Patents

Literature

132results about How to "Reduce aluminum content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

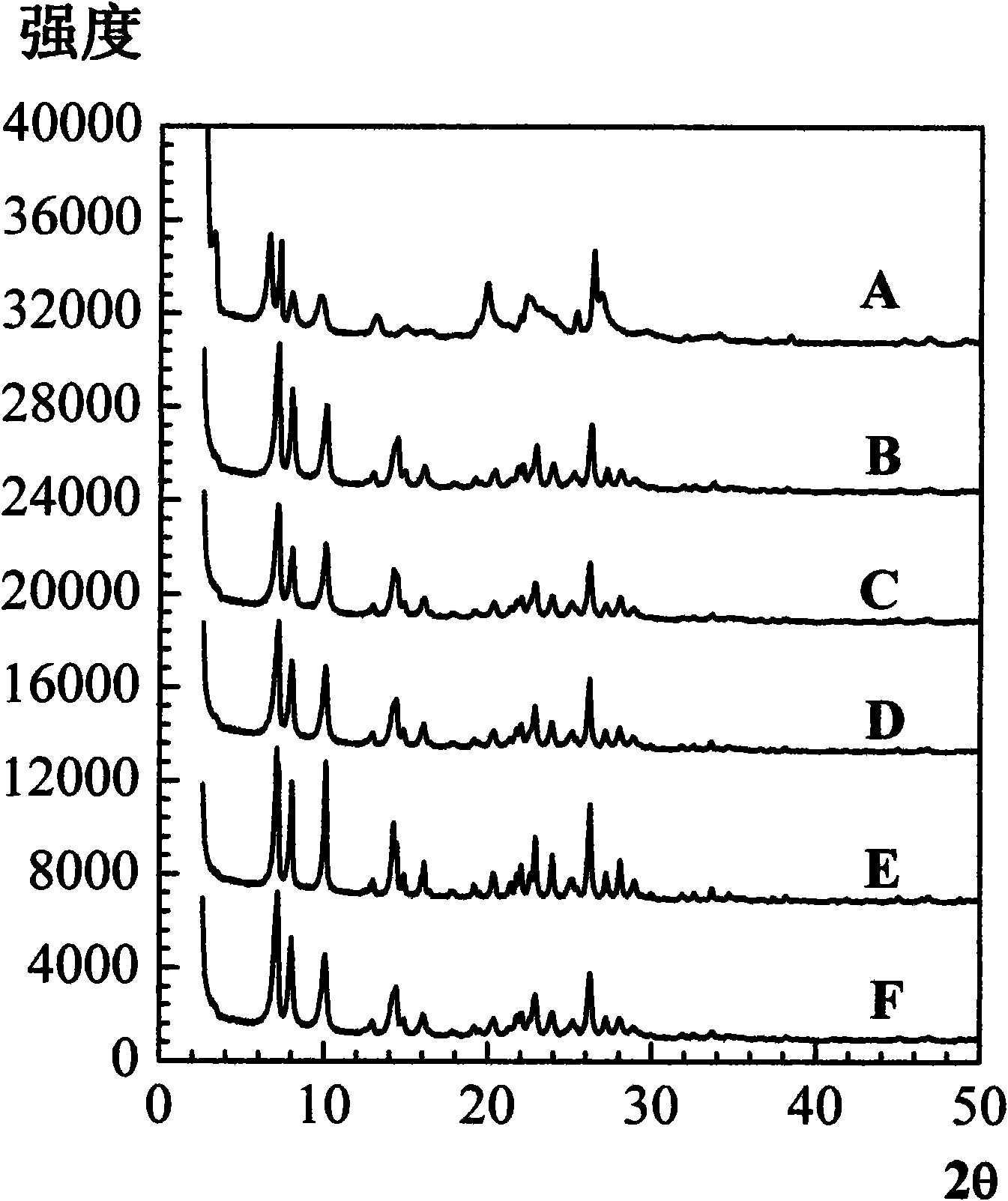

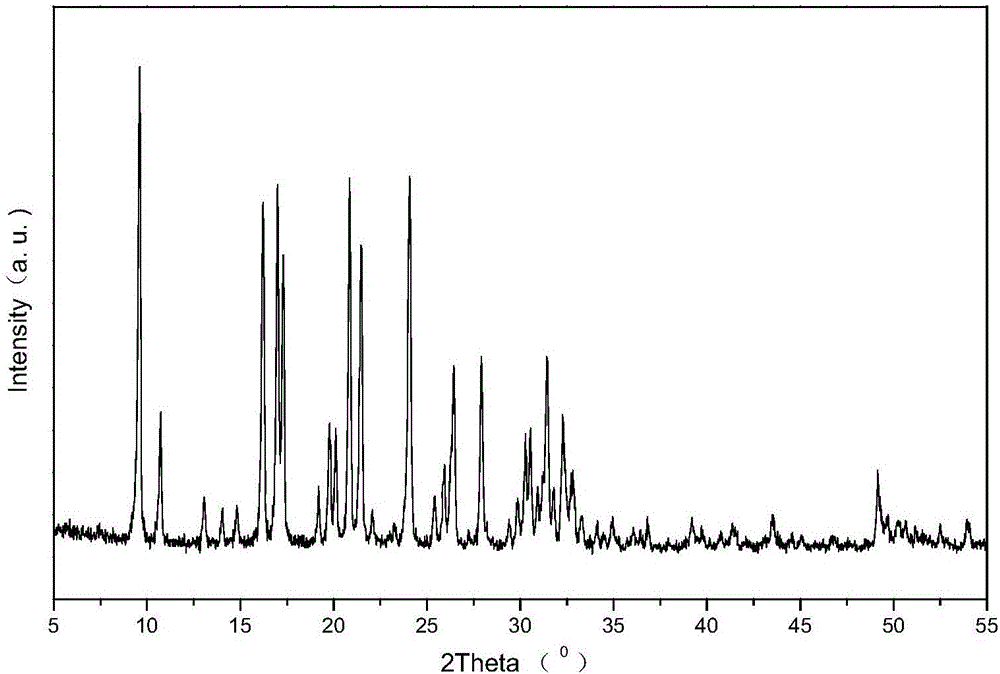

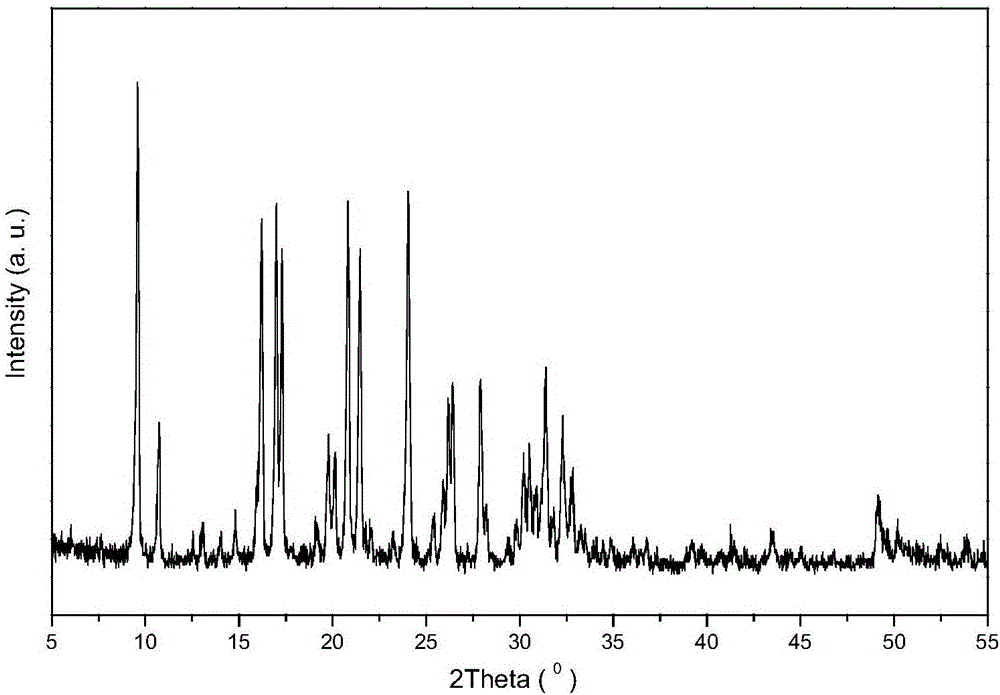

Preparation method of high silica alumina ratio MCM-22 molecular sieve catalyst

InactiveCN101554592AReduce aluminum contentLess acidic surfaceMolecular sieve catalystsHydrocarbon by hydrocarbon crackingAir atmosphereIon exchange

The invention provides a preparation method of a high silica alumina ratio MCM-22 molecular sieve catalyst. The method comprises the following steps: raw materials of sodium source, silicon source, aluminium source, boron source, templeting agent and deionized water are put in a synthesis reactor according to the mixture ratio and statically or dynamically crystallized for 1-20 days at the crystallization temperature of 110-200 DEG C, and the product is filtered, washed and dried to obtain molecular sieve initial powder; and the obtained molecular sieve initial powder is roasted in the air atmosphere at the high temperature of 450-750 DEG C so as to remove the templeting agent and is exchanged into an ammonium type molecular sieve by an ammonium ion exchange method, the ammonium type molecular sieve is roasted at the temperature of 450-750 DEG C to obtain a corresponding hydrogen type molecular sieve, and the hydrogen type molecular sieve is prepared into the high silica alumina ratio MCM-22 molecular sieve catalyst after being molded. By using the method, the MCM-22 molecular sieve catalyst with controllable silica alumina ratio, high crystallization degree and high silica alumina ratio can be prepared, and the invention breaks through the range of the silica alumina ratio of the MCM-22 molecular sieve catalyst of the conventional method and overcomes the problem of descending of crystallization degree generally existing in the post-processing method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

