Preparation method of high silica alumina ratio MCM-22 molecular sieve catalyst

A high-silicon-aluminum ratio, molecular sieve technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems that are not mentioned in the preparation method, achieve the suppression of hydrogen transfer, overcome the decrease of crystallinity, improve Effects on Yield and Reaction Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.90g of aluminum nitrate nonahydrate (99wt%) into 16.2ml of 0.1g / ml sodium hydroxide solution, then add 68.0ml of deionized water, and fully stir to make it a clear solution. Add 14.05g boric acid (99wt%) in the above solution, stir to make it dissolve completely, then add 52.8g silica sol (SiO 2 25.6wt%, Na 2 O 0.29wt%, Al 2 o 3 0.06 wt%, H 2O 74wt%), stirring it to form a uniform colloid. Finally, 26.7 ml of hexamethyleneimine (HMI, analytically pure) was added, and vigorously stirred to make it evenly mixed. The above colloid was transferred into a 200ml synthesis kettle, and the temperature was raised to 175°C at a rate of 1°C / min for dynamic crystallization for 7 days, and the rotation speed of the kettle body was 60rpm. After the crystallization, the product was fully filtered, washed, and then dried at 120°C for 12 hours to obtain the molecular sieve powder. The original powder was calcined at 550°C for 5 hours in an air atmosphere to obtain a Na-type ...

Embodiment 2

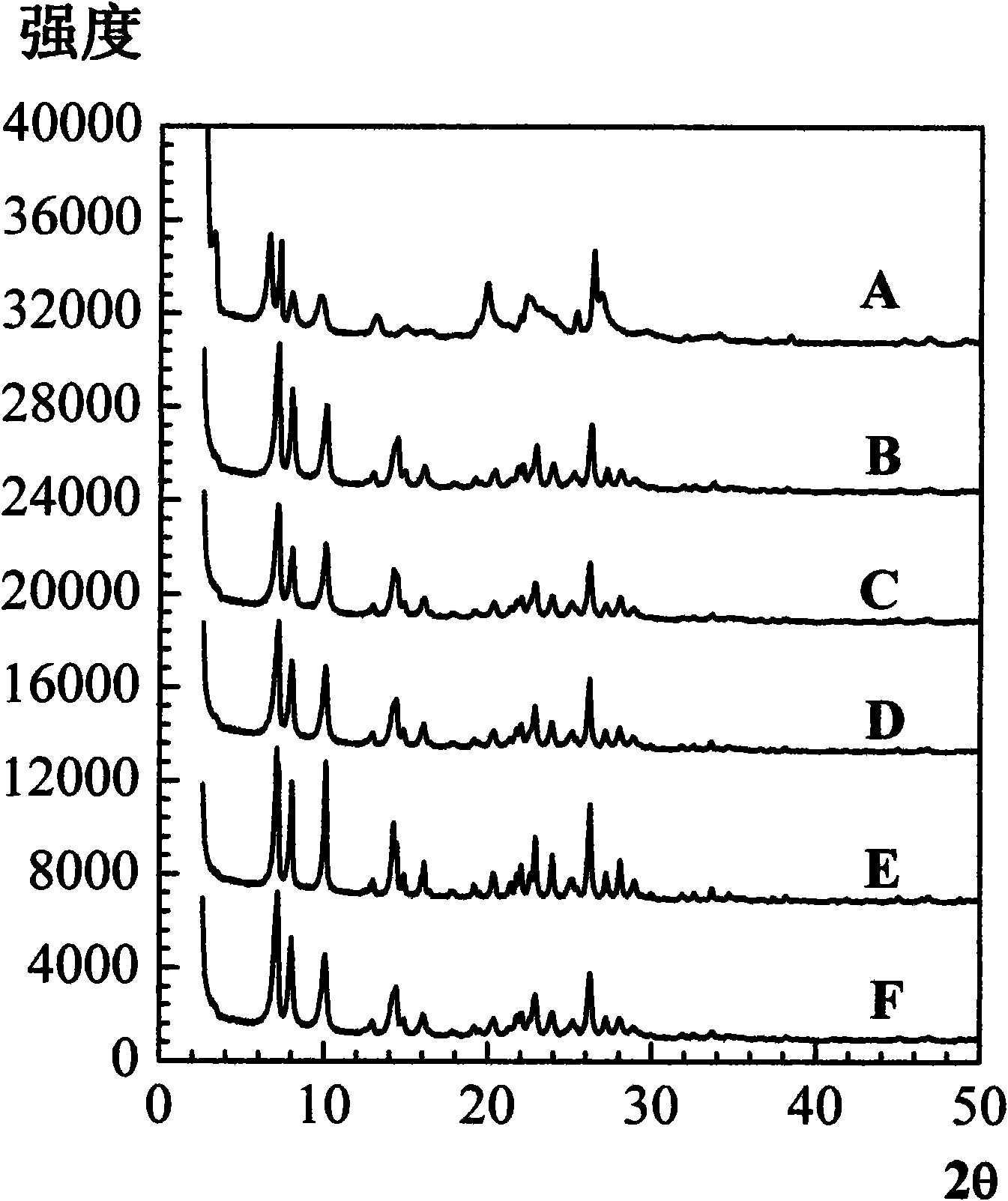

[0025] The amount of aluminum nitrate nonahydrate added in Example 1 was changed to 1.47g, and the remaining steps were the same as in Example 1. The silicon-aluminum ratio of the finally obtained molecular sieve was 98, which was close to the ratio of silicon-aluminum ratio of 100 in the ingredient. The XRD of the molecular sieve after calcination is shown in figure 1 (C), with figure 1 (B) have the same XRD characteristics.

Embodiment 3

[0027] The amount of aluminum nitrate nonahydrate added in Example 1 was changed to 0.62 g, and the remaining steps were the same as in Example 1. The silicon-aluminum ratio of the finally obtained molecular sieve was 218, which was close to the silicon-aluminum ratio of the ingredient 200. The XRD of the molecular sieve after calcination is shown in figure 1 (D), with figure 1 (B) have the same XRD characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com