Automatic polishing and grinding machine of moving bolt in air cylinder of marine diesel engine

A technology for marine diesel engines and moving bolts, applied in grinding/polishing equipment, grinding machines, abrasive belt grinders, etc., can solve the problems of large human factors in manual grinding and polishing, low quality of grinding and polishing, and reduced work efficiency, so as to improve grinding Polishing quality, faster grinding and polishing speed, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

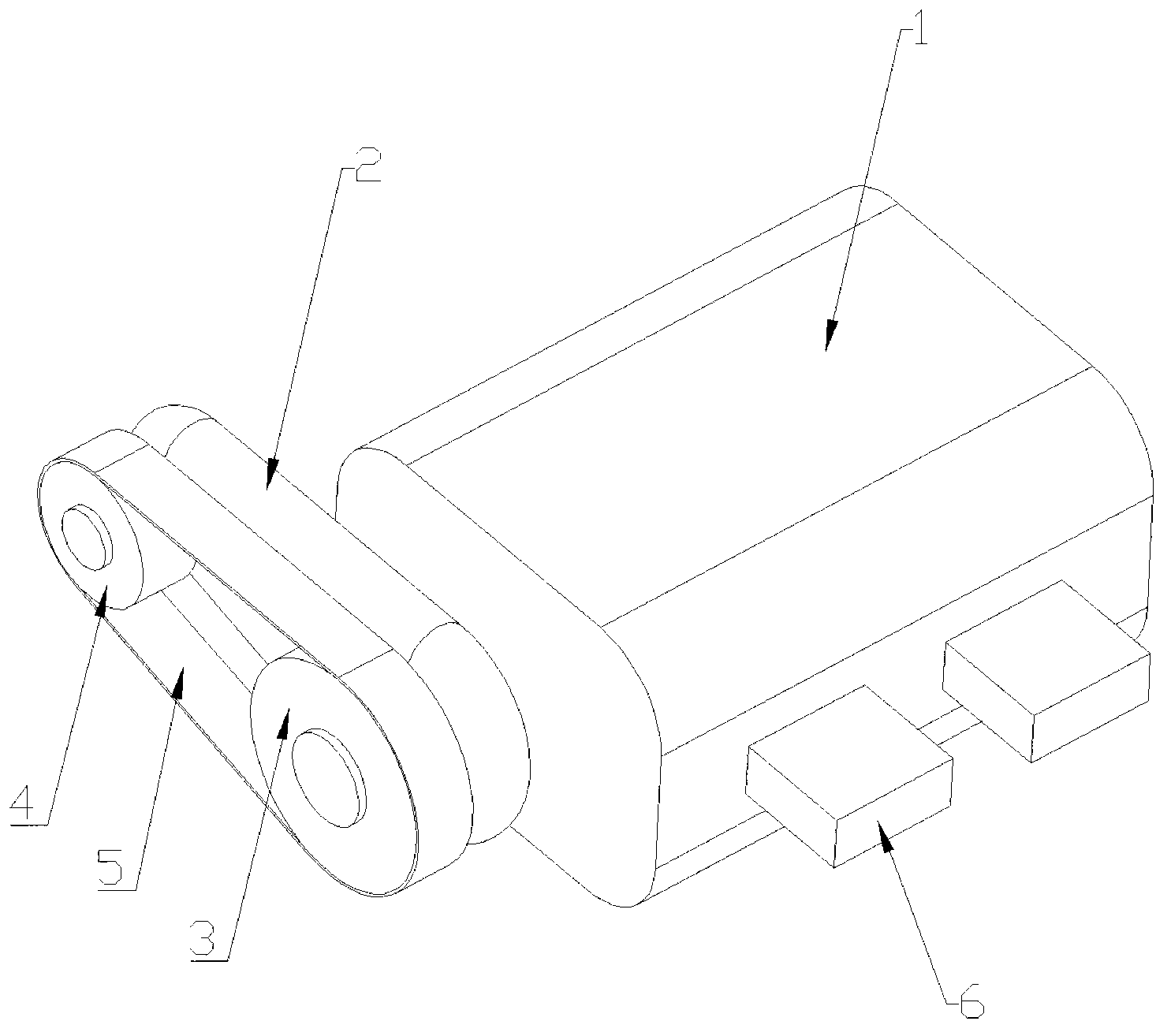

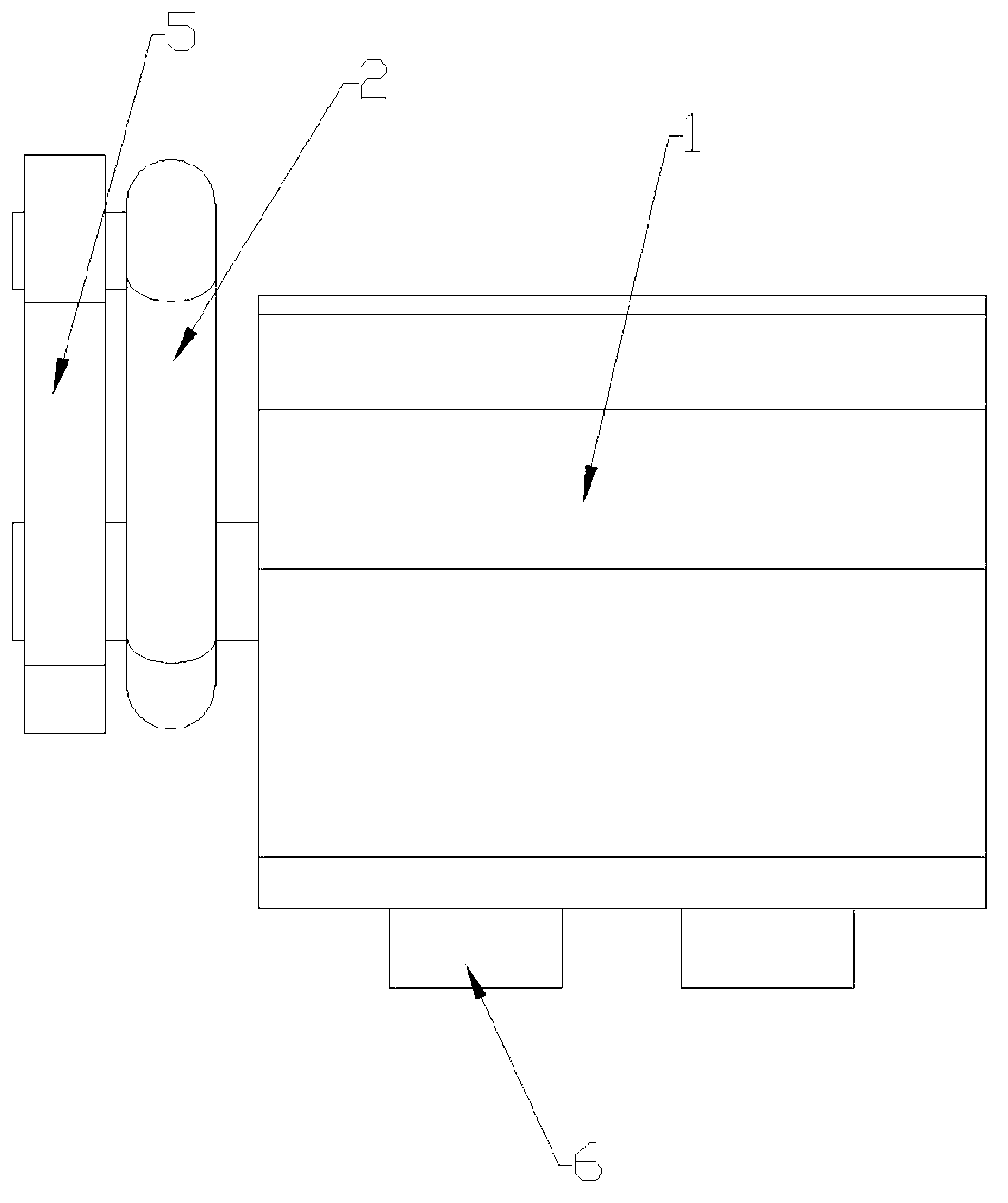

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] Because the lathe is an existing technology, it is not included in the figure 1 and figure 2 displayed in .

[0013] As shown in the accompanying drawings, the automatic polishing and grinding machine for moving bolts in the cylinder of a marine diesel engine of the present invention includes a lathe, which is different from the prior art in that it (herein it refers to the automatic polishing and grinding machine for moving bolts in a cylinder of a marine diesel engine) also It includes a motor 1 clamped on the tool holder of the lathe, and a transmission connection frame 2 fixed at the end of the motor housing.

[0014] The output shaft of the motor 1 passes through the end of the transmission connection frame 2 and is fixedly installed with a driving wheel 3, that is to say, the output shaft of the motor 1 stretches out of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com