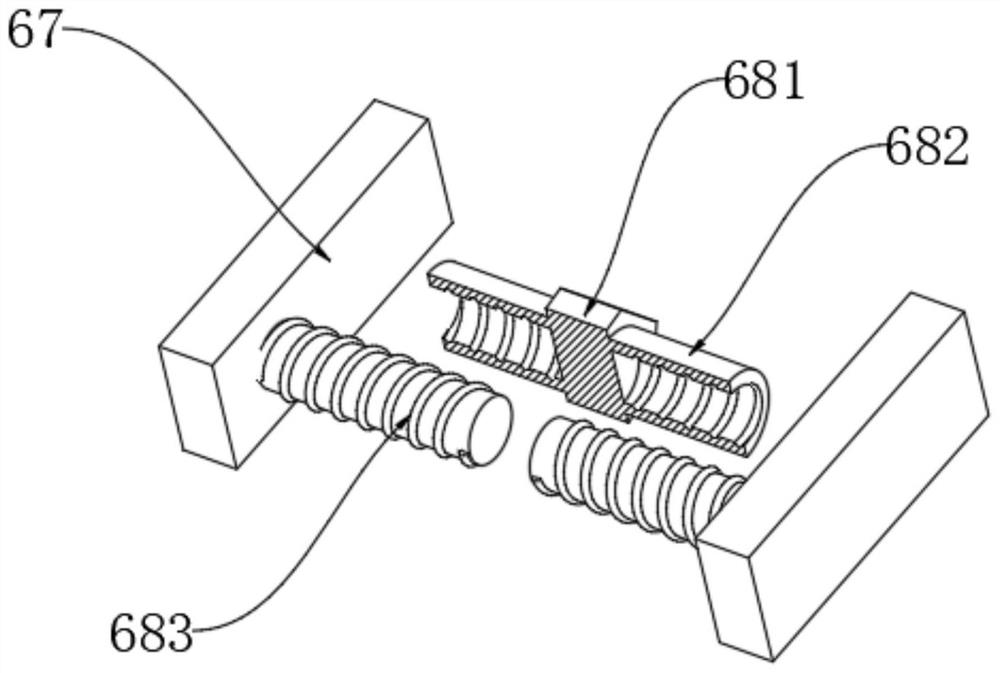

A high-efficiency electrochemical electrode polishing machine and its use method

InactiveCN104526525BIncrease profitEasy to holdPolishing machinesGrinding drivesReciprocating motionEngineering

The invention relates to an efficient electrochemical electrode polisher. The efficient electrochemical electrode polisher comprises an electric appliance control box, a rack bottom plate is arranged above the electric appliance control box, a polish-grinding driving device which can perform reciprocating motion to polish and grind electrochemical electrodes is disposed on the rack bottom plate, supporting columns are symmetrically disposed on left and right sides of the rack bottom plate, a main shaft supporting seat is fixed at tops of the supporting columns, and an electrode clamping device which can clamp the electrochemical electrodes and perform reciprocating rotation is disposed on the main shaft supporting seat. According to the efficient electrochemical electrode polisher, on basis of an electrode clamping plate that can clamp four electrodes, a buffer spring is disposed on a main shaft above the electrode clamping plate, maximum contact of the electrodes with polishing cloth can be guaranteed, the polishing cloth is fully utilized, problems of time wasting, low efficiency and low utilization ratio of the polishing cloth in terms of current electrode grinding and polishing can be solved, the polishing efficiency and the polishing accuracy of the electrochemical electrodes can be greatly improved by means of motor rotating speed adjustment, time setting and clockwise and counterclockwise rotation, the work is smooth, and the working efficiency is high.

Owner:FUZHOU UNIV

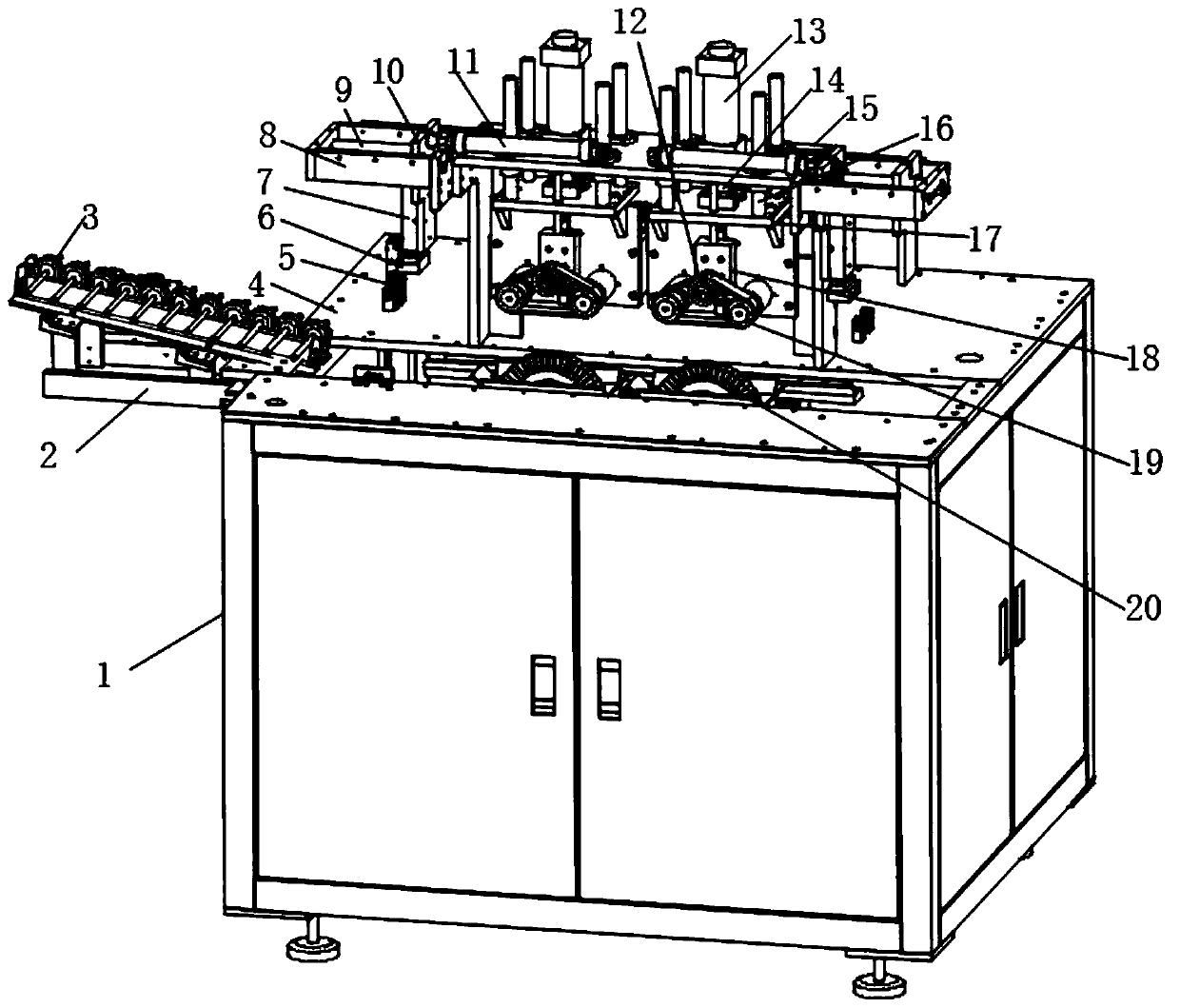

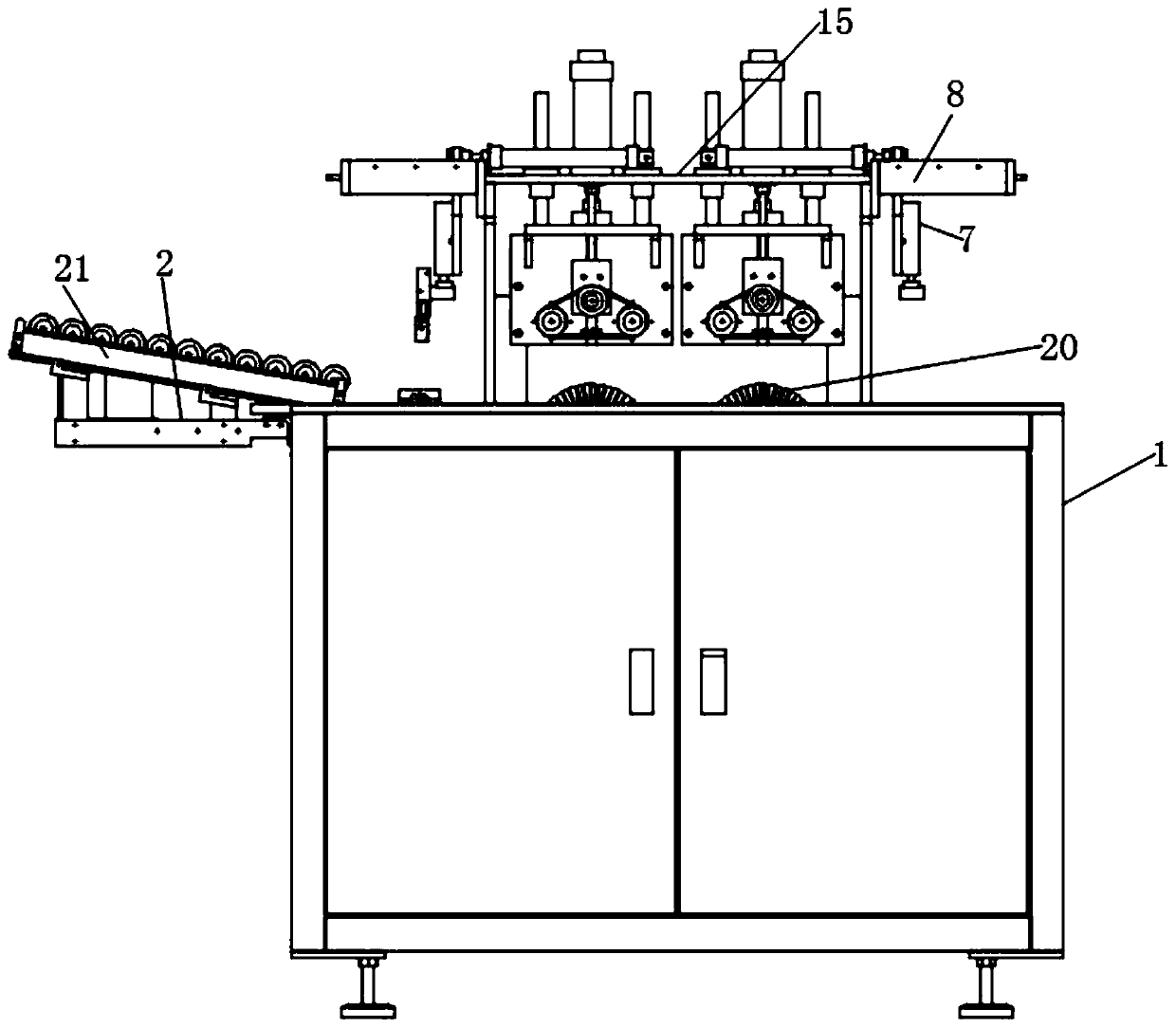

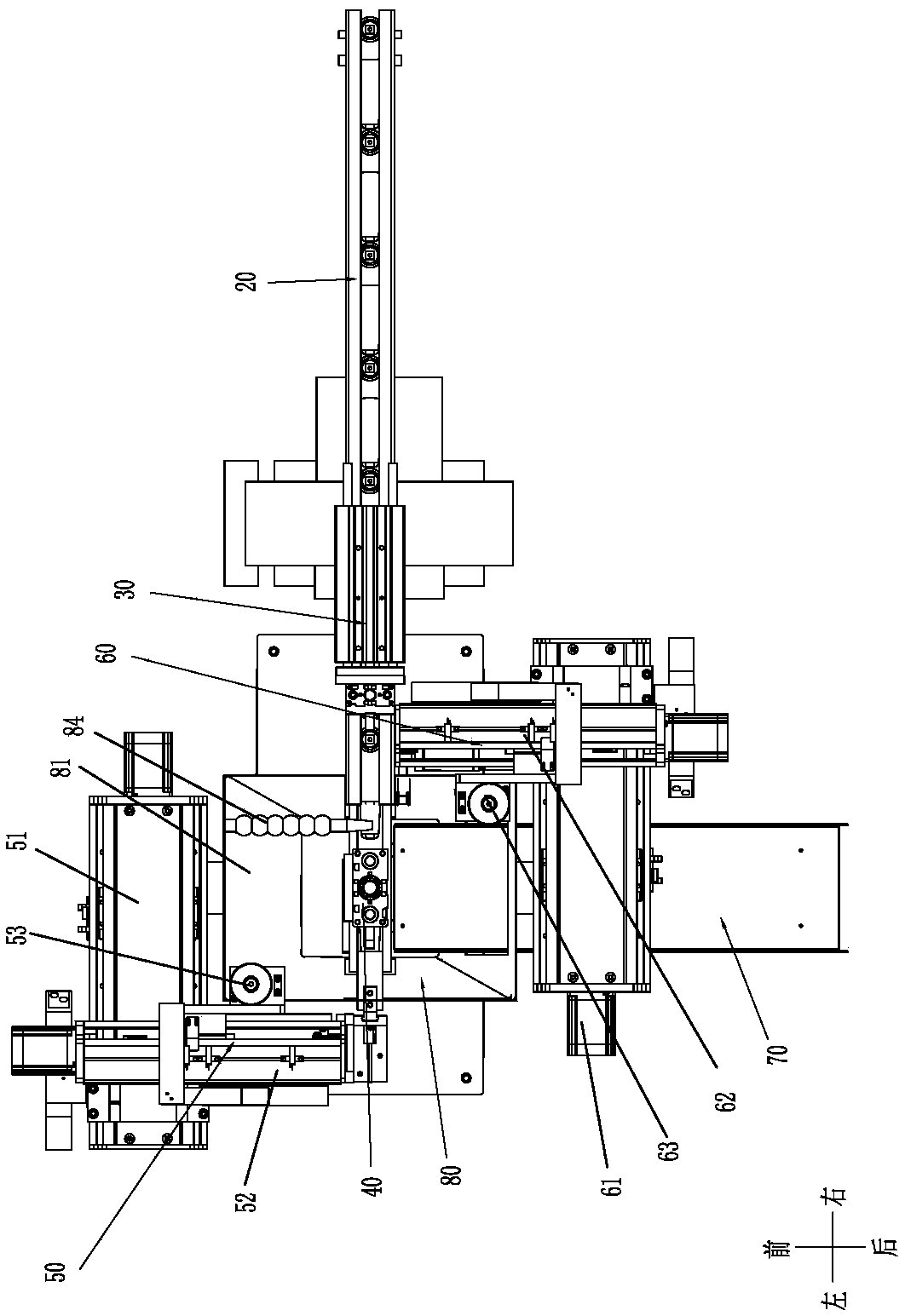

Full-automatic polishing device and method

PendingCN109277918ARealize fully automatic circumferential grinding and polishingAvoid inappropriate phenomenaGrinding drivesAutomatic grinding controlEngineeringMechanical engineering

The invention discloses a full-automatic polishing device and method. The full-automatic polishing device comprises a main control unit, an automatic feeding device, a workpiece clamping and positioning mechanism, a double-platform full-circumferential polishing device and an automatic discharging device. When the full-automatic polishing device works, firstly a workpiece is automatically fed to afeeding area, and then is automatically pushed to a polishing area; afterwards, an upper side clamping fixture and a lower side clamping fixture respectively act on the upper side and lower side of the workpiece so as to clamp and position the workpiece up and down; a first polishing unit polishes one side of the workpiece from a first end to a second end, and meanwhile, a second polishing unit polishes the other side of the workpiece from the second end to the first end, and thus, the circumferential polishing of the workpiece is realized; and finally, the workpiece is automatically discharged. Therefore, the full-automatic polishing device realizes the full-automatic circumferential polishing of the workpiece, substantially improves the working efficiency, reduces the labor cost, meanwhile improves the polishing quality, avoids the phenomenon that the local polishing is not in place, and is suitable for popularization and application.

