Slag former for smelting nanocrystalline master alloy and slagging process thereof

A technology of slag-forming agent and master alloy, which is applied in the field of nanocrystalline master alloy smelting, can solve problems such as reduction, and achieve the effects of reducing production cost, ensuring apparent quality and performance, and reducing aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

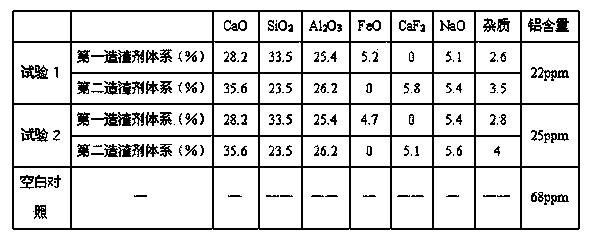

[0026] The slagging agent for smelting nanocrystalline master alloy provided in this example is composed of two slagging agent systems; the composition and weight content of the first slagging agent system are: CaO 20%-30%, SiO 2 30%-40%, Al 2 o 3 20%-30%, FeO 2%-10%, NaO 2%-10% and unavoidable impurities, the composition and weight content of the second slagging agent system are: CaO 30%-40%, SiO 2 20%-30%, Al 2 o 3 20%-30%, CaF 2 2%-10%, NaO 2%-10% and unavoidable impurities.

[0027] Wherein, the melting point of the first slagging agent system is 1150-1200°C.

[0028] Wherein, the melting point of the second slagging agent system is 1150°C to 1200°C.

[0029] Optimally, the particle size of the slagging agent is less than 1mm.

[0030] The technical scheme of the slagging process using the above-mentioned slagging agent for smelting nanocrystalline master alloy provided in this embodiment is:

[0031] In the master alloy smelting process, it includes a step of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com