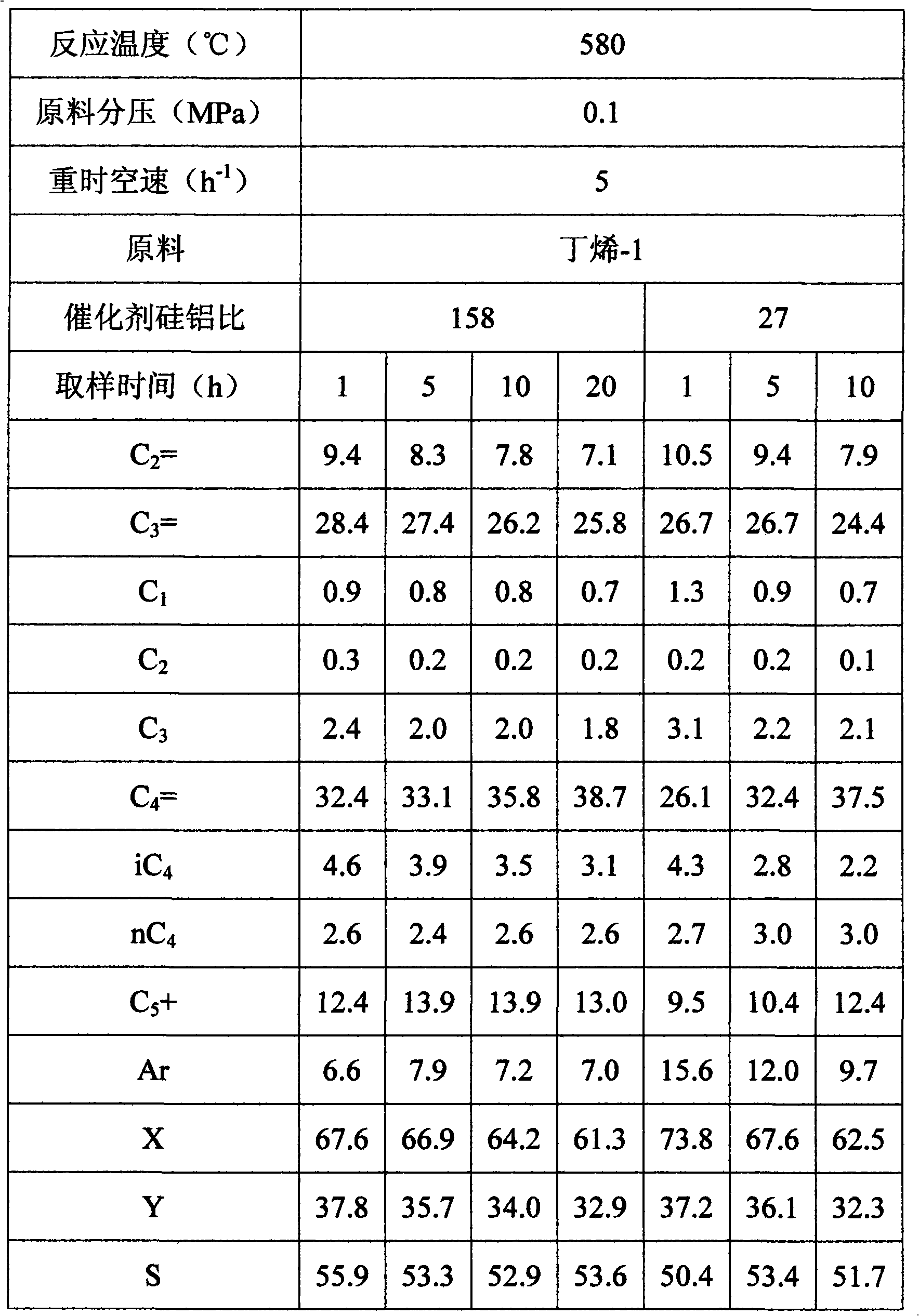

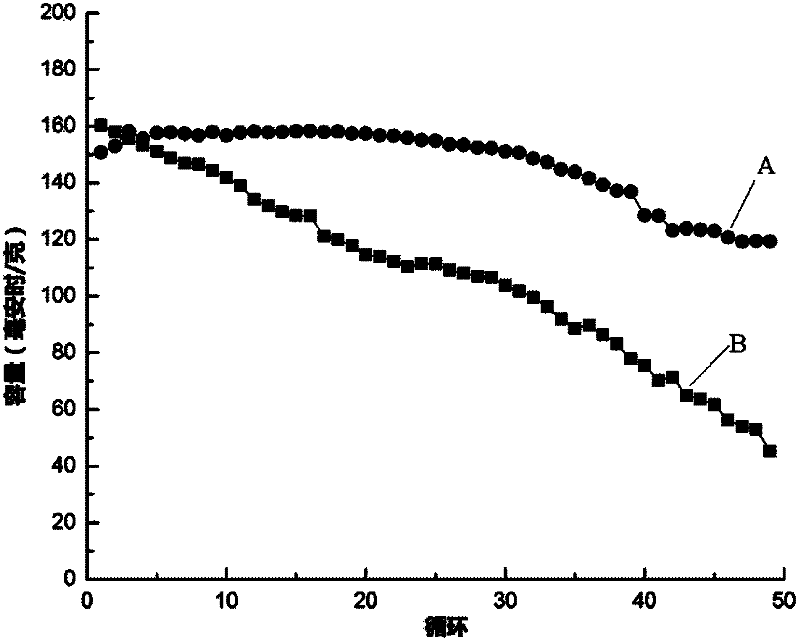

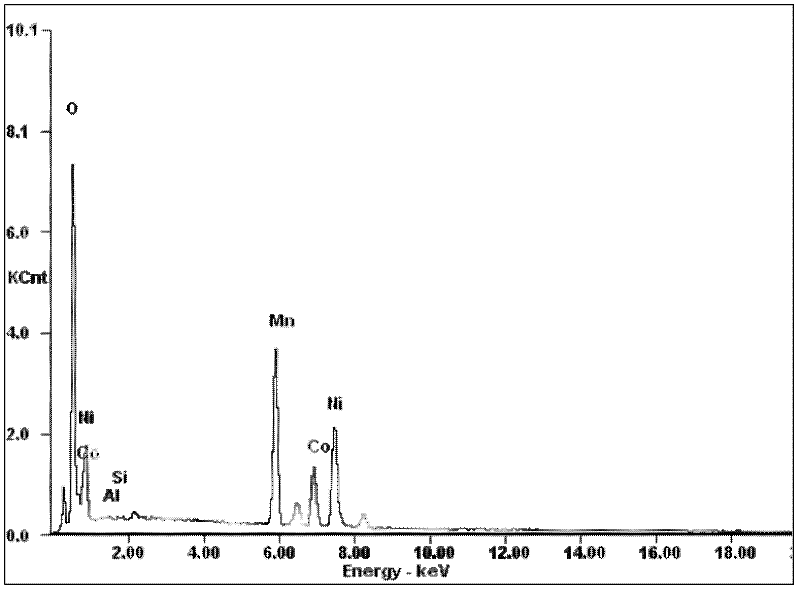

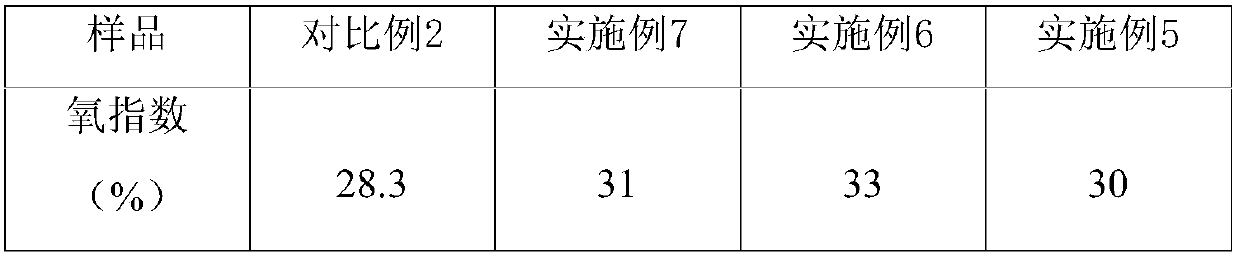

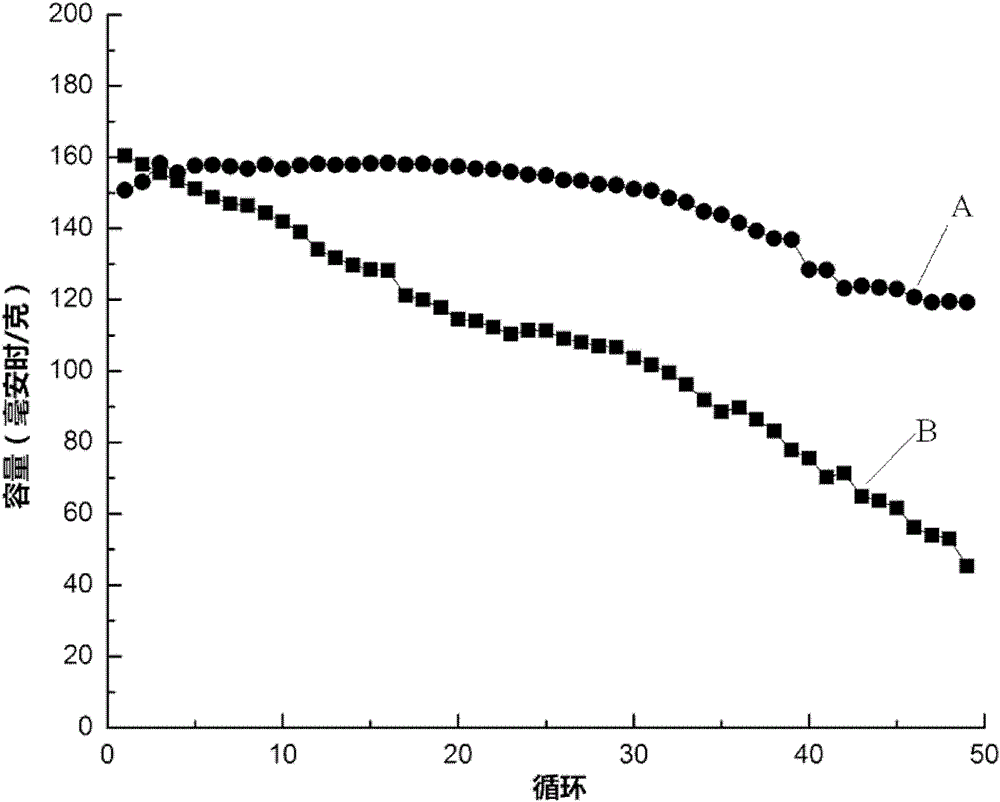

Preparation method of aluminum-doped material of cathode of lithium ion battery with solid phase process

The invention relates to a preparation method of an aluminum-doped material of a cathode of a lithium ion battery with a solid phase process. The preparation method comprises the following steps: controlling certain reaction conditions to prepare a precursor of a nickel, cobalt and / or manganese hydroxide; uniformly mixing the precursor with a lithium salt and a nanometer aluminum compound; and carrying out high temperature processing for a certain period of time in an air or oxygen atmosphere, cooling, and crushing to obtain the aluminum-doped material of the cathode of the lithium ion battery with the solid phase process. The aluminum-doped material of the cathode of the lithium ion battery with the solid phase process which can substantially improve the safety performance and the cycle characteristic of the lithium ion battery at a high temperature can be applied to power batteries.

Owner:山东天骄新能源有限公司

Fluoride-free low-acid zwitterion quartz sand reverse flotation process

The invention relates to fluoride-free low-acid zwitterion quartz sand reverse flotation process, which is characterized by comprising following steps: (1) pretreatment; (2) flotation: adjusting the pH (potential of hydrogen) value of ore pulp to 4-5 by sulfuric acid, performing air agitation, adding 40g / t-80g / t of positive ion collecting agent and 60g / t-75g / t of foaming agent, stirring and removing foams in primary flotation; and adjusting the pH value of the ore pulp to 9-10 by 200g / t-300g / t of sodium carbonate, performing air agitation, adding 80g / t-150g / t of negative ion collecting agent,then adding 60g / t-75g / t of foaming agent, stirring and removing foams in secondary floatation; and (3) washing ores in a flotation tank by water until the ores are neutral, and drying the ores to obtain quartz sand concentrates. The flotation collecting agents are fine in selectivity, the process is simple, cost is low, the purity of the quartz sand is high, the content of iron and aluminum impurities is low, and the problem that traditional fluoride and high-acid process damages equipment and environments is avoided in a flotation process.

Owner:陕西合兴硅砂有限公司

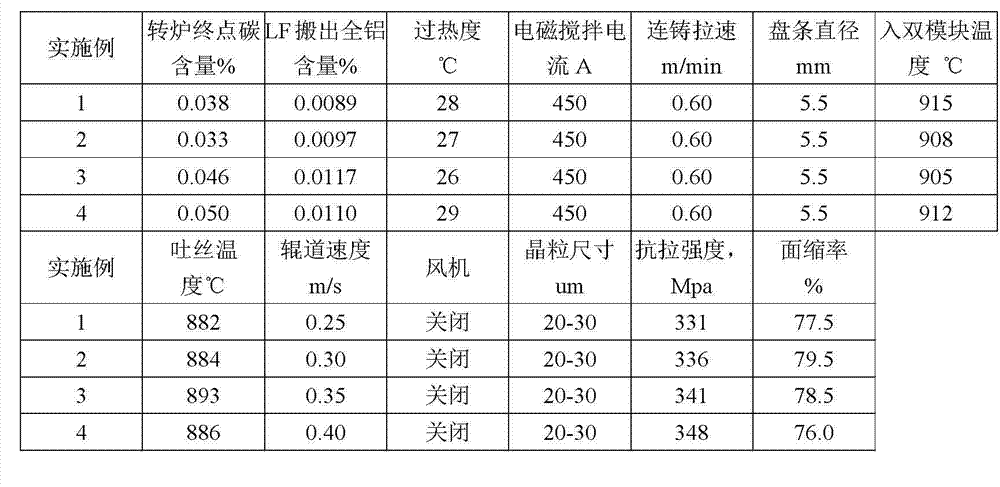

Annealing-free low-carbon steel coil rod and production method thereof

InactiveCN102899554AReduce intensity to create conditionsIncrease oxygen activityManufacturing convertersMetal rolling arrangementsChemical compositionCarbonization

The invention provides an annealing-free low-carbon steel coil rod and a production method thereof. The annealing-free low-carbon steel coil rod comprises the following chemical components: 0.04-0.10% of C, 0.01-0.10% of Si, 0.20-0.35% of Mn, at most 0.015% of P, at most 0.010% of S, at most 0.0060% of N, 0.0030-0.0060% of total oxygen, 0.0020-0.0080% of total aluminum, at most 0.1% of inevitable impurity and the balance of iron. The manufacturing method comprises the steps of converter smelting, LF (ladle furnace) refining, continuous casting and rolling, wherein incomplete deoxidation occurs at the tapping side of a converter, the aluminum content of molten steel is reduced by using the high oxygen activity of the molten steel, the carbonization of the molten steel in the refining process is inhibited, bloom protection casting is performed, the temperature for double module input is controlled at 900-920 DEG C, the loop laying temperature is 870-900 DEG C, the speed of a roller way is 0.2-0.4 m / s, and a blower is closed. Thus, the vacuum treatment procedure is omitted, the technical process is shortened, the production cost is lowered, and the requirement of users for canceling the annealing technique in the drawing process is satisfied. For the annealing-free low-carbon steel coil rod produced according to the components and the production method provided by the invention, the grain size is controlled at 20-30 um, the tensile strength is no more than 350 MPa, and the reduction of area is no less than 75%.

