Laser gyro lens excircle grinding and polishing method

A technology of cylindrical grinding and laser gyroscope, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of poor practicability and low work efficiency, so as to improve the quality of grinding and polishing, improve the efficiency of grinding and polishing, and greatly The effect of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below by means of specific embodiments:

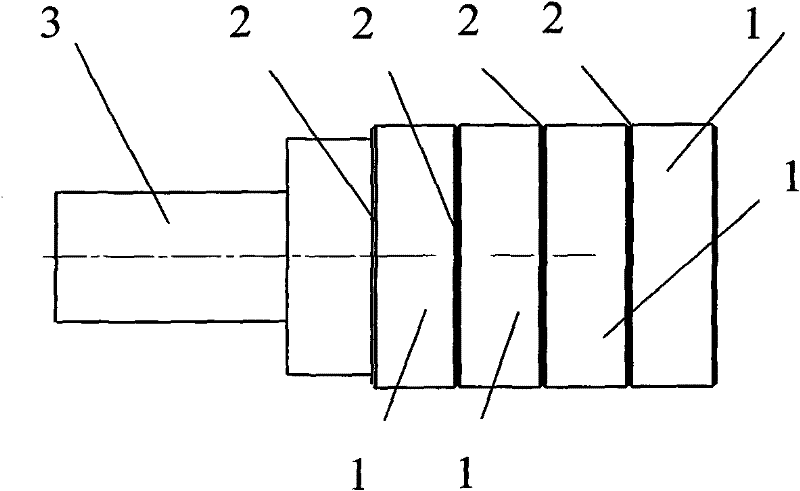

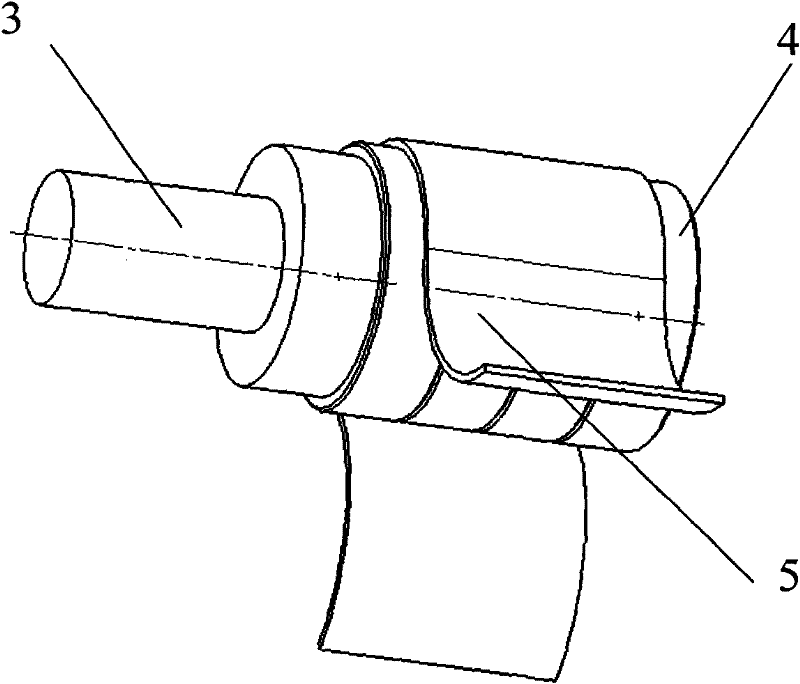

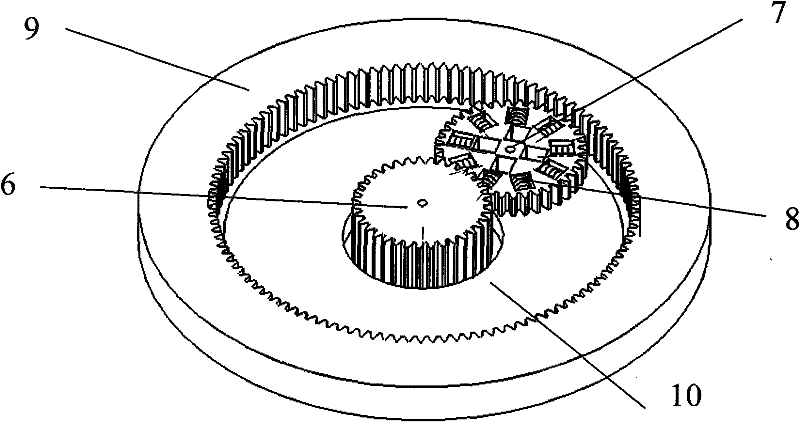

[0026] see image 3 , which is a schematic structural view of the grinding and polishing device involved in the laser gyro lens cylindrical grinding and polishing method of the present invention. The grinding and polishing device includes a double-sided grinding machine or a double-sided polishing machine, a planetary wheel 7, and a lens column. Wherein, the structure of the double-sided grinding machine and the double-sided polishing machine is similar, except that grinding powder and polishing powder are respectively placed during grinding and polishing. The double-sided grinding machine and the double-sided polishing machine include an inner gear 6, an outer gear 9 and a lower plate 8, wherein the inner gear 6 is arranged in the middle of the lower plate 8, and the outer gear 9 is arranged outside the lower plate. ring. Please refer to figure 1 , the lens 1 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com