Patents

Literature

175results about How to "Guaranteed polishing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

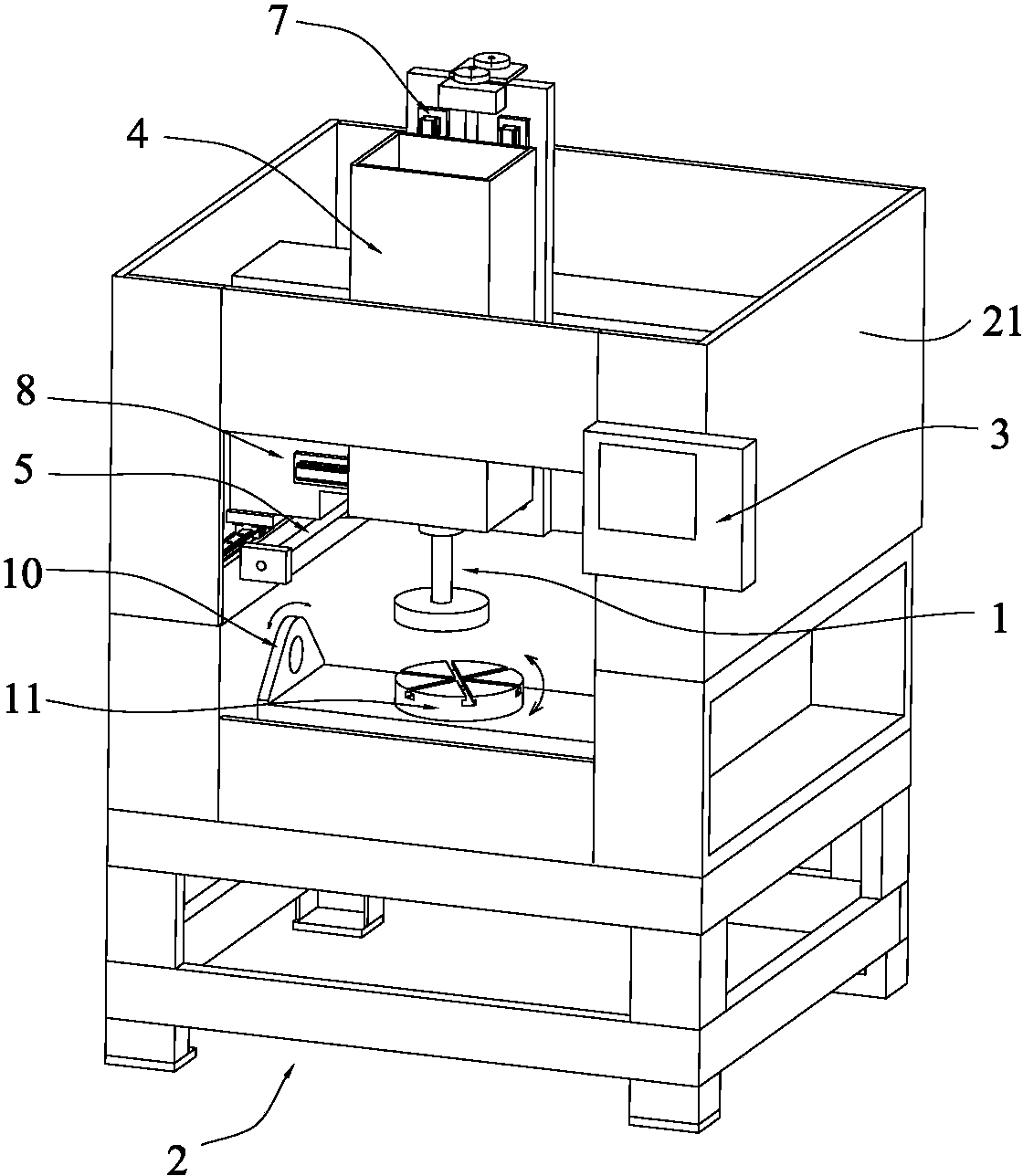

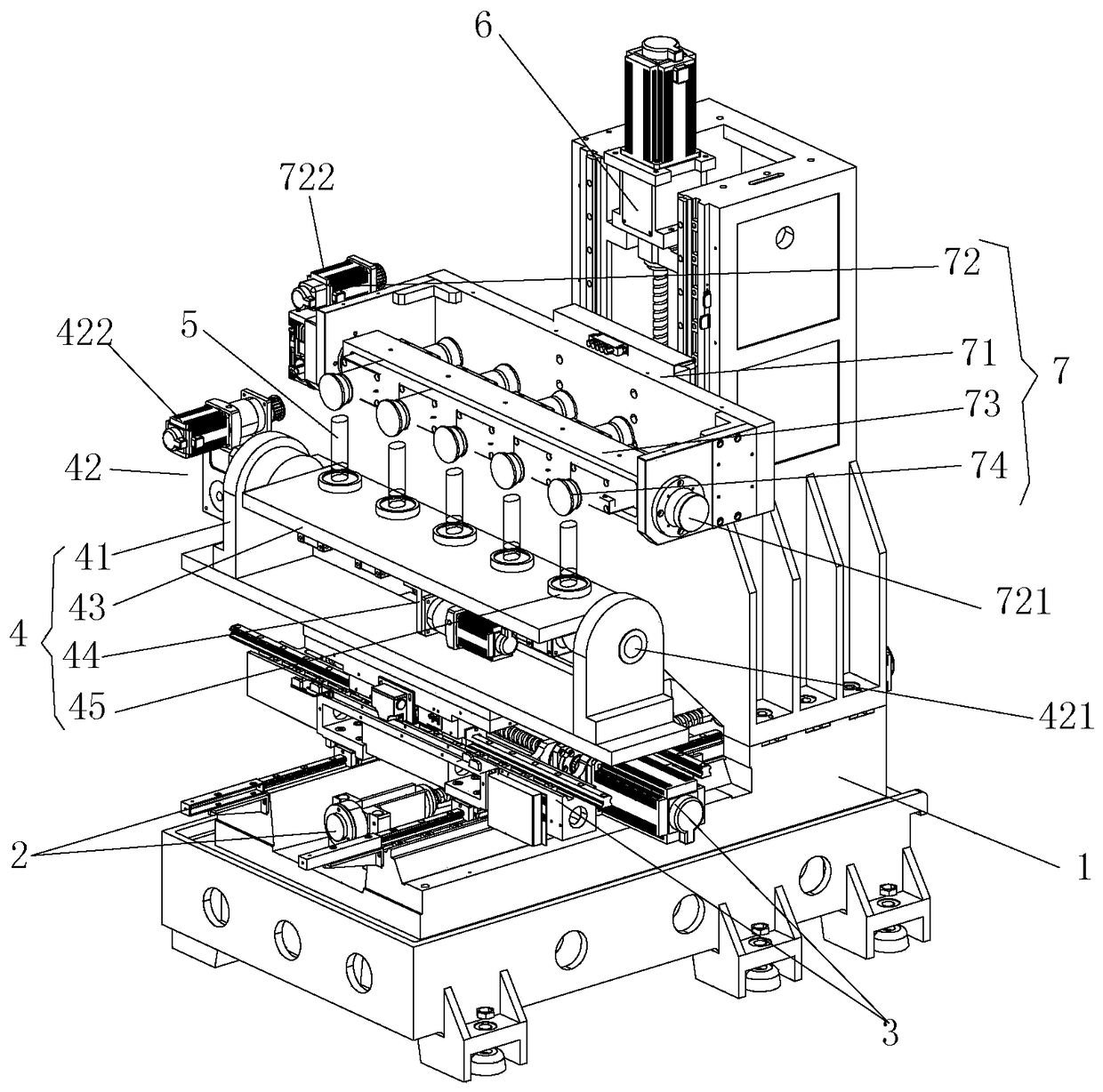

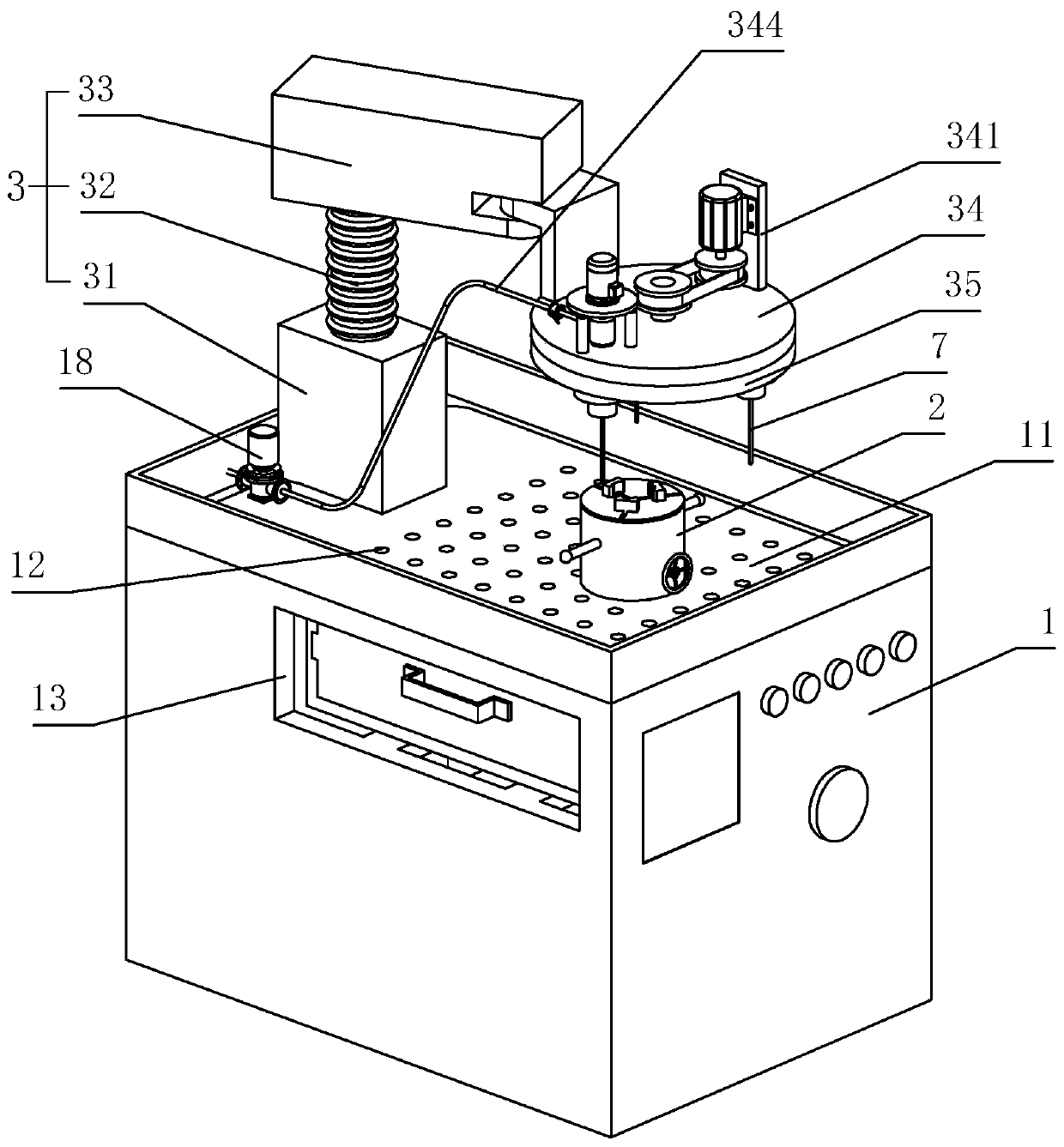

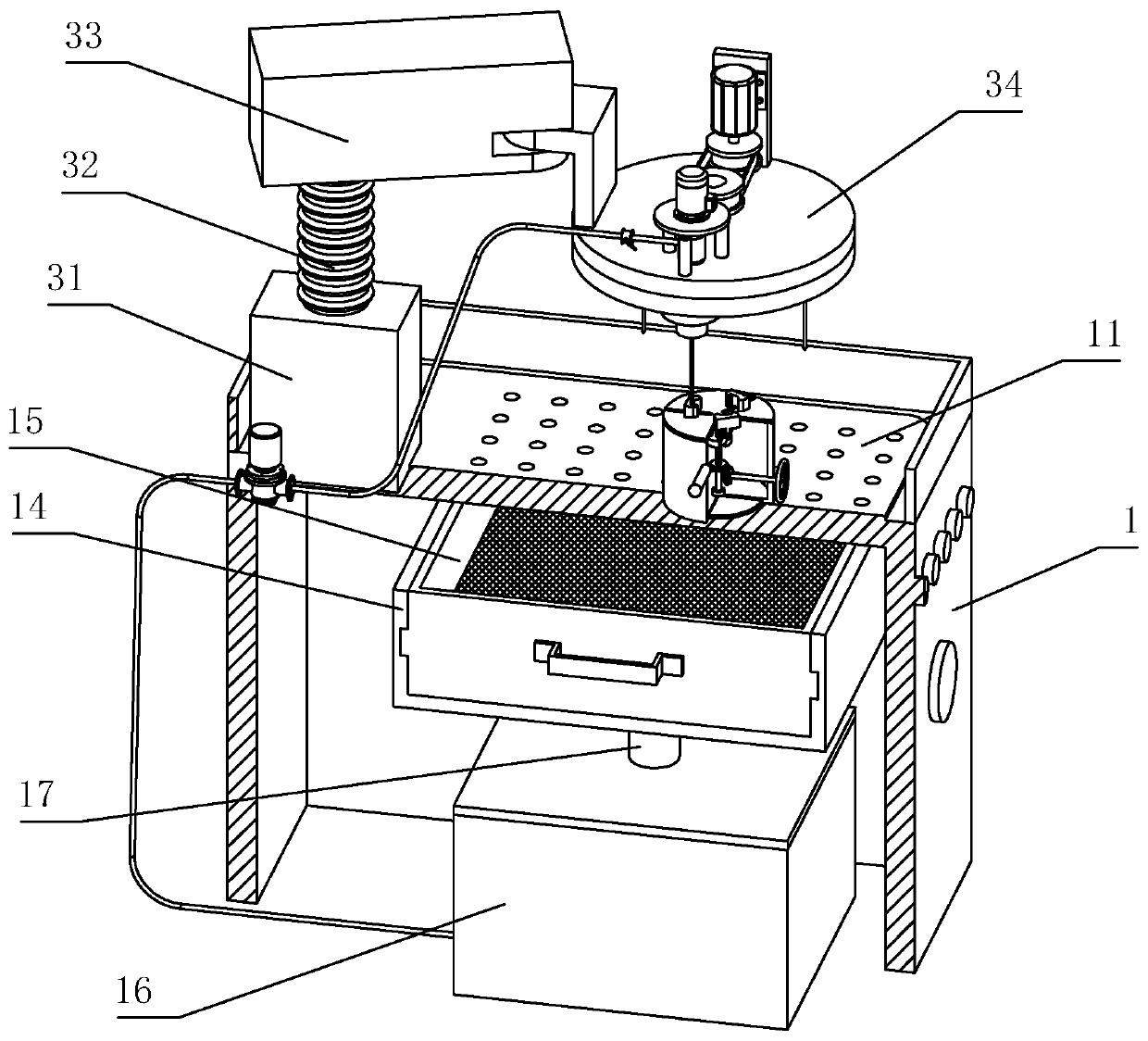

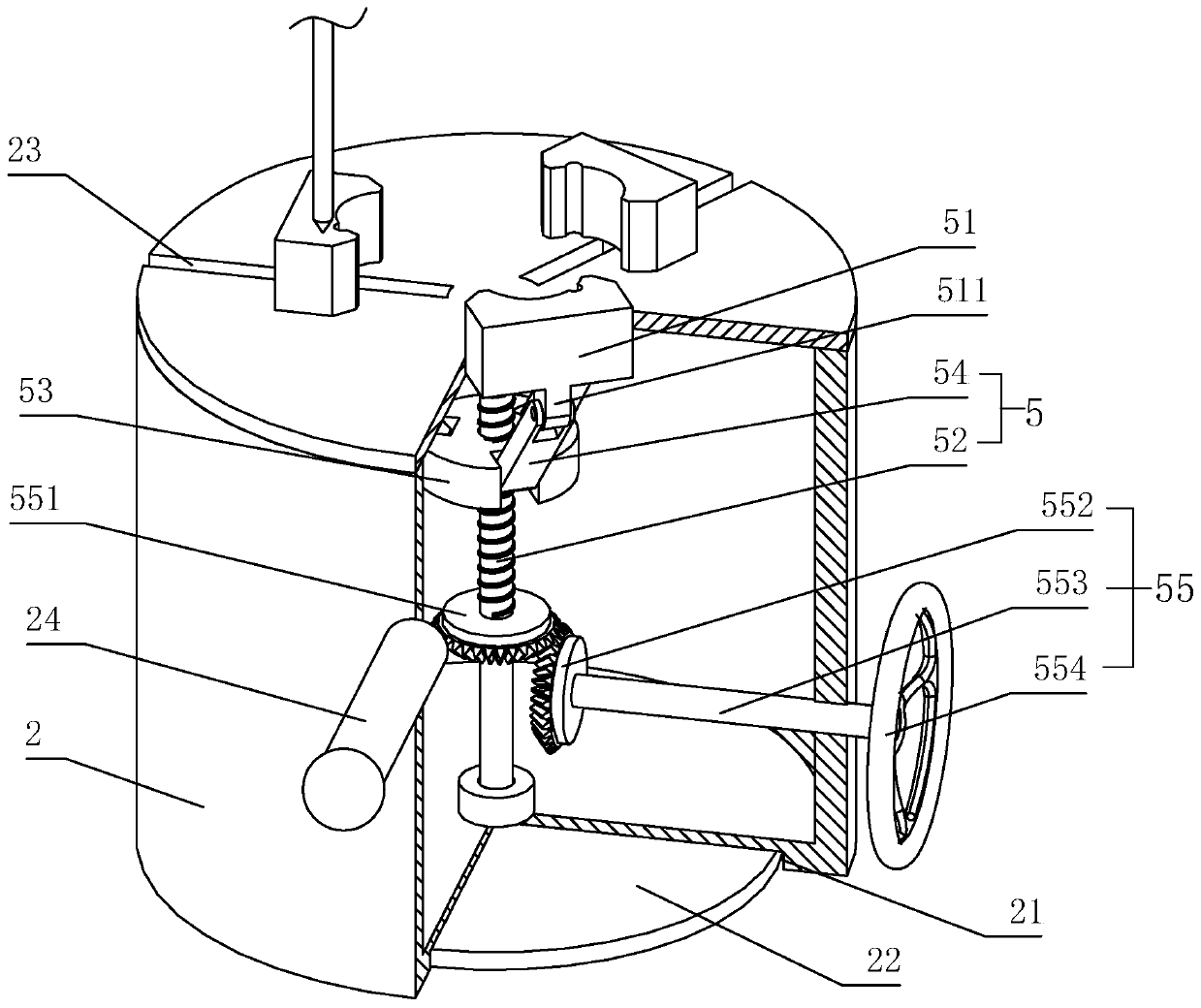

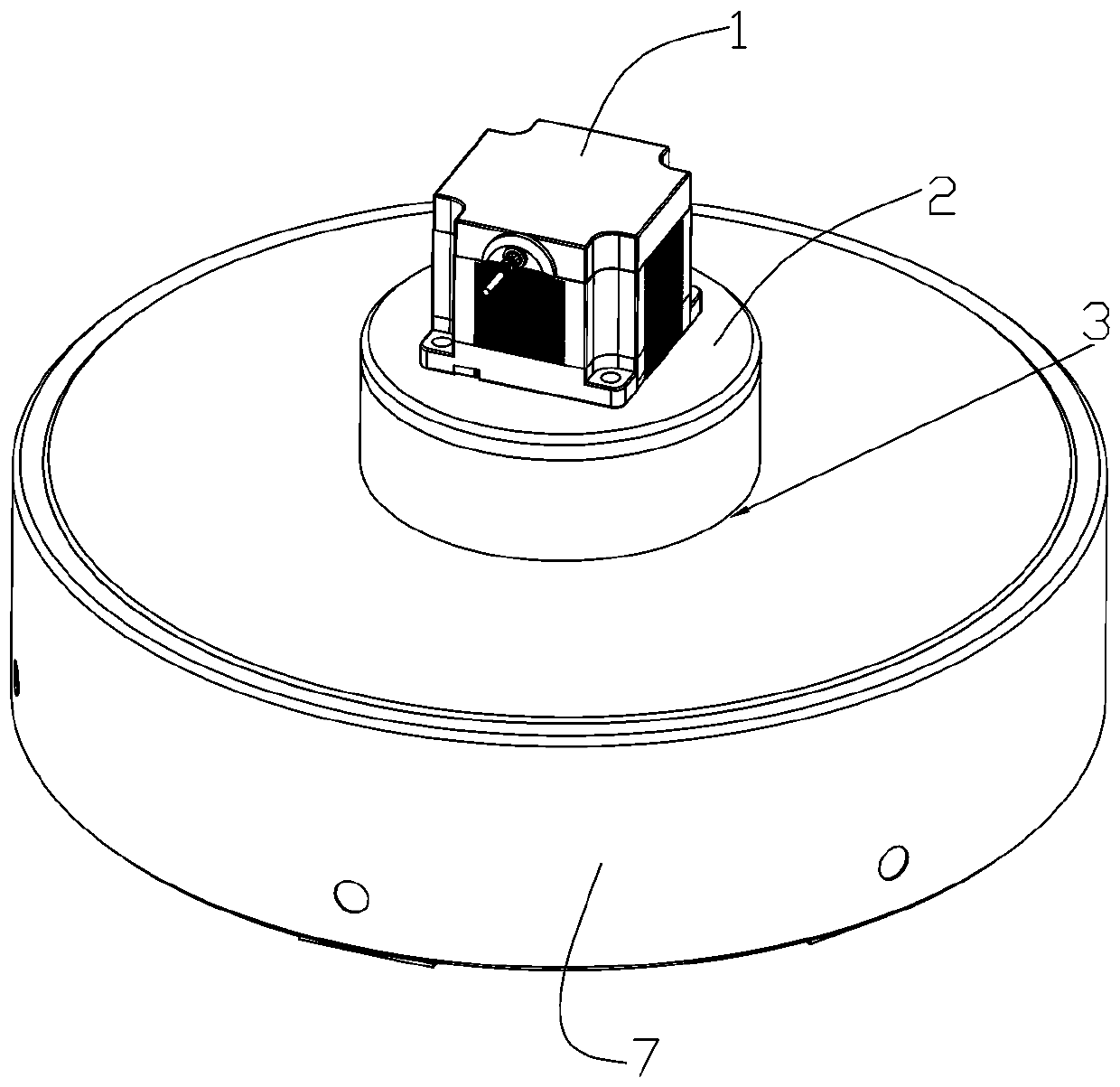

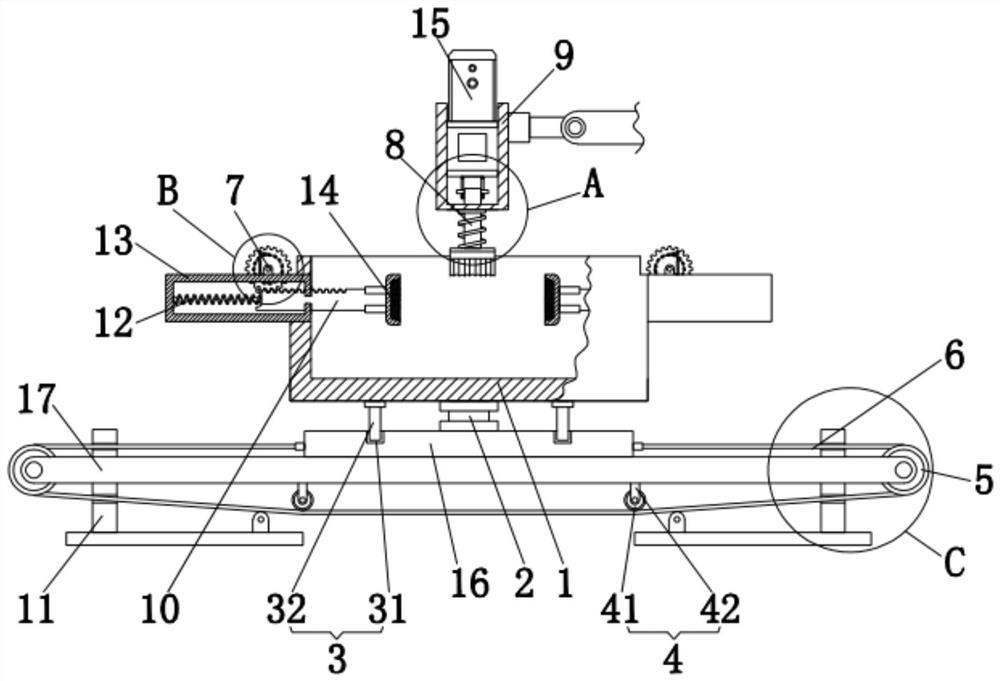

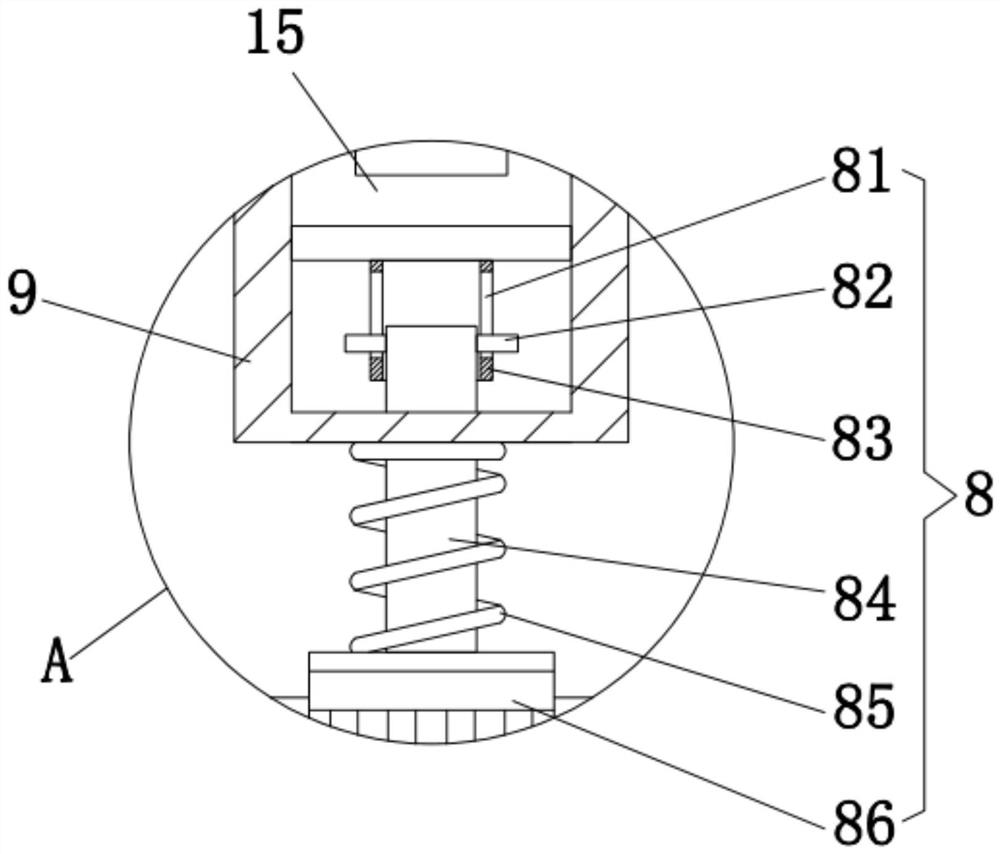

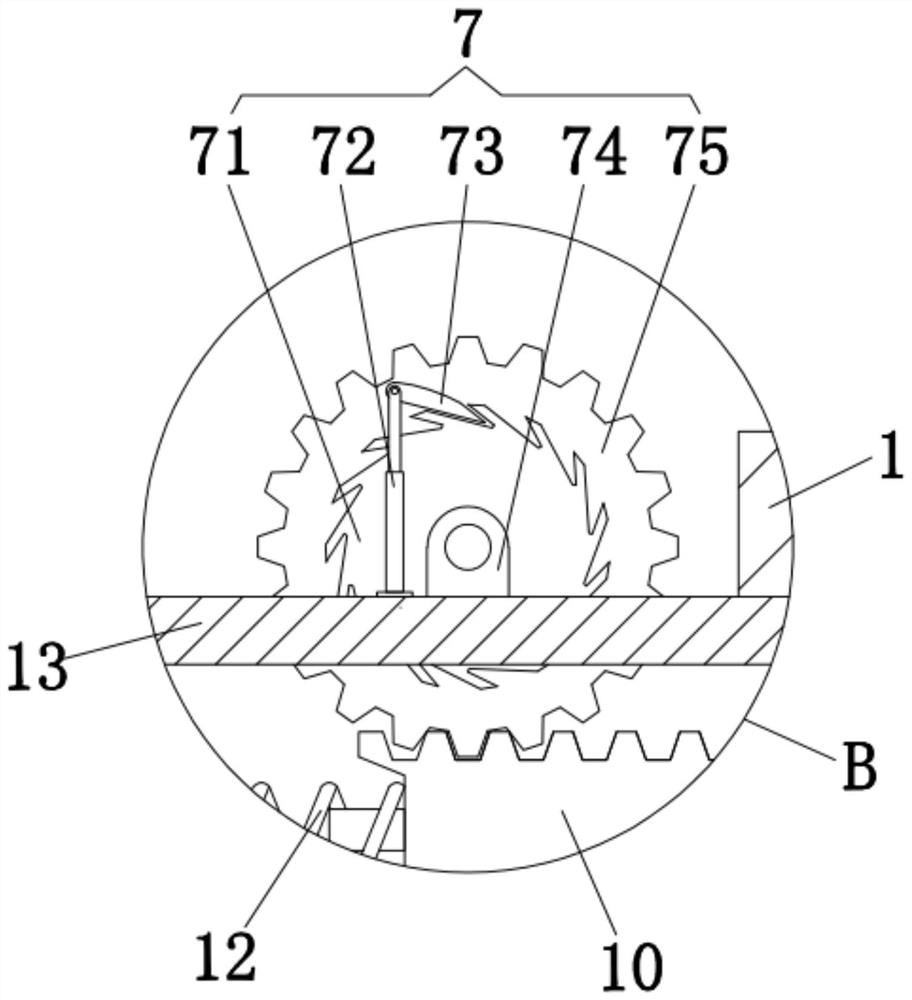

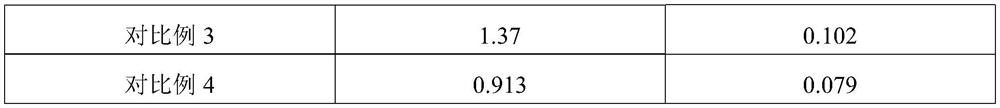

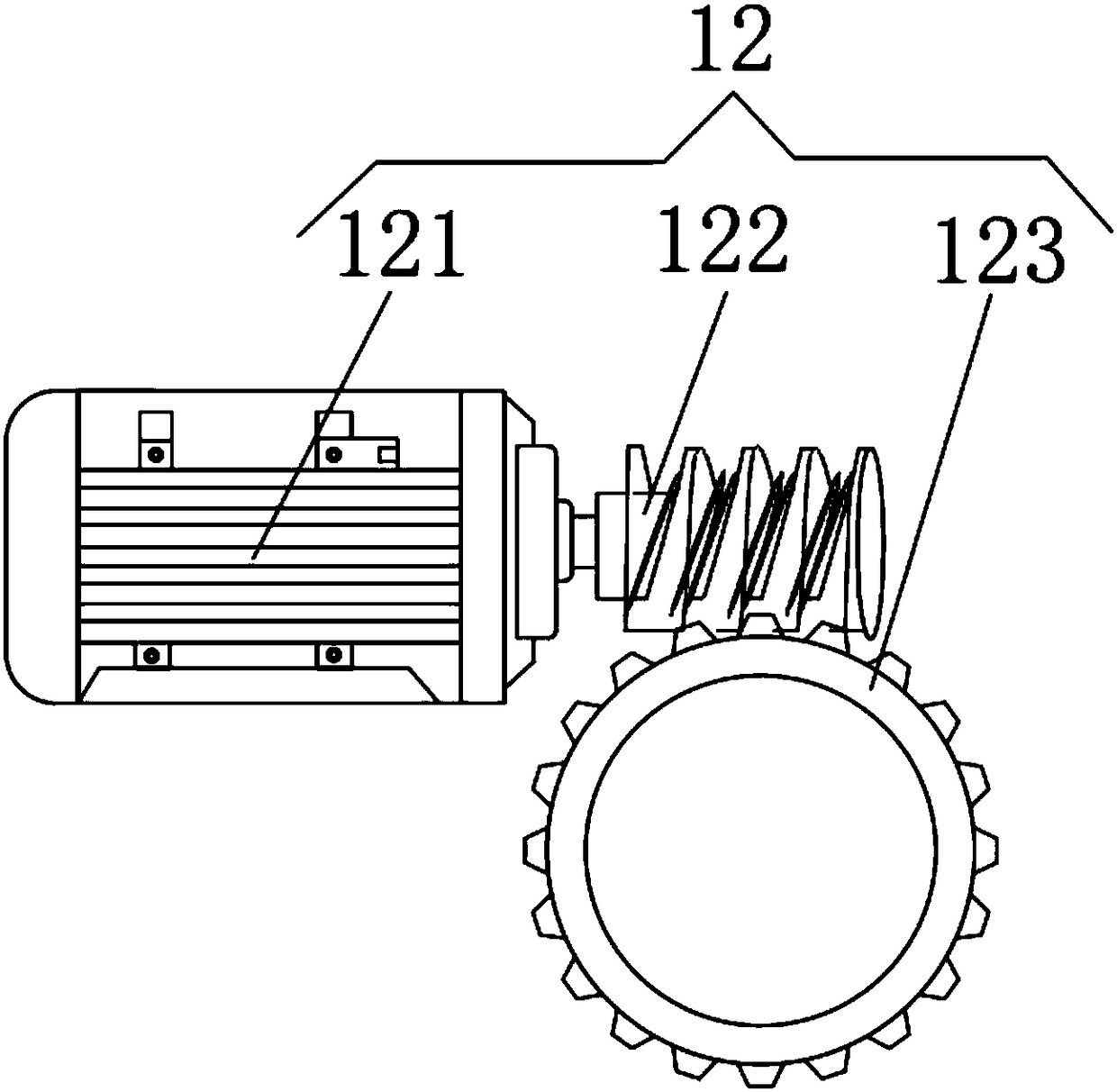

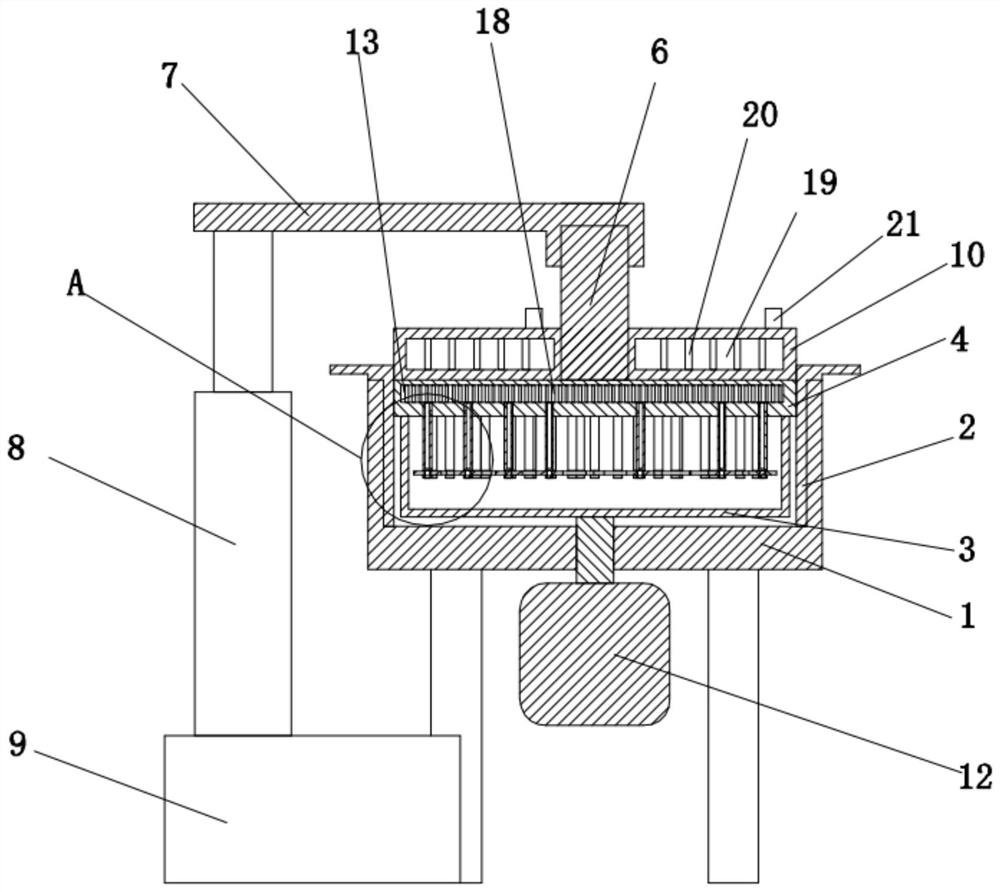

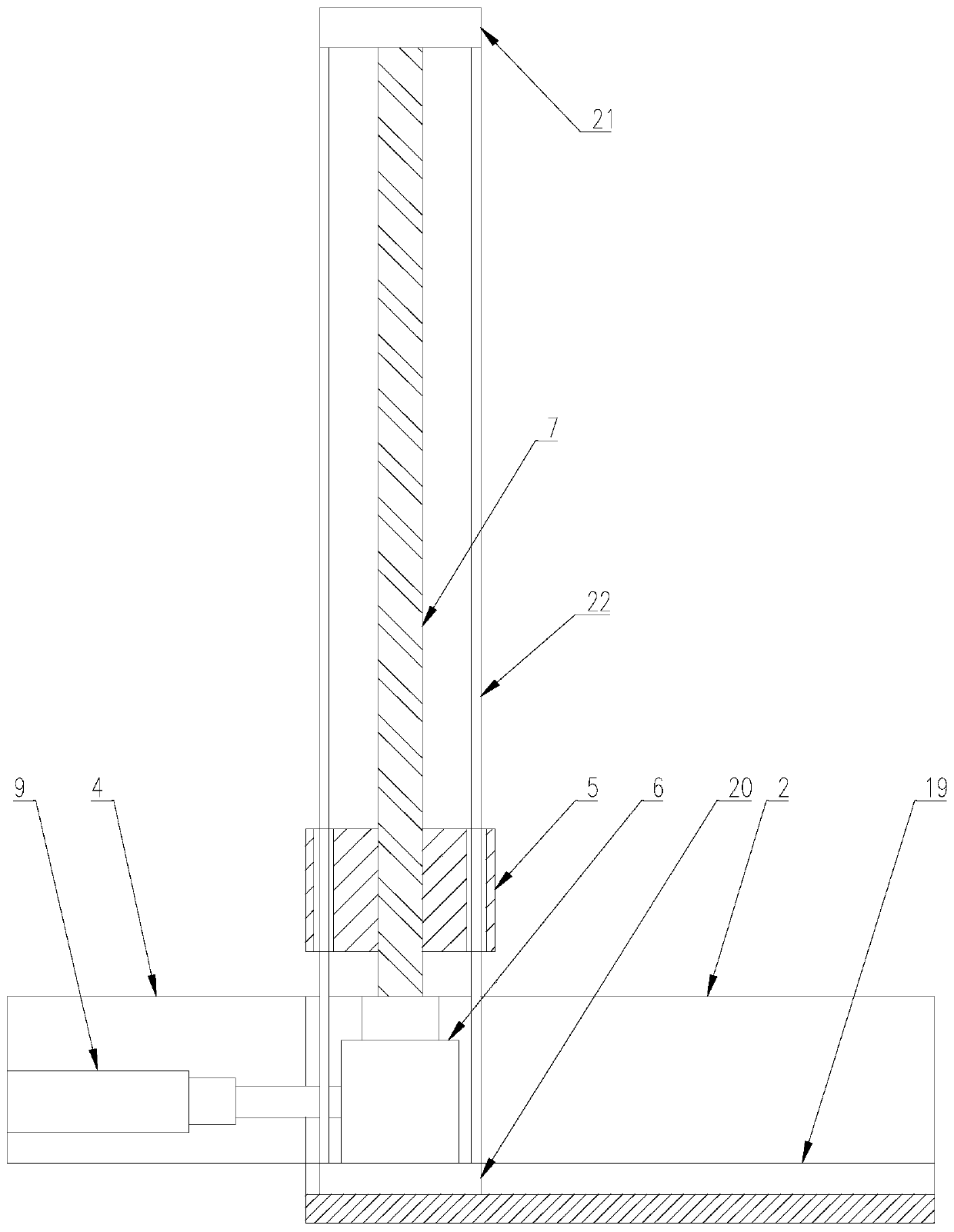

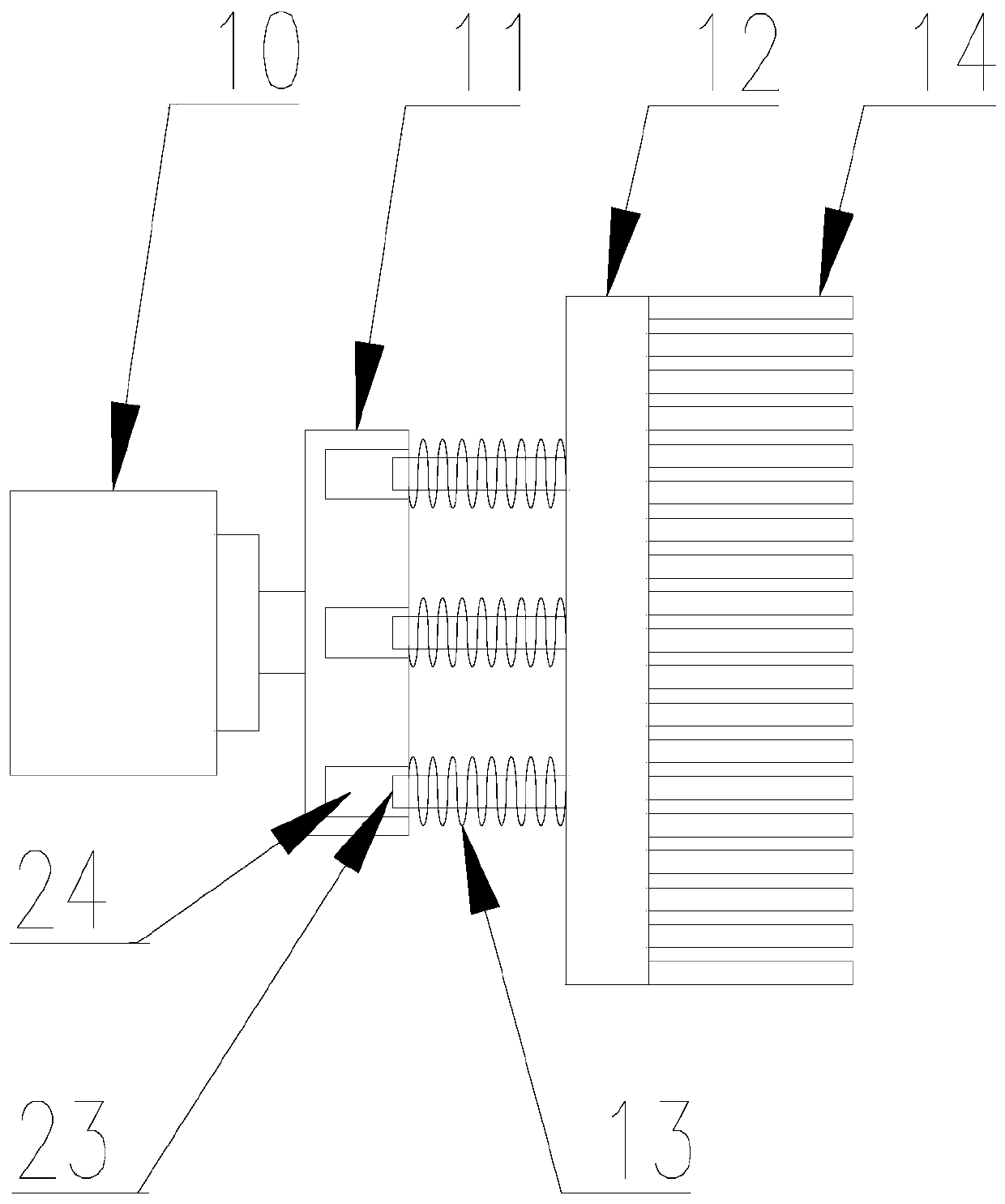

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

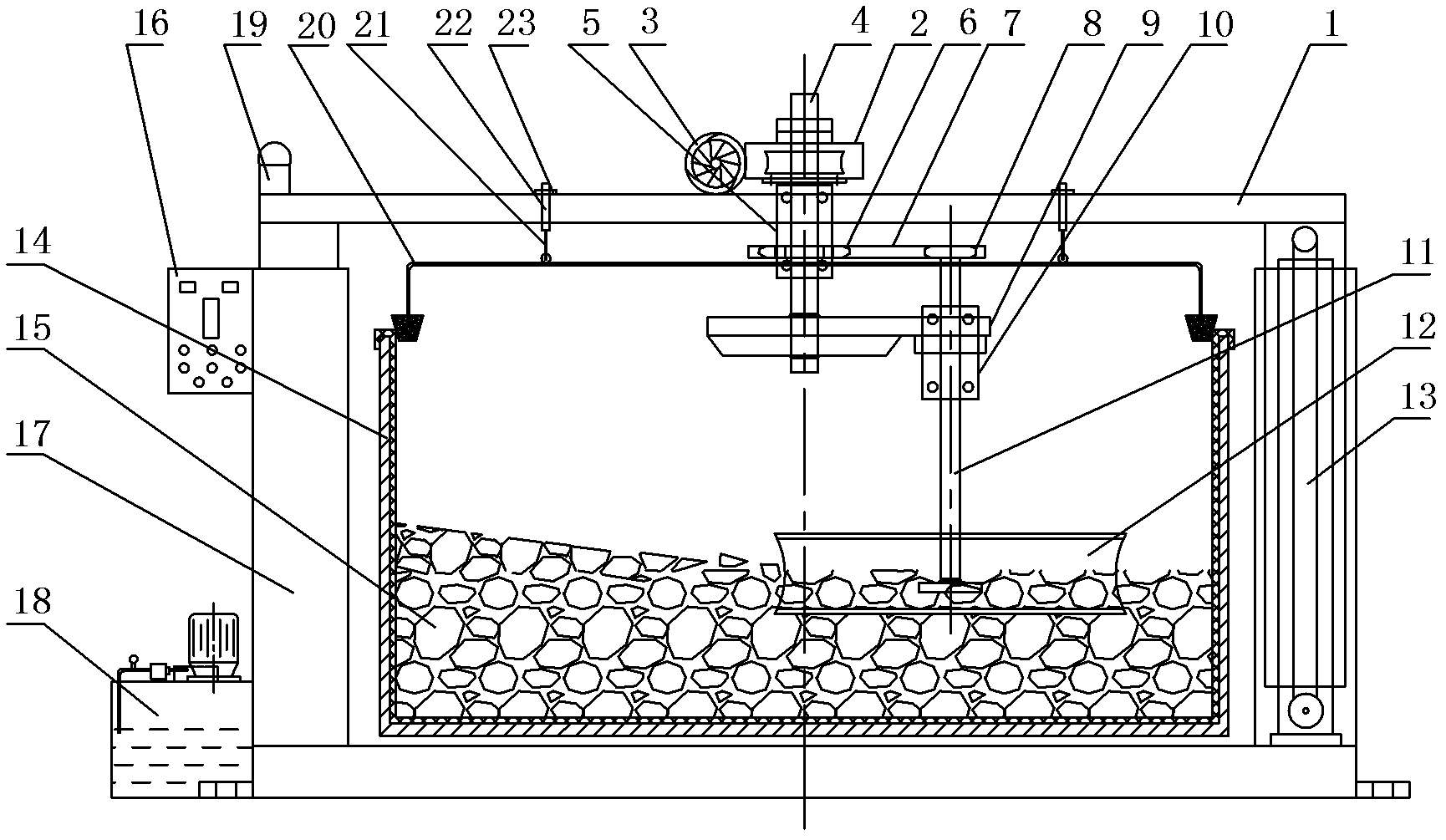

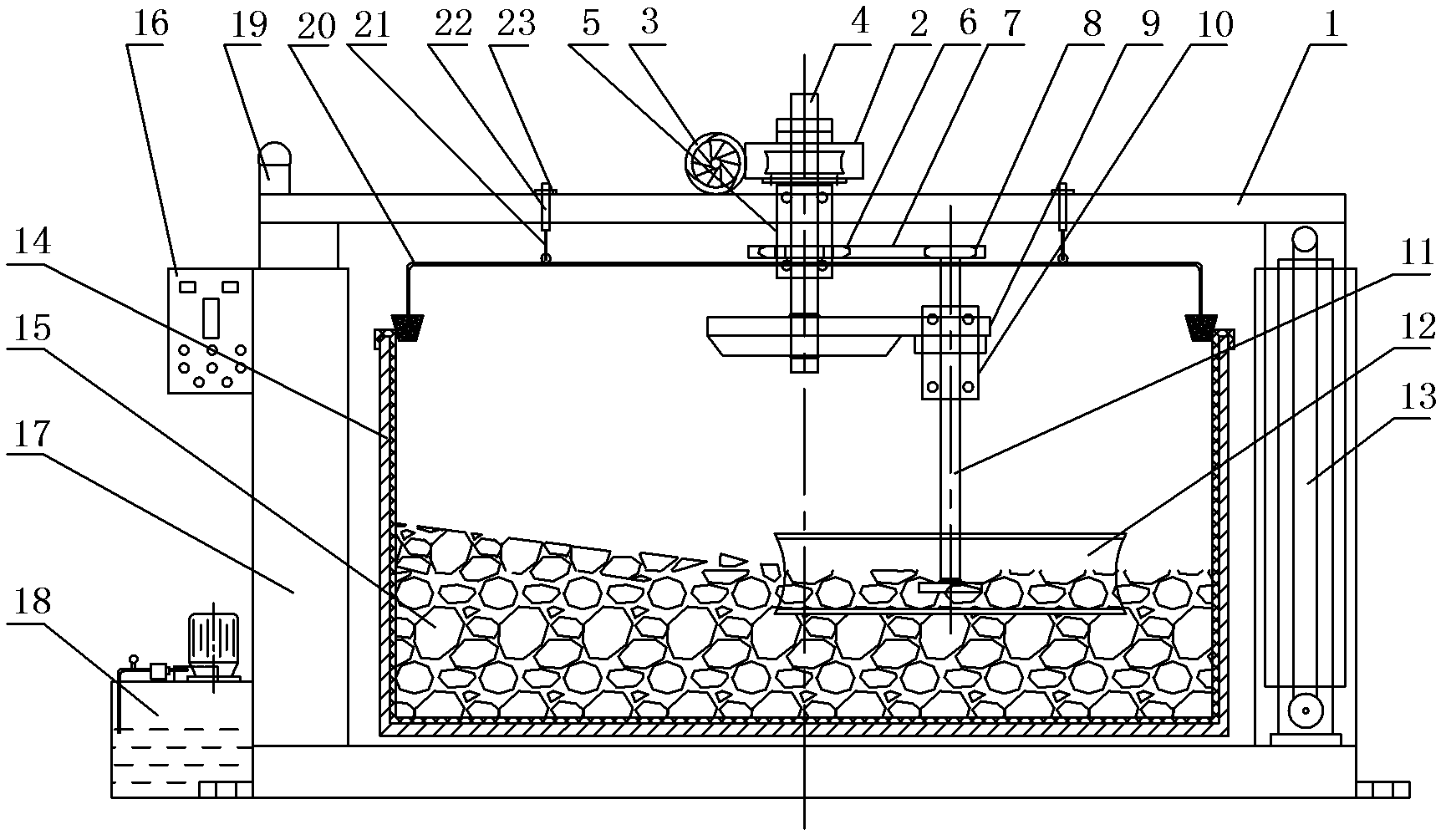

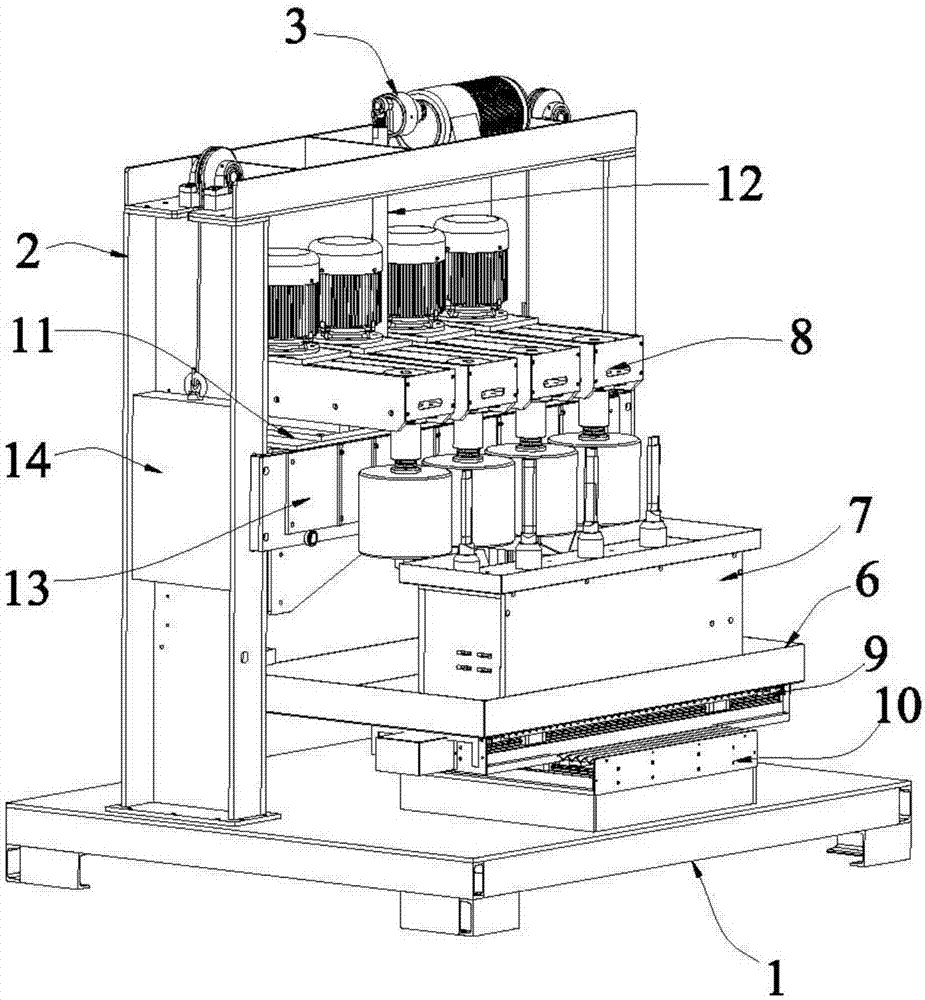

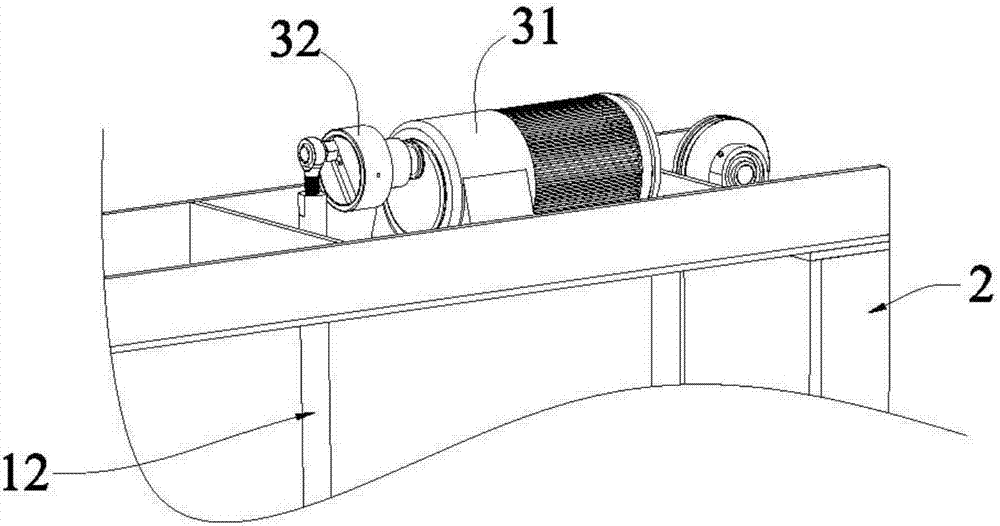

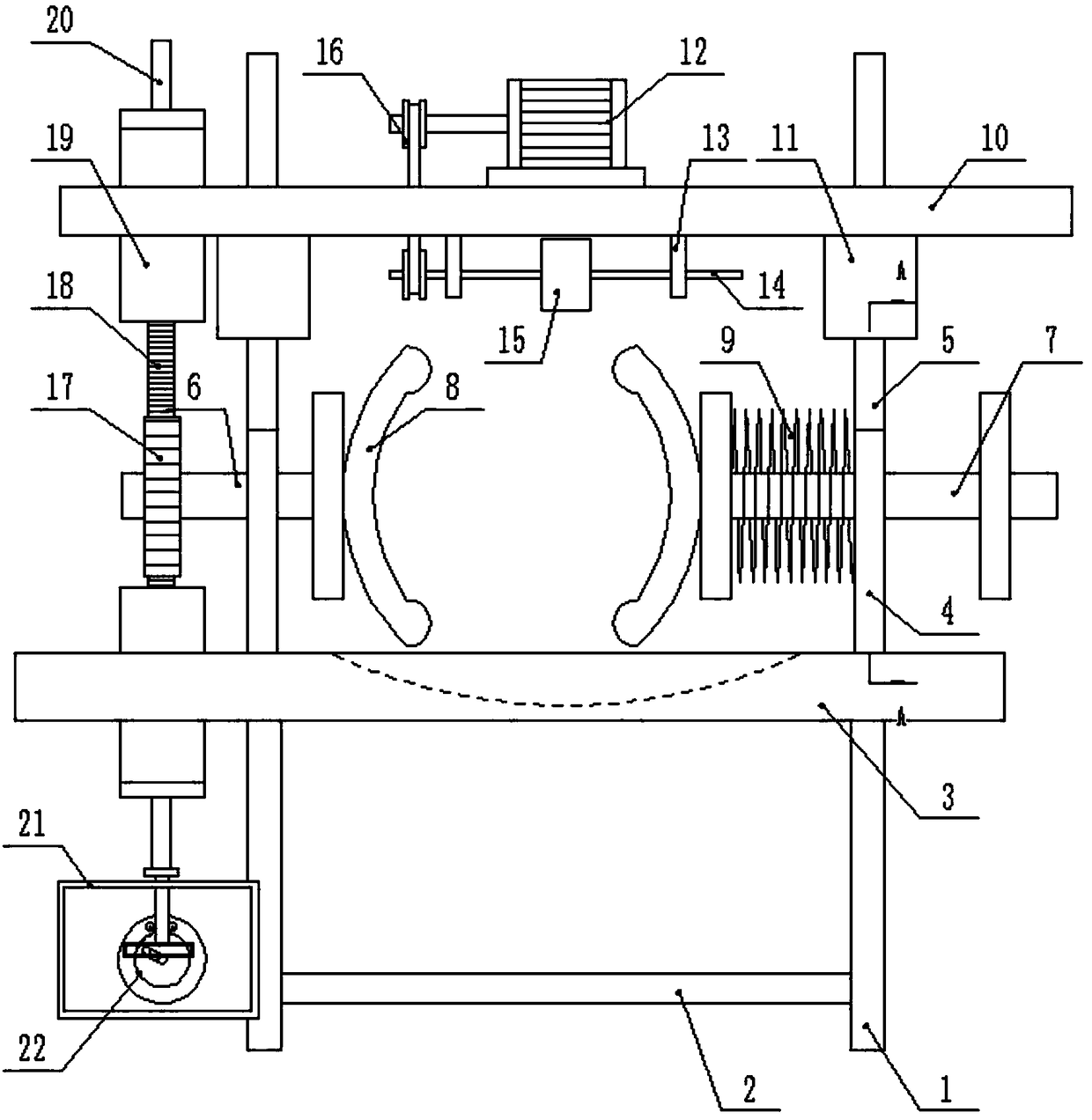

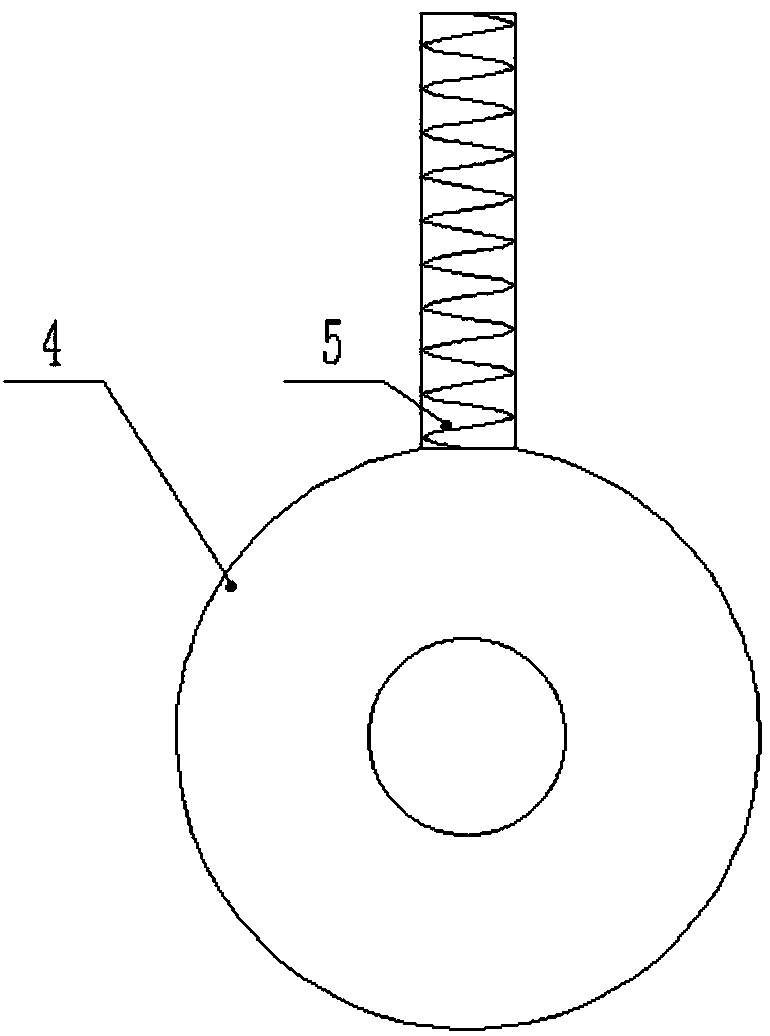

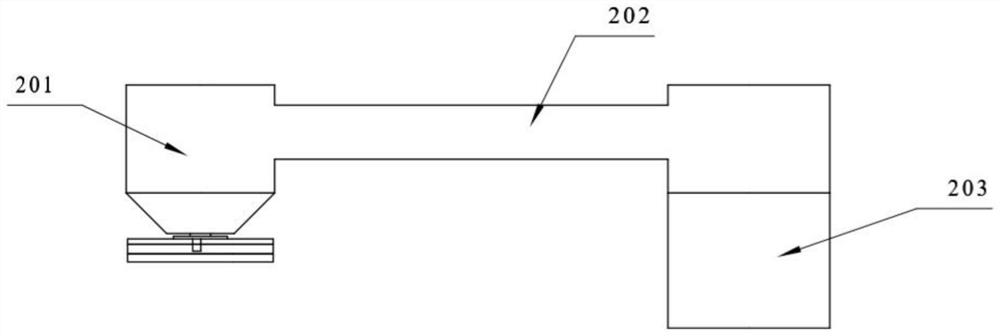

Method for polishing automobile hubs and device

ActiveCN102554752ASmooth rotationStable and safe rotationEdge grinding machinesPolishing machinesHydraulic cylinderAdhesive

The invention discloses a method for polishing automobile hubs and a device. The method for polishing automobile hubs sequentially includes steps of 1, driving an automobile hub to rotate by a rotating device, placing the automobile hub into a polishing device and then leading the automobile hub to realize revolution around the rotating device; 2, roughly polishing the automobile hub which rotates and realizes revolution around the rotating device and rough polishing abrasive materials for the first time; 3, finely polishing the automobile hub which rotates and realizes revolution around the rotating device and fine polishing abrasive materials for the second time; and brilliantly polishing the automobile hub which rotates and realizes revolution around the rotating device and brilliant polishing abrasive materials for the third time. The polishing device comprises a polishing cylinder with a lining made of PU (polyurethane) adhesive, a