Electrolyte plasma polishing machine

A polishing machine and plasma technology, which is applied in the field of polishing machines, can solve the problems of large size and difficult handling of polishing machines, and achieve the effects of good operation, simple and easy installation process, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

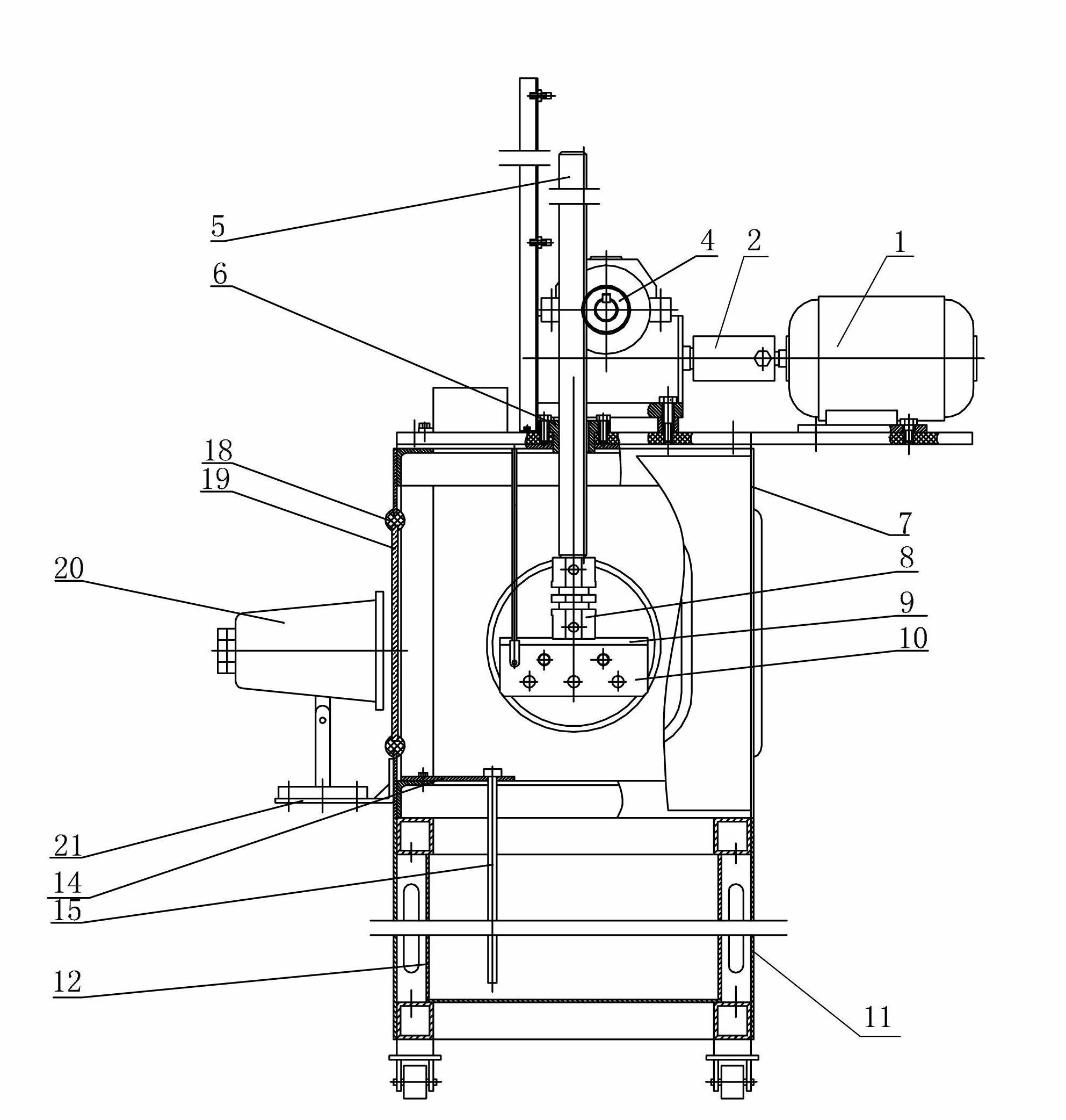

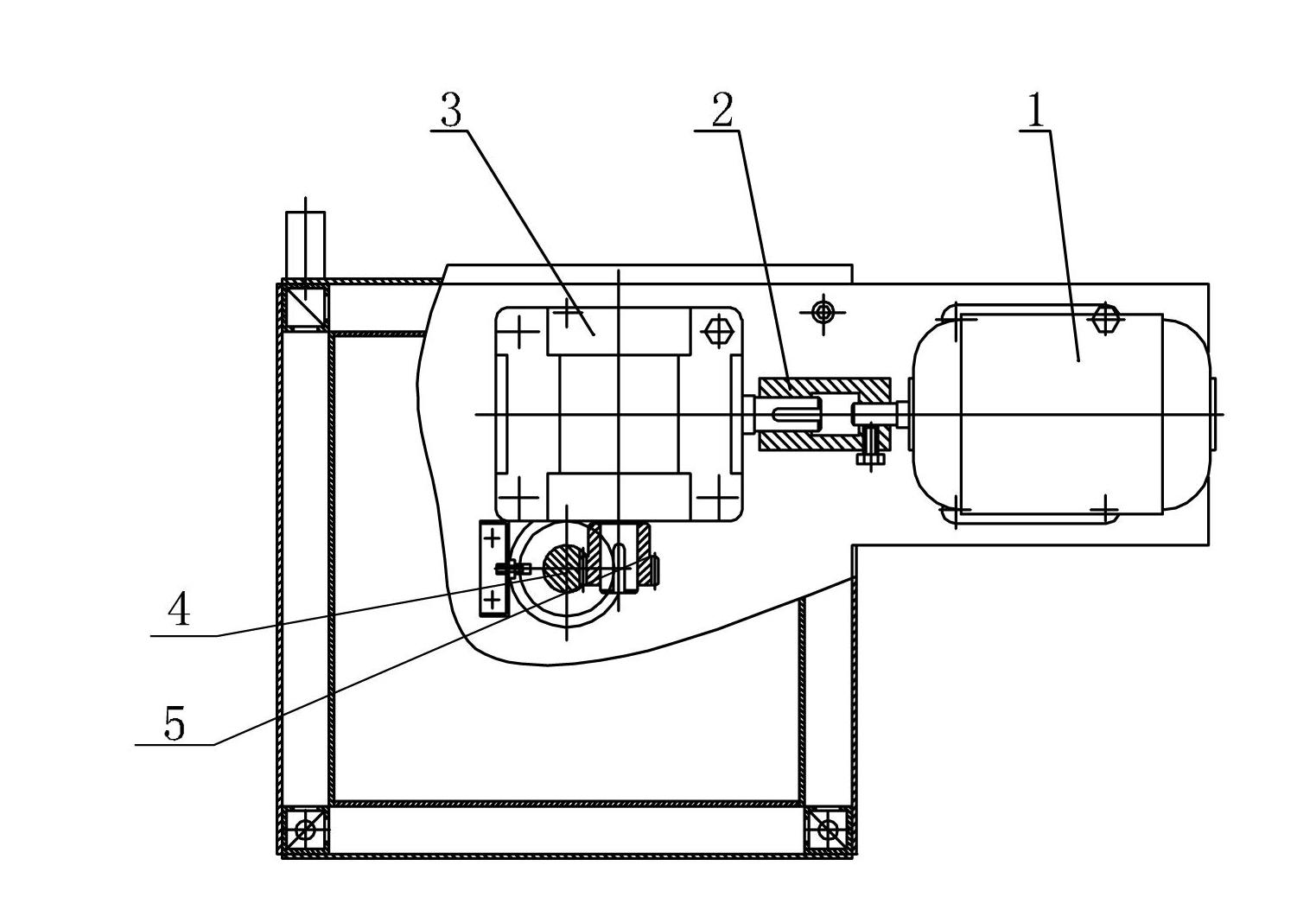

[0007] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the polishing machine of this embodiment includes motor 1, coupling 2, speed reducer 3, gear 4, rack 5, guide sleeve 6, upper box 7, insulator 8, connecting plate 9, anode 10, lower Box 11, working box 12, heater 13, heater rack 14, condensation pipe 15 and pipe joint 22, the output shaft of motor 1 is connected with the input shaft of reducer 3 through coupling 2, the output shaft of reducer 3 A gear 4 is mounted on the top, and the gear 4 meshes with the rack 5. One end of the rack 5 passes through the guide sleeve 6 and is installed in the upper box 7 and connected with the insulator 8. The insulator 8 is connected with the anode 10 through the connecting plate 9, and the guide sleeve 6 is fixed. Installed on the top of the upper box 7, the upper box 7 is installed on the lower box 11 and the two are connected, the lower box 11 is provided with a working box 12 with polishing fluid...

