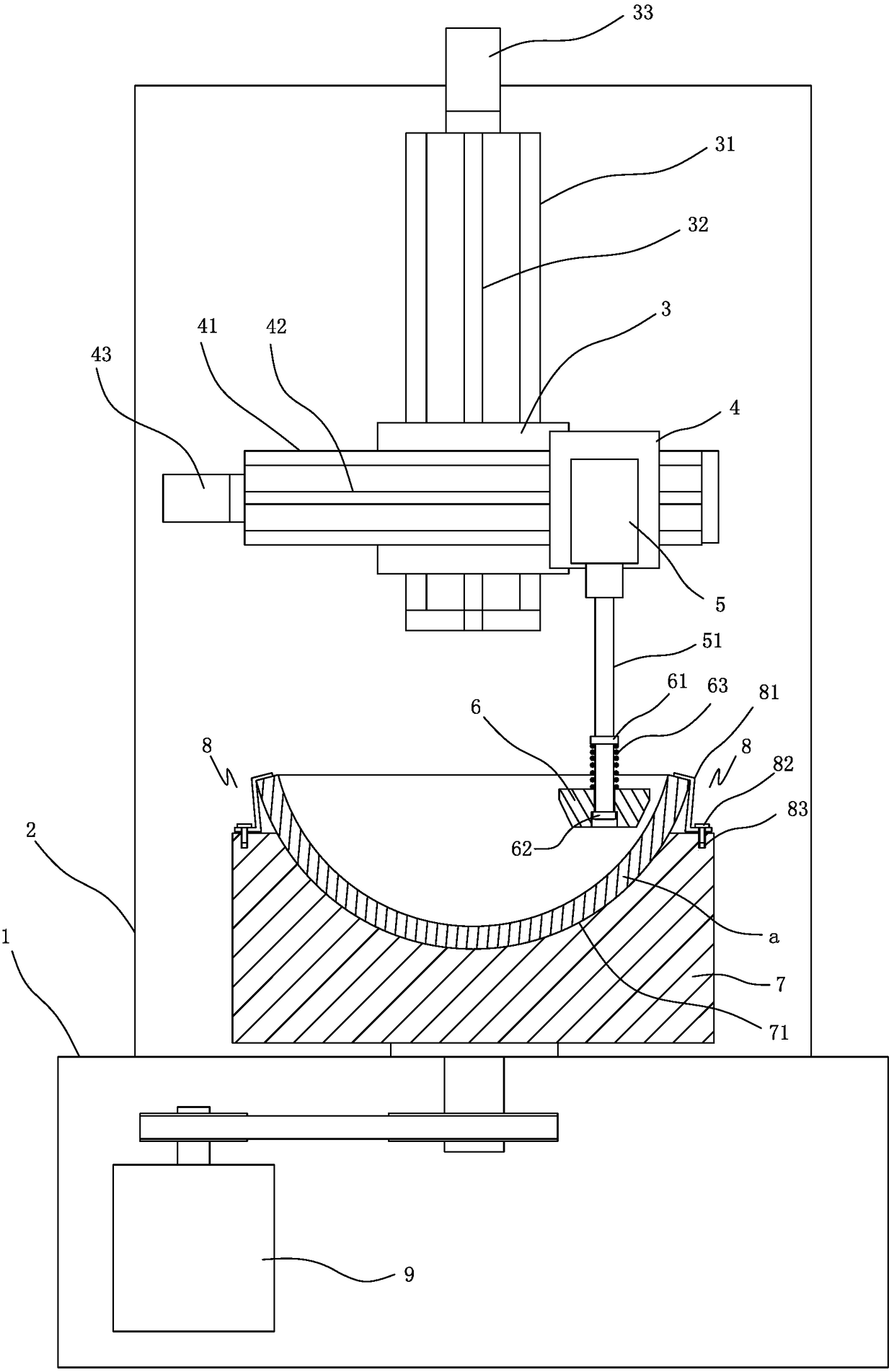

A grinding and polishing device for the outer peripheral surface of a stone washbasin

A technology for peripheral surfaces and washbasins, which is applied to grinding drive devices, grinding/polishing equipment, grinding machines, etc., can solve problems such as high labor costs, high labor intensity, and poor quality, and achieve improved grinding and polishing quality and improved grinding The effect of throwing efficiency and reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] The specific implementation method is: put the washbasin a to be processed on the arc-shaped convex surface 71, then tighten the bolt 82 so that the hook body 81 hooks the lower edge of the washbasin a, realize the fixing of the washbasin a, start the rotating motor 9 to make The washbasin a rotates, and then controls the cooperative action of the lifting mechanism and the rotary mechanism, so that the grinding and polishing wheel 6 is fed and polished along the arc-shaped inner wall of the washbasin a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com