Owner:ANGANG STEEL CO LTD

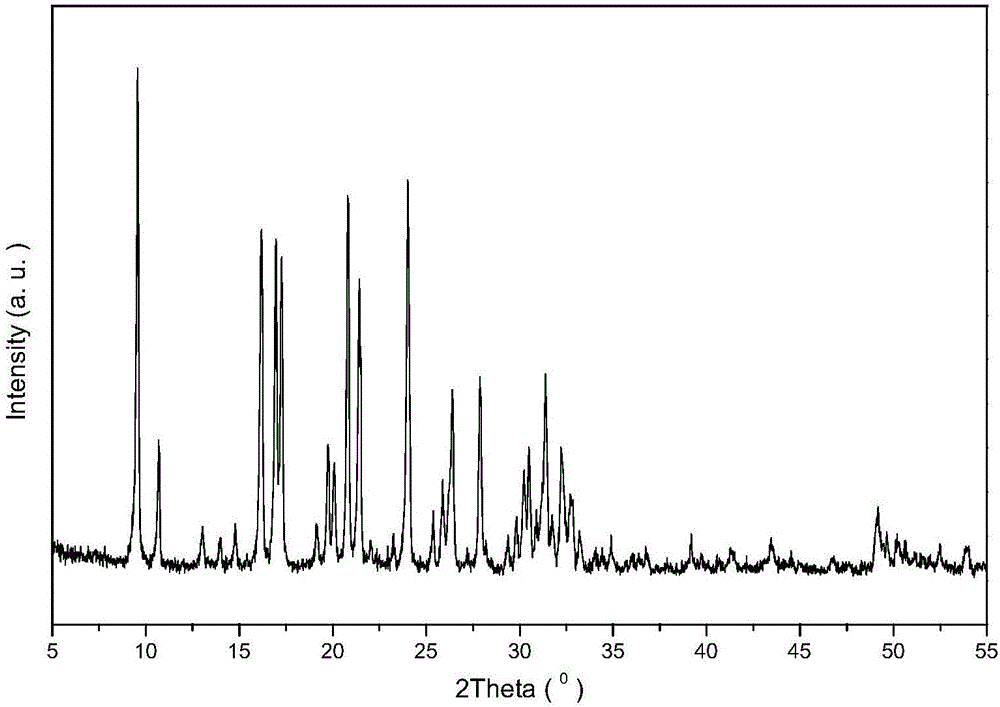

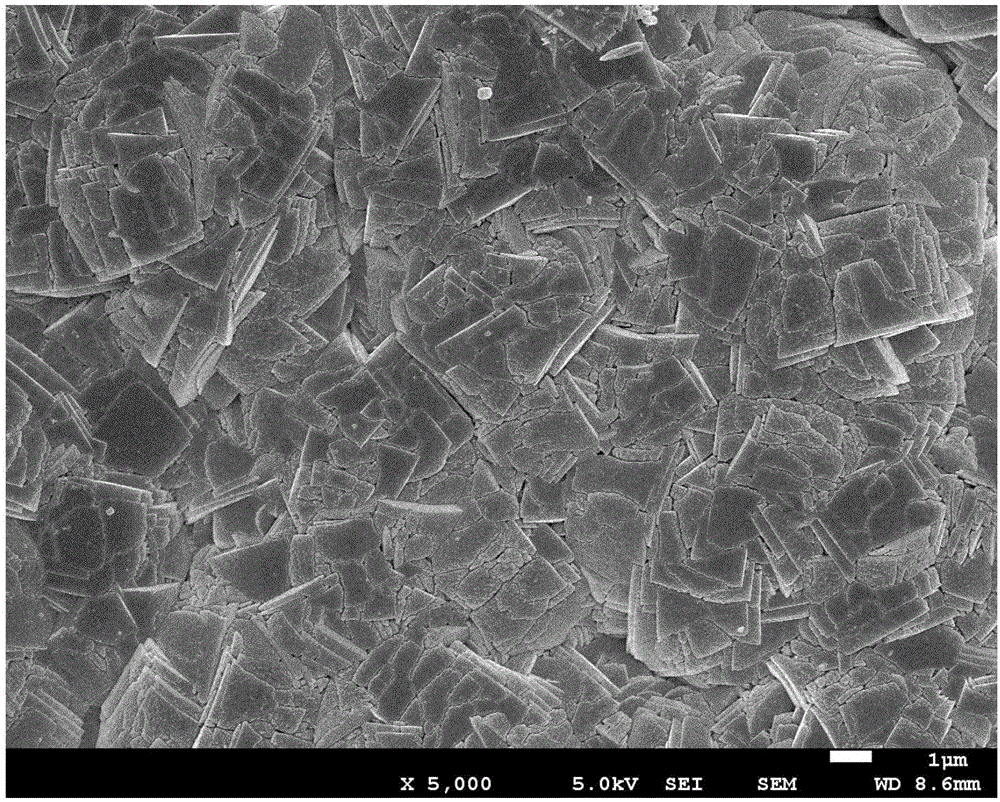

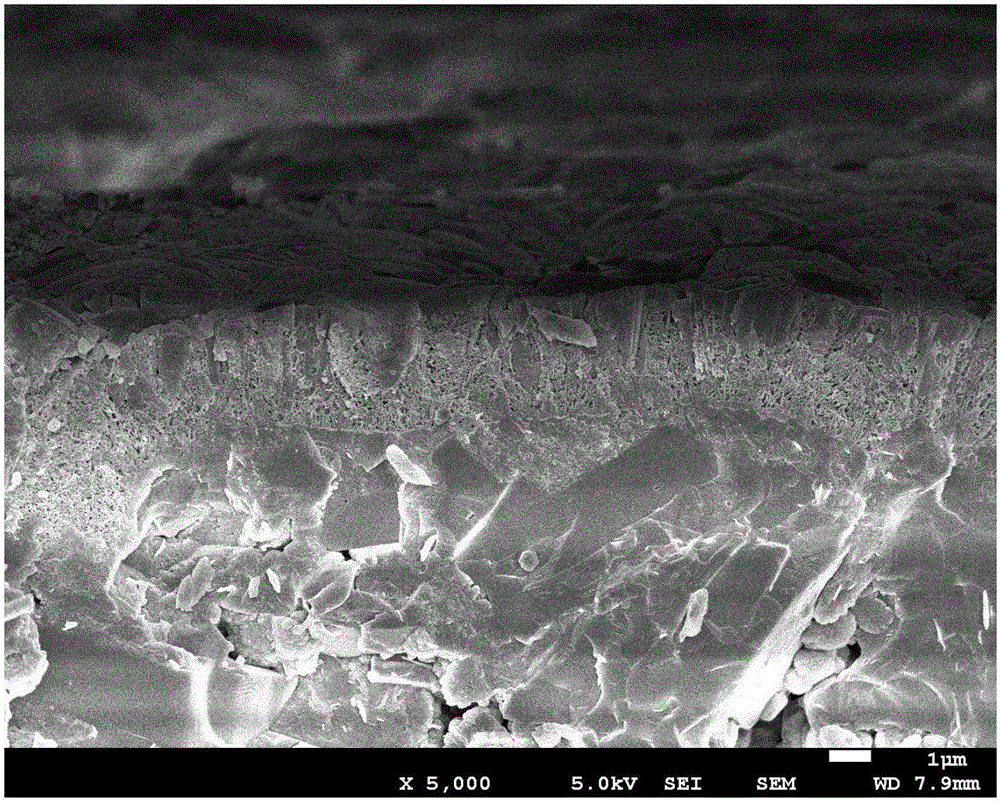

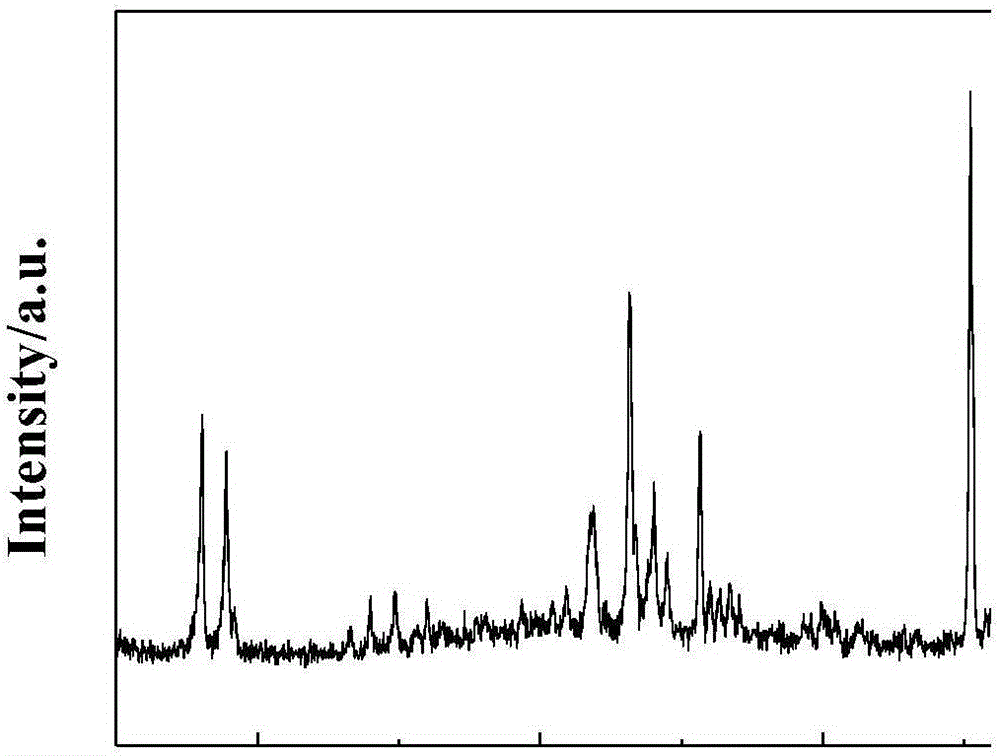

High-silica-alumina-ratio SSZ-39 zeolite, and synthesis and application thereof

ActiveCN106745031AHigh crystallinityOvercome problems such as decreased crystallinityMolecular sieve catalystsOther chemical processesDispersityFiltration

The invention discloses a preparation method of a high-crystallinity high-dispersity adjustable-silica-alumina-ratio high-silicon SSZ-39 molecular sieve catalyst. The method comprises the following steps: proportionally adding a sodium source, a silicon source, an aluminum source, fluorine ions, a template, a growth polymerization inhibitor and deionized water into a synthesis kettle, carrying out dynamic or static crystallization in different temperature sections, and carrying out filtration, washing and drying on the product to obtain molecular sieve raw powder; and carrying out high-temperature roasting to remove the template, carrying out ion exchange, and carrying out high-temperature roasting to obtain the high-silica-alumina-ratio SSZ-39 molecular sieve. The high-silica-alumina-ratio SSZ-39 molecular sieve has appropriate acid site, heat stability and pore size. The high-crystallinity high-dispersity controllable-silica-alumina-ratio SSZ-39 molecular sieve can be used for MTO (methanol to olefins) reaction for catalytically converting organic oxides (such as methanol and / or dimethyl ether and the like) into low-carbon olefins, and has the advantages of very high reaction activity and high selectivity for ethylene and propylene.

Owner:中海亚环保材料有限公司

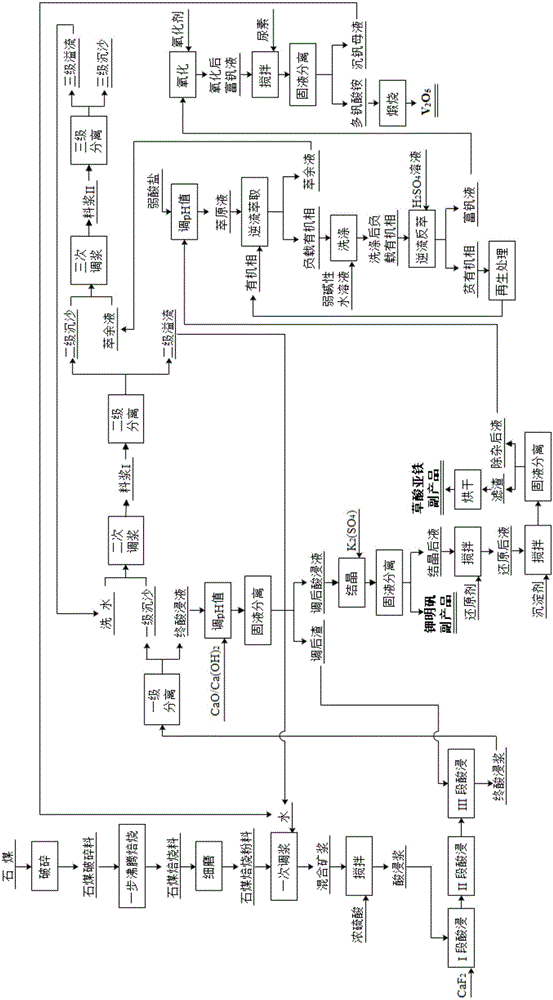

Method for preparing high-purity vanadium pentoxide by use of stone coal one-step method

The invention relates to a method for preparing high-purity vanadium pentoxide by use of a stone coal one-step method. The technical solution is as follows: a fluidized bed furnace for one-step roasting of stone coal is adopted to perform one-step fluidized bed roasting on the stone coal; roasted materials are leached in three segments, final pickling slurry is subjected to primary separation so as to obtain final pickle liquor, secondary overflow is returned to be subjected to primary size mixing, and tertiary overflow is returned to be subjected to secondary size mixing; the pH value of the final pickle liquor is regulated, and slags obtained after regulation are returned to a segment III so as to be leached; the regulated pickle liquor is crystallized to obtain a potassium alum byproduct; after crystallization, the liquid is subjected to reduction and precipitation-based impurity removal, and filter residues are dried to obtained a ferrous oxalate byproduct; after impurity removal, pH value regulation is performed on the liquid by use of weak acid salt, then counter-current extraction is performed on the liquid, and extraction raffinate is returned to be subjected to tertiary size mixing; after being washed, the loaded organic phase is subjected to countercurrent reverse extraction; a lean organic phase is regenerated and then is returned to be extracted; after a vanadium-rich solution is oxidized, urea is added, stirring is performed, the obtained molybdenum precipitation mother solution is returned to be subjected to primary size mixing, and ammonium polyorthovanadate is calcinated to prepare vanadium pentoxide. The method has the characteristics of short process flow, less pollution, low energy consumption, less chemical usage, high vanadium recovery rate and high product purity.

Owner:WUHAN UNIV OF SCI & TECH

Recycling method of waste lithium iron phosphate positive electrode powder

ActiveCN112811404AReduce manufacturing costSolve processing problemsWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphatePhysical chemistry

The invention relates to a recycling method of waste lithium iron phosphate positive electrode powder. The recycling method comprises the following steps: S1, mixing the lithium iron phosphate positive electrode powder with a first inorganic acid, a metal complexing agent and water for aluminum removal treatment, and conducting filtering to obtain an aluminum-removed lithium iron phosphate material; S2, subjecting the aluminum-removed lithium iron phosphate material and a second inorganic acid to mixing and pulping, adding hydrogen peroxide for an oxidation reaction, and conducting filtering to obtain iron-containing phosphorus filter residues; S3, subjecting the iron-phosphorus-containing filter residues and a third inorganic acid to mixing, pulping and dissolving, and conducting filtering to remove graphite so as to obtain an iron-phosphorus-containing filtrate; and S4, adjusting the pH value of the iron-containing phosphorus filtrate by adopting alkali, conducting reacting, separating out a precipitate, carrying out filtering, and taking filter residues so as to obtain iron phosphate. According to the recycling method, the waste lithium iron phosphate positive electrode powder can be used as a raw material to prepare iron phosphate with relatively high purity and relatively few impurities, and the yield of the method is high.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD +1

Zinc-based alloy used in steel hot dipping, and preparation method thereof

The invention discloses a zinc-based alloy used in steel hot dipping, and a preparation method thereof. According to the invention, a zinc ingot and Zn-Al interalloy are placed in a medium-frequency induction furnace; the materials are heated to a temperature of 720 DEG C, such that an alloy liquid is produced; a salt covering agent is added on the surface of the alloy liquid, and Al-Si interalloy is pressed into the alloy liquid; the mixture is smelted and well mixed by stirring; the temperature of the mixture is reduced to 650 DEG C, such that a fused alloy liquid is produced; Al-Mg interalloy and Al-La interalloy are respectively pressed into the fused alloy liquid, and the mixture is continuously stirred until uniform; the temperature is maintained for 30 minutes, and slag is fetched;and the material is cast into a metal mold, such that the zinc-based alloy used in steel hot dipping is obtained, wherein the alloy comprises elements of, by weight: 20 to 40% of Al, 0.5 to 3% of Si,0.5 to 3% of Mg, 0.05 to 1% of La, and balance of Zn. With the method, corrosion resistance of the alloy can be effectively improved, viscosity of alloy melt can be reduced, wettability of the alloy upon a steel substrate can be improved, grains of the alloy can be thinned, dissolubility of iron in a zinc tank can be continuously and effectively reduced, zinc slag production in the zinc tank can be reduced, and the zinc slag with a limited amount in the zinc tank can be converted from bottom slag into dross.