Owner:王华

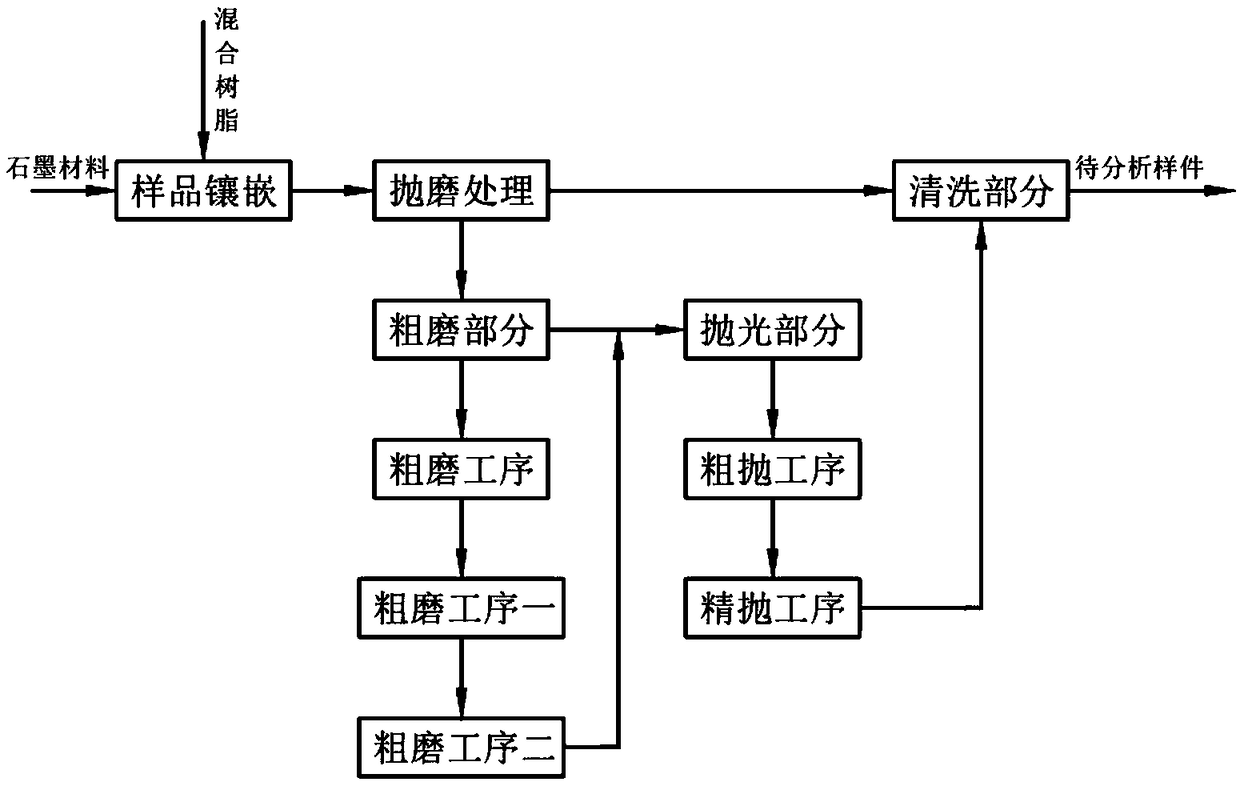

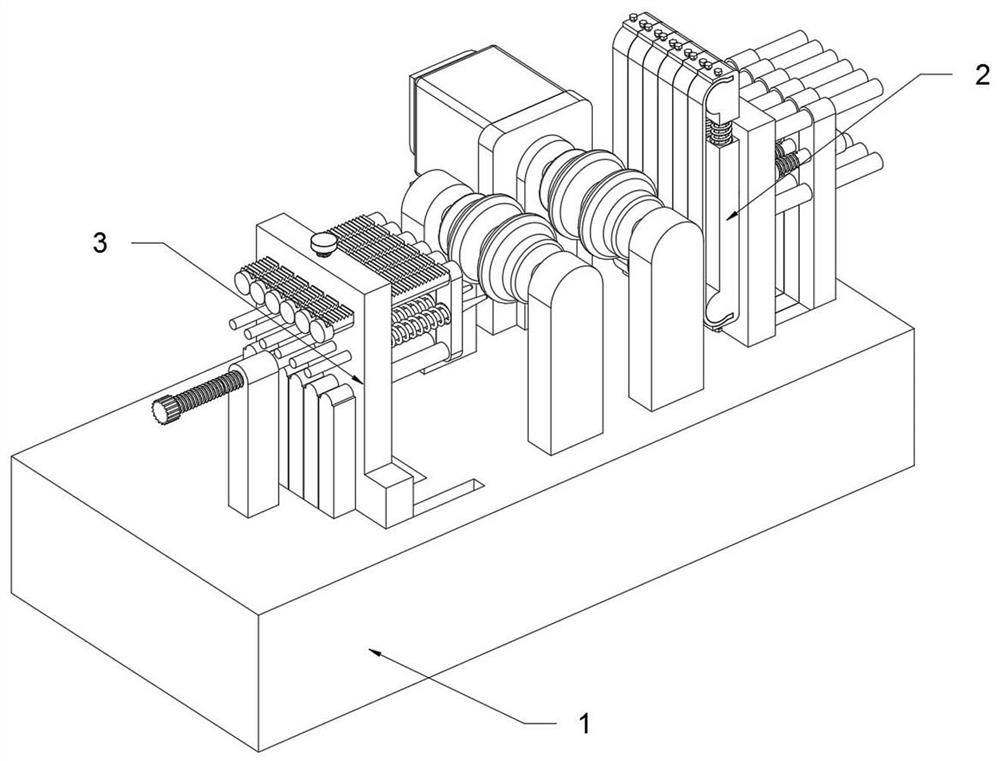

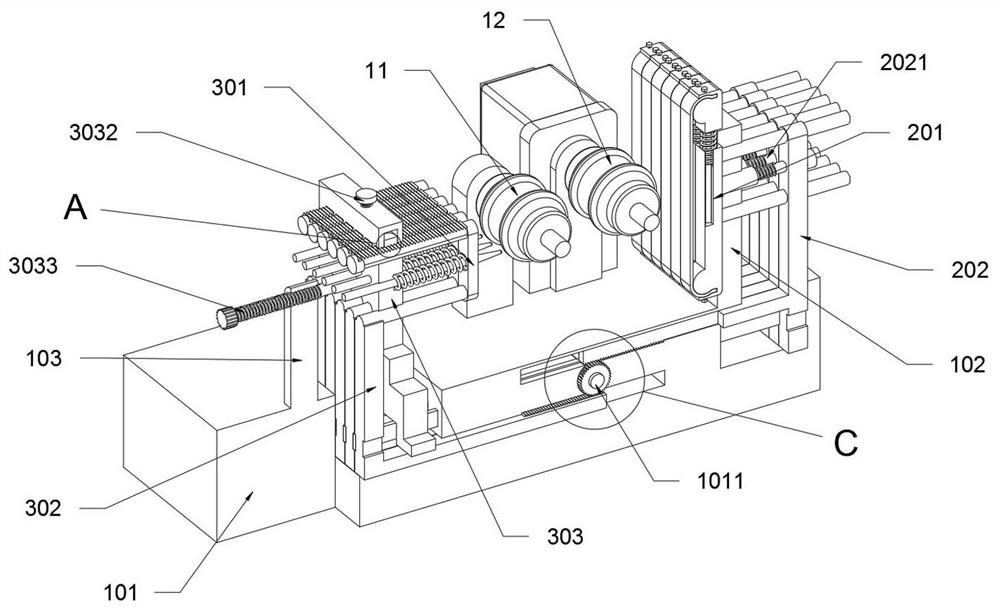

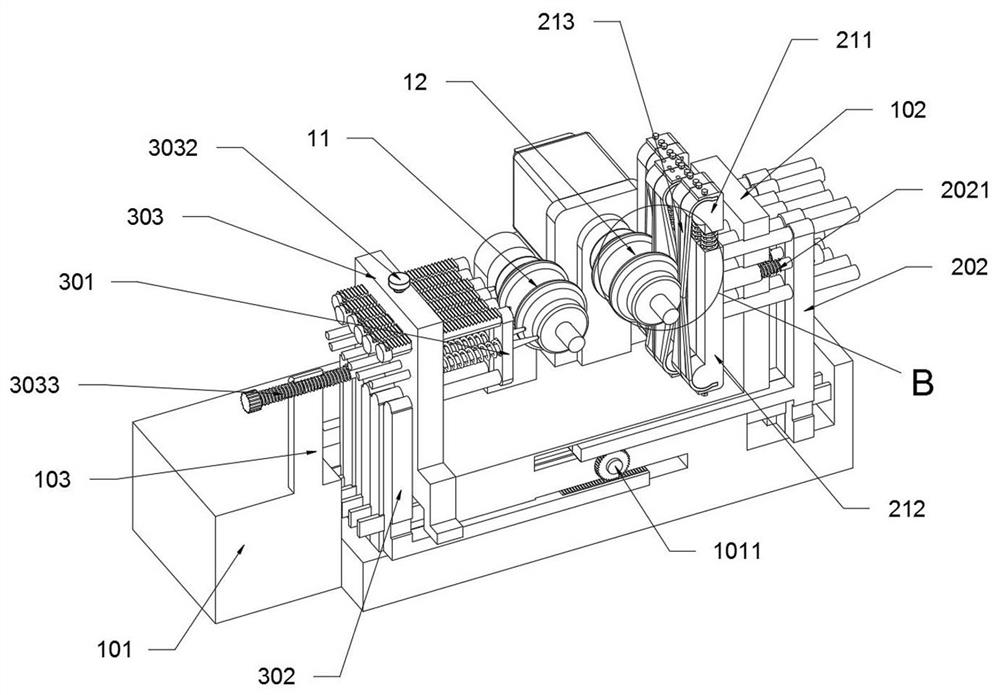

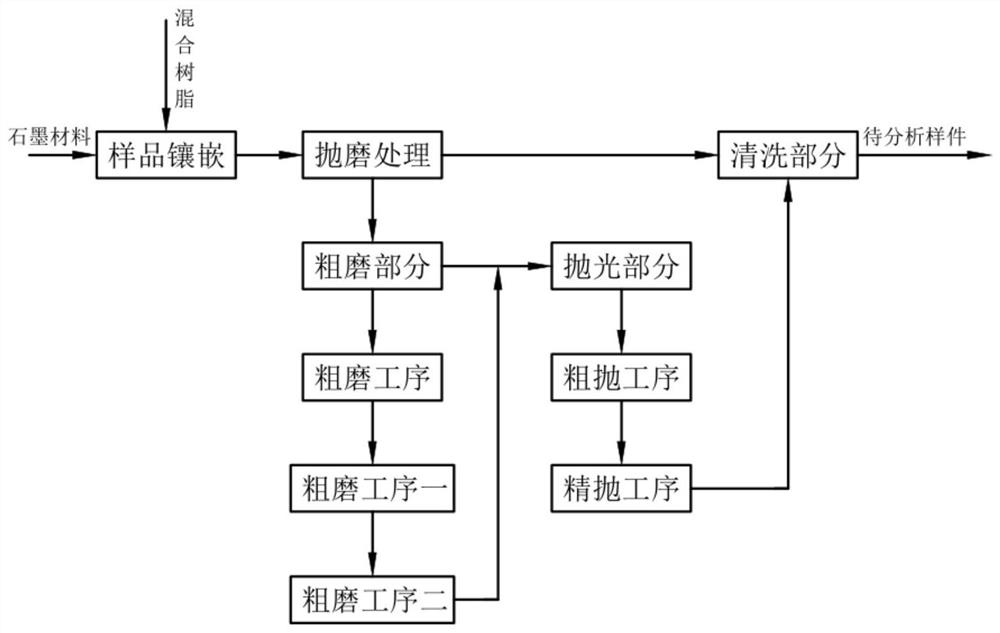

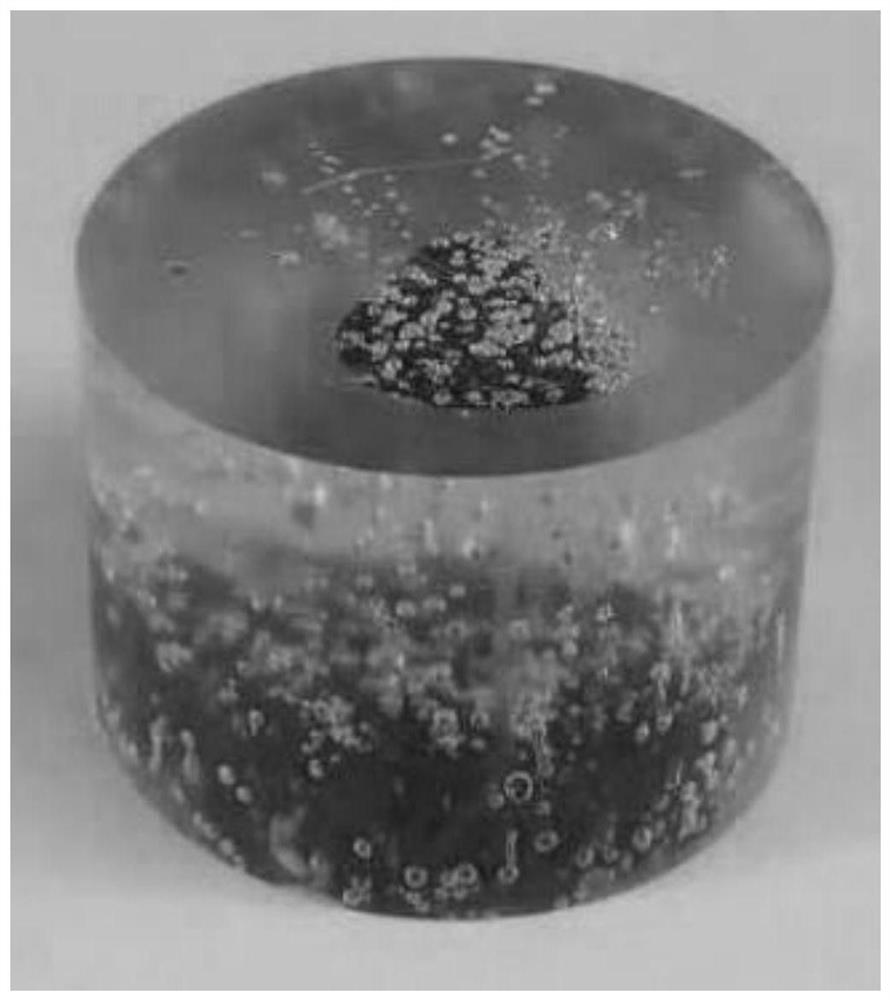

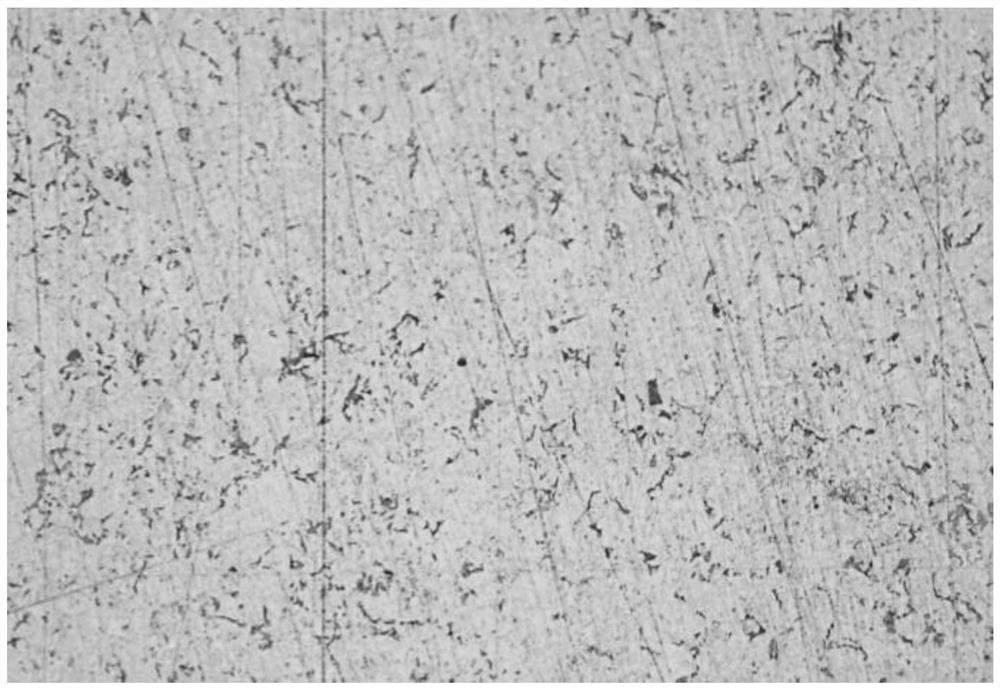

Preparation method of sample for representing graphite optical microscopic structure

ActiveCN108871892ASelf-removalHigh surface flatnessPreparing sample for investigationTest sampleGraphite

The invention relates to the technical field of the production of artificial graphite, in particular to a preparation method of a sample for representing a graphite optical microscopic structure. Thepreparation method comprises the following steps: inlaying a sample, grinding and polishing, cleaning, performing the gas emission for a graphite material and mixed resin in a vacuumizing way, mixingthe graphite material and the mixed resin in a pouring way, clamping a sample to-be-ground part on a grinding and polishing device by virtue of a horizontal positioning manner, pressing the sample to-be-ground part in an elastic pressurizing way, performing the multisection grinding treatment for the sample, cleaning, washing and blowing the sample, and forming a test sample; and discharging the gas in the graphite material and mixed resin by virtue of a negative-pressure exhaust way, mixing and solidifying the graphite material and mixed resin, horizontally fixing the test sample by virtue ofa horizontal positioning and clamping way, and performing the multi-step surface grinding for the sample by virtue of a variable pressing and loading force, so that the technical problem in the priorart the grinding effect of the test sample is poor can be solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Copper bar edge polishing equipment

PendingCN114290165AQuick sanding smoothQuick collectionEdge grinding machinesGrinding drivesPolishingEngineering

The invention discloses copper bar edge polishing equipment, and particularly relates to the field of copper bar polishing, the copper bar edge polishing equipment comprises a supporting mechanism, the top of the supporting mechanism is fixedly provided with a polishing mechanism used for polishing a copper bar, and the top of the supporting mechanism is provided with an adjusting mechanism used for controlling the polishing mechanism to operate; the supporting mechanism comprises an operation table and supporting legs, a bearing table used for lifting a copper bar is fixedly installed on the horizontal center line of the operation table, a protective cover used for clamping the copper bar is arranged at the top of the bearing table, and a plurality of first springs used for being connected with the operation table are fixedly installed at the bottom of the protective cover; the first bearing type support is fixedly installed on the top of the operation table through bolts. The dust collecting cover is arranged on the outer wall of the grinding piece, so that copper cuttings are rapidly collected in an inner cavity of the dust collecting cover in the rotating process of the grinding piece, the situation of splashing of the cuttings is avoided, and actual use is better facilitated.

Owner:GUIXI HONGSHI METAL

Automatic pot grinding machine

ActiveCN107303647AHigh technical requirementsImprove consistencyAbrasive surface conditioning devicesGrinding machinesCollection systemMachine

The invention discloses an automatic pot grinding machine which comprises a clamping system, a grinding wheel repair system, a signal collection system and a flexible strengthening system. The grinding wheel repair system, the signal collection system and the flexible strengthening system are arranged on the platform. The flexible strengthening system is arranged on a connection shaft of a large arm and a small arm. The flexible strengthening system acts on a small arm shaft. A grinding wheel on the small arm makes elastic contact and grinds a machined pot make. A diamond roller wheel of the grinding wheel repair system makes elastic contact with the grinding wheel for repairing the grinding wheel. The pot grinding efficiency is greatly improved, each worker can operate 6-8 machines, the pot grinding labor cost can be reduced by 80% or more, the manufacturing cost is greatly reduced, the pot grinding consistency and uniformity are greatly better than manual strengthening, grinding wheel consumption is low, the surface quality of the ground pot is greatly improved, and the grinding wheel consumption is reduced by 30% or more. Meanwhile, grinding is more reasonable and uniform. The pot base body weight can be reduced by 10% under the premise that the grinding quality is ensured, the pot base body material utilization rate is improved, and the pot manufacturing cost is reduced.

Owner:绵阳市川星锅厂

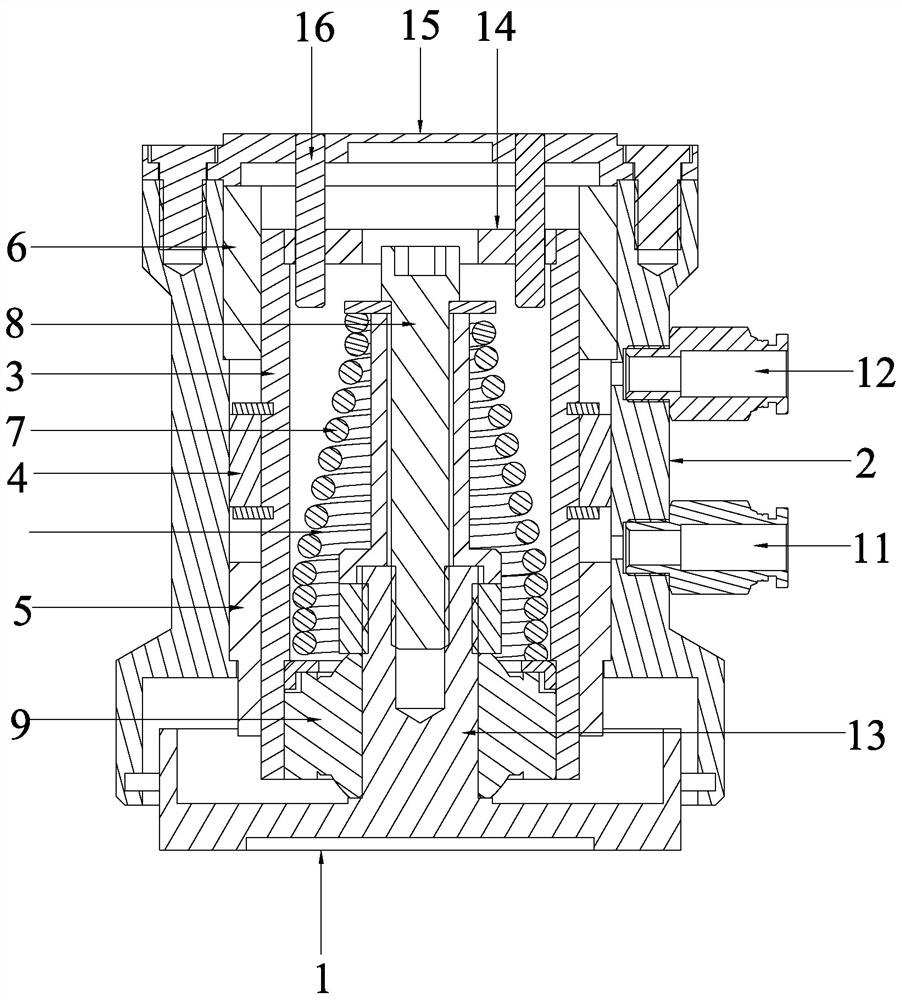

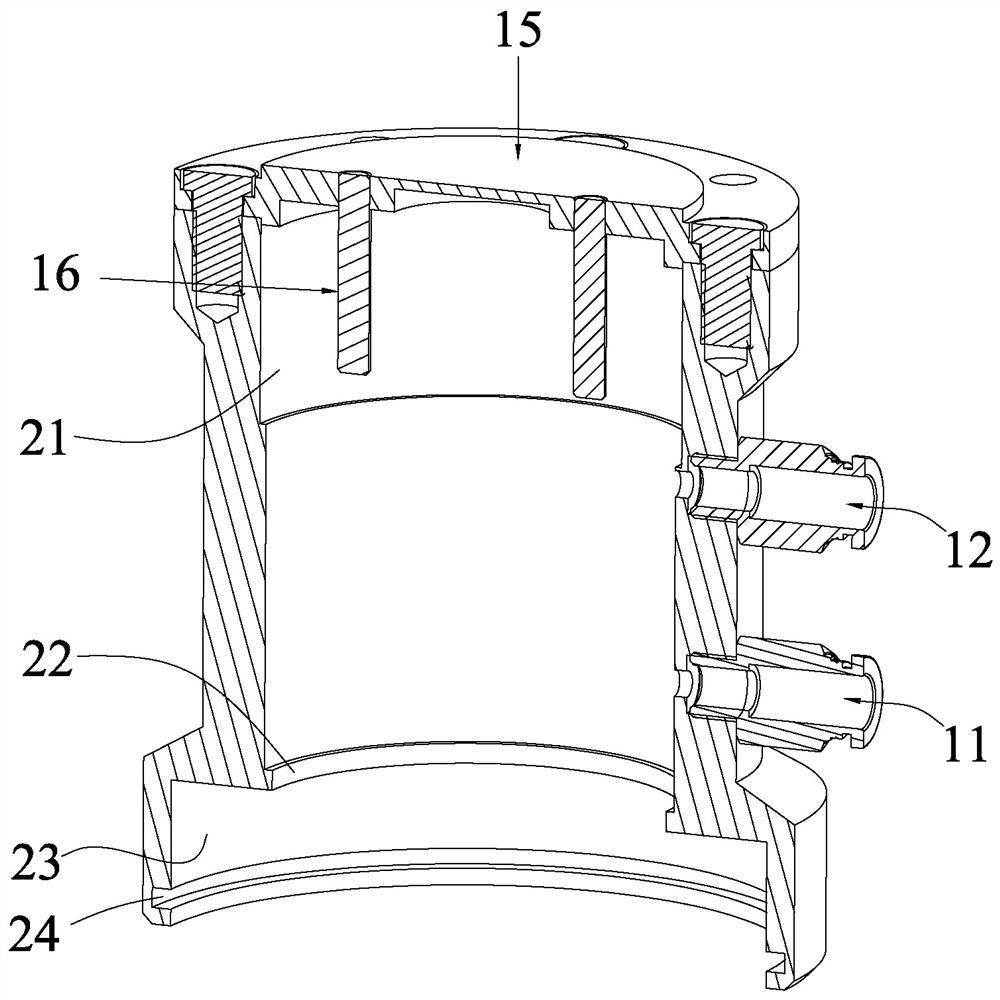

High-sensitivity flexible grinding device

PendingCN113894652AImprove the coordination effectEasy to attachGrinding machine componentsGrinding machinesEngineeringIndustrial robotics

The invention discloses a high-sensitivity flexible grinding device which comprises a mounting seat, a cylinder body, a hollow piston rod, a piston body, a front guide sleeve, a rear guide sleeve, a conical spring, a torque extension rod and a universal bearing. According to the high-sensitivity flexible grinding device provided by the invention, the matching effect between a grinding tool and an industrial robot can be improved, the torque extension rod is arranged in the grinding device, the length of a force arm with a universal bearing as a fulcrum can be increased, and the tail end of the torque extension rod can swing greatly even if the mounting seat is slightly subjected to radial acting force, so that the feedback sensitivity is high; then the conical spring provides reaction to control the torque extension rod to reset quickly, so that a grinding head is well attached to the grinding surface; and meanwhile, when the mounting seat is subjected to axial acting force, the torque extension rod is stressed to stretch the conical spring and correspondingly drive the cylinder body to move backwards to compress air, and the axial acting force is buffered through cooperation of elastic force and air pressure, so that the consistency of the grinding acting force can be well guaranteed, and the grinding and polishing quality is improved.

