A device and conversion method for removing and converting tar in biomass synthesis gas

A synthesis gas and biomass technology, applied in chemical instruments and methods, separation methods, combustible gas purification, etc., can solve the problems of difficult tar removal, difficult regeneration, and easy clogging of adsorbents, so as to avoid catalyst carbon deposition and deactivation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A device for removing and converting tar in biomass synthesis gas, comprising a tar removal reactor, and the tar removal reactor is respectively connected to a synthesis gas inlet pipeline, a purified synthesis gas outlet pipeline, an air inlet pipeline, a smoke Gas outlet pipeline, cooling water inlet pipeline and cooling water outlet pipeline, the air inlet pipeline is connected to the air preheater, and a set of casing-type reaction tubes are arranged inside the tar removal reactor, and the The sleeve-type reaction tube is composed of an inner tube and an outer tube, the inner tube communicates with the cooling water inlet pipeline and the cooling water outlet pipeline, and the outer tube is gas-permeable The filter tube is loaded with a catalyst that catalyzes tar oxidation, and the annular space formed by the inner tube and the outer tube communicates with the synthesis gas inlet pipeline and the flue gas outlet pipeline.

[0035] The device for removing and conver...

Embodiment 2

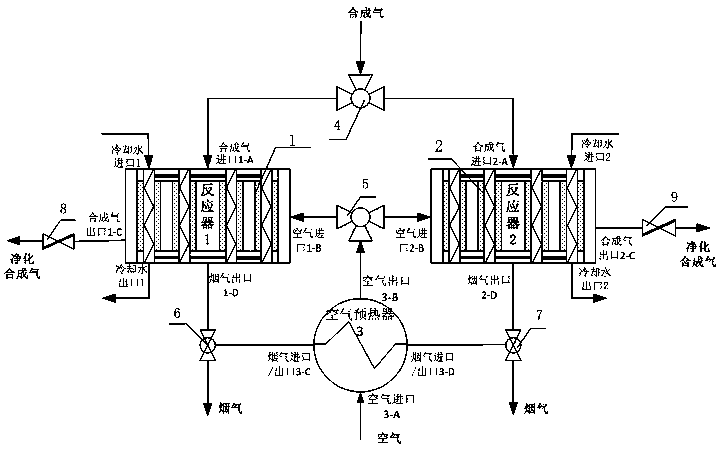

[0048] The difference between this example and Example 1 is that in the device for removing and converting tar in biomass synthesis gas described in this example, the described tar removal reactor adopts two pairs of the first tar The removal reactor 1 and the second tar removal reactor 2, the synthesis gas inlet 1-A of the first tar removal reactor 1 and the synthesis gas inlet 2-A of the second tar removal reactor 2 pass through the The syngas inlet pipeline of a switching valve is connected, the air inlet 2-A of the first tar removal reactor 1 and the air inlet 2-B of the second tar removal reactor 2 pass through the air inlet with the second switching valve Pipeline connection; the synthesis gas outlet 1-C of the first tar removal reactor 1 is connected to the first control valve, and the synthesis gas outlet 2-C of the second tar removal reactor 2 is connected to the second control valve; the first tar removal The flue gas outlet 1-D of the removal reactor 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com