hydraulic cylinder is disposed on one side of the polishing cylinder, a portal frame is disposed on the upper portion of the hydraulic cylinder, the rotating device used for driving the automobile hub to rotate is arranged on the portal frame, an adjusting screw stem provided with an adjusting nut is disposed on the portal frame, and a suspension cover which is placed above the polishing cylinder is connected onto the adjusting screw stem by an iron chain. By the aid of the method for polishing automobile hubs and the device, polishing efficiency can be improved, labor cost is lowered, a polishing effect is guaranteed, and the device is simple in structure and low in manufacturing cost.

Owner:湖州中云机械制造股份有限公司

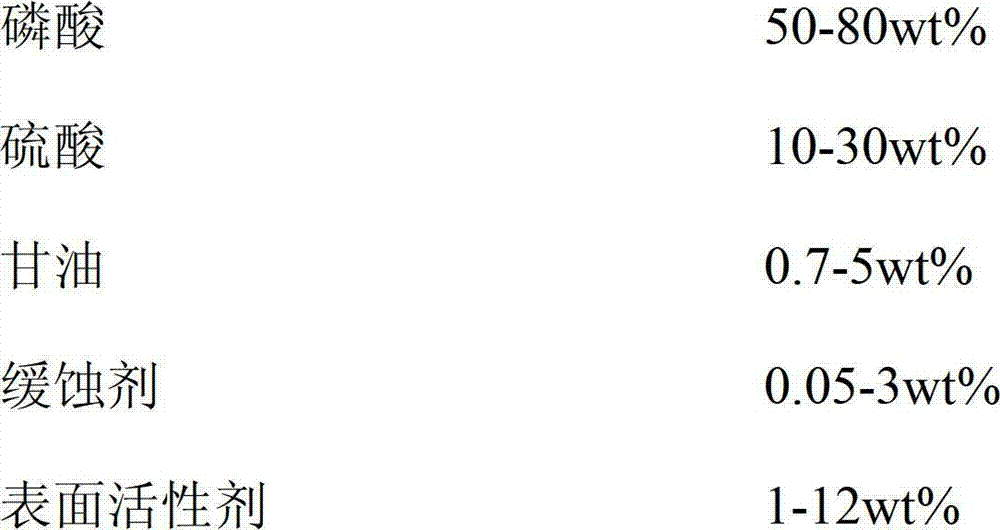

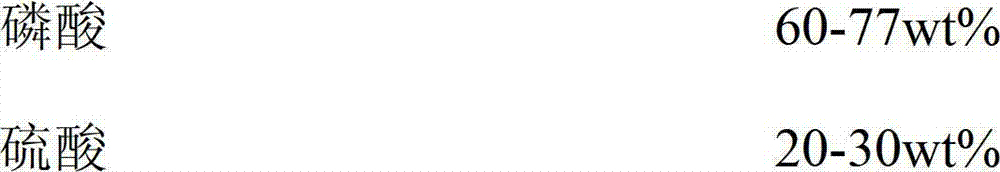

Aluminum alloy polishing solution and preparing method thereof

The invention relates to an aluminum alloy polishing solution, which includes the following components according to mass percent: 50 to 80wt% of phosphoric acid, 10 to 30wt% of sulfuric acid, 0.7 to 5wt% of glycerin, 0.05 to 3wt% of corrosion inhibitor, and 1 to 12wt% of surfactant. The aluminum alloy polishing solution has low corrosivity, excellent polishing effect and good market prospect, and produces no toxic nitrogen dioxide.

Owner:DONGGUAN DONGHUI TRADE

Steel plate polishing device for processing metal product

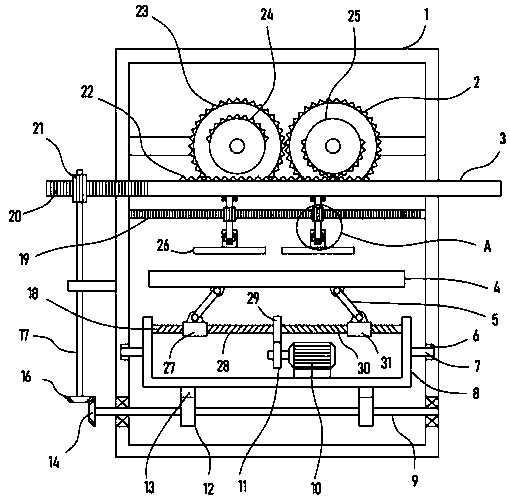

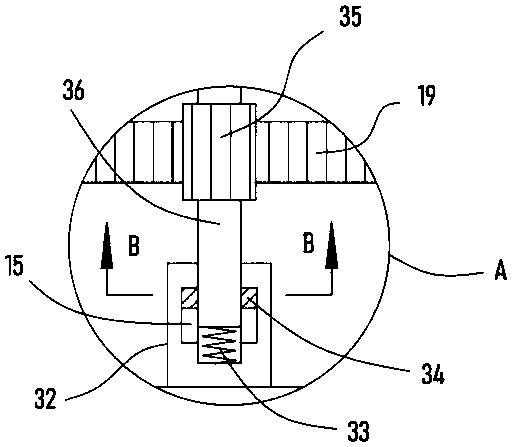

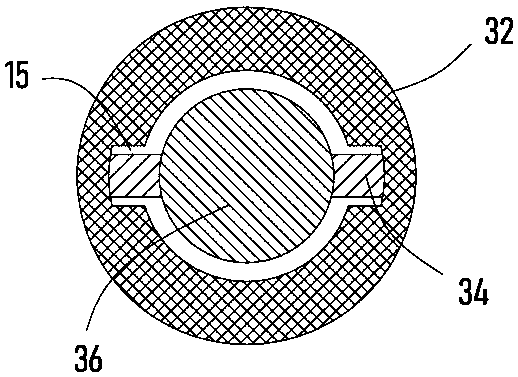

ActiveCN109015311AEasy to operateIncrease the range of grinding and polishingGrinding carriagesPolishing machinesSheet steelReciprocating motion

The invention discloses a steel plate polishing device for processing a metal product, and relates to the technical field of metal product processing machinery. The steel plate polishing device includes a supporting frame, a bearing frame is arranged in the supporting frame, a supporting plate is mounted on the bearing frame, and a sliding plate is arranged on the supporting frame in a horizontalsliding and penetrating mode; and a first incomplete gear and a second incomplete gear are fixed on a first transmission