Medical titanium implant polishing technology

An implant and process technology, which is applied in the polishing process of medical titanium implants, can solve problems such as difficult cleaning, high aluminum content on the surface of titanium parts, and aluminum element enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of additive manufacturing medical titanium implant, the mass fraction of its each component is as follows: Fe:0.10wt%, C:0.020wt%, H:0.025wt%, N:0.022wt%, O:0.14wt% and Ti: margin. The medical titanium implants used in this example are 4 craniofacial bone plates of the same size, 50 mm long, 10 mm wide, and 2 mm thick, with 4 screw holes evenly distributed on the plate, and the diameter of the screw holes is 2 mm.

[0035] The above-mentioned medical titanium implant was made by 3D printing, (SLM, selective laser melting technology, laser powder bed printing) forming parameters are as follows: substrate temperature: 200°C; laser power: 100W; scanning speed: 360mm / s; scanning distance: 0.08mm; layer thickness: 0.03mm. The surface roughness Ra of the obtained printed part was 4.27 μm.

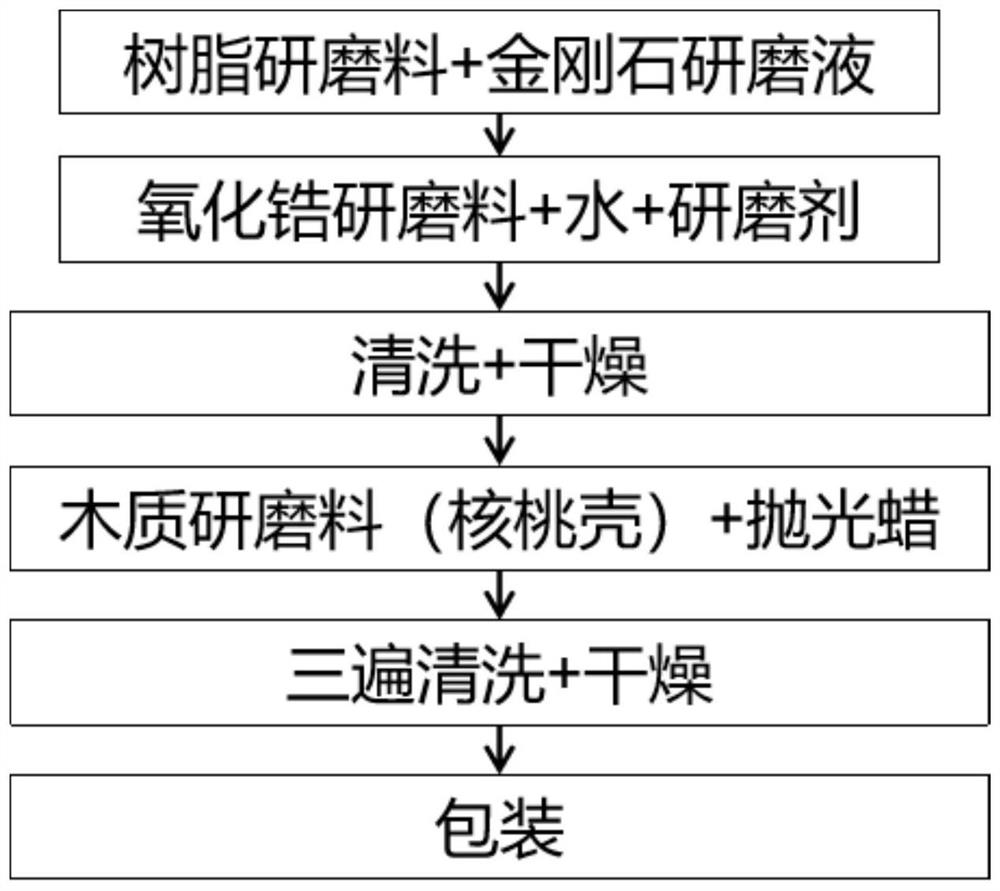

[0036] This embodiment provides the aluminum-less polishing treatment method for the above-mentioned additive manufacturing of medical titanium implants, according to figure 1 Th...

Embodiment 2

[0044] Using the same additive as in Example 1 to manufacture medical titanium implants, according to figure 1 The shown aluminum-less polishing treatment process method of the present invention carries out polishing treatment:

[0045] Step 1, coarse grinding, resin grinding material (composition is phenolic resin+quartz sand, specification is conical 4*4mm) and diamond abrasive liquid (particle size is 15 microns, solid concentration is 3%) in the centrifugal grinder (according to Resin abrasive: medical titanium implant = 9:1 volume ratio, and resin abrasive: diamond abrasive liquid = 3:1 mass ratio), set 100r / min (40-200r / min is acceptable) for grinding for 20min ( 10 to 30 minutes), remove the surface dirt and sharp edges of the resin abrasive, and then add the medical titanium implant, set the machine speed to 480r / min, and the time is 1h; the concave surface roughness Ra of the medical titanium implant after grinding is 1.58μm;

[0046] Step 2, fine grinding, the zirc...

Embodiment 3

[0052] Using the same additive as in Example 1 to manufacture medical titanium implants, according to figure 1 Shown less aluminum polishing treatment process method of the present invention is polished:

[0053] Step 1, coarse grinding, resin grinding material (composition is phenolic resin+quartz sand, specification is conical 4*4mm) and diamond abrasive liquid (particle size is 15 microns, solid concentration is 3%) in the centrifugal grinder (according to Resin abrasive: medical titanium implant = 9:1 volume ratio, and resin abrasive: diamond abrasive liquid = 3:1 mass ratio), set 100r / min (40-200r / min is acceptable) for grinding for 20min ( 10 to 30 minutes), remove the surface dirt and sharp edges of the resin abrasive, and then add the medical titanium implant, set the machine speed to 400r / min, and the time is 2h; the concave surface roughness of the medical titanium implant after grinding is Ra 1.43μm;

[0054] Step 2, fine grinding, the zirconia abrasive and the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com