Patents

Literature

69results about How to "Improve grinding and polishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond grinding block and preparation thereof

InactiveCN101407045AReduce heat damageLower sintering temperatureAbrasion apparatusGrinding devicesEpoxyProduction line

The invention provides a method for preparing a diamond grinding block, which belongs to the technical field of powder metallurgy metal base composite material. The method comprises the following steps: using Fe-Cu-Sn superfine prealloyed powder and low grade diamond as raw materials, using a nontoxic gel injection mold forming technology and a low temperature pressureless sintering technology to prepare tool bits, and then adhering the tool bit by using epoxy resin to assemble the tool bits together so as to obtain a high performance diamond grinding block which is applied to the stone materials and ceramics polishing production line. The method has the advantages of no noble metals such as Co, Ni and the like, low cost, low sintering temperature for the tool bits, small thermal damage to the diamond, good grinding and polishing effect, long service life, and good product consistency, environmental protection and no pollution.

Owner:UNIV OF SCI & TECH BEIJING

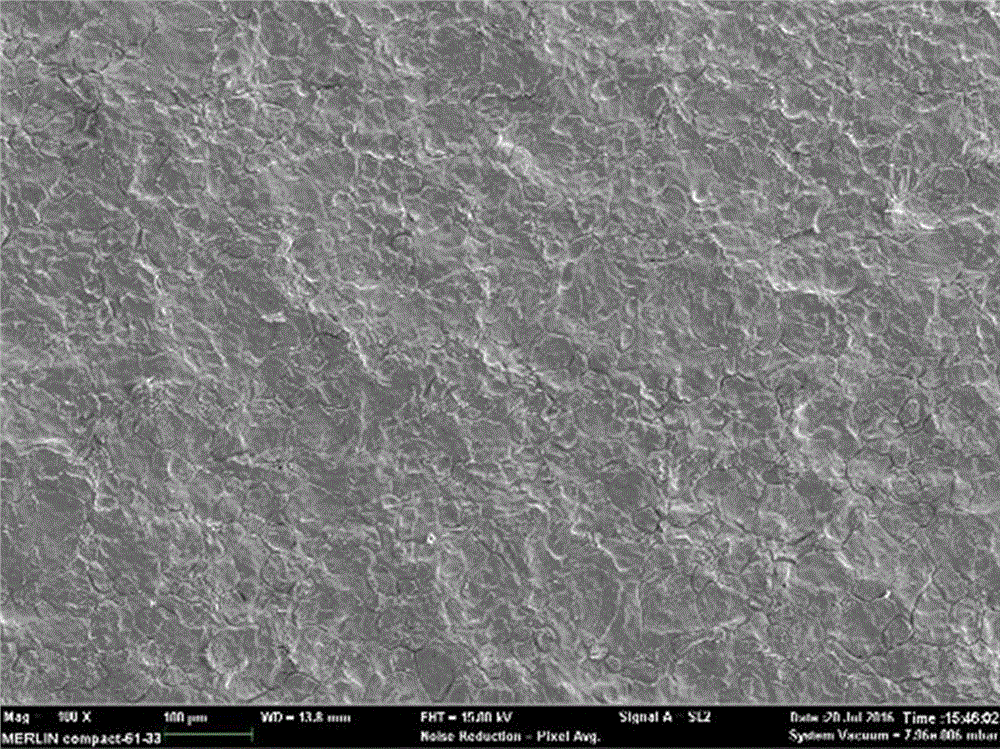

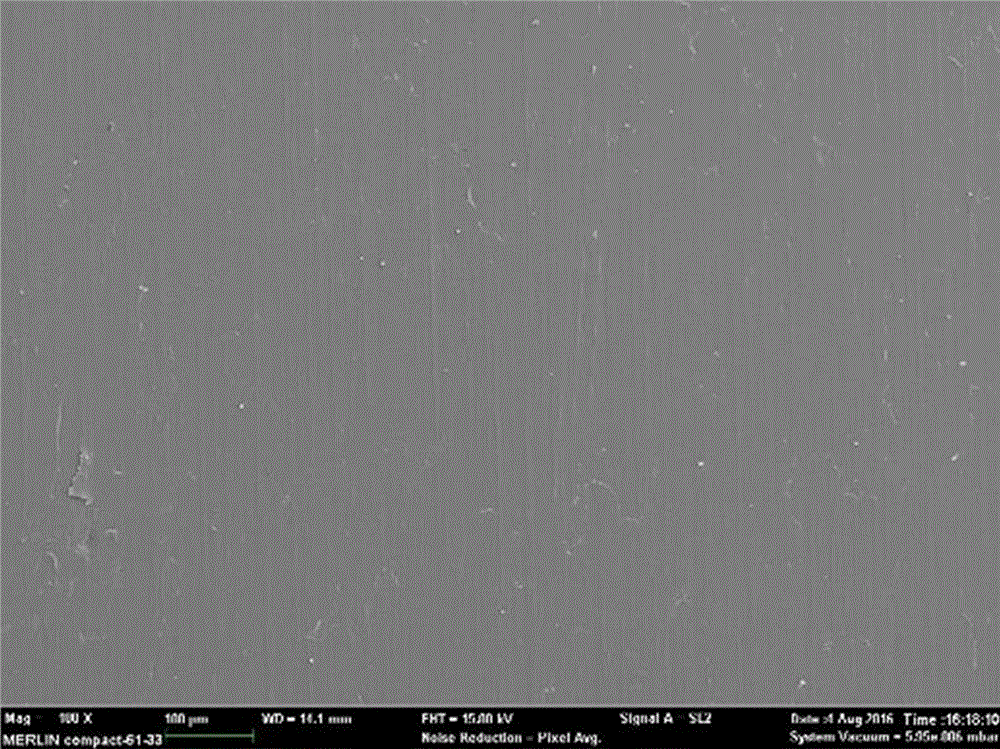

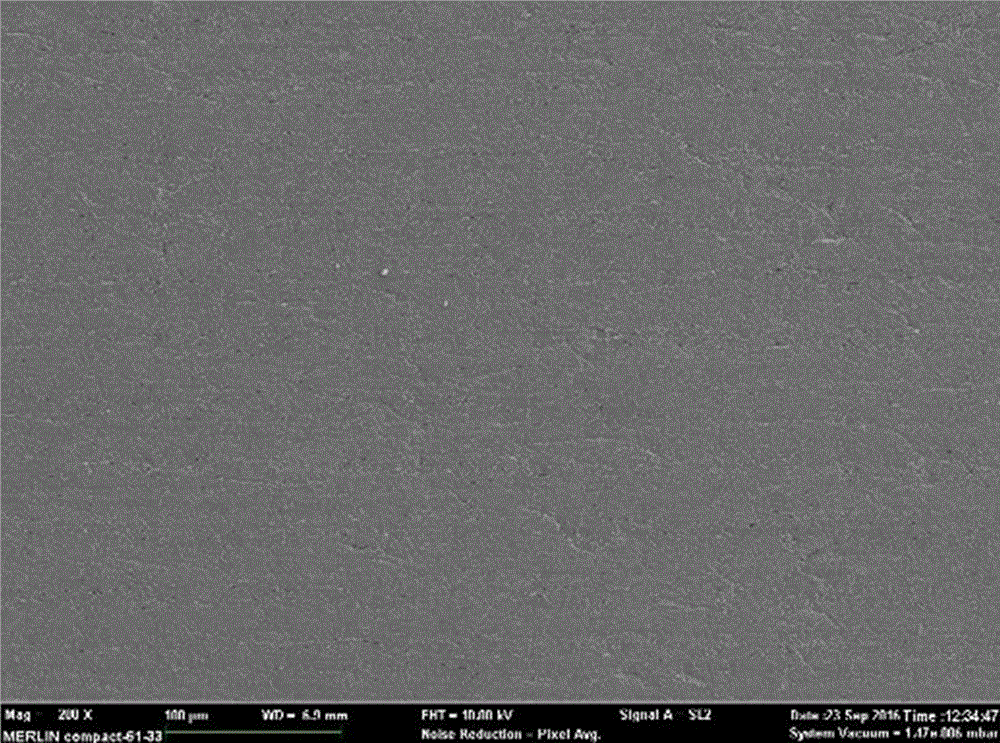

Cold rolling process for 304 stainless steel 2B base material for decorative panel

ActiveCN106807751AReduce depthReduce surface roughnessRoll force/gap control deviceBelt grinding machinesFault coverageSolution treatment

The invention discloses a cold rolling process for a 304 stainless steel 2B base material for a decorative panel. The cold rolling process specifically comprises the following steps of: solution treatment, online pickling, pickling, coping, cold rolling, cold rolling and annealing, pickling after cold rolling and annealing, leveling, shearing and packaging by means of a transverse shear. The cold rolling process disclosed by the invention has the advantages that by combining optimization of a cold rolling step in three aspects, the surface roughness of the final 2B base material is low, the fault coverage is extremely small, the surface of strip steel is uniform and smooth, and the 304 stainless 2B which is excellent in grinding and polishing properties can directly replace a 304 stainless BA plate to be used as the base material of the decorative panel which is relatively high in surface requirement. The production process is simpler than a step of the 304 stainless steel BA plate, so that the production cost is lowered, and the processing efficiency is increased.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

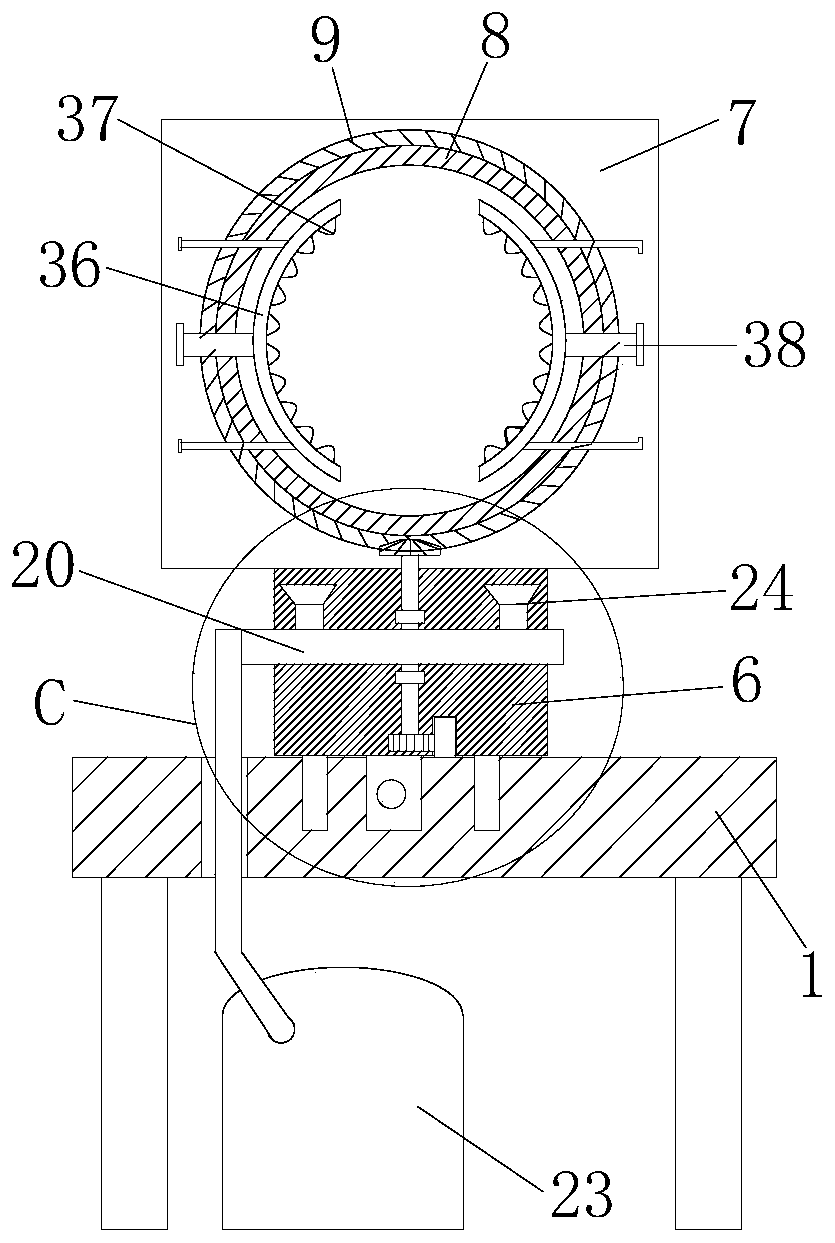

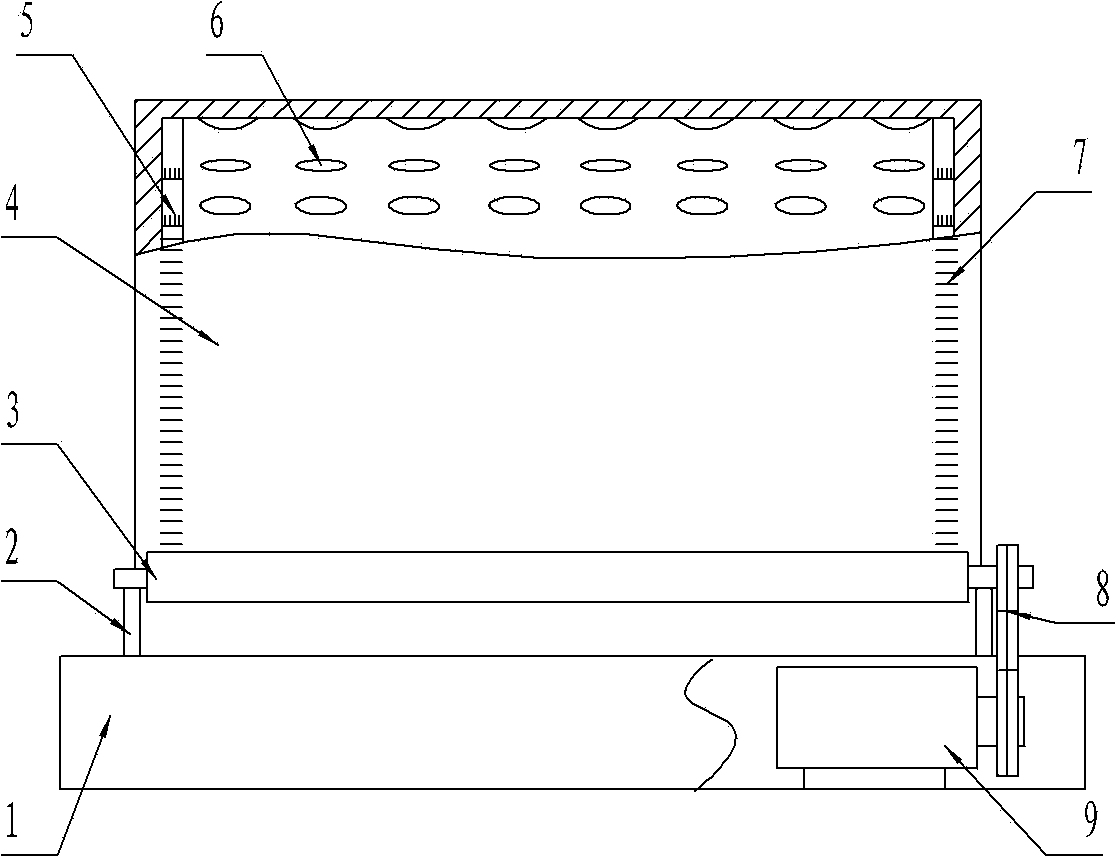

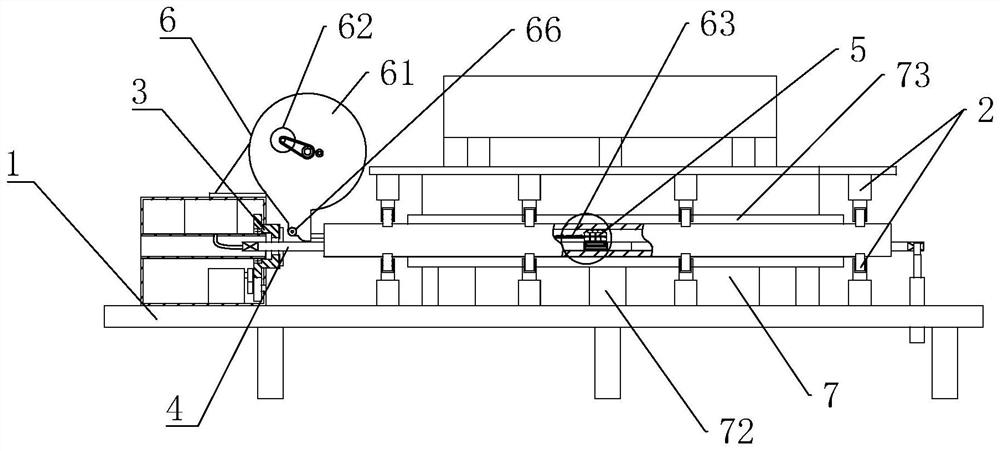

Grinding system of casting machine

ActiveCN110405617APlay a supporting roleReduce frictionPolishing machinesGrinding drivesPipe fittingEngineering

The invention belongs to the technical field of hardware pipe grinding, in particular to a grinding system of a casting machine. The invention aims to solve the problems that existing pipe fitting grinding equipment is mostly fixed in size, the adaptability is poor, the grinding efficiency is poor, grinding is not uniform, so that the working quality is greatly influenced, and dust generated by grinding cannot be treated, according to the technique scheme, the grinding system comprises a grinding table, the top of the grinding table is provided with two supporting parts, the two supporting parts are rotationally provided with turnover parts, a plurality of guide cylinders are installed between the supporting parts and the turnover parts in a rolling manner, a groove is formed in the top ofthe grinding table, a screw rod is rotationally installed in the groove, a servo motor is connected to the bottom of the grinding table, the screw rod is matched with the servo motor, the screw rod is in threaded connection with a sliding block, and the sliding block is in sliding connection with the groove. The grinding system has the advantages that the structure is simple, the operation is convenient, pipelines with different sizes can be polished, the grinding machining efficiency is good, the grinding is uniform, the working quality is not influenced, and the dust generated by the grinding can be treated.