Owner:东莞市钜铧机械有限公司

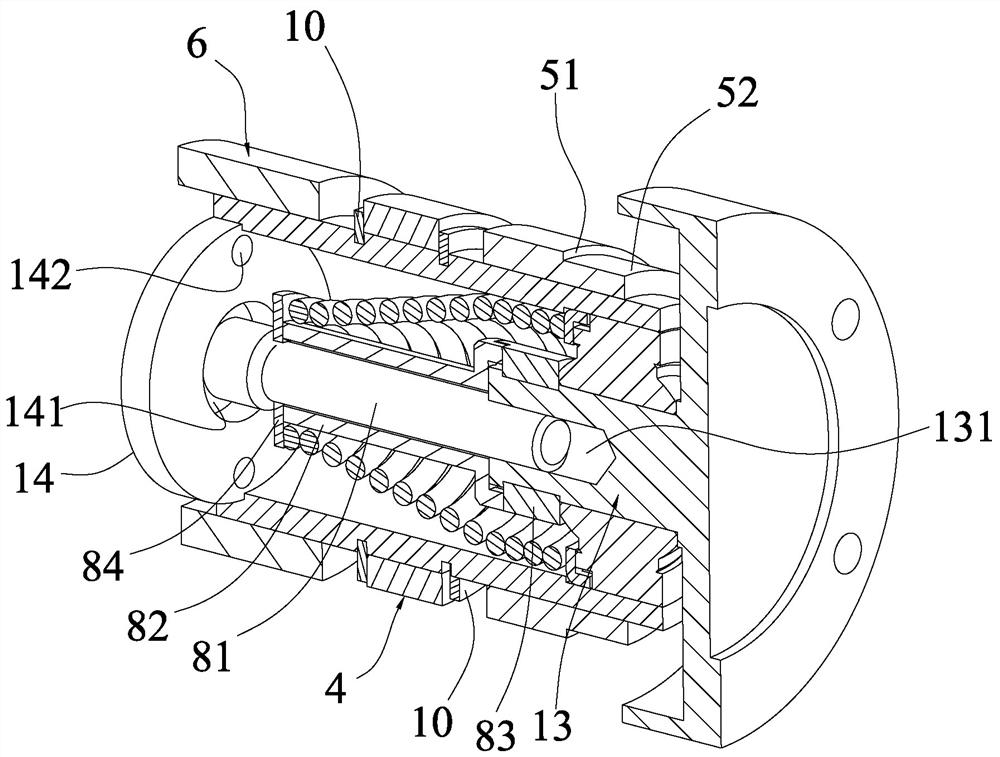

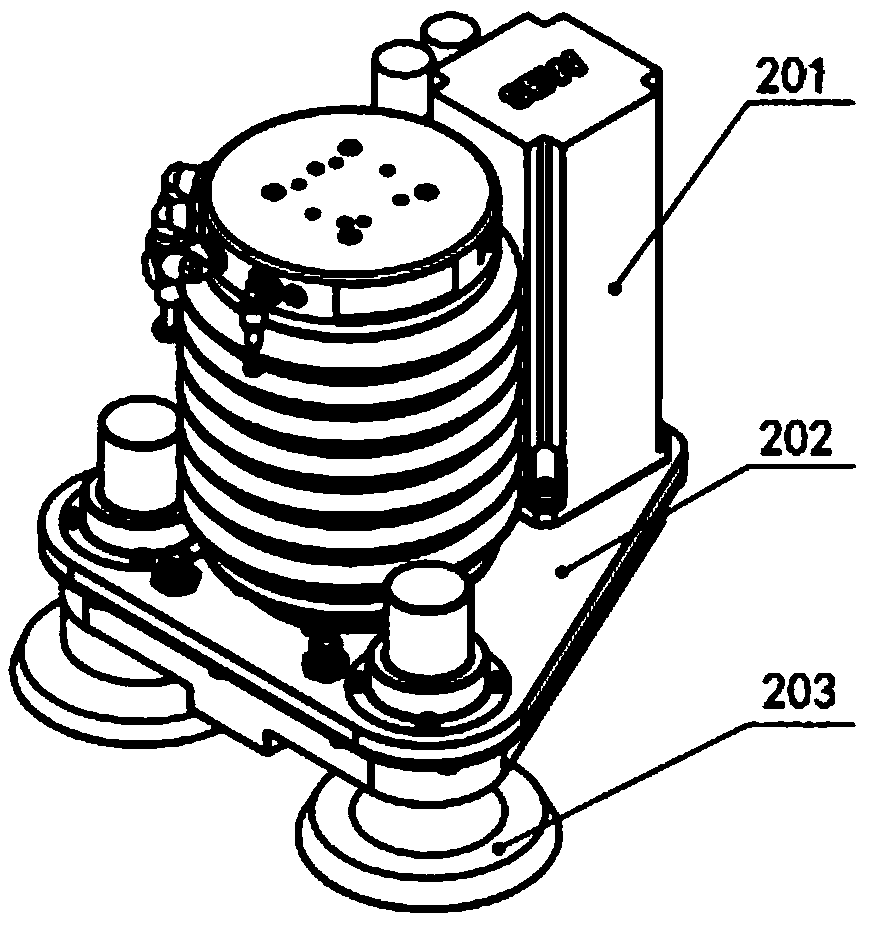

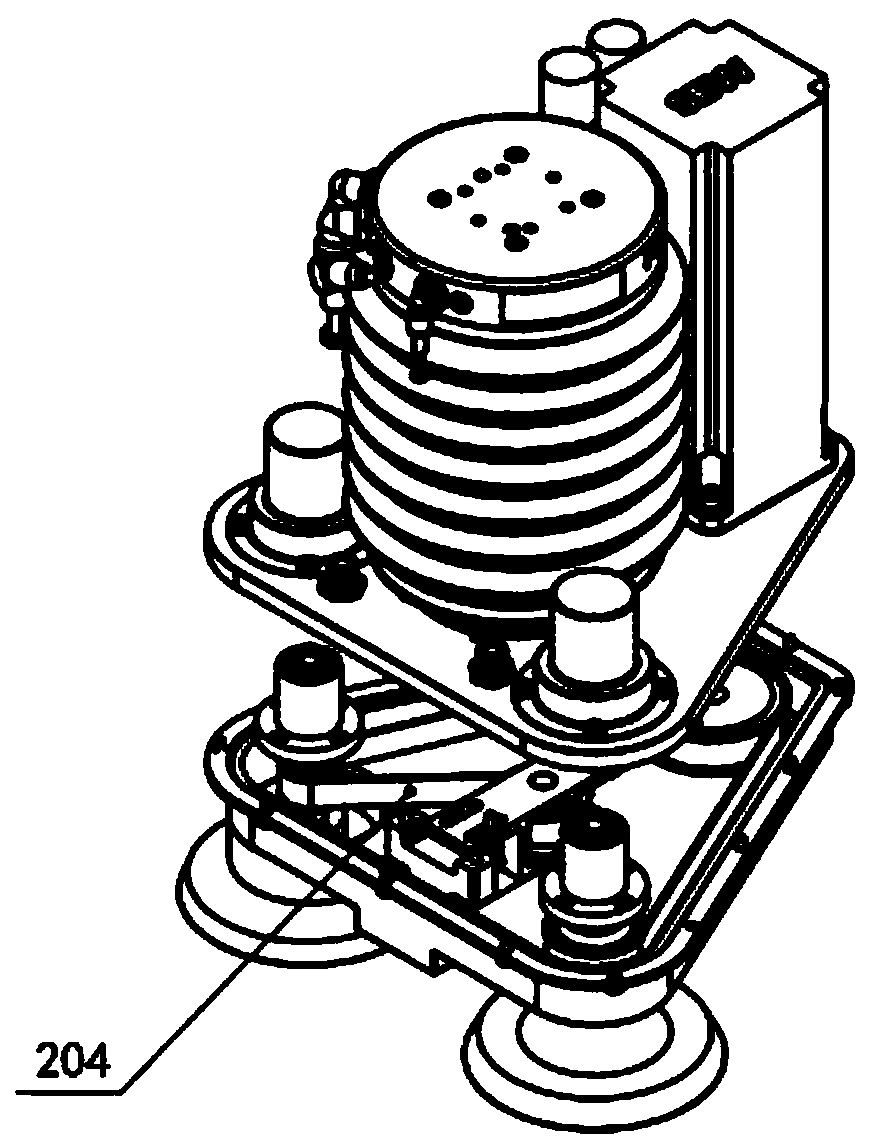

Double grinding and polishing device for robot end

ActiveCN108942658AShorten the takt timeExtended service lifeGrinding drivesPulp and paper industryEmery paper

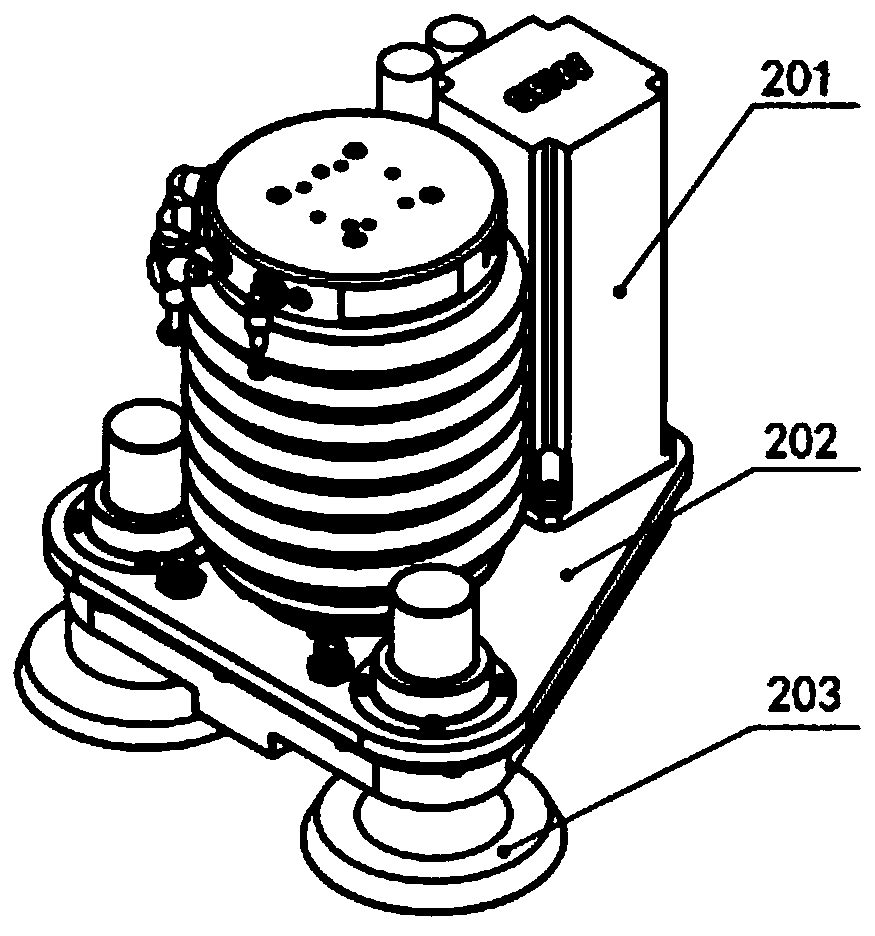

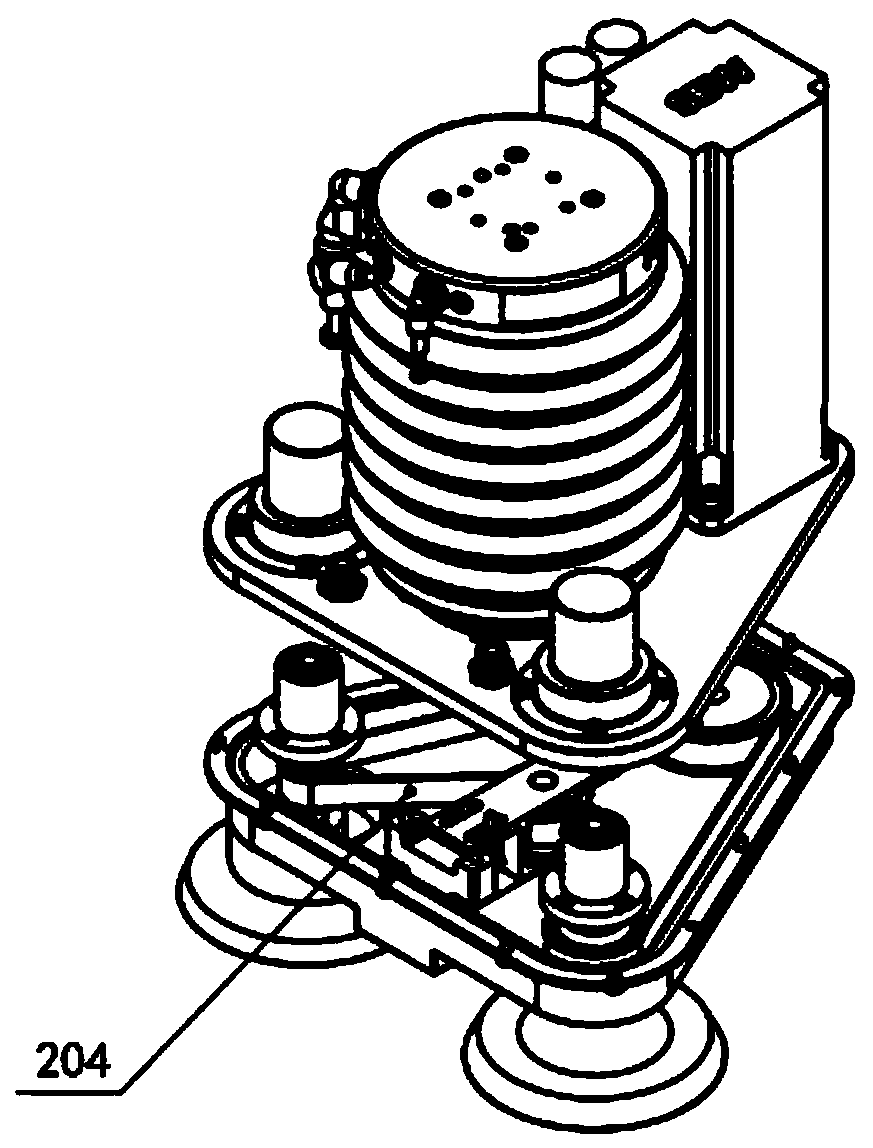

The invention provides a double grinding and polishing device for a robot end. The double grinding and polishing device comprises a driving device (201), a fixing rack (202), an executive device (203)and a transmission device (204); the driving device (201) and the transmission device (204) are both fixedly installed on the fixing rack (202), and the executive device (203) is connected to the transmission device (204); and the transmission device (204) comprises an eccentric mechanism and / or a non-eccentric mechanism. According to the double grinding and polishing device, two working procedures of grinding and polishing can be finished with no need of replacing tools, and the production tact of a station can be decreased by 20s or above; the service life of abrasive paper is prolonged greatly, and the number of door frames which are polished by a piece of abrasive paper is increased to 5-6 from 2-3; and the use efficiency of the abrasive paper is increased by 2 times or above, and thereturn on investment of the overall device is improved.

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

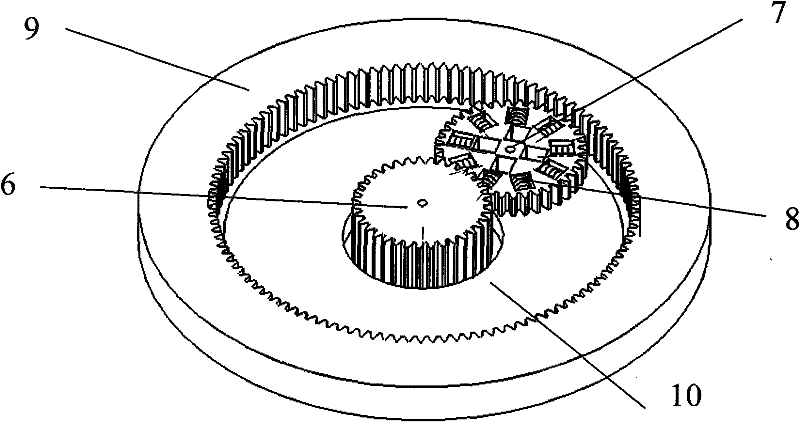

Laser gyro lens excircle grinding and polishing method

ActiveCN102049728BImprove grinding and polishing efficiencyHigh practical application valueLapping machinesAdhesiveEngineering

The invention relates to a laser gyro lens excircle grinding and polishing method which comprises the following steps of: bonding a lens and a bonded joint into a pillar with the bonded joint (see the figure 1) by using a bonding adhesive, and fixing the bonded joint by using a three-jaw clamp of a grinding machine to ensure that the runout of the excircle of the lens pillar is less than 0.3 mm; disconnecting the adhesive to remove the bonded joint after the excircle of the lens pillar is ground to grinding size, and chamfering the sharp edges of both end faces of the lens pillar; placing a wandering star wheel carrier on a double-face grinding machine or polishing machine, and placing the lens pillar in the wandering star wheel carrier; starting the machine, introducing a liquid (a grinding powder liquid or a polishing powder liquid), and driving the wandering star wheel carrier to rotate through the rotation of an inner gear ring and an outer gear ring; and suspending an upper disc of the equipment to ensure that the lens pillar rotates around central axis per se on a lower disk to achieve the effect of grinding and polishing the excircle. The laser gyro lens excircle grinding and polishing method provided by the invention is convenient to operate and has the advantages of high grinding and polishing efficiency, good machining consistency and high quality.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