Owner:CHANGZHOU UNIV

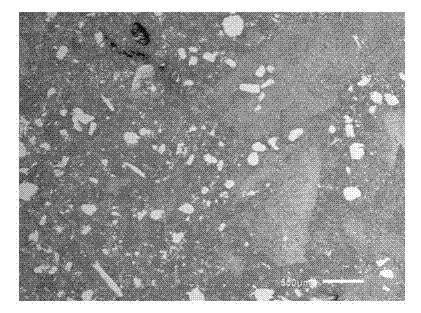

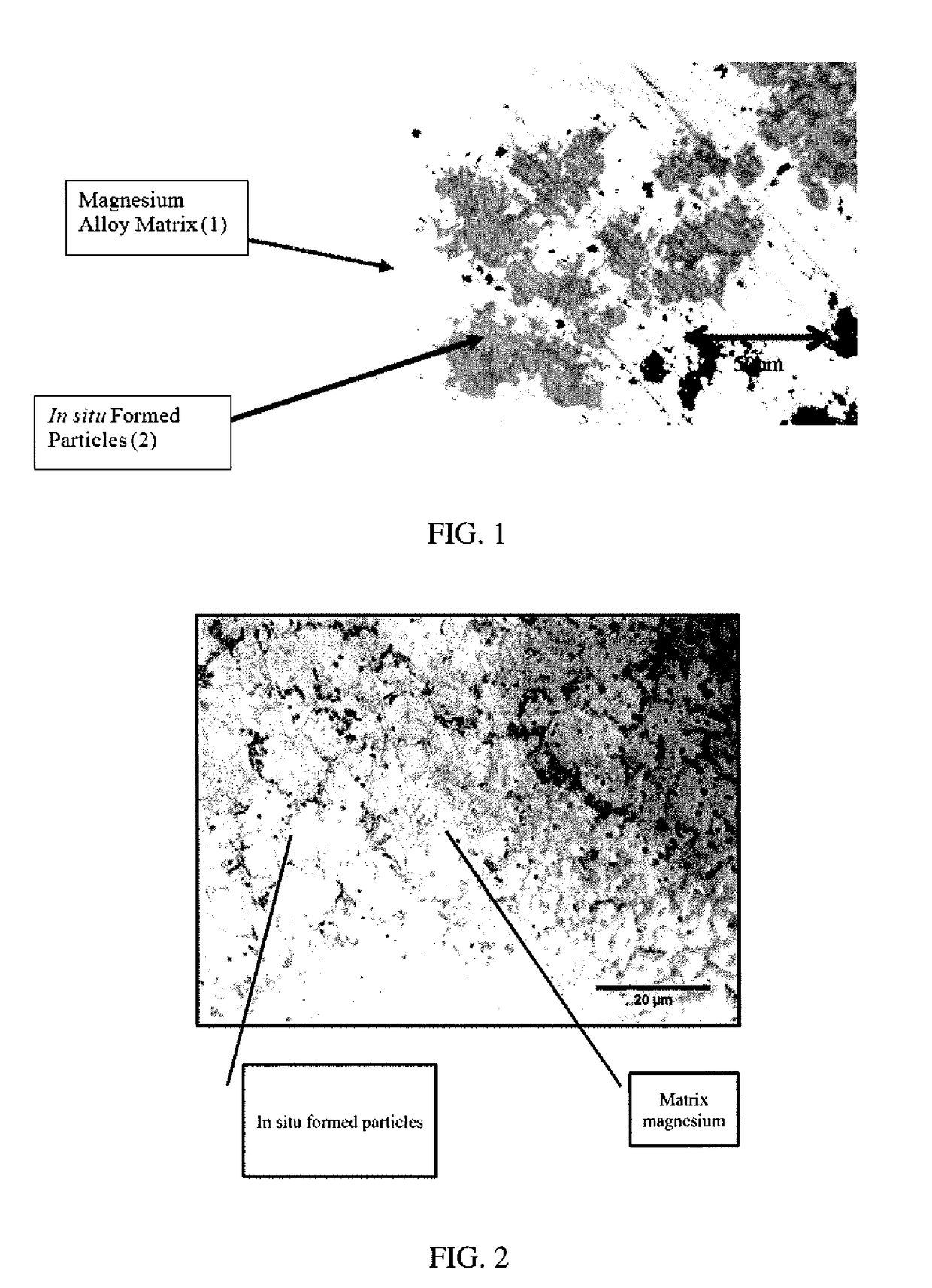

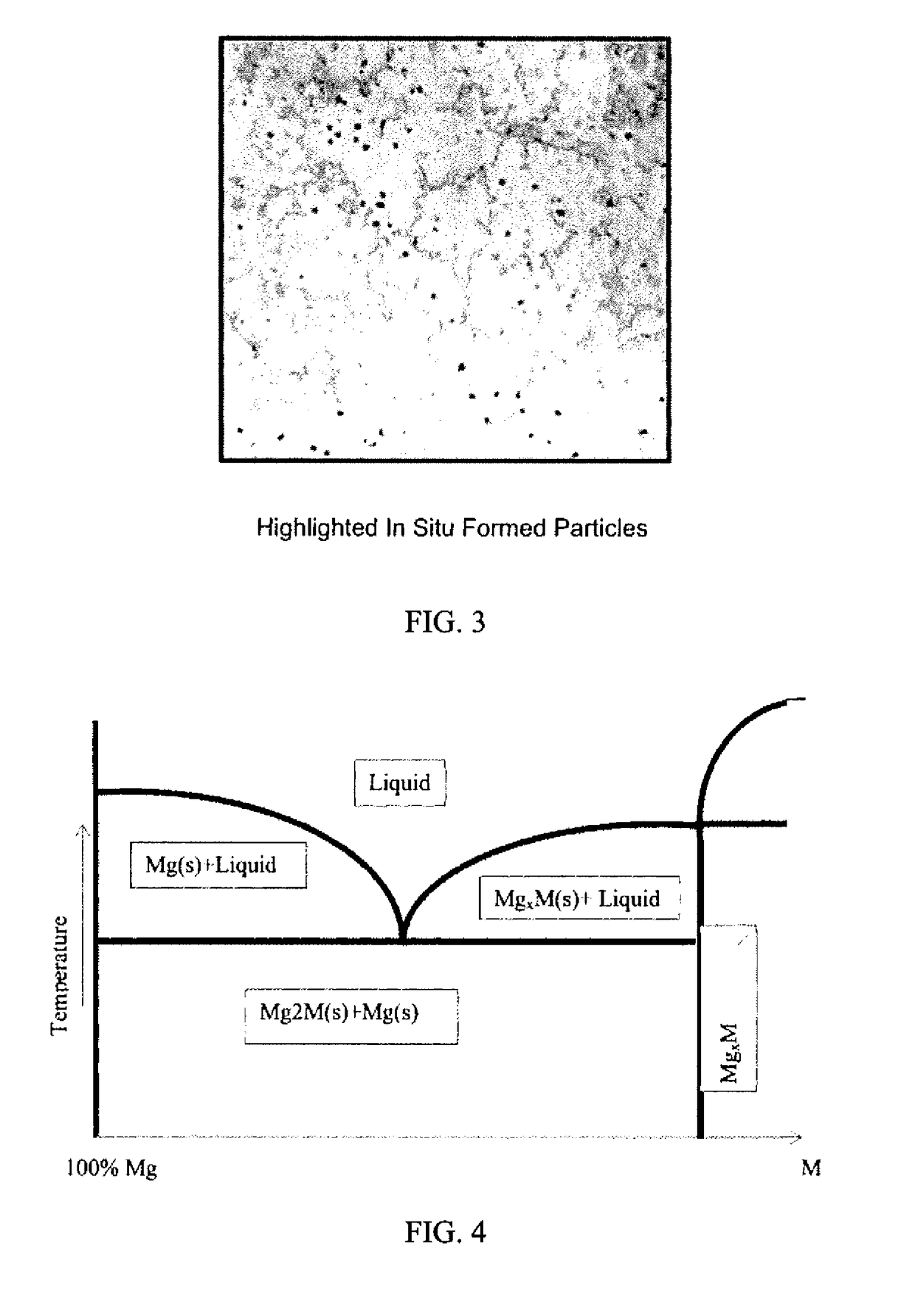

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

ActiveUS20190054523A1High incipient melting pointIncrease corrosion rateTransportation and packagingMetal-working apparatusAlloyElectrochemistry

A tastable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

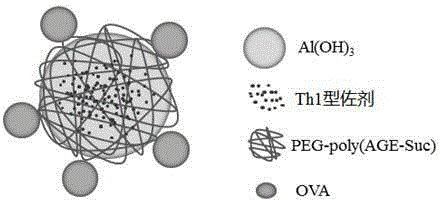

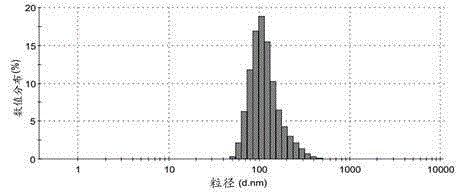

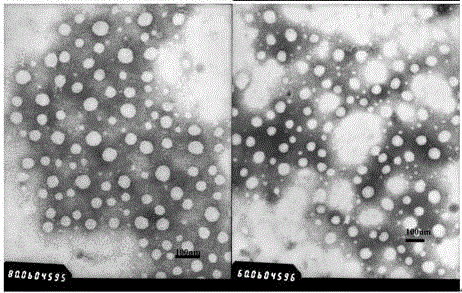

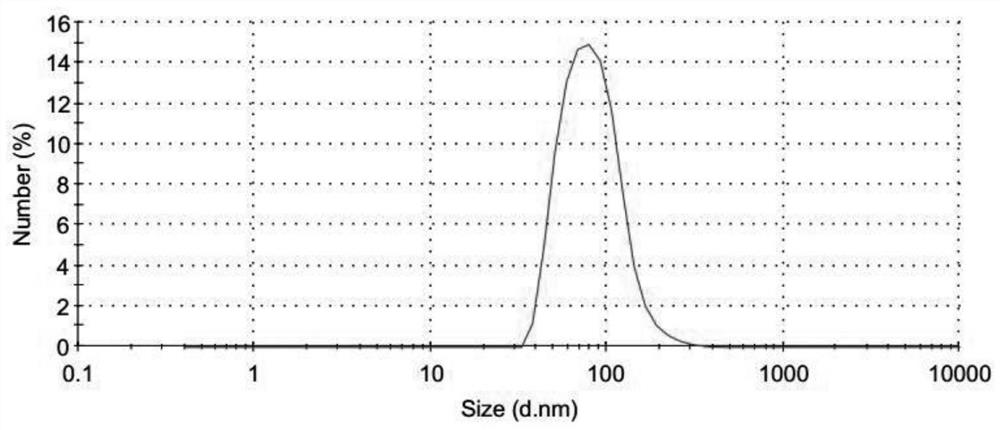

Vaccine vector based on aluminum hydoxide nano-particles

ActiveCN104587464AReduce aluminum contentNo inflammationPharmaceutical non-active ingredientsImmunological disordersDendritic cellTGE VACCINE

The invention provides an aluminum adjuvant used as a vaccine vector. The adjuvant is characterized in that a PEG derivative bio-material and aluminum are compounded to form nano-particles, so that the property of strong Th2 body fluid immunologic adjuvant of aluminum salt is maintained, and the adjuvant can be efficiently transferred to draining lymph nodes in the body and can be easily ingested by dendritic cells to perform effective cross-presentation and induce cellular immunologic response. The aluminum adjuvant has strong Th1 immunologic response.