Owner:平湖市华晟精密机械股份有限公司

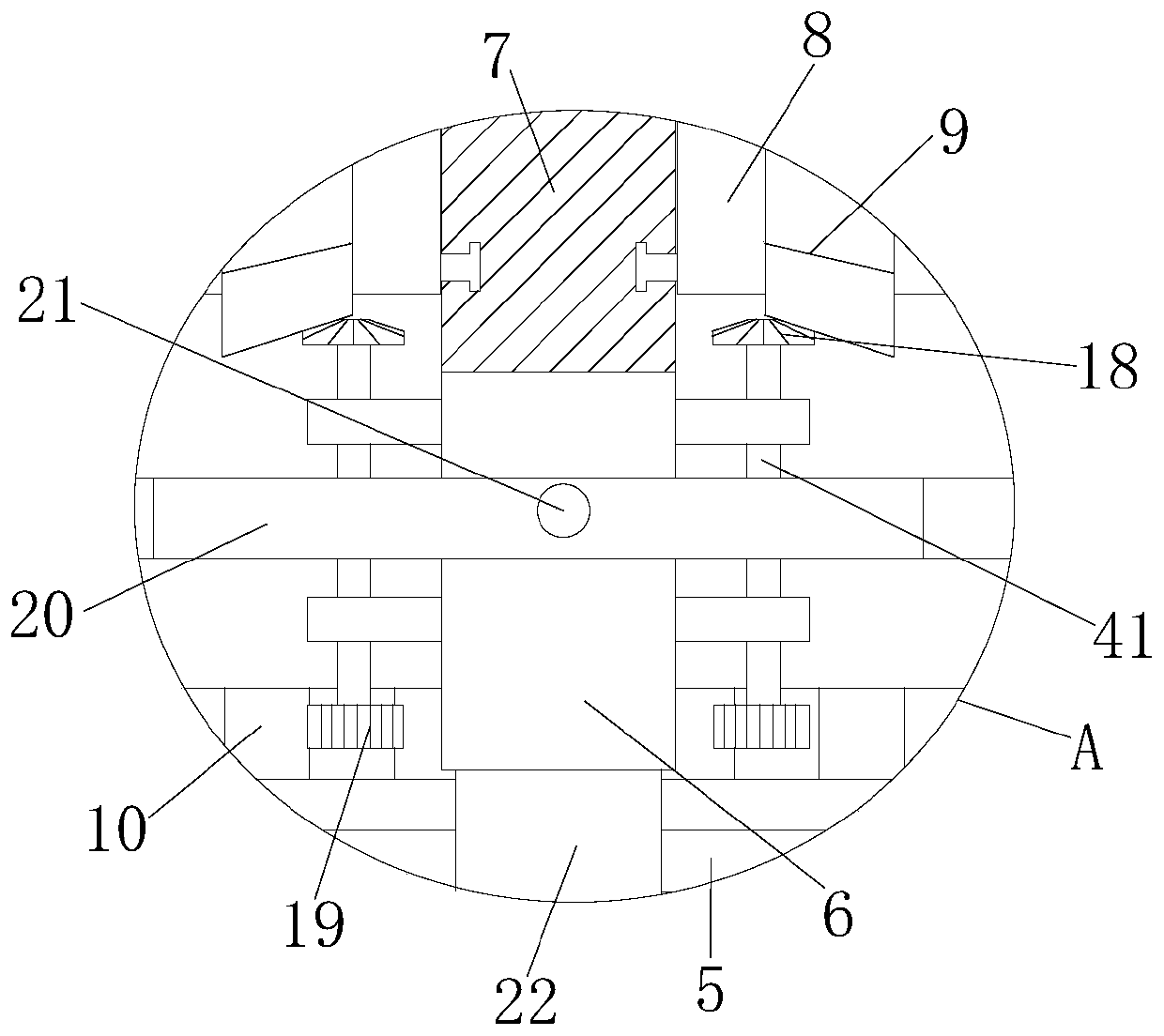

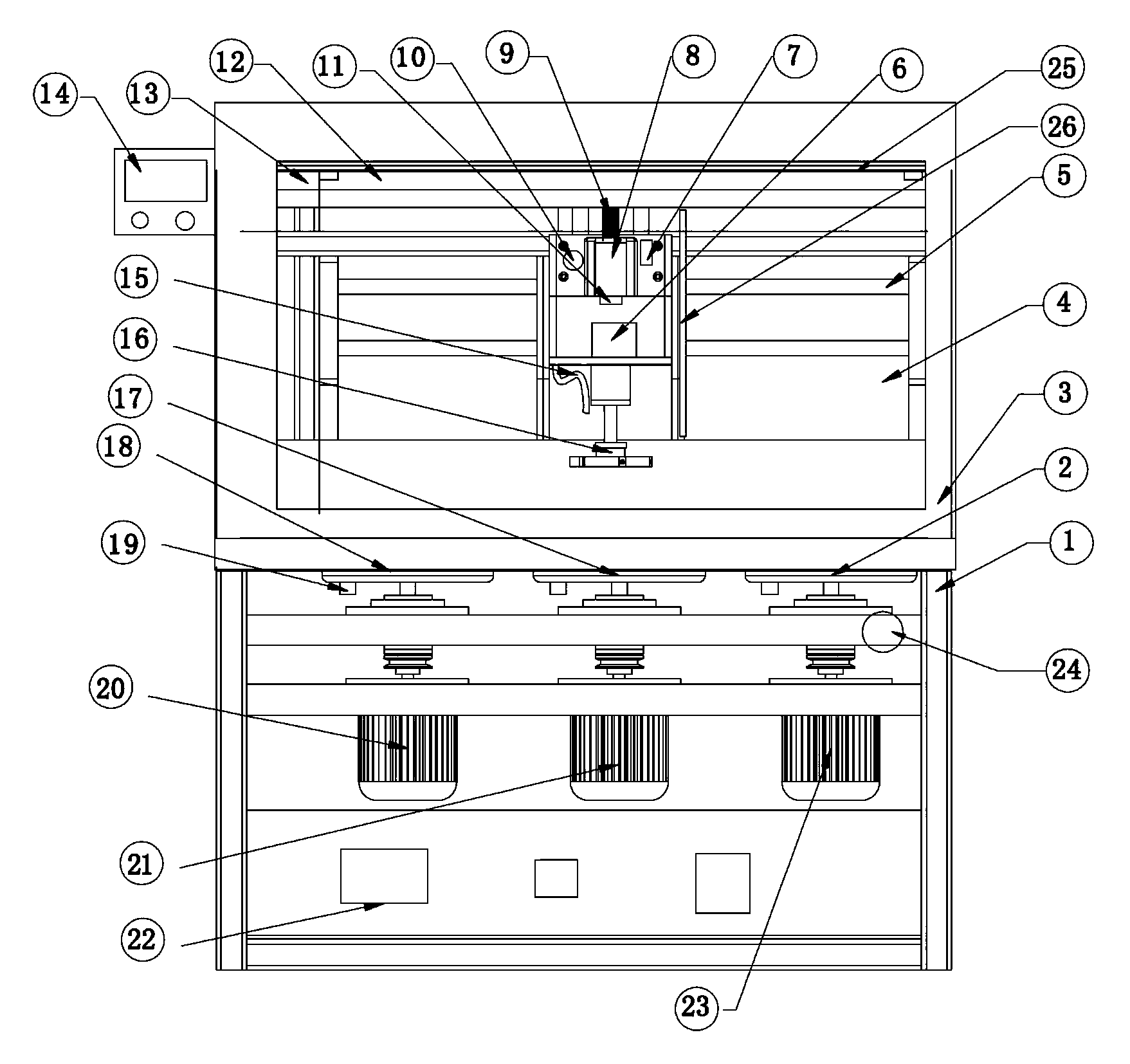

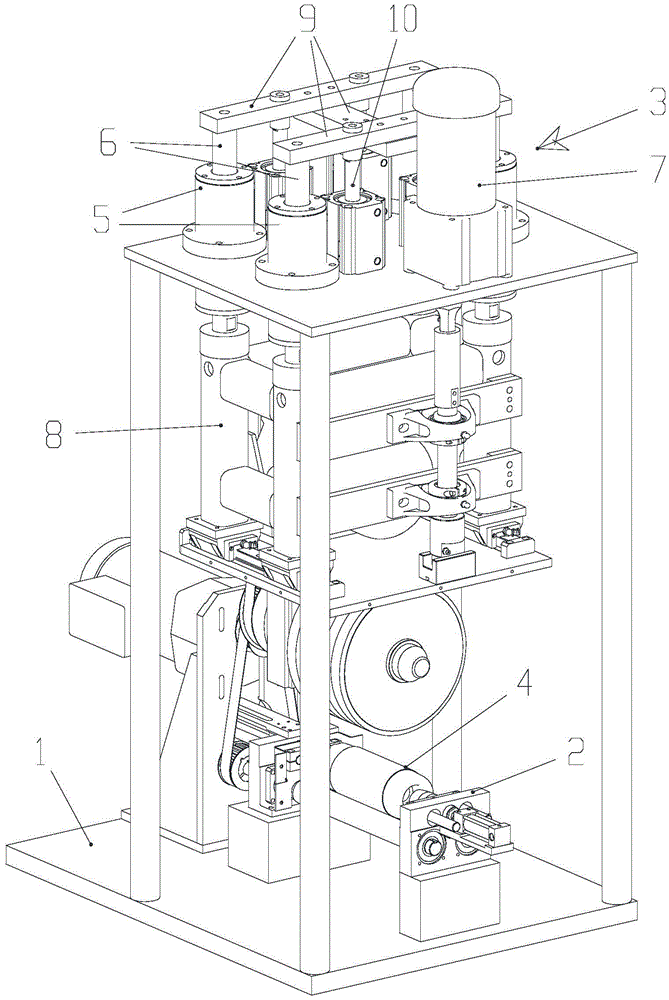

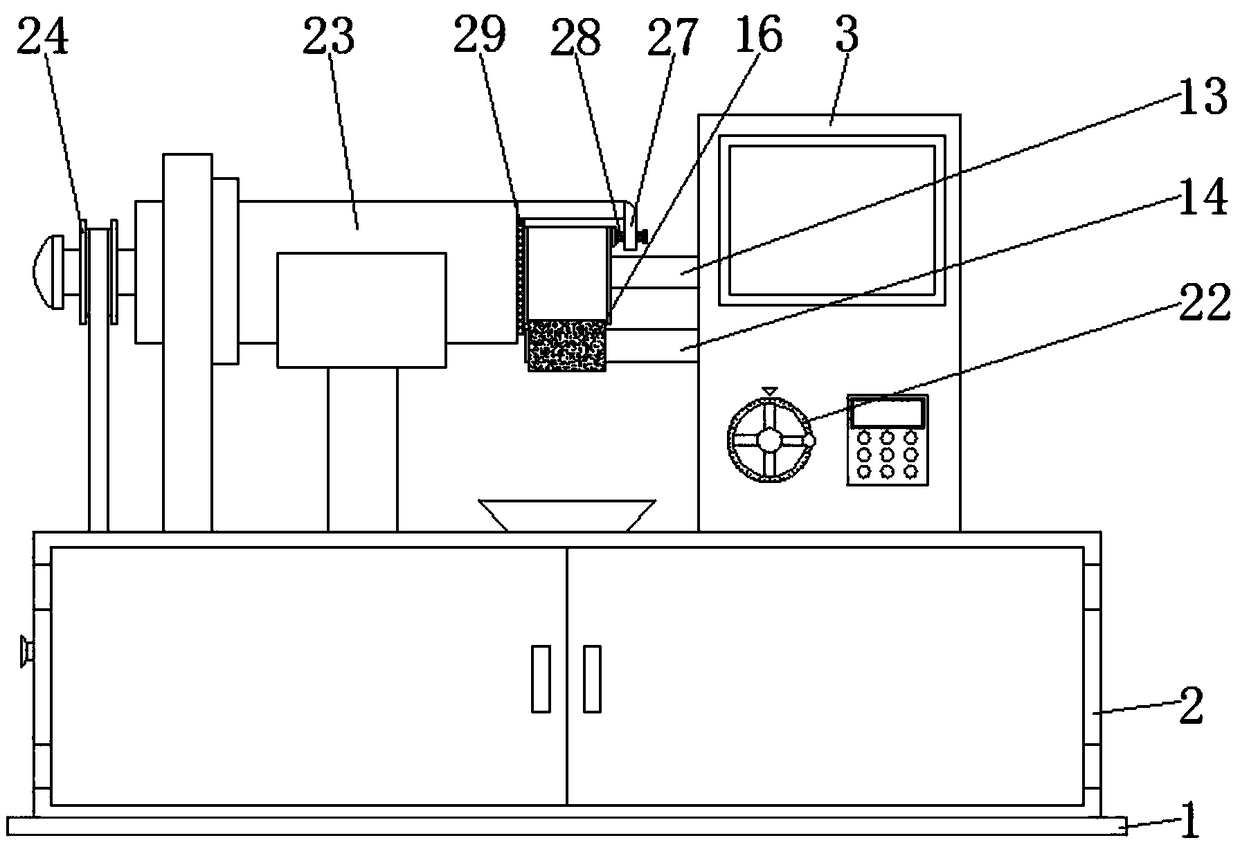

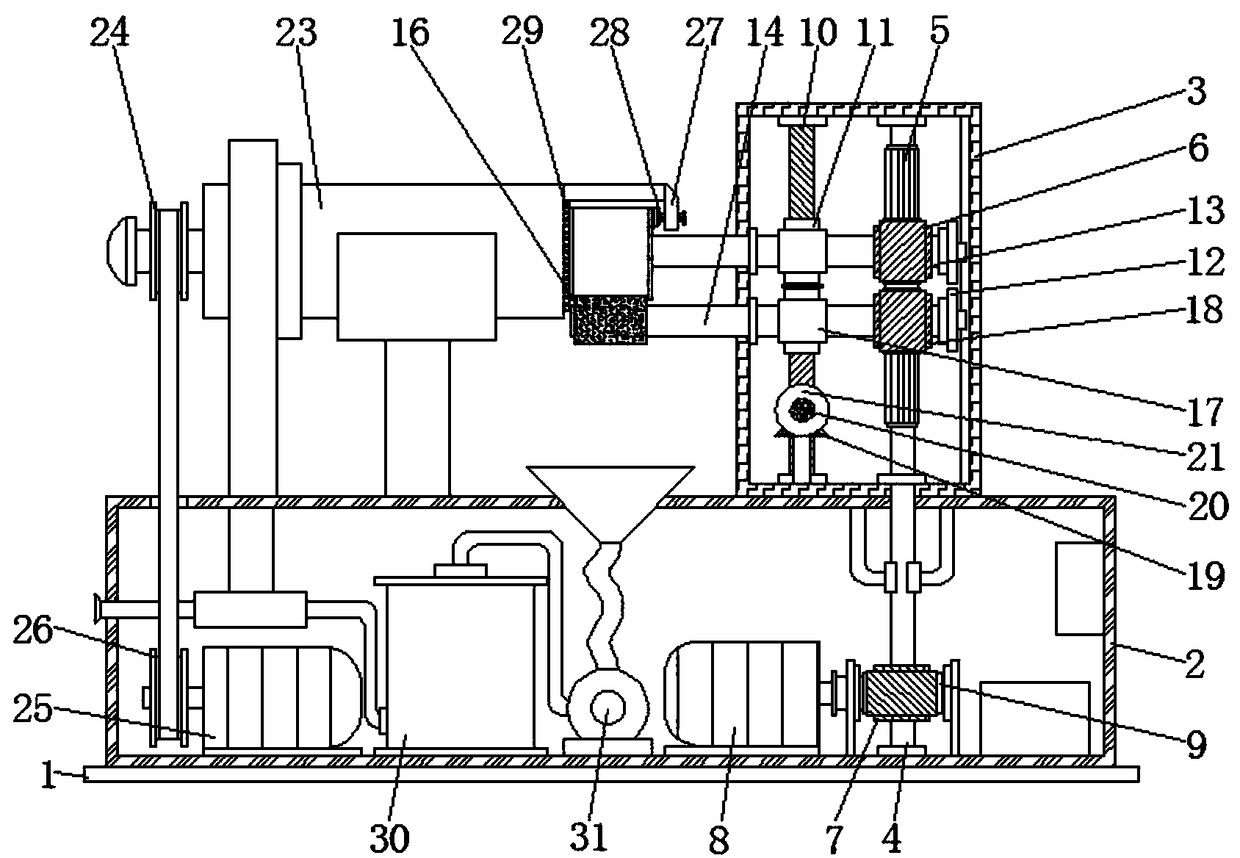

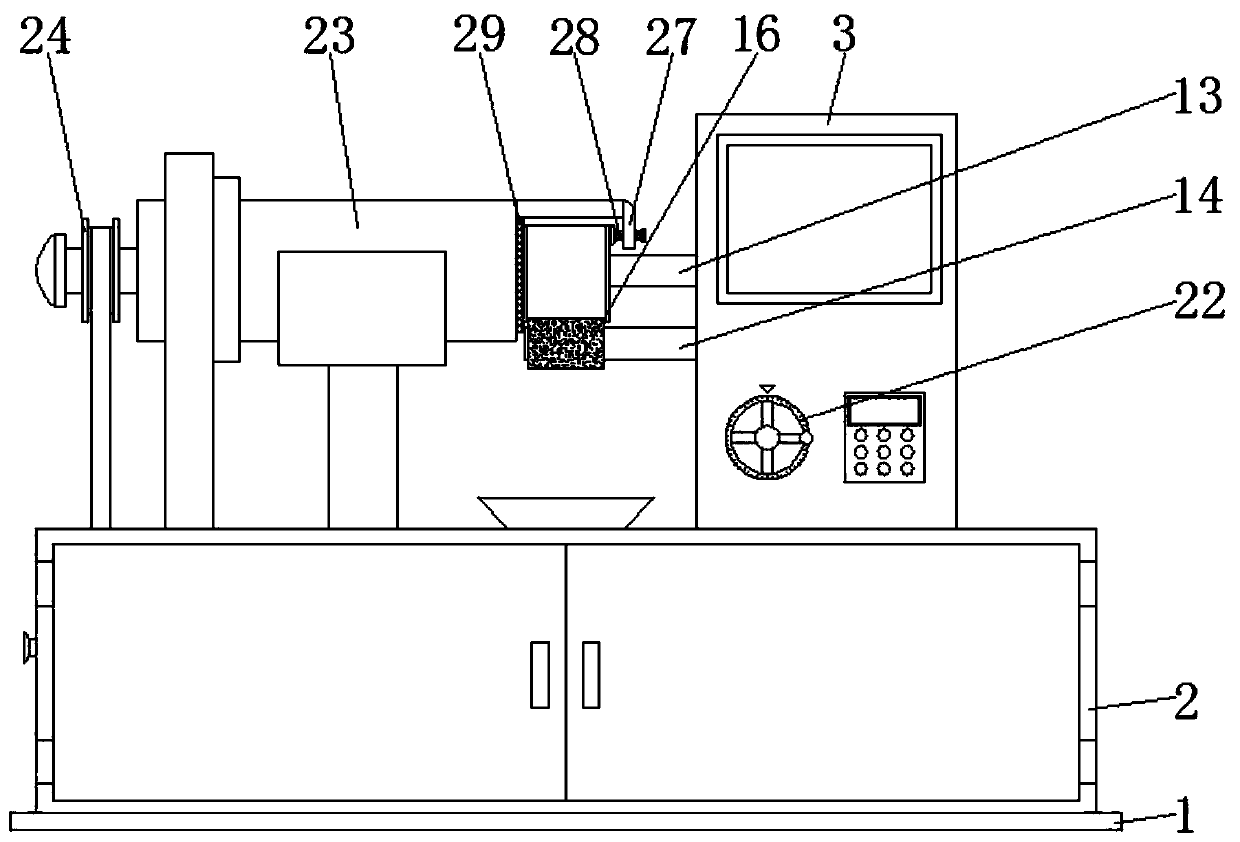

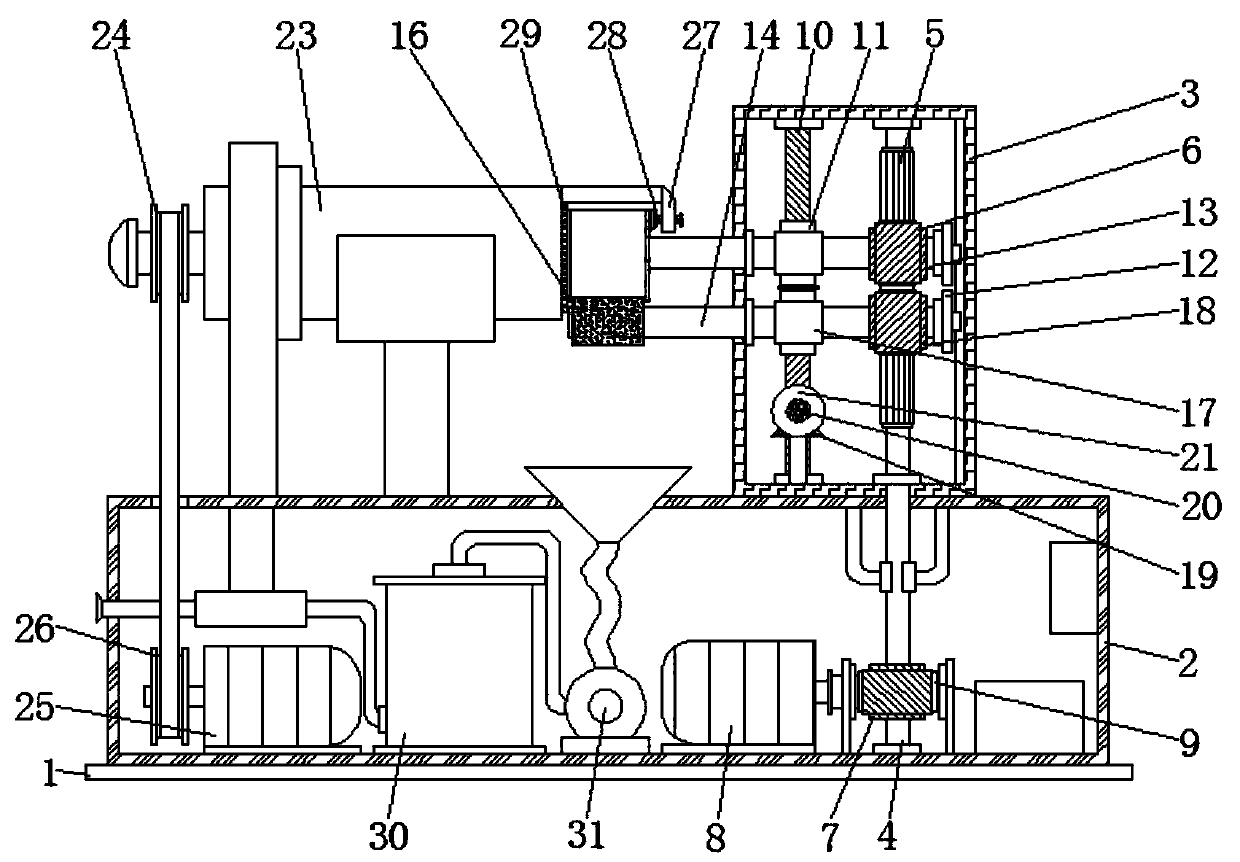

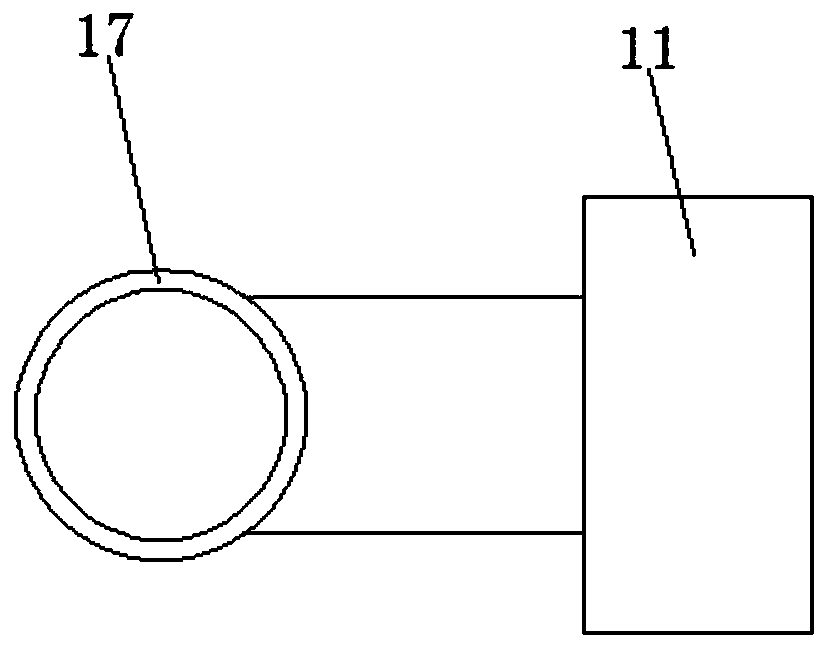

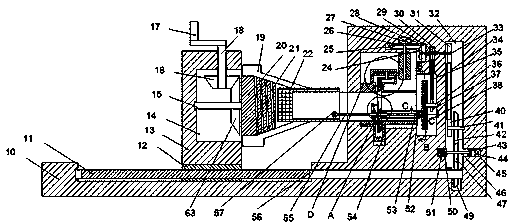

Intelligent automatic metallographic grinding and polishing machine

ActiveCN104044059AReduce work intensityConvenience and meet grinding and polishing requirementsPreparing sample for investigationLapping machinesOptical axisEngineering

The invention discloses an intelligent automatic metallographic grinding and polishing machine, and relates to grinding and polishing machines. The upper portion of a movable polished shaft (5) is fixed to a main machine frame (1) through a left-right transmission lead screw (12). A grinding head set (26) is installed on the movable polished shaft (5). A grinding material box (7) is installed at the upper portion of the grinding head set (26). The left side of the grinding material box (7) is connected with a charging pump (10). The grinding head set (26) is internally provided with a grinding head rotating motor (8). The middle of the right side inside the main machine frame (1) is provided with a polishing disc (2). An accurate grinding disc (17) is installed above an accurate grinding motor (21). The left side inside the main machine frame (1) is provided with a drainage tube (19). The lower portion of the main machine frame (1) is internally provided with a PLC (22). According to the intelligent automatic metallographic grinding and polishing machine, a colorful touch screen and the PLC are adopted for control, the degree of automation is high, the full-automatic intelligent operation is achieved in the whole grinding and polishing process, the working intensity of operators is relieved, and working efficiency is greatly improved.

Owner:上海中研仪器制造有限公司

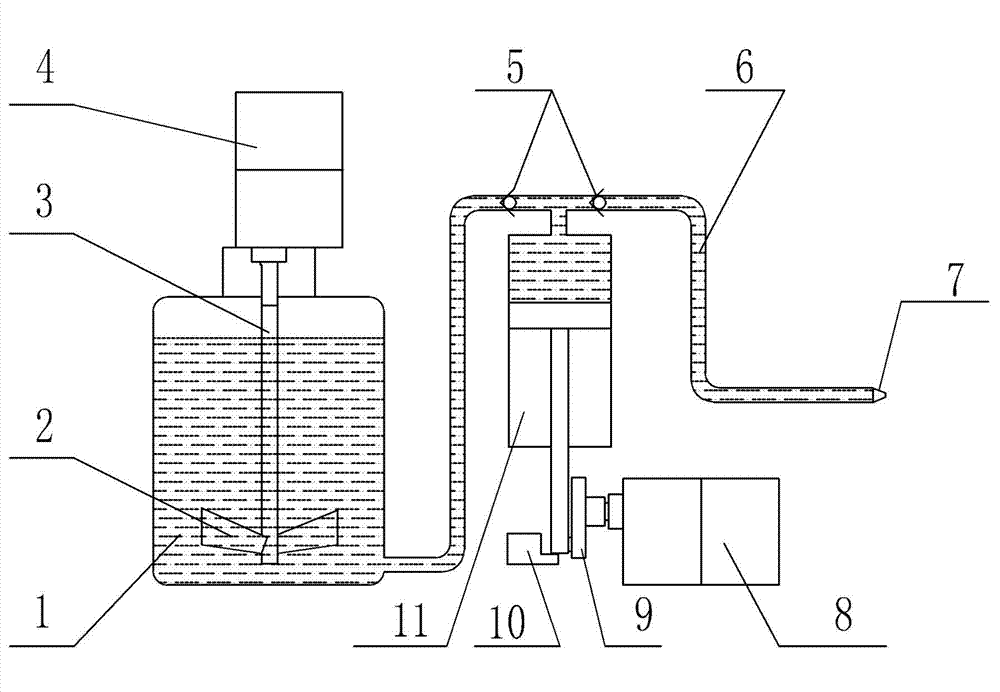

Metallographic phase polishing solution automatic feeding machine

InactiveCN103170915AAvoiding Corrosion ProblemsReduce use costGrinding/polishing apparatusMicrocontrollerMicrocomputer

The invention provides a metallographic phase polishing solution automatic feeding machine which is used for grinding and polishing of metallographic specimens. The metallographic phase polishing solution automatic feeding machine is formed by a stirring motor, a liquid storage cylinder, a stirring shaft, blades, a liquid pump motor, a plunger liquid pump, check valves, connecting ducts, a nozzle and a single-chip microcomputer. The metallographic phase polishing solution automatic feeding machine is characterized in that the stirring motor is installed on the upper portion of the liquid storage cylinder, the output end of the stirring motor is connected with the stirring shaft, the blades are installed at the lower end of the stirring shaft, the output end of the liquid pump motor is connected with a cam, the cam is connected with the piston of the plunger liquid pump, the cylinder block of the plunger liquid pump is connected with the liquid storage cylinder and a liquid outlet end nozzle respectively through the ducts, and check valves are respectively arranged on the ducts at two ends of the plunger liquid pump to control liquid to flow only along a single direction. The metallographic phase polishing solution automatic feeding machine has the advantages of being accurate in liquid outlet quantity, capable of setting liquid outlet time intervals, high in degree of automation, and capable of achieving the switching usage between an automatic function and a manual function according to different operation requirements.

Owner:潘湛

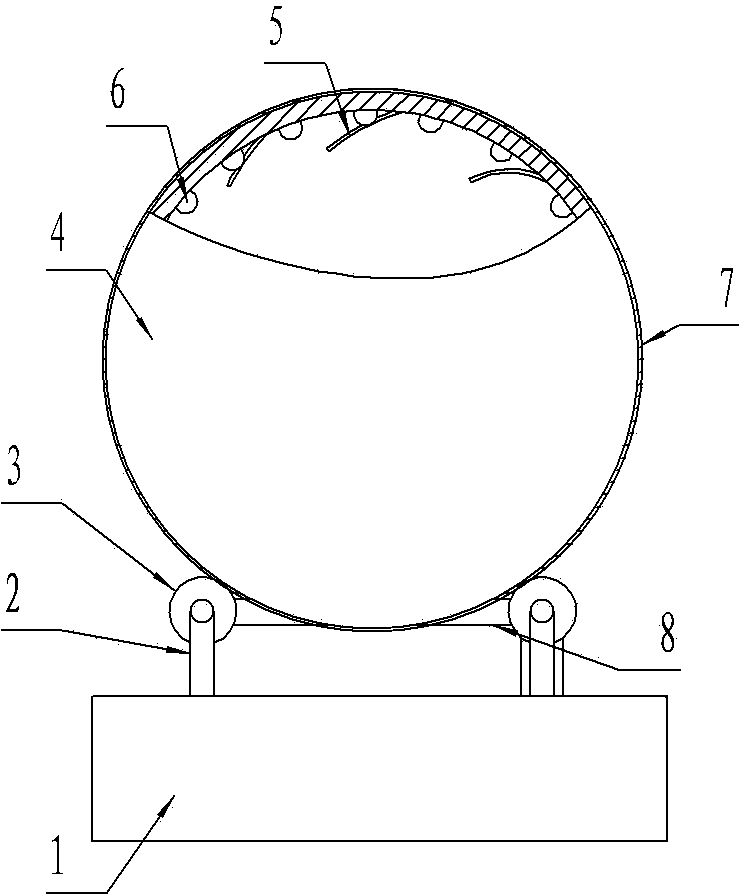

Gem forming machine

InactiveCN104175207AFew influencing factorsAvoid strandedEdge grinding machinesPolishing machinesMolding machinePower transmission

The invention relates to the technical field of gem processing machinery and discloses a gem forming machine which a drum. Two ends of the drum are arranged on a pair of transmission rollers, the transmission rollers are connected with a power machine through a power transmission device and arranged on a bottom box through a support, multiple protrusions are arranged on the inner wall of the drum, flexible brushing strips are arranged inside two ends of the drum, and the protrusions are elongated. Compared with the prior art, the gem forming machine has the advantages that the problem that an existing gem forming machine is severe in vibration, thereby having influence on polishing effect, and poor in forming quality.