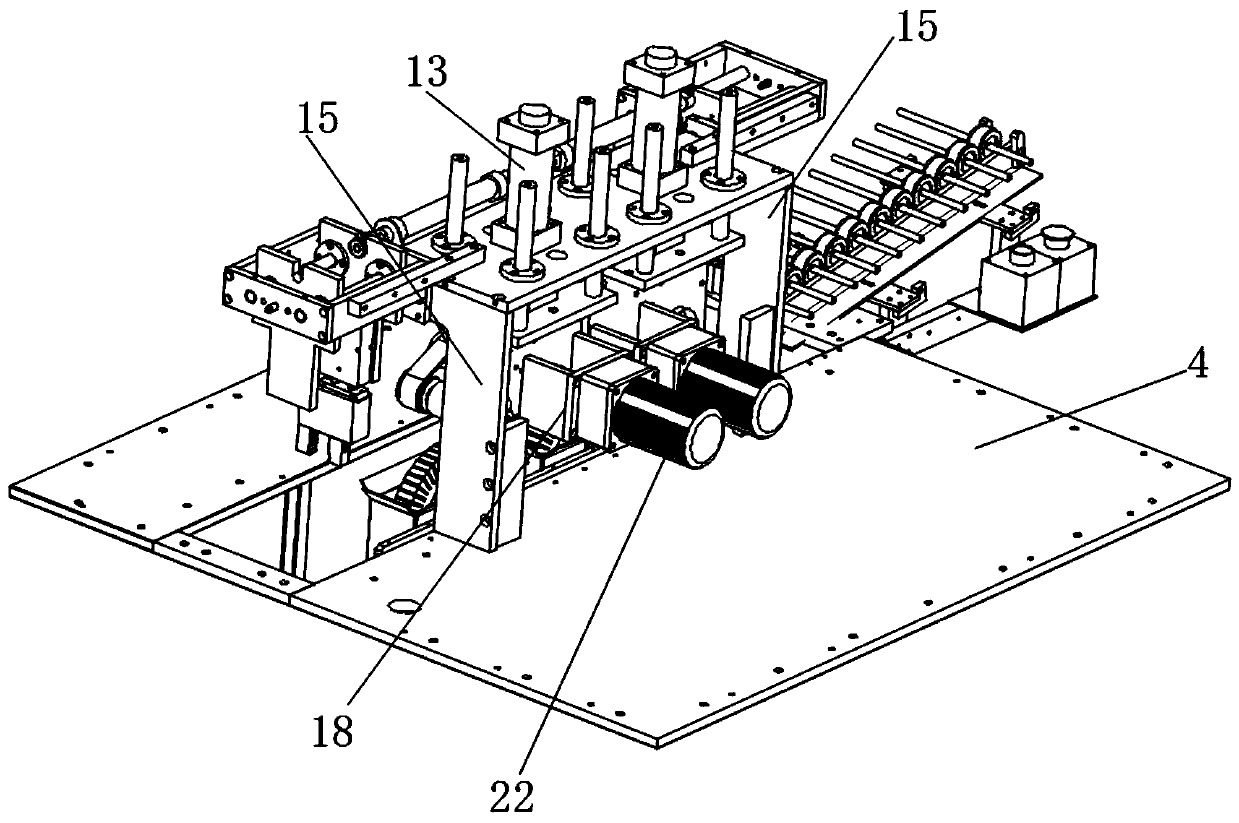

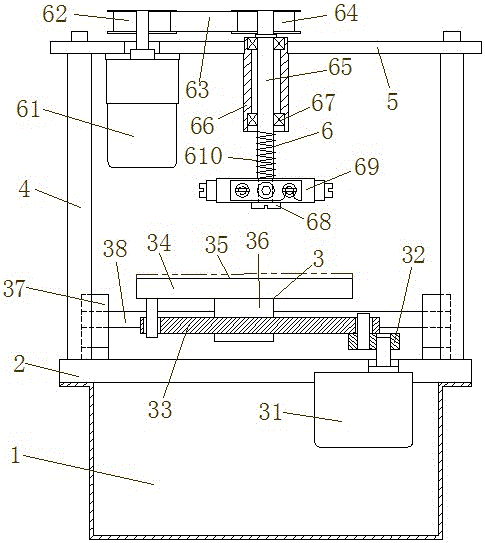

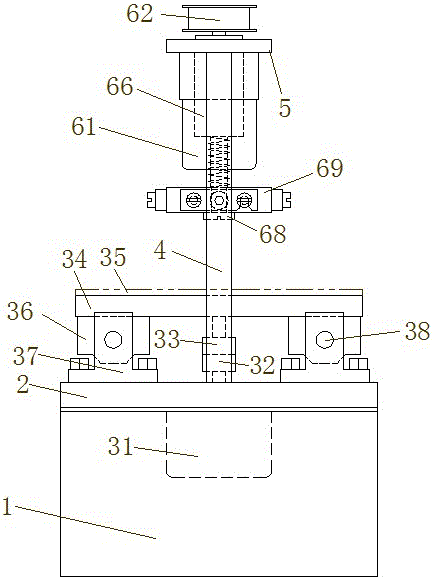

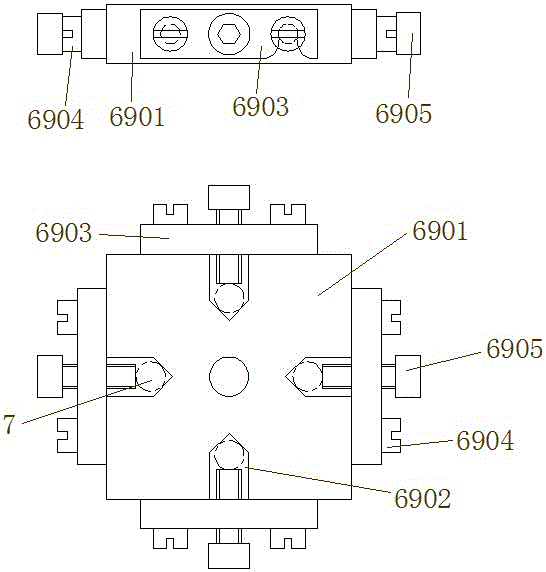

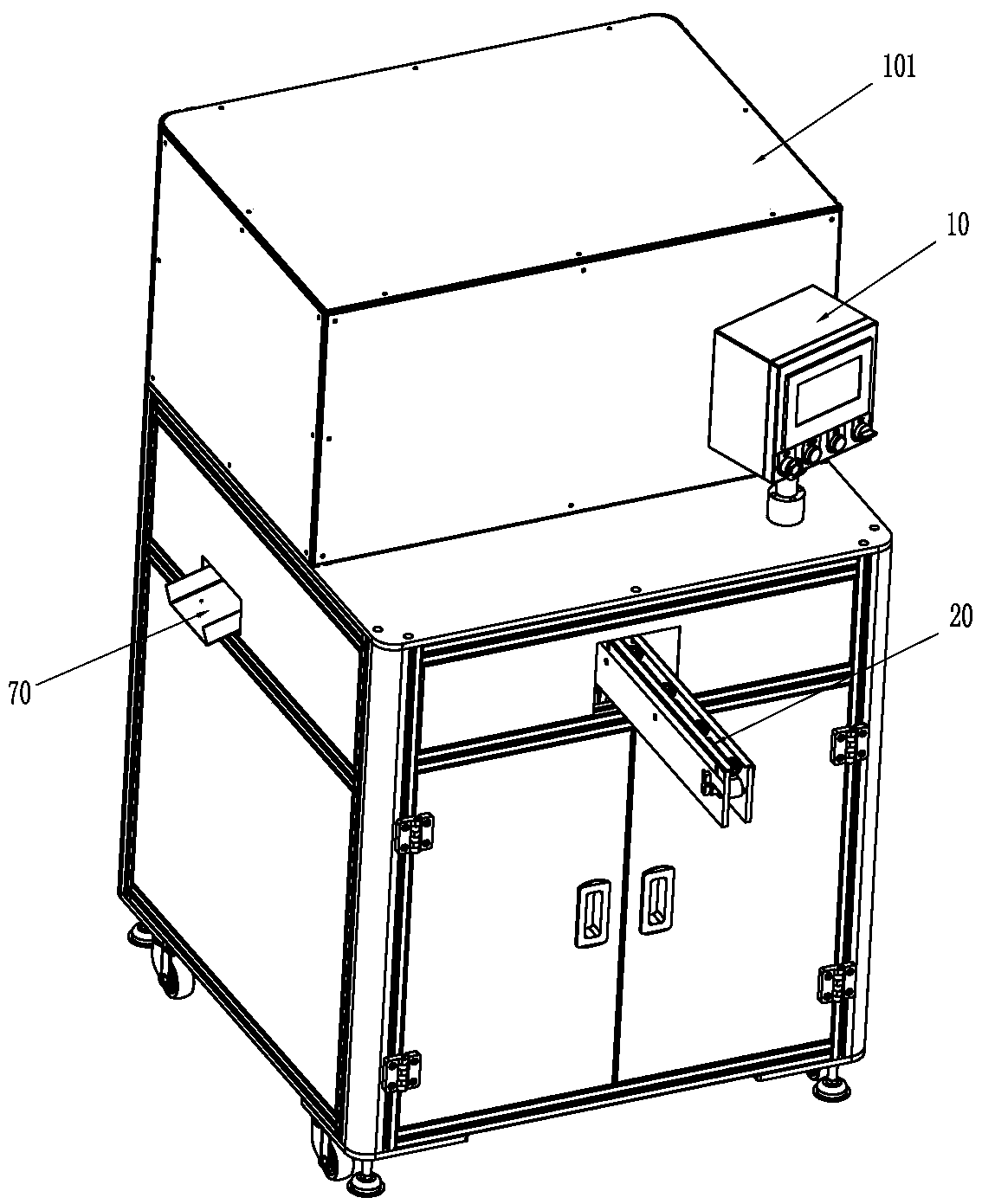

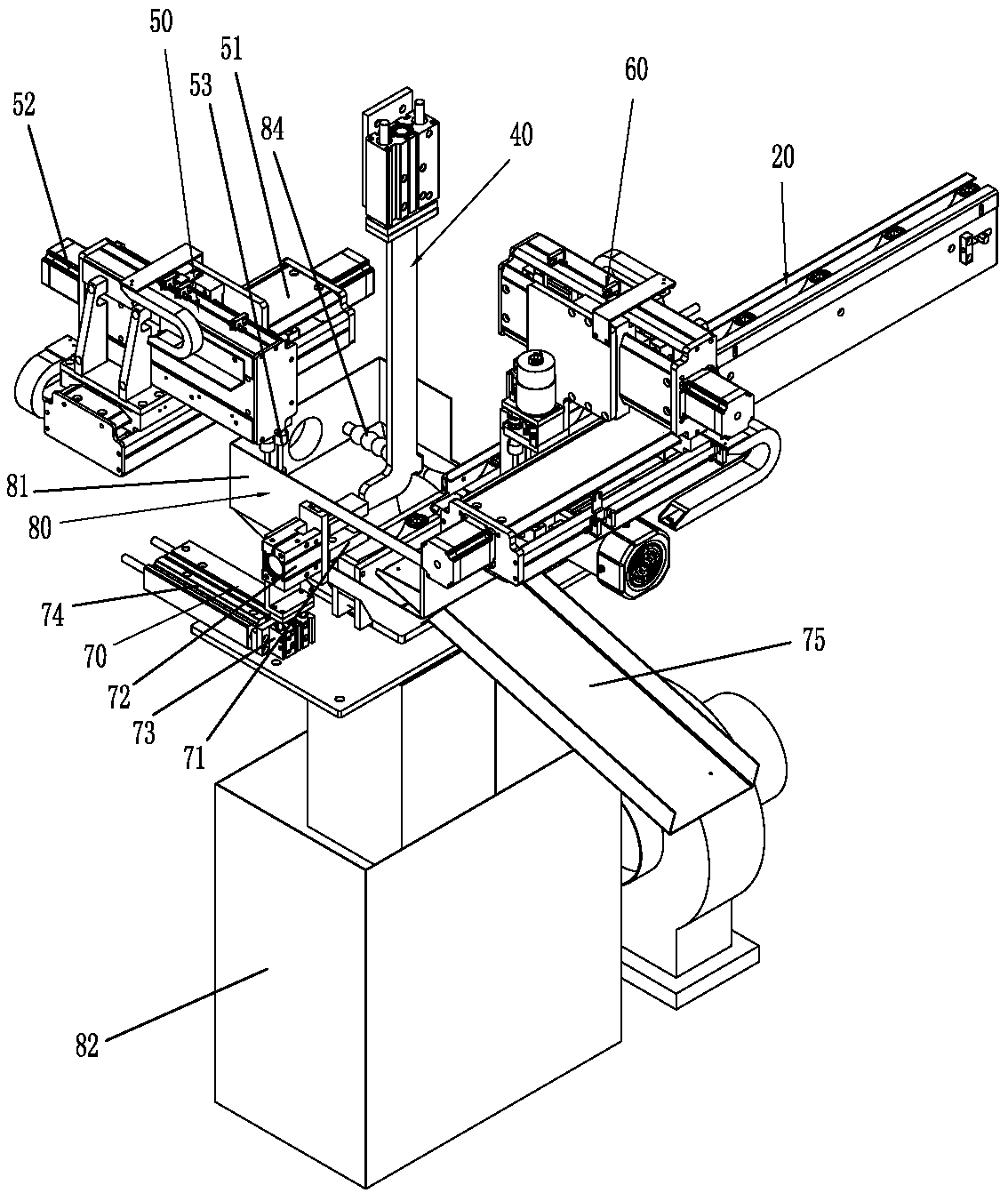

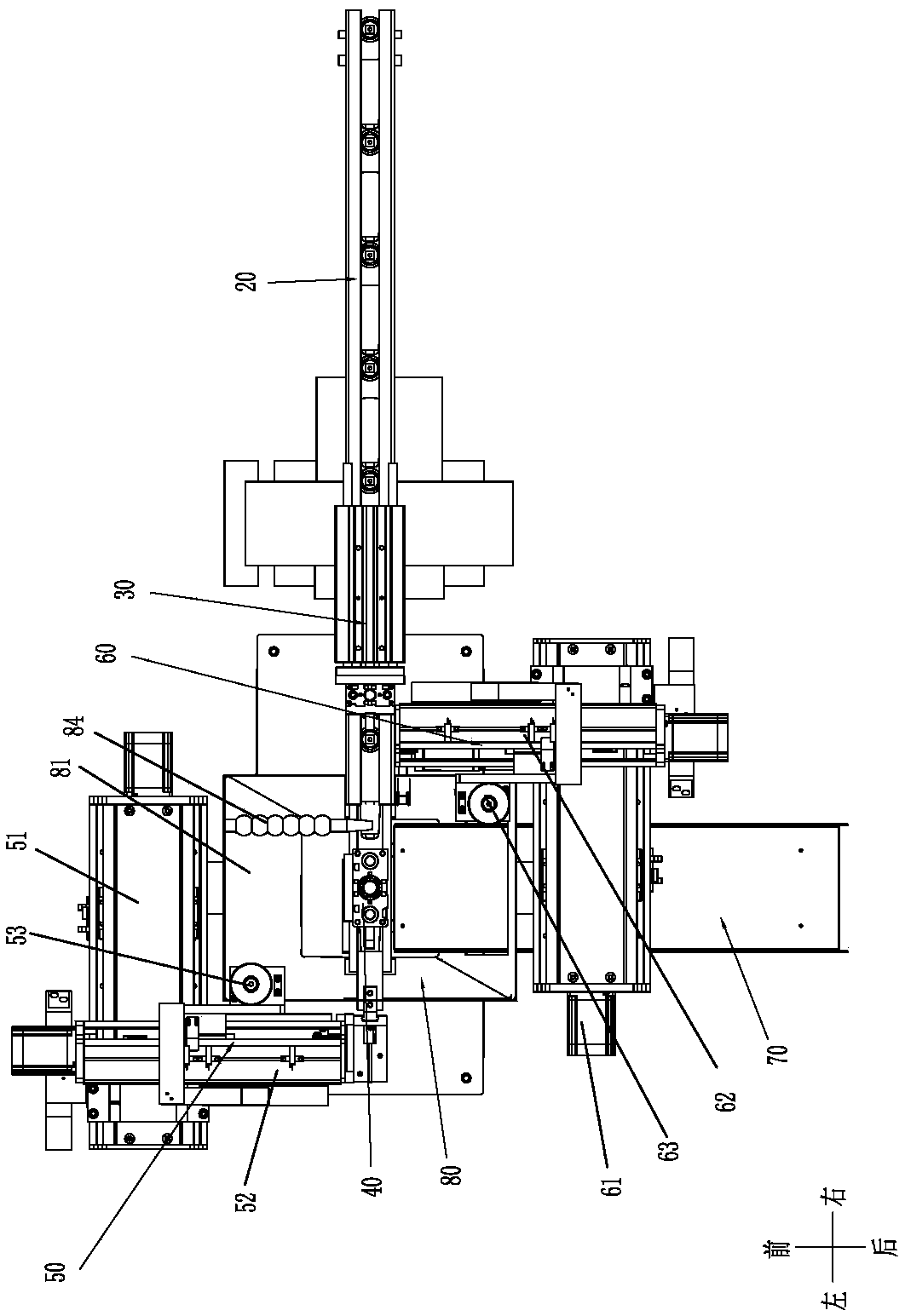

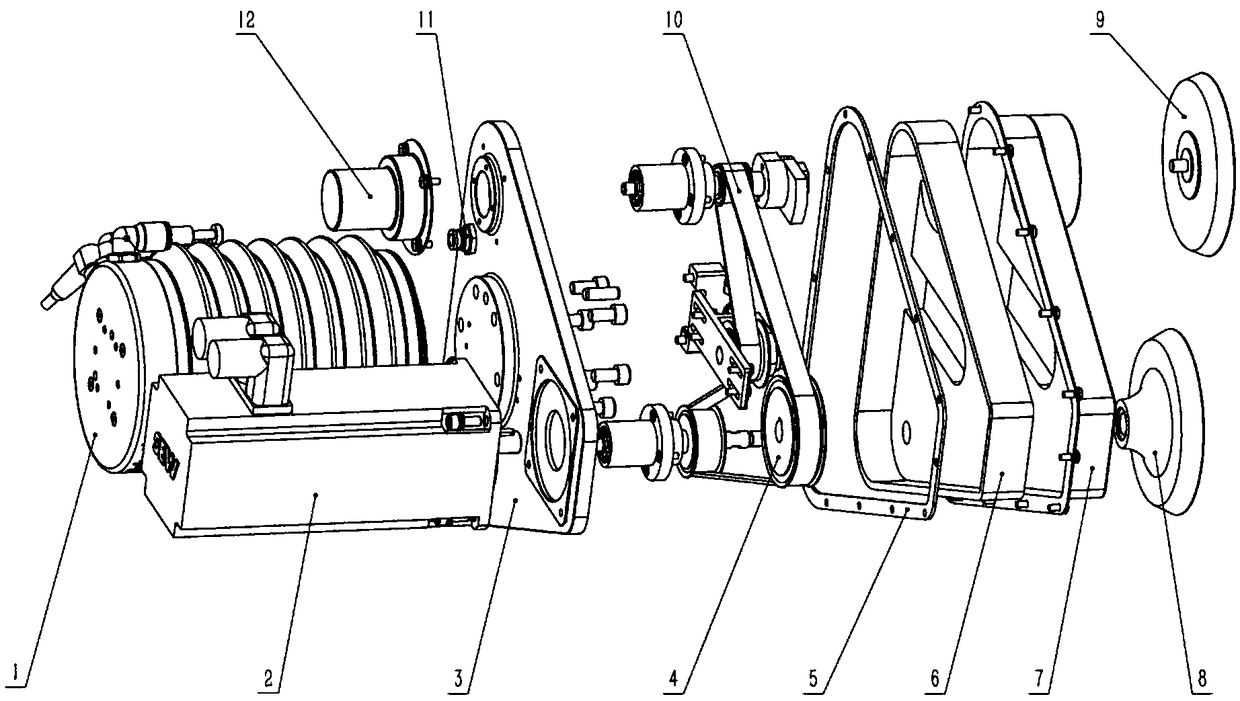

