Automatic grinding and polishing device and grinding and polishing method thereof

A polishing device and automatic technology, applied in the direction of grinding drive device, grinding/polishing equipment, grinding machine, etc., can solve the problems of low grinding and polishing quality, improve the grinding and polishing quality, improve the grinding and polishing environment, and facilitate disassembly and replacement quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

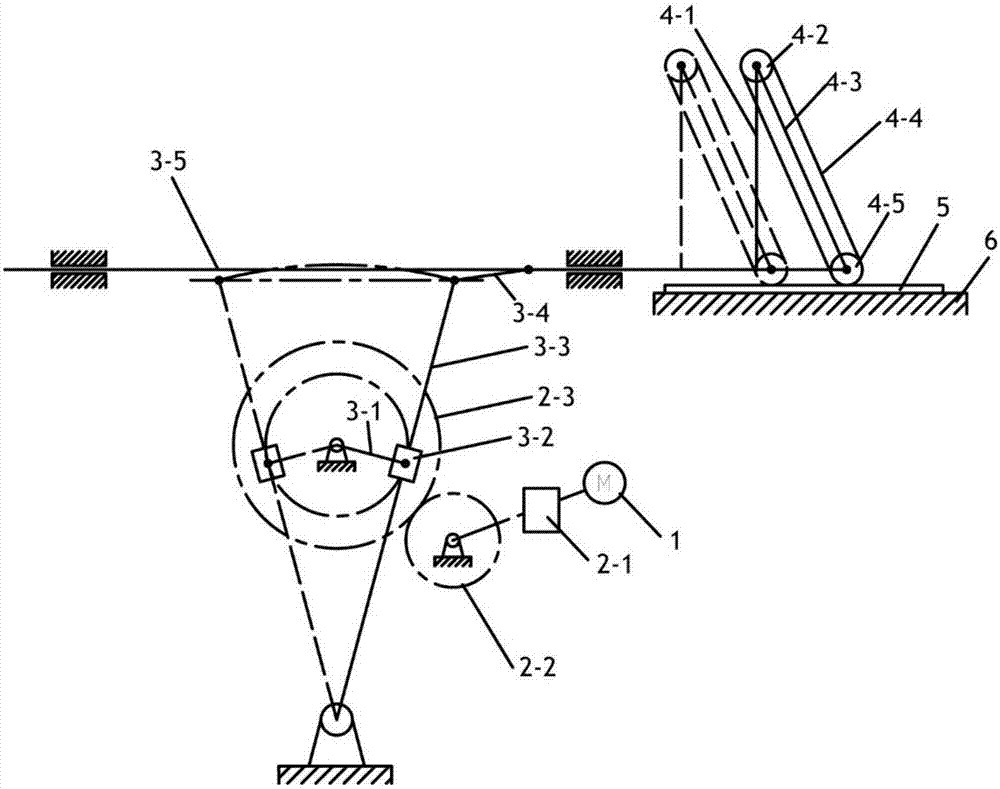

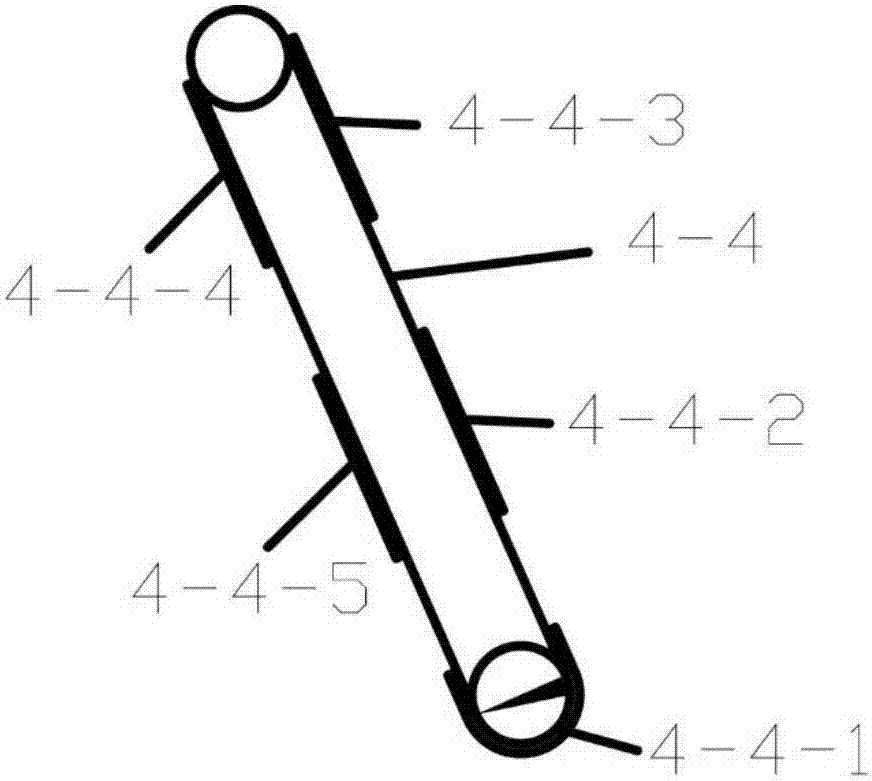

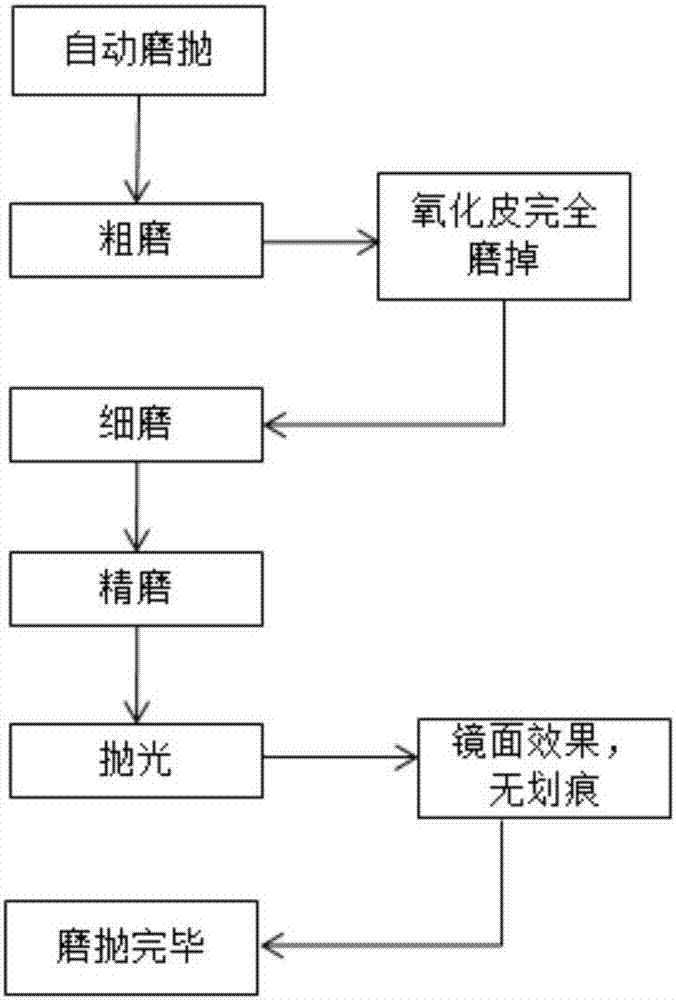

[0041] The first embodiment of the present application provides an automatic grinding and polishing device, such as figure 1 As shown, it includes a grinding and polishing mechanism. The grinding and polishing mechanism is provided with several grinding parts and polishing parts. Specifically, the grinding part includes four different types of water sandpaper 4-4-1, 4-4-2, 4-4-3 , 4-4-4, the polishing part is a polishing cloth 4-4-5, and the roughness of each polishing part is different from each other;

[0042] The parts to be polished are installed on the loading platform 6, and the main control unit controls the power mechanism to move the loading platform or the grinding and polishing mechanism, so that the parts to be polished and the grinding part or polishing part rub against each other to realize grinding or polishing.

[0043] In this application, the power mechanism moves one of the loading platform or the grinding and polishing mechanism, so that the two can move re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com