Owner:梧州市黎蒙珠宝有限公司

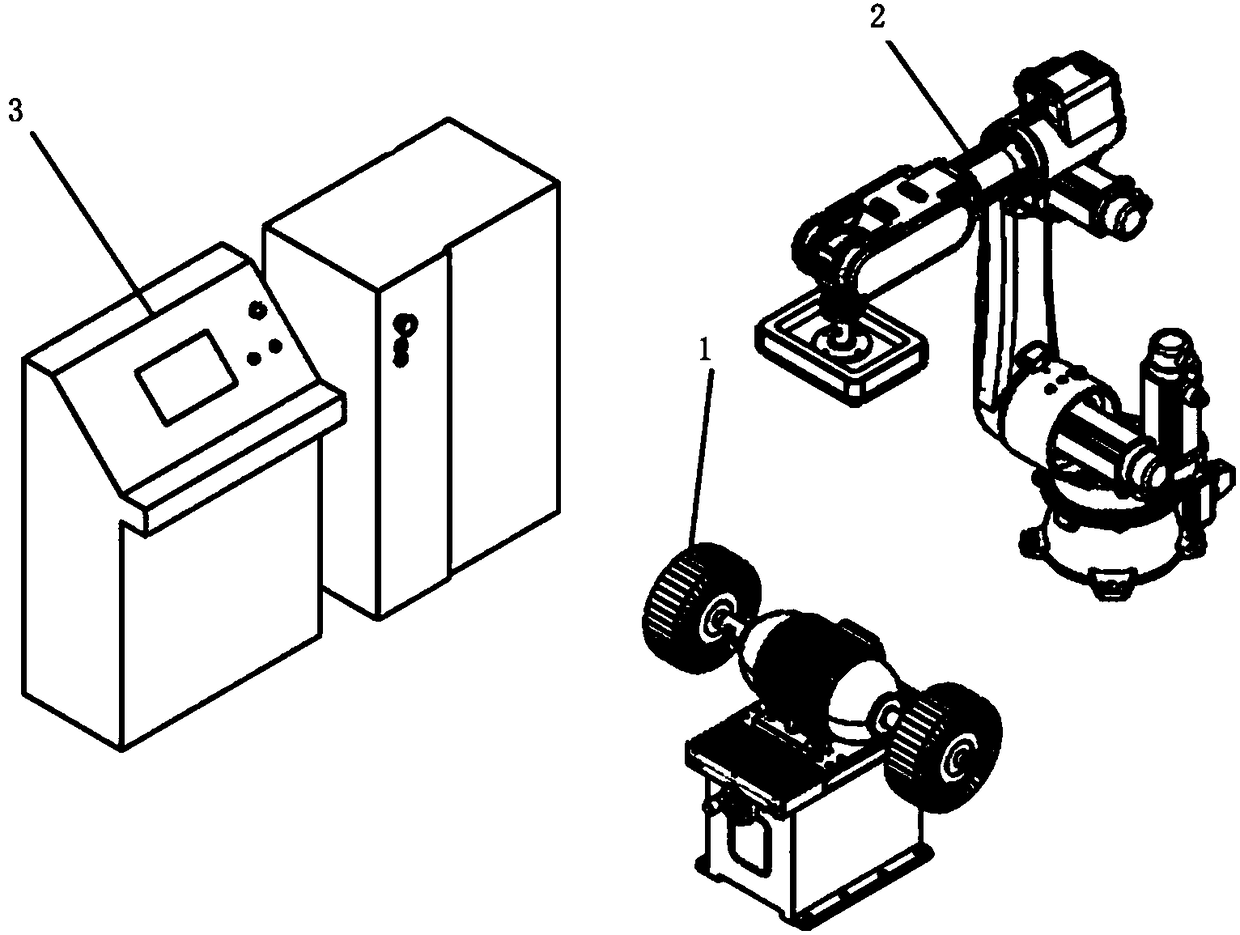

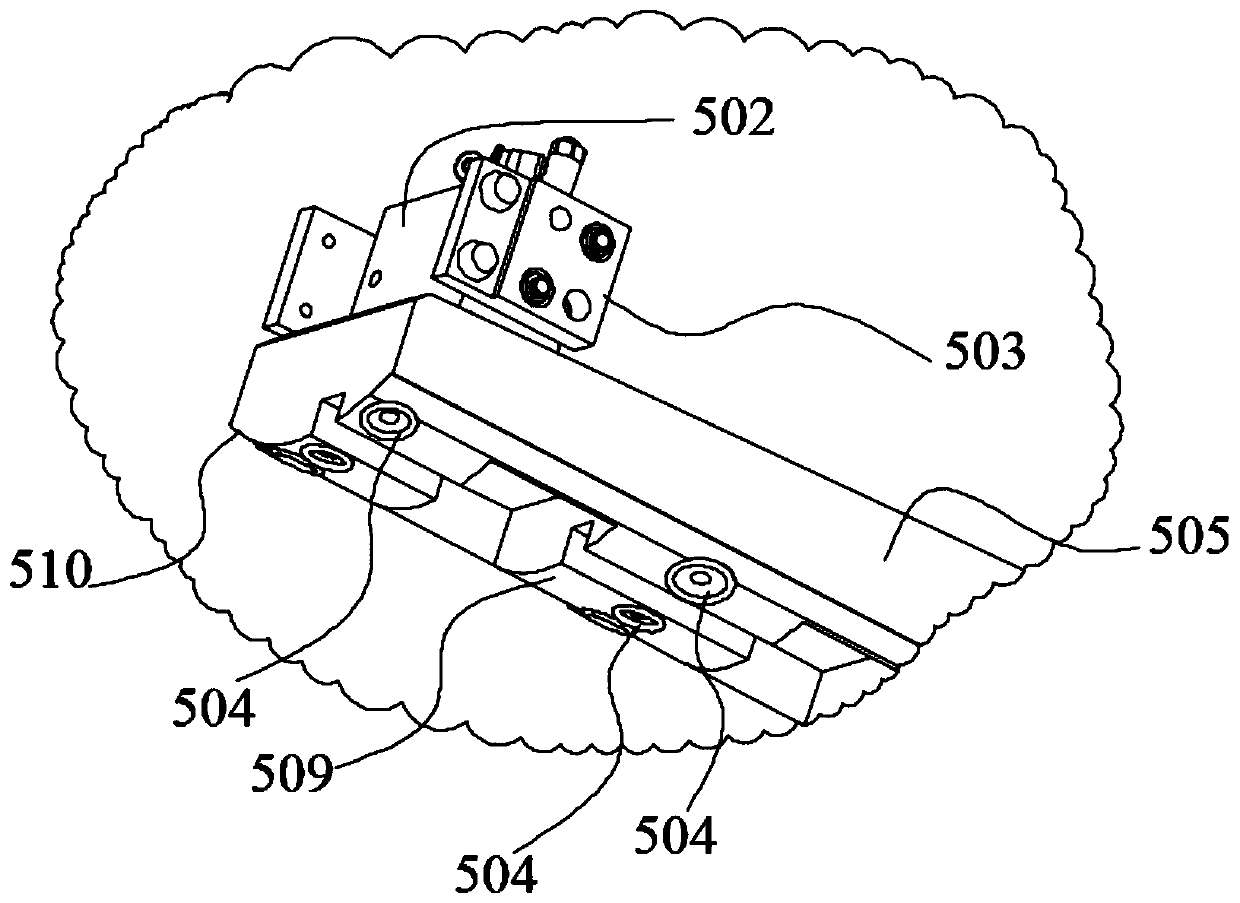

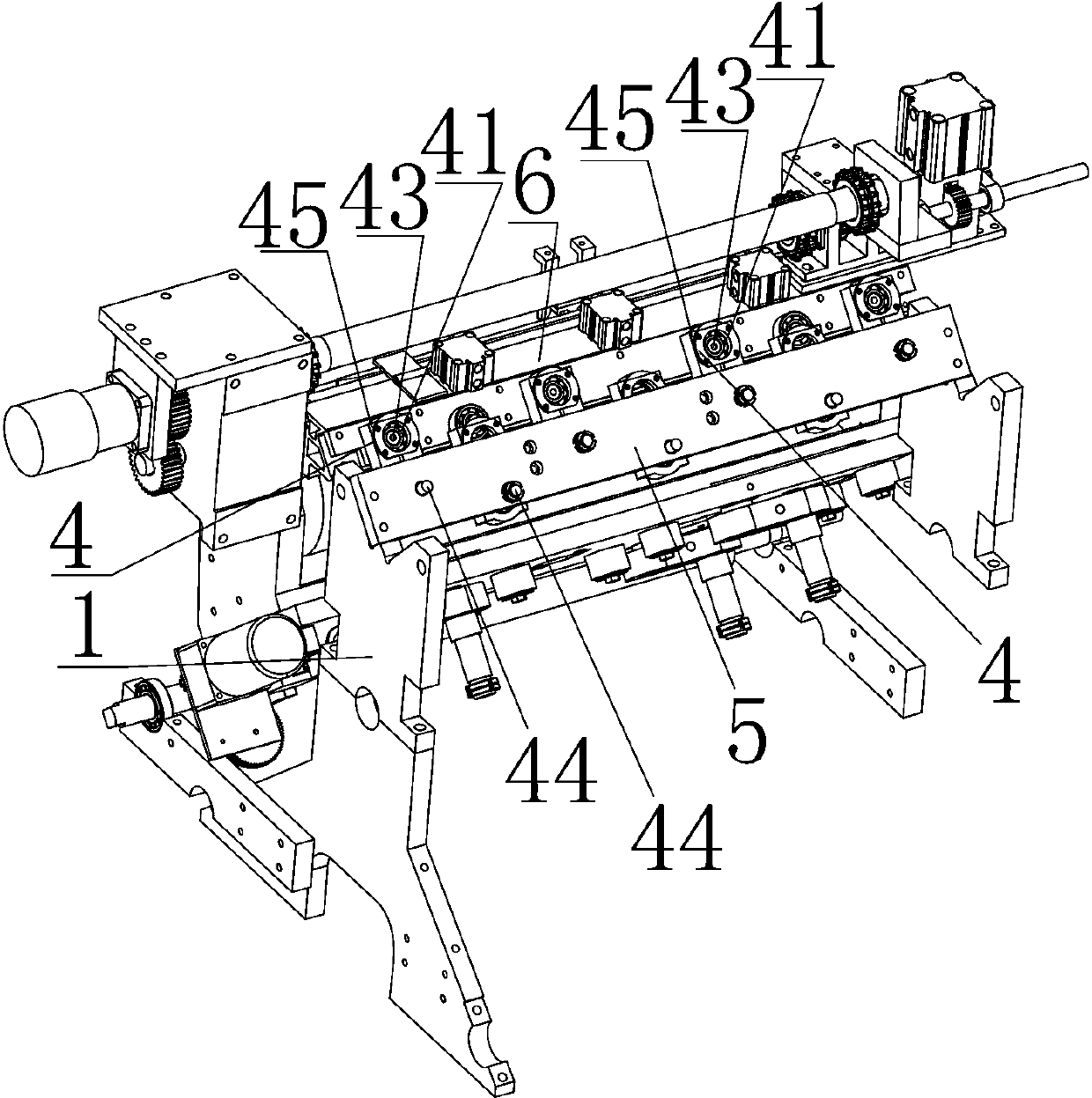

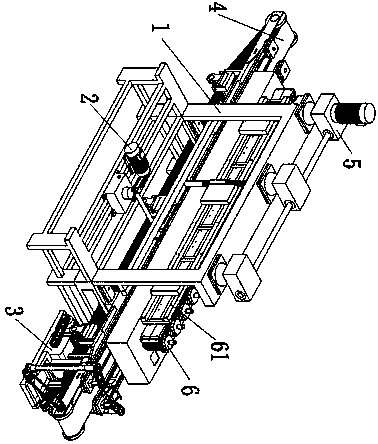

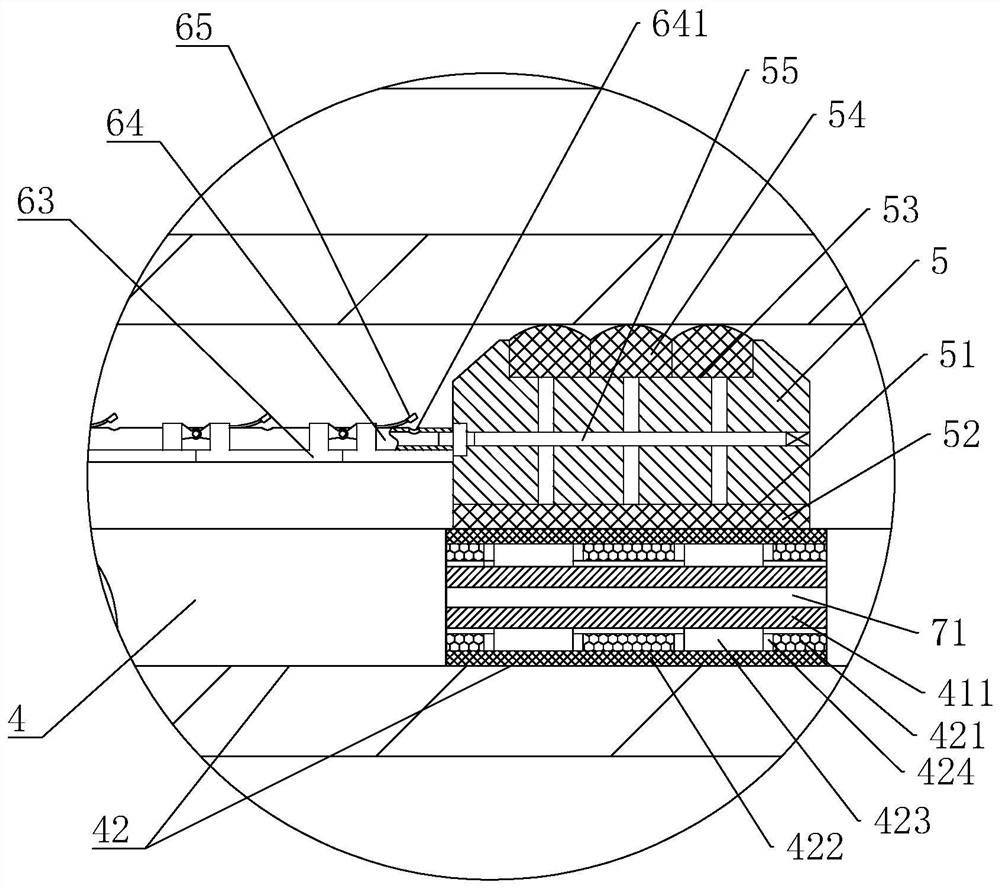

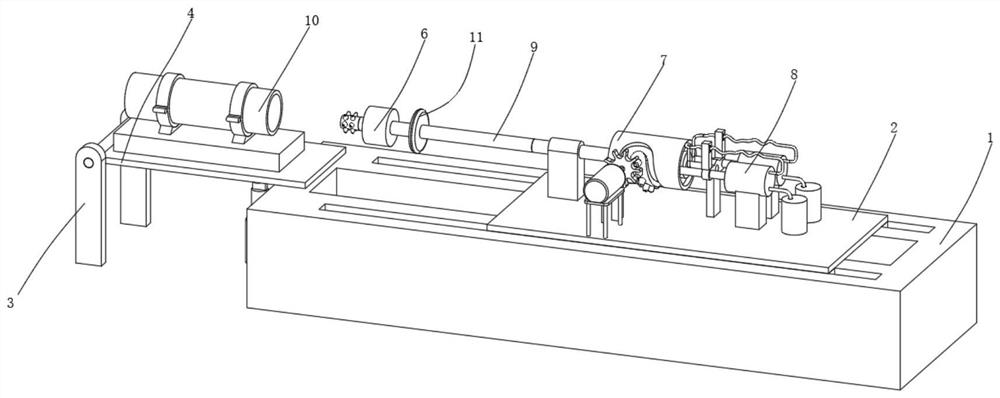

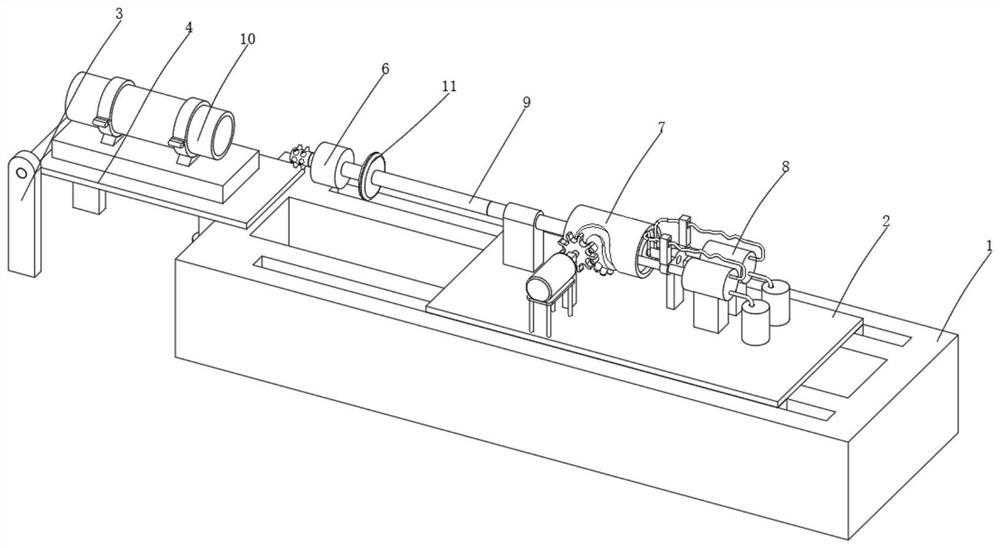

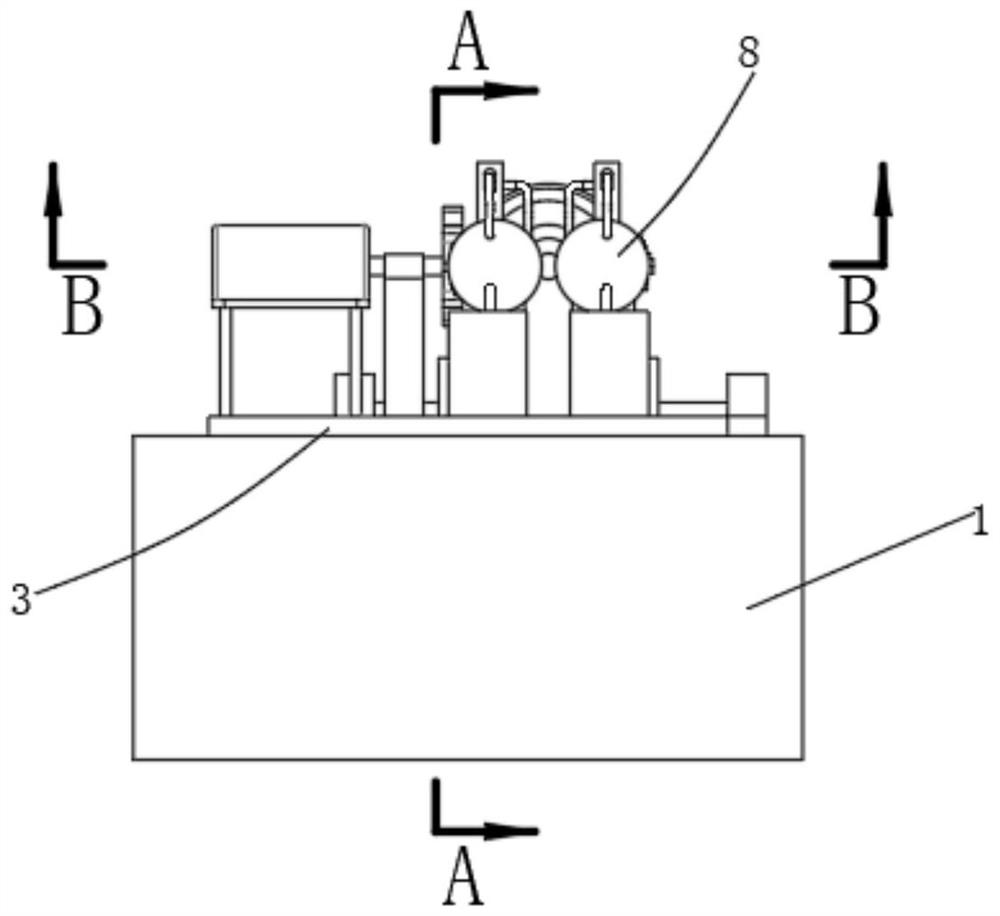

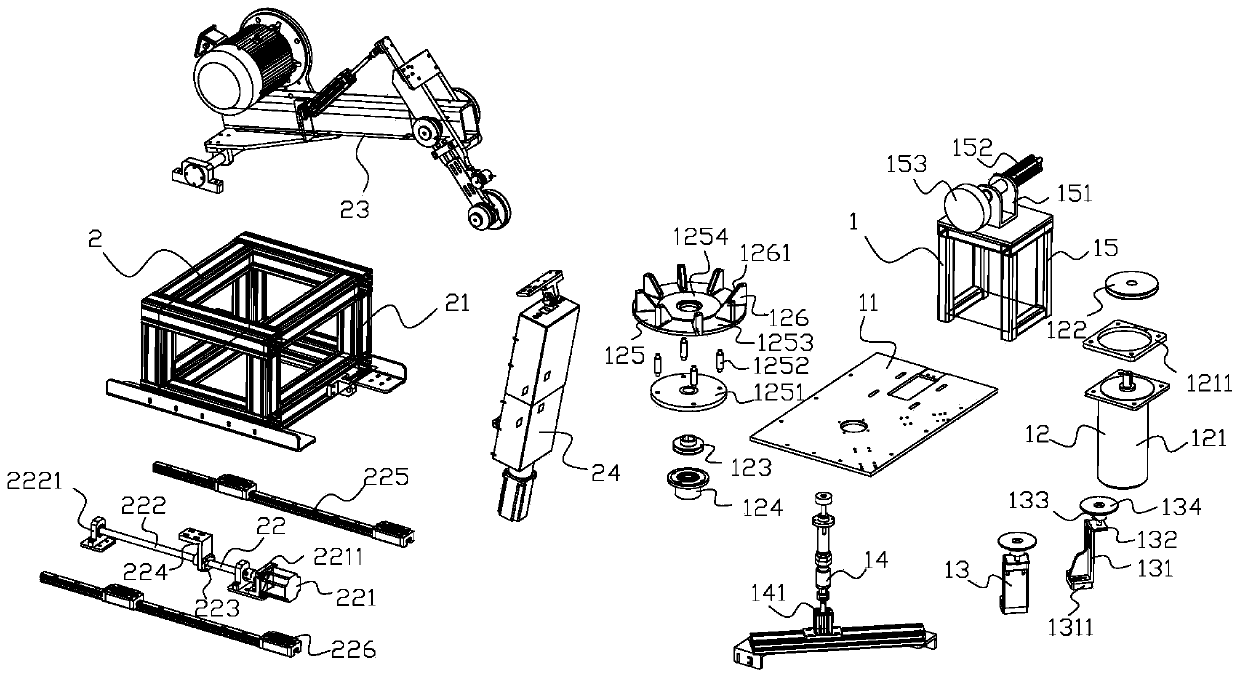

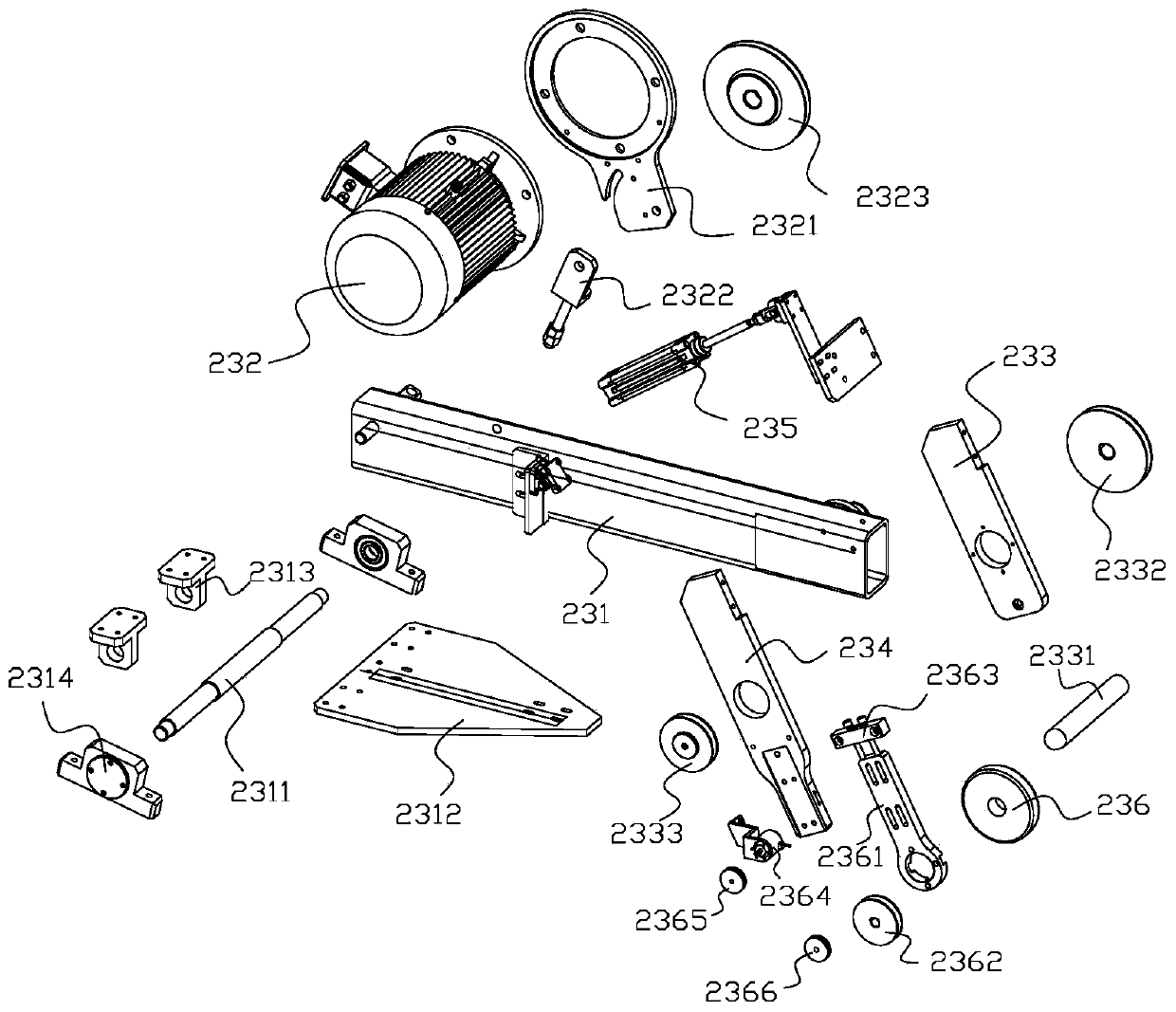

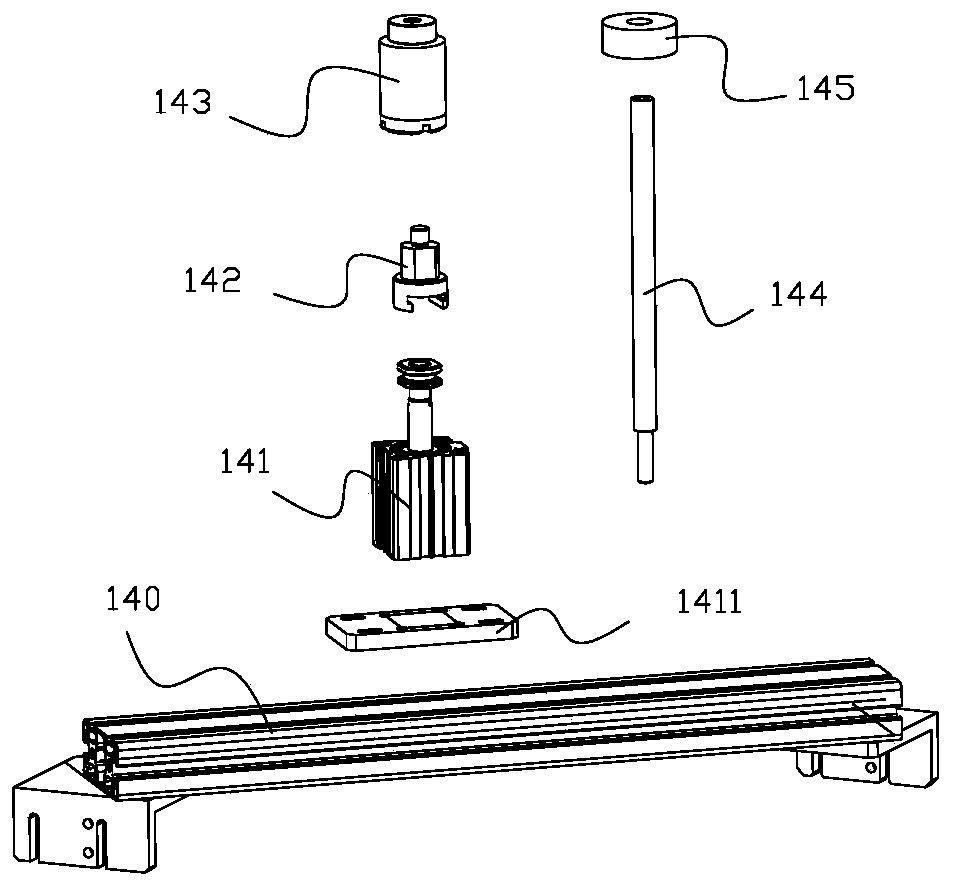

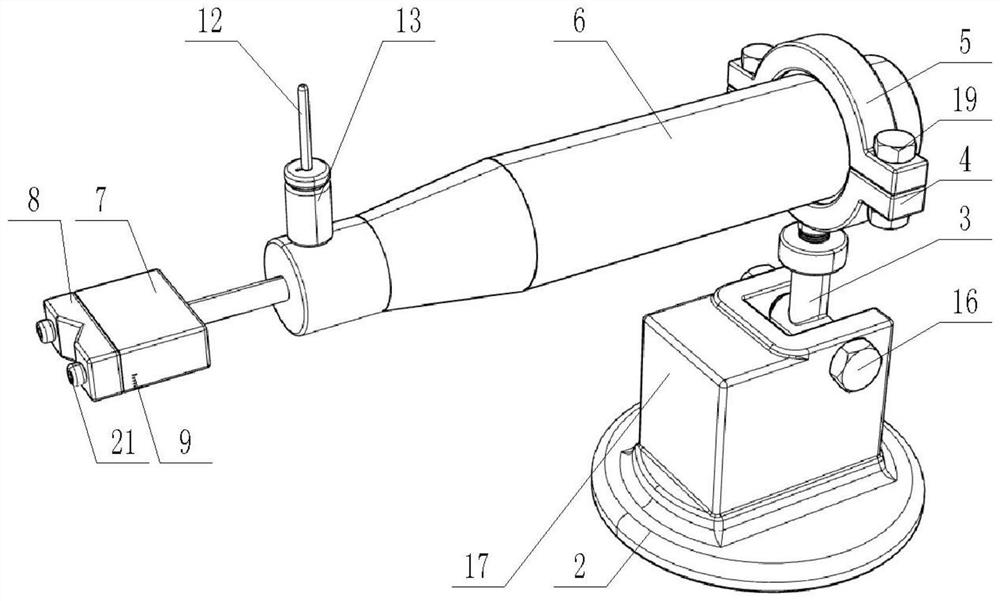

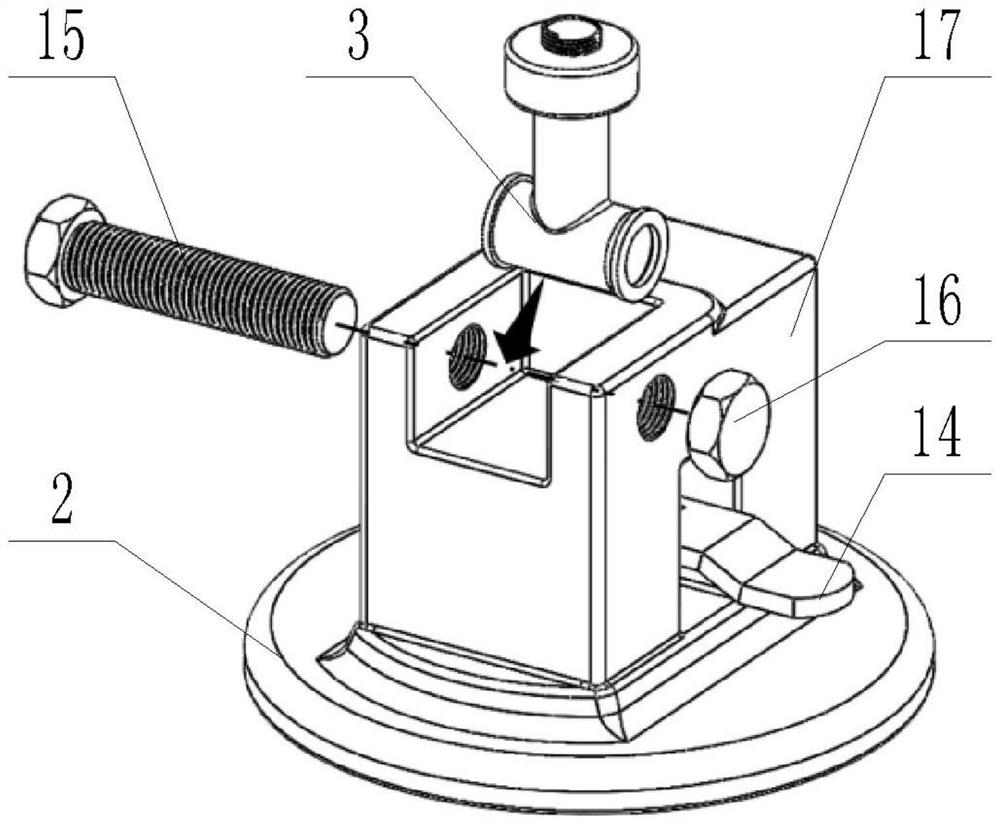

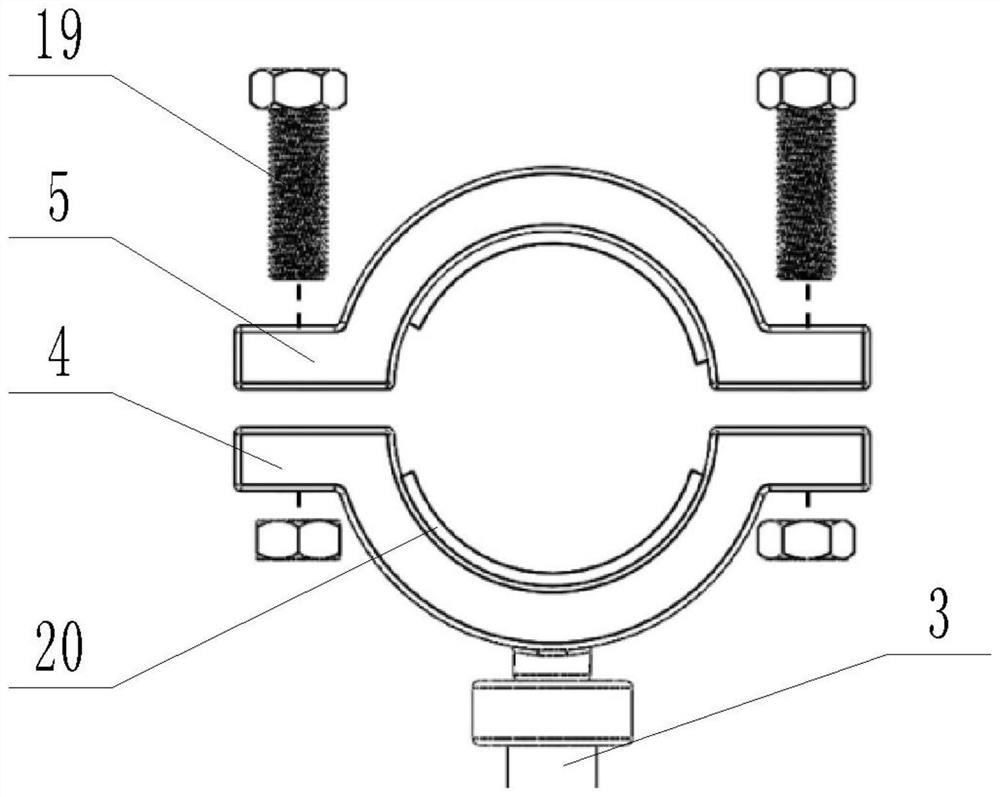

Pressure-controllable industrial robot grinding and polishing system and grinding and polishing method

PendingCN108296962AImprove grinding and polishing effectImprove production efficiency and product qualityPolishing machinesGrinding drivesPulp and paper industryIndustrial robot

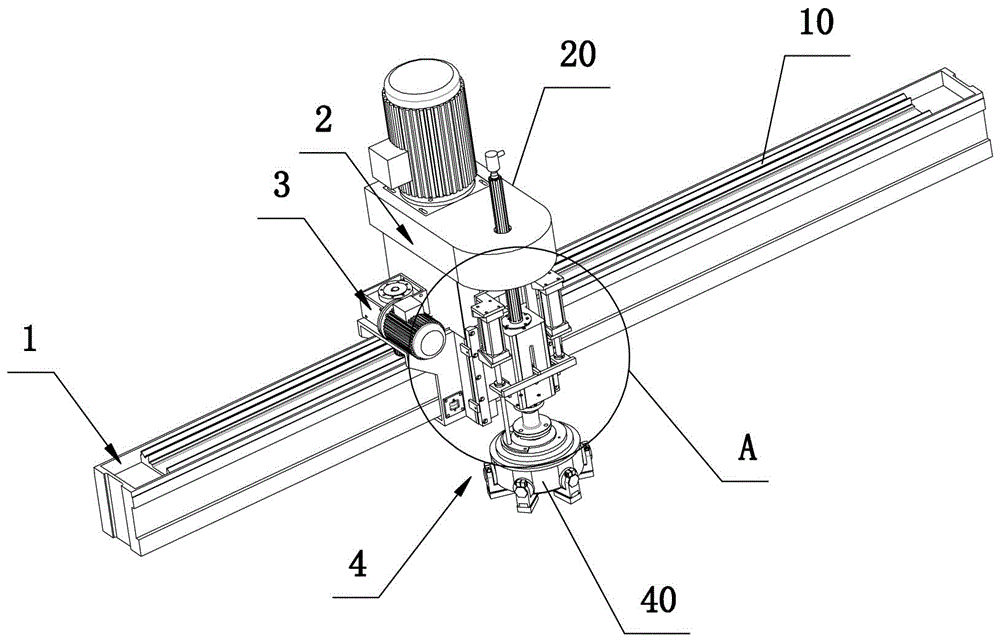

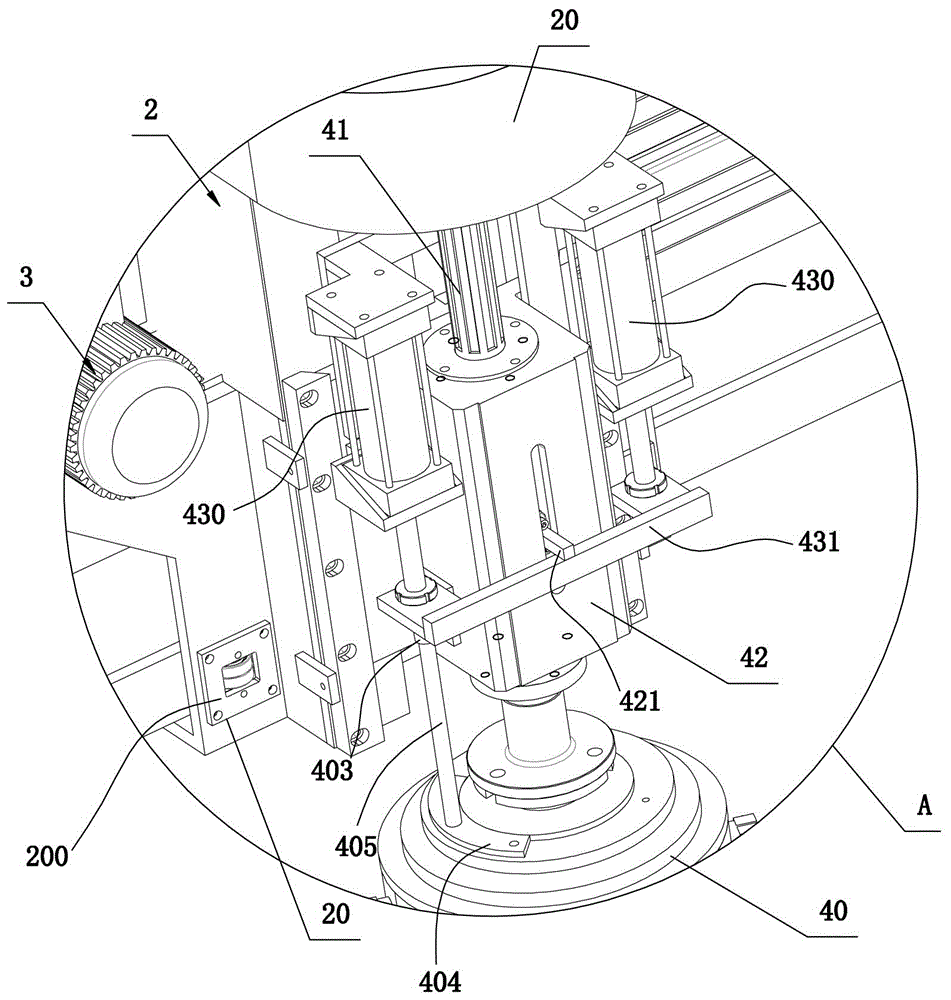

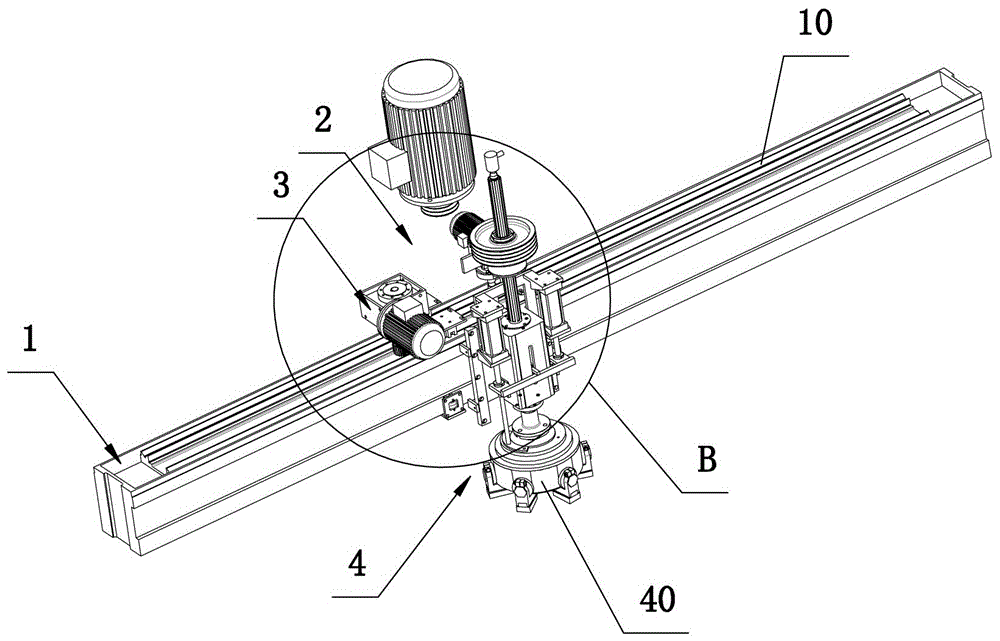

The invention provides a pressure-controllable industrial robot grinding and polishing system. The pressure-controllable industrial robot grinding and polishing system is characterized by comprising apolishing device, a feeding device and a controller, and the polishing device comprises a fixed base, a mounting seat, a polishing mechanism, first slide rails, a position adjusting mechanism and a cylinder. The cylinder is connected with the mounting seat, and the mounting seat is slidably connected with the first slide rails to realize that the cylinder pushes the mounting seat to move in the length direction of the first slide rails to drive the polishing mechanism to move. The cylinder is connected with the controller to enable the controller to control the cylinder to control grinding pressure between the polishing mechanism and a workpiece. The cylinder is disposed on the fixed base through the position adjusting mechanism. The pressure-controllable industrial robot grinding and polishing system can improve grinding and polishing effects and improve production efficiency and product quality. The invention further provides an industrial robot grinding and polishing method which is capable of realizing constant grinding pressure between the polishing mechanism and the workpiece, effectively improving the grinding and polishing effects and improving the production efficiency and the product quality.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