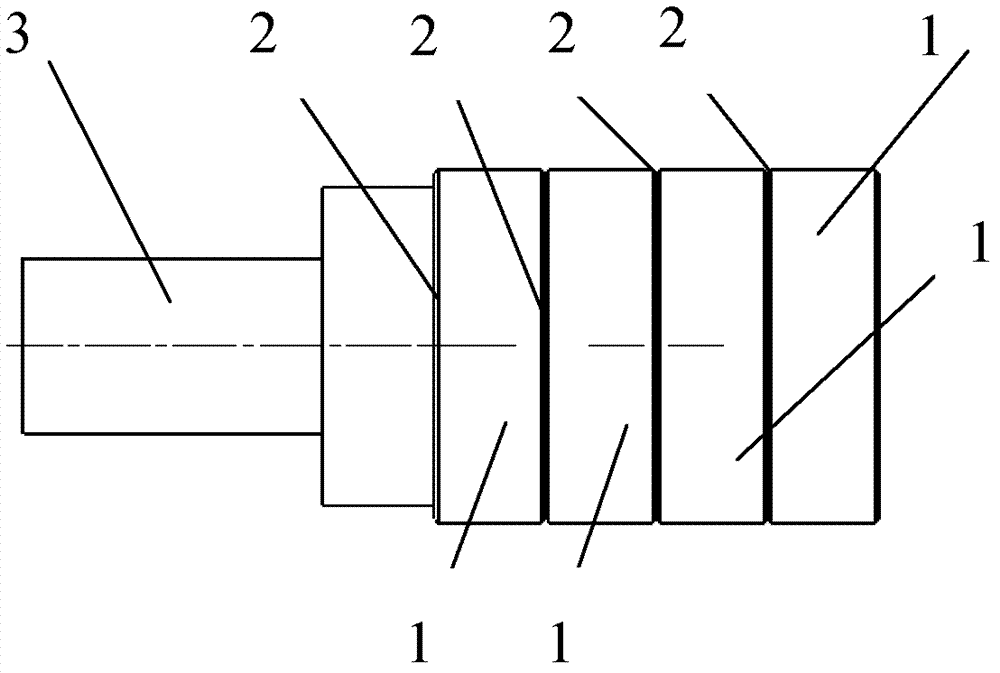

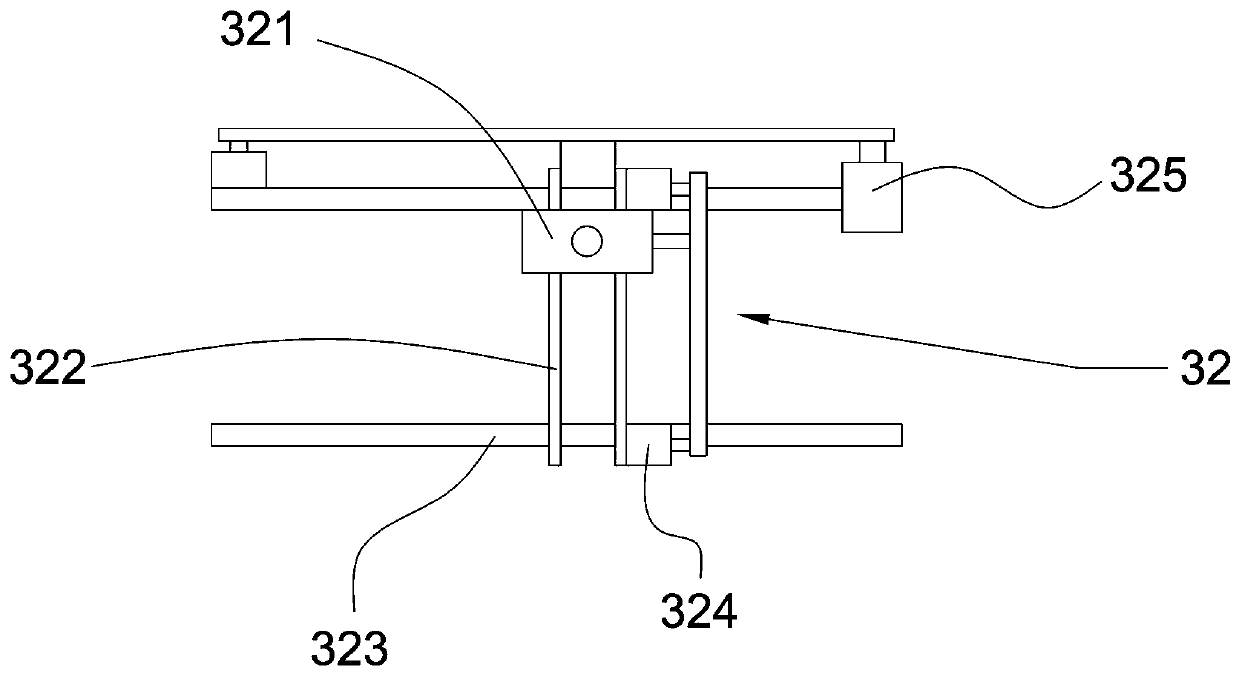

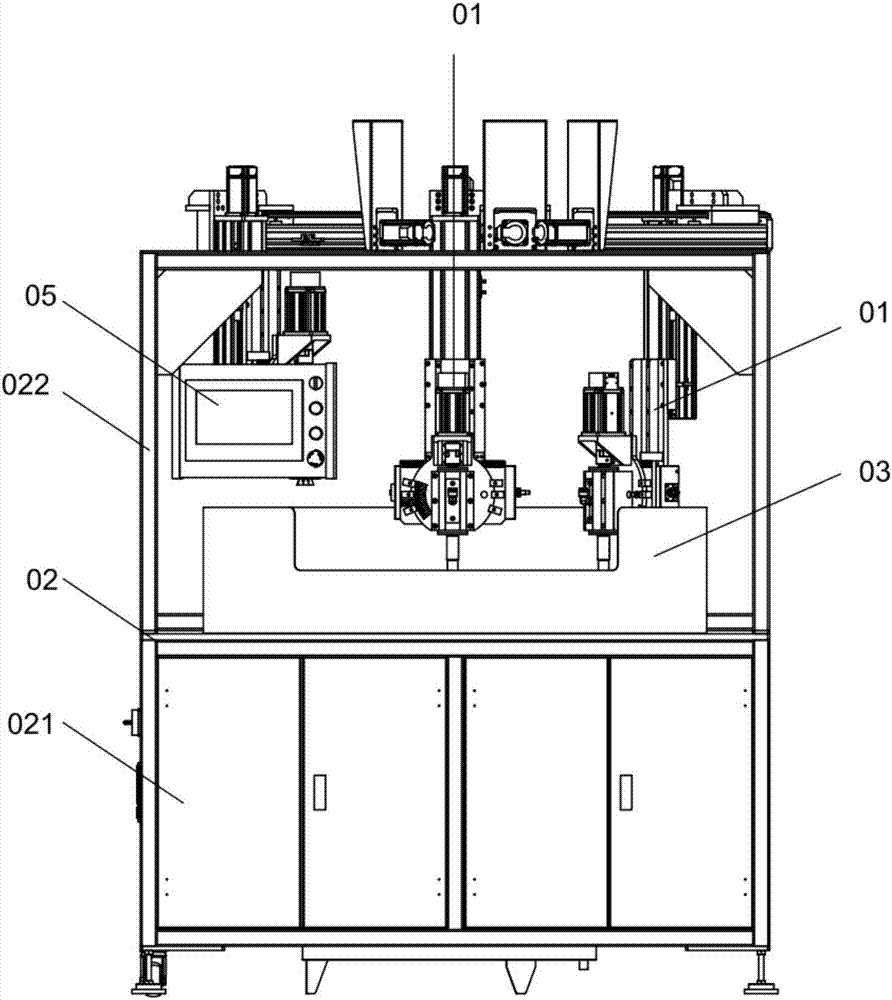

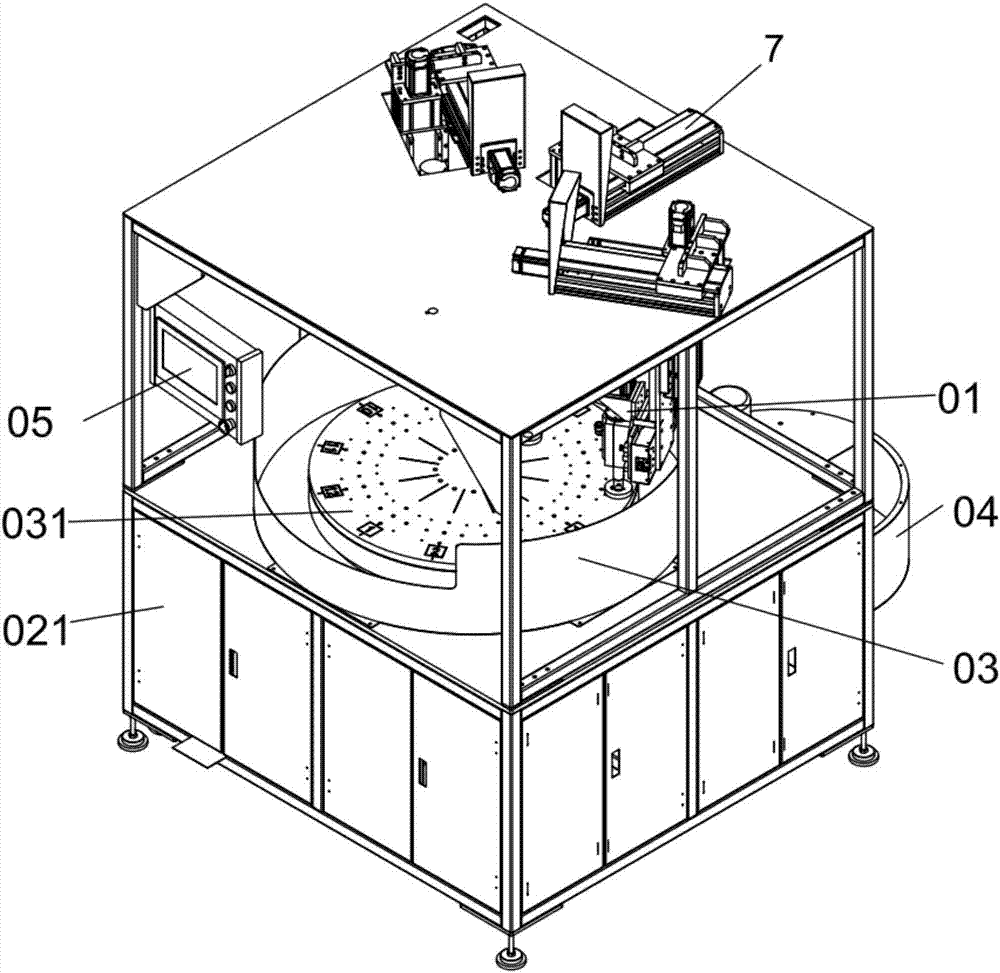

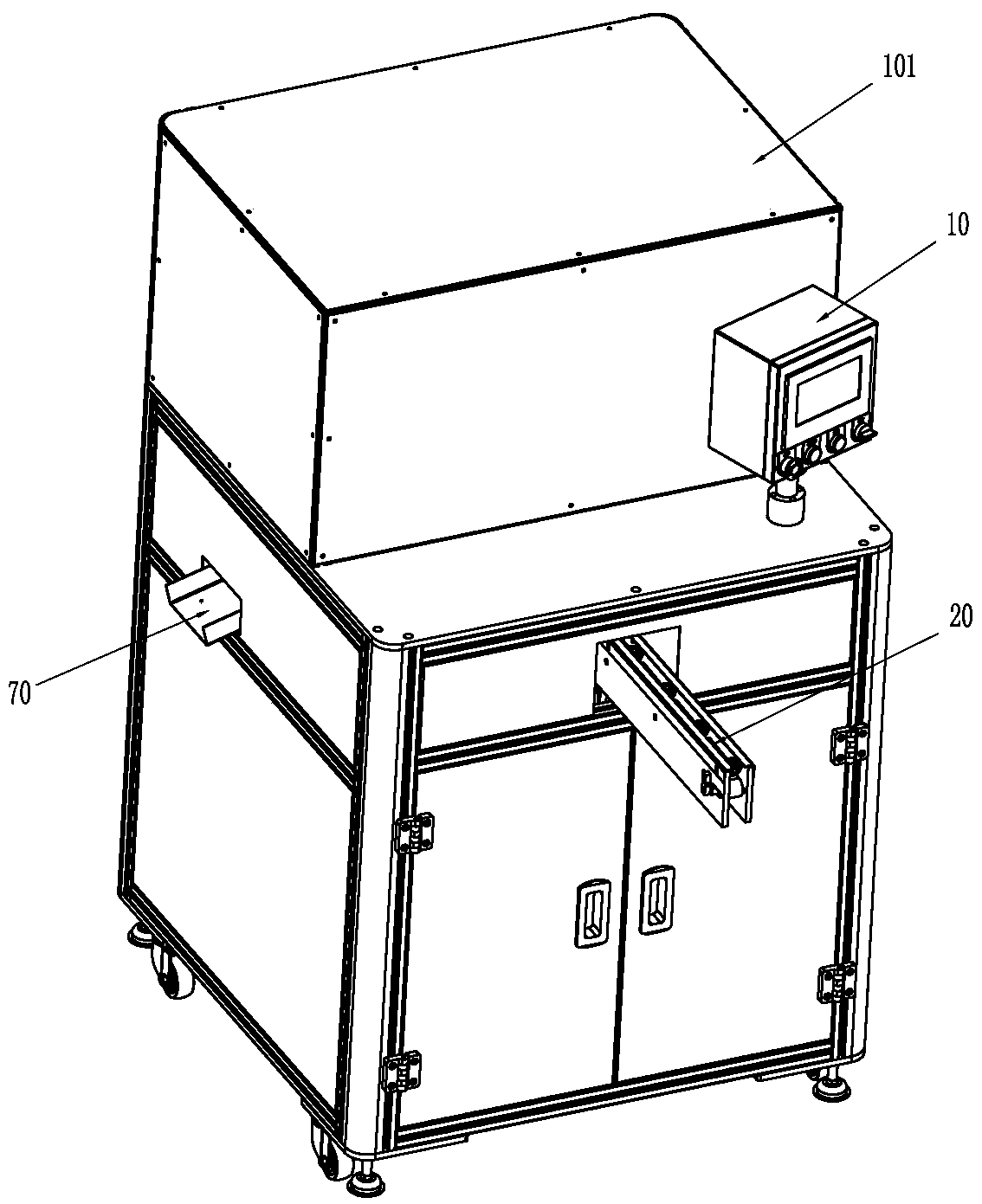

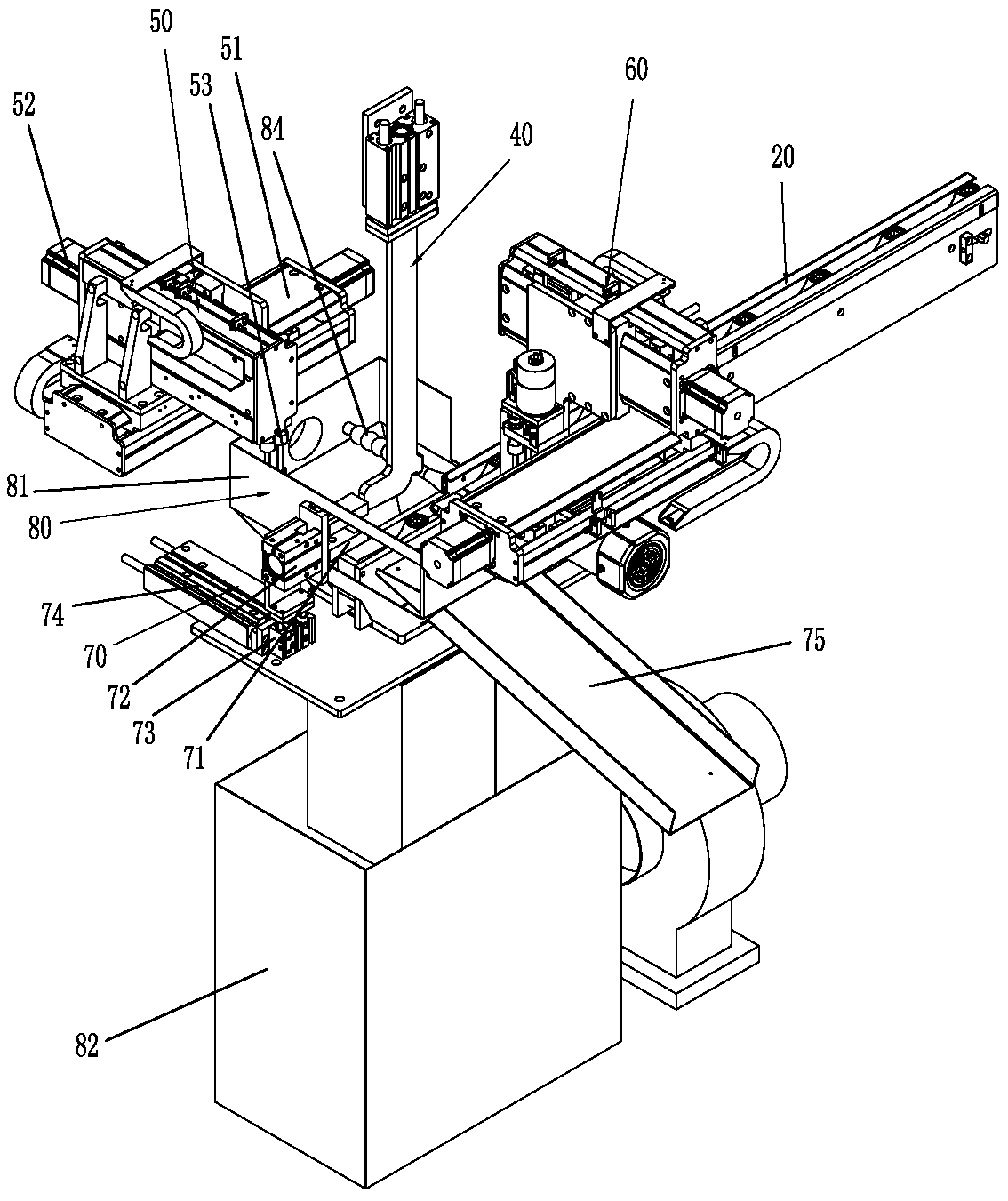

Automatic grinding and polishing device and grinding and polishing method thereof