gear and a second transmission gear coaxially, and a limiting rack meshed and connected with a second cylindrical straight gear is fixedly mounted in the supporting frame. According to the steel plate polishing device, a steel plate placed on a supporting plate can be ground andpolished through the left and right reciprocating motion and rotation of a polishing disc, meanwhile, the supporting plate can reciprocate back and forth, the range of grinding and polishing of the steel plate is greatly increased, the polishing efficiency is greatly improved, the lifting operation of the supporting plate is simple and fast, the fact that the steel plate on the supporting plate keeps contact with the polishing disc is ensured, meanwhile, through the limit spring elastic action, the sufficient pressure of the polishing disc on the steel plate is achieved, and the polishing effect of the steel plate is ensured.

Owner:兴化市新泰铸钢有限公司

Chemical polishing method of stainless steel by high-temperature oxidation

InactiveCN103046053AIncrease loading capacityFast and effective mechanical peeling actionCavitationPhosphoric acid

The invention discloses a chemical polishing method of stainless steel by high-temperature oxidation, and belongs to the field of surface treatment of stainless steel parts. The method comprises the following steps: using phosphoric acid, sulfuric acid and nitric acid as main materials; supplementing additives: polyethylene glycol, sulfosalicylic acid and nicotinic acid which are used to prepare a chemical polishing liquor; introducing an ultrasonic cleaning instrument in the chemical polishing process; and polishing the surface of a stainless steel part within a short time by means of cavitation of ultrasonic wave in the polishing liquor. The chemical polishing method provided by the invention is high in polishing efficiency, less in pollution and strong in operability. Polished parts are bright and white in surface, and uniform and meticulous. The method is especially suitable for polishing treatment of stainless steel parts with precision screws, high precision sizes, deep holes, blind holes, superfine holes and complex structures.

