Method for grinding and polishing CdZnTe wafer without wax

A cadmium zinc telluride wafer, grinding and polishing technology, applied in the field of wax-free grinding and polishing of cadmium zinc telluride wafers, can solve the problems of increased fragmentation rate, time-consuming chip removal process, difficult to remove, etc., to achieve accurate wafer thickness control, reduce cracks and Scratch, improve the effect of grinding and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

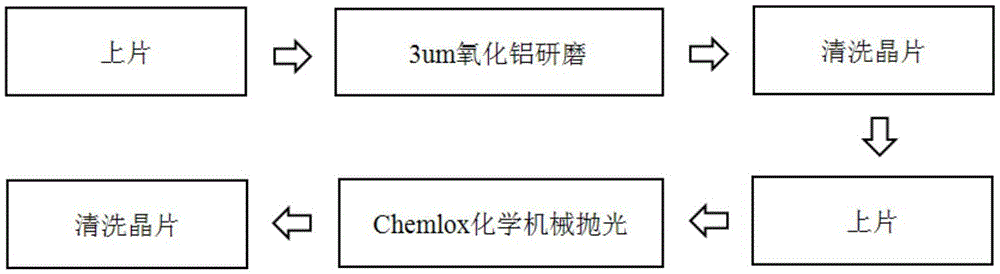

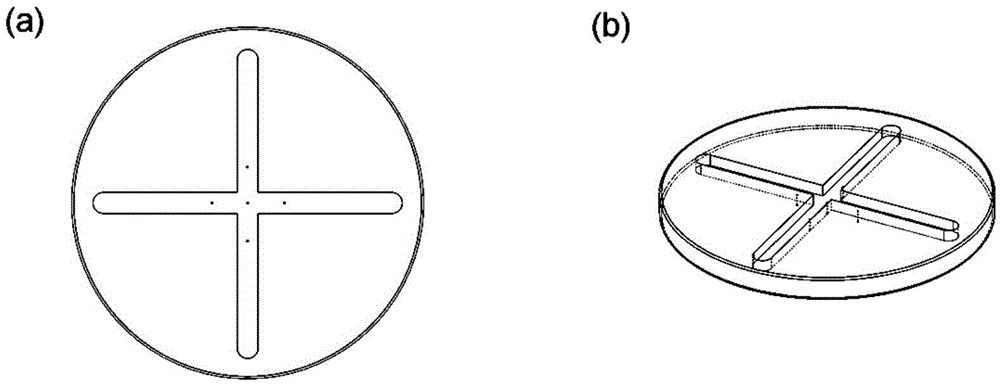

[0022] 1 Upper wafer: first place the groove of the transfer plate with the small hole facing down on the vacuum adsorption surface of the grinding and polishing fixture, and then place the rectangular wafer with a size of 3cmX4cm horizontally on the turntable with the surface to be polished facing upward. On the transfer tray, gently move the wafer to the center of the transfer tray, so that the wafer covers all the small holes on the transfer tray. Connect the grinding and polishing fixture with the vacuum generator, the vacuum is converted by the adapter plate, and the groove and the small hole will generate vacuum immediately, and the wafer will be adsorbed and fixed.

[0023] 23um alumina grinding: Prepare alumina particle suspension grinding liquid with a volume ratio of 3um alumina powder to deionized water of 1:10, stir evenly and set aside. Use a flat glass grinding disc, set the rotation speed of the grinding disc to 5rpm / min, and the drop rate of the grinding liquid...

Embodiment 2

[0029] 1 Upper wafer: first place the groove of the transfer plate with the small hole facing downward on the vacuum adsorption surface of the grinding and polishing fixture, and then place the square wafer with a size of 4cmX4cm horizontally on the turntable with the surface to be polished facing upward. On the transfer tray, gently move the wafer to the center of the transfer tray, so that the wafer covers all the small holes on the transfer tray. Connect the grinding and polishing fixture with the vacuum generator, the vacuum is converted by the adapter plate, and the groove and the small hole will generate vacuum immediately, and the wafer will be adsorbed and fixed.

[0030]23um alumina grinding: Prepare alumina particle suspension grinding liquid with a volume ratio of 3um alumina powder to deionized water of 1:10, stir evenly and set aside. Use a flat glass grinding disc, set the rotating speed of the grinding disc to 20rpm / min, and the drop rate of the grinding liquid ...

Embodiment 3

[0036] 1. Upper wafer: firstly place the groove of the transfer plate with the small hole facing downward on the vacuum adsorption surface of the grinding and polishing fixture, and then place the irregularly shaped wafer with a size of more than 2cmX2cm horizontally with the grinding and polishing surface facing upward On the transfer plate, gently move the wafer to the center of the transfer plate so that the wafer covers all the small holes on the transfer plate. Connect the grinding and polishing fixture with the vacuum generator, the vacuum is converted by the adapter plate, and the groove and the small hole will generate vacuum immediately, and the wafer will be adsorbed and fixed.

[0037] 23um alumina grinding: Prepare alumina particle suspension grinding liquid with a volume ratio of 3um alumina powder to deionized water of 1:10, stir evenly and set aside. Use a flat glass grinding disc, set the rotation speed of the grinding disc to 30rpm / min, and the drop rate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com