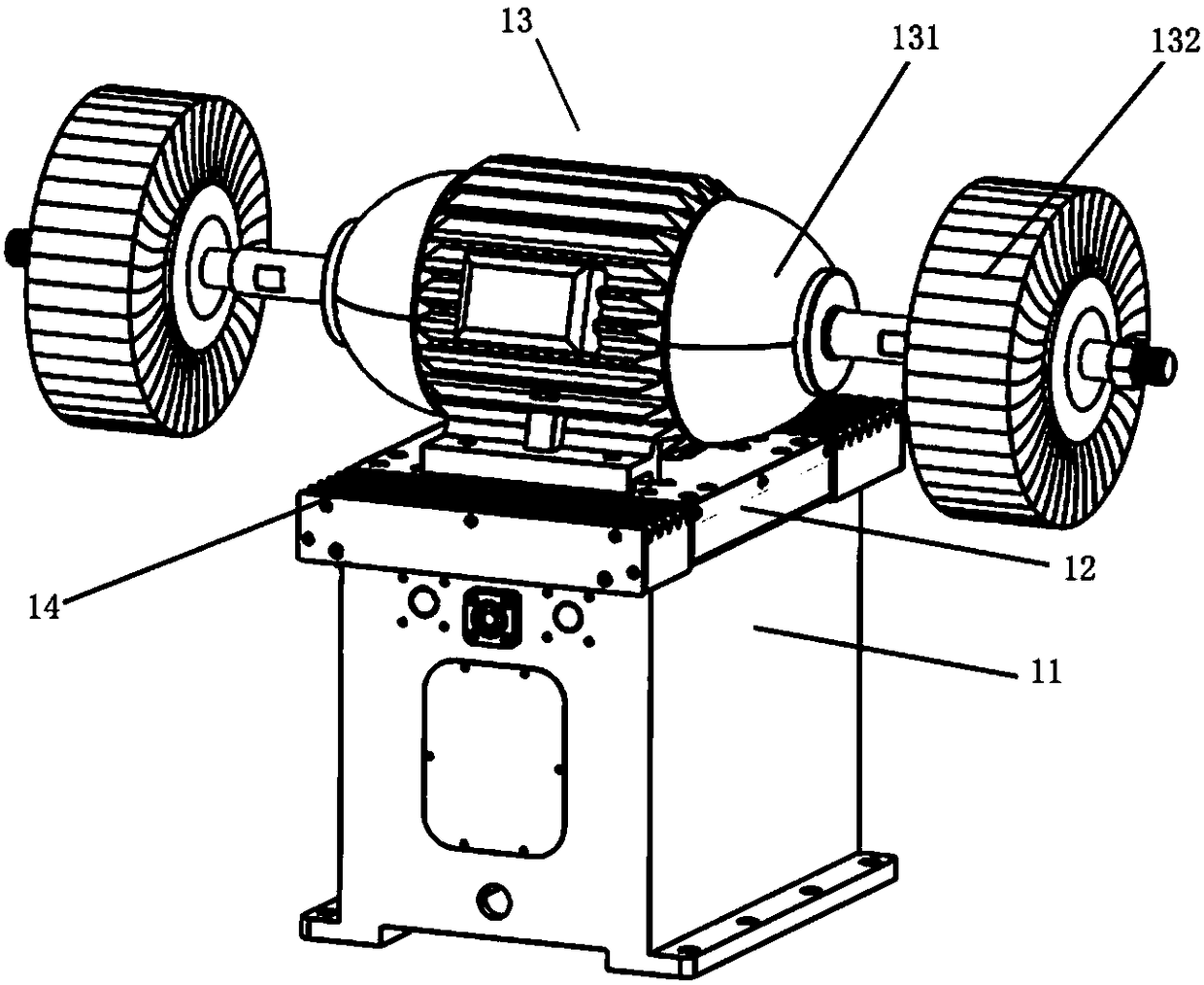

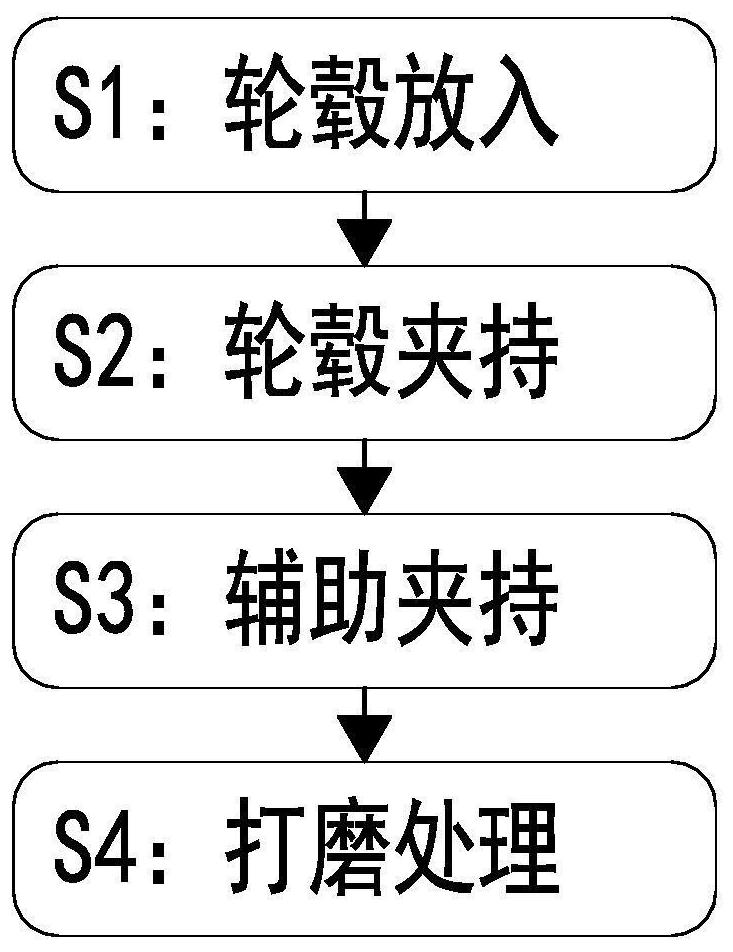

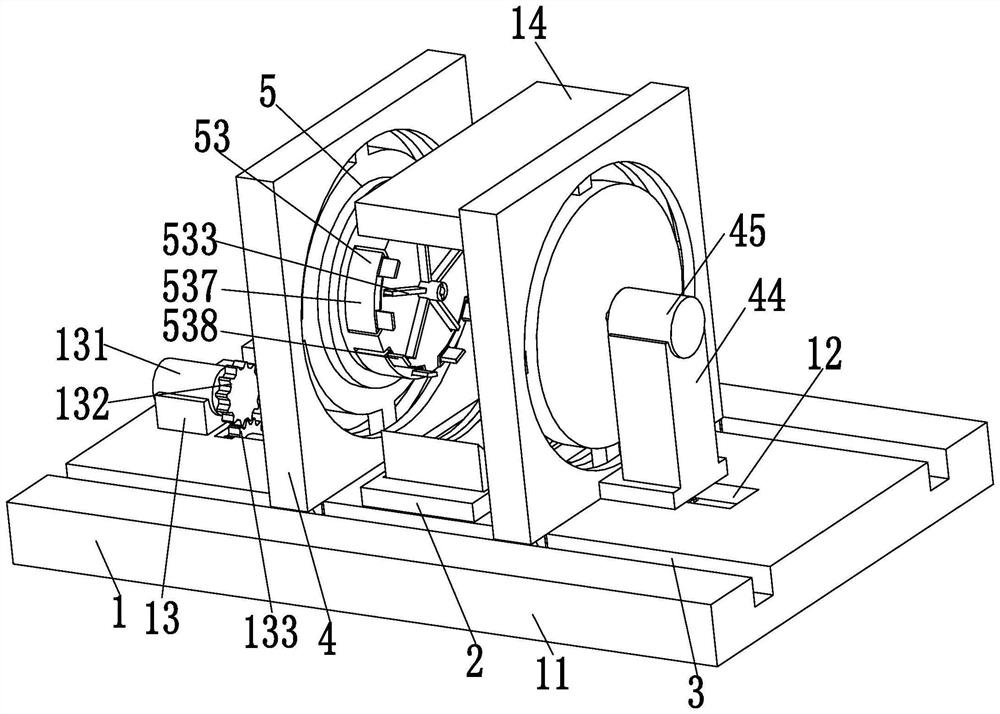

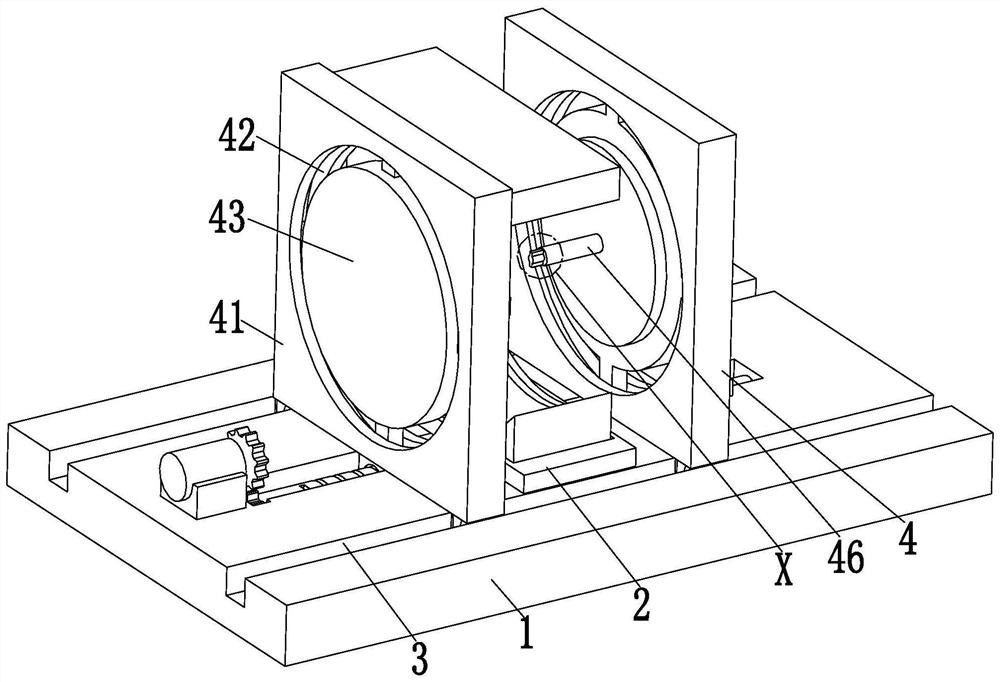

Manufacturing and machining method for new energy automobile alloy hub

InactiveCN112428069AQuality assuranceAvoid hard-to-sand issuesEdge grinding machinesRevolution surface grinding machinesNew energyStructural engineering

The invention relates to a manufacturing and machining method for a new energy automobile alloy hub. The method mainly comprises the following steps of hub placing-in, hub clamping, auxiliary clamping, polishing treatment and the like, and a used machining machine comprises a fixed base, a placing table, limiting grooves, mounting bottom plates and clamping devices. The placing table is installedin the middle of the upper end of the fixed base, the limiting grooves are symmetrically formed at the front side and the rear side of the upper end of the fixed base, the mounting bottom plates are symmetrically arranged at the left sides and the right sides of the limiting grooves in a sliding manner, and the clamping devices are installed on the mounting bottom plates at the left sides of the limiting grooves. The problems that according to a traditional automobile alloy hub manufacturing and machining method, when manual handheld grinding equipment is used for grinding, a grinding mechanism is difficult to attach to the surface of a hub, so that the grinding and polishing effect of the partial surface of the hub is poor, a common hub clamping mechanism can block the grinding area of the hub, unstable clamping is likely to happen, and the grinding effect is not uniform are solved.

Owner:杭州佳顿智能科技有限公司

Polishing and grinding device for inner wall of glass pipeline

InactiveCN108044492AGood sandingImprove grinding effectPolishing machinesGrinding drivesWire gauzeReciprocating motion

The invention discloses a polishing and grinding device for the inner wall of a glass pipeline. The device comprises a bottom plate and a lead screw, wherein the lead screw is arranged above the bottom plate in parallel; four mounting legs are rectangularly distributed at the lower end of the bottom plate and are fixedly connected to the bottom plate; a sleeve sleeves the column surface of the lead screw; an inner thread corresponding to an outer thread of the lead screw is arranged on the inner wall of the sleeve; the sleeve is fixedly connected to the bottom plate through a sleeve support; the end, close to the sleeve, of the lead screw is fixedly connected to a joint bearing; the end, far from the lead screw, of the joint bearing is fixedly connected to a connecting block; and a connecting rod is hinged to the connecting block. The device disclosed by the invention is simpler in structure, small in power input and strong in co-movement, and is stronger in co-movement compared with that of an existing device in structure while solving the problem that the manual grinding cost is high. A grinding head also reciprocates in the glass pipeline while rotating. In addition to the action of oilstones and an asbestosed wire gauze, the grinding and polishing effect is better.

Owner:合肥挺泰环保科技有限公司

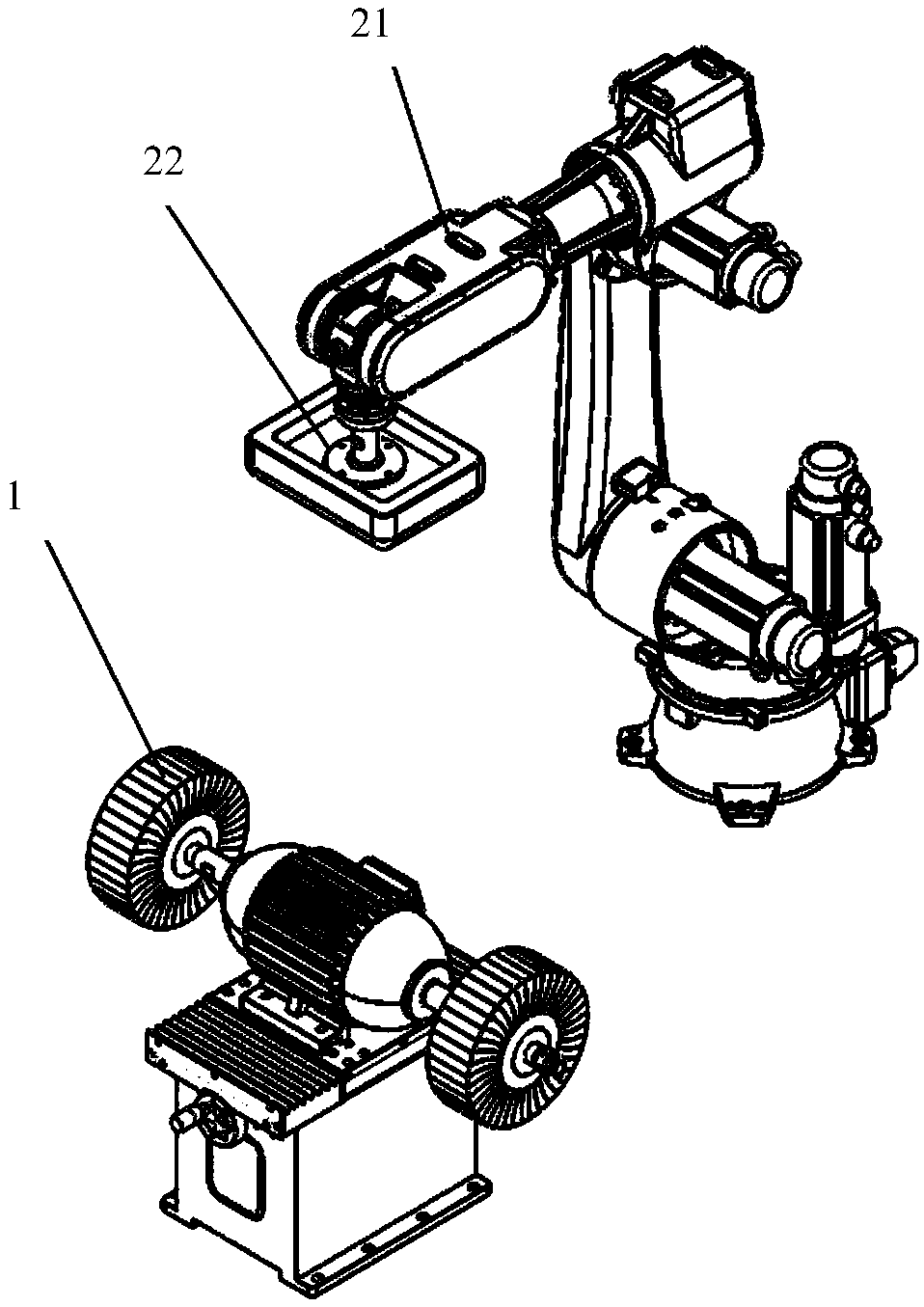

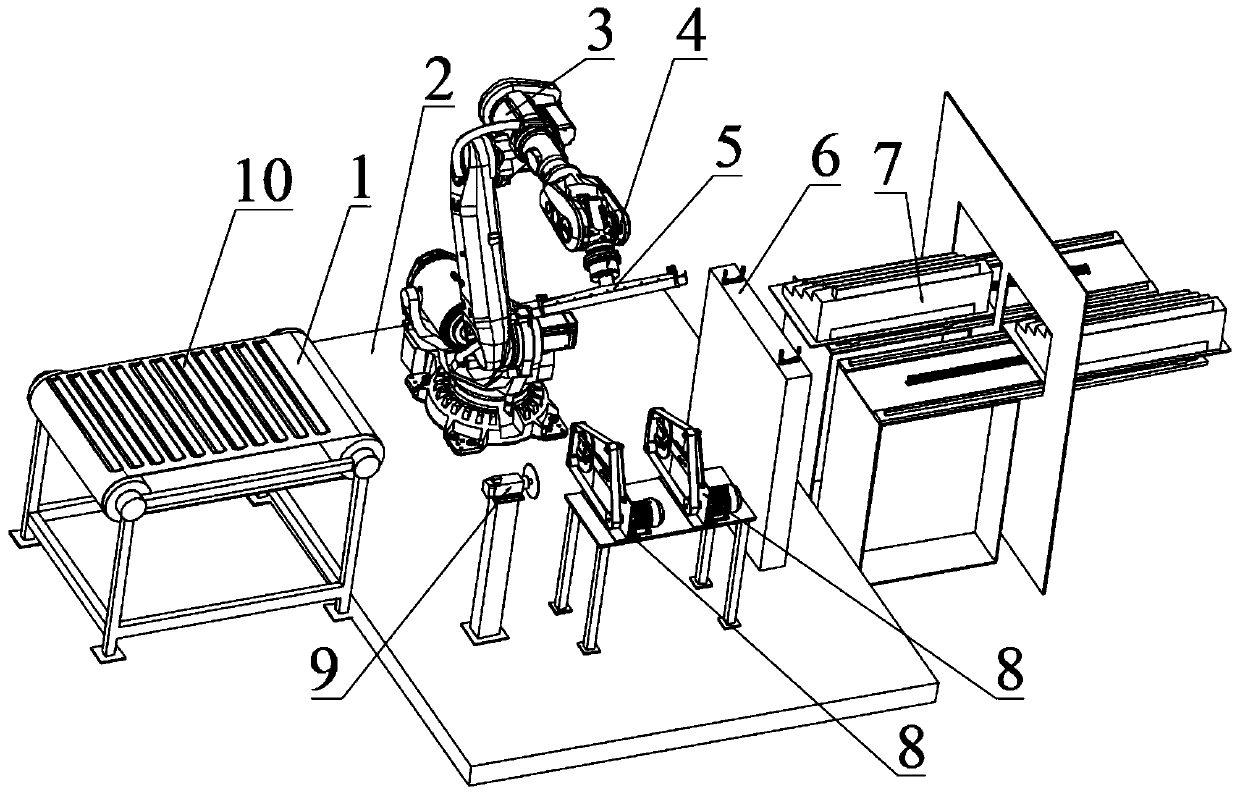

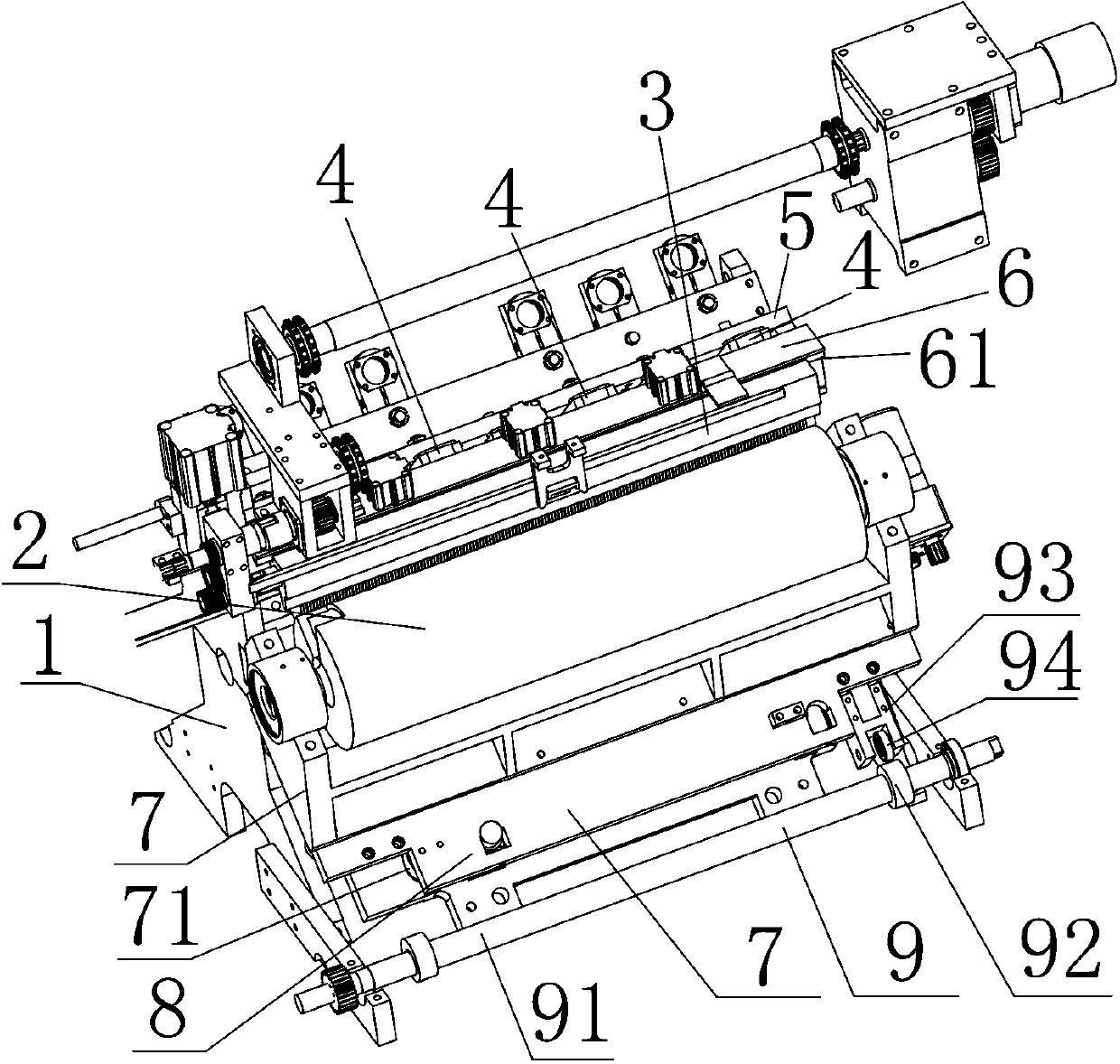

Automatic polish-grinding system and automatic polish-grinding process for thin-wall stamping part

ActiveCN109940400AAchieve grinding pressure controlClose contactOther manufacturing equipments/toolsManipulatorSanderEngineering

The invention provides an automatic polish-grinding system and an automatic polish-grinding process for a thin-wall stamping part. The automatic polish-grinding system mainly comprises a mounting base, a six-axis robot, a pneumatic clamp, a force control sensor, a slicer, a belt sander, a lock seat, an automatic feeding device, a conveying belt and the like, wherein the force control sensor and the pneumatic clamp are arranged on a flange plate at the tail end of the six-axis robot; the slicer, the belt sander and the lock seat are all arranged on the base through a mounting seat; and the automatic feeding device and the conveying belt are respectively arranged on two sides of the base. After a workpiece is grabbed from the automatic feeding device by the pneumatic clamp for an industrialrobot, the workpiece is sequentially machined by the slicer and the belt sander, and then is discharged by the conveying belt. According to the automatic polish-grinding system, the automatic grindingand polishing of the thin-wall stamping part is achieved, the efficiency and the quality of grinding and polishing are higher than those of manual grinding and polishing, and meanwhile, the use of manpower in grinding and polishing is reduced, so that the automatic polish-grinding system has broad application prospects in thin-wall stamping part machining, and is able to improve production efficiency to bring considerable benefits for enterprises.

Owner:WUHAN UNIV OF TECH

Polishing buffing device for machine manufacturing

InactiveCN109664191AEasy to useImprove grinding efficiencyPolishing machinesGrinding work supportsIndustrial engineering

The invention discloses a polishing buffing device for machine manufacturing, and belongs to the technical field of polishing buffing. The polishing buffing device comprises a bottom plate, side plates and a top plate; the side plates are fixedly connected to the two sides of the bottom plate; the top plate is fixedly connected to the tops of the two side plates; a screw rod is horizontally arranged under the top plate, one end of the screw rod is rotationally connected with one side plate through a bearing seat, and the other end of the screw rod penetrates through the other side plate to beconnected with a first motor; a second slide block is arranged on the screw rod in a matched mode; an air cylinder is vertically installed at the bottom of the second slide block, a second motor is installed at the telescopic end of the air cylinder, and a buffing wheel is installed at the output end of the second motor through a second rotary shaft; and a supporting plate is installed on the bottom plate through a support frame, and a workpiece is placed on the supporting plate. According to the polishing buffing device provided by the invention, compared with a common polishing buffing device, the screw is driven to rotate through the first motor, horizontal moving of the buffing wheel can be achieved, the buffing wheel is driven to conduct polishing buffing through the second motor, time and labor are saved, in addition, the polishing efficiency is high, and the polishing effect is good.

Owner:JINGDEZHEN CERAMIC INSTITUTE

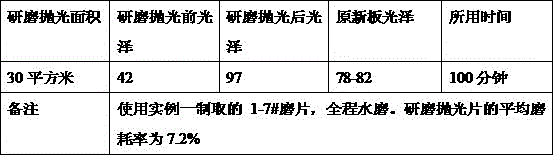

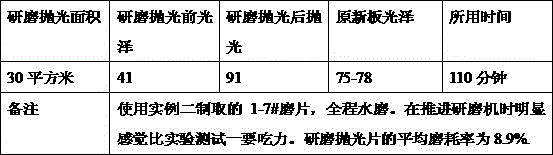

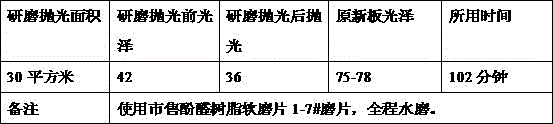

Preparation method of polyurethane matrix stone grinding and polishing disc

ActiveCN106272125AGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideZinc

The invention discloses a preparation method of a polyurethane matrix stone grinding and polishing disc, and relates to a synthesis technology adopting a prepared polyurethane matrix and mixed artificial diamond micro powder, silicon carbide, silicon oxide, aluminium oxide and zinc oxide super fine powder as abrasive components. The novel stone grinding and polishing material can better meet the requirement on high luster during the decorative stone processing process or the later renovation process, the efficiency is higher, and the material has better environmental protection property.