Owner:中国兵器工业第二一三研究所

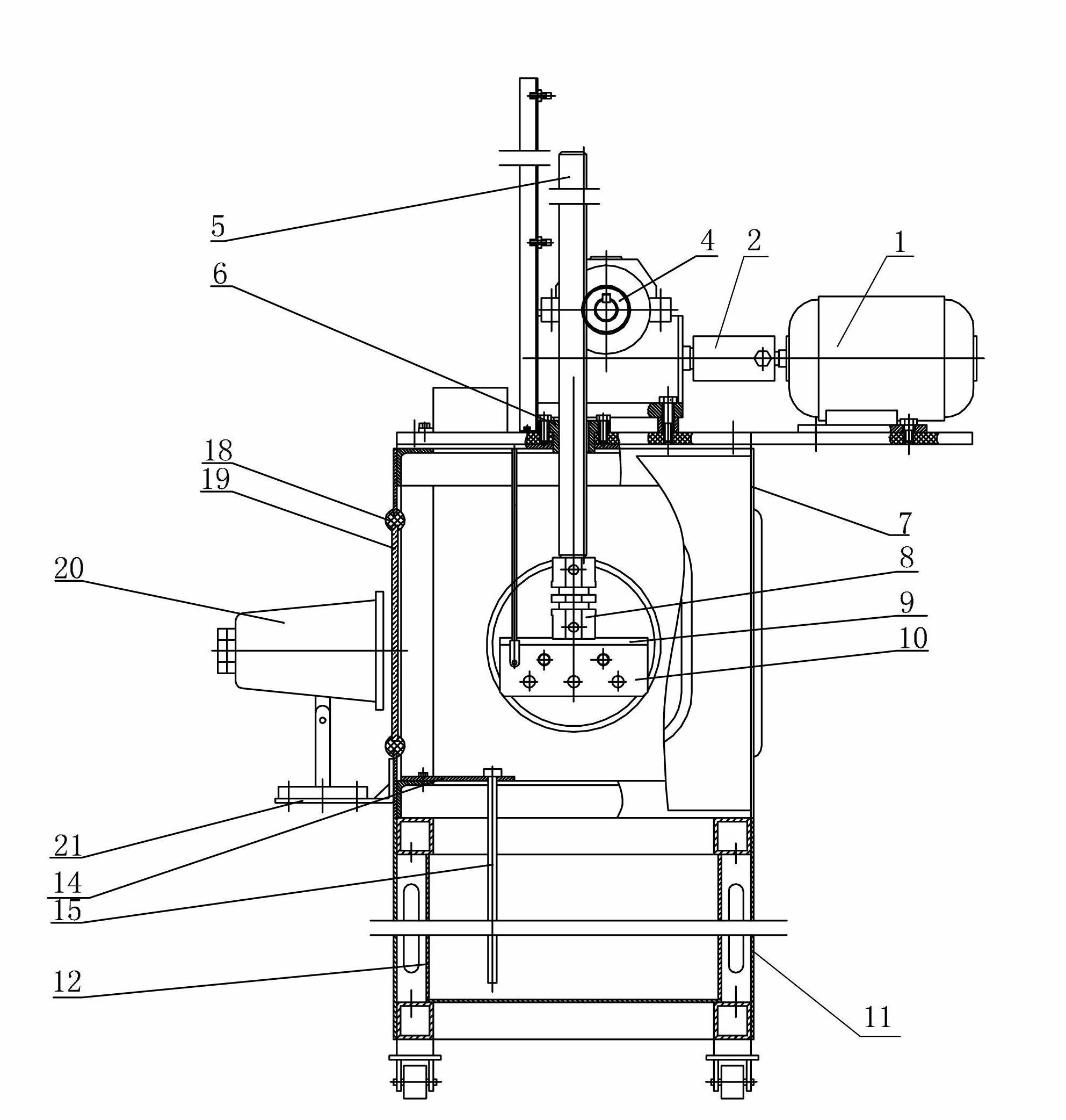

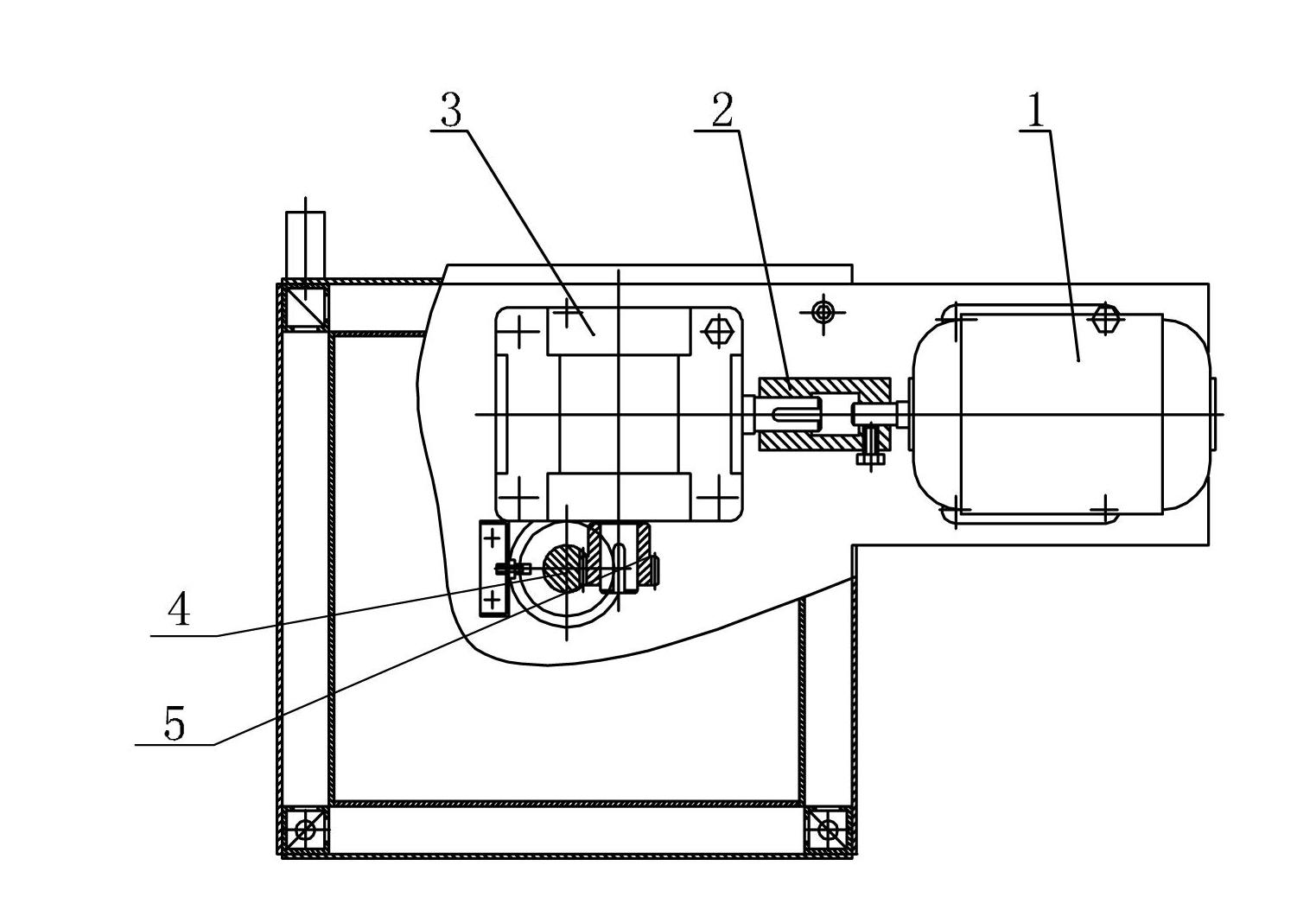

Electrolyte plasma polishing machine

The invention discloses an electrolyte plasma polishing machine, which relates to a polisher and is used for solving the problem of difficulty in carrying the conventional large-sized polishing machine. An output shaft of a motor is in transmission connection with an input shaft of a speed reducer through a shaft coupling; a gear is arranged on an output shaft of the speed reducer, and is meshed with a rack; one end of the rack passes through a guide sleeve, is arranged in an upper box, and is connected with an insulator; the insulator is connected with an anode through a connecting plate; the guide sleeve is fixedly arranged on the top of the upper box; the upper box is arranged on and is communicated with the lower box; a working box filled with a polishing liquid is arranged in the lower box, and is connected with a cathode; one end of the heater is fixedly arranged at the bottom of the upper box through a heater frame; the other end of the heater is arranged in the working box; and the side wall of the upper box is communicated with a condensing tube through a pipe joint. The electrolyte plasma polishing machine can be used for polishing parts.

Owner:HARBIN INST OF TECH

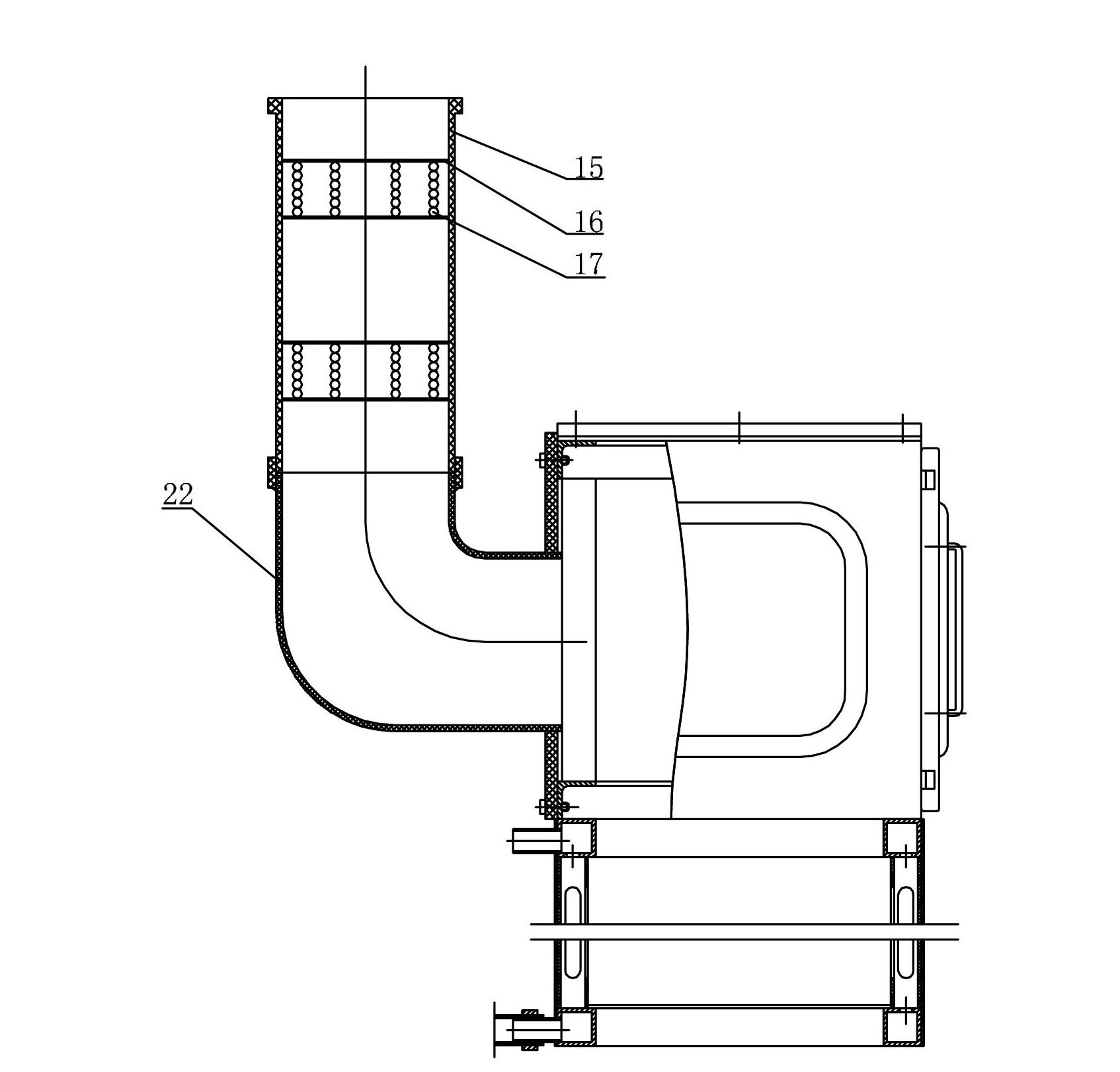

Rice polishing device

InactiveCN106732880AGuaranteed polishing effectImprove the finishGrain huskingGrain polishingEngineeringBrush device

The invention discloses a rice polishing device which comprises a device body. A feeding hopper is arranged in the middle of the top end of the device body. A dampening device is arranged on the left side of the device body. A circulation draught fan is arranged at the upper end of the right side of the device body. A conical discharging bin is arranged at the bottom end of the device body. A first filtering net is arranged at the upper end of the interior of the device body, and a second filtering net is arranged at the upper middle end of the interior of the device body. A polisher is arranged at the middle end of the interior of the device body, a rice brushing device is arranged at the lower middle end of the interior of the device body, and a third filtering net is arranged at the lower end of the interior of the device body. According to the rice polishing device, the problems that in the prior art, polishing equipment is high in rice breaking rate, poor in polishing effect and uneven in polishing are solved, rice is wetted in an atomization spraying dampening manner, water mist and the rice can be sufficiently mixed, and evenness of polishing is ensured; furthermore, the design of multiple polishing rollers is adopted, and the polishing effect is further improved; and in addition, the rice brushing device is arranged so that attachments on the surfaces of rice can be rapidly wiped away, the smoothness of the rice is improved, and the polishing effect is good.

