Isothermal reactor and its device and method for methanation reaction

An isothermal reactor, methanation technology, applied in chemical instruments and methods, chemical/physical processes, gas fuels, etc., can solve the problems of difficult catalyst filling, high reactor temperature, low energy utilization, etc., to reduce separation and purification. cost, shorten the process flow, reduce equipment investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

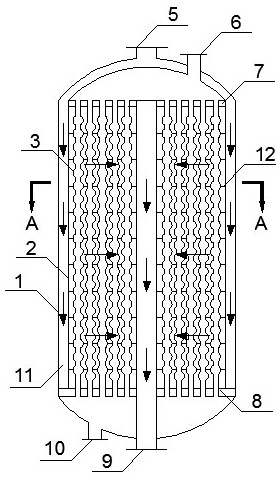

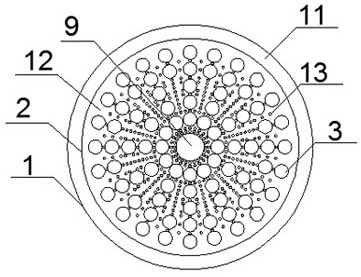

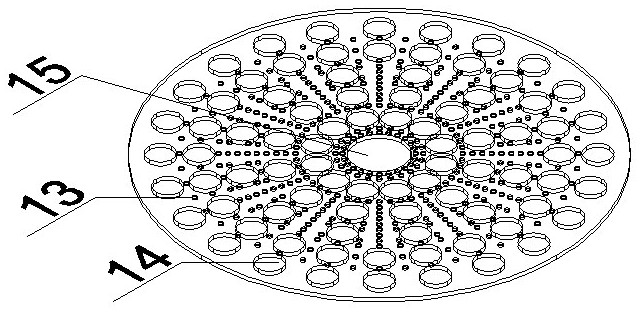

[0042] Such as Figures 1 to 3 As shown, an isothermal reactor includes an outer cylinder 1, an inner cylinder 2, several heat exchange tubes 3, several catalyst packing plates 12, raw material gas inlet pipe 5, raw material gas outlet pipe 9, and water vapor inlet pipe 10 and water vapor outlet pipe 6; the outer cylinder body 1 and the inner cylinder body 2 are coaxially arranged, and the axial centerline of the raw material gas outlet pipe 9 coincides with the axial centerline of the inner cylinder body 2;

[0043] The outer cylinder 1 is horizontally provided with a lower partition 8, the inner cylinder 2 is arranged on the upper part of the lower partition 8, and the inner cylinder 2 is horizontally provided with an upper partition 7, and the upper partition 7, the lower partition 8 and the The side wall of the inner cylinder 2 forms a catalytic reaction chamber, the upper partition 7 cooperates with the top of the inner cylinder 2 to form a closed first chamber, and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com