Multi-station numerically controlled side polishing machine

A polishing machine and multi-station technology, which is applied in the field of polishing machines, can solve the problems of shortening the service life of the Z-axis lifting motion mechanism, difficulty in ensuring the quality of working polishing, and poor stability of lifting work, achieving good polishing effect, ingenious structural design, The effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

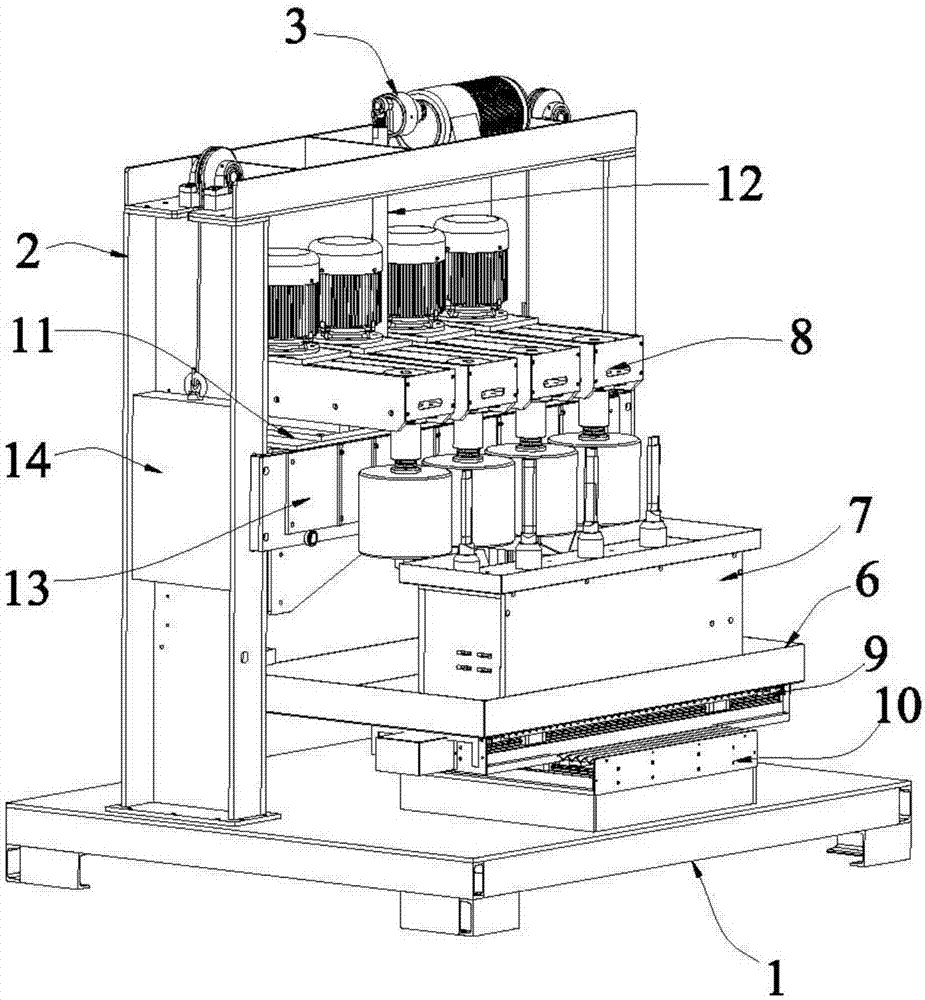

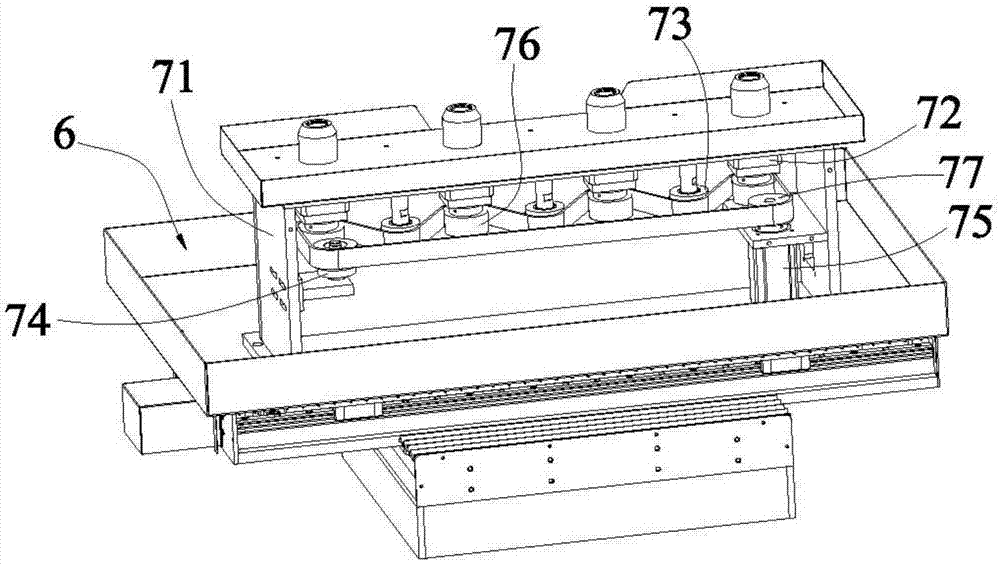

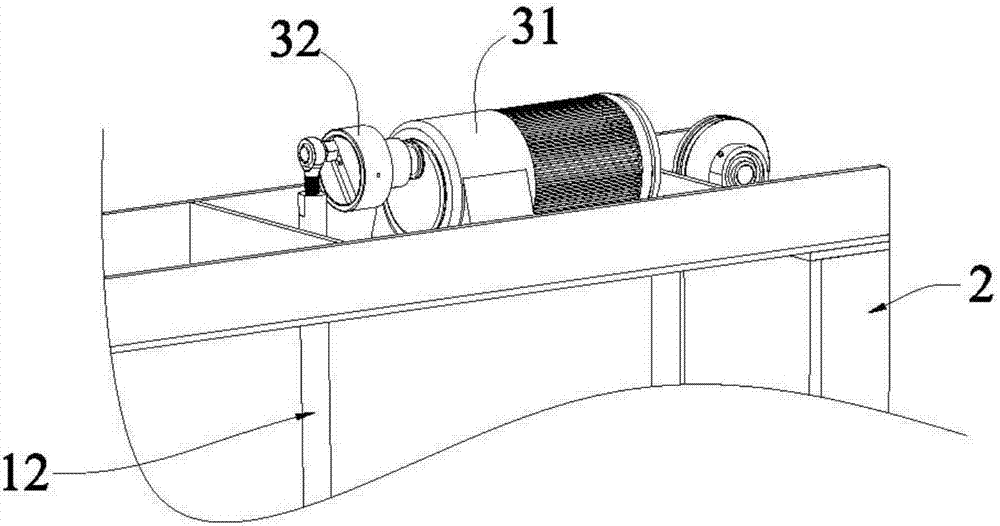

[0026] Examples, see Figure 1 to Figure 7 , a multi-station CNC side polishing machine provided in this embodiment, which includes a base 1, a gantry frame 2, an up and down reciprocating device 3, a lifting height adjustment device 4, a feed motion mechanism 5, a water basin 6, and a workpiece clamping Module 7, polishing device 8, X-axis motion mechanism 9, Y-axis motion mechanism 10, lifting beam 11 and lifting screw 12, the gantry 2 is vertically arranged on the base 1, and the Y-axis motion mechanism 10 corresponds to the gantry 2 The front position is set on the base 1, the X-axis motion mechanism 9 is set on the Y-axis motion mechanism 10, and is driven by the Y-axis motion mechanism 10 to reciprocate along the Y-axis; the water basin 6 is set on the X-axis The moving mechanism 9 is driven by the X-axis moving mechanism 9 to reciprocate along the X-axis; the workpiece clamping module 7 is fixed on the water basin 6; The height adjusting device 4 is arranged in the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com