Method for removing ferric iron ion contained in metatitanic acid by adopting electrolytic reduction

A technology of metatitanic acid and ferric iron, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increased product quality fluctuations, unsolved problems, high production costs, etc., and achieve simplified production processes and excellent removal effects , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

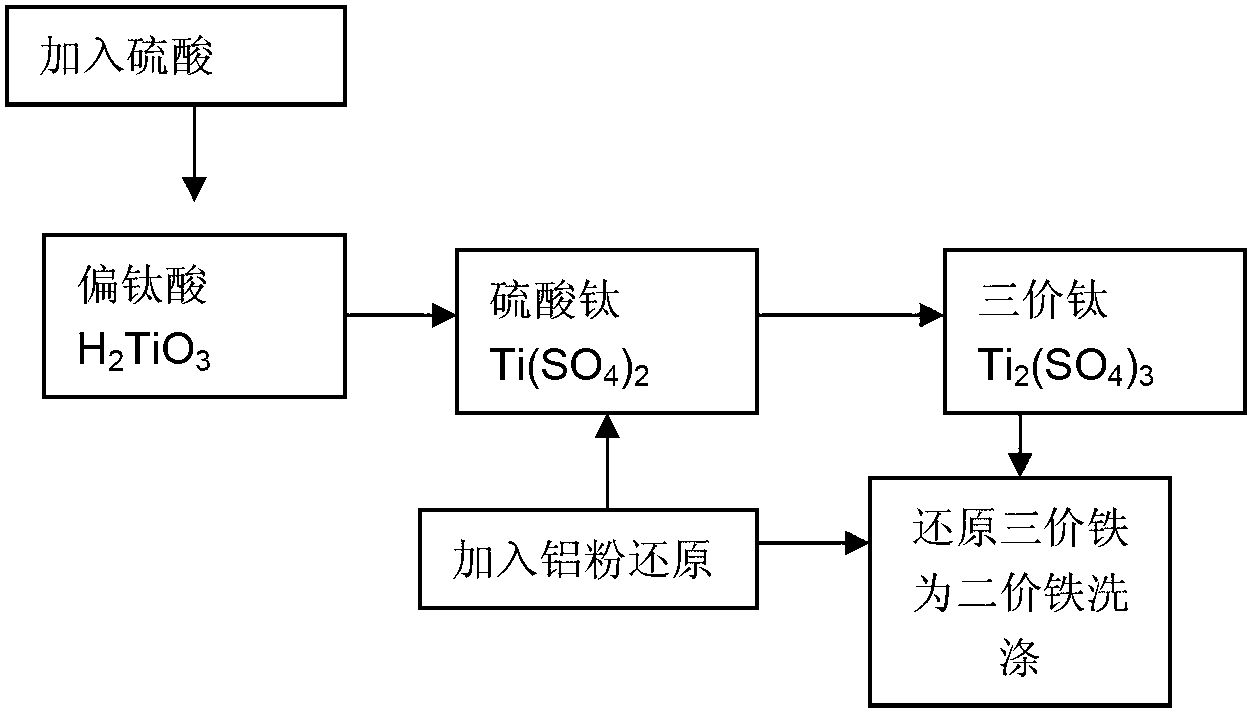

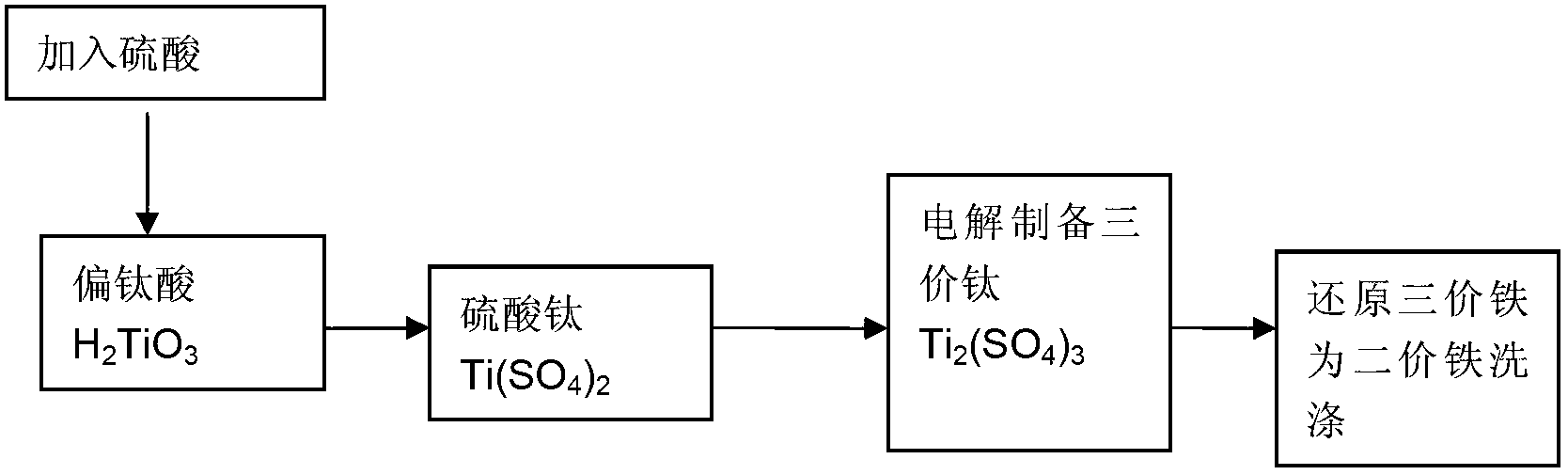

Problems solved by technology

Method used

Image

Examples

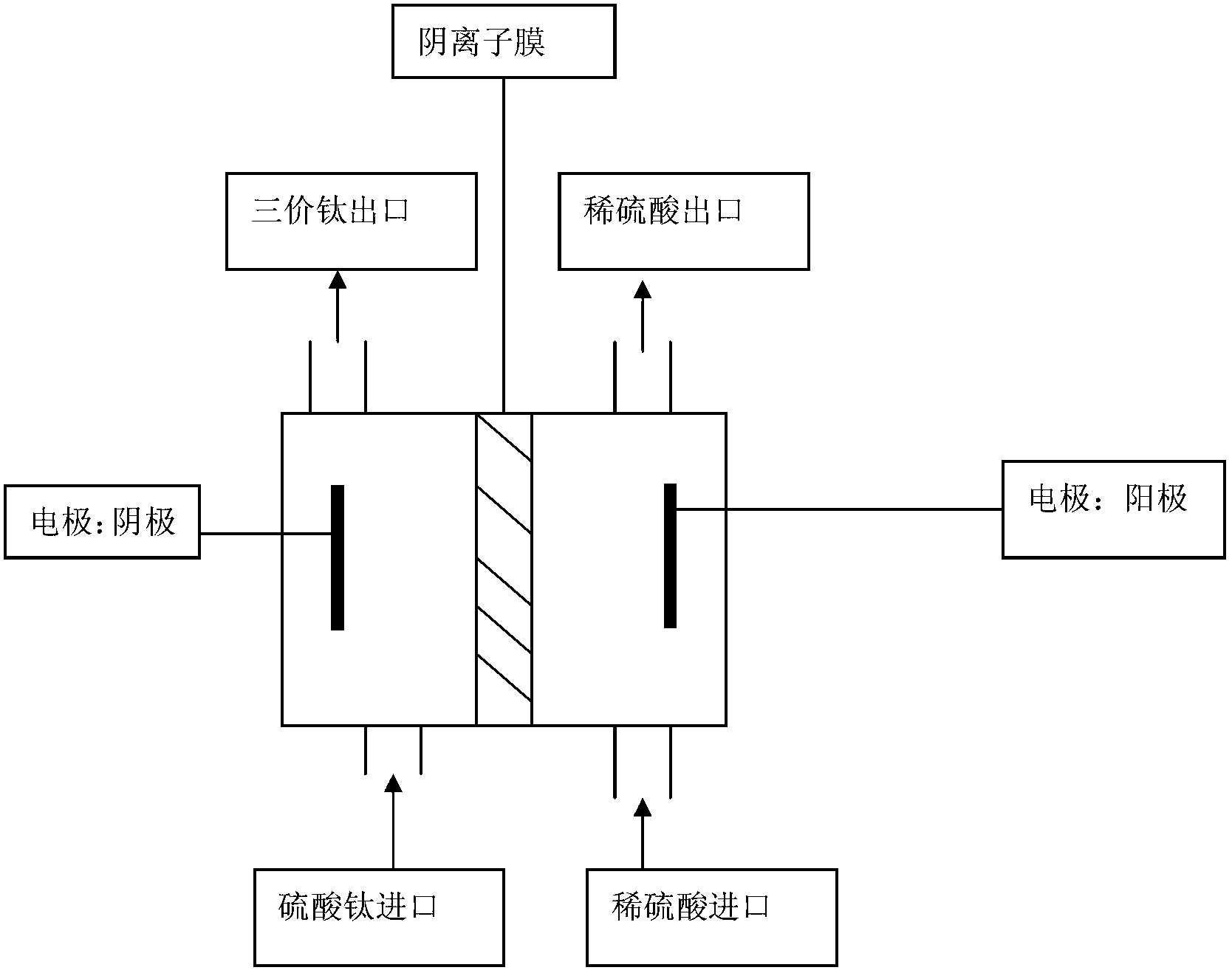

Embodiment 1

[0031] Prepare 100g of metatitanic acid with 0.5L deionized water to form a 200g / L slurry. After stirring evenly, slowly add sulfuric acid. The amount of sulfuric acid added is based on the mass ratio H 2 SO 4 : TiO 2 =5:1 join. Continue to stir evenly and heat until the material boils to dissolve it into a titanium sulfate solution. Cool the titanium sulfate solution to 50°C and add it to the electrolytic cell, control the electrolysis time at 1 hour, and the voltage at 0.8V, and