Annealing-free low-carbon steel coil rod and production method thereof

A low-carbon steel, anneal-free technology, used in the manufacture of converters, metal rolling, etc., can solve problems such as increasing the cost of alloys, and achieve the effects of reducing deoxidation costs, reducing aluminum content, and reducing grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment the present invention will be further described.

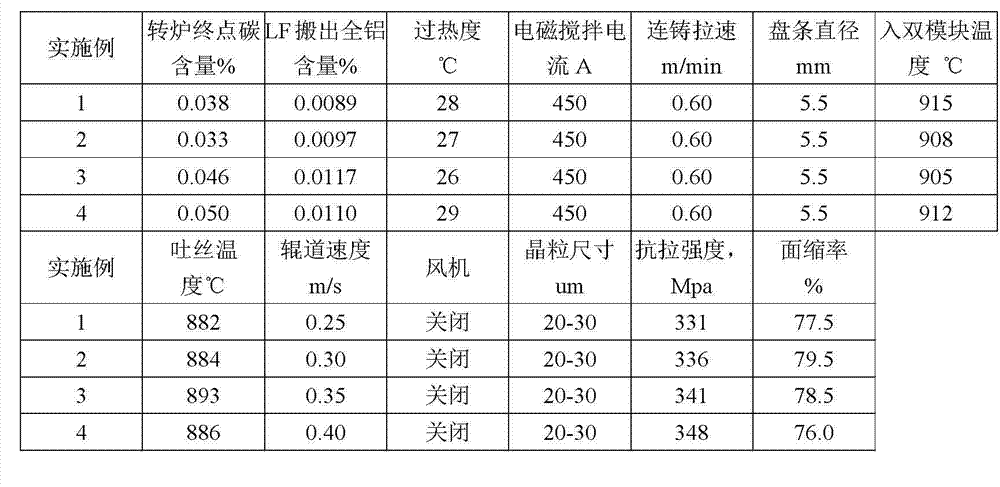

[0020] In the embodiment of the present invention, smelting and rolling are carried out according to the composition ratio of the technical solution. The chemical composition of the steel of the embodiment of the present invention is shown in Table 1. See Table 2 for the rolling process and performance of the steel of the embodiment of the present invention.

[0021] Add 2-2.5Kg / t carbon ferromanganese and 5-6Kg / t aluminum manganese ferromanganese in deoxidizer to incomplete deoxidation during converter blowing process, and control the carbon content of tapped steel at 0.03%-0.06%; LF furnace refining submerged arc heating, blowing Argon, adding medium-carbon ferromanganese or metal manganese alloying, the LF furnace can take out no more than 0.012% of the total aluminum, and the guaranteed take-out temperature is 1620°C; the size of the continuous casting billet is 280×380mm, and the superheat of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com