Owner:王建秋

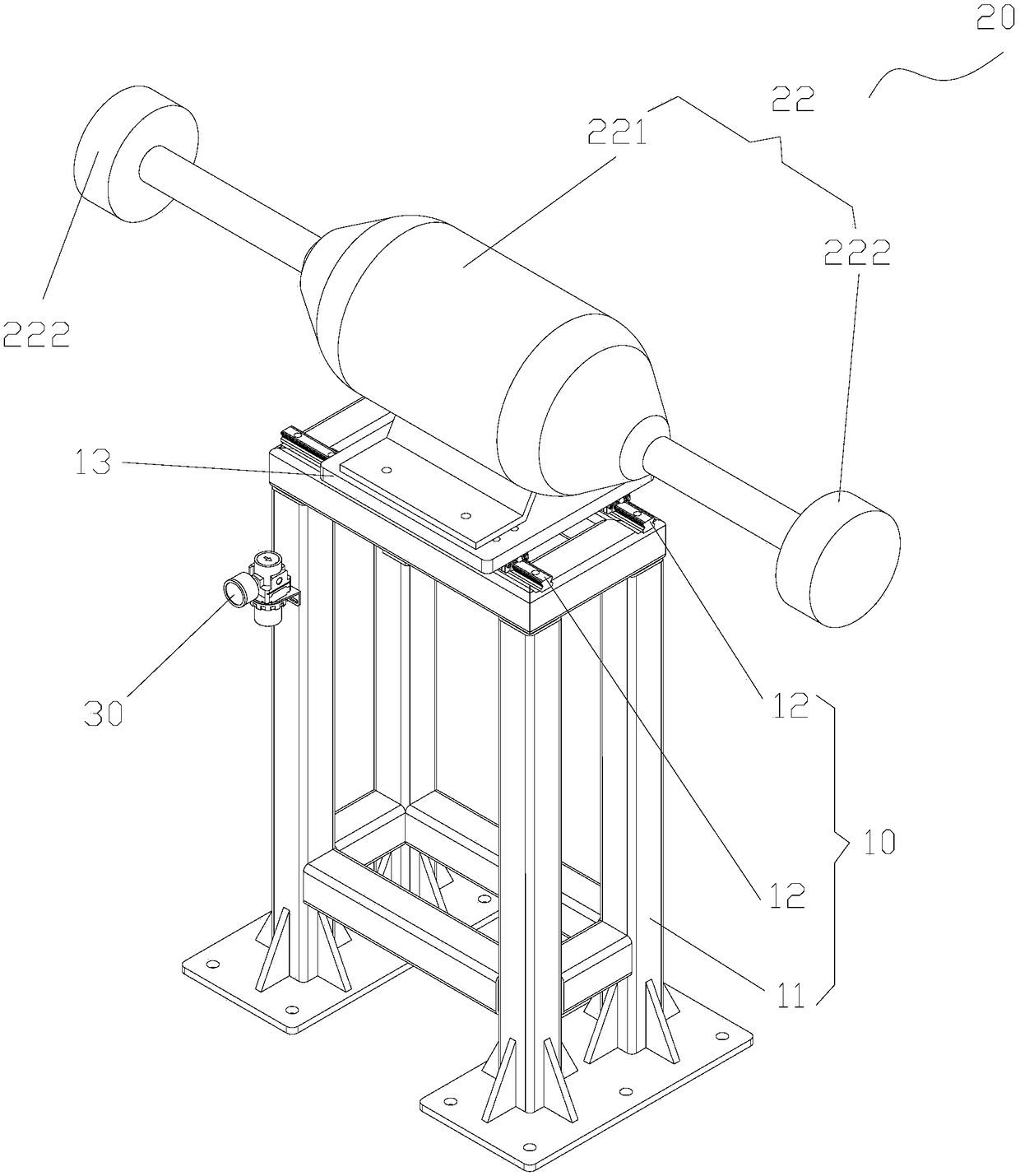

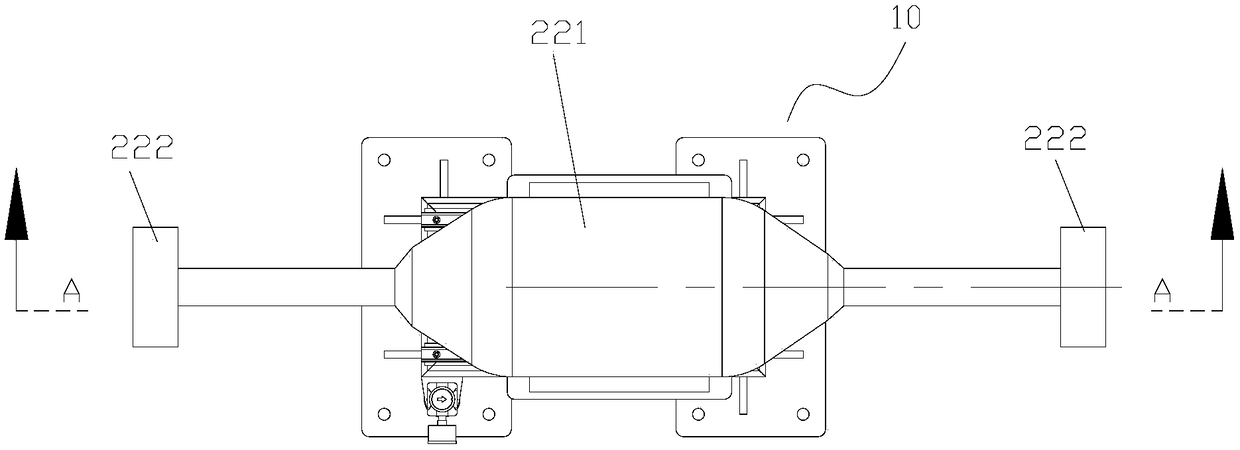

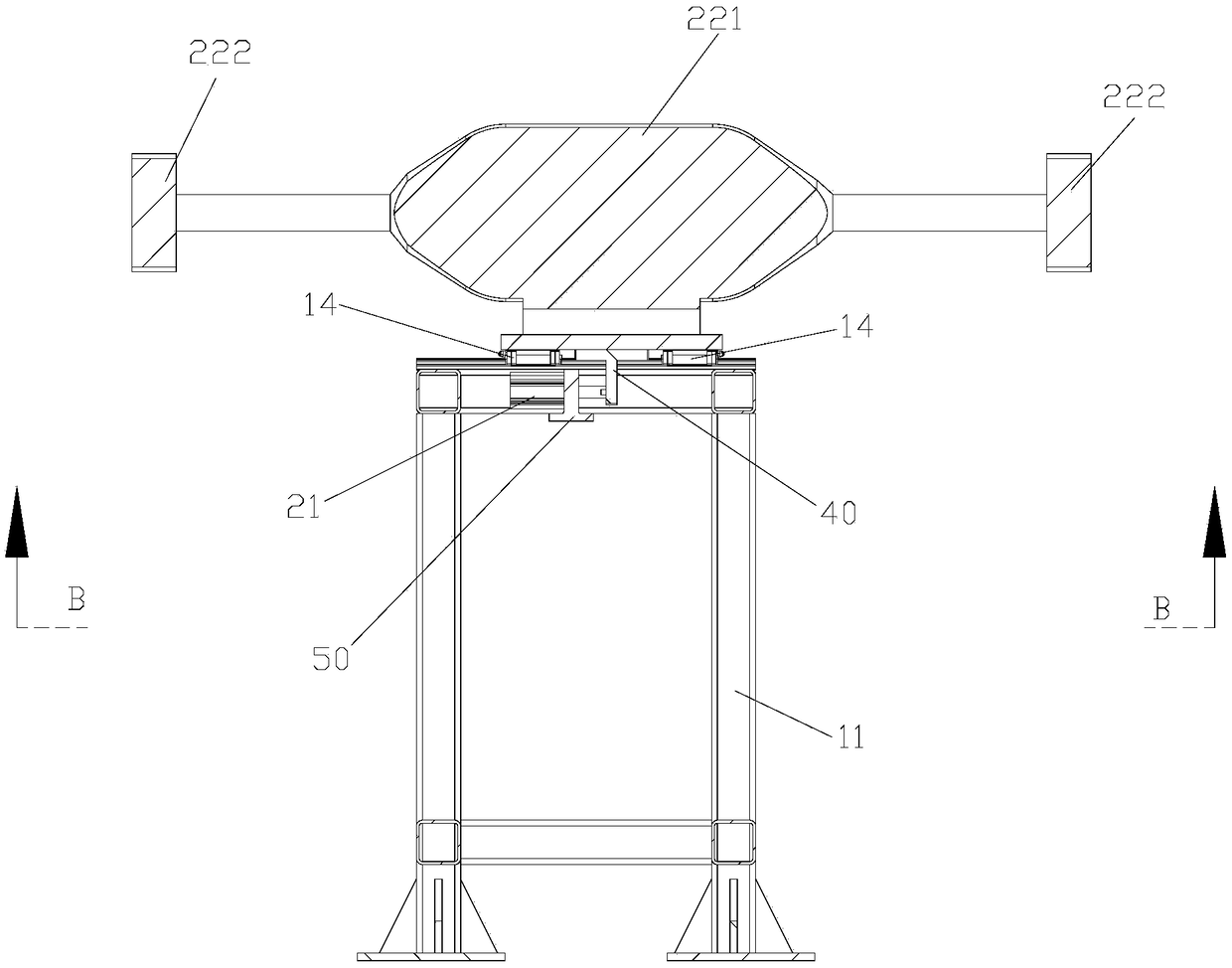

Outer surface flexibility polishing device of motor rotor

ActiveCN105553194ARealize grinding and polishing operationsImprove work efficiencyPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The invention relates to an automatic polishing device, in particular to an automatic polishing device for a motor. An outer surface flexibility polishing device of a motor rotor comprises a big support, an automatic fixture and a flexibility polishing mechanism, the automatic fixture is used for installing the motor rotor, the flexibility polishing mechanism is used for polishing the motor rotor, the automatic fixture and the flexibility polishing mechanism are fixedly connected to the big support, the flexibility polishing mechanism is arranged at the upper part of the automatic fixture, and the motor rotor is connected onto the automatic fixture. By the outer surface flexibility polishing device, the outer surface of the motor rotor is polished, the outer surface flexibility polishing device of the motor rotor, disclosed by the invention is high in manufacturability, the motor rotor can be automatically clamped and driven to rotate at a certain speed, a hemp wheel has functions of rotating at a high speed and doing axial movement along the motor rotor, and the polishing quality and efficiency are greatly improved.

Owner:江门市杰出五金制品有限公司

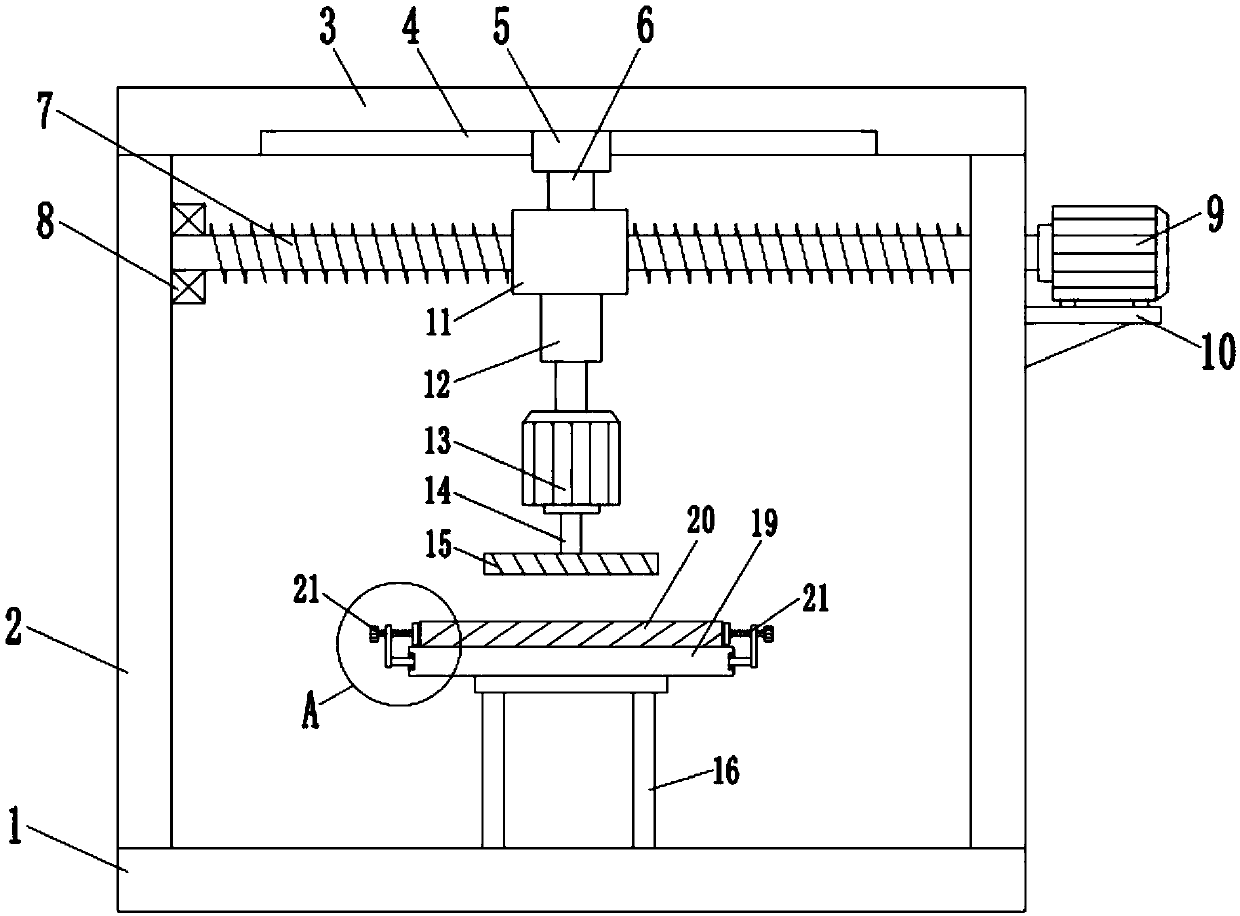

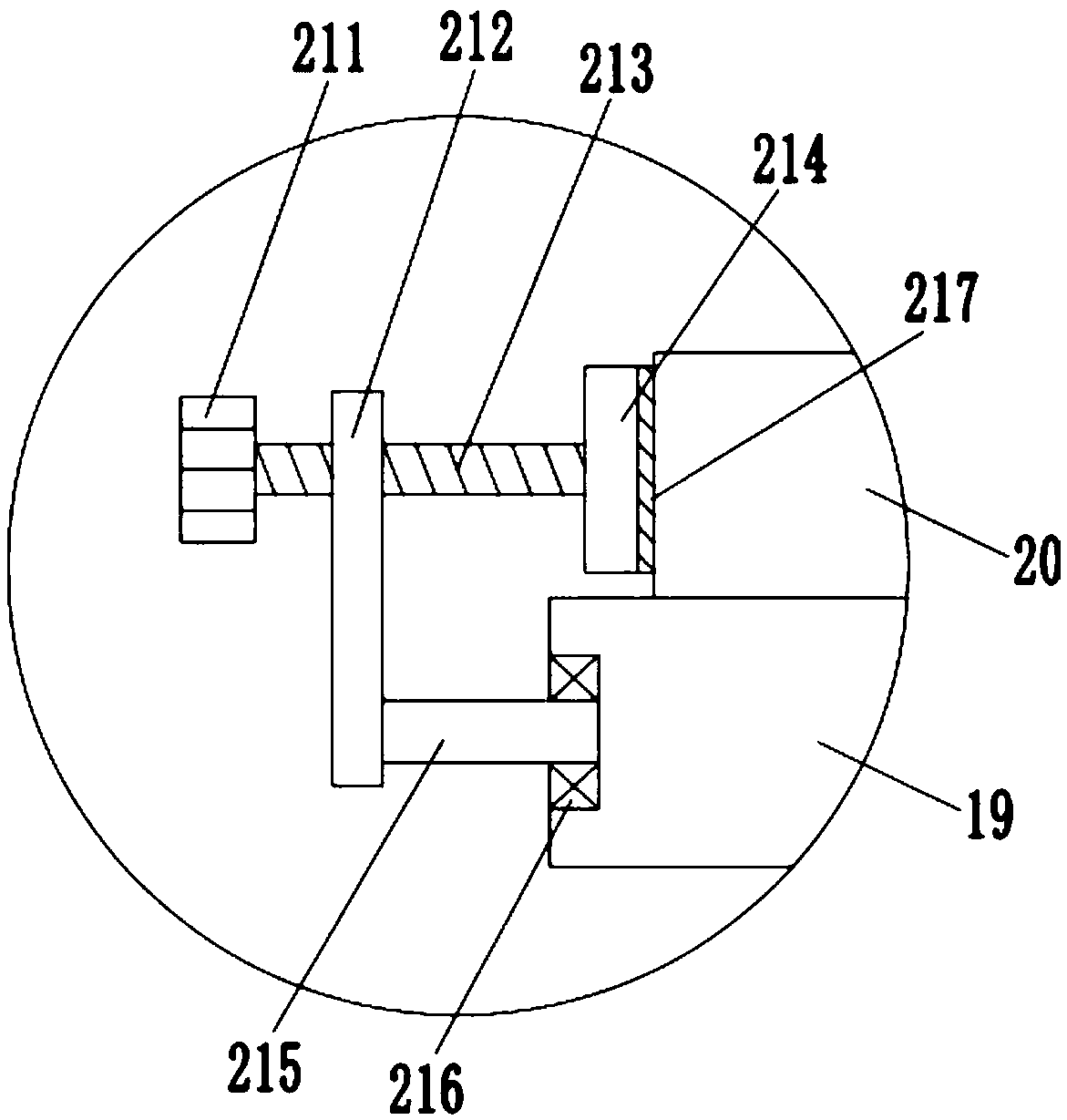

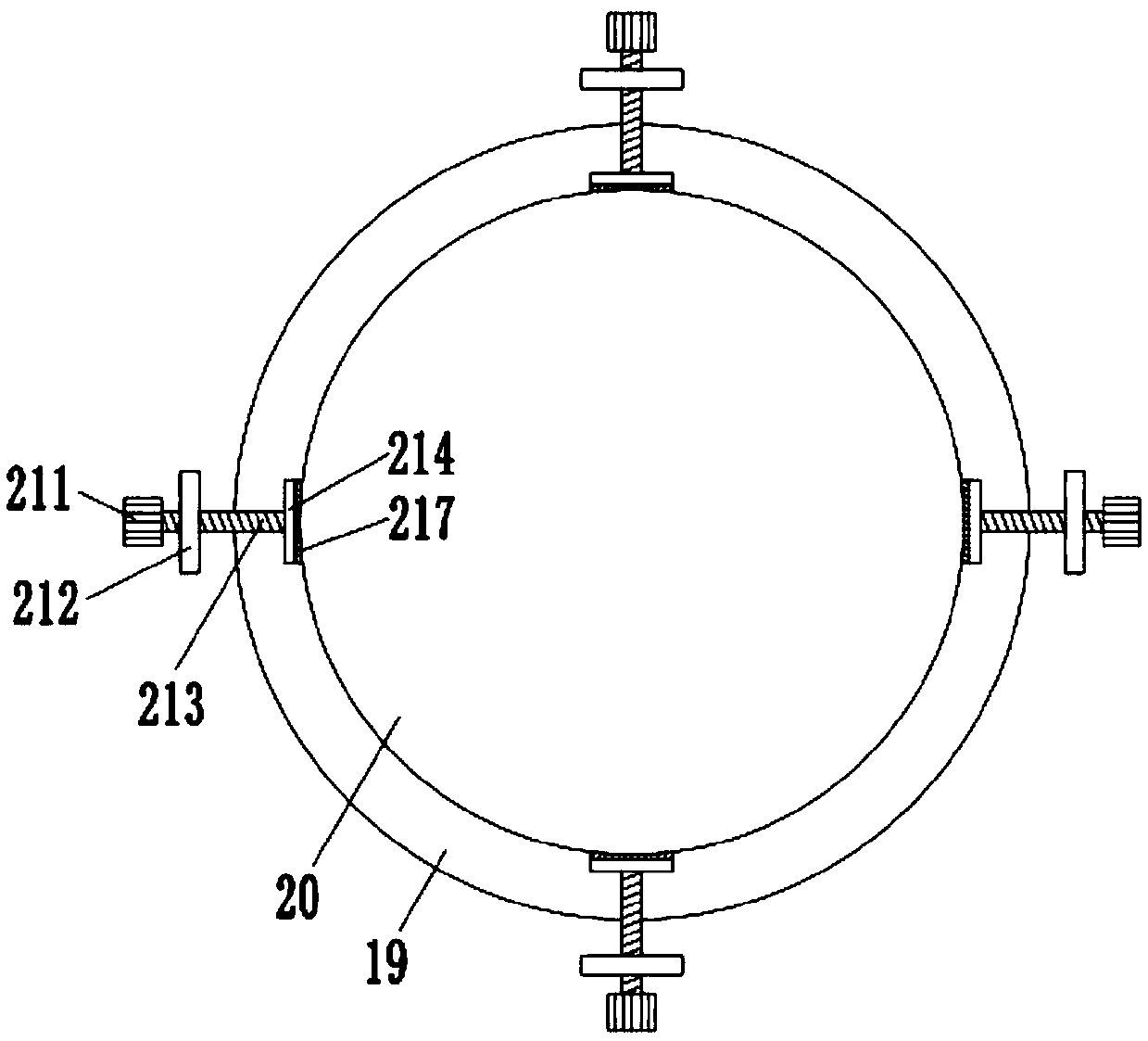

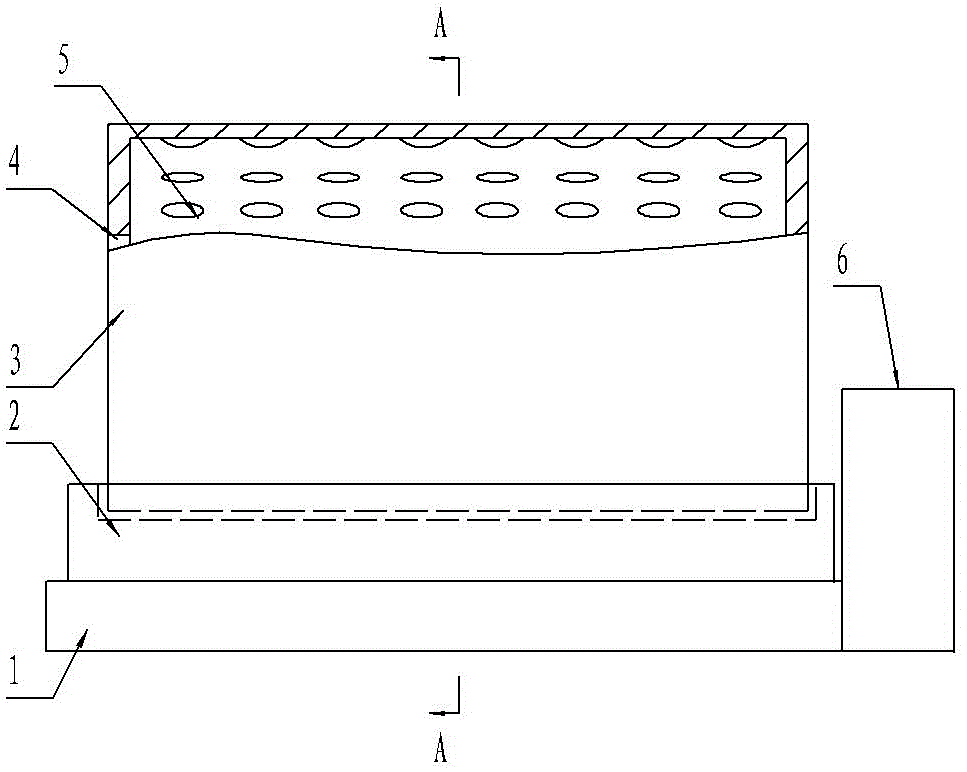

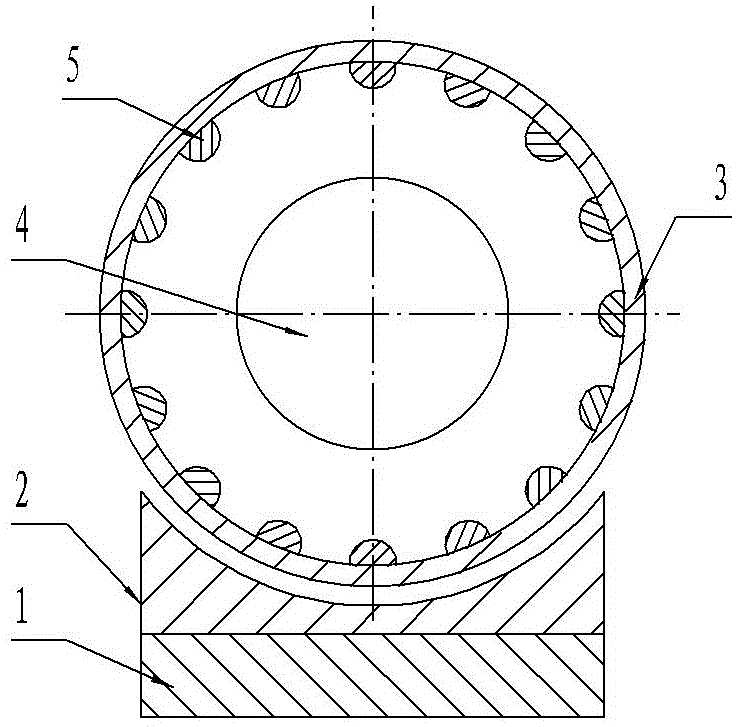

Internal combustion machine bearing bush machining device and machining method thereof

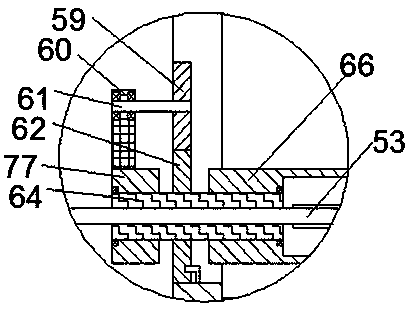

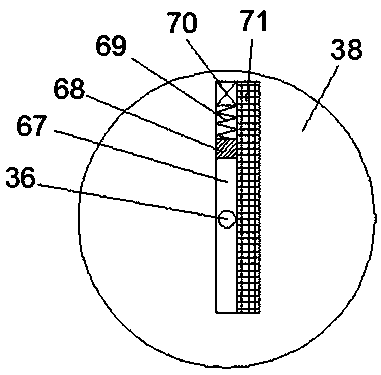

ActiveCN108356648AEasy dischargeImprove grinding and polishing effectRevolution surface grinding machinesGrinding work supportsCombustionEngineering

The invention discloses an internal combustion machine bearing bush machining device, and relates to the technical field of internal combustion machine bearing bush production equipment. The device comprises a bottom plate, the top of the bottom plate is fixedly connected with a box body, one side of the top of the box body is fixedly connected with a transmission box, the bottom of the inner wallof the box body is rotatably connected with a rotating shaft through a bearing pedestal, the top end of the rotating shaft sequentially penetrates the box body and the transmission box and extends into the transmission box, and the rotating shaft extends into the outer surface inside the transmission box and is rotatably connected with the top of the inner wall of the transmission box through a bearing. According to the internal combustion machine bearing bush machining device and the machining method thereof, the grinding and polishing effect is greatly improved, the grinding and polishing efficiency is well improved, a person does not need to waste a large amount of time for grinding and polishing a bearing bush, work burdens of the person are well reduced, work efficiency of the personis improved, the inner surface and the outer surface of the bearing bush can be rapidly and efficiently ground and polished at the same time, and grinding machining of the bearing bush by the personis greatly facilitated.

Owner:湖北安达精密工业有限公司

Stone grinder of modified structure

ActiveCN106425724AQuick grinding and polishingSimple structureGrinding carriagesGrinding headsMechanical engineeringEngineering

A stone grinder of a modified structure comprises a rack provided with a cross beam, a grinding and polishing mechanism and a travelling mechanism. The grinding and polishing mechanism comprises a grinding and polishing frame body, a slide base unit, a first lifting unit and a grinding and polishing execution device, and the grinding and polishing execution device comprises a grinding head unit, a spline shaft, a spindle box unit used for mounting the spline shaft, a second lifting unit used for driving the spline shaft to move vertically along the spindle box unit and a driving unit used for driving the spline shaft to rotate. According to the stone grinder, the whole slide base unit is firstly lifted up and down through the first lifting unit, since the first lifting unit can adopt a stable screw rod lifting structure, the stroke of the grinding head unit can be additionally increased by about 300 mm, the stroke of the grinding head unit in the whole stone grinder can reach 420 mm based on an original stroke of a cylinder, and therefore the stone grinder can fully suitable for quick grinding and polishing of stones with the thicknesses being 400 mm or above.

