Method for characterizing microstructure evolution of bonding area of IGBT (Insulated Gate Bipolar Translator) chip

A technology of microstructure evolution and chip bonding, which is used in instruments, measuring devices, scientific instruments, etc. to improve efficiency, reduce roughness, and avoid signal drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

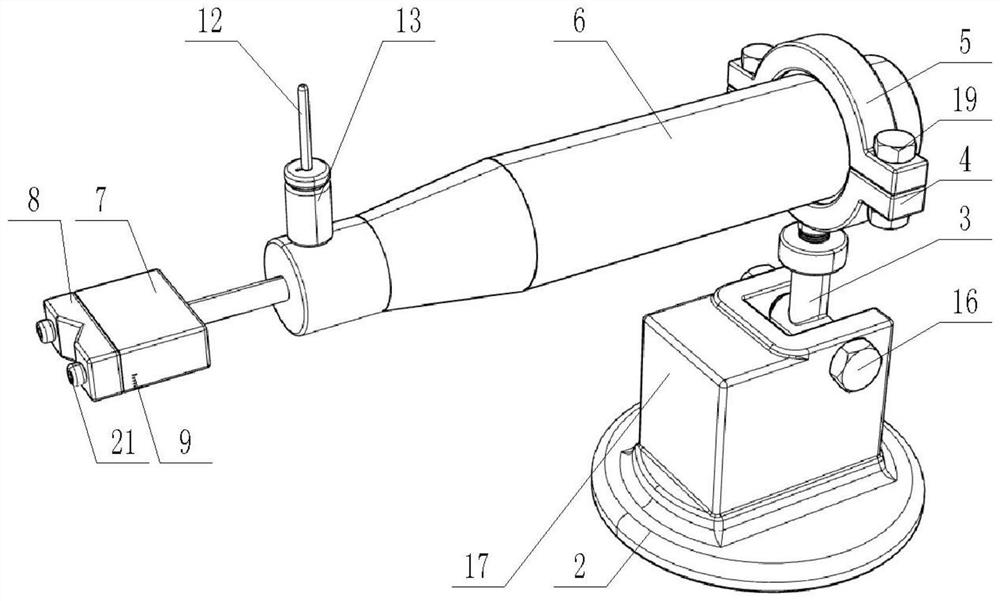

[0042] The invention provides a method for characterizing the microstructure evolution of the IGBT chip bonding region,

[0043] S1. Obtaining samples: preprocessing the IGBT module to obtain samples. Disassemble the existing IGBT module, and process the IGBT module, remove the structure on the IGBT module that is not related to the test, and perform surface treatment on the IGBT module to facilitate the next operation step.

[0044] In a specific embodiment of the present invention, the model of the IGBT module is BOG450H12E2, the power level is 1200V / 450A, and the chip size is 150mm×60mm×17mm.