Owner:HARBIN MIMI RICE IND TECH CO LTD

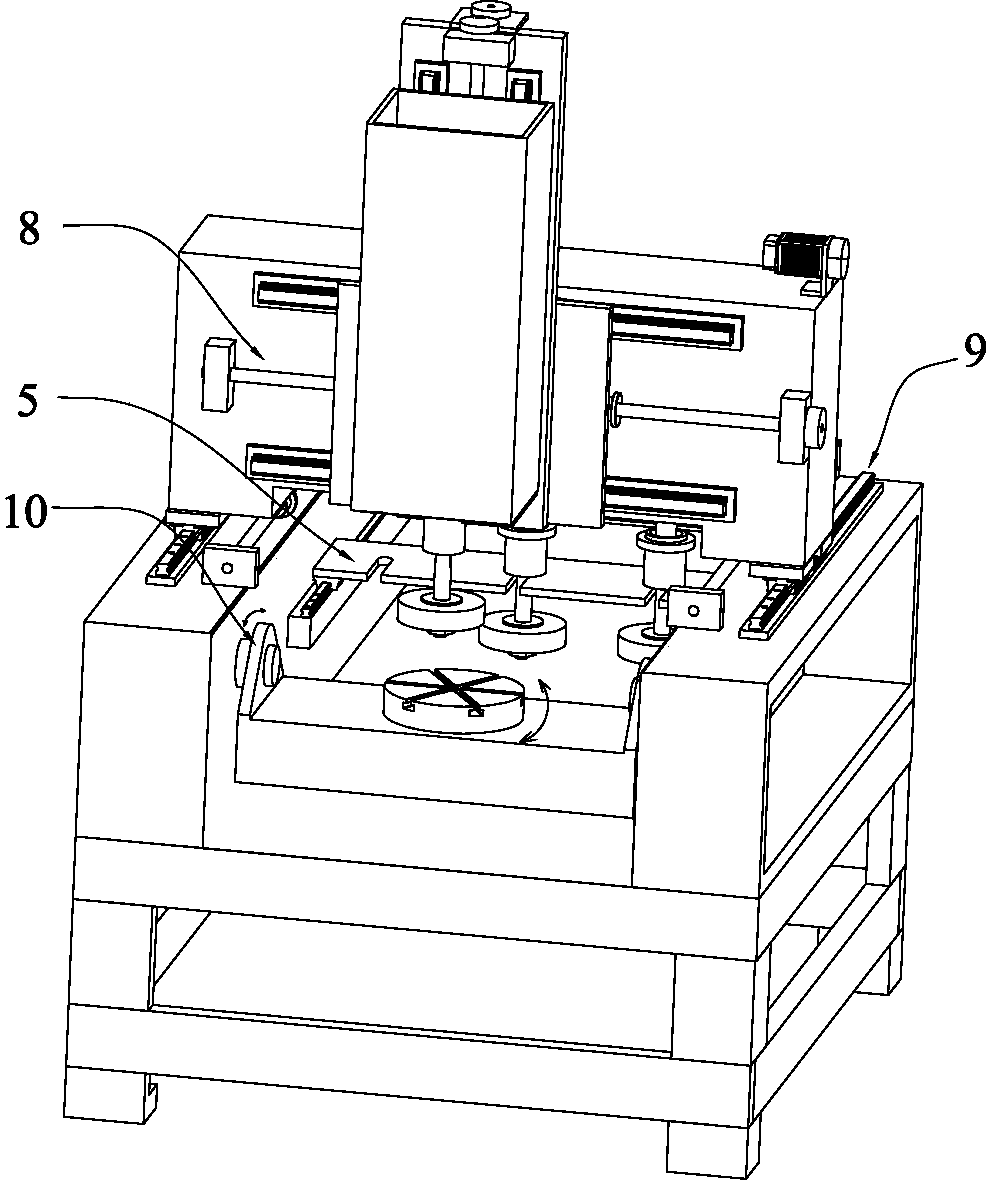

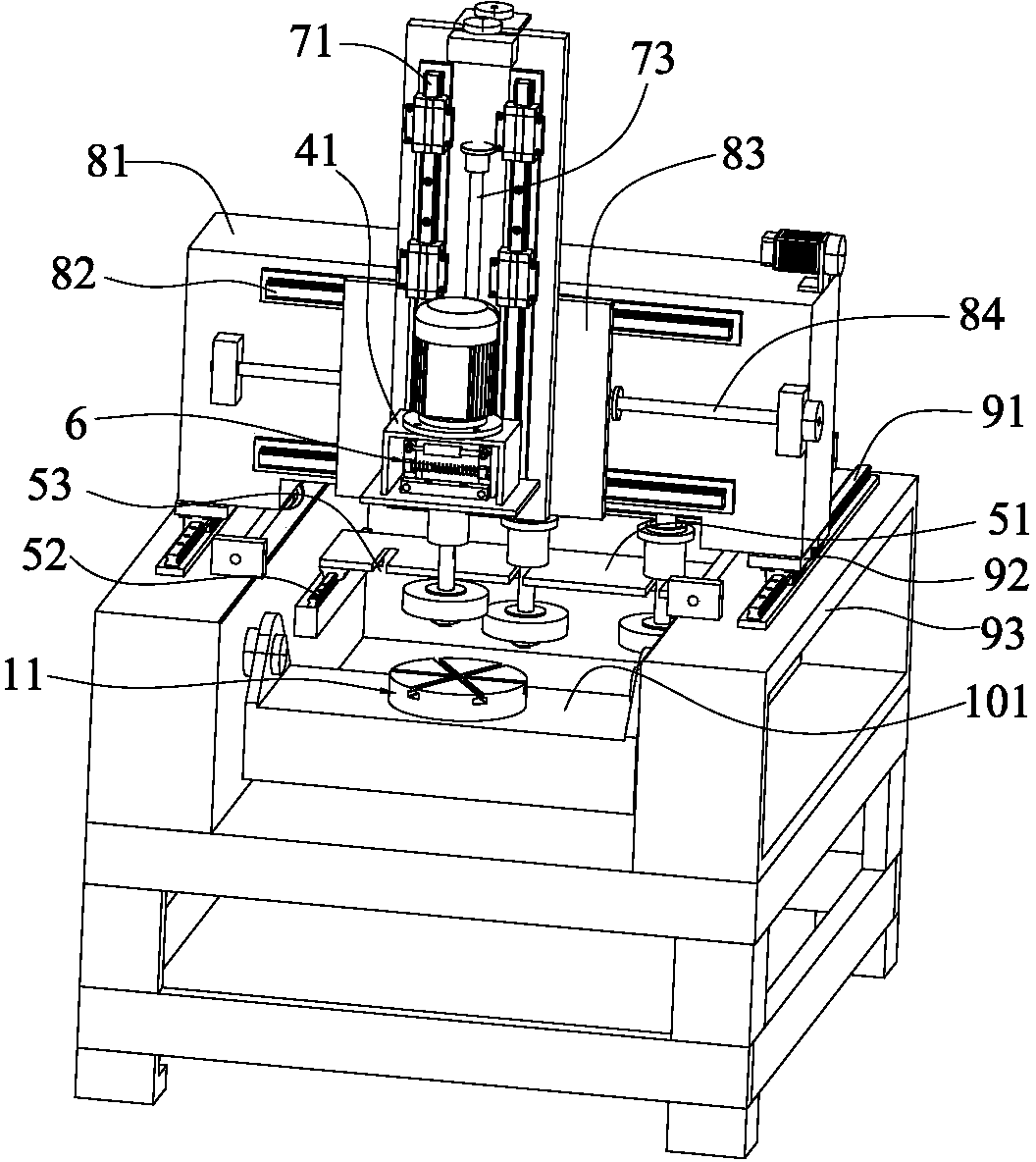

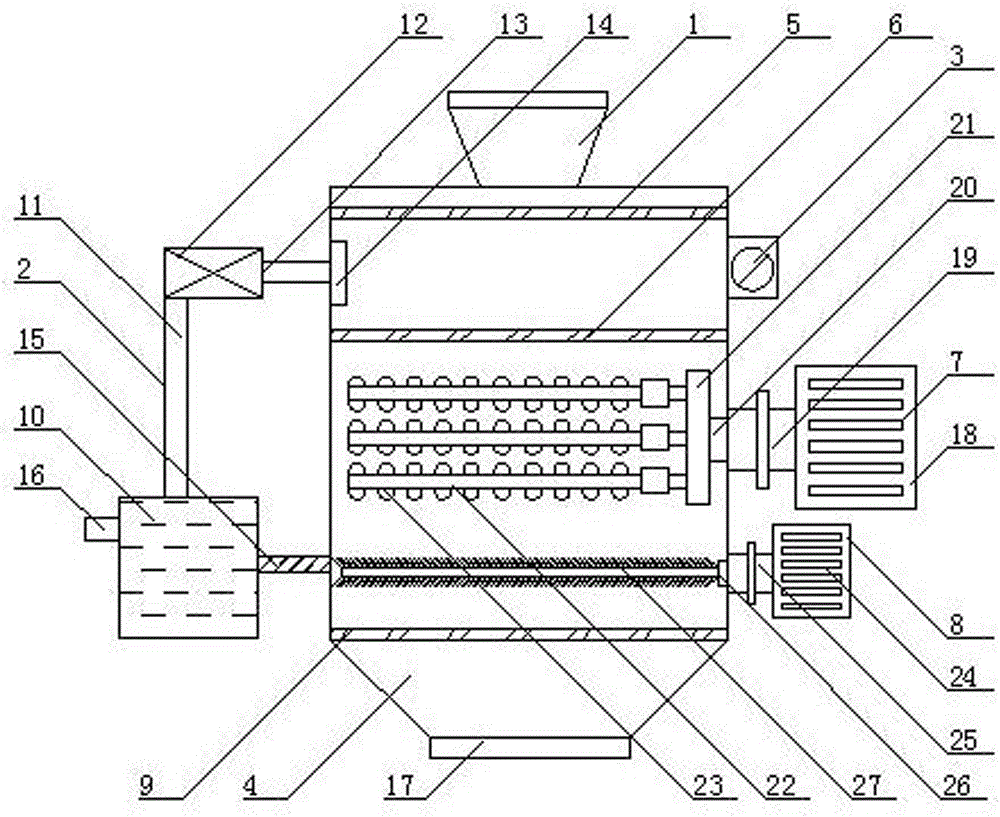

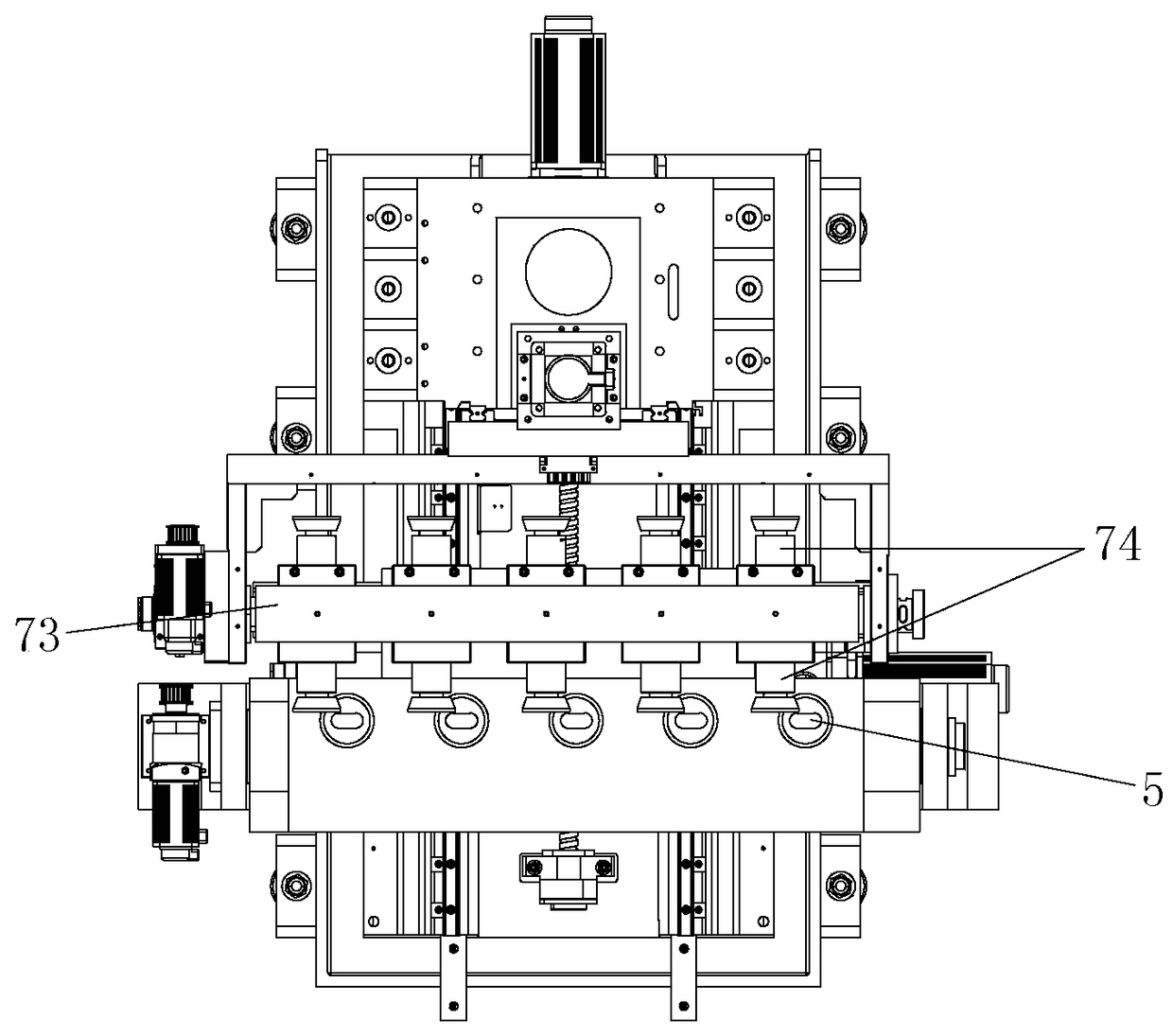

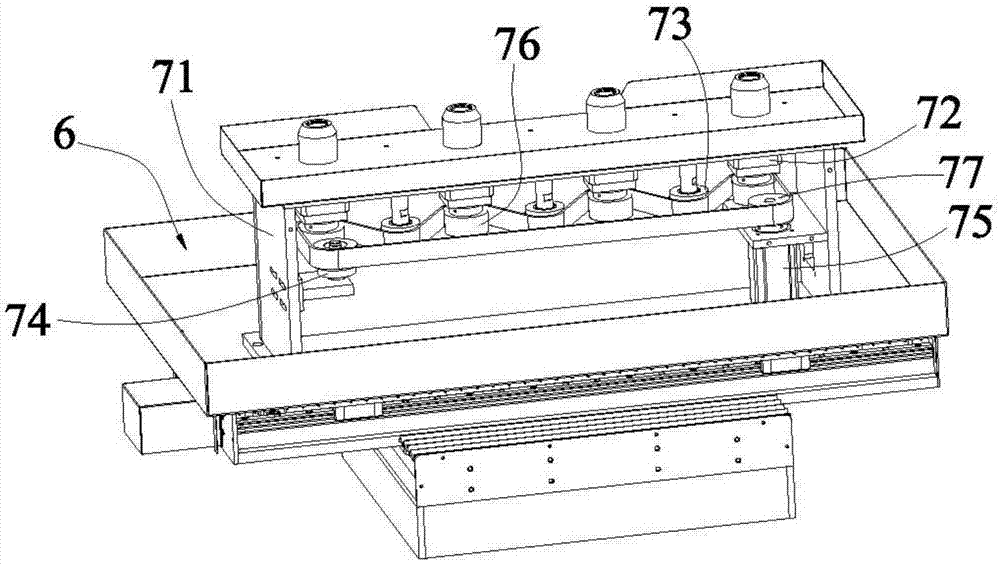

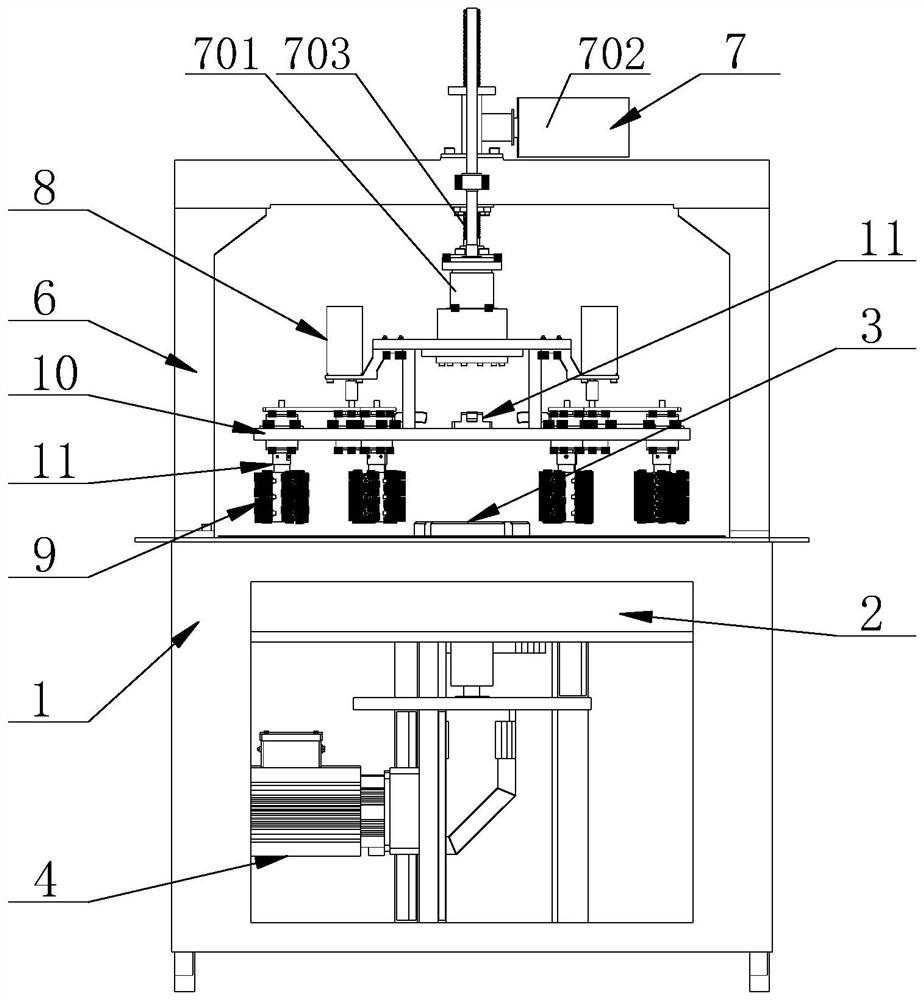

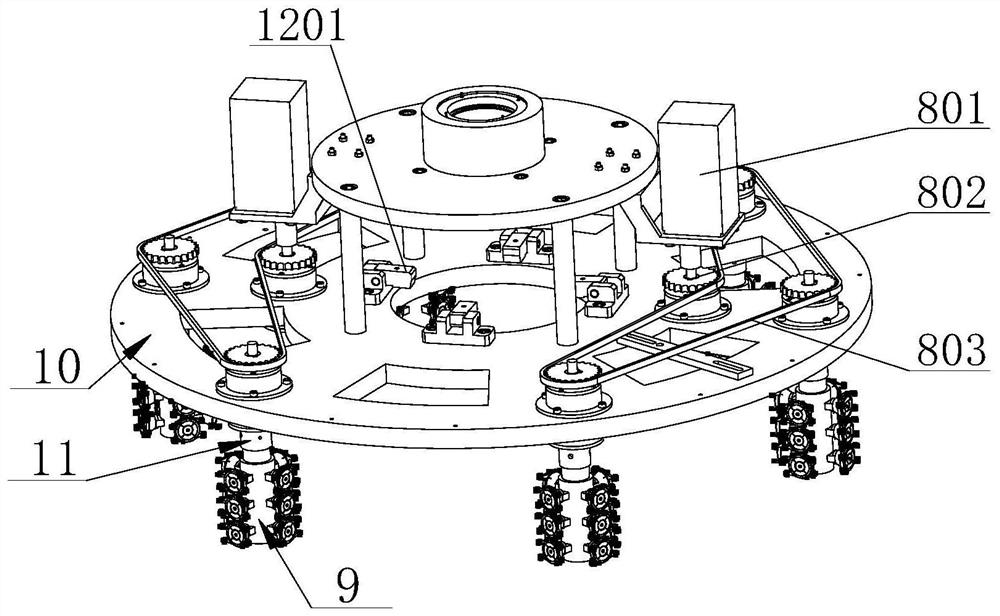

Intelligent double-five-axis-linkage five-station numerical control polishing machine

PendingCN108637864AFast and efficient polishingReduce labor intensityGrinding carriagesPolishing machinesNumerical controlMechanical engineering

The invention discloses an intelligent double-five-axis-linkage five-station numerical control polishing machine, and relates to metal and nonmetal curved surface polishing equipment. The technical defects that an existing polishing machine cannot meet the technological requirement for polishing workpieces with complex curved surface shapes, and the machining efficiency is low are overcome. A lower workbench comprises a lower fixing base, wherein the lower fixing base is connected with an X-axis driving mechanism in an installed mode. The lower fixing base is connected with a lower turnover plate through an A-axis driving mechanism. Two or more C-axis rotating mechanisms which are used for driving workpieces to conduct autorotation are perpendicularly arranged on the lower turnover plate side by side, and workpiece clamps which are used for clamping the workpieces are arranged on the C-axis rotating mechanisms. A polishing and grinding head installation platform comprises an upper fixing base. The upper fixing base is connected with a grinding head fixing base through a B-axis driving mechanism, and the grinding head fixing base and the lower turnover plate are arranged side by side. A front row of polishing and grinding heads and a rear row of polishing and grinding heads are arranged on the grinding head fixing base, and two or more polishing and grinding heads are arranged on each row and correspond to the workpiece clamps in a one-to-one mode. Rapid and efficient polishing operation of the workpieces with the complex curved surface shapes can be achieved, the flexibility is high, the application range is broad, and the structural design is ingenious and reasonable.

Owner:于正华

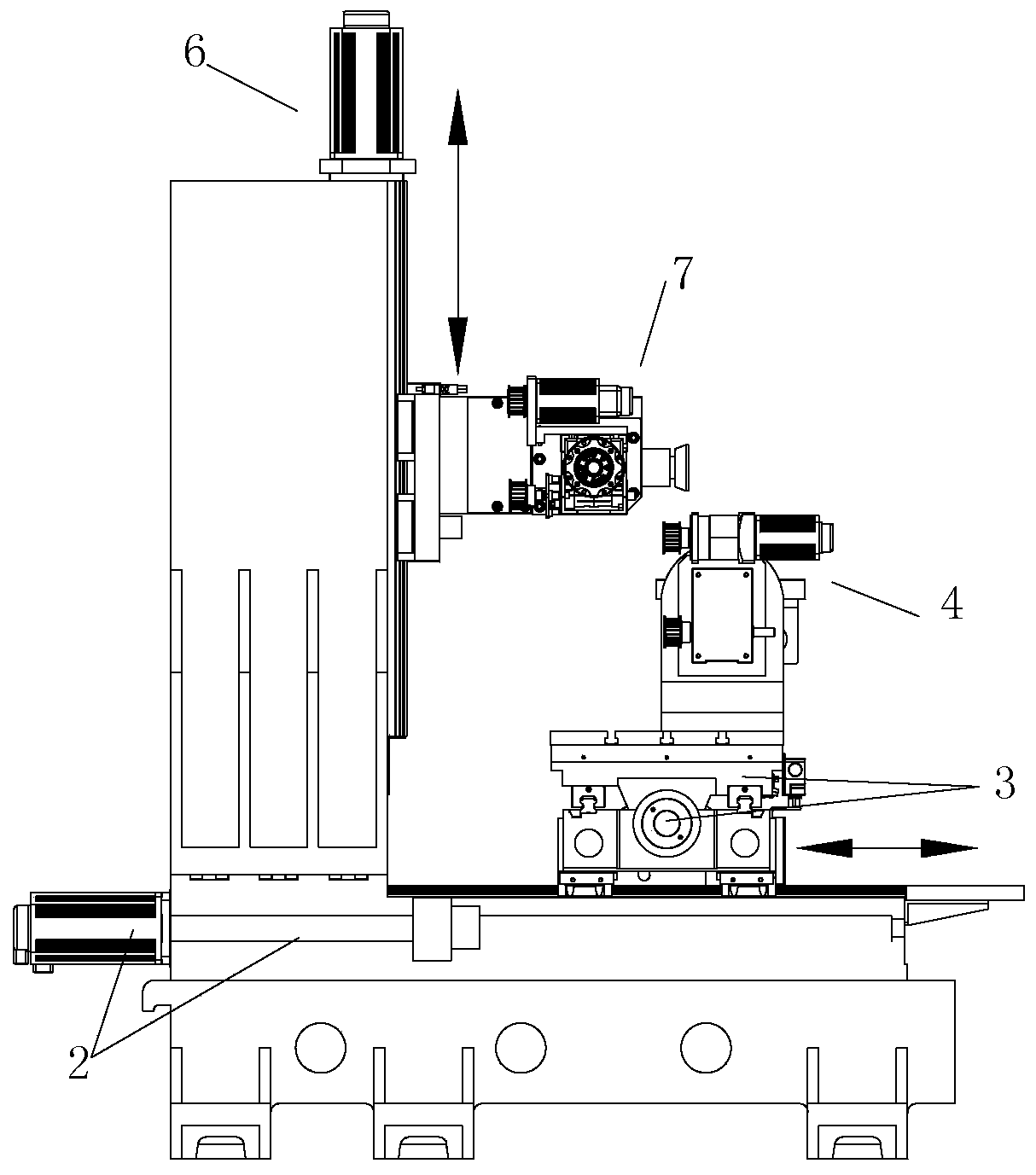

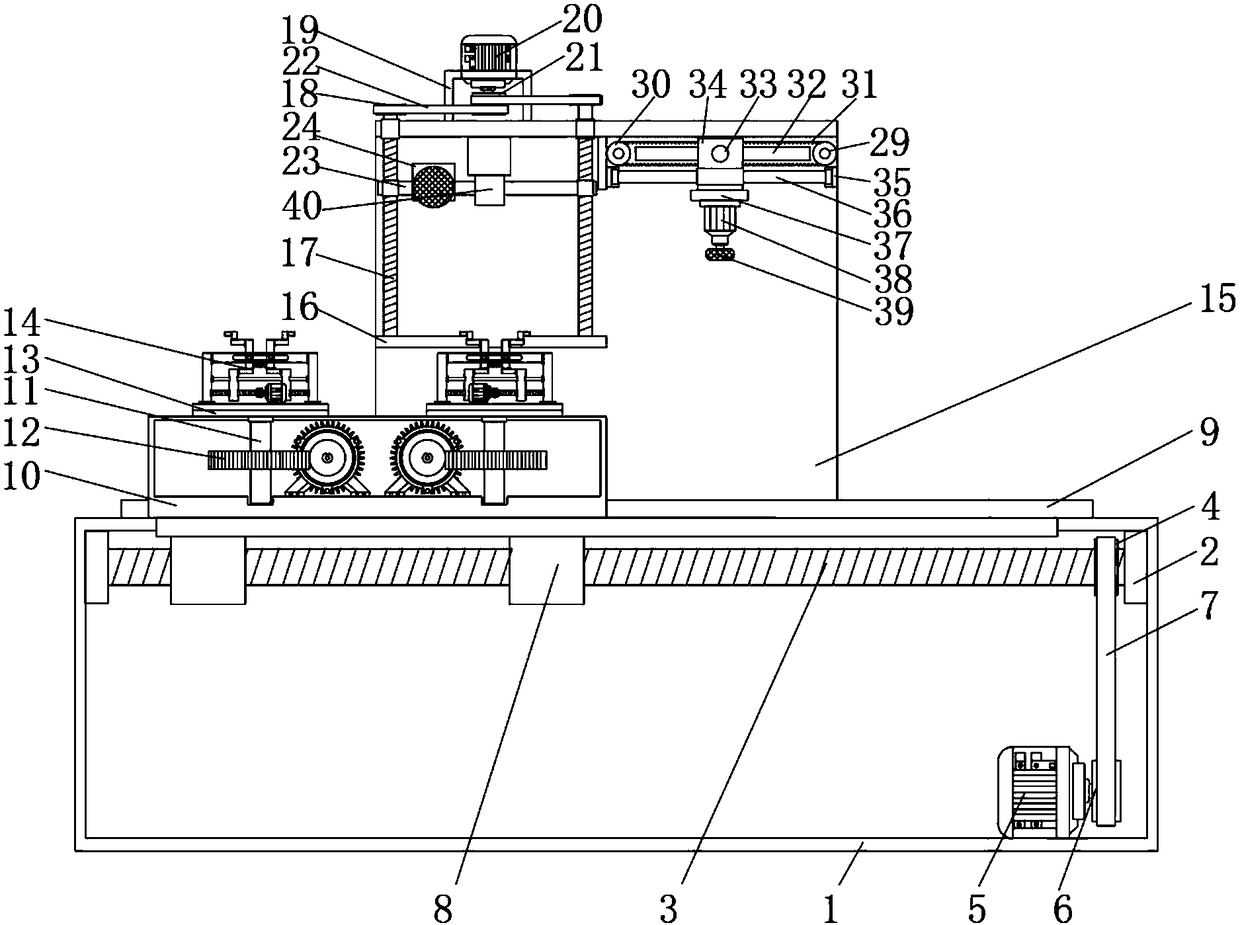

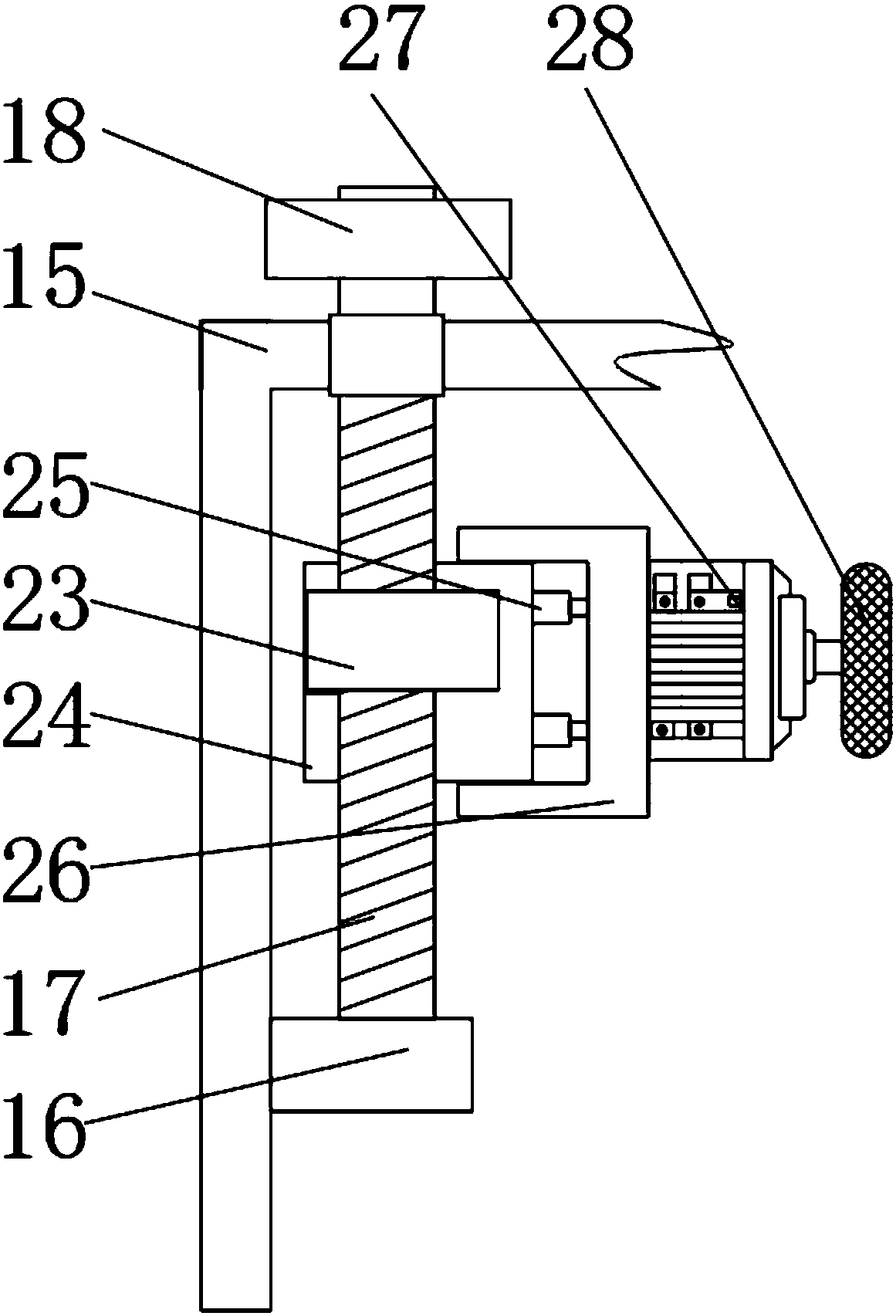

Multi-station numerically controlled side polishing machine

ActiveCN107971900AReduce workloadIngenious structural designGrinding machinesAutomatic grinding controlEngineeringWorkload

The invention discloses a multi-station numerically controlled side polishing machine which comprises a base, an X-axis moving mechanism, a Y-axis moving mechanism, a portal frame, a lifting cross beam, a lifting lead screw, an up-down reciprocating device, a lifting height adjusting device, a feeding moving mechanism, a basin, a workpiece assembling module and a plurality of polishing devices. The multi-station numerically controlled side polishing machine disclosed by the invention is skillful and reasonable in structural design. The polishing devices are lifted to predetermined positions through the lifting height adjusting device, and then are driven by the up-down reciprocating device to reciprocate up and down quickly to polish the side face, so that the polishing efficiency is enhanced greatly, the working stability is ensured, and the polishing effect of a product is ensured effectively. Meanwhile, the workload of the lifting height adjusting device is alleviated too, and the service life is prolonged greatly; in addition, multi-shaft arc-shaped interpolation can be carried out, so that the multi-station numerically controlled side polishing machine can grind and polish a complicated surface well, and is good in polishing effect.

Owner:东莞市钜铧机械有限公司

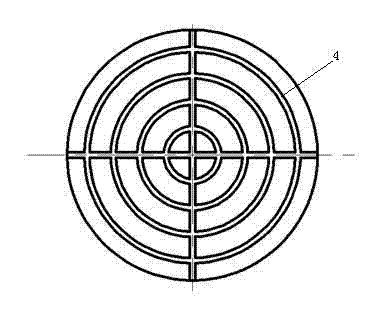

Polishing device and technology for false tooth machining

ActiveCN111251143APrevent overthrowUndershootGrinding drivesLapping machinesPolishingFixed prosthodontic

The invention relates to a polishing device for false tooth machining. The polishing device comprises a base, an installation seat which is placed on the base and is used for fixing a false tooth in the polishing process, a support fixed to the base and a grinding tool which is installed at the end, away from the base, of the support and is used for grinding the false tooth. The polishing device is characterized in that a magnetic worktable is arranged on the upper end face of the base; multiple concentric ring-shaped grooves are formed in the lower end face of the installation seat; magnets are arranged in the ring-shaped grooves; and a clamping mechanism used for clamping and fixing the false tooth is arranged on the installation seat. The polishing device has the effects that the relative position between the installation seat and the base is conveniently adjusted, and therefore the grinding process is more convenient.

Owner:泉州市超维医疗科技有限公司

Polishing buffing device for machine manufacturing

InactiveCN109664191AEasy to useImprove grinding efficiencyPolishing machinesGrinding work supportsIndustrial engineering

The invention discloses a polishing buffing device for machine manufacturing, and belongs to the technical field of polishing buffing. The polishing buffing device comprises a bottom plate, side plates and a top plate; the side plates are fixedly connected to the two sides of the bottom plate; the top plate is fixedly connected to the tops of the two side plates; a screw rod is horizontally arranged under the top plate, one end of the screw rod is rotationally connected with one side plate through a bearing seat, and the other end of the screw rod penetrates through the other side plate to beconnected with a first motor; a second slide block is arranged on the screw rod in a matched mode; an air cylinder is vertically installed at the bottom of the second slide block, a second motor is installed at the telescopic end of the air cylinder, and a buffing wheel is installed at the output end of the second motor through a second rotary shaft; and a supporting plate is installed on the bottom plate through a support frame, and a workpiece is placed on the supporting plate. According to the polishing buffing device provided by the invention, compared with a common polishing buffing device, the screw is driven to rotate through the first motor, horizontal moving of the buffing wheel can be achieved, the buffing wheel is driven to conduct polishing buffing through the second motor, time and labor are saved, in addition, the polishing efficiency is high, and the polishing effect is good.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Polishing process and device for 3D arc surface of ceramic member

ActiveCN106078469ARepair bad camberGuaranteed service lifePolishing machinesBelt grinding machinesTool marksEngineering

Disclosed is a polishing process and device for a 3D arc surface of a ceramic member. The polishing process includes: A, clamping a product needing arc surface polishing by a clamp, enabling a to-be-polished face of the product to be exposed outside, and mounting a polishing belt on a machine capable of adjusting horizontal and vertical positions of the belt; B, adjusting positions of the polishing belt and the to-be-polished face of the product to enable the polishing belt to compress the to-be-polished face of the product and to completely contact with an arc surface of the to-be-polished face of the product; C, spraying a polishing liquid into a contact face of the product and the polishing belt, and controlling the polishing belt to rotate to polish the to-be-polished face of the product. The device comprises the clamp and the polishing belt. By using the polishing process and device, processing requirements on surface coarseness of ceramic structural member polishing can be met, over-polishing of holes in the arc surface is avoided, the process is simple, defects like grinding wheel lines and tool marks on the arc surface can be well removed, processing yield can be increased effectively, and production cost can be saved.

Owner:LENS TECH CHANGSHA

Electrochemical polishing method for surface of copper material

The invention relates to an electrochemical polishing method for a surface of a copper material. The electrochemical polishing method comprises the following step of preparing a polishing solution; and switching on a power supply to polish after a to-be-polished copper material is immersed into the polishing solution, wherein the step of preparing the polishing solution comprises the following steps of calculating the dosages of solutes according to the total volume of the to-be-prepared solution, the solutes comprising phosphoric acid, glycerin, thiourea and polyoxyethylene alkanolamide; weighing phosphoric acid and glycerin according to the calculating result and importing the same into a corrosion-resistant container, adding water to the total volume, and stirring and dissolving the mixture to obtain a first intermediate solution; weighing thiourea according to the calculating result and adding the thiourea into the first intermediate solution, and stirring and dissolving the mixture to obtain a second intermediate solution; and weighing polyoxyethylene alkanolamide according to the calculating result and adding the polyoxyethylene alkanolamide into the second intermediate solution, and uniformly stirring the mixture to obtain the polishing solution. According to the electrochemical polishing method, the surface roughness of a copper precision part can be increased from Ra0.4 [mu]m to Ra0.2 [mu], so that the using demand on a vacuum electronic apparatus is met.

Owner:NANJING SANLE GROUP

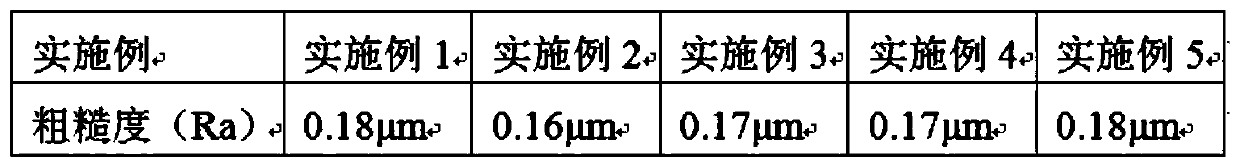

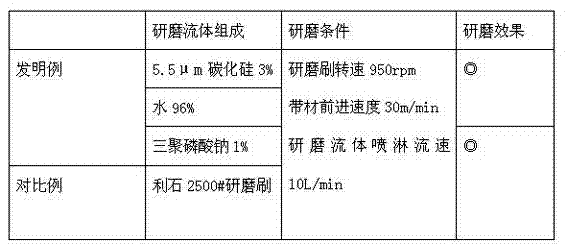

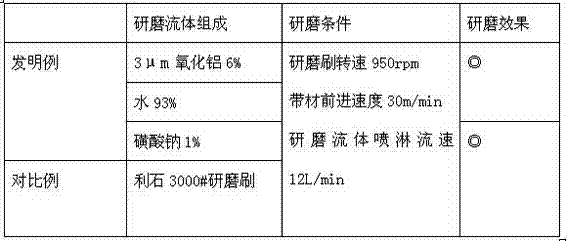

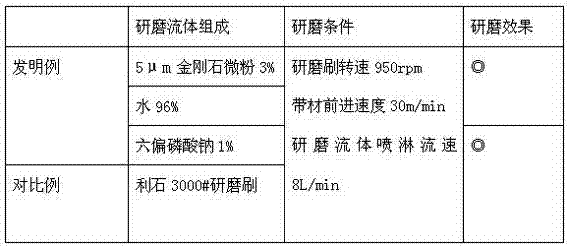

Grinding and polishing method of metal strip

InactiveCN103495929AReasonable designGuaranteed polishing effectLapping machinesLapping toolsWoven fabricSurface-active agents

The invention discloses a grinding and polishing method of a metal strip, and belongs to the technical field of metal surface polishing. The method comprises the following steps that the metal strip is grinded through a high-speed-rotating grinding brush in a grinding region and grinding fluid is sprayed on the metal strip at the same time, wherein the grinding fluid comprises grinding materials, a surface active agent and water, the weight of grinding materials account for 0.5-15% of that of the water, and the weight of the surface active agent accounts for 0.25-3% of that of the water, and the grinding brush is composed of a bakelite barrel and grinding fabrics fixed to the outer side the bakelite barrel. The grinding and polishing method of the metal strip is reasonable in design, the grinding materials are evenly scattered in the water through the surface active agent, serve as the grinding fluid and replace clear water to be sprayed, the grinding brush is made from non-woven fabrics free of grinding materials or canvases free of grinding materials or other fiber capable of being used for grinding and polishing, and accordingly polishing effect is guaranteed, and the production cost is greatly reduced by over 30% at least.