Owner:SICHUAN UNIV

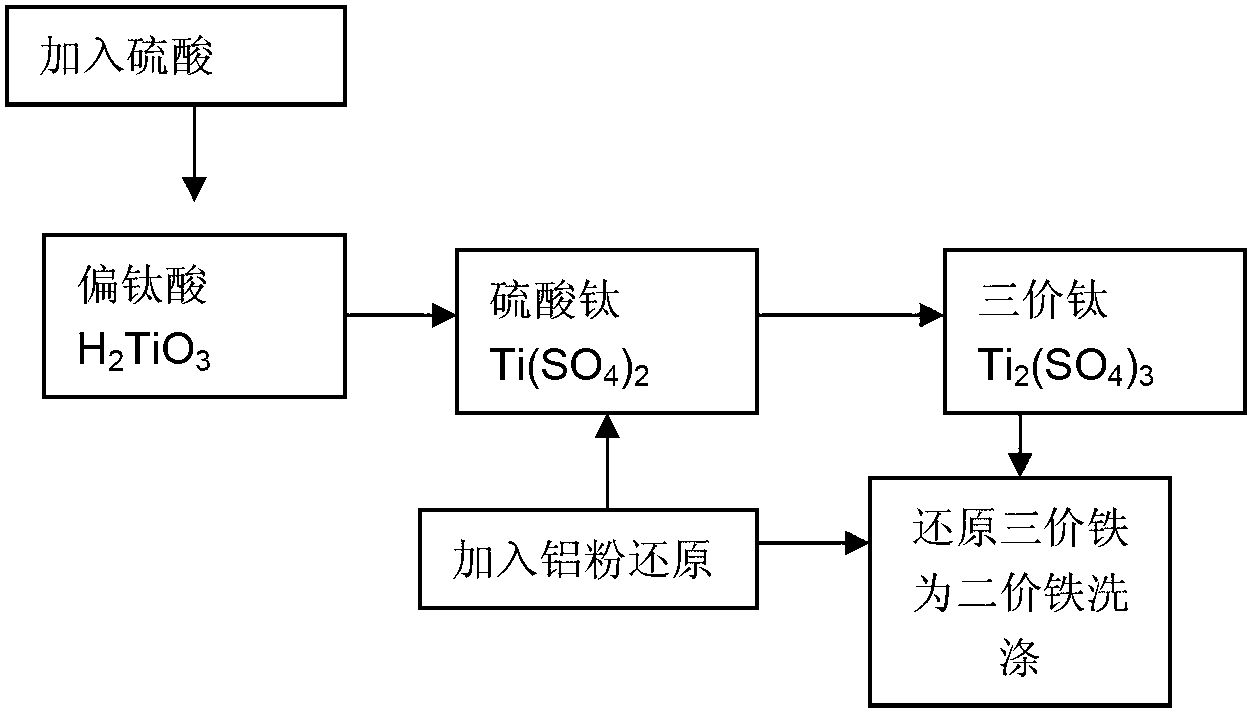

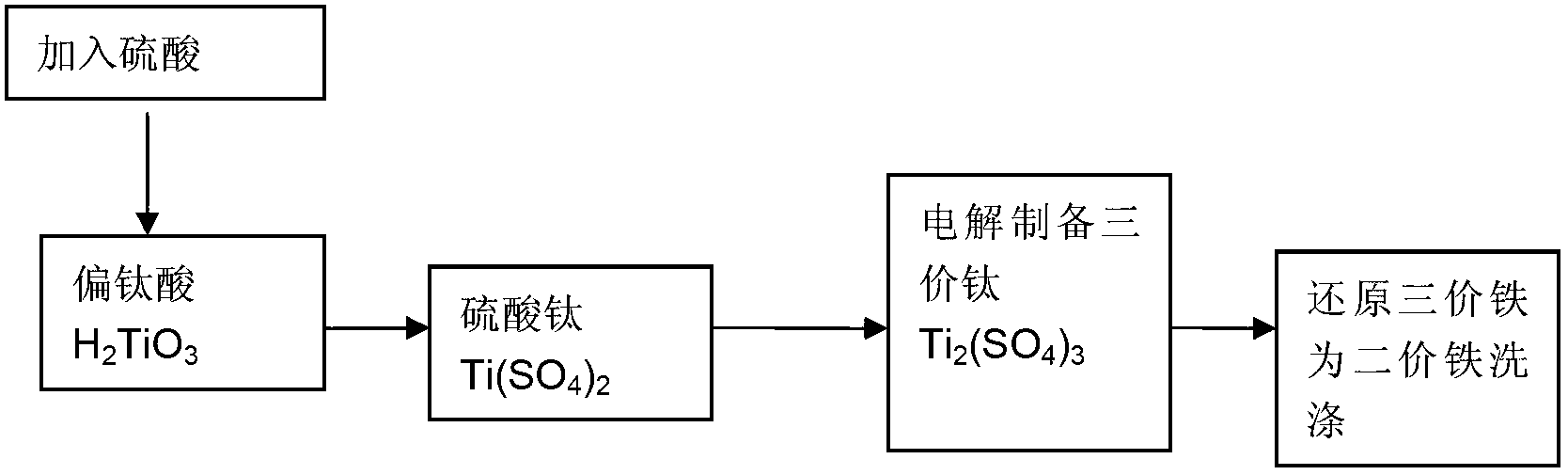

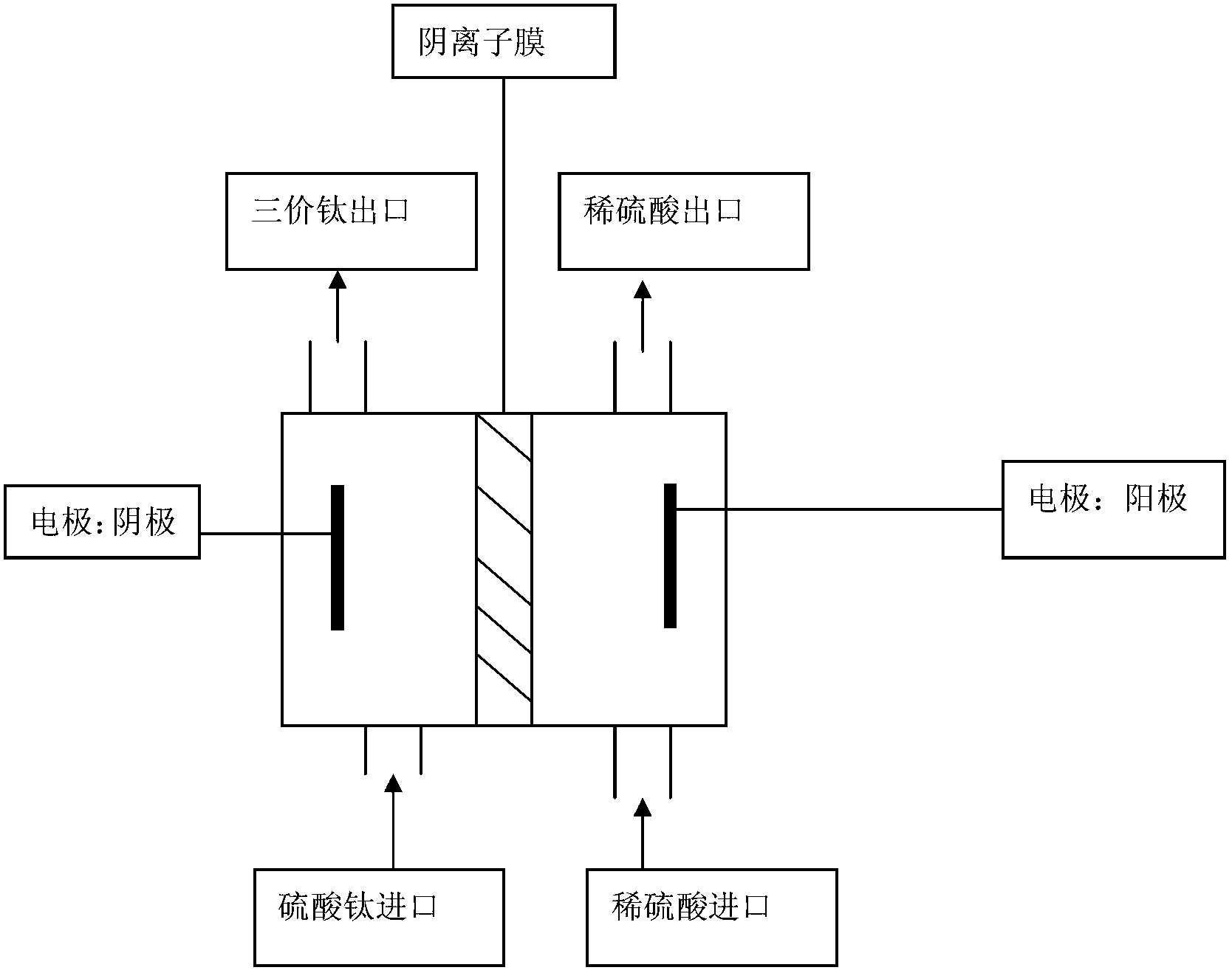

Method for removing ferric iron ion contained in metatitanic acid by adopting electrolytic reduction

The invention relates to the technical field of preparation of titanium dioxide pigments, and particularly relates to a method for preparing titanous ions by acidifying and then electrolytically reducing metatitanic acid. The method comprises the following steps of: firstly acidifying the metatitanic acid; then electrolyzing to prepare a titanous solution; and finally adding the obtained titanous solution to the raw material metatitanic acid to reduce ferric iron into ferrous iron, and then washing. Compared with the traditional method, the method disclosed by the invention is unnecessary to add the aluminum powder, reduces the usage amount of sulfuric acid, simplifies the production process, saves the production cost and has the advantages of environment protection, safety, easiness for operation, low content of aluminum contained in products and product quality enhancement.

Owner:SHANDONG DONGJIA GRP CO LTD

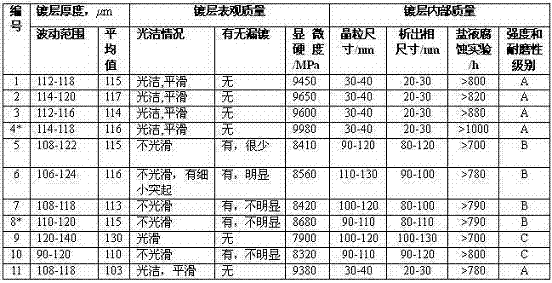

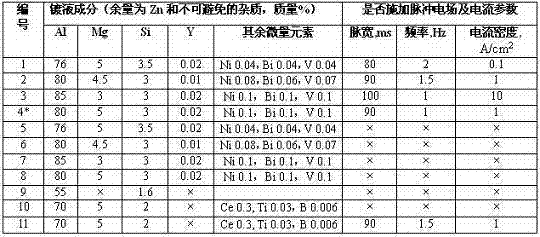

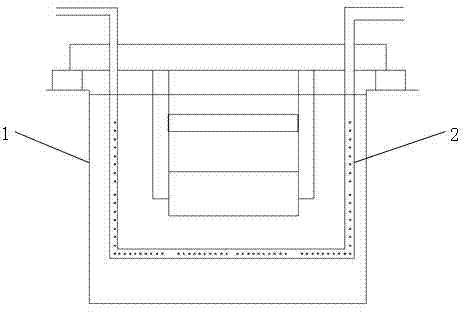

A method for hot-dip aluminum plating of steel structure parts

InactiveCN102268625AImprove corrosion resistanceExcellent immersion performanceHot-dipping/immersion processesMelting tankRare earth

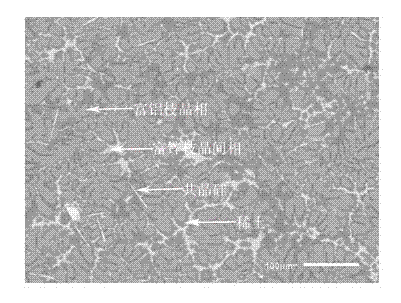

The invention relates to the technical field of metal surface coatings, in particular to a hot dipping method for a steel structure. A hot dipping alloy consists of the following components in percentage by mass: 75 to 85 percent of Al, 3 to 5 percent of Mg, 3 to 5 percent of Si, 0.01 to 0.02 percent of rare earth Y, 0.04 to 0.10 percent of Ni, 0.04 to 0.10 percent of Bi, 0.04 to 0.10 percent of V, and the balance of Zn and inevitable impurities; and in the hot dipping process, a pulsed electric field is applied to a weld pool, and the parameter ranges of the pulsed electric field are that: the pulse width is 80 to 100ms, the acting frequency is 1 to 2Hz and the peak density of pulse current introduced into the weld pool is 0.1 to 10A / cm<2>. By the synergism of the rare earth Y, Ni, Bi and V, the fluidity and wettability of aluminum are improved; the strength and corrosion resistance of a coating are improved by nano Si and Mg2Si phases separated under the action of the pulsed electric field; and the pulsed electric field also has effects of refining grains and improving the compactness of the coating. By the invention, the coating quality is improved, metal consumption is reduced, a process is simple, the conventional process and equipment are mature, the cost is low and the method is worth promoting.

Owner:JIANGSU UNIV

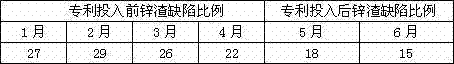

Treatment method for purifying zinc pot in hot galvanizing production

The invention discloses a treatment method for purifying a zinc pot in hot galvanizing production. A purification treatment process comprises the steps that hot galvanizing production is carried out while aluminium content of molten zinc is maintained to be 0.025-0.030wt% and scummings in the zinc pot are cleaned in a hot galvanizing production process. The treatment method for purifying the zinc pot in the hot galvanizing production has the advantages that generation of iron in the zinc pot is inhibited by increasing the aluminium content in the molten zinc from 0.18-0.20% at ordinary times to 0.025-0.030%, so as to improve zinc layer adhesiveness and glossiness of a galvanized plate, and quality of the galvanized plate is effectively improved; iron content in the zinc pot after being purified by adopting the treatment method is obviously reduced, and thus a foundation is laid for follow-up generation.

