High-sensitivity flexible grinding device

A sensitive and flexible technology, applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of poor control of the grinding force of the workpiece, affect the grinding and polishing effect, time-consuming and labor-intensive problems, and improve the quality of grinding and polishing , The structural design is ingenious, and the effect of improving the matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

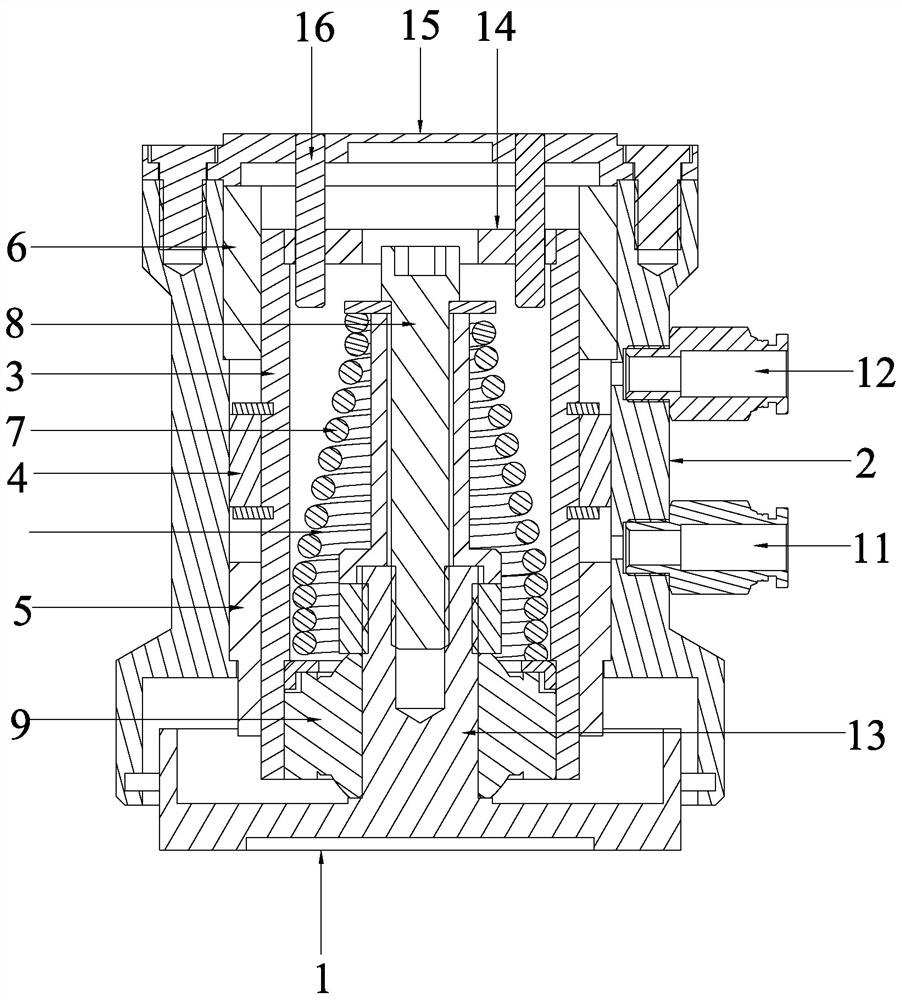

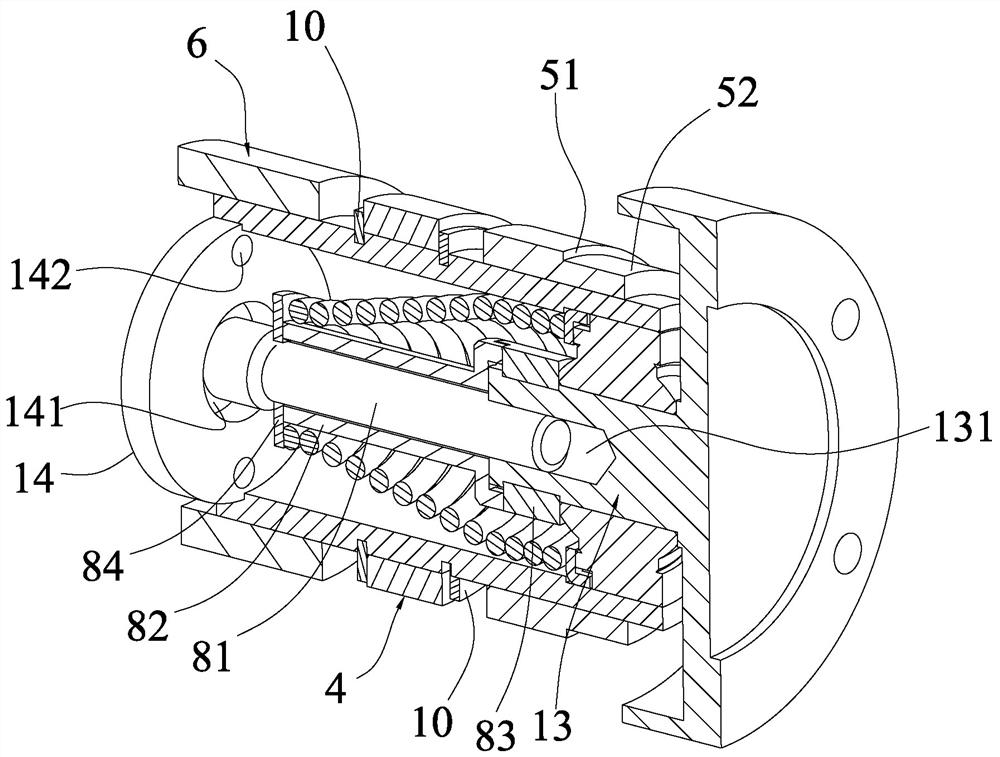

[0020] Examples, see Figure 1 to Figure 3 , a highly sensitive and flexible grinding device provided in this embodiment, which includes a mounting seat 1, a cylinder body 2, a hollow piston rod 3, a piston body 4, a front guide sleeve 5, a rear guide sleeve 6, a conical