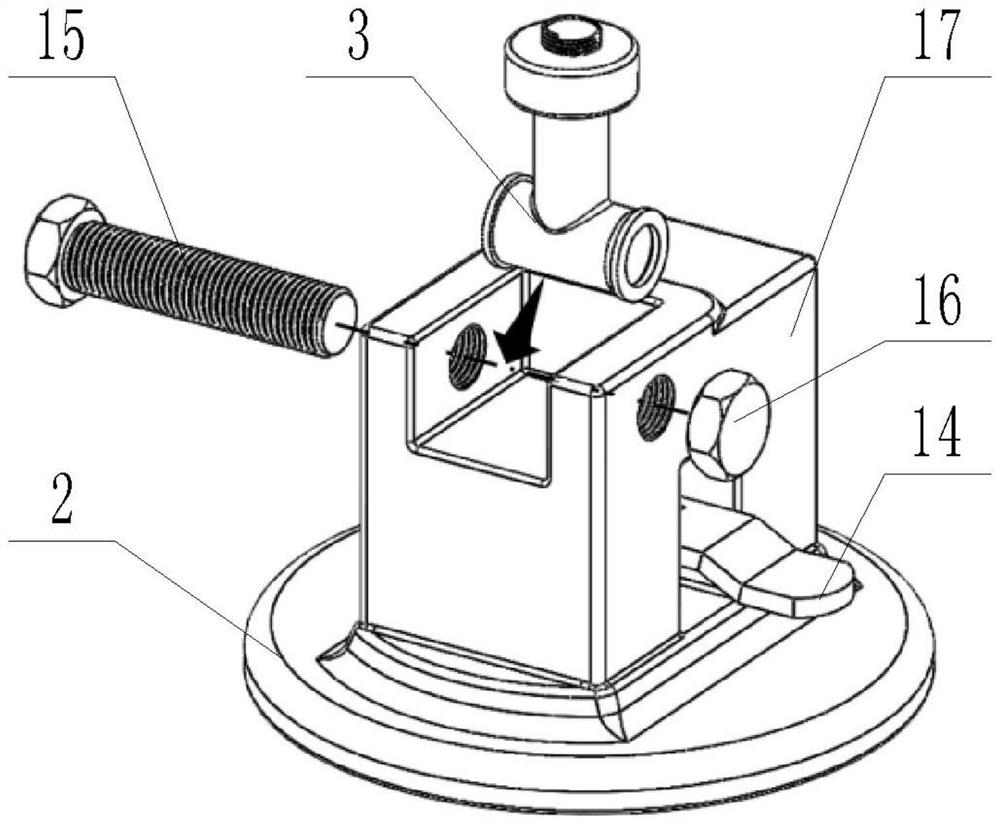

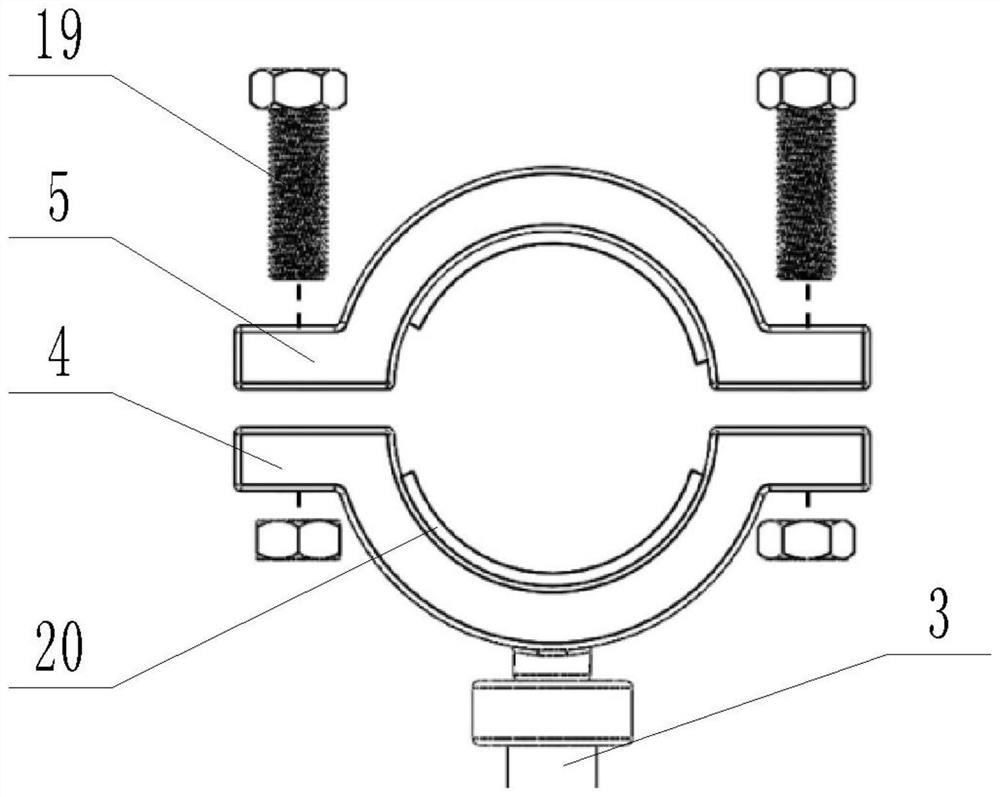

[0045]S2. Obtaining the sample to be etched: the sample is installed on the automatic grinding and polishing fixture, and then the sample is polished to obtain the sample to be etched. Adjust the automatic grinding and polishing fixture, fix the sample on the automatic grinding and polishing fixture, so that the sample is inclined relative to the grinding and polishing plane, and by...

Embodiment 2

[0086] The difference between this example and Example 1 is that in step S2, the clamping method of the sample on the automatic grinding and polishing fixture is different, and in this example, the damage morphology is characterized, and the surface roughness does not need to meet the requirements of EBSD acquisition. Therefore, the polishing process can be omitted, and the fine grinding process can be added. The implementation steps include:

[0087] Obtain slice images of the sample to be characterized after etching: Slice the target area of the sample to be characterized after etching, and obtain SEM images of all slices of the sample to be characterized after etching. After the fine grinding process is completed, the focused ion beam is used to continuously trim the target area of the etched sample to be characterized, and at the same time, use SEM to detect each section after each slice.

[0088] Wherein, the thickness of each slice is preferably set to 50 nm, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com