Owner:HEBEI IRON AND STEEL

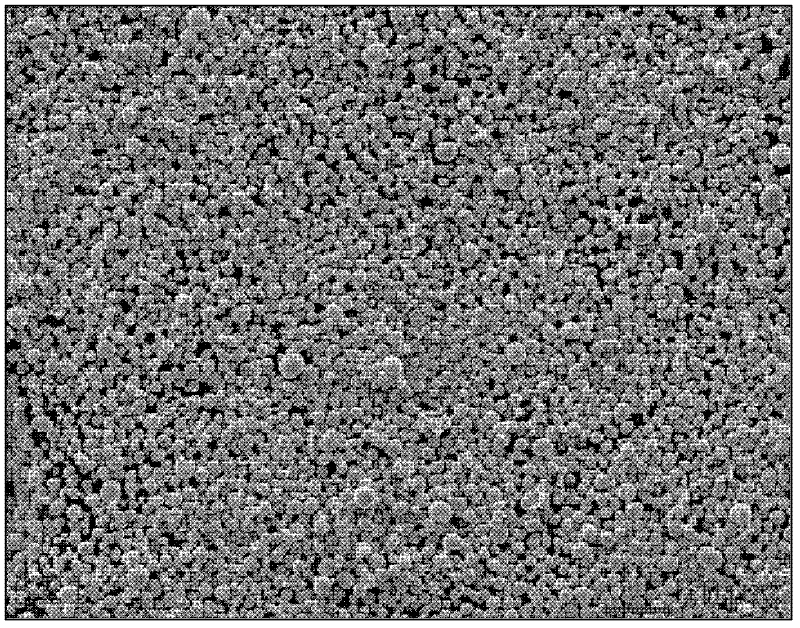

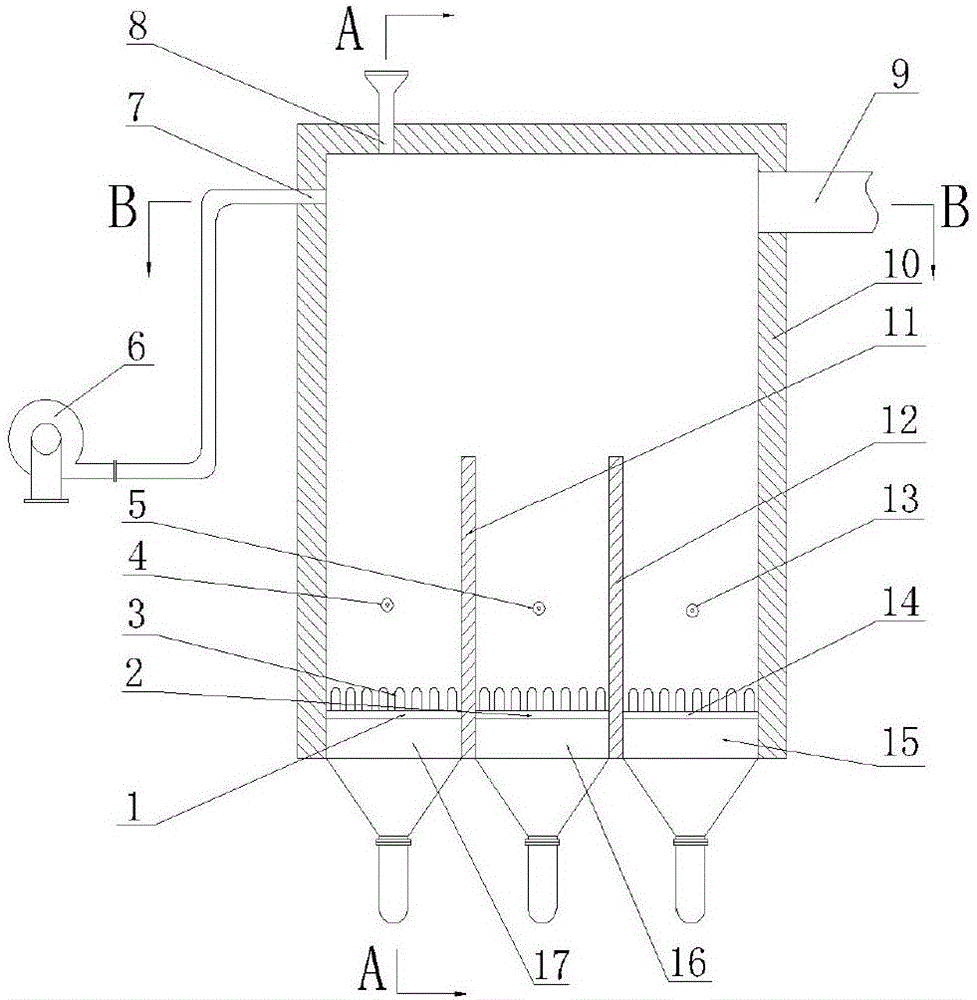

Ultralow density ceramsite proppant and preparation method thereof

InactiveCN106967408AReduce aluminum contentHigh outputFluid removalDrilling compositionAluminum fluorideKaolinite

The invention discloses an ultralow density ceramsite proppant and a preparation method thereof. The ultralow density ceramsite proppant is prepared from, by weight percent, 45-65% of calcined coal gangue, 25-30% of uncalcined coal gangue, 5-20% of alumina powder, 1-3% of aluminum fluoride, 3-5% of vanadium pentoxide. The ultralow density ceramsite proppant is prepared by kaolinite coal gangue with low cost and low volume density, and is applicable to hyposmosis unconventional oil and gas reservoir hydrofracture.

Owner:TAIYUAN UNIV OF TECH

Smelting method for metal chromium with low aluminum content

The invention provides a smelting method for metal chromium with low aluminum content. The smelting method comprises the following steps: mixing industrial dichromium trioxide, calcium oxide, aluminumoxide or magnesium oxide and sodium oxide according to the mass ratio of (1 to 5) to (0.01 to 0.1) to (6 to 9) to (0.01 to 0.4) by utilizing a mixer, so as to obtain a mixture A; mixing the industrial dichromium trioxide and carbon according to the mass ratio of 1 to (0.1 to 0.5) by utilizing the mixture, so as to obtain a mixture B; putting the mixture A into an electric furnace; adding the mixture B after the mixture A is completely melted; raising the smelting temperature of the electric furnace to be higher than 1750 DEG C, so as to completely melt the added materials; naturally cooling until the temperature is less than 100 DEG C and then discharging the materials out from the furnace; cleaning dreg on the surfaces to obtain a metal chromium block; and after crushing, packaging to obtain commodity metal chromium. The method provided by the invention has the advantages of low energy consumption and high product purity.

Owner:锦州市金属材料研究所

Method for producing ferrovanadium by electric thermite method

Owner:攀钢集团西昌钒制品科技有限公司

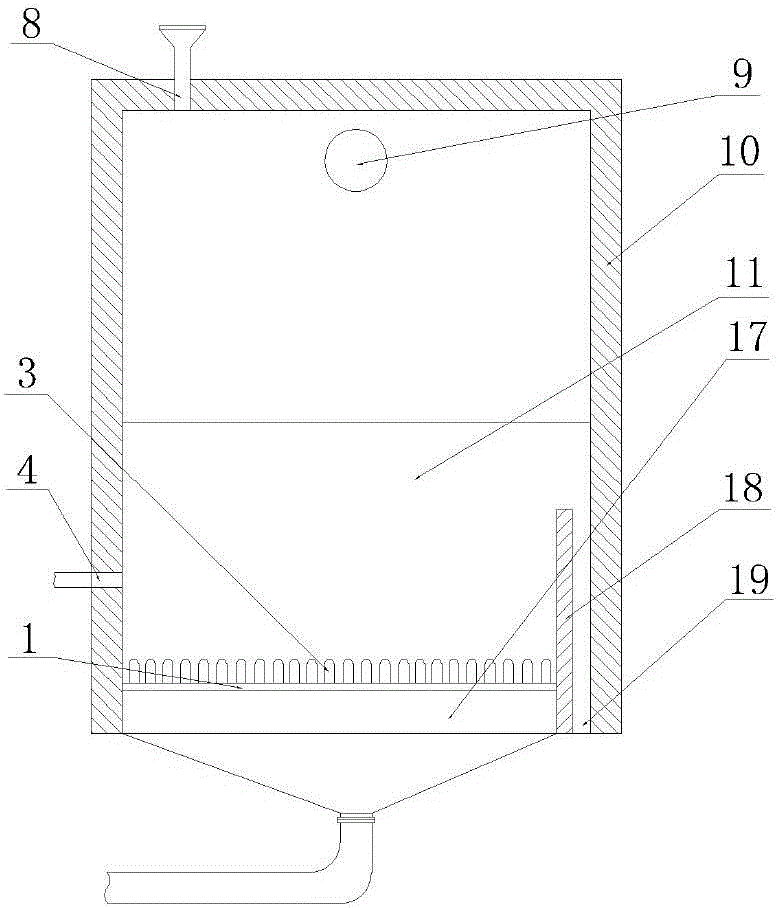

Harmless treatment method for aluminum ash

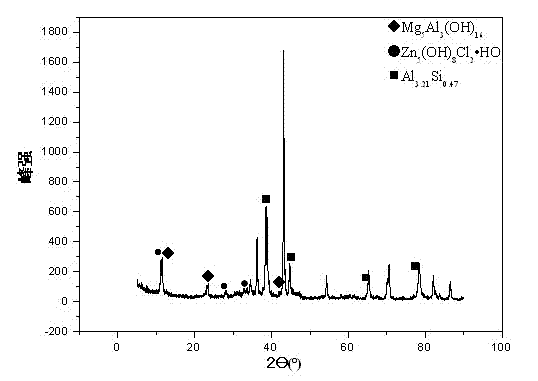

InactiveCN110723746AReduced aluminum contentReduce releaseProcess efficiency improvementAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMetallic aluminumRefractory

A harmless treatment method for aluminum ash comprises the following steps: (1) mixing the aluminum ash with water, performing stirring to form a slurry, and grading the slurry to obtain a fine particle slurry; or mixing the graded aluminum ash with water, and performing stirring for forming a slurry to obtain the fine particle slurry; (2) adding a leaching agent, and carrying out a leaching reaction to obtain a nonmetal slurry; and (3) carrying out ball-milling deamination on the oxidized slurry, and washing, filtering, washing and drying the deaminated slurry to obtain harmless aluminum ash.The method has the advantages of high safety coefficient in the production process, simplicity, low cost, and suitableness for industrial production; and the obtained harmless aluminum contains, by mass, 95% of Al2O3, 0.02% or below of aluminum nitride, 0.01% or less of metallic aluminum and 0.2% or less of salt, meets the bauxite ore standard of GB / T 24483-2009, and can be used as a raw materialof a water purifying agent, ceramic, glass, a refractory material, a building material or electrolytic aluminum.

Owner:湖南绿脉环保科技股份有限公司

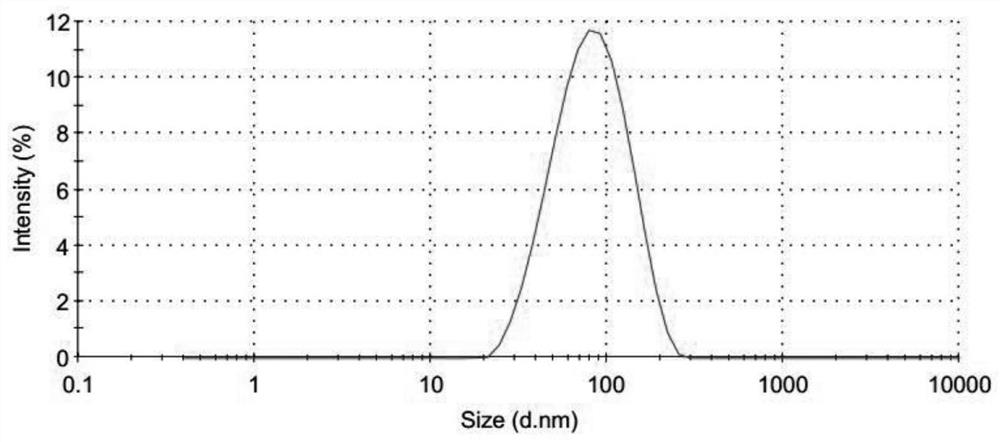

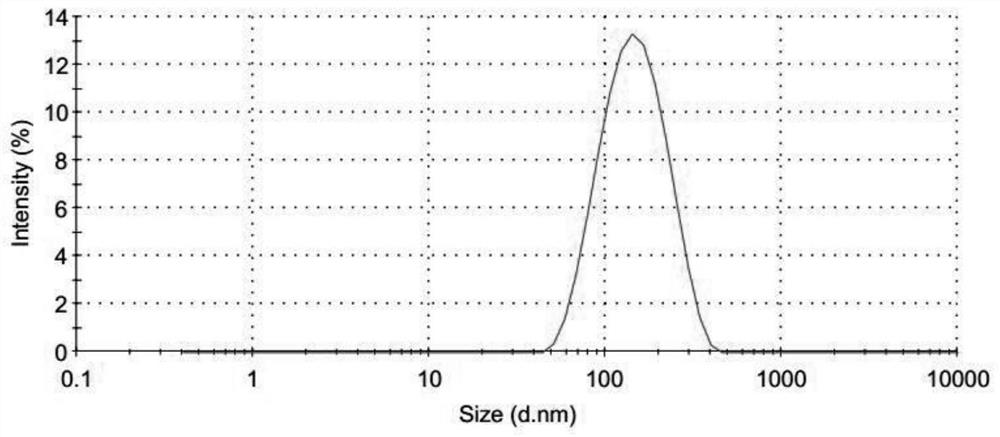

Freeze-dried preparation of vaccine containing aluminum adjuvant, and preparation method and application of freeze-dried preparation

PendingCN111658617AWill not cause denaturation inactivationThe preparation method is simple and quickPowder deliveryPharmaceutical non-active ingredientsCold chainAdjuvant

The invention discloses a freeze-dried preparation of a vaccine containing an aluminum adjuvant, and a preparation method and application of the freeze-dried preparation. The aluminum salt vaccine freeze-dried preparation contains nanoparticles or microparticles formed by compounding anionic polymers or derivatives thereof and aluminum salt, a vaccine antigen, an adjuvant and a freeze-dried protective agent; and a freeze-drying method provided by the invention avoids the massive aggregation of aluminum hydroxide in the vaccine, and reduces the damage to the activity of the antigen. The stability of the vaccine in the freeze-drying process and the storage process can be improved; the vaccine can get rid of cold-chain transportation; the cost is reduced; energy is saved; and particularly, the technical problem that a low-temperature cold chain in a remote area is difficult to guarantee is solved.