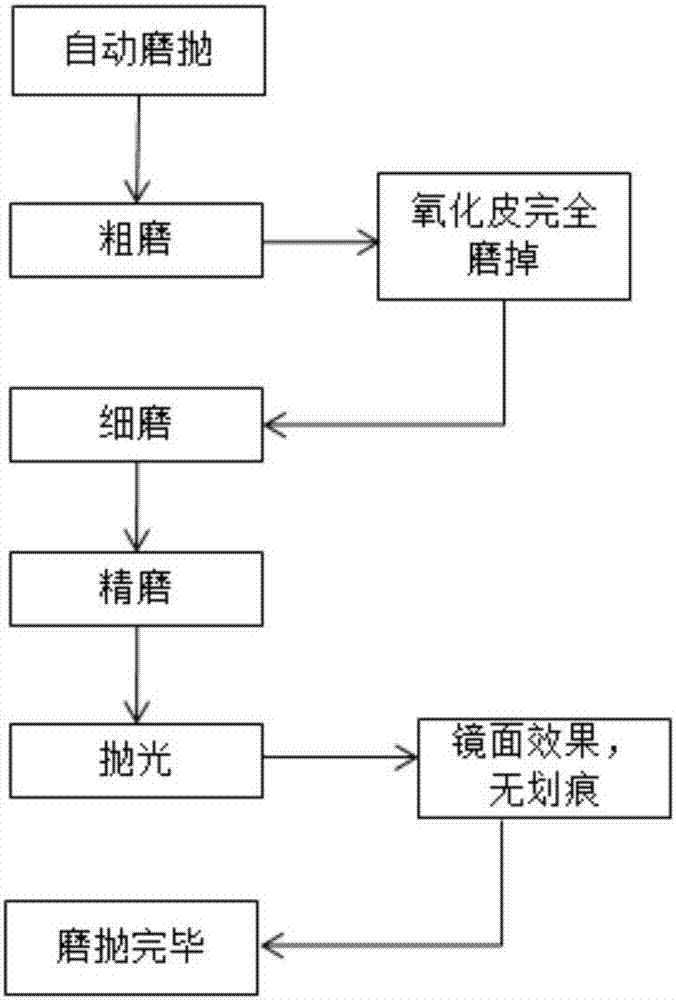

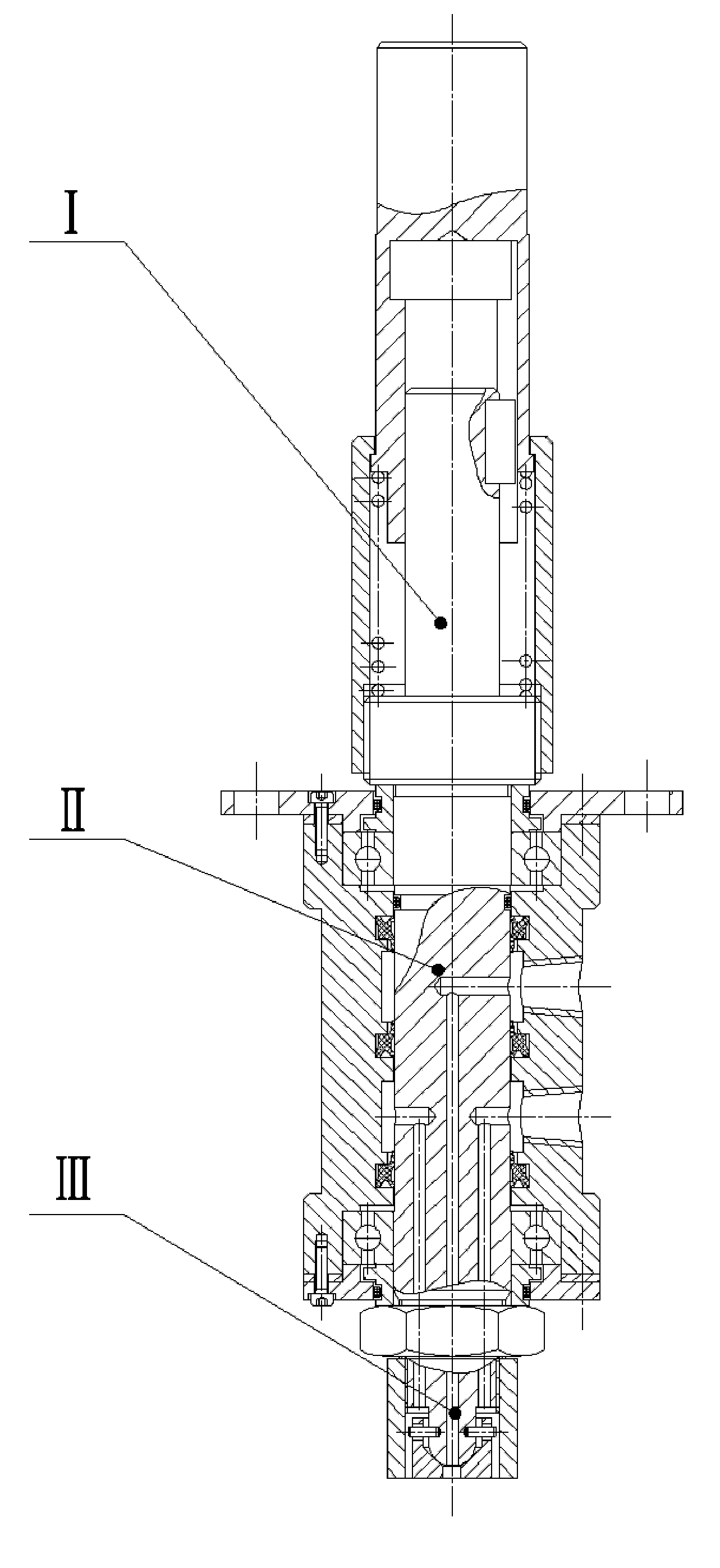

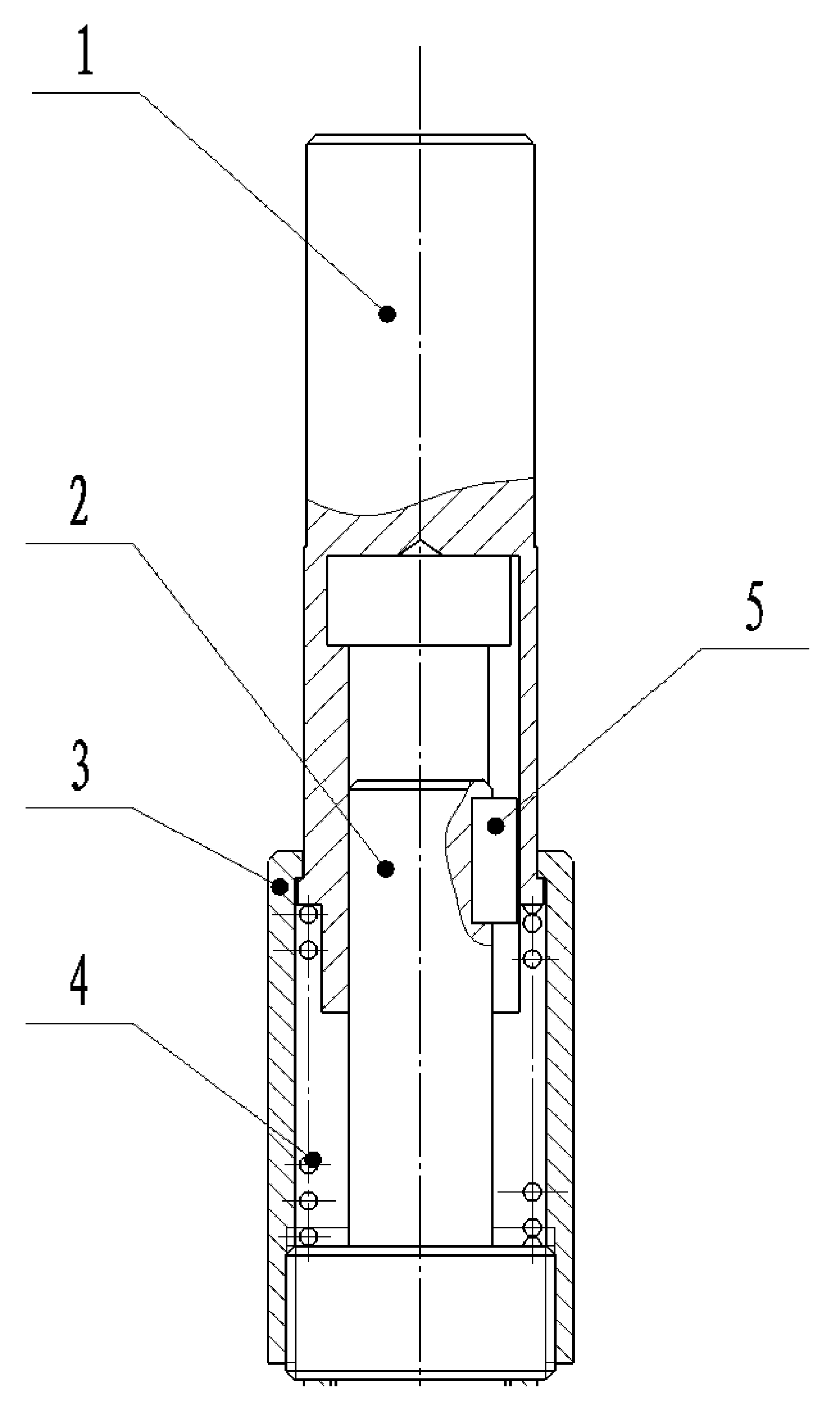

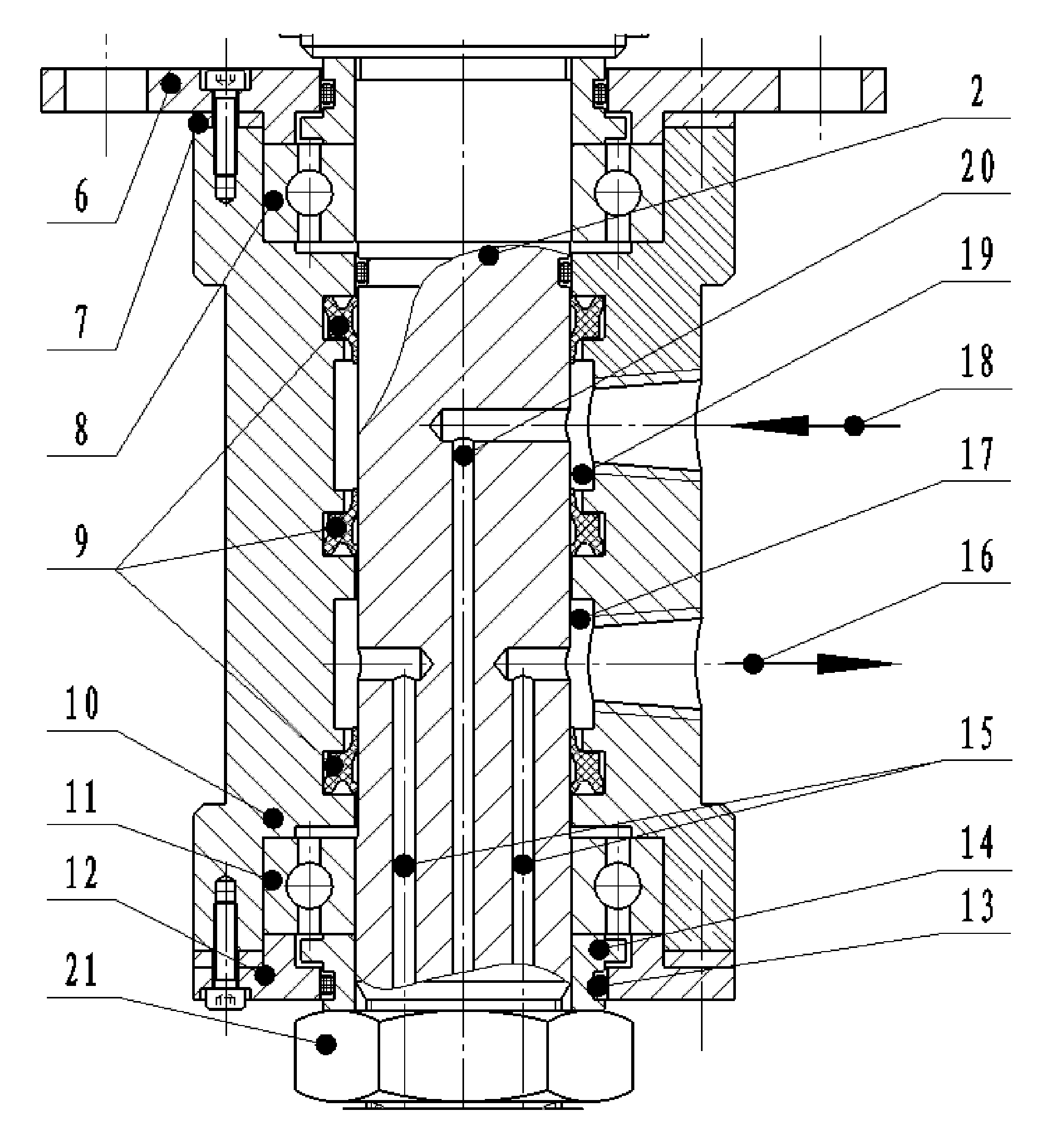

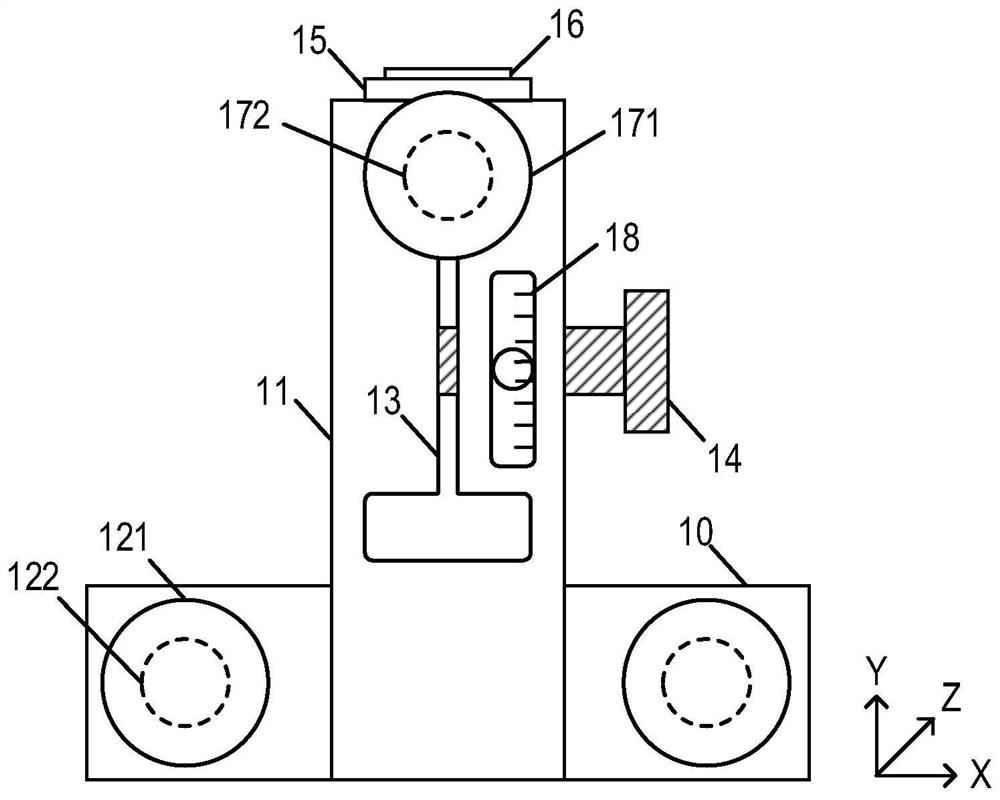

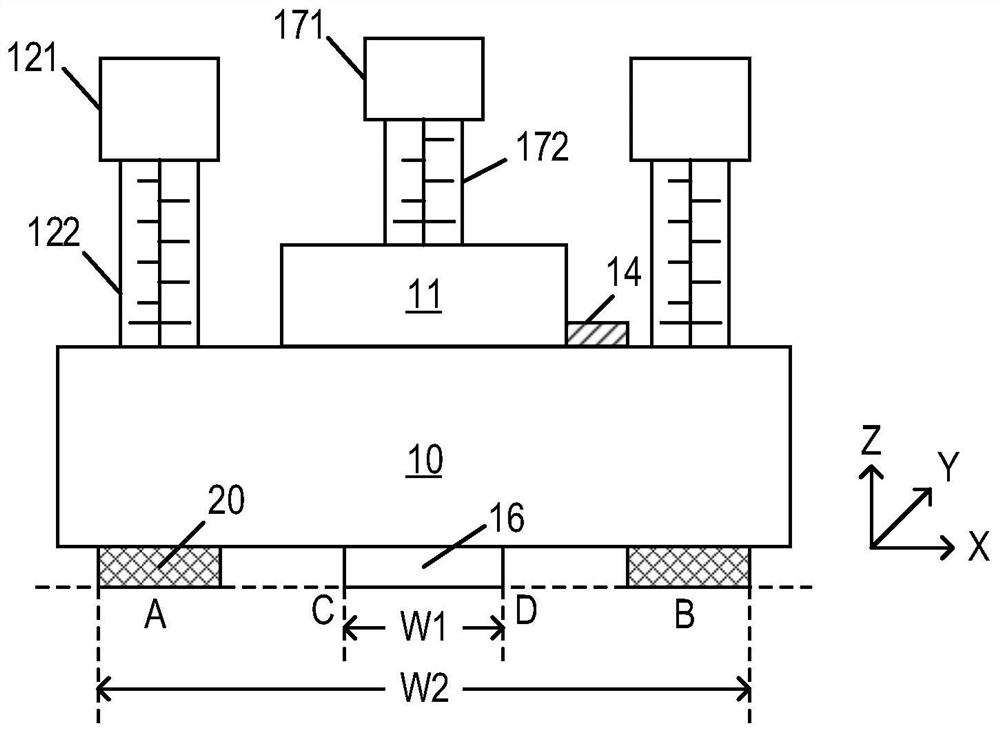

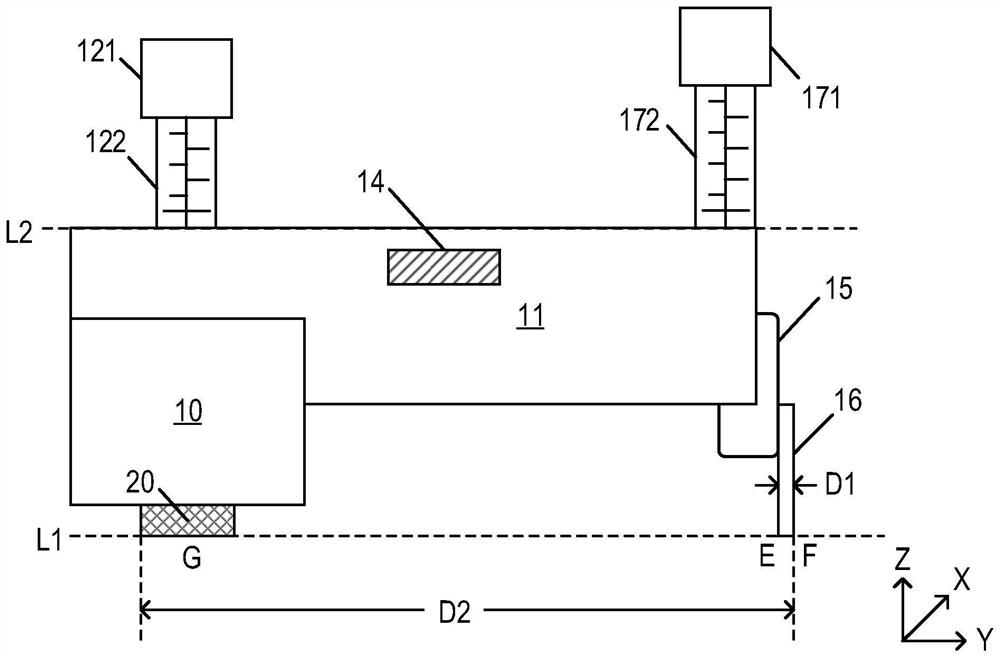

ActiveCN106217194BImprove grinding efficiencyEasy to installGrinding carriagesGrinding drivesEngineeringControl unit

The invention provides an automatic grinding and polishing apparatus and a grinding and polishing method. The grinding and polishing apparatus comprises a grinding and polishing mechanism. The grinding and polishing mechanism is equipped with a plurality of grinding parts and polishing parts, wherein roughness of each grinding part is different; a to-be-grinded part is installed on a loading platform; and a main control unit controls a power mechanism to move the loading platform or a grinding-polishing mechanism, so friction between the to-be-grinded part and the grinding parts or the polishing parts can be achieved and grinding and polishing procedures can be realized. Through the design, the grinding and polishing method via the automatic grinding and polishing apparatus can achieve rough-grinding, fine-grinding, accurate-grinding and polishing together; and full automatic grinding can be controlled by the main control unit, so grinding balance degree can be improved.

Owner:SHANGHAI JIAOTONG UNIV

Self-cleaning grinding and polishing tool

ActiveCN102615576BAvoid wastingFully contactedPolishing machinesGrinding/polishing safety devicesEngineeringScrap

The invention relates to a self-cleaning grinding and polishing tool, which relates to a grinding and polishing tool for self-cleaning overflow grinding and polishing liquid and grinding and polishing scraps through vacuum absorption while grinding and polishing a surface in the central liquid supplying process. The tool consists of a pressurization unit, a liquid supplying and cleaning unit and a grinding and polishing operation unit, wherein the pressurization unit is used for adjusting grinding and polishing pressure; the liquid supplying and cleaning unit is used for introducing grinding and polishing media and vacuumizing and absorbing the grinding and polishing media; and a grinding and polishing effect is achieved by the grinding and polishing operation unit. The grinding and polishing tool moves in a certain track under the control of a computer, so that a large plane can be totally flattened. The tool has the advantages that the grinding and polishing media are introduced into the center of a grinding and polishing head, so that the grinding and polishing media can be fully contacted with grinding and polishing materials, and the grinding and polishing quality and the grinding and polishing efficiency are improved; and by a vacuumized pore passage of an outer ring of the grinding and polishing tool, the grinding and polishing media which are subjected to a grinding and polishing process is sucked away in time, so that the ground and polished surface is prevented from being polluted, the effect of self-cleaning the surface of a workpiece in the grinding and polishing process is achieved, subsequent cleaning processes are eliminated, and processing efficiency is improved.

Owner:DALIAN UNIV OF TECH

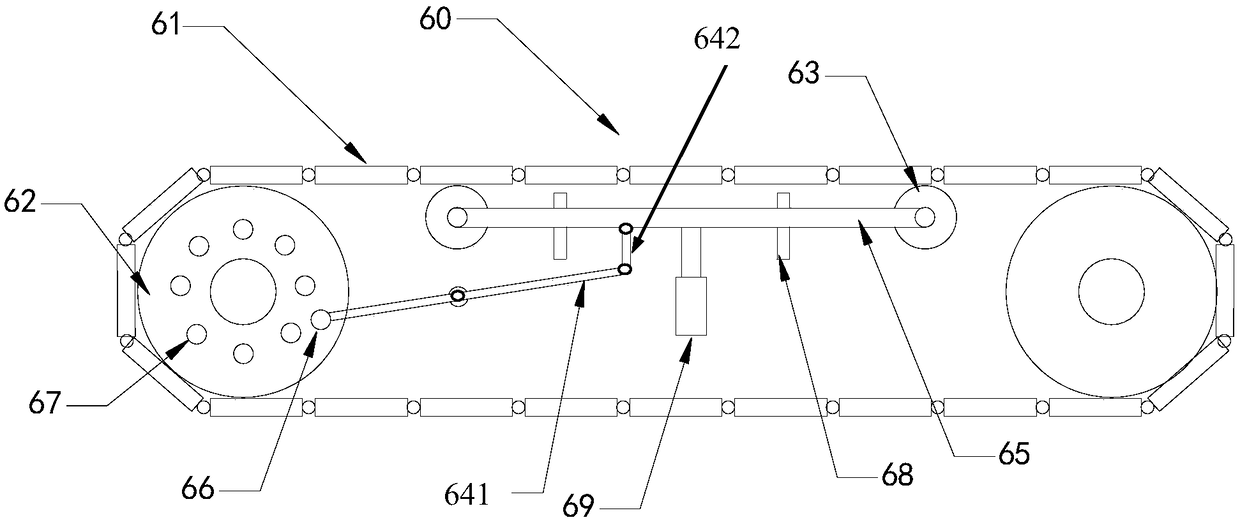

Longitudinal vibration type double-main-shaft wood polishing equipment

ActiveCN108326715AImprove grinding and polishing effectAvoid wear and tearEdge grinding machinesPolishing machinesEngineeringLongitudinal vibration

The invention discloses longitudinal vibration type double-main-shaft wood polishing equipment which comprises a base, a workbench, a portal frame, a first main shaft, a second main shaft and a longitudinal vibration conveying device; the longitudinal vibration conveying device is arranged on the workbench and is used for conveying a workpiece; the portal frame is arranged on the workbench; the portal frame comprises a cross beam and two upright columns supporting the cross beam; the first main shaft and the second main shaft are arranged on the cross beam of the portal frame; and grinding wheels are arranged at the output ends of the first main shaft and the second main shaft correspondingly. In the grinding and polishing process, a conveying crawler belt of the longitudinal vibration conveying device can generate longitudinal vibration, the workpiece on the conveying crawler belt is vibrated accordingly, longitudinal engagement and disengagement motion is generated between the grinding wheels and the workpiece, and through the longitudinal engagement and disengagement motion, grinding threads of the grinding wheels can penetrate into deep seams of the workpiece and bring out sawdust in the deep seams, so that the grinding and polishing effect on the deep seams is improved.

Owner:合肥龙智机电科技有限公司

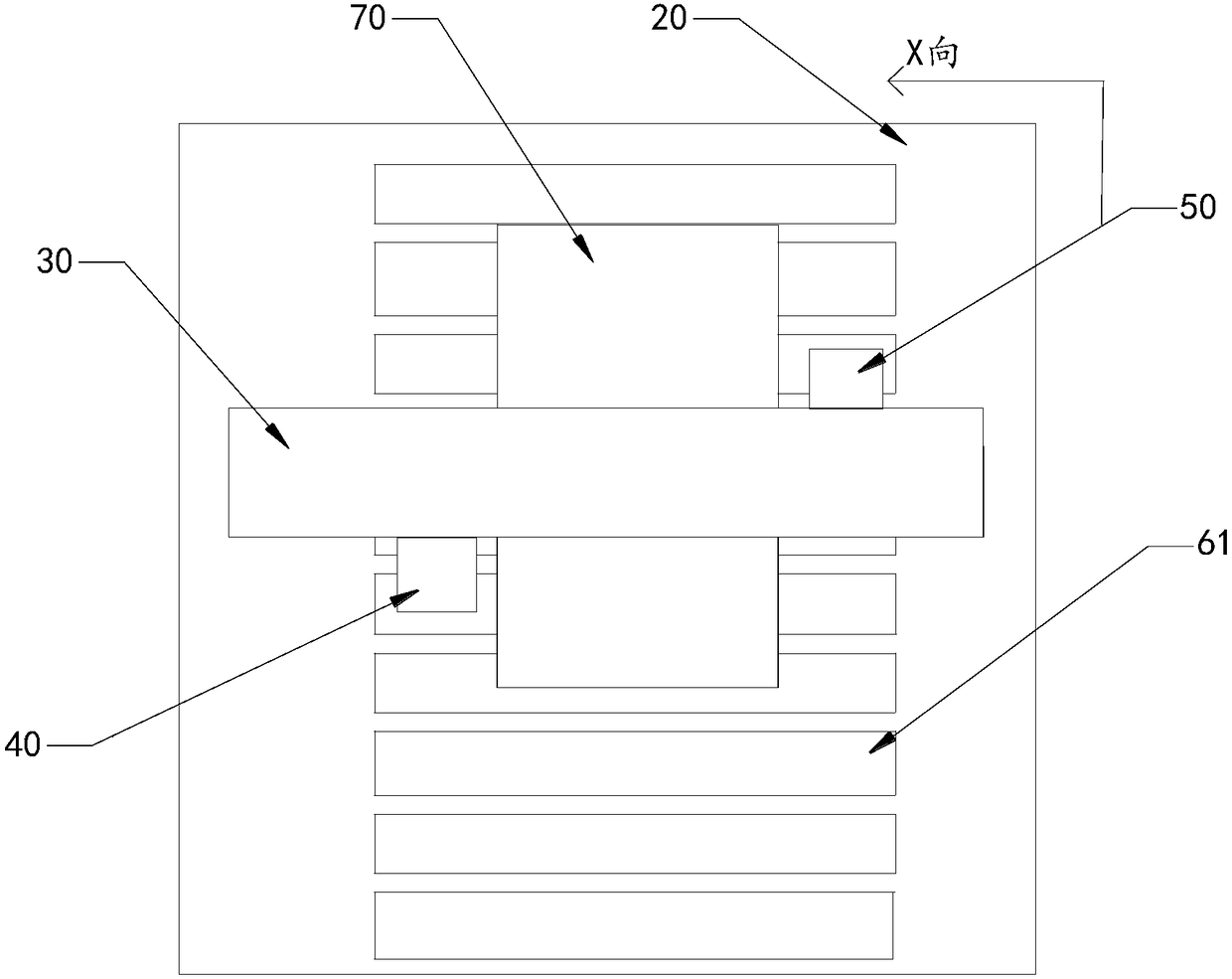

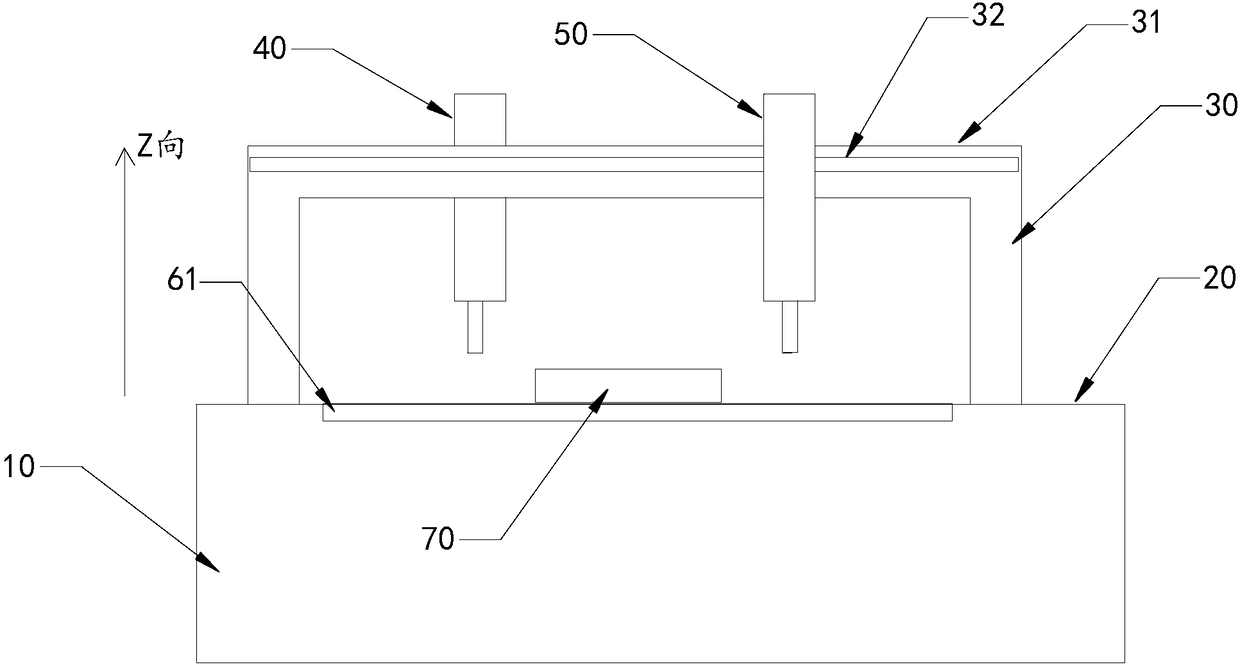

Intelligent metal plate flexible polishing and grinding equipment

PendingCN110497295AImprove grinding and polishing qualityEfficient grinding and polishingGrinding carriagesGrinding feed controlEngineeringMetal

The invention discloses intelligent metal plate flexible polishing and grinding equipment, and relates to the technical field of metal plate polishing and grinding equipment. The intelligent metal plate flexible polishing and grinding equipment comprises an execution platform for fixing a metal plate, a first polishing mechanism and a second polishing mechanism which are arranged above the execution platform; wherein the first polishing mechanism comprises a horizontally arranged polishing shaft and a first motor for driving the polishing shaft to rotate; the second polishing mechanism comprises a vertically arranged spherical polishing device, a motion device connected with the spherical polishing device for driving the spherical polishing device to move in a horizontal plane, a second motor for driving the spherical polishing device to rotate, an image acquisition device arranged between the first polishing mechanism and the second polishing mechanism for acquiring reflective information on the surface of the metal plate and a central computer for receiving the reflective information and controlling the operation of the motion device according to the reflective information. According to the intelligent metal plate flexible polishing and grinding equipment, a computer is used to control to carry out intelligent mobile polishing, so that high efficiency and precision and good effect are realized.

Owner:ANJI IDEA OFFICE FURNITURE CO LTD

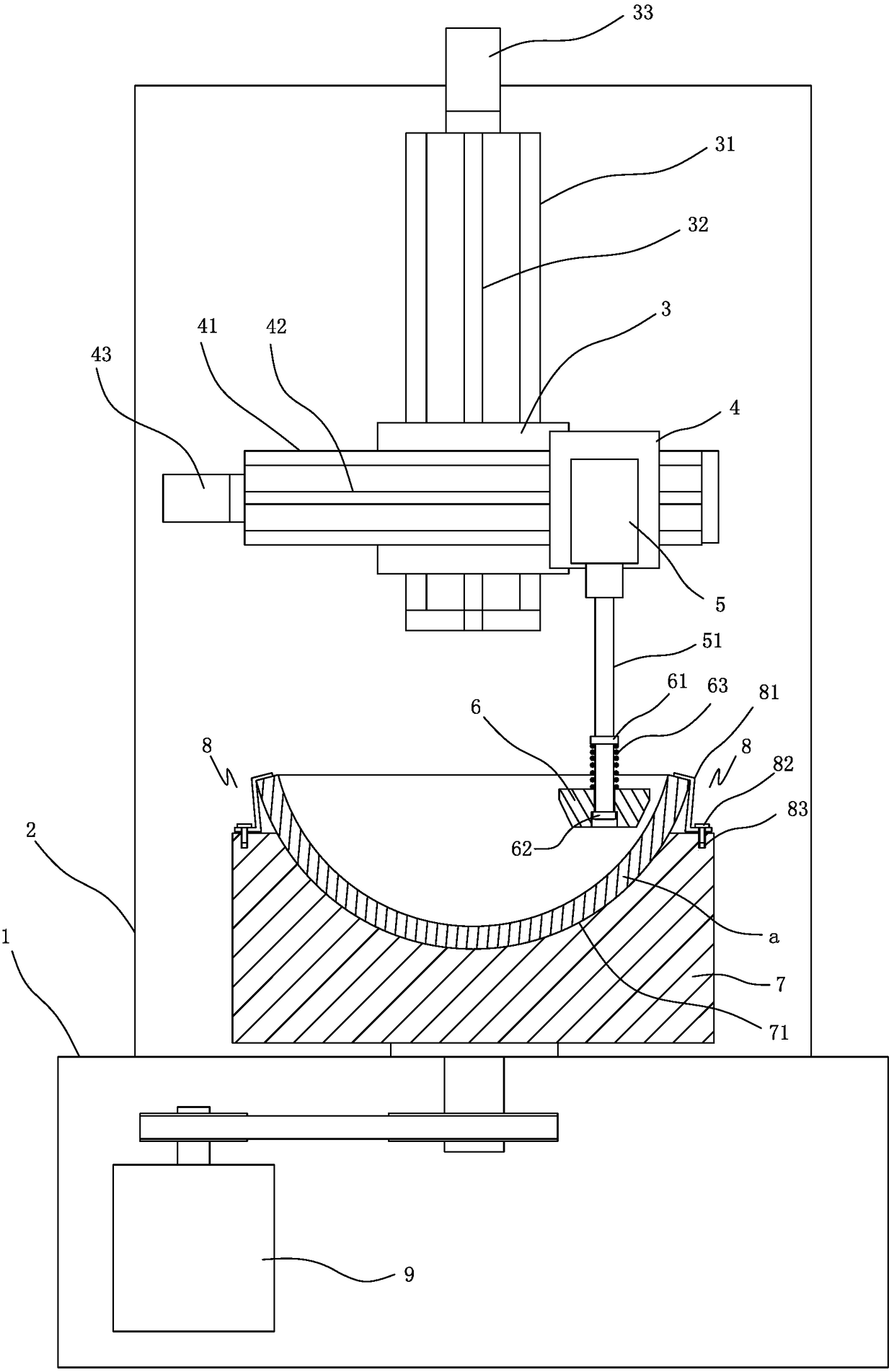

A grinding and polishing device for the outer peripheral surface of a stone washbasin

ActiveCN106493621BQuick fixGuaranteed no jitterGrinding drivesGrinding machinesHorizontal axisEngineering