carry out electrolysis to prepare trivalent titanium, so that the ratio of trivalent titanium to tetravalent titanium is greater than 90%; The final trivalent titanium solution is added to the raw material metatitanic acid to reduce the mixed ferric iron to ferrous iron and then washed to achieve less than 30ppm of ferric oxide, which meets the requirements of pigment grade titanium dioxide.

Embodiment 2

[0033] Prepare 100g of metatitanic acid with 0.5L deionized water to form a 200g / L slurry. After stirring evenly, slowly add sulfuric acid. The amount of sulfuric acid added is based on the mass ratio H 2 SO 4 : TiO 2 =4:1 join. Continue to stir evenly and heat until the material boils to dissolve it into titanium sulfate. Cool the titanium sulfate solution to 40°C and add it to the electrolytic cell, control the electrolysis time at 1.5 hours, and the voltage at 1.0V, and perform electrolysis to prepare trivalent titanium, so that the ratio of trivalent titanium to tetravalent titanium is greater than 90%; The final trivalent titanium solution is added to the raw material metatitanic acid to reduce the mixed ferric iron to ferrous iron and then washed to achieve less than 30ppm of ferric oxide, which meets the requirements of pigment grade titanium dioxide.

Embodiment 3

[0035] Prepare 100g of metatitanic acid with 0.5L deionized water to form a 200g / L slurry. After stirring evenly, slowly add sulfuric acid. The amount of sulfuric acid added is based on the mass ratio H 2 SO 4 : TiO 2 =6:1 join. Continue to stir evenly and heat until the material boils to dissolve it into titanium sulfate. Cool the titanium sulfate solution to 60°C and add it to the electrolytic cell, control the electrolysis time at 2 hours, and the voltage at 1.1V, and perform electrolysis to prepare trivalent titanium, so that the ratio of trivalent titanium to tetravalent titanium is greater than 90%; The final trivalent titanium solution is added to the raw material metatitanic acid to reduce the mixed ferric iron to ferrous iron and then washed to achieve less than 30ppm of ferric oxide, which meets the requirements of pigment grade titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com