Polishing buffing device for machine manufacturing

A polishing device and mechanical manufacturing technology, applied in the direction of grinding/polishing equipment, manufacturing tools, surface polishing machine tools, etc., can solve problems such as not being suitable for large-scale production, affecting the effect of grinding and polishing, and difficult to control the strength, etc., to achieve High grinding efficiency, good effect, enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

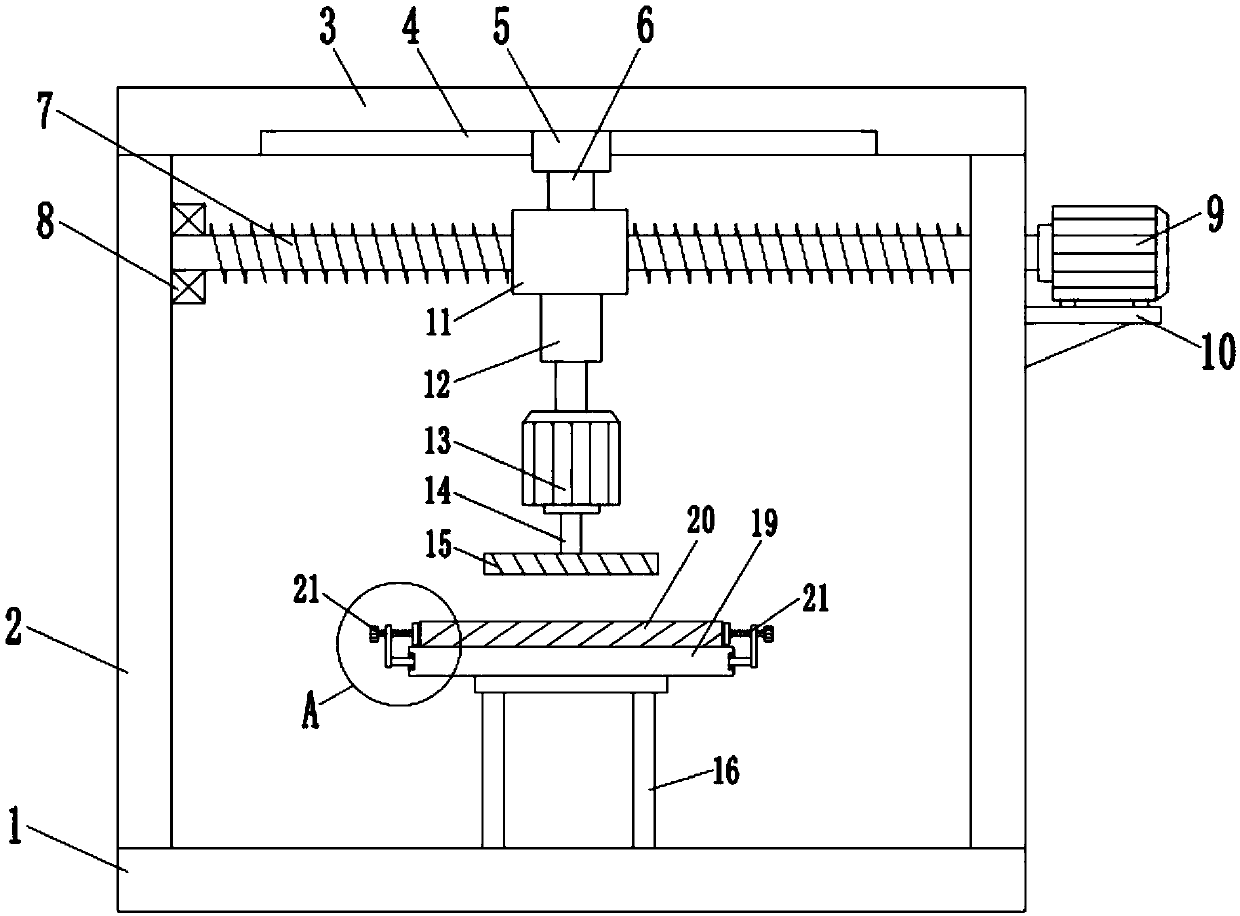

[0022] See Figure 1~3 In the embodiment of the present invention, a grinding and polishing device for machine manufacturing includes a bottom plate 1, a side plate 2 and a top plate 3. Both sides of the bottom plate 1 are vertically fixed with a side plate 2, and two side plates 2 A top plate 3 is fixedly connected to the top, the top plate 3 is provided with a sliding groove 4, a first sliding block 5 is slidably installed in the sliding groove 4, and a screw rod 7 is horizontally arranged under the top plate 3, and one end of the screw rod 7 passes The bearing seat 8 is rotatably connected to a side plate 2. The other end of the screw rod 7 passes through the other side plate 2 and is connected to the output end of the first motor 9, and the first motor 9 is installed on the side of the side plate 2 through a bracket 10 , The screw rod 7 is provided with a second slider 11, a connecting piece 6 is fixedly connected between the second slider 11 and the first slider 5, and the...