spring 7, and a torque extension Rod 8 and universal bearing 9, and mounting seat 1 is used for installing grinding tool, as pneumatic grinding machine or electric grinding machine etc.

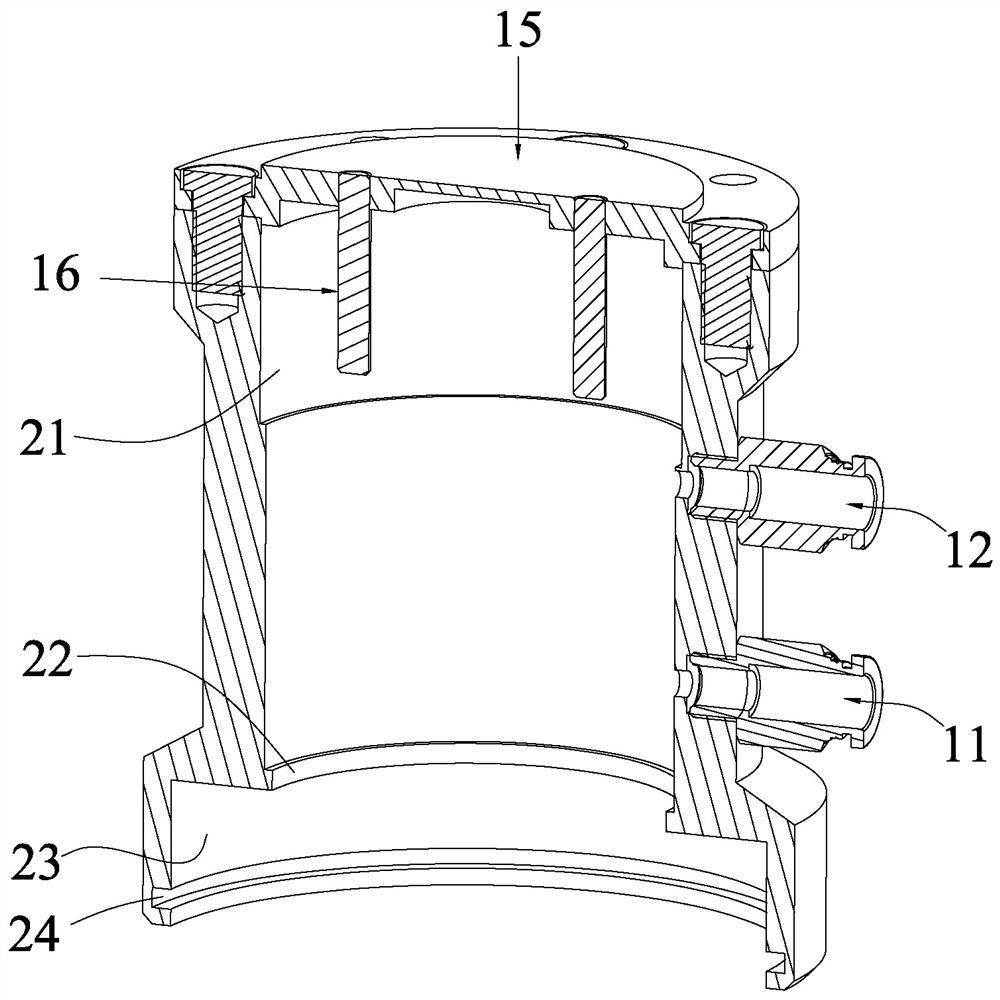

[0021] The hollow piston rod 3 is movably arranged in the cylinder body 2 through the front guide sleeve 5 and the rear guide sleeve 6, and can move telescopically relative to the cylinder body 2; for the convenience of installation, the outer diameter of the rear guide sleeve 6 is larger than the The outer diameter of the front guide sleeve 5 , the upper part of the inner cavity of the cylinder body 2 is radially recessed to form an upper installation cavity 21 that matches the outline of the rear guide sleeve 6 . The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com