Metal surface grinding and polishing agent and preparation method thereof

A metal surface and polishing agent technology, applied in the field of metal surface treatment, can solve the problems of shortening the polishing time, complicated preparation methods, long grinding time, etc., and achieve the effect of improving the grinding and polishing efficiency, reducing the grinding process, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

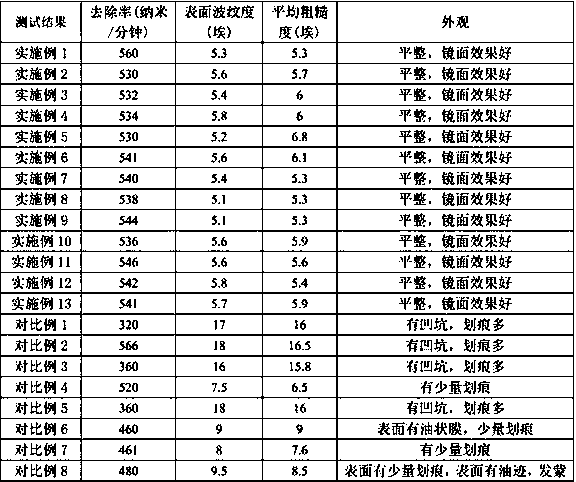

[0075] A metal surface grinding and polishing agent, the components contained in it and the corresponding weight ratio of each component are as shown in Examples 1-14.

[0076] Table 1 is a summary of the components contained in Examples 1-9 and the corresponding proportions by weight of each component.

[0077]

Embodiment 10

[0079] A metal surface grinding and polishing agent, the difference between embodiment 10 and embodiment 1 is that nano-diamond powder is changed to zirconia.

Embodiment 11

[0081] A metal surface grinding and polishing agent, the difference between embodiment 11 and embodiment 1 is that nano-diamond powder is changed to cerium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com