Owner:SICHUAN UNIV

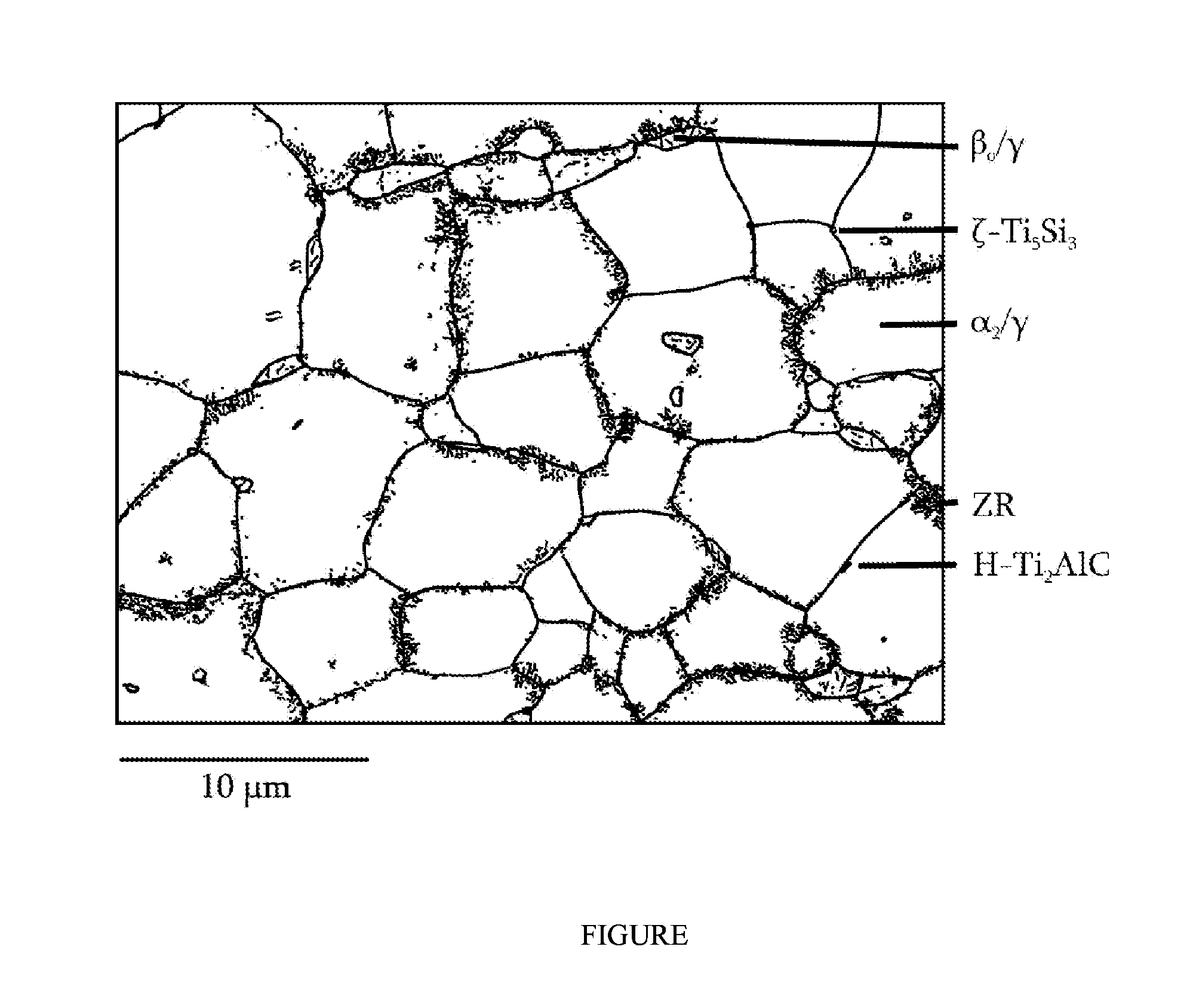

CREEP-RESISTANT TiAl ALLOY

Disclosed is a TiAl alloy for high-temperature applications which comprises not more than 43 at. % of Al, from 3 at. % to 8 at. % of Nb, from 0.2 at. % to 3 at. % of Mo and / or Mn, from 0.05 at. % to 0.5 at. % of B, from 0.1 at. % to 0.5 at. % of C, from 0.1 at. % to 0.5 at. % of Si and Ti as balance. Also disclosed is a process for producing a component made of this TiAl alloy and the use of corresponding TiAl alloys in components of flow machines at operating temperatures up to 850° C.

Owner:MTU AERO ENGINES GMBH

Titanium alloy for forging aviation disc piece

The invention discloses a titanium alloy for forging an aviation disc piece. The titanium alloy comprises the following components in percentage by weight: 5.20-5.80% of Al, 3.50-4.50% of Mo, 0.80-2.50% of Zr, 0.80-2.50% of Sn, 0.70-1.50% of W, 0.10-0.25% of Si, 0.05-0.10% of Fe, 0.15-0.20% of C, 0.10-0.20% of Cr, less than or equal to 0.15% of O, less than or equal to 0.04% of N, less than or equal to 0.012% of H, less than or equal to 0.10% of Cu and the balance of Ti.

Owner:AVIC EXCELLENCE FORGING WUXI

Titanizing and aluminizing agents for sponge titanium reactor and method

InactiveCN101691649AControl contentPrevent infiltrationSolid state diffusion coatingLevel indicators by floatsArgon atmosphereTime control

The invention provides titanizing and aluminizing agents for a new reactor for producing sponge titanium and coating and permeating methods. Components of the aluminizing agent comprise aluminum powder, alumina and ammonium chloride; and components of the titanizing agent comprise titanium powder, alumina and ammonium chloride. The coating method comprises the following steps: coating the aluminizing agent on the external surface of the reactor, and coating the titanizing agent on the internal surface, wherein the total thickness of the aluminizing and titanizing coatings is 0.4 to 0.7 millimeter; and putting the coated reactor into heating equipment, degassing the reactor for 2 to 5 hours at the low temperature of between 150 and 300 DEG C, heating the reactor to between 650 and 1,100 DEG C under the protection of argon atmosphere, and preserving the heat for 4 to 10 hours. Through test, FeAl and Fe3A1 phases are mainly positioned on the external surface of steel in the method, and the content of aluminum is 18 to 55 weight percent. The method for aluminizing outside and titanizing inside at the same time controls the content of impurity iron in the sponge titanium to be lower than 0.02 percent while keeping the cost, improves the usage times of the reactor, and greatly reduces the production cost of the sponge titanium.

Owner:朝阳金达钛业股份有限公司

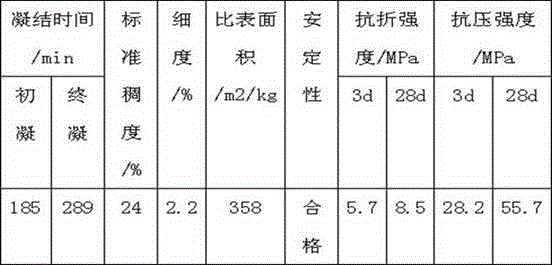

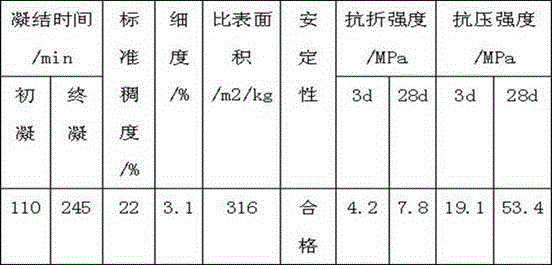

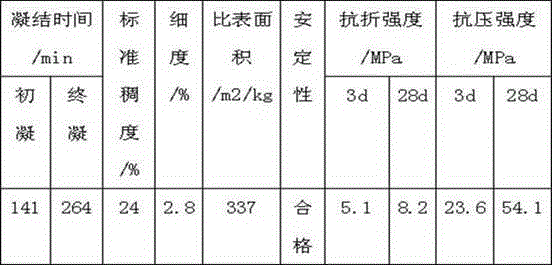

Method for preparing sulfate/silicate-resistant cement clinker by taking low-aluminum stone coal vanadium-extracting slag and nitric phosphate slag as main raw materials

The invention relates to a method for preparing sulfate / silicate-resistant cement clinker by taking low-aluminum stone coal vanadium-extracting slag and nitric phosphate slag as main raw materials. The method comprises the following steps: performing fluidized bed roaster decarburization roasting, rotary kiln oxidizing roasting, acid leaching and other treatment processes on raw stone coal to obtain low-aluminum stone coal vanadium-extracting slag and nitric phosphate slag, mixing the 3-16 percent by mass of low-aluminum stone coal vanadium-extracting slag, 76-79 percent by mass of nitric phosphate slag, and 7-20 percent by mass of other various aluminum and iron raw materials, grinding into powder of which the particle size is less than 0.074mm, carrying out a clinkering reaction at the temperature of 1350-1450 DEG C, and performing shock cooling to obtain the sulfate / silicate-resistant cement clinker. The sulfate / silicate-resistant cement clinker is prepared by the method in the invention; the raw materials are industrial waste residues, the cost is low, and the environmental load is favorably reduced. Meanwhile, in the method, the adaptability of the aluminum and iron raw materials is wide, the sources are diverse, and various aluminum / iron-containing wastes can be fully utilized.

Owner:CENT SOUTH UNIV

Preparation method of hierarchical porous molecular sieve membrane

InactiveCN106006662AReduce aluminum contentGood repeatabilityFerrosilicatesPentasil aluminosilicate zeoliteElemental compositionMolecular sieve

The invention provides a preparation method of a hierarchical porous molecular sieve membrane. According to the method, a micropore-mesopore / macropore hierarchical porous structure is acquired through alkali treatment on the molecular sieve membrane; the alkali treatment means that the molecular sieve membrane is subjected to dissolution for a certain period of time at a certain temperature with a mixed system containing a molecular sieve, inorganic base or organic ammonium base and water, namely, a molecular sieve-alkaline suspension; a crystal form of the molecular sieve in the molecular sieve-alkaline suspension is matched with that of the molecular sieve membrane. Compared with a traditional microporous molecular sieve membrane, the hierarchical porous molecular sieve membrane prepared with the method has higher gas permeation flux. Besides, elemental composition of the molecular sieve membrane can be regulated through the alkali treatment. The method has a simple and efficient process, good repeatability and high success rate, and the prepared hierarchical porous molecular sieve membrane is applicable to chemical processes such as catalysis, separation and the like.

Owner:QINGDAO UNIV OF SCI & TECH

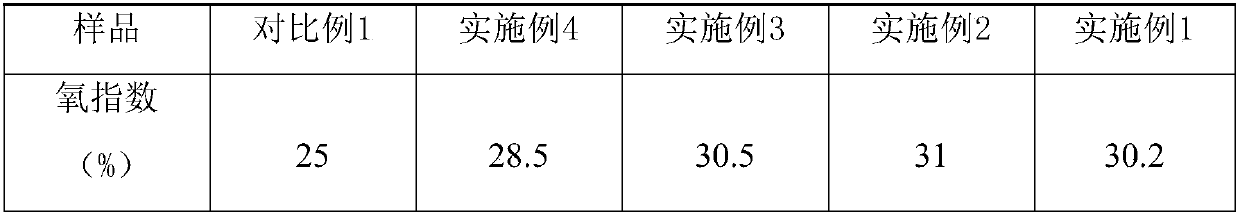

Fire resistant viscose fiber and preparation method thereof

ActiveCN108035004AGood flame retardant performanceOvercoming filtration difficultiesMonocomponent cellulose artificial filamentChemistrySodium silicate

The invention belongs to the technical field of textiles, and particularly relates to a fire resistant viscose fiber and a preparation method thereof. The preparation method of the fire resistant viscose fiber includes the procedures of impregnation, aging, yellowing, dissolving, filtering, defoaming, spinning, washing and desulfurization. When any procedure from dissolving to spinning is performed, sodium silicate is added into viscose solution and uniformly mixed with the viscose solution. By the preparation method of the fire resistant viscose fiber, the viscose solution is more easily filtered, fire retardants are saved, and the fire resistance of the prepared viscose solution in filtration is good.

Owner:HEBEI JIGAO CHEM FIBER

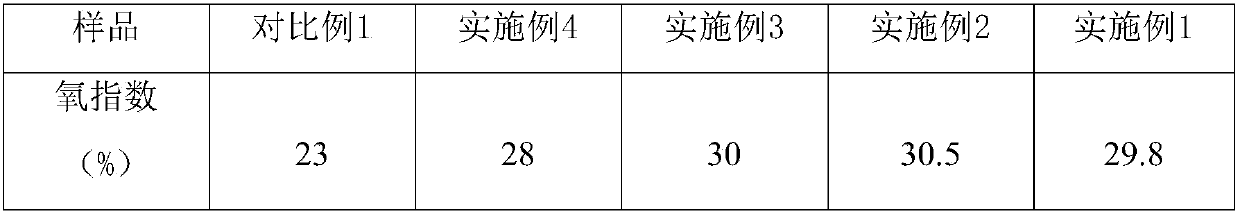

Preparation method of lithium-ion battery positive electrode material doped with aluminum by solid phase method

The invention relates to a preparation method of an aluminum-doped material of a cathode of a lithium ion battery with a solid phase process. The preparation method comprises the following steps: controlling certain reaction conditions to prepare a precursor of a nickel, cobalt and / or manganese hydroxide; uniformly mixing the precursor with a lithium salt and a nanometer aluminum compound; and carrying out high temperature processing for a certain period of time in an air or oxygen atmosphere, cooling, and crushing to obtain the aluminum-doped material of the cathode of the lithium ion battery with the solid phase process. The aluminum-doped material of the cathode of the lithium ion battery with the solid phase process which can substantially improve the safety performance and the cycle characteristic of the lithium ion battery at a high temperature can be applied to power batteries.