specific Embodiment approach 2

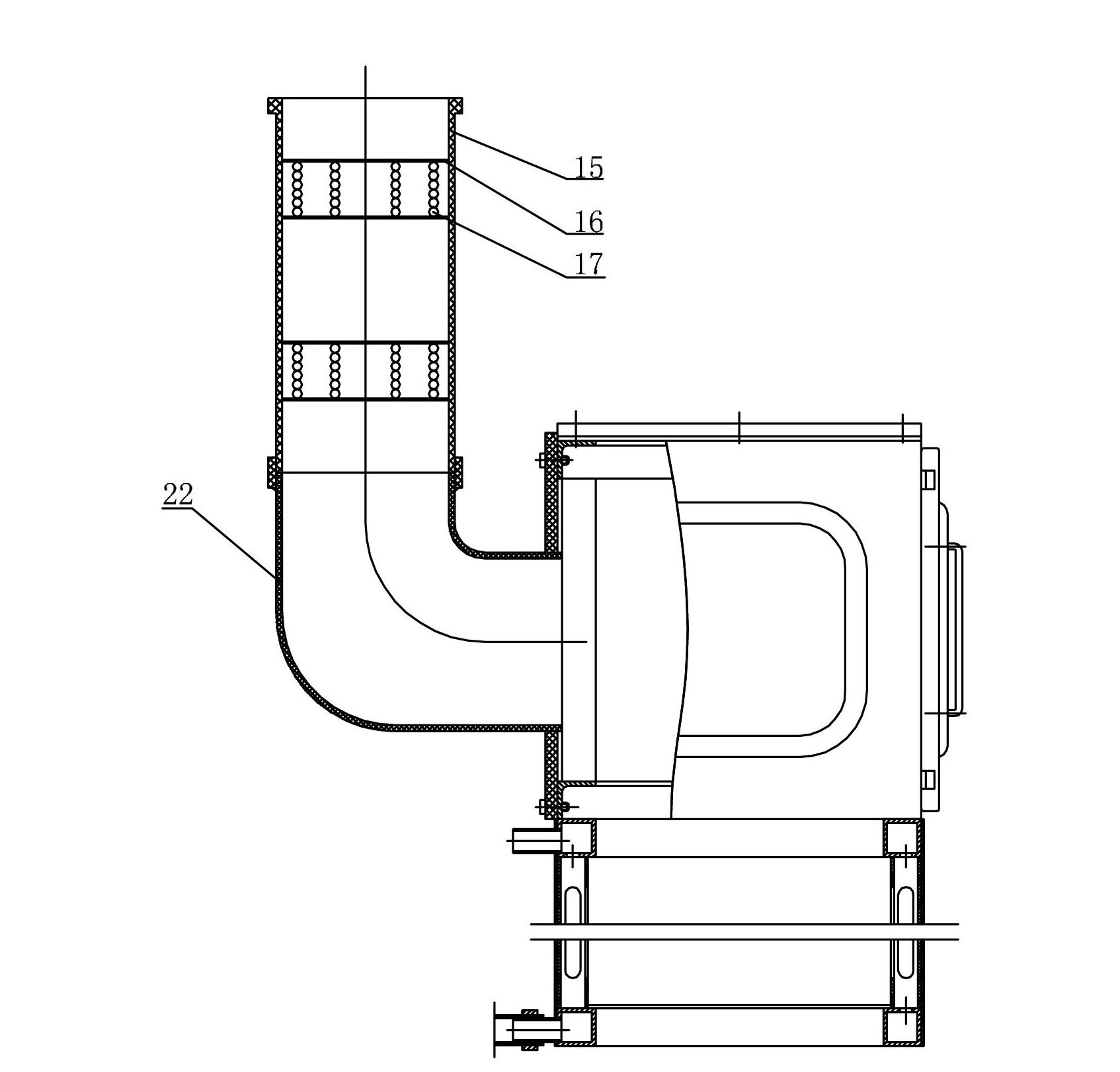

[0008] Specific implementation mode two: combination image 3 Illustrate this embodiment, the polishing machine of this embodiment also comprises water spray sheet 16 and water spray ball 17, and described polishing machine also comprises multiple groups of water spray sheet 16 and multiple groups of water spray ball 17, and multiple groups of water spray are housed in condenser tube 15 Sheet 16, the number of each group of water spray sheets 16 is 2, each group of water spray sheets 16 is provided with multiple groups of water spray balls 17, the water vapor generated in the polishing process is cooled when passing through the water spray balls 17, becomes water, and flows back into the workbox 12. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, the polishing machine of this embodiment also comprises six rubber strips 18 and three glass windows 19, glass windows 19 are housed on the three side walls of upper case 7, and each glass window 19 is provided with two rubber strips Article 18, the main purpose of this portable device is to display and process small-volume parts, and three observation windows are added to facilitate the display of the polishing process. Other implementation modes are the same as the specific implementation mode 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com