Owner:杭州百木表面技术有限公司

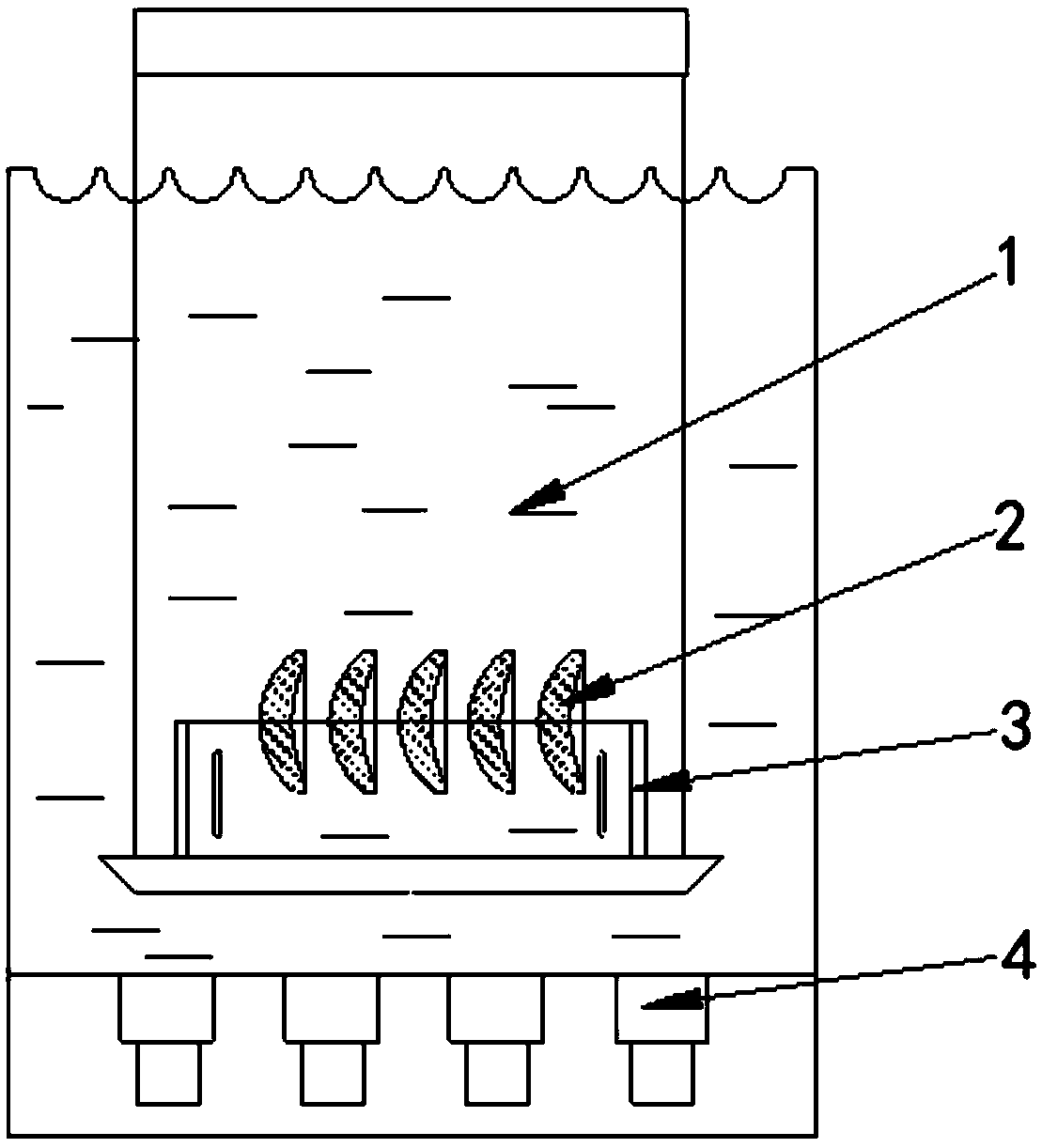

Method for polishing surface of optical lens

InactiveCN109623510ASmall macro forceSolve the problem of poor surface finishOther chemical processesPolishing compositions with abrasivesSurface finishUltrasonic vibration

The invention relates to a method for polishing the surface of an optical lens. The method includes the steps that S1, materials are arranged in working solutions added with suspension abrasives; S2,the working solutions are heated to a preset temperature and kept constant; and S3, ultrasonic vibration is applied to the working solutions to polish the surfaces of the materials. The method for polishing the surface of the optical lens can effectively solve the problem of poor surface finish caused by mildewing and misting due to turnover process contamination and excessive storage time after surface mirror finishing is conducted on an infrared optical material lens.

Owner:NINGBO SUNNY INFRARED TECH COMPANY

Polishing complete machine capable of tool replacing automatically and polishing method

ActiveCN110788722AGreatly Polishing EfficiencyRealize tool change functionPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses a polishing complete machine capable of tool replacing automatically and a polishing method. The polishing complete machine capable of tool replacing automatically comprises aobject placing table used for placing polished objects, wherein a suspension arm is arranged above the object placing table, a plurality of polishing structures are arranged on the suspension arm, a vacuum slot is arranged on a dust collecting cover seat, the two ends of a square rotating shaft are rotationally connected to an outer supporting ring and a main rotating disc correspondingly, a grinding tool is arranged on the square rotating shaft, a tool replacing driving motor electrically communicates with a collecting ring through a rolling wheel conductive part, a driving bevel gear wheel is connected to the output end of the tool replacing driving motor, and a driven bevel gear wheel is connected to one end of the square rotating shaft. According to the polishing complete machine capable of tool replacing automatically, the tool replacing function can be achieved automatically, so that workers are not needed to dismount and replace a tool, the polishing efficiency of a workpiece isgreatly improved, and the production rate is improved.

Owner:精海联科(宁波)智能设备有限公司

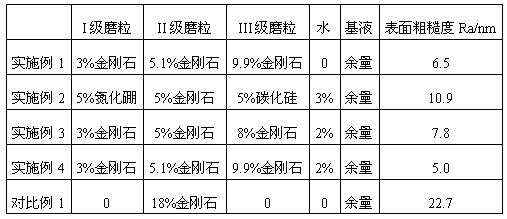

Composite polishing solution and preparation method thereof

ActiveCN108034362AEfficient removalGood dispersionOther chemical processesPolishing compositions with abrasivesMicrometerThree stage

The invention relates to a composite polishing solution and a preparation method thereof, and belongs to the field of precise processing. The composite polishing solution is characterized by being prepared from the following ingredients in percentage by mass: 1 to 25 percent of abrasive material particles and 75 to 99 percent of base liquid, wherein the abrasive material particles consist of firststage abrasive particles, second stage abrasive particles and third stage abrasive particles according to the mass ratio of 1:(0.5 to 2):(0.5 to 5); the average particle diameter of each stage of abrasive particles is 0.5 to 50 micrometers; the particle diameter of the first stage abrasive materials is greater than that of the second stage abrasive particles; the particle diameter of the second stage abrasive particles is greater than that of the third stage abrasive particles; the three kinds of abrasive particles are respectively and independently selected from diamond particles, cube BN particles and SiC particles. The polishing liquid is prepared from 1 to 25 percent of abrasive material particles and 75 to 99 percent of base liquid in percentage by mass. The abrasive material particles comprise three stages of abrasive particles; the average particle diameters of the abrasive particles are different; bulges at different degrees on the surface of the materials can be effectively removed.

Owner:深圳市永霖科技有限公司

Internal polishing equipment for stainless steel plate machining

InactiveCN112223094APolished evenlyIncreased polishing rangeGrinding carriagesPolishing machinesPolishingEngineering

The invention relates to polishing equipment, in particular to internal polishing equipment for stainless steel plate machining. The technical purpose to be achieved by the invention is to provide theinternal polishing equipment for stainless steel plate machining, wherein the internal polishing equipment is easy to operate, high in efficiency and relatively low in technical requirements on workers. In order to achieve the technical purpose, the internal polishing equipment for stainless steel plate machining comprises a base, wherein a mounting plate is connected to the top of the base; a mounting column mounted on the base; a moving mechanism arranged among the base, the mounting column and the mounting plate; a polishing assembly arranged between the mounting plate and the moving mechanism; and a rotary disc arranged on the base and connected with the moving mechanism. By means of the moving mechanism and the polishing assembly, a polishing head can move on a plate, the polishing range of the plate can be enlarged, the interior of the plate is comprehensively polished, and the effect of uniform polishing of the plate is guaranteed.

Owner:罗紫武

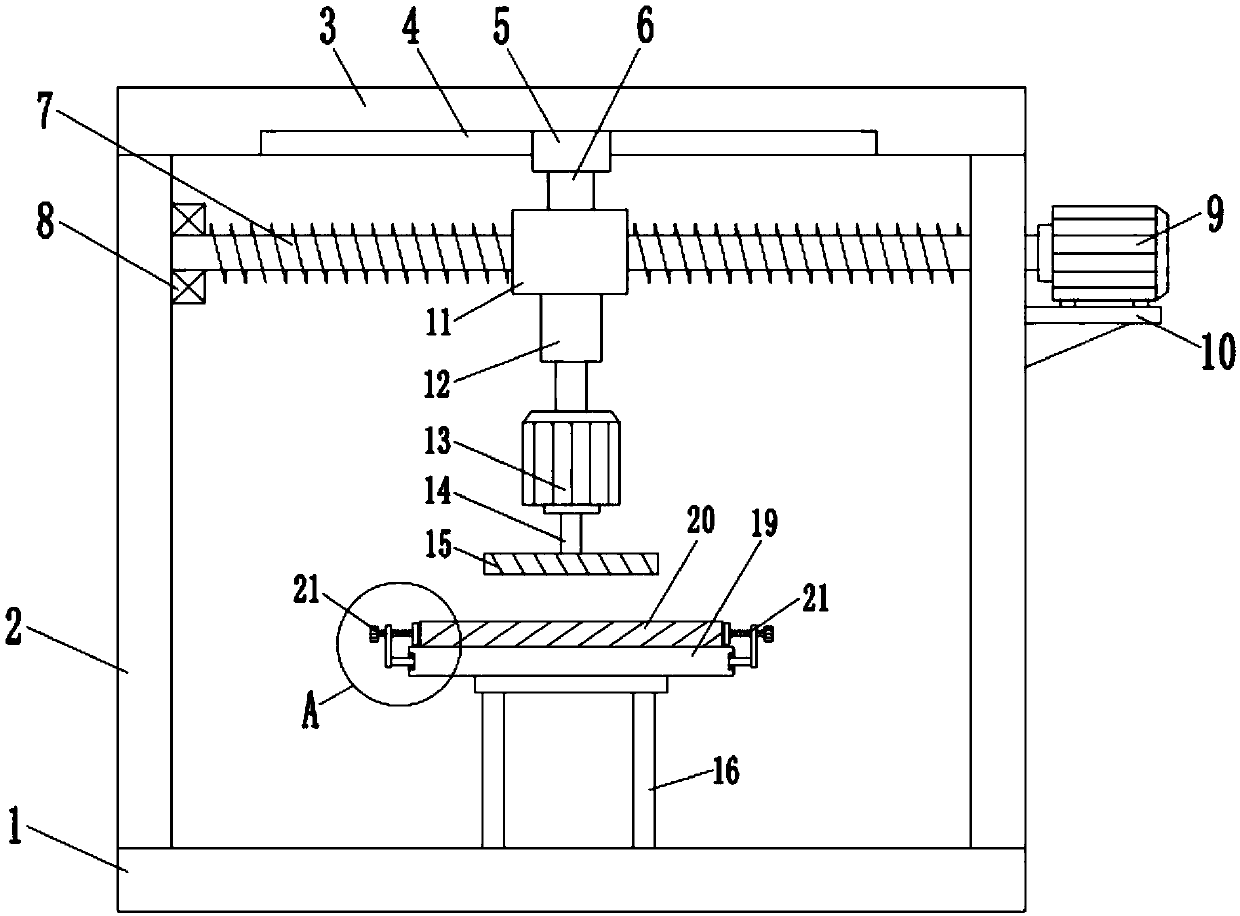

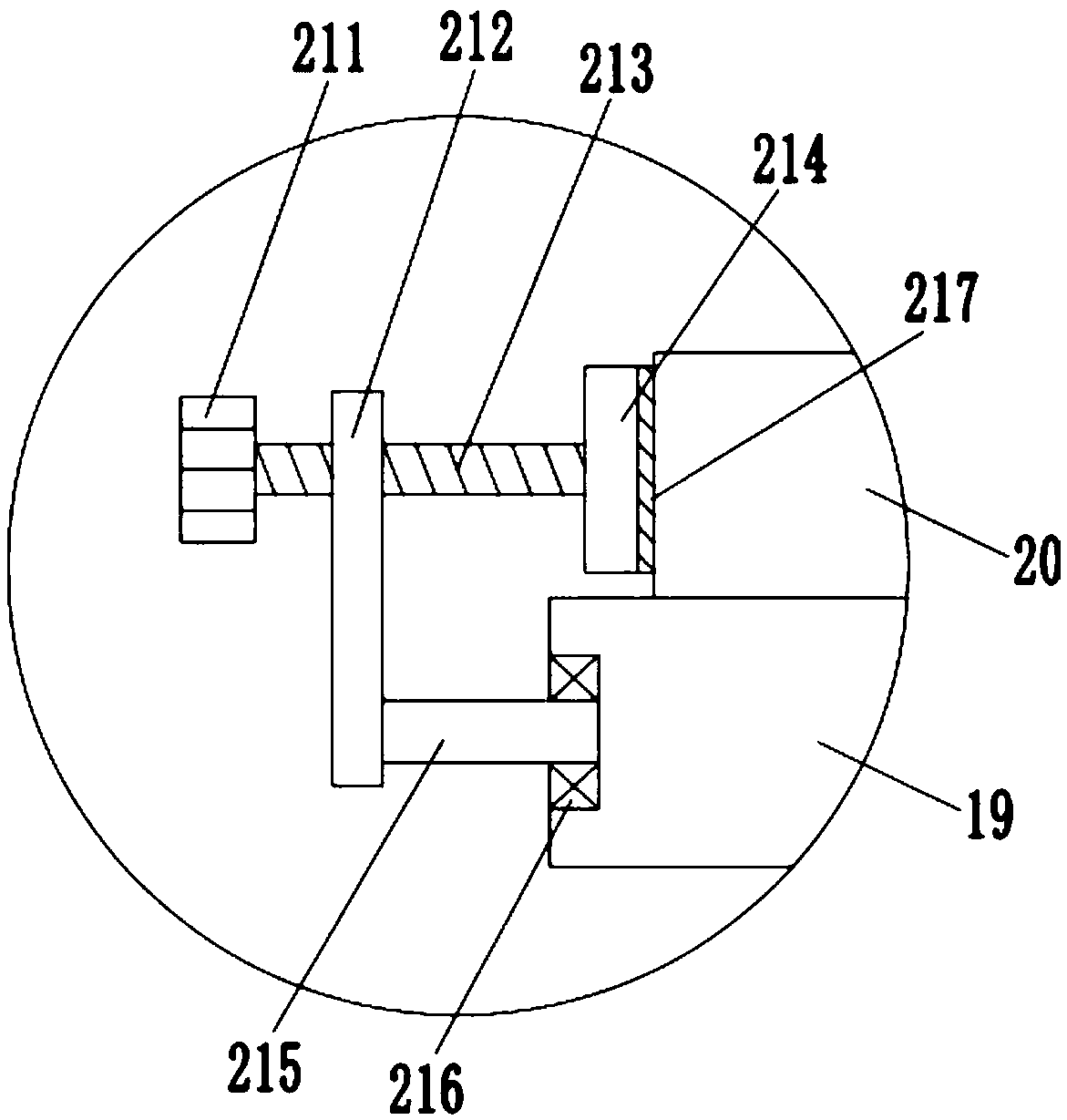

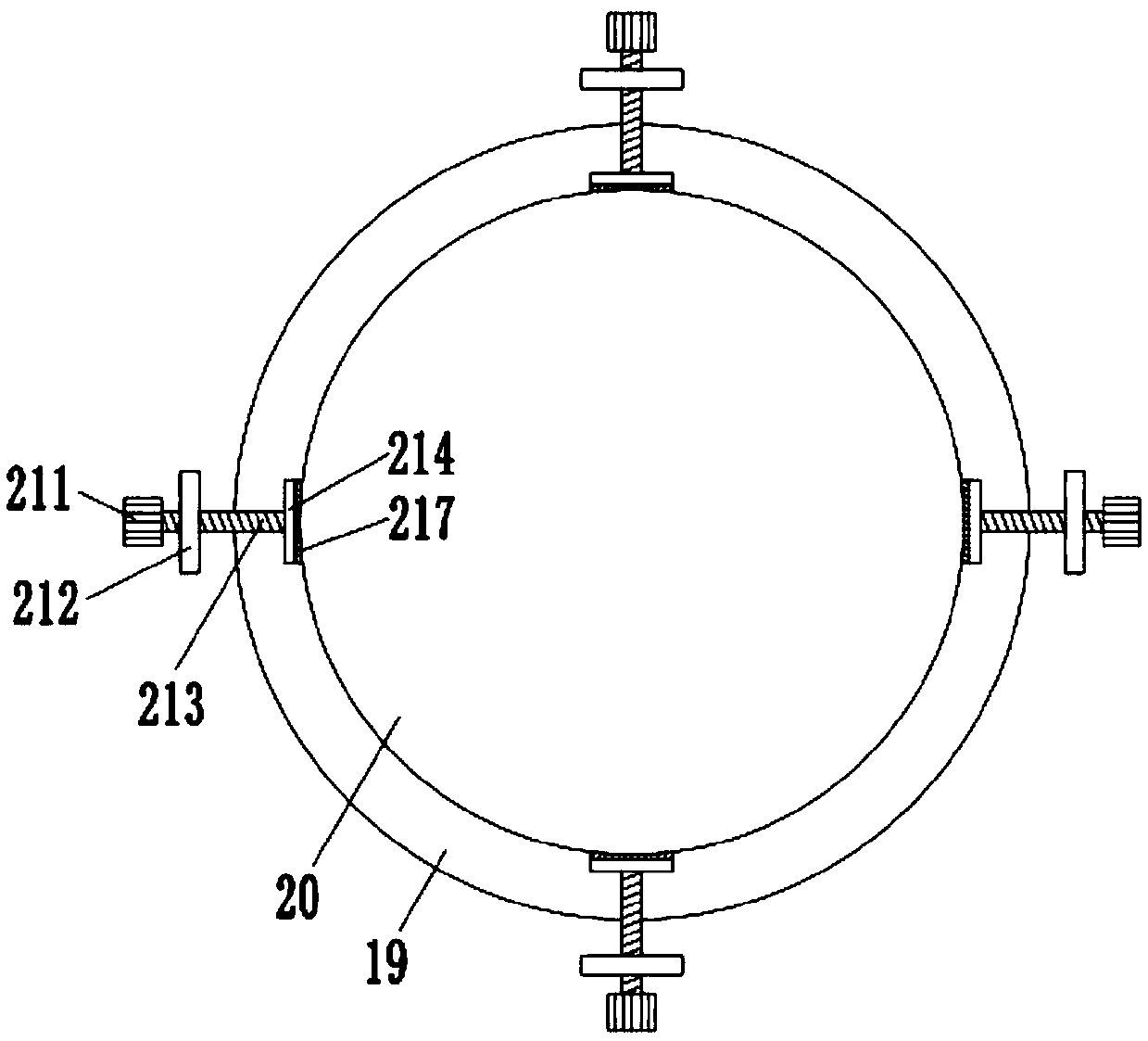

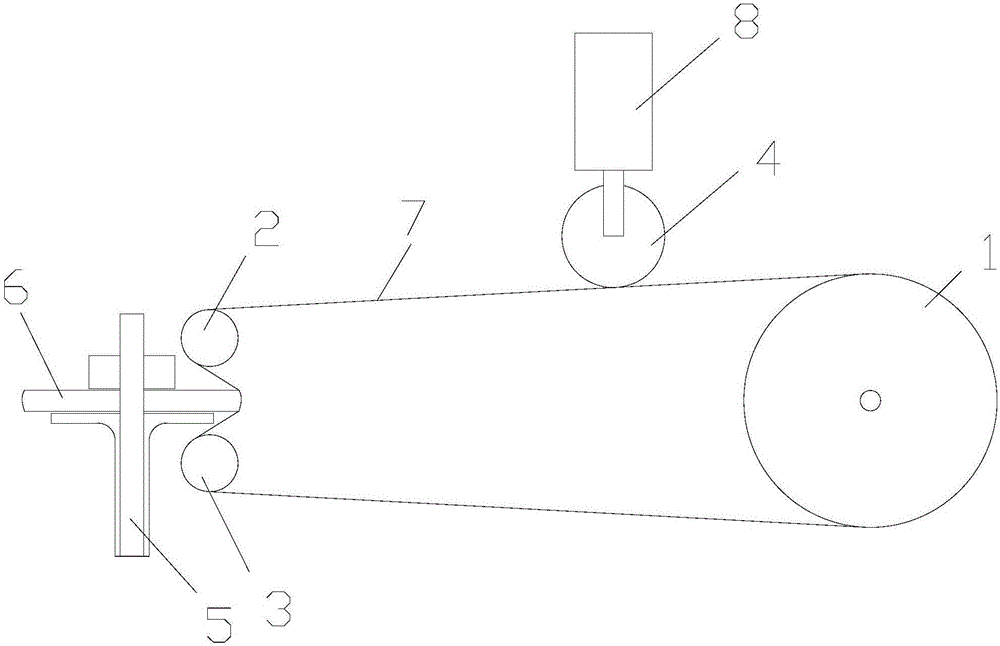

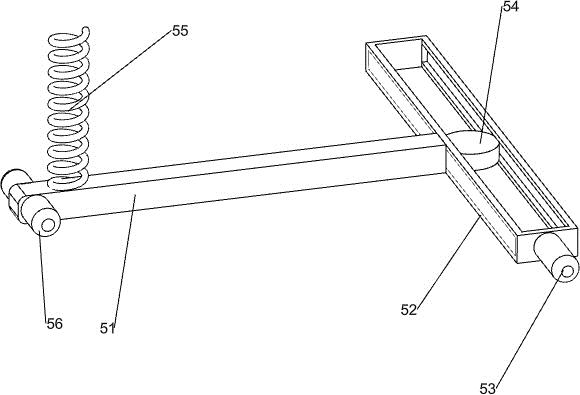

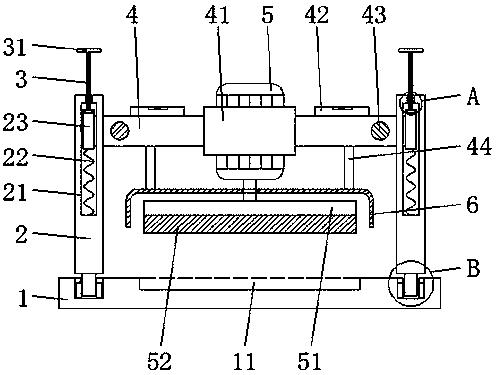

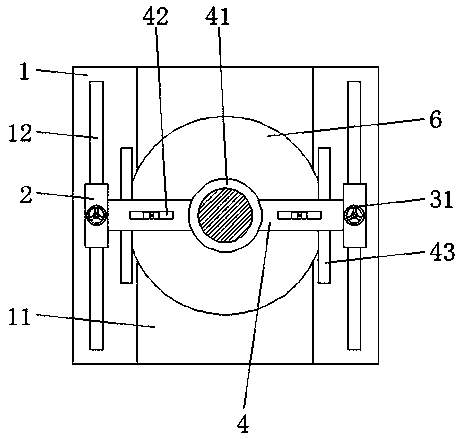

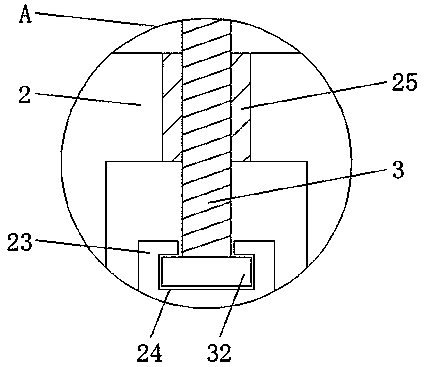

Three-dimensional curved surface polishing device

PendingCN112123163AGuaranteed clamping effectEnough room to flipGrinding carriagesPolishing machinesPolishingSlide plate