Owner:福建省泉州万龙石业有限公司

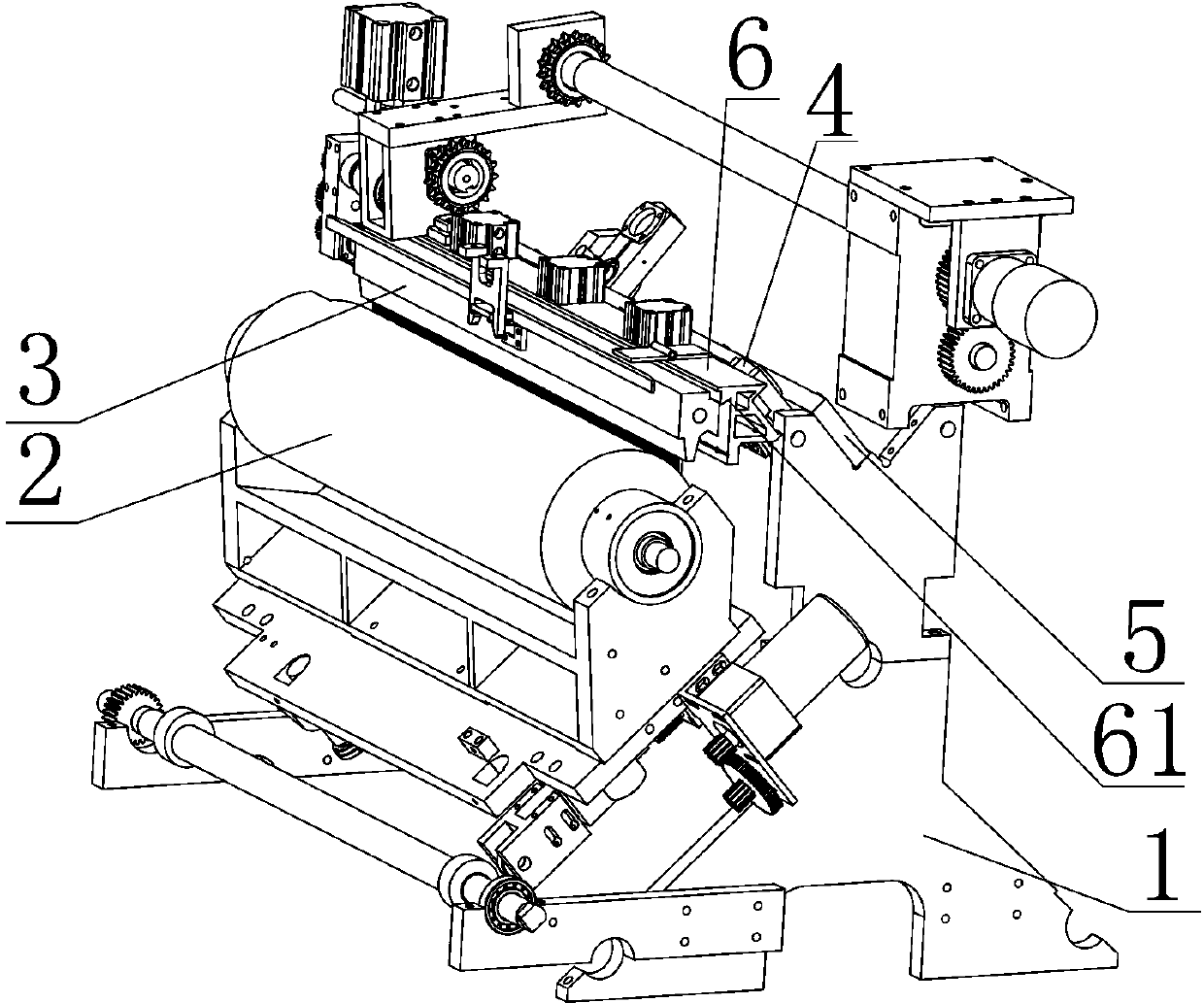

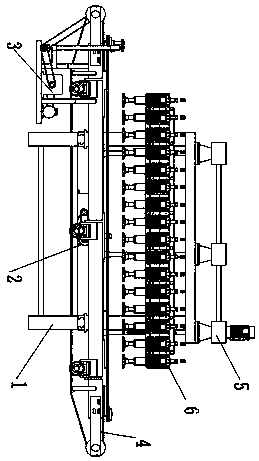

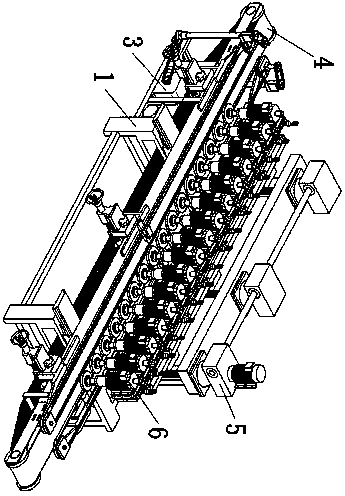

Full-automation rhinestone grinding and polishing machine

ActiveCN103341802AImprove grinding and polishing effectImprove qualityEdge grinding machinesEngineeringAutomation

The invention relates to a full-automation rhinestone grinding and polishing machine. The full-automation rhinestone grinding and polishing machine comprises a rack, a grinding and polishing wheel and a fixture. The grinding and polishing wheel and the fixture are arranged on the rack. A rhinestone is positioned in a station of the fixture. The grinding and polishing wheel is provided with grinding and polishing wheel forward and backward moving tracks which enable the grinding and polishing wheel to be close to the fixture and away from the fixture, and the grinding and polishing wheel moves forwards or backwards along the grinding and polishing wheel forward and backward moving tracks. The grinding and polishing wheel abuts against the rhinestone and acts on the rhinestone in a grinding and polishing mode. The grinding and polishing wheel and the fixture swing relative to each other, the relative swinging track between the grinding and polishing wheel and the fixture is in the shape of an arc, and a swinging surface formed by the arc-shaped swinging track is parallel with a surface, wherein grinding and polishing processing is conducted by the rhinestone on the surface, and the surface is a cutting surface finally formed by the rhinestone. A flat cutting surface can be provided by the full-automation rhinestone grinding and polishing machine, and therefore quality of the rhinestone is improved.

Owner:抚州市金奇科技发展有限公司

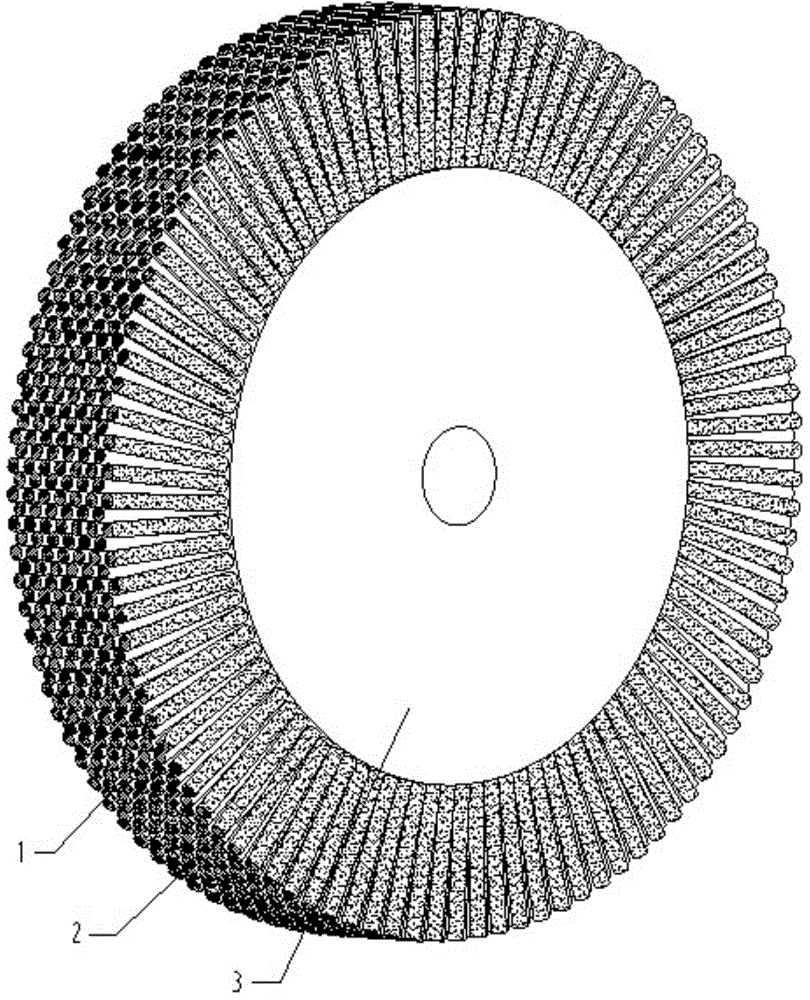

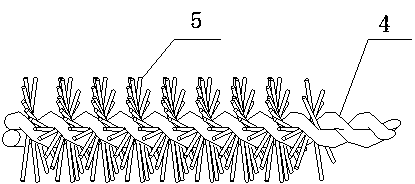

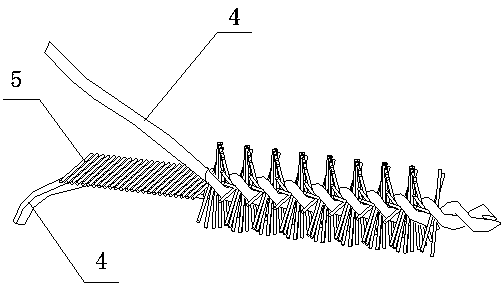

Polishing wheel based on fiber adhesive rope coated abrasive tool

InactiveCN103552002AReduce manufacturing costReduced grinding and polishing process costsFlexible-parts wheelsGrinding devicesFiberEngineering

The invention discloses a polishing wheel produced with a fiber adhesive rope coated abrasive tool, which comprises a skeleton core and fiber adhesive rope sections, and the fiber adhesive rope sections are evenly and radially stuck on the circumferential surface of the skeleton core by binder, shaped and solidified. The polishing wheel can greatly reduce the manufacturing cost of polishing abrasive disk disks, so the cost of the grinding and polishing process is reduced as well; moreover, the grooves between the abrasive rope sections play the role of dissipating heat and removing chips; the circumferential edge of an abrasive disk can be inserted into the groove of a workpiece to be ground for grinding and polishing; and the polishing wheel has the characteristics of high grinding and polishing efficiency and long service life.

Owner:谢泽

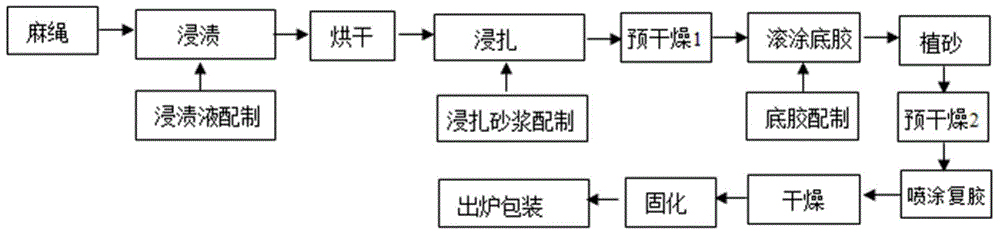

Clean water grinding and polishing technology

ActiveCN110465836AHigh mechanical strengthImprove wear resistanceGrinding machine componentsAbrasion apparatusEngineeringSlurry

The invention relates to the technical field of grinding and polishing, in particular to a clean water grinding and polishing technology. The clean water grinding and polishing technology comprises the following steps that in the first stage, coarse grinding is conducted for 20-30 minutes by using a coarse grinding and polishing disc, wherein the coarse grinding and polishing disc comprises a coarse grinding agent; in the second stage, fine grinding is conducted for 15-25 minutes by using a fine grinding and polishing disc, wherein the fine grinding and polishing disc comprises a fine grindingagent; and in the third stage, polishing is conducted by using a fine polishing and grinding disc for 5-15 minutes, wherein the fine polishing and grinding disc comprises a fine polishing grinding agent. According to the clean water grinding and polishing technology, grinding and polishing can be carried out under the condition that only clean water is used, environmental pollution caused by grinding powder or slurry containing a grinding agent is avoided, and harm to human health is avoided. The technology can be applied to materials such as glass, silicon crystals and metal ceramic, and canachieve a series of operations such as coarse grinding, fine grinding and fine polishing, so that the leveling and brightening effects of the materials are improved.

Owner:海南亿鑫和科技有限公司

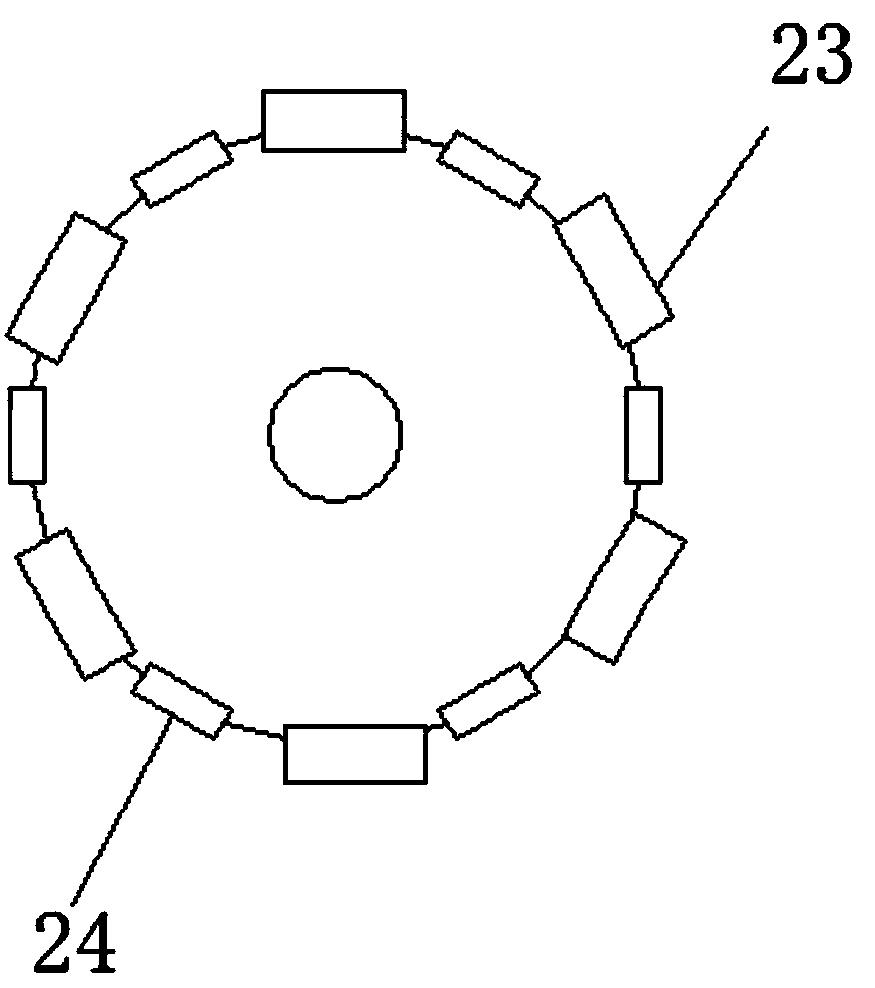

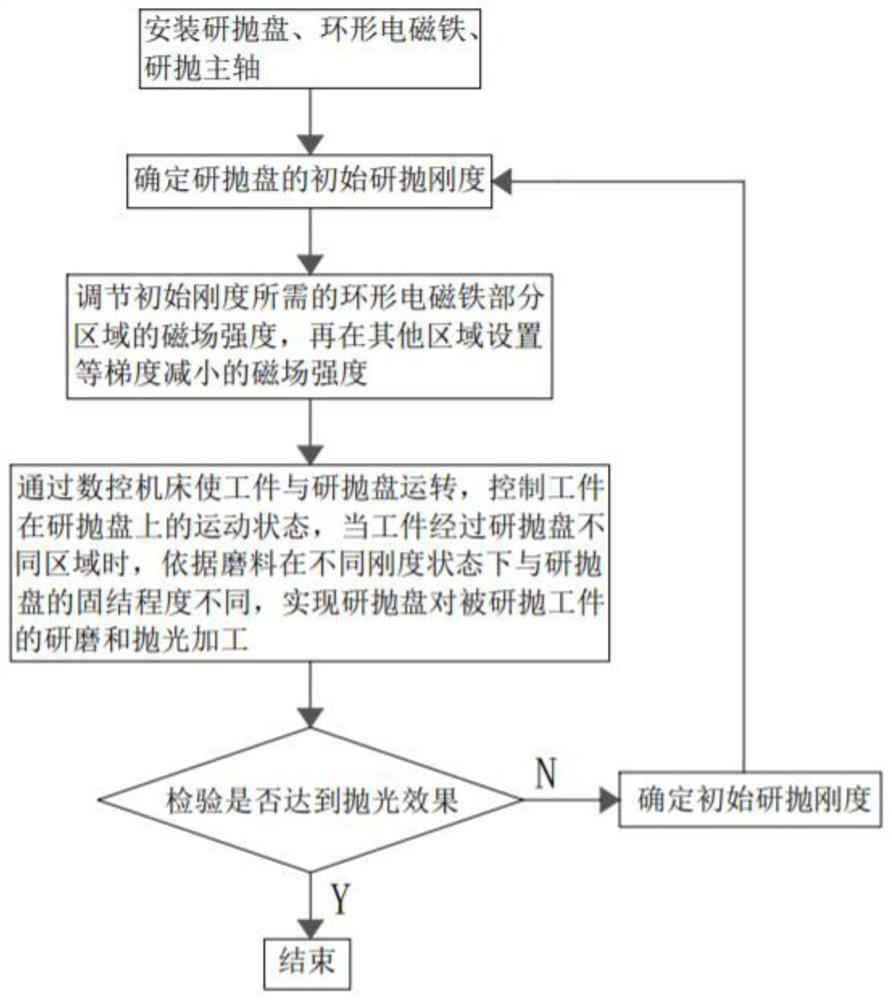

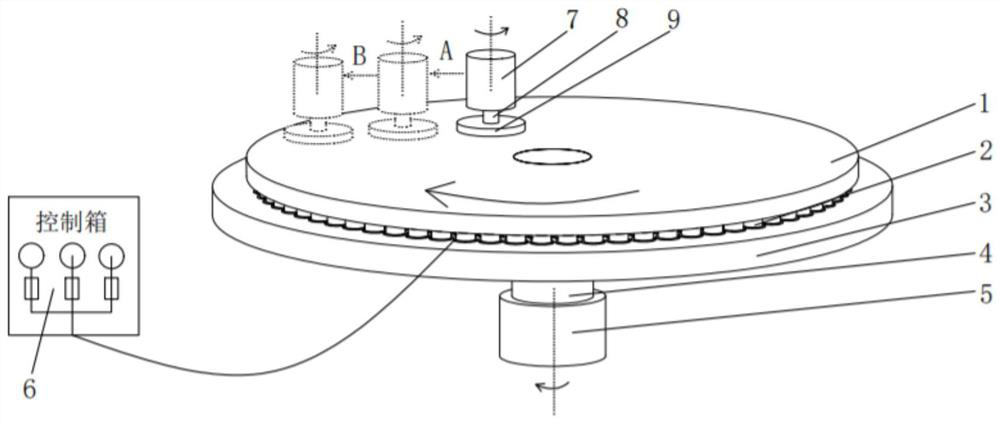

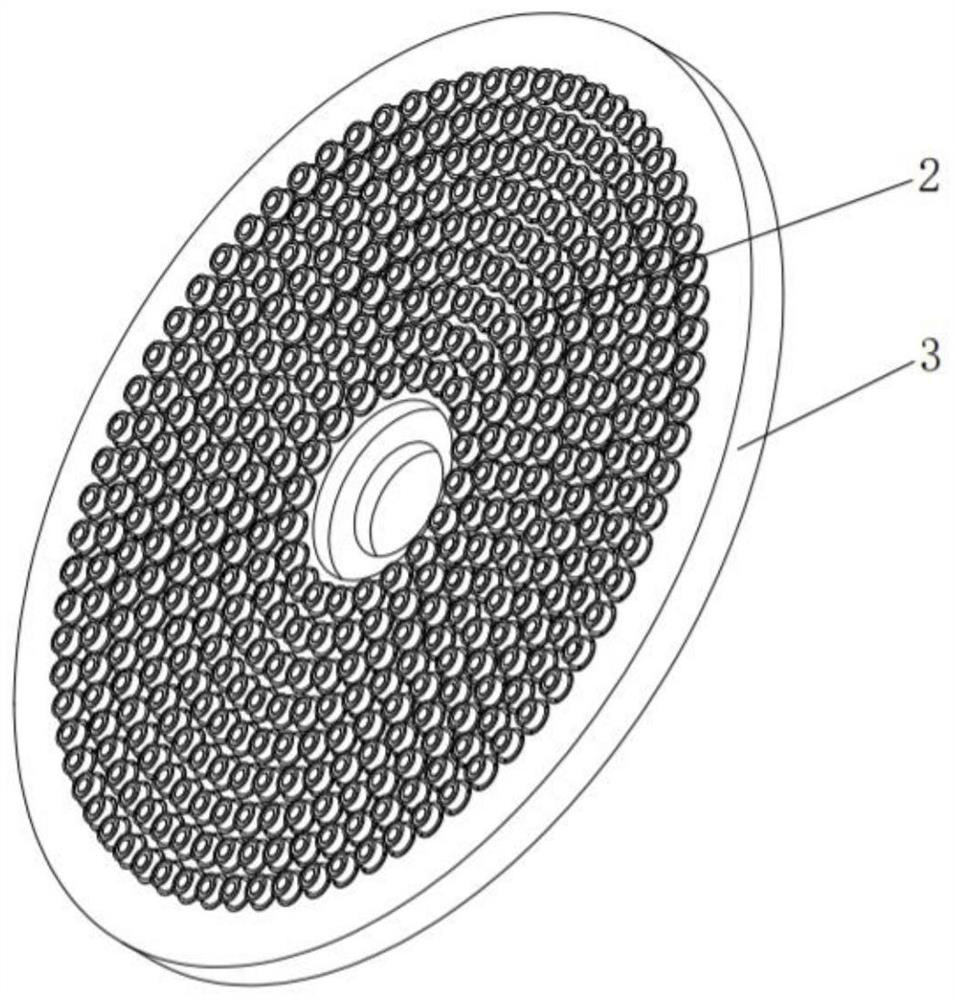

Composite grinding and polishing method and device

InactiveCN111906683AQuick responseGood reversibilityAbrasion apparatusLapping machinesNumerical controlPolishing

The invention relates to a composite grinding and polishing method and device and aims to solve the problems of long polishing time, low efficiency and the like of a single magnetic field. The composite grinding and polishing method is provided and comprises the following steps that a grinding and polishing main shaft and a grinding and polishing disc are installed on a numerical control machine tool, and annular electromagnets arranged on a base in a circumferential array manner are fixed to the lower portion of the grinding and polishing disc; and magnetic fields of different areas of the grinding and polishing disc are adjusted through the annular electromagnets, so that the rigidity of the different areas of the grinding and polishing disc is different, and efficient grinding and polishing of parts are achieved. The invention further provides the composite grinding and polishing device which mainly comprises the annular electromagnets, the base, the grinding and polishing disc, thecontrol box, the grinding and polishing main shaft and the like. The annular electromagnets are distributed on the base in the circumferential array manner and arranged below the grinding and polishing disc, and the current of the annular electromagnets can be independently controlled. According to the composite grinding and polishing method and device, the rigidity of the corresponding areas onthe grinding and polishing disc can be adjusted by adjusting the magnetic fields of the annular electromagnets in different areas, grinding and polishing integrated machining of a workpiece is achieved, and the machining efficiency is improved.