Owner:山东天骄新能源有限公司

High-temperature phase-change heat storage composite material and preparation method thereof

ActiveCN112589092ALow costSimple preparation processTransportation and packagingMetal-working apparatusAlloyHYDROSOL

The invention relates to a high-temperature phase-change heat storage composite material and a preparation method thereof. According to the technical scheme, the method comprises the steps that ternary aluminum-based alloy powder is alternately washed with an acid solution and deionized water, dried in a protective atmosphere and placed in pressurized steam to be pretreated, and the pretreated ternary aluminum-based alloy powder is obtained; the pretreated ternary aluminum-based alloy powder is put into aluminum sol for vacuum impregnation, taken out, filtered, put into silica sol for vacuum impregnation, filtered, and taken out; the steps are repeated for 3-5 times according to an alternate impregnation method, and filtering and drying are performed to obtain the pre-coated ternary aluminum-based alloy powder; and the pre-coated ternary aluminum-based alloy powder is put into a high-temperature furnace, fired at 1100-1400 DEG C under an air atmosphere condition, and cooled to obtain the high-temperature phase-change heat storage composite material. The preparation method is simple in process, low in cost and easy for industrial production, and the prepared high-temperature phase-change heat storage composite material is high in shell strength, high in phase-change temperature, high in heat storage density, high in heat utilization rate and high in utilization efficiency, and is suitable for solar power generation, high-temperature industry and the like.

Owner:WUHAN UNIV OF SCI & TECH

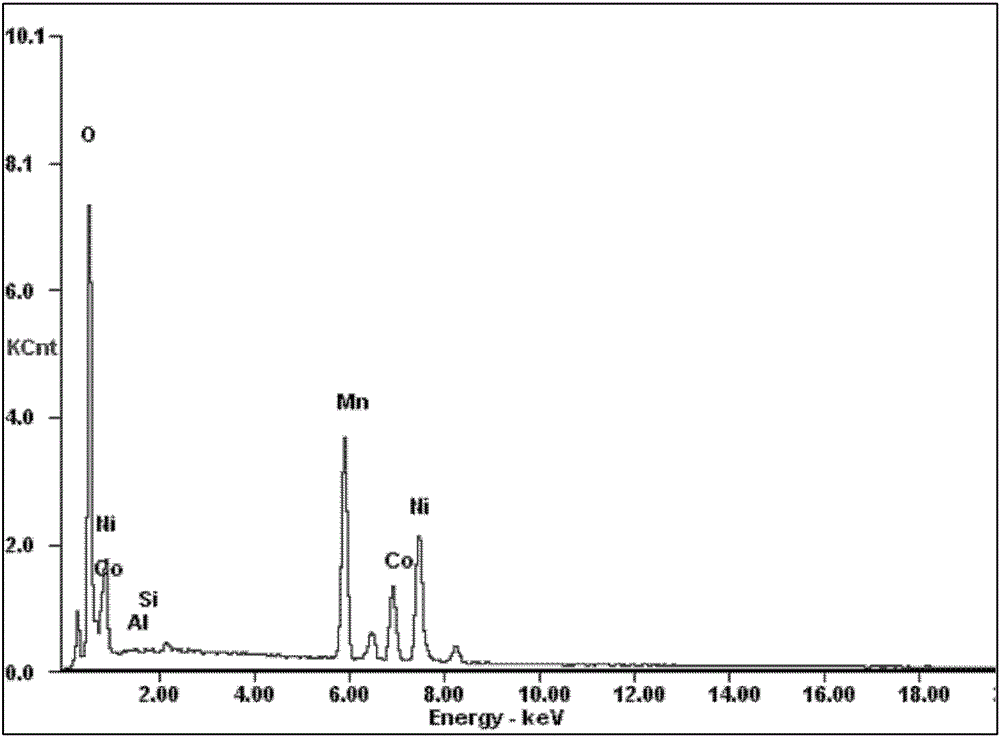

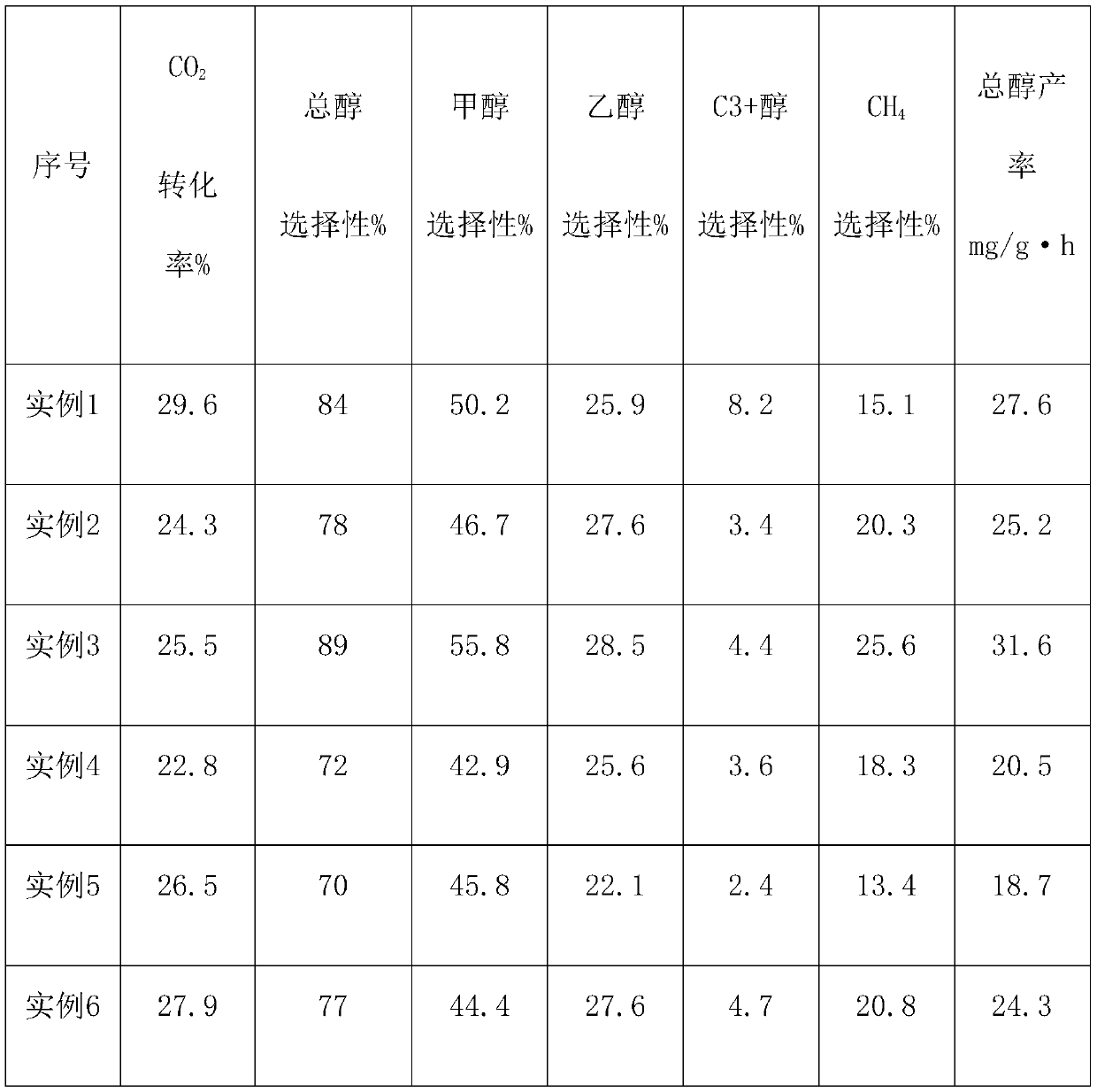

Catalyst for synthesizing low-carbon mixed alcohol by hydrogenation of carbon dioxide and preparation method thereof

ActiveCN110201711AAvoid Carbon DeactivationGood hydrothermal stabilityMolecular sieve catalystsOrganic compound preparationDispersityAlcohol

The invention provides a catalyst for synthesizing a low-carbon mixed alcohol by hydrogenation of carbon dioxide and a preparation method thereof. SSZ-13 molecular sieve is adopted as a carrier for synthesizing the low-carbon alcohol by the carbon dioxide, and the SSZ-13 molecular sieve has a large specific surface area, thereby greatly improving the dispersity of active components; at the same time, the SSZ-13 molecular sieve has strong hydrothermal stability and avoids carbon deposition deactivation of the catalyst caused by hot spot temperature in the process of synthesizing the low carbonmixed alcohol. Copper sources can be simultaneously introduced in the synthesis process of the molecular sieve, so that the selectivity of catalytic synthesis of the low-carbon alcohol is high, the synthesis method is simple, and large-scale production is easy; and the catalyst is particularly suitable for synthesis of the low-carbon mixed alcohol by catalytic hydrogenation reaction of the CO2, added value of products is high, and the catalyst has good application prospect.

Owner:CHINA HUANENG GRP CO LTD +1

Slag removing agent used for smelting aluminum alloy

The invention provides a slag removing agent used for smelting an aluminum alloy. The slag removing agent is characterized in that components of the slag removing agent comprise, by mass, 6-12% of sodium fluoride, 8-16% of calcium fluoride, 6-16% of sodium fluoroaluminate, 16-24% of potassium chloride, 5-10% of potassium nitrate, 12-18% of potassium fluorosilicate, 14-20% of sodium silicofluoride,4-10% of carbon powder, 5-10% of cryolite, and the rest sodium chloride added to 100%. The slag removing agent is adopted and has the beneficial effects that the heating effect is good, slag and aluminum separation is benefitted, the aluminum amount in slag is extremely low, the slag is dry slag, the slag removing effect is excellent, and moreover, the slag removing agent is easy to clear and convenient to use. Compared with the prior art, energy sources are saved, and labor hours are shortened.

Owner:徐州轩辕铝业有限公司

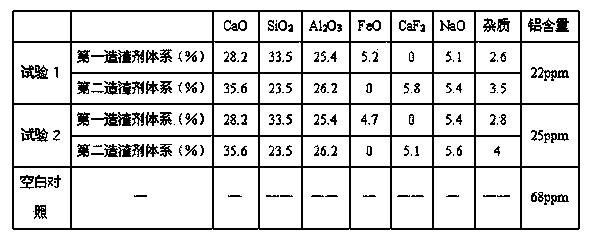

Slag former for smelting nanocrystalline master alloy and slagging process thereof

The invention belongs to the technical field of nanocrystalline master alloy smelting, and in particular relates to a slag former for smelting a nanocrystalline master alloy and a slagging process thereof. The slag former is formed by two slag former systems, respectively, a first slag former system and a second slag former system. The slagging process comprises the steps of slag former preparation and secondary slagging during the smelting of a master alloy. According to the slag former and the slagging process provided by the invention, the content of aluminum in the nanocrystalline master alloy can be effectively decreased.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

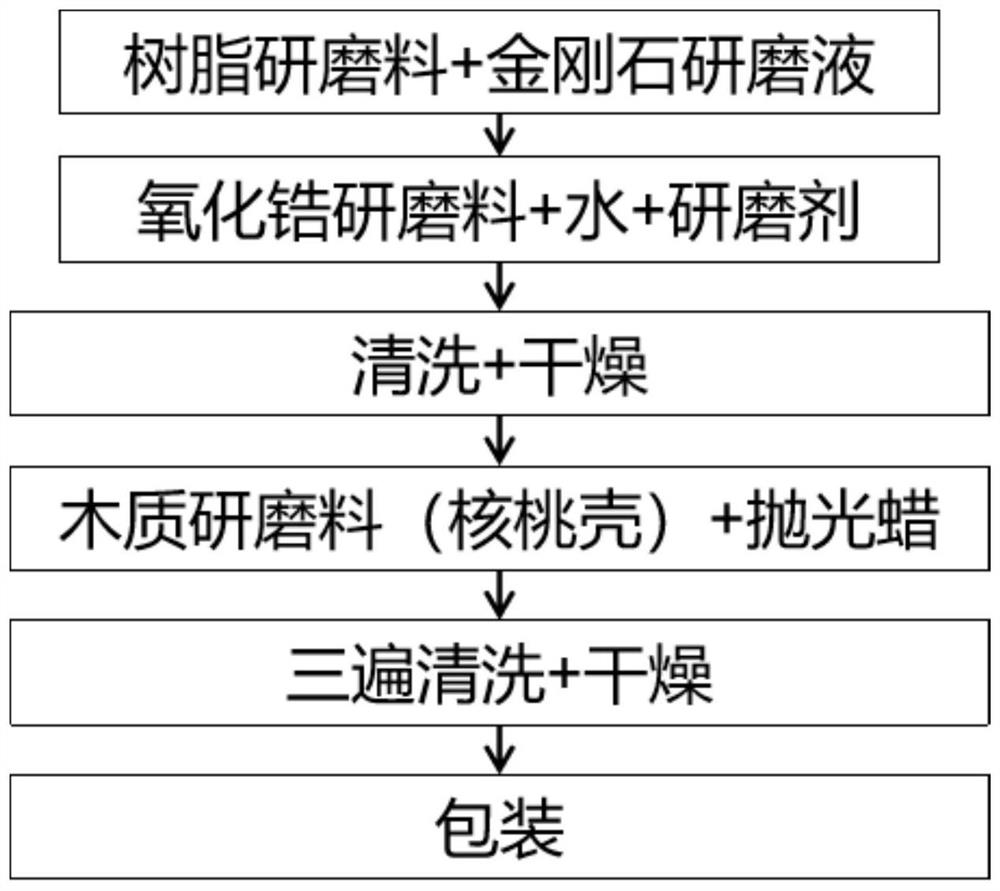

Medical titanium implant polishing technology

The invention discloses a medical titanium implant polishing technology. The technology includes the steps of the adoption of resin abrasives, rough grinding carried out by diamond grinding liquid, the adoption of zirconia abrasives, fine grinding carried out by an abradant without containing aluminum, and lightening carried out by wood abrasives. According to the technology, through the selectionof grinding composition, medical titanium implant is subjected to the rough grinding, the fine grinding, and surface lightening, a polishing product with good roughness and low aluminum content is obtained, the polishing effect is guaranteed, and meanwhile the problem of high aluminum content on the surface after mechanical polishing in an existing technology can be overcome.

Owner:FOSHAN YIHE BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com