Polishing device for high-temperature alloy inwards-protruding tube

A high-temperature alloy and polishing device technology, applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problem of destroying the structure of the disturbance factor, affecting the performance of the furnace tube, and easily damaging the disturbance Factors and other issues, to achieve the effect of convenient use, improve the efficiency of grinding work, and improve the quality of grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

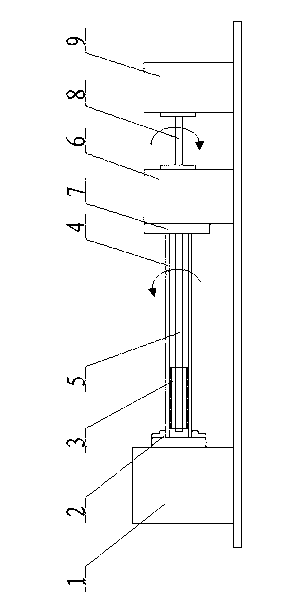

[0017] figure 1 As shown, a high-temperature alloy inner convex tube polishing device includes a rotating device 1 , an abrasive brush 3 , a connecting rod 5 , a cooling liquid delivery device 6 , a rotating rod 8 and an abrasive tool rotation driving device 9 . The rotating device 1 rotates and clamps one end of the high-temperature alloy inner convex tube 4 through the chuck 2, and the other end of the high-temperature alloy inner convex tube 4 is sealed and rotated on the top plate 7 of the coolant delivery device 6, and the coolant delivery device 6 passes through the top plate 7 It communicates with the superalloy inner convex tube 4, one end of the connecting rod 5 passes through the coolant delivery device 6 and connects to the rotary rod 8 of the abrasive rotary drive device 9, and the other end of the connecting rod 5 passes through the top plate 7 and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com