Owner:WUHAN UNIV OF SCI & TECH

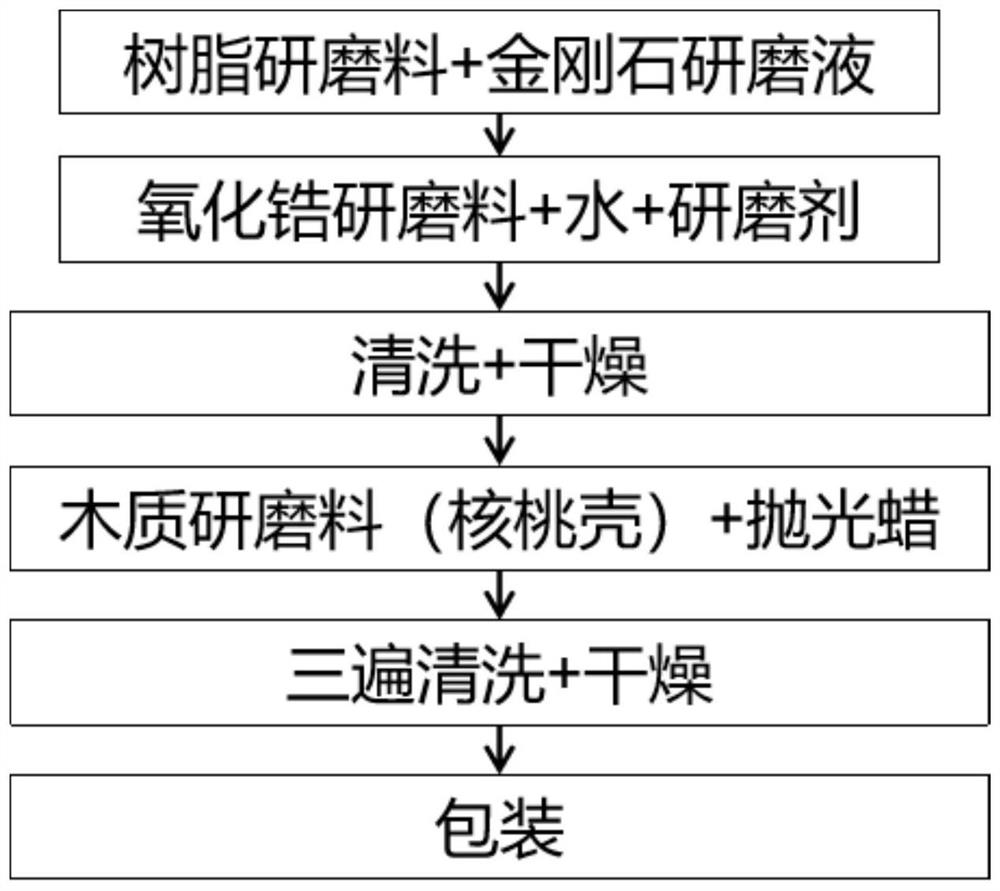

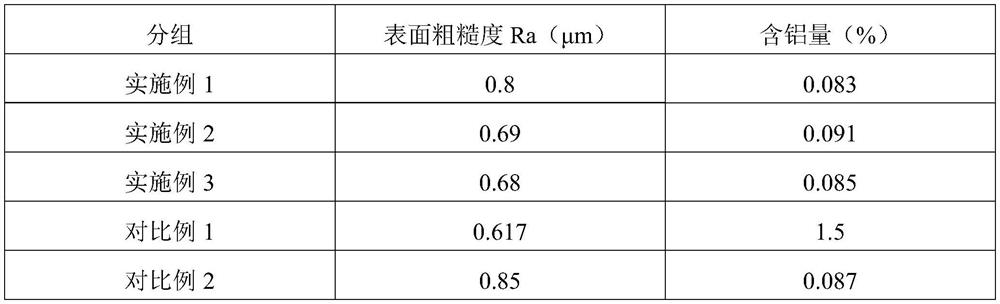

Medical titanium implant polishing technology

The invention discloses a medical titanium implant polishing technology. The technology includes the steps of the adoption of resin abrasives, rough grinding carried out by diamond grinding liquid, the adoption of zirconia abrasives, fine grinding carried out by an abradant without containing aluminum, and lightening carried out by wood abrasives. According to the technology, through the selectionof grinding composition, medical titanium implant is subjected to the rough grinding, the fine grinding, and surface lightening, a polishing product with good roughness and low aluminum content is obtained, the polishing effect is guaranteed, and meanwhile the problem of high aluminum content on the surface after mechanical polishing in an existing technology can be overcome.

Owner:FOSHAN YIHE BIOTECHNOLOGY CO LTD

High-brightness polishing paste and preparation method and application thereof

InactiveCN104592901AHigh glossGuaranteed polishing effectPolishing compositions with abrasivesParaffin waxWater baths

The invention discloses a high-brightness polishing paste and preparation method and application thereof. The preparation method comprises the following steps: heating stearic acid, paraffin wax, palm wax, bee wax and ethanol in a water bath to obtain a mixture M1; adding calcium carbonate and calcium oxide in the mixture M1 to obtain the high-brightness polishing paste; with respect to 100 parts of stearic acid by weight, the use amount of the paraffin wax is 5-50 parts, the use amount of the palm wax 5-50 parts by weight, the use amount of ethanol is 1-30 parts by weight, the use amount of calcium carbonate is 50-150 parts by weight, the use amount of calcium oxide is 50-150 parts by weight, and the use amount of bee wax is 1-30 parts by weight. After stearic acid, paraffin wax, palm wax, ethanol, calcium carbonate, calcium oxide and bee wax are mixed, the polishing paste prepared from above materials in proportion is capable of effectively promoting the surface gloss of the metal in actual use, and further the metal polishing effect can be effectively guaranteed.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

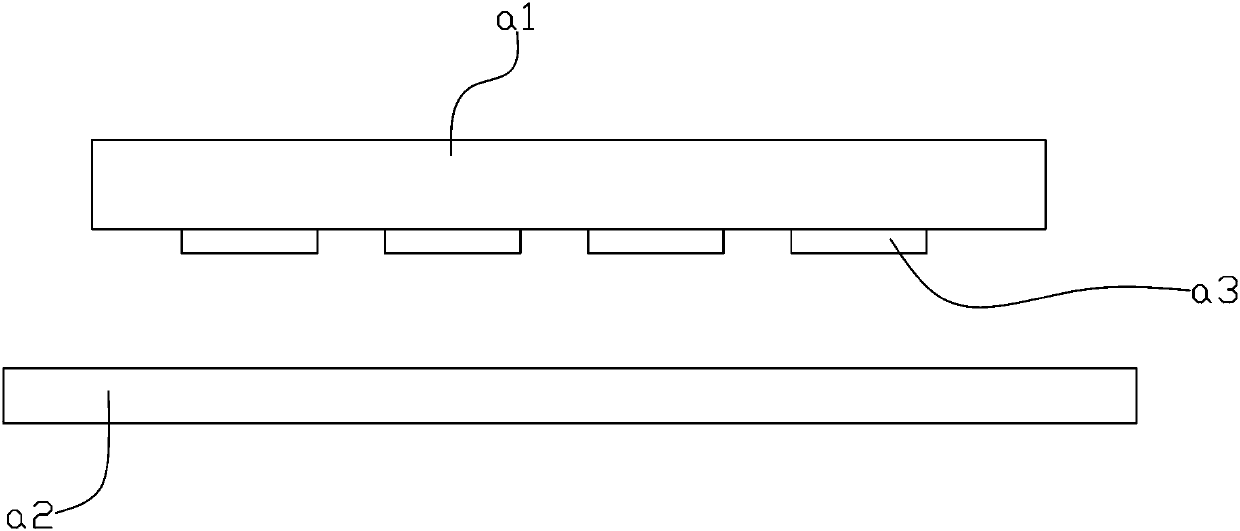

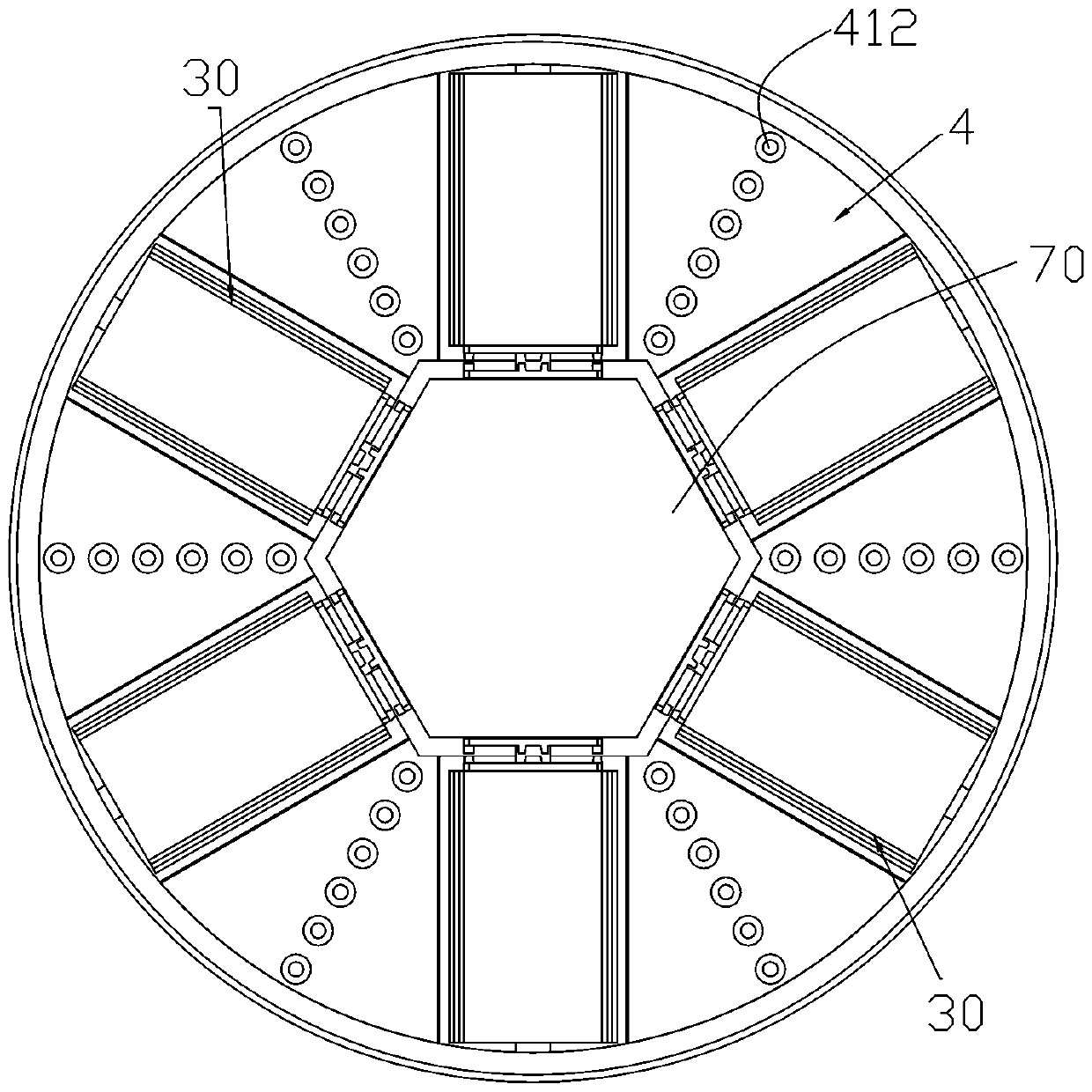

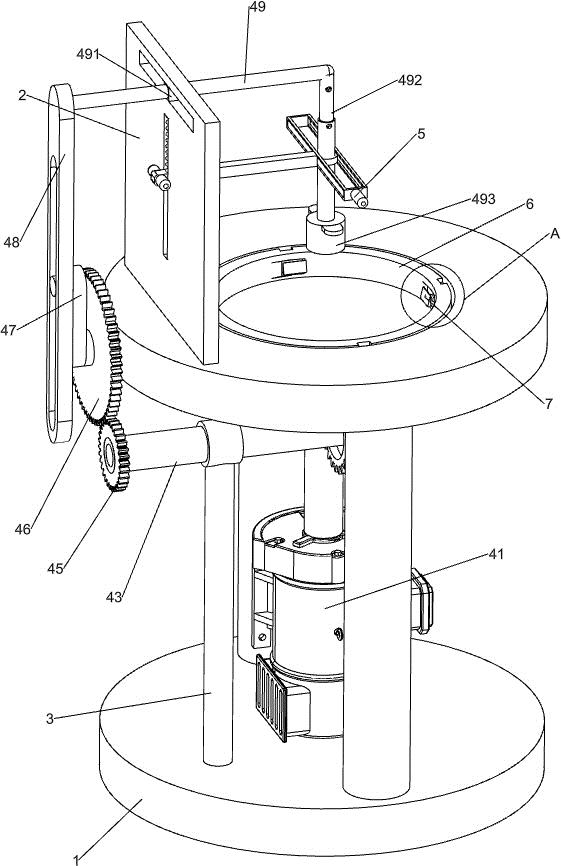

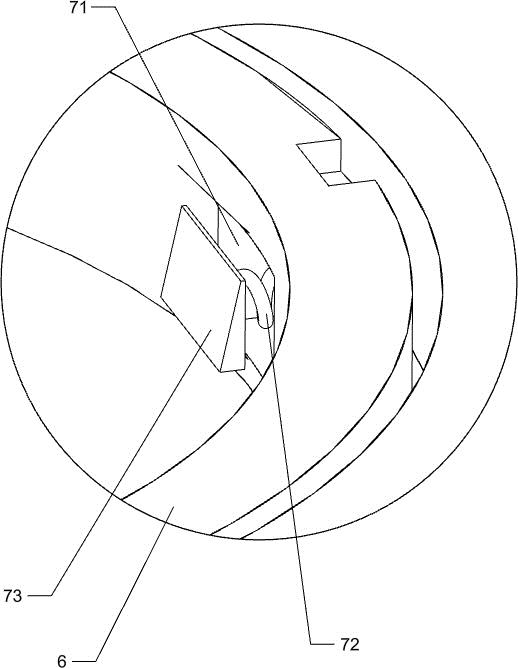

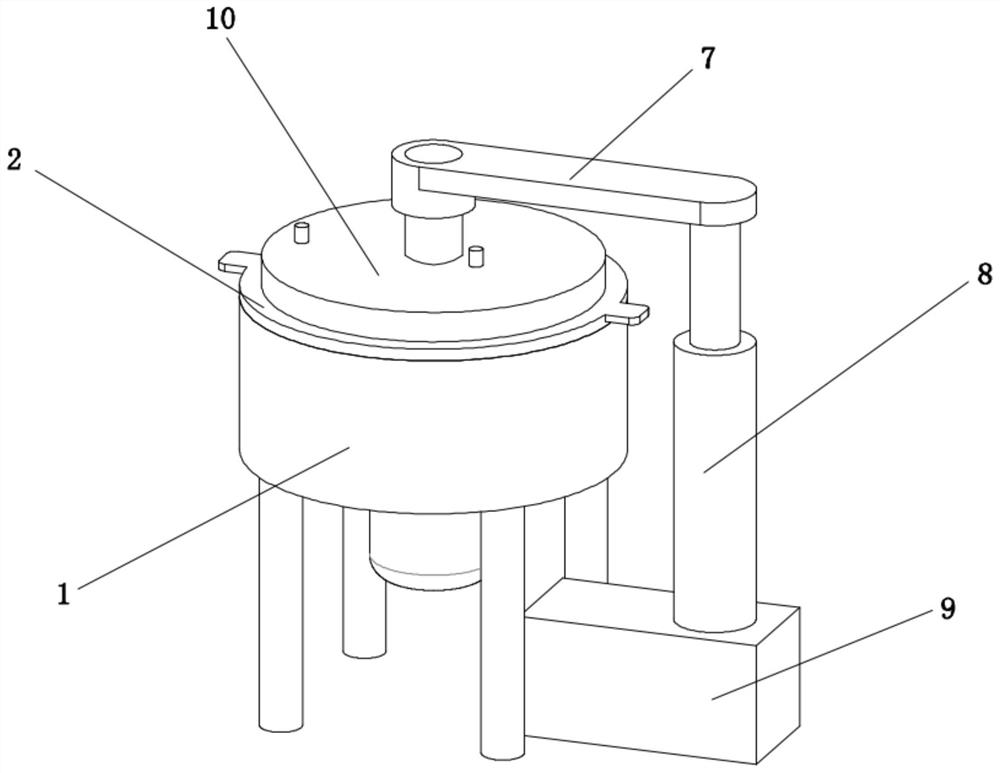

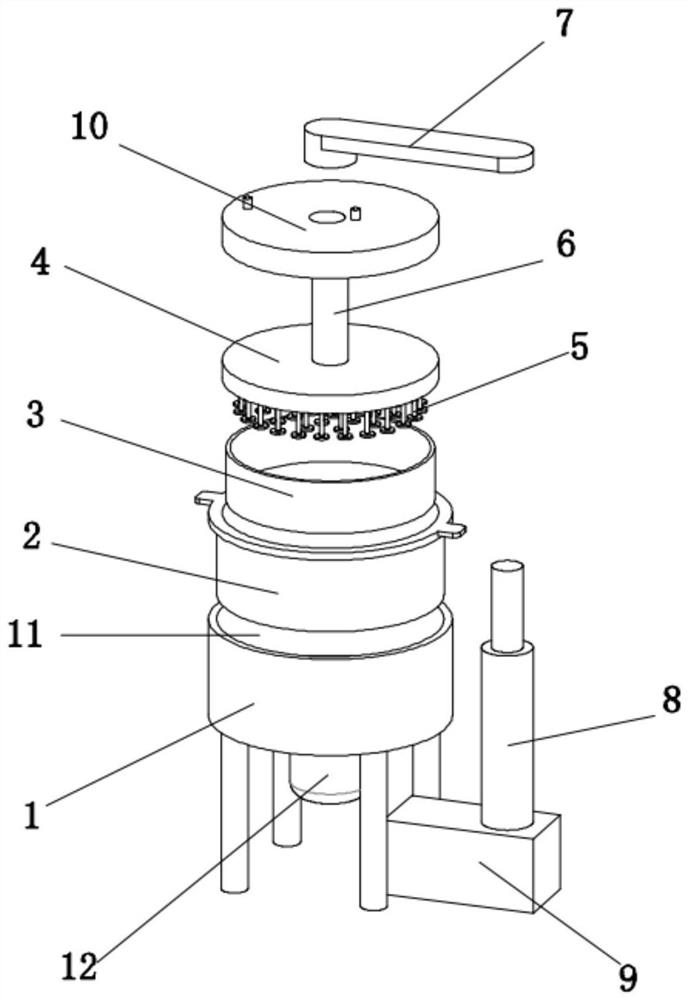

Brush auxiliary force rheological polishing device for thin-wall annular part and polishing method

PendingCN114147620AHas a flow control effectImprove polishing effectEdge grinding machinesPolishing machinesPolishingElectric machine

The brush auxiliary force rheological polishing device for the thin-wall annular part comprises a mounting table, a polishing circular groove is formed in the mounting table, and a rotary table is arranged in the center of the bottom of the polishing circular groove and connected with a rotary motor; powerful rheological polishing liquid is contained in the polishing circular groove, and a brush is annularly arranged on an inner cavity of the polishing circular groove; a mounting rack is further arranged on the mounting table, a lifting device is mounted on the mounting rack, a rotating disc is mounted on a mounting seat of the lifting device, the rotating disc and the mounting seat form a rotating pair, and the rotating center line of the rotating disc and the rotating center line of the rotating table coincide with each other; a rotating shaft is annularly arranged on the lower end face of the rotating disc, the rotating shaft and the rotating disc form a rotating pair, and the rotating shaft is connected with a driving device. Buckle mechanisms matched with each other are arranged on the rotating disc and the rotating table. The polishing device has the advantages of being high in machining efficiency, good in polishing effect and low in manufacturing cost. Correspondingly, the invention further provides a brush auxiliary force rheological polishing method for the thin-wall annular part.

Owner:新昌浙江工业大学科学技术研究院

Water purification power pump shell polishing device

InactiveCN108466159AImprove processing efficiencyReduce labor intensityGrinding carriagesPolishing machinesEngineeringManufacturing technology

The invention discloses a water purification power pump shell polishing device and relates to the technical field of water purification power pump manufacturing. A bottom box is included; the tops ofthe two opposite sides of the inner wall of the bottom box are rotationally connected with a first lead screw through a base; the surface of the first lead screw is fixedly connected with a moving boxthrough a moving block; the bottom of the inner wall of the moving box is connected with a rotating shaft through a driving device; one end of the rotating shaft is fixedly connected with a fixed device through a rotating disk; the top of the bottom box is fixedly connected with a fixed frame; one side of the inner wall of the fixed frame is rotationally connected with a pair of second lead screws through a fixed block; the second lead screws are in threaded connection with a moving device through a moving rod; one side of the moving device is fixedly connected with a first polishing wheel through a third motor; the inner wall of the fixed frame is connected with a second sliding rod in an engaged manner through a sliding device; and the surface of the second sliding rod is fixedly connected with a second polishing wheel through a crossed fixed block and a fourth motor. The water purification power pump shell polishing device solves the problems that an existing polishing technology is not uniform in force and poor in polishing effect.

Owner:江苏世丰企业管理咨询有限公司

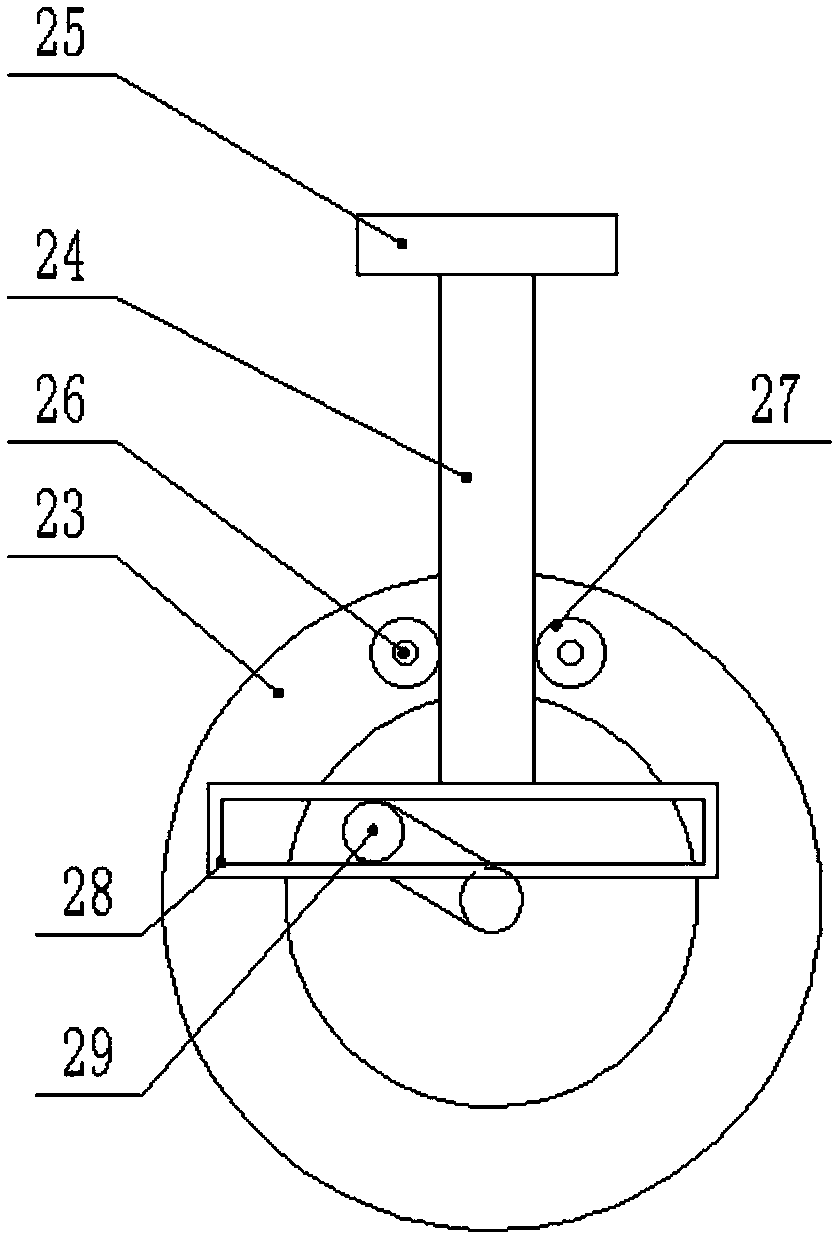

Spherical loudspeaker box shell joint polishing device of disc sliding type structure

ActiveCN108515412AGuaranteed polishing effectEasy to handleGrinding machinesCircular discFixed frame

The invention discloses a spherical loudspeaker box shell joint polishing device of a disc sliding type structure. The spherical loudspeaker box shell joint polishing device comprises a device body, supporting frames are arranged on the device body, a supporting plate is arranged at the tops of the supporting frames, fixing frames are arranged on the supporting plate, threaded columns are arrangedat the tops of the fixing frames, a rotating rod A and a rotating rod B are arranged on the fixing frames, the device body is provided with a supporting top plate, a polishing motor is arranged on the supporting top plate, a driven gear is arranged at the end part, arranged at the outer side of the left fixing frame, of the rotating rod A, the device body is provided with a power box, and a powerassembly is arranged in the power box. The spherical loudspeaker box shell joint polishing device has the advantages that the structure is simple, through the circulating type vertical movement, a spherical loudspeaker box shell clamped in clamping plates is driven to rotate, so that a joint of the spherical loudspeaker box shell can be effectively processed, protruding burrs can be avoided, in addition, through a circulation type power structure, the effect of polishing the joint of the spherical loudspeaker box shell can be guaranteed, the processing effect can be better, the use is convenient, and the practicability is high.