Owner:XIANGTAN UNIV

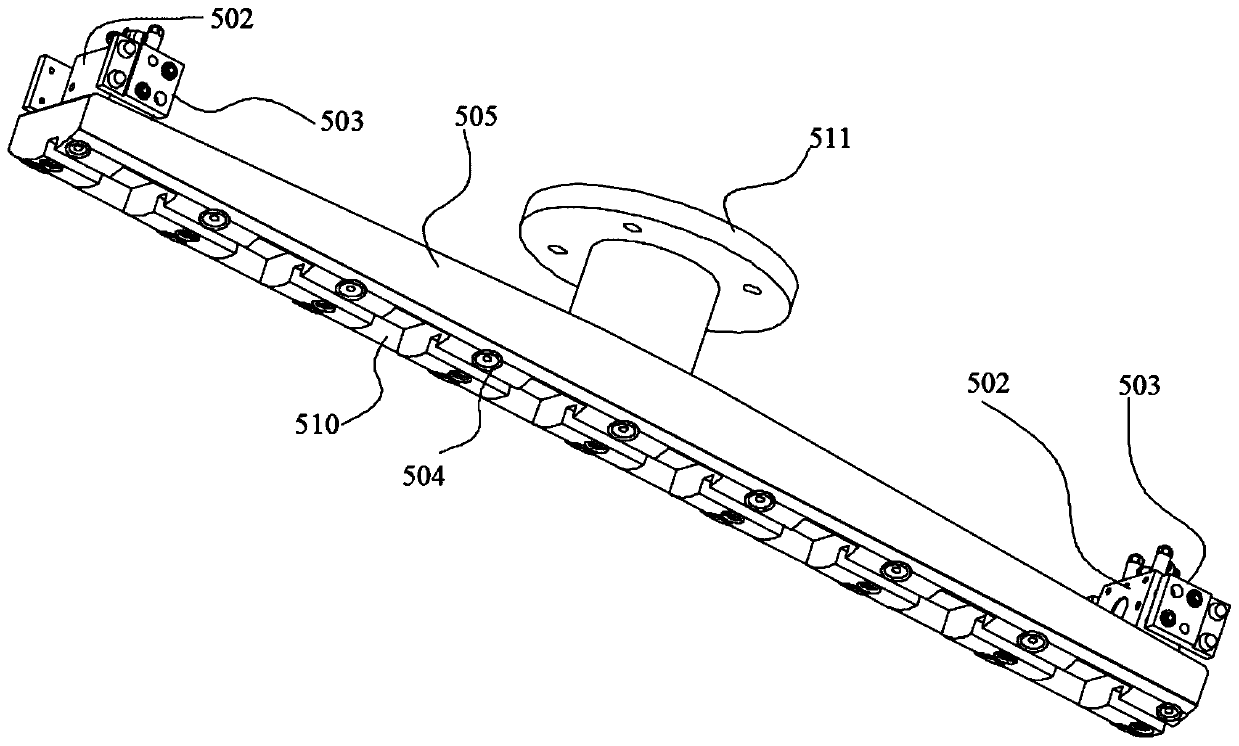

Grinding and polishing device and grinding and polishing method

ActiveCN106625161BImprove grinding and polishing effectGrinding carriagesPolishing machinesConstant forceEngineering

The invention provides a grinding-polishing device and a grinding-polishing method. The grinding-polishing device comprises a support part; a grinding-polishing part for grinding and polishing a workpiece, wherein the grinding-polishing part can be movably arranged on the support part and adjust the relative position with the support part according to the suffered action force from the workpiece, thereby enabling the grinding-polishing part to contact the workpiece to perform the grinding-polishing. The grinding-polishing device cancels the hard limiting mounting mode in the prior art, so that the grinding-polishing part can enable the grinding-polishing device to perform the grinding-polishing operation always clinging to the workpiece by adjusting the self-polishing position, guarantees that the ground and polished workpiece performs the grinding-polishing operation always under the effect of a certain of constant force, and the grinding-polishing effect of the grinding-polishing device is improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

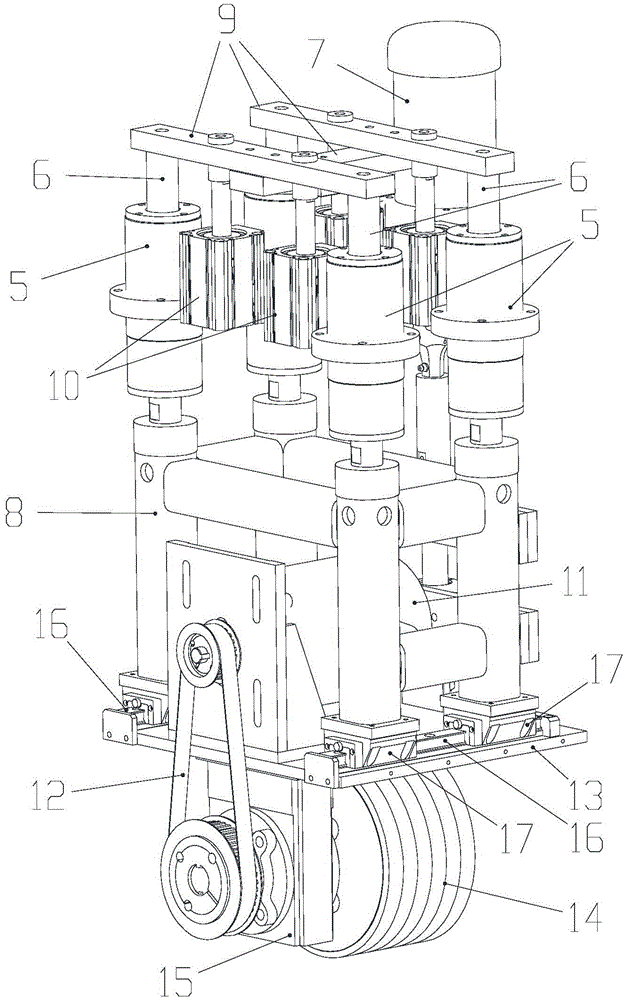

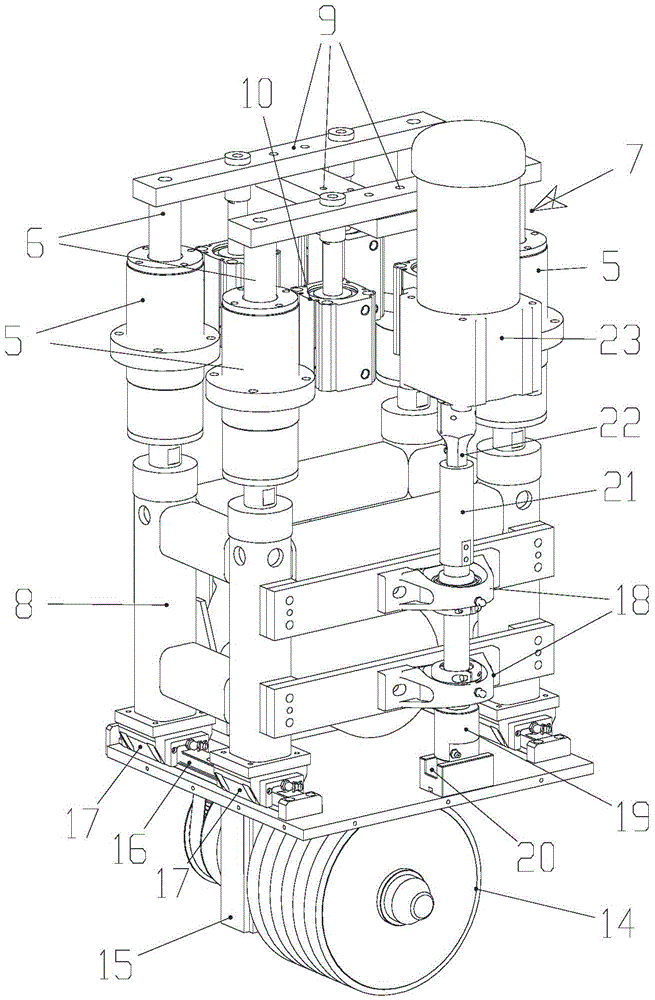

Glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention

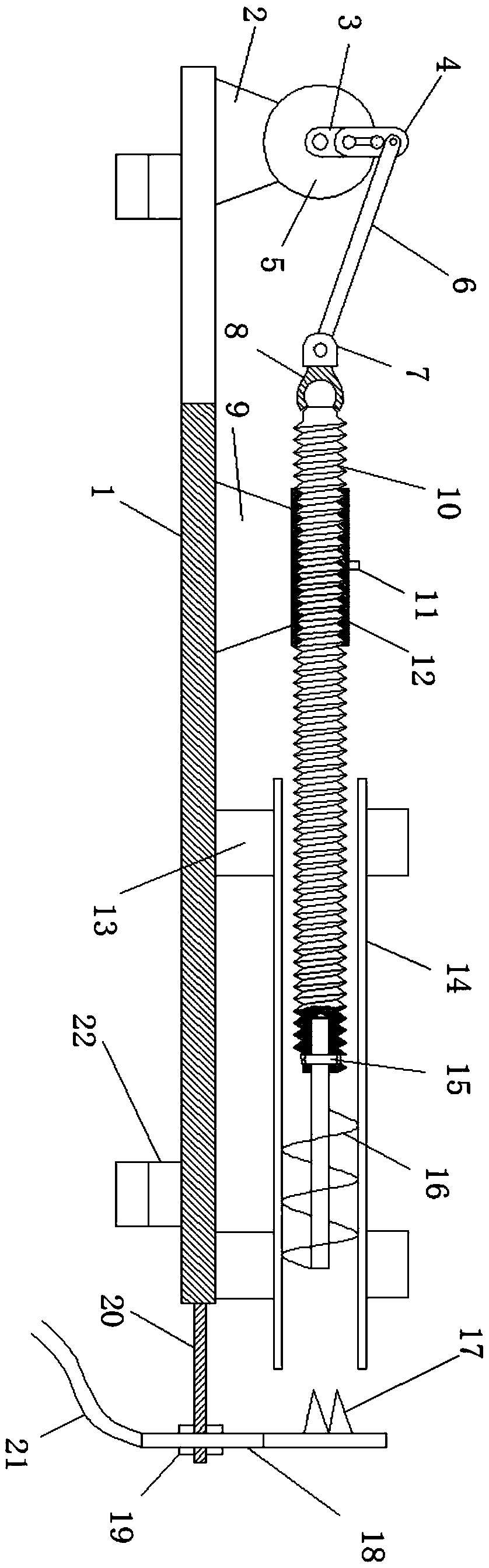

PendingCN107914207AAvoid quality problemsGood orientationGrinding machinesGrinding feedersAutomatic transmissionEngineering

The invention relates to a glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention. The glass plane grinding and polishing machine comprises arack, a swinging mechanism, a power transmission mechanism, a transportation mechanism, a lifting mechanism and a grinding and polishing mechanism, wherein the swinging mechanism is mounted on one side of a rack platform; the other side of the rack platform is connected with the transportation mechanism through an orbit; one side of the transportation mechanism is connected with the swinging mechanism through a connecting rod; a power transmission group is arranged at one end of the transportation mechanism; the lifting mechanism is mounted at the top end of the rack; and the grinding and polishing mechanism is connected to a screw of the lifting mechanism. According to the glass plane grinding and polishing machine capable of achieving automatic transportation and deviation prevention,an assembly line working mode is adopted, a plurality of polishing groups arranged in the machine are mutually independent, up-down displacement of each polishing group can be independently adjusted automatically or manually, the continuous production requirement of a production line is met, production efficiency is improved, and polishing quality and the polishing effect of polished surfaces of crystal ornaments are greatly improved.

Owner:张世鹏

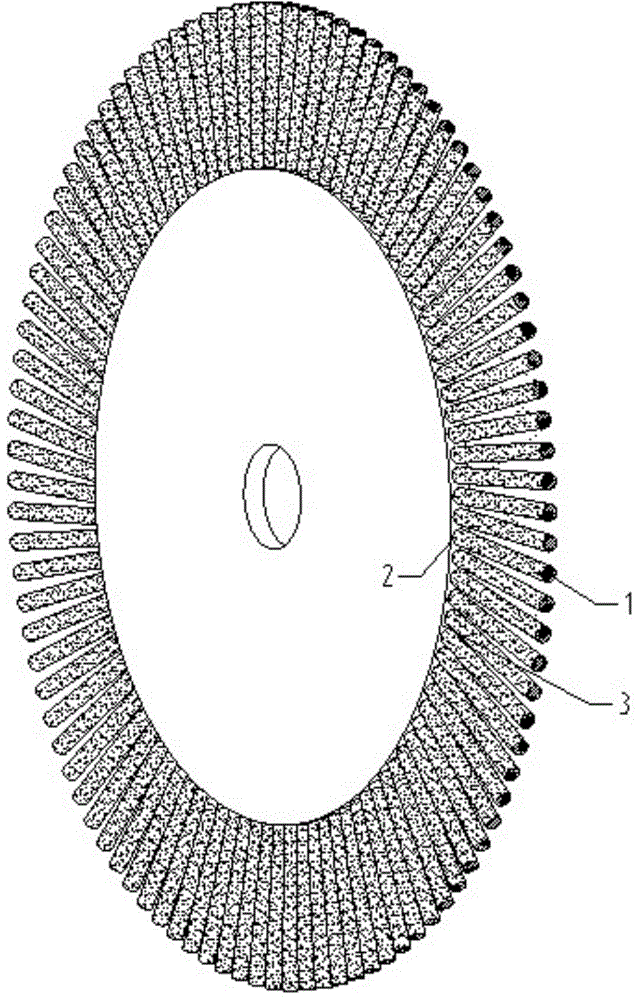

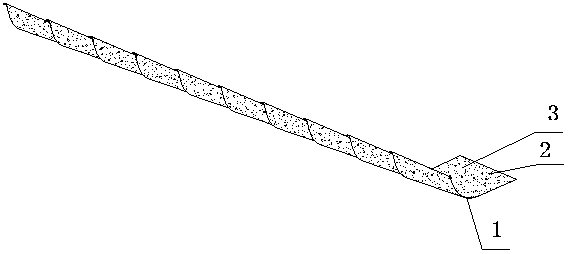

Coated abrasive tool based on fiber substrate sand rope, polishing and grinding wheel and manufacturing method thereof

InactiveCN103846825AImprove performanceImprove grinding and polishing effectFlexible-parts wheelsGrinding devicesFiberPolishing

The invention discloses a coated abrasive tool based on a fiber substrate sand rope. Fiber substrates containing abrasive grinding materials are twisted into a sand rope and are cured for obtaining the coated abrasive tool. The invention also discloses a polishing and grinding wheel manufactured by the coated abrasive tool based on the fiber substrate sand rope (or fiber substrate sand rope containing chopped fiber). The coated abrasive tool and the polishing and grinding wheel provided by the invention have the advantages that the three-dimension structure and the controllable degree in the processing process are sufficiently utilized for realizing the respective correspondence of different use environment and conditions, so the performance of the adhesive grounding materials and the fiber is sufficiently realized, the polishing and grinding performance is improved, and the use cost is reduced.

Owner:谢泽

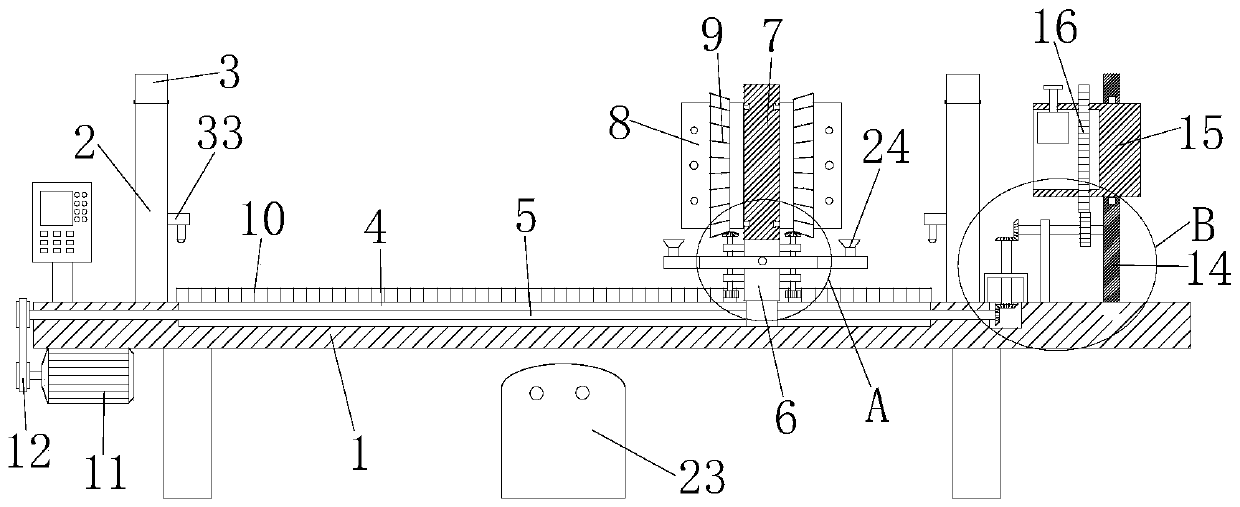

Production process and equipment for sanitary stainless steel pipe

ActiveCN113275408AUniform processing pressureImprove polishing efficiencyPolishing machinesGrinding drivesPolishingSS - Stainless steel

The invention discloses a production process for a sanitary stainless steel pipe and in-pipe polishing equipment. The process and the equipment solve the problems that a sanitary stainless steel inner wall is obvious in polishing mark, fluid flowing through the stainless steel inner wall is easy to stay in the polishing mark, and the sanitary requirement is influenced. The production process includes the steps of (1) molding and welding; (2) solution annealing; (3) sizing and straightening; (4) stain removing; (5) polishing; (6) pickling; (7) passivating; (8) coating; and (9) warehousing. According to the production process for the sanitary stainless steel pipe and the in-pipe polishing equipment, the inner surface and the outer surface of the produced stainless steel pipe are each provided with three different protective films, so that the stainless steel pipe can be prevented from rusting when encountering chemical substances in the ocean climate, and electrochemical corrosion is avoided; and the inner wall of the stainless steel pipe is provided with a silver film with the nanoscale thickness, so that germs in liquid can be removed, and the sanitation level of the stainless steel pipe is improved.

Owner:温州国乐不锈钢管业有限公司

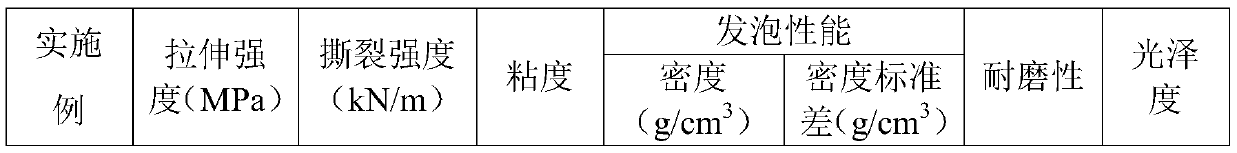

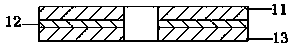

Soft grinding and polishing disk

ActiveCN103465153ANot easy to produceImprove the excellent rateLapping toolsMetallurgyUltimate tensile strength

The invention relates to a soft grinding and polishing disk. The soft grinding and polishing disk at least comprises a grinding layer and a strengthening layer; the grinding layer is made of soft metal; the strengthening layer is made of materials and the intensity and the melting point of the materials are both higher than those of the grinding layer so as to avoid deformation of the grinding layer in the machining process; one side of the strengthening layer is provided with a reverse layer; the thickness of the reverse layer is equal to that of the grinding layer; the reverse layer is also made of low melting point and intensity soft metal. The soft grinding and polishing disk has the advantages of being simple in structure, being capable of solving the problem of the deformation during grinding, meanwhile avoiding adhesive dust during the grinding, improving the machining accuracy and efficiency and being quite practical.

Owner:NANTONG CHUNGUANG AUTOMATIC CONTROL EQUIP ENG

Inner surface polishing machine for stainless steel pipe production

ActiveCN114473826AEffective polishingEasy to handlePolishing machinesGrinding drivesPolishingEngineering

The inner surface polishing machine for stainless steel pipe production comprises a base, a mounting plate and a stainless steel pipe fixedly mounted at the top of the mounting plate, the top of the base is slidably connected with a mounting platform, and a mounting groove is formed in the top of the mounting platform; and an operation mechanism used for grinding and polishing the interior of the stainless steel pipe is arranged at the top of the mounting platform, the operation mechanism comprises a bearing seat, a mounting rod is rotationally connected to the inner wall of the bearing seat, the mounting rod and the stainless steel pipe are coaxially arranged, and a polishing head is fixedly connected to the outer wall, close to the supporting legs, of the mounting rod. Through cooperation of the structures, the inner walls of pipelines with different lengths can be polished and ground, scraps generated by polishing can be pushed and cleaned, and polishing and grinding can be matched with spraying of a polishing agent.

Owner:山东科耐特管业有限公司

Non-stick pan forming processing equipment

ActiveCN111331450AImprove stabilityIncrease contact areaGrinding carriagesRevolution surface grinding machinesNon-stick surfaceMaterials science

The invention relates to the field of non-stick pan processing. Non-stick pan forming processing equipment comprises a rotating mechanism and a grinding and polishing mechanism. The rotating mechanismcomprises a bottom plate, a rotating device, a pan pressing device and a pan jacking device. The rotating device comprises a rotating motor, a driving belt wheel, a driven belt wheel, a bearing shaft, a supporting base and a pan placing clamp. The pan pressing device is used for pressing a non-stick pan on the pan placing clamp. The pan jacking device controls the rotating device to move up and down through a pan jacking air cylinder. The grinding and polishing mechanism comprises a support, a horizontal moving device, a grinding and polishing device and a lifting device. The grinding and polishing device comprises a cross beam, a grinding and polishing motor, a short side plate, a long side plate, a fine adjustment air cylinder and a grinding wheel. The lifting device is connected to thelower portion of the cross beam and used for adjusting the height of the cross beam. The non-stick pan forming processing equipment has the advantages that the fine adjustment air cylinder adjusts the angle of the short side plate and the angle of the long side plate, the position of the grinding wheel is changed, the grinding wheel can carry out more comprehensive grinding and polishing operation on the non-stick pan, and an encoder can effectively control the rotating speed of the grinding wheel and improve the grinding and polishing effect.

Owner:胡海明

A kind of internal combustion engine bearing bush processing equipment and processing method thereof

ActiveCN108356648BImprove grinding and polishing effectImprove grinding and polishing efficiencyRevolution surface grinding machinesGrinding work supportsRotational axisEngineering

The invention discloses an internal combustion machine bearing bush machining device, and relates to the technical field of internal combustion machine bearing bush production equipment. The device comprises a bottom plate, the top of the bottom plate is fixedly connected with a box body, one side of the top of the box body is fixedly connected with a transmission box, the bottom of the inner wallof the box body is rotatably connected with a rotating shaft through a bearing pedestal, the top end of the rotating shaft sequentially penetrates the box body and the transmission box and extends into the transmission box, and the rotating shaft extends into the outer surface inside the transmission box and is rotatably connected with the top of the inner wall of the transmission box through a bearing. According to the internal combustion machine bearing bush machining device and the machining method thereof, the grinding and polishing effect is greatly improved, the grinding and polishing efficiency is well improved, a person does not need to waste a large amount of time for grinding and polishing a bearing bush, work burdens of the person are well reduced, work efficiency of the personis improved, the inner surface and the outer surface of the bearing bush can be rapidly and efficiently ground and polished at the same time, and grinding machining of the bearing bush by the personis greatly facilitated.

Owner:湖北安达精密工业有限公司

Precious stone polishing machine

InactiveCN104999363ASmooth rotationSave electricityEdge grinding machinesPolishing machinesEngineeringEnergy consumption

The invention discloses a precious stone polishing machine and relates to the technical field of precious stone machining. The precious stone polishing machine comprises a roller arranged transversely; a concave base is arranged below the roller; the upper end face of the concave base is concaved; the roller and the concave base are electromagnets; the directions of the electromagnetic poles of the roller and the concave base are opposite; multiple protrusions are arranged on the inner wall of the roller and are long-strip-shaped protrusions; an opening is formed in one end of the roller. Compared with the prior art, the problems that an existing precious stone polishing machine is poor in polishing effect and large in energy consumption can be solved.

Owner:LIUZHOU XUPING JEWELRY

Method for characterizing microstructure evolution of bonding area of IGBT (Insulated Gate Bipolar Translator) chip

ActiveCN114371184ASelf-removalReduce roughnessMaterial analysis using wave/particle radiationEpoxyIon beam

The invention discloses an IGBT chip bonding area microstructure evolution characterization method. The method comprises the following steps: S1, obtaining a sample: preprocessing an IGBT module to obtain the sample; s2, preparing a sample to be etched: mounting the sample on an automatic grinding and polishing clamp, and then grinding the sample to obtain the sample to be etched; and S3, obtaining an etched sample to be characterized: determining a target area of the etched sample to be characterized. According to the invention, the method of etching the bonding area by using the focused ion beam is adopted for sample preparation, so that the EBSD acquisition efficiency is improved, the EBSD image without drift stretching is obtained, and the microstructure of the bonding area is effectively represented; meanwhile, the problems of signal drifting, image distortion and the like caused by the fact that epoxy resin is not conductive and exposed metal parts in devices are reduced in a traditional sample preparation method are solved. In addition, the automatic grinding and polishing clamp is arranged to fix the sample, and the surface flatness and the surface neatness effect of the ground and polished sample are improved.

Owner:BEIJING UNIV OF TECH

Device for grinding inner hole of metal pip

InactiveCN110919480AWon't moveImprove grinding and polishing effectGrinding carriagesRevolution surface grinding machinesPhysicsGrinding

The invention discloses a device for grinding an inner hole of a metal pipe. The device comprises an outer shell in which a displacement cavity is formed. A helical gear cavity is formed above the displacement cavity. A belt pulley cavity is formed in the right side of the helical gear cavity. A transmission cavity is formed in the right side of the belt pulley cavity. A motor is fixedly mounted in the upper end wall of the helical gear cavity. A first shaft is arranged below the motor in a power connection manner. The first shaft is rotationally mounted between the helical gear cavity and thedisplacement cavity. The device has a good grinding and polishing effect. A work piece is not moved, and clamping vibration errors cannot be generated. The grinding tool can rotate around itself andaround an inner hole of a metal pipe and slowly move forwards at the same time to achieve an automatic grinding effect. The operation is simple, and the labor cost is greatly saved.

Owner:PUJIANG SIHONG MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com