Catalyst for synthesizing low-carbon mixed alcohol by hydrogenation of carbon dioxide and preparation method thereof

A low-carbon mixed alcohol and carbon dioxide technology, applied in the preparation of organic compounds, the preparation of hydroxyl compounds, catalysts for physical/chemical processes, etc., to achieve strong hydrothermal stability, avoid carbon deposition and deactivation, and improve the effect of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

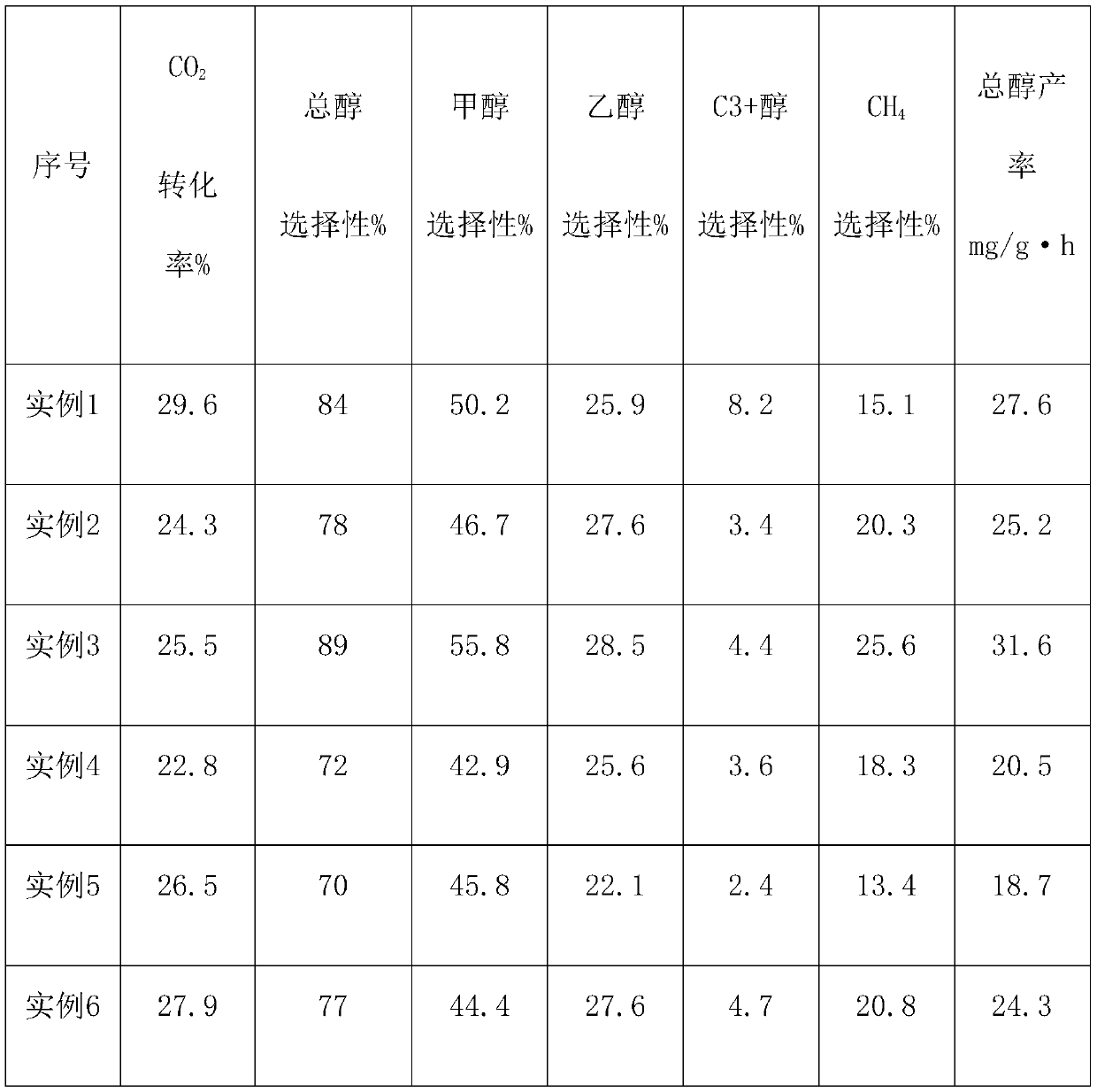

Examples

preparation example Construction

[0028] A method for preparing a catalyst for the synthesis of low-carbon mixed alcohols from carbon dioxide, the specific preparation steps are as follows:

[0029] S1: Weigh aluminum salt, copper salt, zinc salt, potassium salt, TEPA, NaOH and silicon source; among them, the molar ratio of aluminum salt, copper salt, zinc salt, potassium salt, TEPA, NaOH and silicon source is 1 :(0.2-3):(0.2-2):(0.1-1):(1-5):(1-5):(3-10);

[0030] S2: Dissolve the weighed aluminum salt in deionized water, heat it to 60-90°C, stir evenly at a rotating speed of 100-500r / min, and then add copper salt, TEPA, sodium hydroxide, and silicon source in sequence, mix and stir evenly A slurry mixture is obtained;

[0031] S3: Transfer all the slurry mixture obtained in S2 to a hydrothermal synthesis kettle, and fix it in a homogeneous reactor for crystallization at 120-170°C for 48-120 hours to obtain a crystalline product;

[0032] S4: Weigh a metered amount of zinc salt and dissolve it in deionized water to ...

Embodiment 1

[0042] This embodiment includes the following steps:

[0043] 1. Weigh 5g of sodium metaaluminate and dissolve it in 50ml of deionized water, stir well at 90℃ and 300r / min, then add 15g of CuSO sequentially 4 ·5H2O, 13g of TEPA, 5g of NaOH, 60g of large particles of silica sol are mixed and stirred to obtain a slurry mixture; all the slurry mixture is transferred to the hydrothermal synthesis kettle and installed in a homogeneous reactor at 180℃ After crystallization for 72 hours, the crystallization product is a precursor of Cu-SSZ-13 molecular sieve.

[0044] 2. Weigh 16g of Zn(CH 3 COO) 2 Dissolve in 50ml deionized water at 90℃, add dropwise to the above crystallized product for ion exchange for 8h. After the exchange is complete, cool the mixture, filter with suction, and wash with deionized water three times to PH=7. After washing The filter cake was dried in a microwave drying oven at 100°C for 30 minutes to obtain a dried product. The dried product was calcined in a muffle f...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] 1. Weigh 7g of sodium metaaluminate and dissolve it in 50ml of deionized water, stir well at 90℃ and 500r / min, then add 20g of CuSO successively 4 ·5H2O, 20g of TEPA, 8g of NaOH, 70g of small particles of silica sol are mixed and stirred uniformly to obtain a slurry mixture; all the slurry mixture is transferred to the hydrothermal synthesis kettle and installed in a homogeneous reactor at 170℃ After 72h, the crystallized product is the precursor of Cu-SSZ-13 molecular sieve.

[0049] 2. Weigh 24g of Zn(CH 3 COO) 2 Dissolve in 50ml of deionized water, add dropwise to the crystalline product obtained above at 90°C for ion exchange for 8 hours. After the exchange is complete, cool the mixture, filter with suction, and wash with deionized water three times to pH=7 , The washed filter cake was dried in a microwave drying oven at 100°C for 20 minutes to obtain a dried product. The dried product was placed in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com