Owner:嵊州市格瑞特电子有限公司

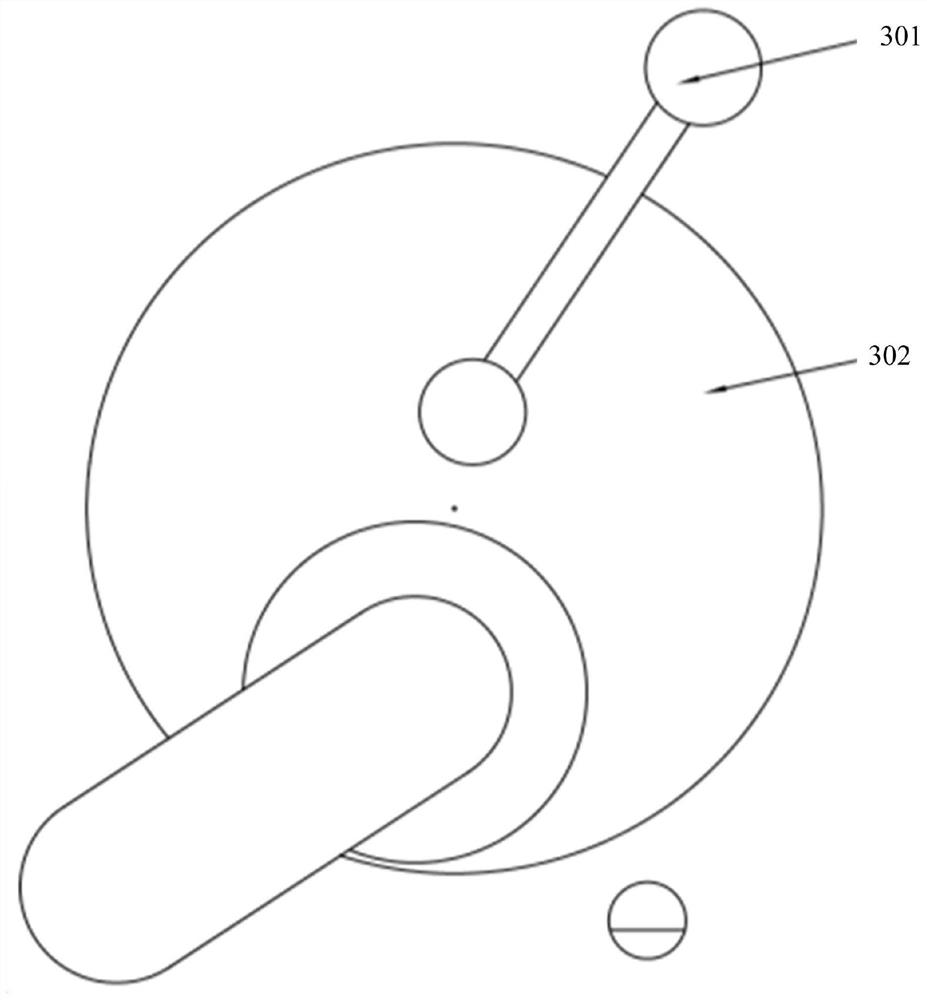

Finishing head rotating part, polishing pad finishing head and finisher

PendingCN113183031AGuaranteed polishing effectFit tightlyAbrasive surface conditioning devicesPolishingGrinding wheel

The invention discloses a dressing head rotating part, a polishing pad finishing head and a finisher. An inner ring lower pressing cover is arranged in a cavity formed between a transmission film and a grinding base, and an universal transmission pin is arranged between the inner ring lower pressing cover and the grinding base, so that a transmission film transmission structure is formed, due to the transformable characteristic of the transmission film, after a grinding wheel plate arranged below the grinding base makes contact with a polishing pad, certain pressure is applied downwards to the dressing head rotating part, the transmission film deforms with the universal transmission pin as an adjusting fulcrum along with the attachment of the grinding wheel plate to the polishing pad, and therefore universal adjustment is achieved, the grinding wheel plate is closely attached to the polishing pad, and the polishing effect of the dressing head on the polishing pad is guaranteed.

Owner:HANGZHOU ZHONGGUI ELECTRONICS TECH CO LTD

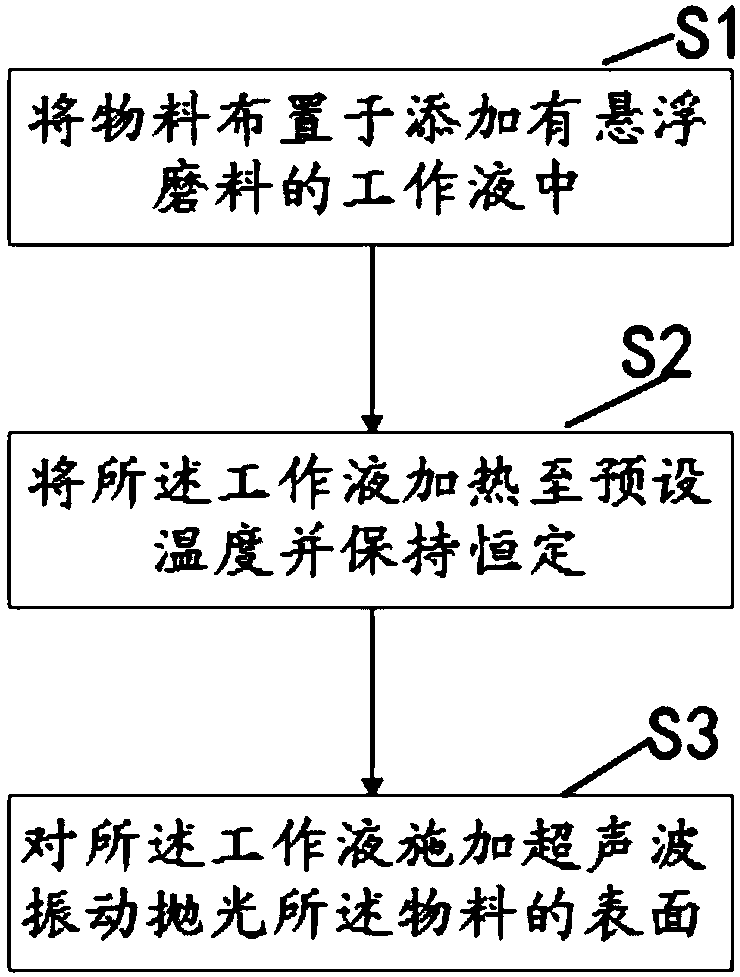

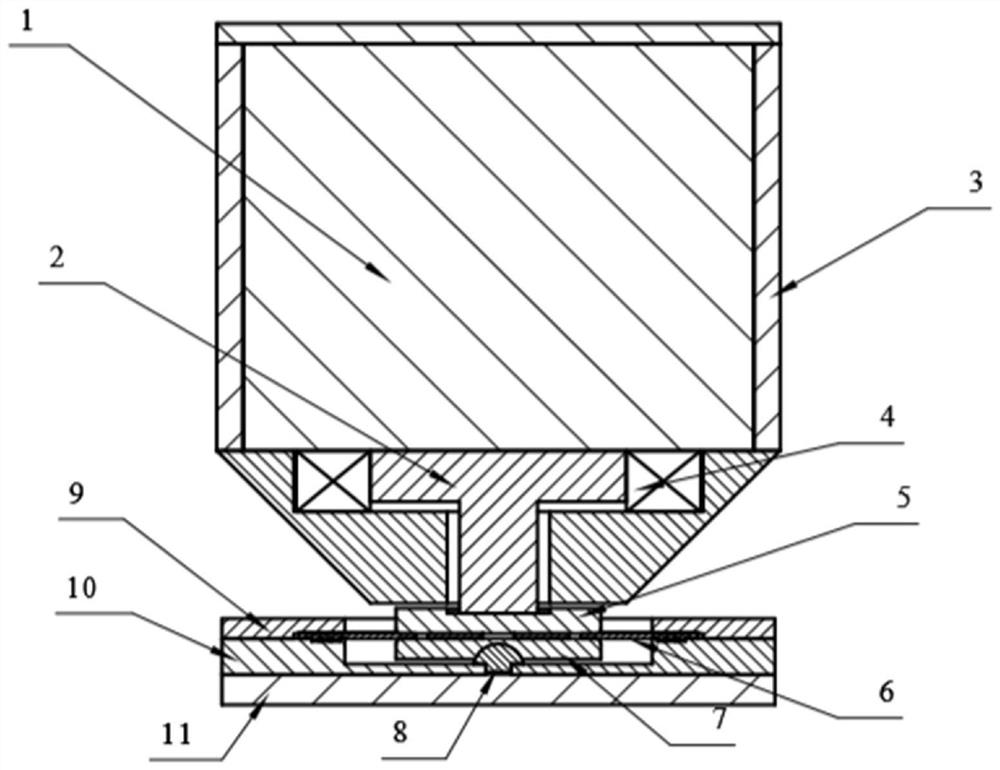

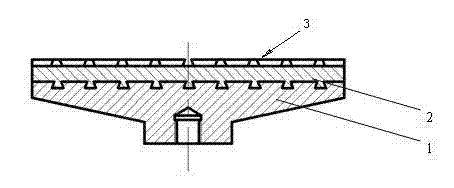

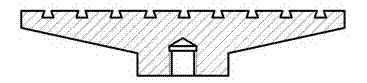

Frozen consolidated abrasive polishing pad bearing device and polishing pad thereof

InactiveCN102049739AGuaranteed polishing effectSlow melting rateFlexible-parts wheelsThermal insulationEngineering

The invention discloses a frozen consolidated abrasive polishing pad bearing device and a polishing pad thereof. The frozen consolidated abrasive polishing pad bearing device consists of a rigidity providing layer (1) and a thermal insulation layer (2) and is characterized in that the thermal insulation layer (2) is arranged on the rigidity providing layer (1), and the diameters of the rigidity providing layer (1) and the thermal insulation layer (2) are same; the rigidity providing layer (1) is integrally in a wing shape; the thermal insulation layer (2) is made of thermal insulation material such as polytetrafluoroethylene and the like; and a dovetail groove is arranged on the surface of the thermal insulation layer (2). The invention aims to enable a frozen consolidated abrasive polishing disc bearing device to have certain rigidity and uniformly control the melting speed of a frozen fixed abrasive polishing disc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Polishing device having environmental protection function and used for gear blank machining

ActiveCN113386041AStable temperatureGuaranteed polishing effectEdge grinding machinesPolishing machinesElectric machinePolishing

The invention discloses a polishing device having an environmental protection function and used for gear blank machining, and belongs to the technical field of gear machining. The polishing device comprises a polishing barrel, a polishing cavity is formed in the upper end of the polishing barrel, a polishing rotary barrel is arranged in the polishing cavity, a polishing motor is arranged in the center of the bottom of the polishing barrel, an output shaft of the polishing motor penetrates through the bottom of the polishing barrel, the upper end of the output shaft of the polishing motor is fixedly connected with the center of the bottom of the polishing rotary barrel, polishing liquid is loaded in the polishing cavity, and a polishing medium is loaded in the polishing rotary barrel. The polishing medium is driven by the polishing rotary barrel to rotate, so that a to-be-polished gear blank is ground and polished; through an arranged evaporation heat pipe, heat generated by grinding and polishing can be quickly guided out close to the to-be-polished gear blank, the temperature of the to-be-polished gear blank is kept stable, the polishing effect is guaranteed, a cooling liquid circulating device does not need to be additionally arranged, the grinding energy consumption is greatly reduced, the subsequent treatment step of the cooling liquid is omitted, and the polishing device is more energy-saving and environment-friendly.

Owner:重庆天力通科技开发有限公司

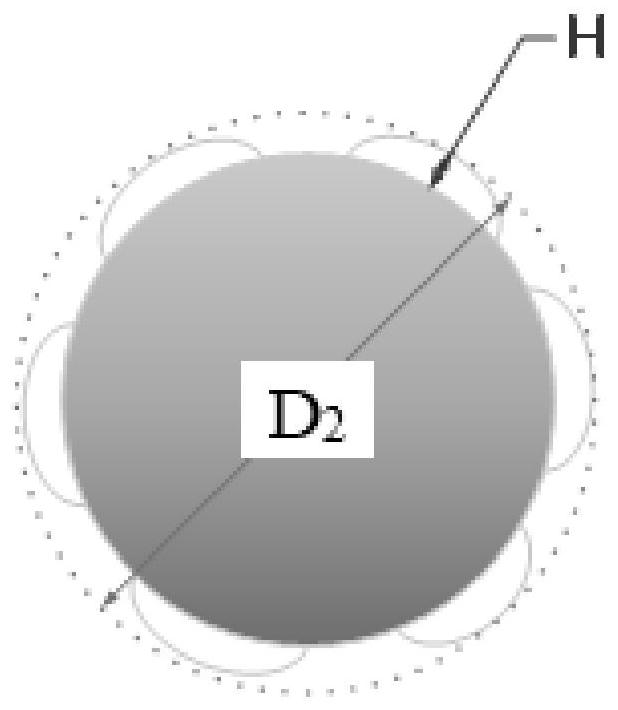

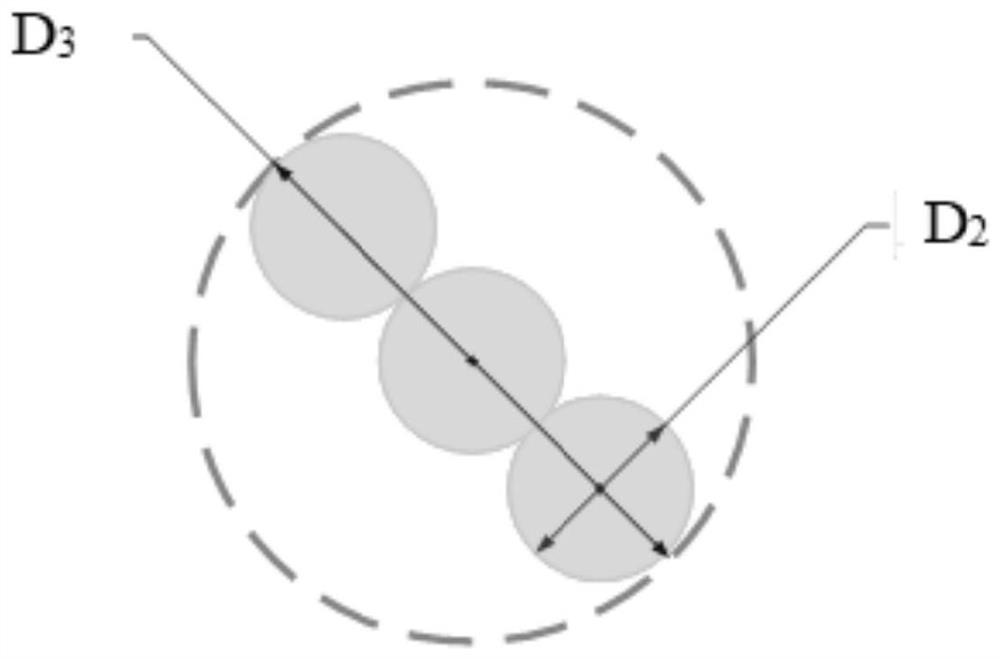

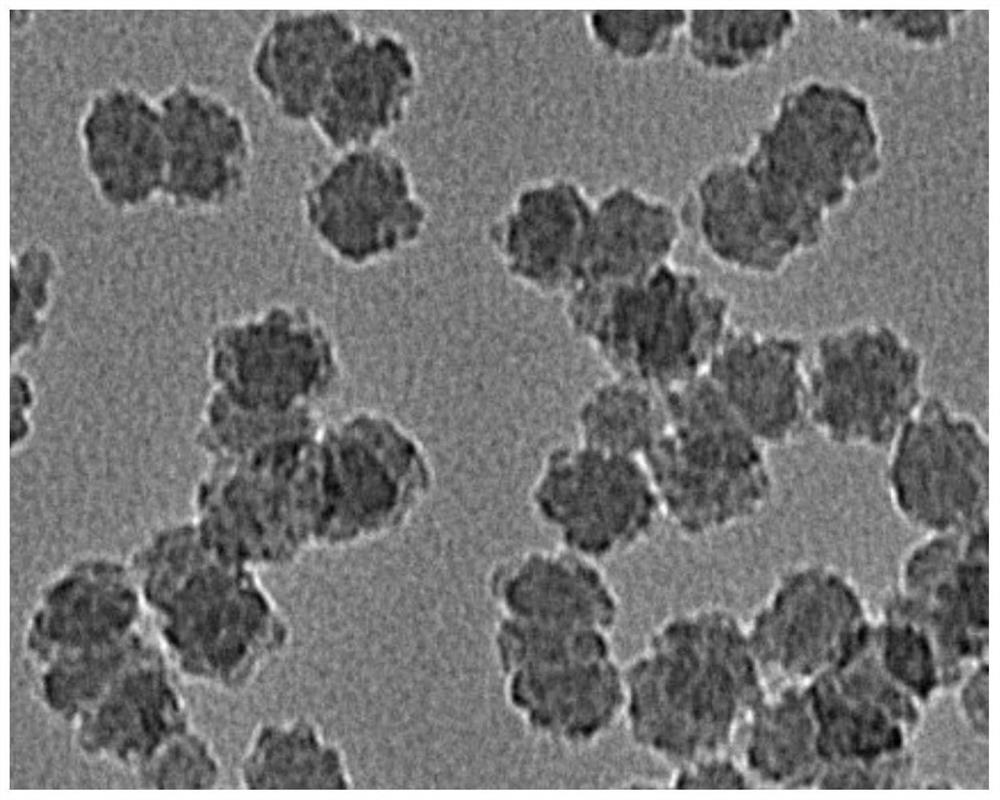

Silica sol with convex colloid surface, preparation method and application of silica sol

ActiveCN112299425AReduce contact timeReduce defectsNanotechnologySilicon compoundsLiquid mediumDynamic light scattering

The invention relates to the technical field of chemical mechanical polishing of semiconductors, and particularly discloses silica sol with a convex colloid surface, a preparation method and application of the silica sol. The silica sol with a convex colloid surface comprises a liquid medium and colloidal particles, the colloidal particles are wolf-tooth-stick-shaped silicon dioxide colloidal particles with bulges on the surface, and the heights H of the bulges are 1-8nm; the nitrogen adsorption BET specific surface area fitting particle size of the silicon dioxide colloid particles is D1, theshort-axis particle size obtained through characterization of a transmission electron microscope is D2, the particle size measured through dynamic light scattering is D3, D2 / D1 is larger than or equal to 1.2 and smaller than or equal to 1.8, and D3 / D1 is larger than or equal to 2.0 and smaller than or equal to 6.3. The silica sol provided by the invention has high roughness and special-shaped degree, can effectively reduce the contact time with a ground object and reduce the generation of defects and scratches, and is beneficial to improving the polishing efficiency when being used in a polishing solution.

Owner:河北硅研电子材料有限公司

Novel bamboo-wood floor polishing machine

InactiveCN108527081AEasy to operateEasy to adjustPolishing machinesGrinding machinesEngineeringRisk stroke

The invention discloses a novel bamboo-wood floor polishing machine which comprises a placement plate, support pillars, a cross rod, first sliding chutes and second sliding chutes. The first sliding chutes are formed in the upper surface of the placement plate; stroke blocks are slidably arranged in the first sliding chutes; support pillars are welded to the upper ends of the stroke blocks; sliding blocks are movably arranged in the second sliding chutes; threaded rods are rotatably arranged in screw holes through threads; rotating blocks are fixed to the lower ends of the threaded rods and are rotatably arranged in rotating grooves; rotating handles are welded to the upper ends of the threaded rods; an electromotor is embedded into a fixing sleeve; a polishing plate is rotatably arrangedat the lower end of the electromotor; a polishing hairbrush is embedded to the lower surface of the polishing plate; and symmetrically distributed level gauges are fixed to the upper surface of the cross rod. According to the novel bamboo-wood floor polishing machine provided by the invention, through arranging the threaded rods and the level gauges, the cross rod can be ensured to be at a horizontal state, so that the polishing hairbrush and a bamboo-wood floor are ensured to fit horizontally, and a polishing effect is improved.

Owner:王盈

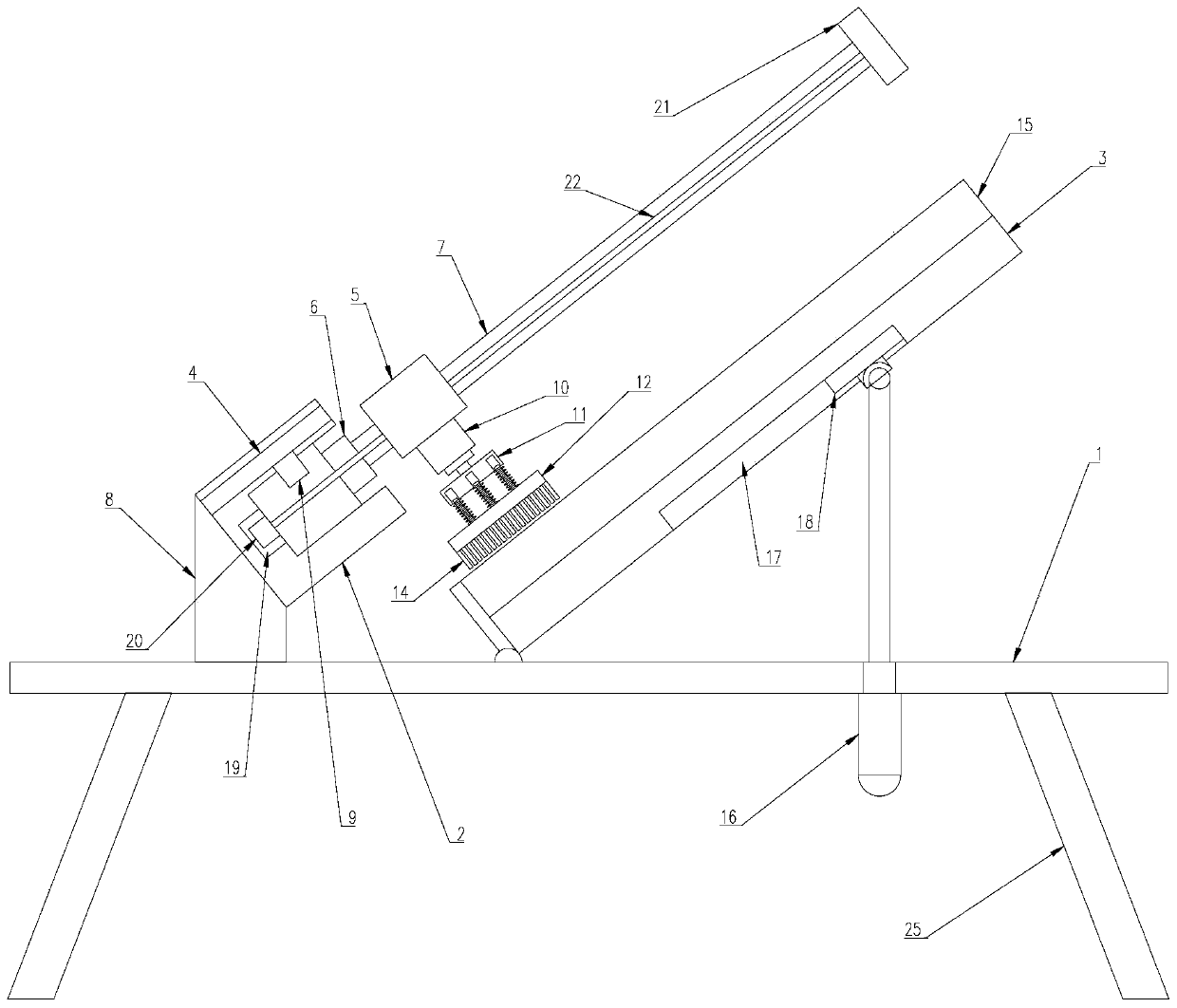

Wooden door polishing device

InactiveCN111037443AGuaranteed polishing effectImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a wooden door polishing device. The wooden door polishing device comprises a supporting plate, a supporting sliding groove formed in the supporting plate, a fixing plate hingedto the supporting plate, a linear lifting mechanism arranged in the supporting sliding groove, a mounting plate connected to one end of the supporting sliding groove, a sliding seat arranged on the linear lifting mechanism and a polishing mechanism mounted on the sliding seat, wherein the supporting sliding groove is obliquely formed; the polishing mechanism comprises a driving motor, a rotary fixing disc and a polishing disc; and baffles are arranged at the lower end and the two sides of the fixing plate correspondingly. According to the polishing device, the linear lifting mechanism capableof horizontally moving in a reciprocating mode is arranged, meanwhile, the polishing mechanism capable of moving up and down is arranged, the fixing plate is arranged, thus, a wooden door is fixed conveniently and then polished rapidly, the wooden door polishing effect is ensured, the requirement for polishing the surface of the uneven wooden door is met, meanwhile, the most ideal polishing effect on wooden doors with different thicknesses can be achieved, and the wooden door polishing device is convenient to use and practical.

Owner:重庆市豪迈家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com