Owner:南安市鑫能机械有限公司

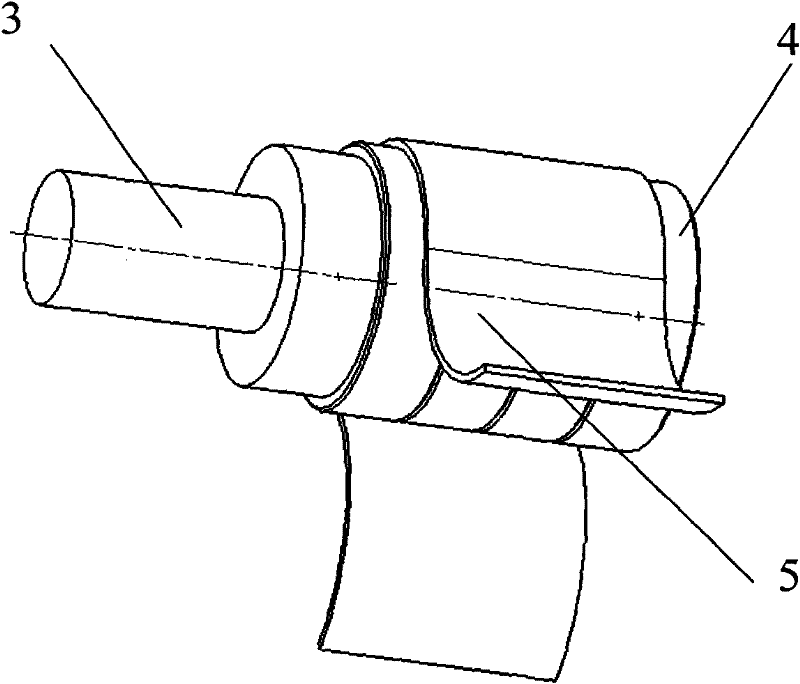

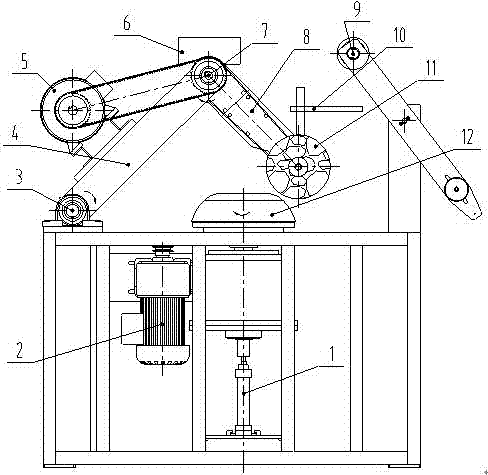

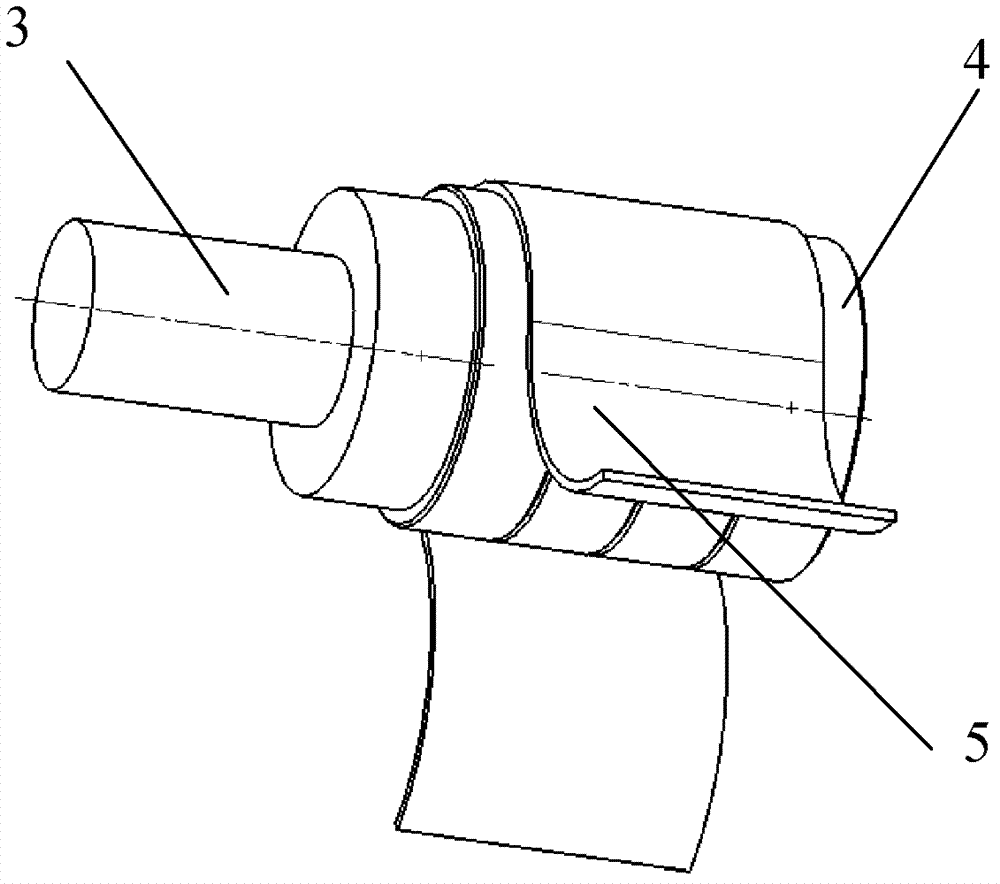

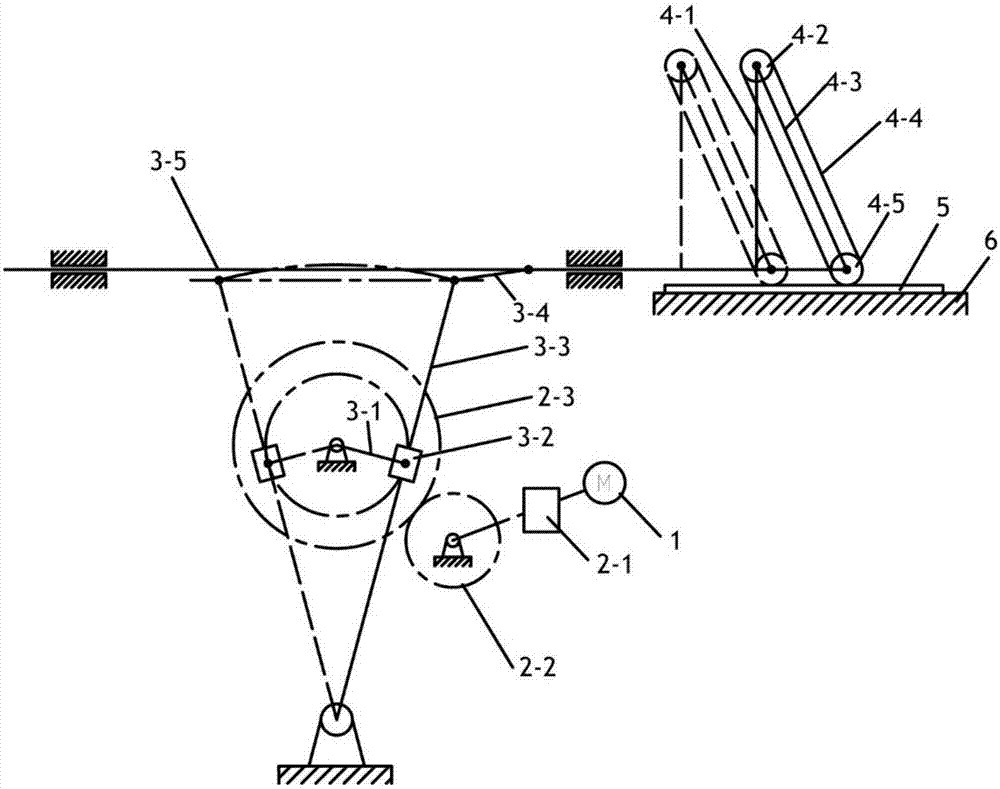

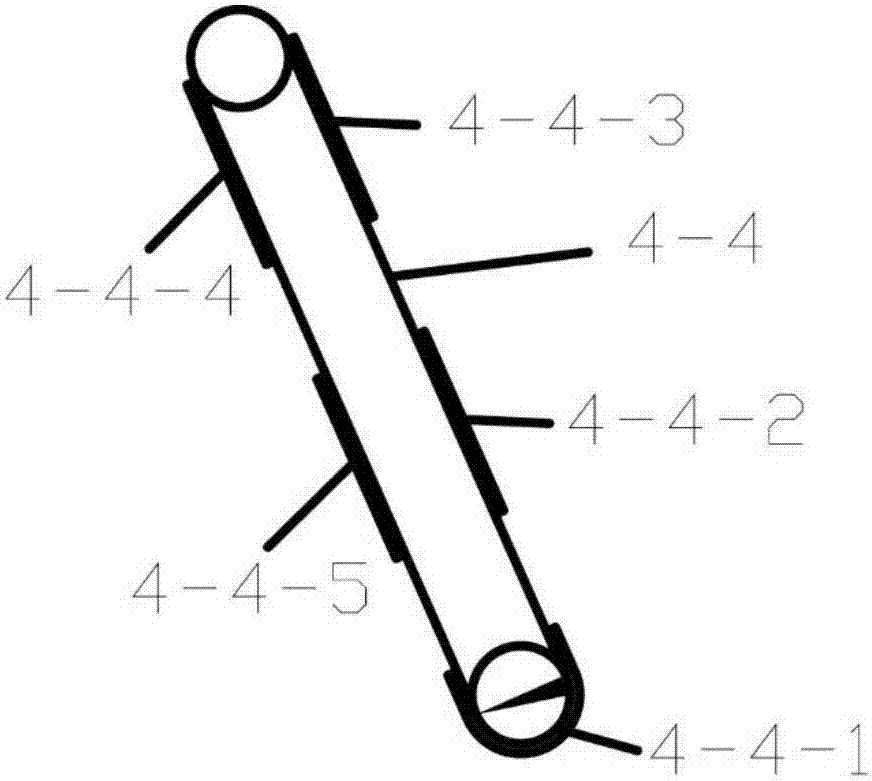

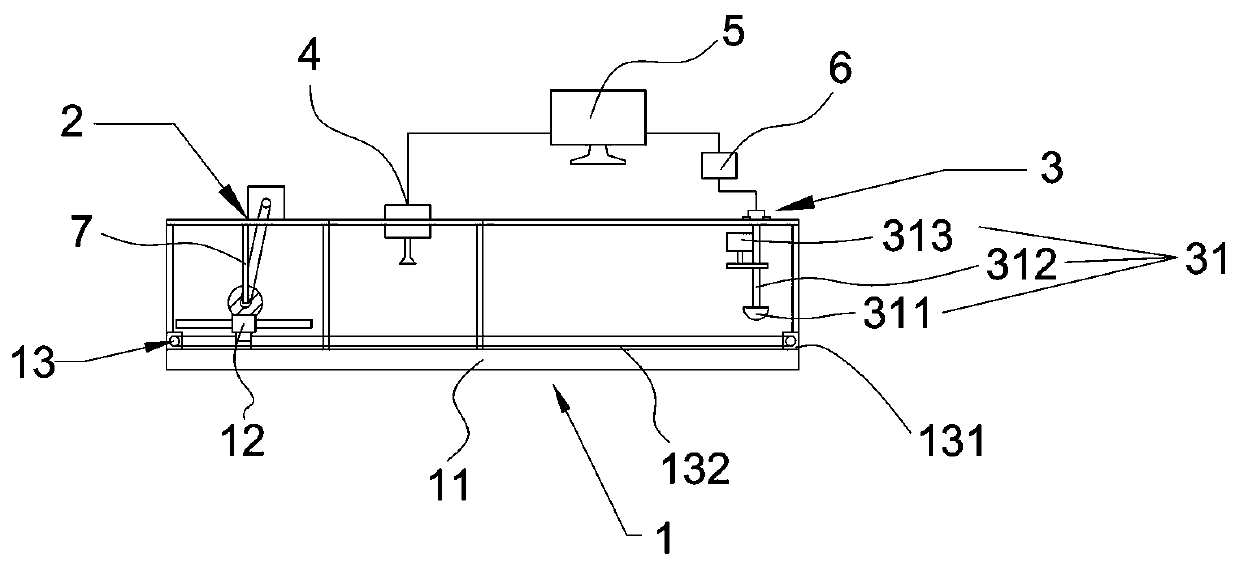

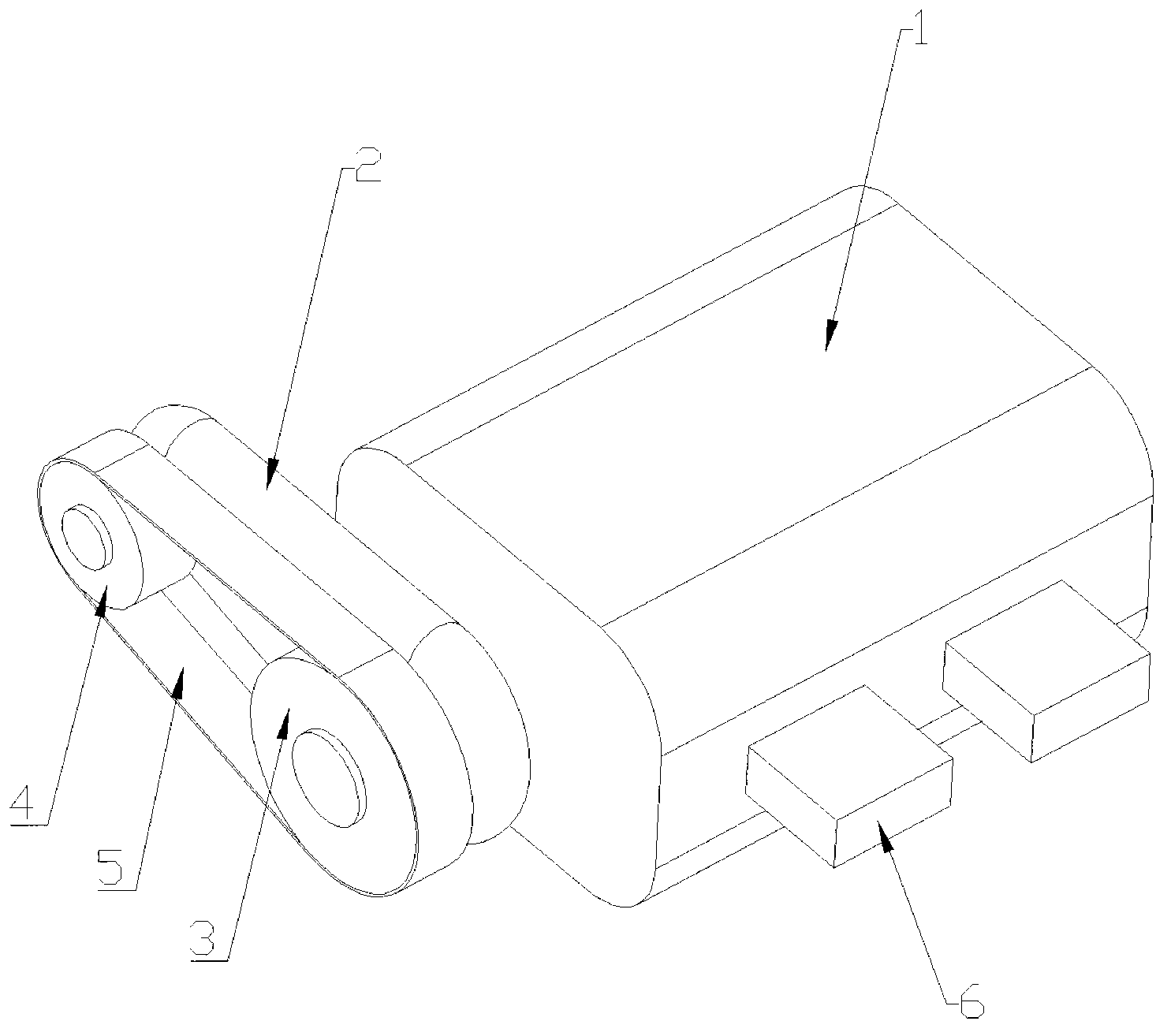

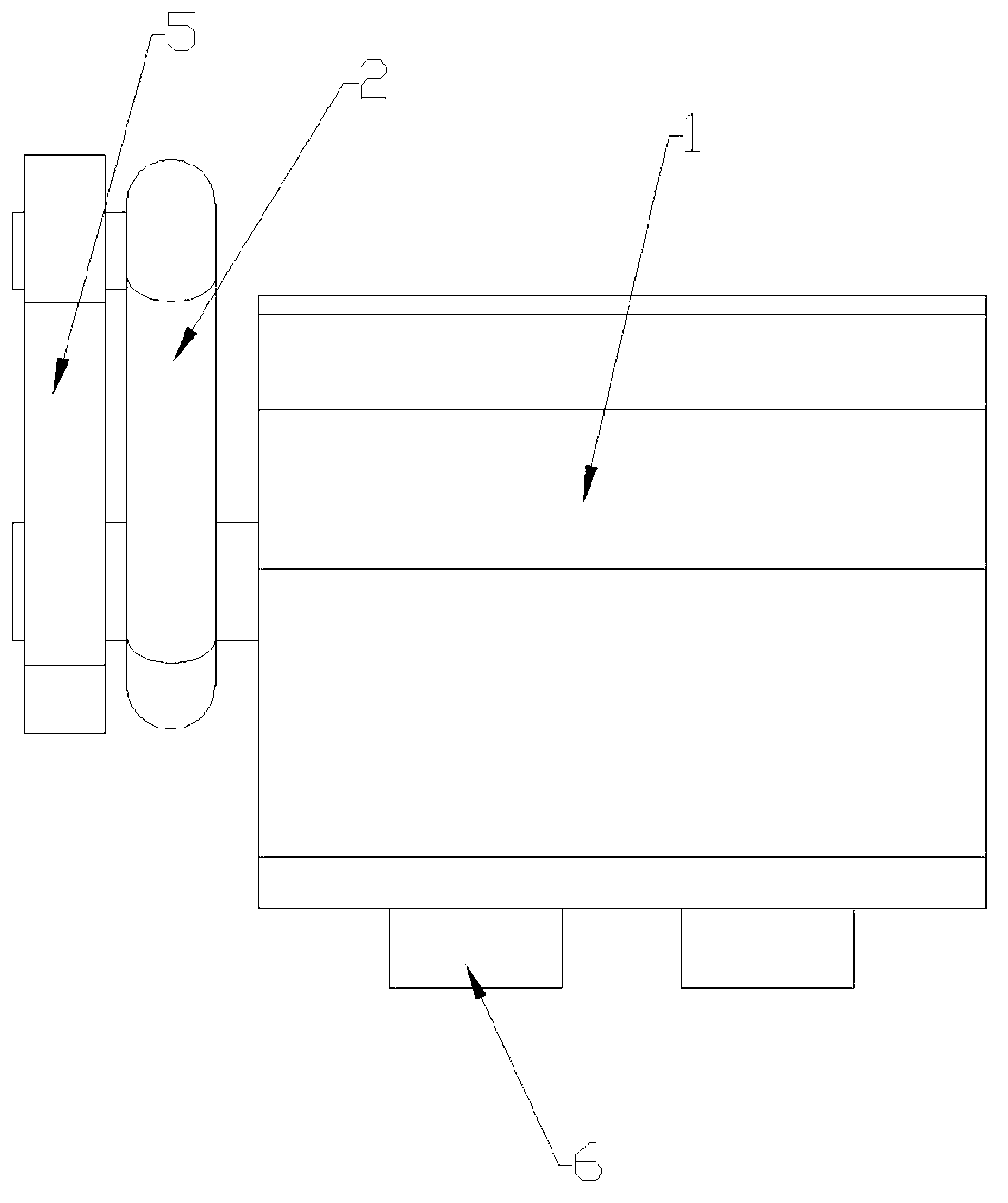

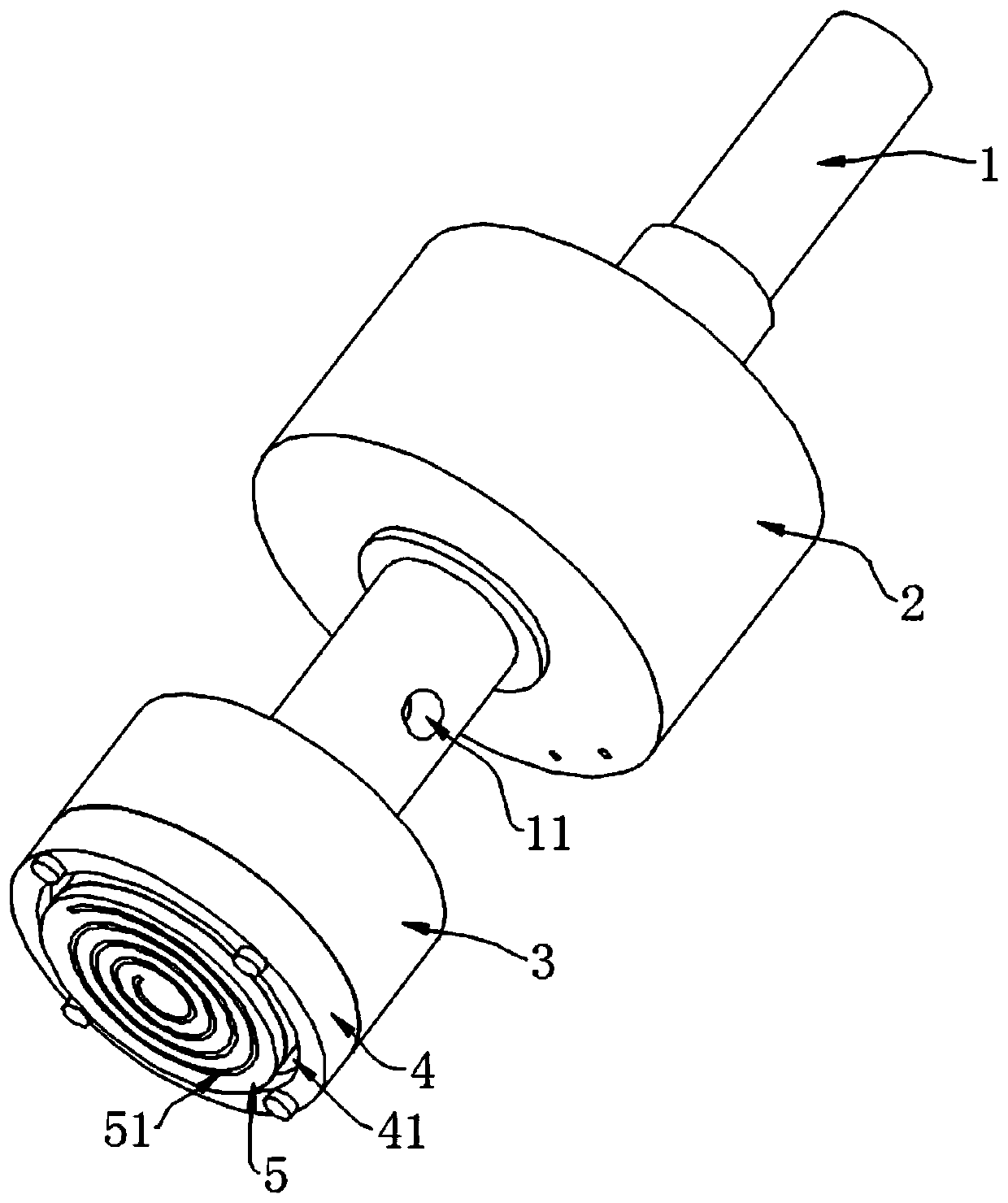

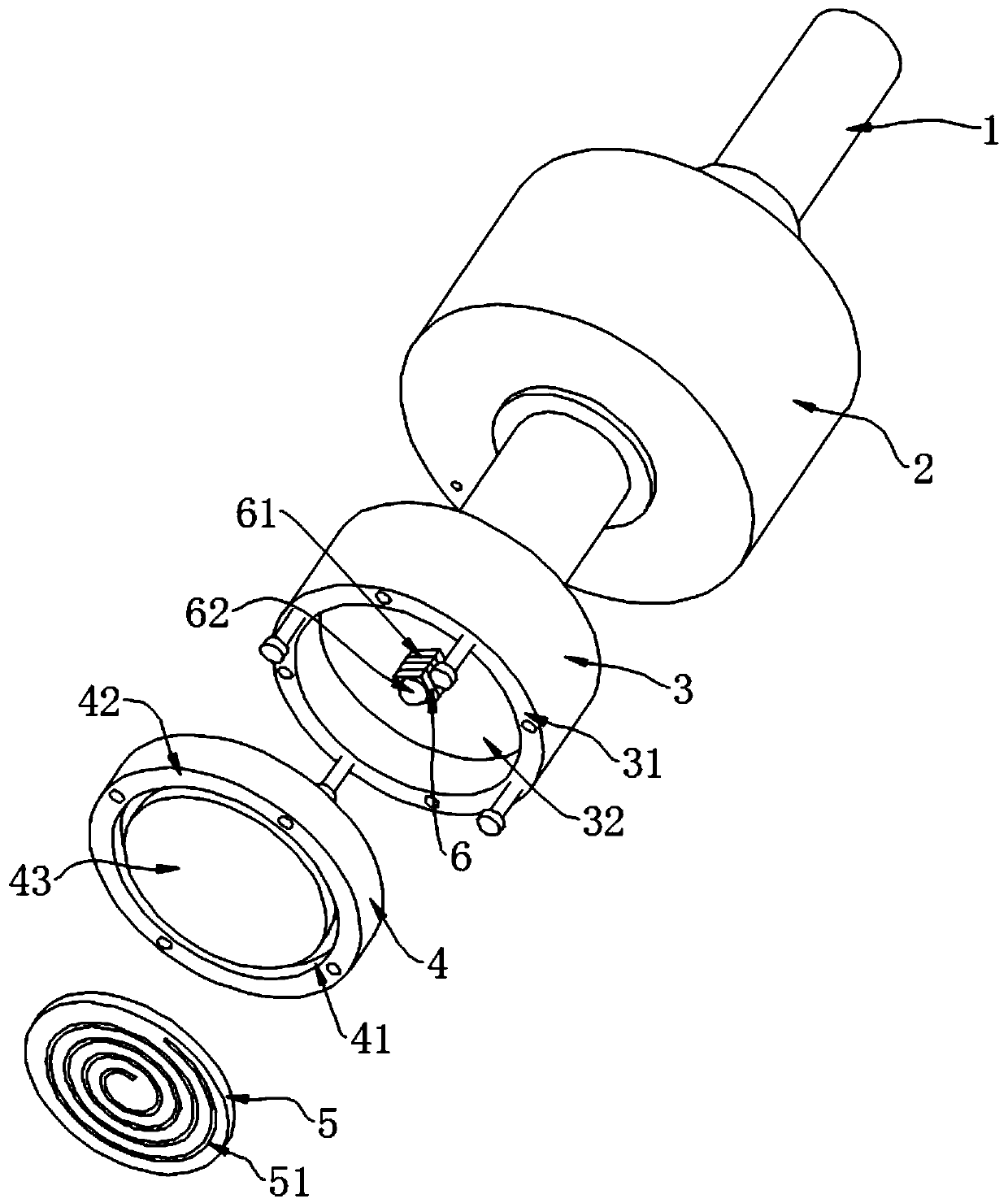

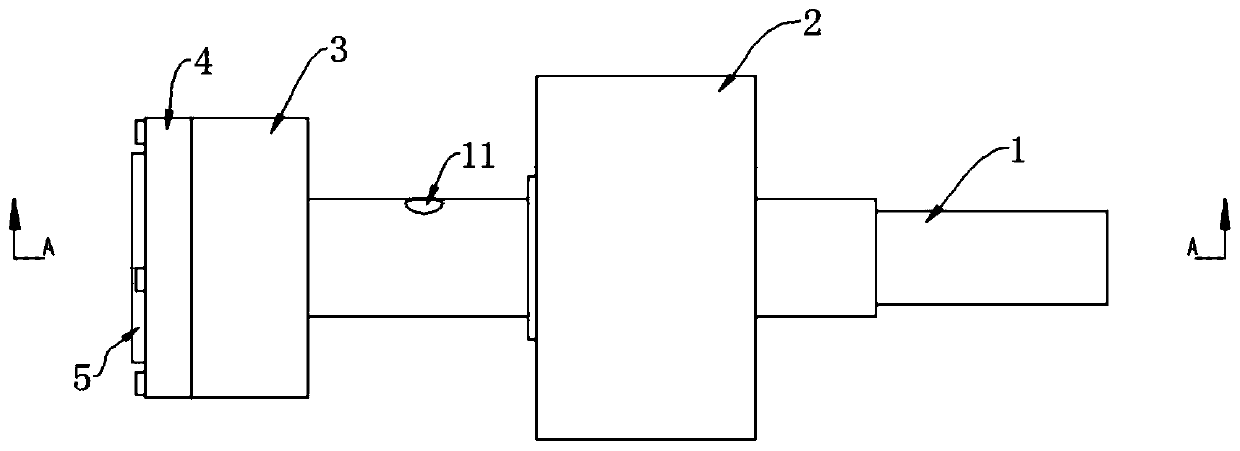

Automatic polishing and grinding machine of moving bolt in air cylinder of marine diesel engine

InactiveCN103264341AGrinding and polishing process time shortenedSpeed up grinding and polishingBelt grinding machinesDrive wheelDiesel engine

The invention discloses an automatic polishing and grinding machine of a moving bolt in an air cylinder of a marine diesel engine. The automatic polishing and grinding machine comprises a lathe, a motor (1) clamped on a lathe saddle, and a drive connecting rack (2) fixed to the end part of a shell of the motor, wherein an output shaft of the motor (1) passes through the tail end of the drive connecting rack (2) and is fixedly provided with a driving wheel (3); a driven wheel (4) is rotatably mounted at the front end of the drive connecting rack (2); and drive sanding belts (5) are sleeved on the driving wheel (3) and the driven wheel (4). The automatic polishing and grinding machine of the moving bolt in the air cylinder of the marine diesel engine has the advantages of high polishing and grinding efficiency and high quality.

Owner:宁波瑞亚紧固件制造有限公司

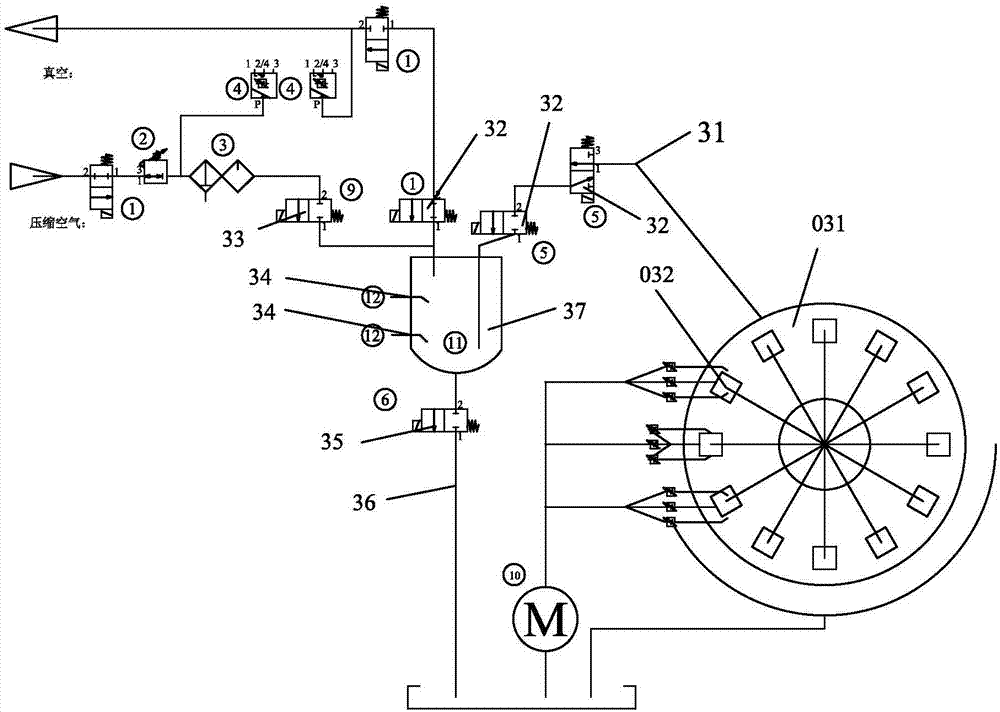

Multifunctional grinding and polishing machine

PendingCN107336125AIncrease productivityImprove grinding and polishing qualityGrinding carriagesPolishing machinesIntelligent control systemGrinding

The invention discloses a multifunctional grinding and polishing machine. The multifunctional grinding and polishing machine is characterized by comprising main shaft mechanisms arranged on a rack, a rotary disc part, a gas circuit and liquid circuit system and an intelligent control system; and the rotary disc part is installed on the gas circuit and liquid circuit system in a machine case, the multiple main shaft mechanisms are adjustable in angle and up-and-down and left-and-right position, and the multiple main shaft mechanisms adjustable in angle and up-and-down and left-and-right position surround the rotary disc part and are opposite arranged. According to the multifunctional grinding and polishing machine, the intelligent control system is adopted for controlling multiple main shafts to independently or simultaneously run, different stations and different processes can be set through procedures for grinding and polishing, the production efficiency is improved, glass, ceramic and hardware meeting the technical quality requirement can be conveniently ground and polished, and the production efficiency and the grinding and polishing quality are improved.

Owner:东莞市玮明实业有限公司

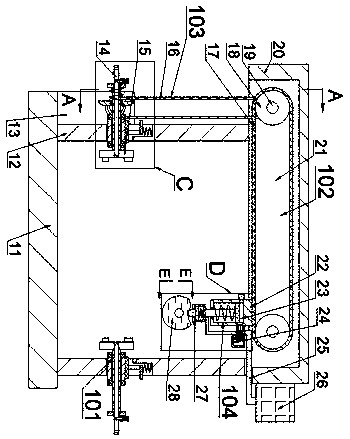

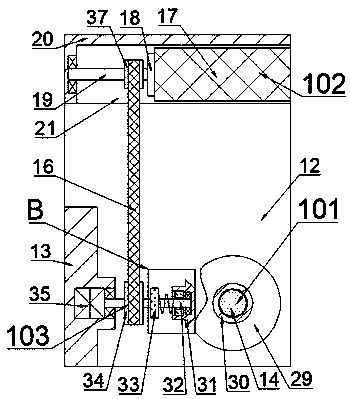

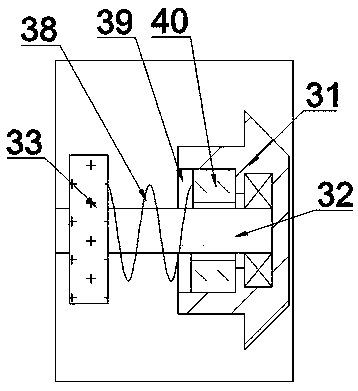

A vibration compound flexible grinding and polishing device

ActiveCN107414665BEasy to cleanAvoid cloggingLapping machinesLapping toolsHelical lineVibration amplitude

The invention provides a vibrating and flexible compound grinding and polishing device. The grinding and polishing device comprises a connecting shaft, a back plate, piezoelectric ceramics, a grinding disc and a grinding pad, wherein the back plate is fixed at one end of the connecting shaft; the grinding disc is fixed on the back plate; an accommodating cavity is formed in the back plate; the edge, directly facing the grinding disc, of the back plate protrudes to form an annular fixing part; the grinding disc comprises an annular shoulder and a boss positioned at the middle of the annular shoulder; the annular shoulder is fixedly connected with the fixing part; the boss is connected with the annular shoulder through a flexible hinge; the piezoelectric ceramics is arranged in the accommodating cavity and at the position corresponding to the boss; and the grinding pad is arranged in a manner of being clung to the boss. According to the vibrating and flexible compound grinding and polishing device provided by the invention, the vibration amplitude of the middle of the boss is greater than that of the periphery of the boss, so that the structural flexibility and the grinding material removal rate are controlled; furthermore, as a spirally distributed fine groove is formed in the grinding plane of the grinding pad, a more excellent and uniform grinding and machining material removing effect is achieved, and the grinding and polishing quality of the grinding plane is improved.

Owner:江苏普锐斯钻石工具有限公司

Double-platform full-cycle grinding and polishing device and method

PendingCN109590868ACircumferential grinding and polishingAvoid inappropriate phenomenaGrinding machinesGrinding/polishing safety devicesEngineeringControl unit

The invention discloses a double-platform full-cycle grinding and polishing device and a method. The double-platform full-cycle grinding and polishing device comprises a first grinding and polishing unit, a second grinding and polishing unit and a main control unit, wherein the first grinding and polishing unit and the second grinding and polishing unit are arranged around a grinding and polishingarea, and the grinding and polishing area is provided with a first end working station point and a second end working station point; the first grinding and polishing unit takes the first end workingstation point as a grinding and polishing starting point and takes the second end working station point as a grinding and polishing end point, and the first grinding and polishing unit moves between the first end working station point and the second end working station point in a reciprocating mode on one side of the grinding and polishing area;the second grinding and polishing unit takes the second end working station point as a grinding and polishing starting point and takes the first end working station point as a grinding and polishing end point, and the second grinding and polishing unitmoves between the first end working station point and the second end working station point in a reciprocating mode on the other side of the grinding and polishing area. Therefore, the circumferentialpolishing of workpiece is realized, the operation efficiency is greatly improved, and the labor cost is reduced. Meanwhile, the grinding and polishing quality is improved, the situation that the grinding and polishing are not in place is avoided, and the double-platform full-cycle grinding and polishing device and the method is suitable for popularization and application.