Embodiment 2

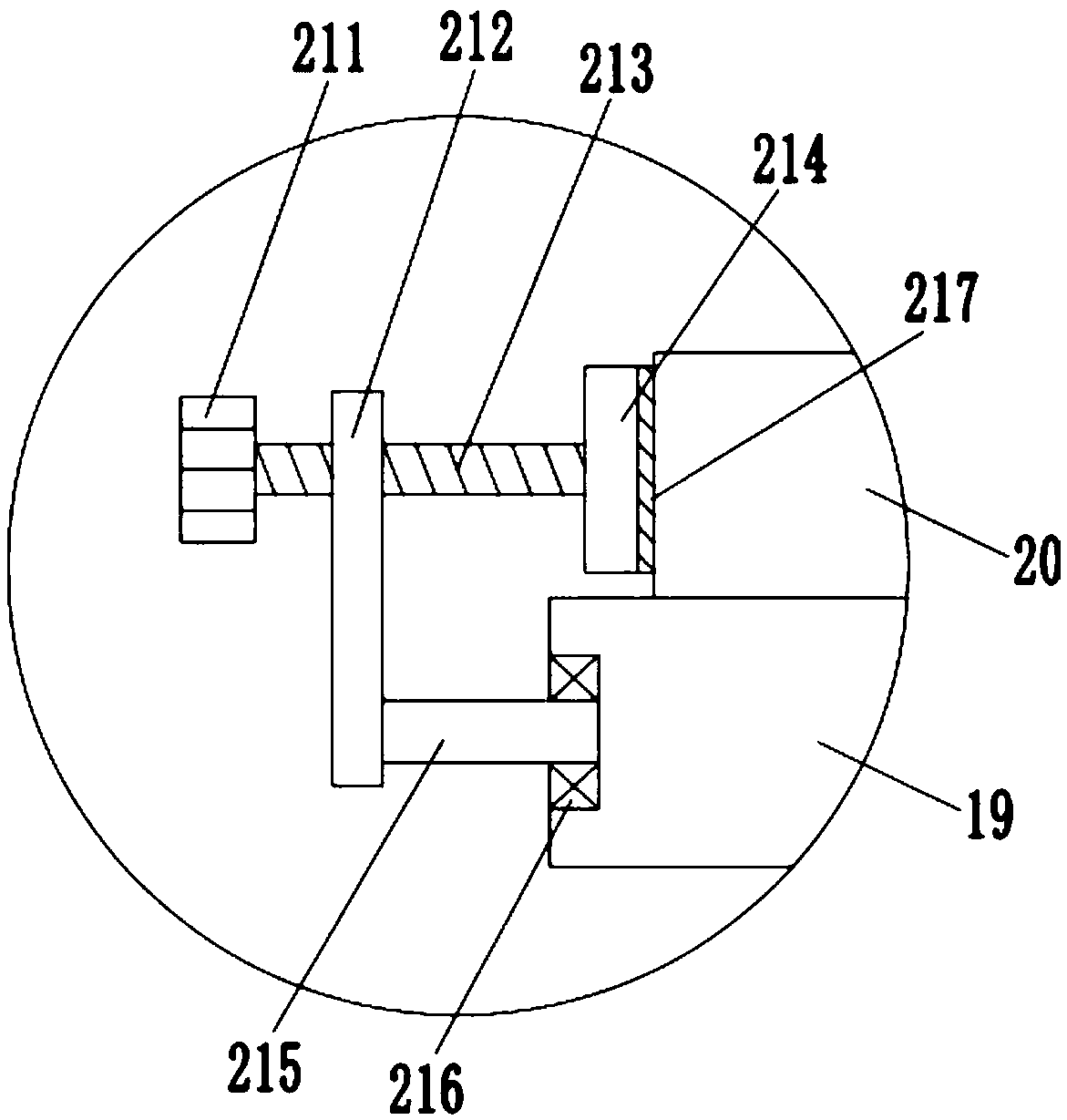

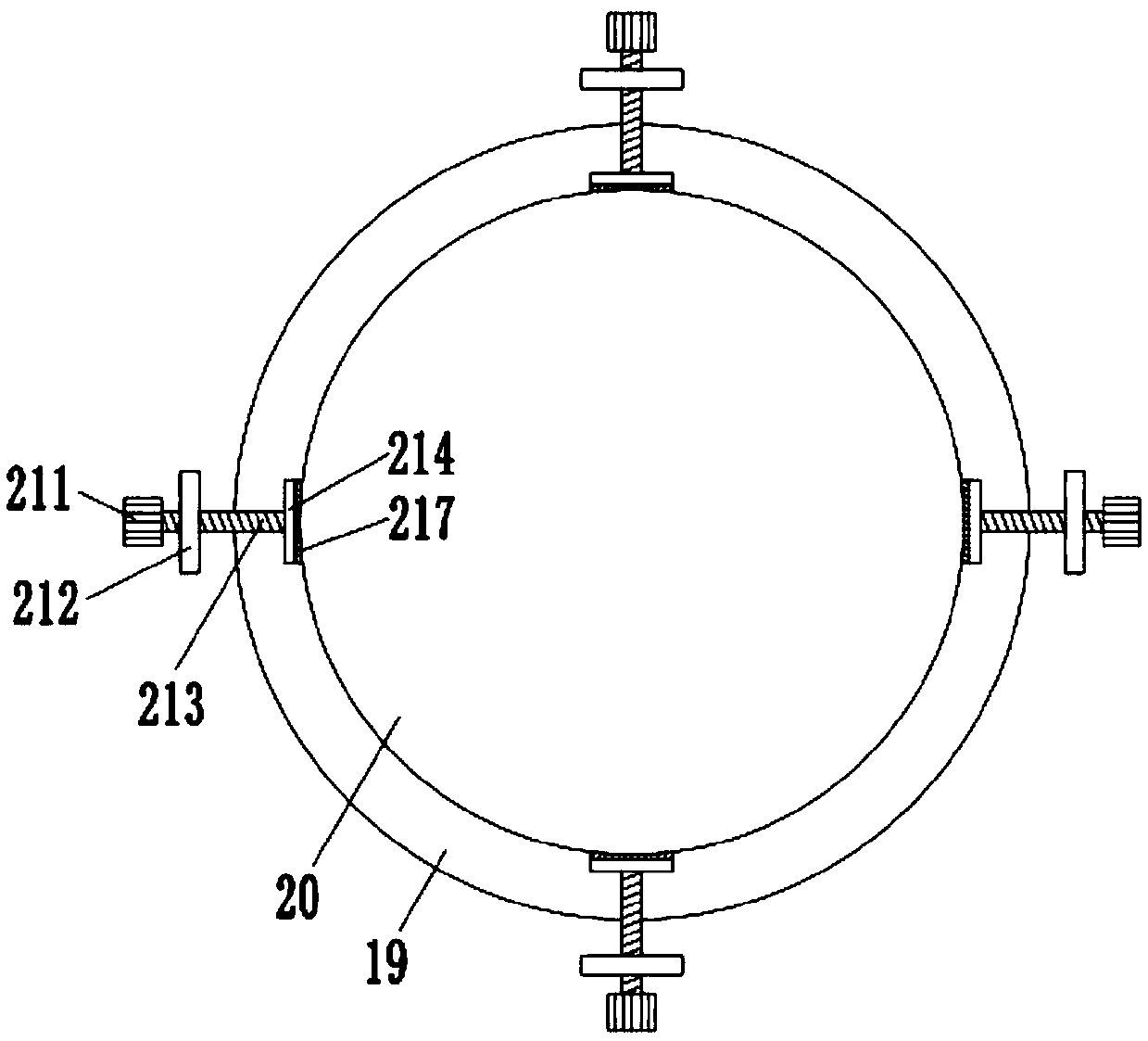

[0028] See Figure 1~3 This embodiment is mainly a further upgrade of the clamping device 21 on the basis of the first embodiment, that is, the clamping device 21 includes a knob 211, a vertical plate 212, a screw 213, a pressure plate 214 and a connecting rod 215, and the connection The rod 215 is horizontally connected to the side of the pallet 19, and the end of the connecting rod 215 away from the pallet 19 is connected to a vertically arranged vertical plate 212. The vertical plate 212 passes through a threaded screw 213. Both ends of the screw 213 The knob 211 and the pressing plate 214 are respectively connected, and the pressing plate 214 is pressed against the side surface of the workpiece 20.

[0029] When the clamping device 21 is used to clamp and fix the workpiece 20, it is only necessary to rotate the screw 213 inward through the knob 211, and the screw 213 drives the pressure plate 214 to move inward until it touches the side of the workpiece 20, thereby realizing ...

Embodiment 3

[0033] See Figure 4 This embodiment is mainly a further upgrade on the basis of the second embodiment, that is, a third motor 17 is added between the support plate 19 and the support plate 16 to enhance the polishing effect of the workpiece 20. The support plate 19 A third motor 17 is arranged between the support plate 16 and the output end of the third motor 17 is connected with a third rotating shaft 18, and the top end of the third rotating shaft 18 is fixedly connected to the bottom center of the supporting plate 19.

[0034] Further, the third motor 17 is a servo motor.

[0035] Here, by controlling the third motor 17 and the second motor 13 to rotate in opposite directions, the workpiece 20 can be rotated and polished, which effectively enhances the polishing effect and improves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com