Owner:王华

Polishing device for high-temperature alloy inwards-protruding tube

InactiveCN103286666AExtended service lifeReduce temperature rise and generate heatPolishing machinesGrinding/polishing safety devicesSuperalloyHigh heat

The invention relates to a polishing device for a high-temperature alloy inwards-protruding tube. The polishing device comprises a rotating device, a grinding-tool rotation driving device, a connecting rod and a grinding tool. The rotating device is rotatably snapped at one end of the high-temperature alloy inwards-protruding tube, the grinding-tool rotation driving device is connected with one end of the connecting rod, a top plate is arranged on a coolant delivery device, the other end of the high-temperature alloy inwards-protruding tube is hermetically and rotatably supported on the top plate, the coolant delivery device is communicated with an inner cavity of the high-temperature alloy inwards-protruding tube through the top plate, one end of the connecting rod penetrates the coolant delivery device to be connected with a rotating rod of the grinding-tool rotation driving device, the other end of the connecting rod penetrates the top plate and the inner cavity of the high-temperature alloy inwards-protruding tube to be connected with the grinding tool. The coolant delivery device is adopted to rotatably support the high-temperature alloy inwards-protruding tube and grinding cooling is performed inside the high-temperature alloy inwards-protruding tube, so that requirements on polishing inside an elongated inwards-protruding tube are met, and the polishing device has the advantages of simple structure, convenience in use, high efficiency, long service life, good grinding quality and high accuracy.

Owner:江苏久保联实业有限公司

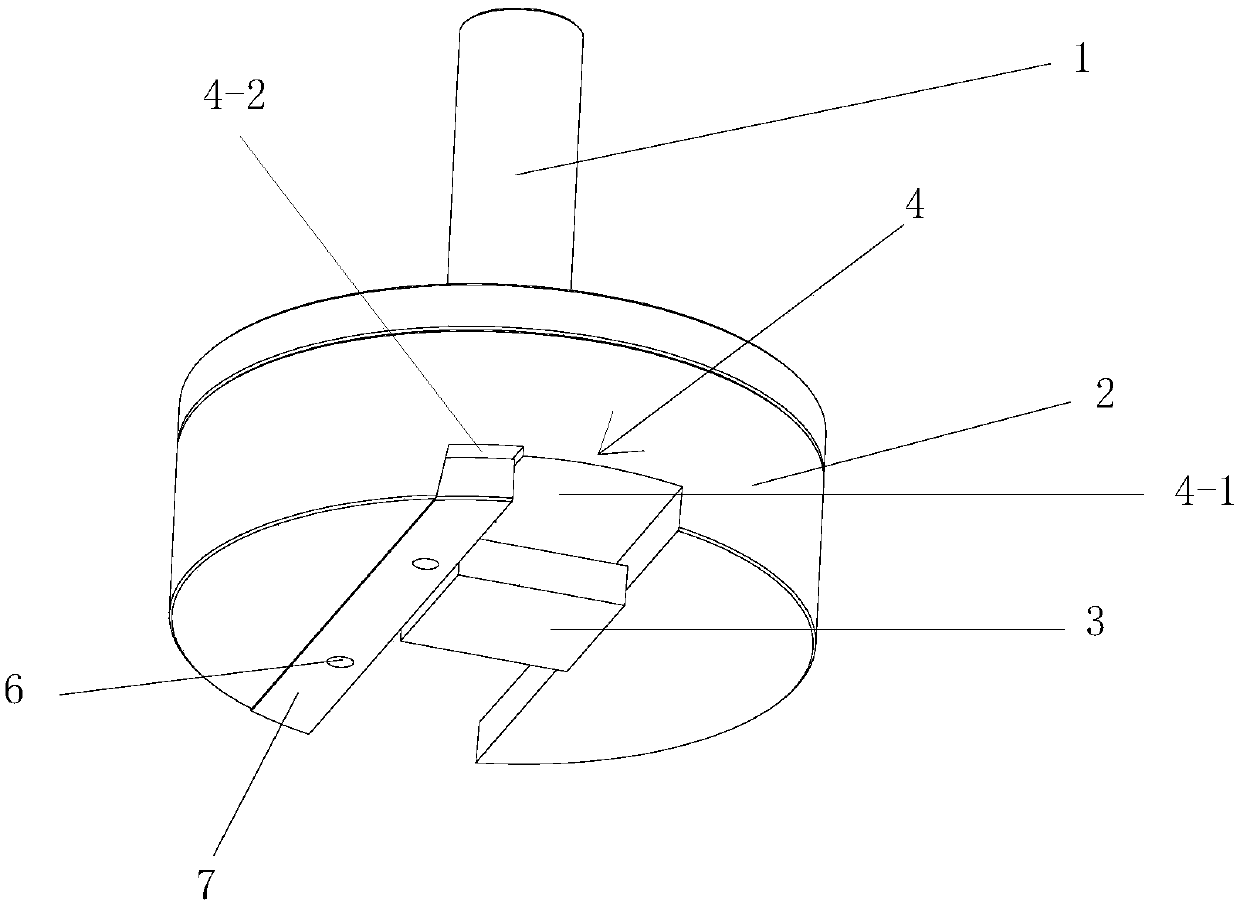

Bottom mold fixture device for metallographic sample automatic grinding and polishing machine

InactiveCN106737103BSimple structureReasonable designPolishing machinesPreparing sample for investigationMetal moldMechanical engineering

The invention discloses a bottom die clamp device for an automatic polish-grinding machine of a metallographic specimen, comprising a bottom die, connecting mechanisms and a clamp mechanism. The connecting mechanisms each comprise a boss and a positioning pin, the boss is of a stair-stepping cylindrical boss which comprises a big cylindrical boss and a small cylindrical boss, the bottom die is of a round bottom die, a bottom surface of the bottom die is provided with a mounting groove which is of a stair-stepping groove, the mounting groove comprises a first groove and a second groove communicated with the first groove, the clamp mechanism comprises a first adjustment block and a fixing piece, the first adjustment block is of a wedge block, and the width of the first adjustment block increases gradually from top to bottom. The bottom die clamp device is reasonable in design, simple and convenient in operation, strong in adaptability and good in positioning effect, can improve the polish-grinding quality of the metallographic specimen and the metallographic analysis accuracy, and is high in accuracy and strong in practicability.

Owner:XIAN UNIV OF SCI & TECH

Dual grinding and polishing unit for robot end

The invention provides a double grinding and polishing device for a robot end. The double grinding and polishing device comprises a driving device (201), a fixing rack (202), an executive device (203)and a transmission device (204); the driving device (201) and the transmission device (204) are both fixedly installed on the fixing rack (202), and the executive device (203) is connected to the transmission device (204); and the transmission device (204) comprises an eccentric mechanism and / or a non-eccentric mechanism. According to the double grinding and polishing device, two working procedures of grinding and polishing can be finished with no need of replacing tools, and the production tact of a station can be decreased by 20s or above; the service life of abrasive paper is prolonged greatly, and the number of door frames which are polished by a piece of abrasive paper is increased to 5-6 from 2-3; and the use efficiency of the abrasive paper is increased by 2 times or above, and thereturn on investment of the overall device is improved.

Owner:YUYI INTELLIGENT TECH SHANGHAI CO LTD

Grinding and polishing device

ActiveCN110549203BAdjust the first height in real timeHigh control precisionGrinding carriagesPolishing machinesMechanical engineeringSemiconductor

Owner:YANGTZE MEMORY TECH CO LTD

A surface treatment device for the manufacture of insulating objects

ActiveCN114029828BImprove grinding and polishing qualityAdaptableGrinding drivesBelt grinding machinesPolishingSurface preparation

The invention provides a surface treatment device for the manufacture of insulating objects, which relates to the technical field of surface treatment, comprising: a polishing treatment assembly, the polishing control block is plugged inside the driven seat, and the polishing positioning assembly passes the surface shape of the sample insulator The use position of each polishing control block of the polishing treatment component is limited, so that the device can adapt to the grinding and polishing operation of insulators of different types, specifications and shapes, and has strong adaptability, and the polishing treatment component can attach the polishing belt to the The surface of the insulator to be treated, and the degree of fit is fine-tuned, which improves the quality of the insulator's grinding and polishing, and solves the problem that the existing insulator surface grinding and polishing device mold can only polish and polish one type of insulator, which has poor adaptability. When manufacturing insulators of different specifications, it is necessary to prepare multiple types of molds, which is a problem of cumbersome steps and high production costs.

Owner:江苏玫源新材料有限公司

A sample preparation method for graphite optical microstructure characterization

ActiveCN108871892BSelf-removalHigh surface flatnessPreparing sample for investigationTest samplePhysical chemistry

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com