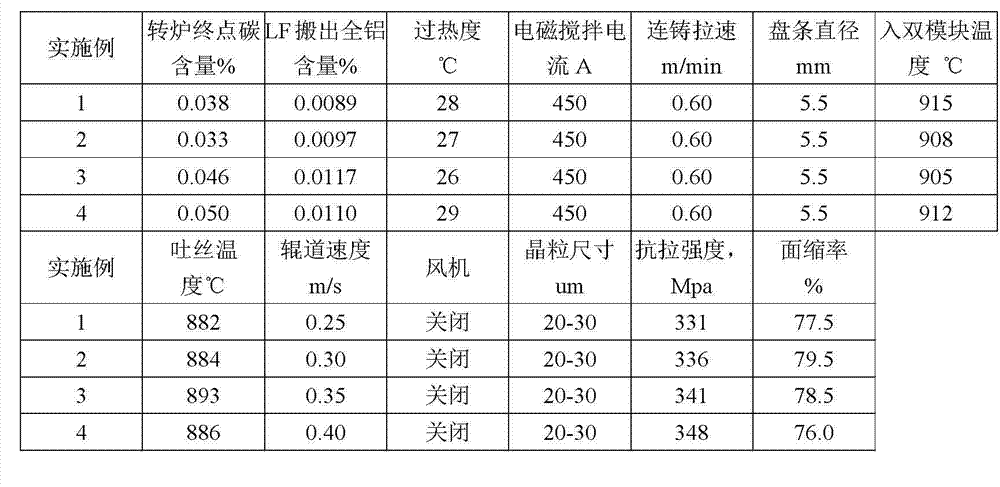

Patents

Literature

37results about How to "Shorten the smelting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

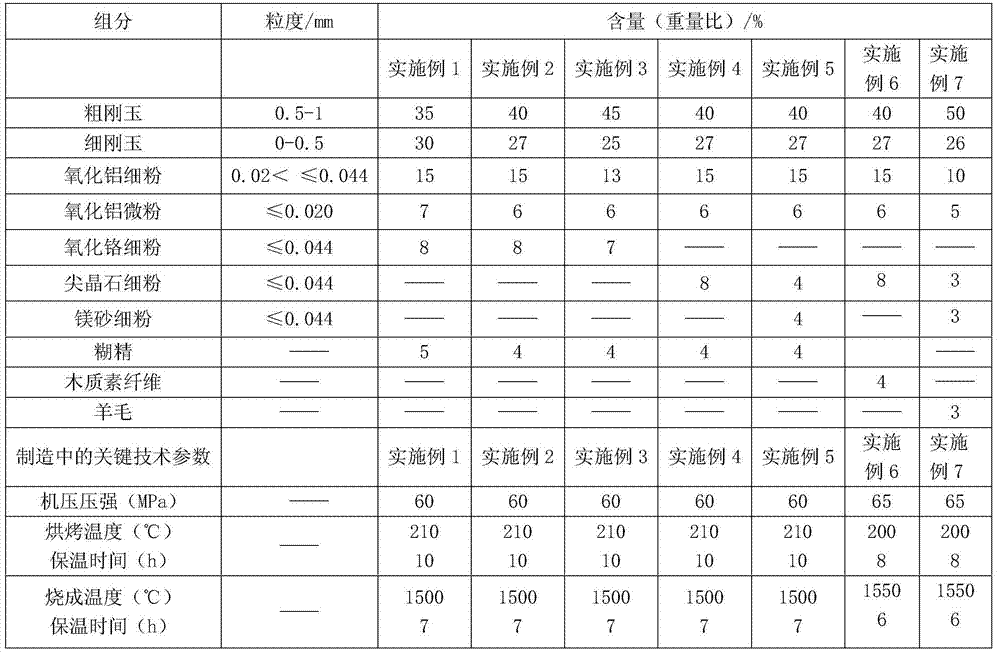

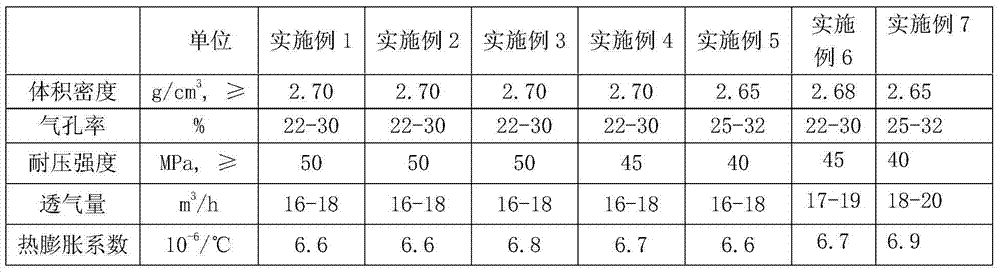

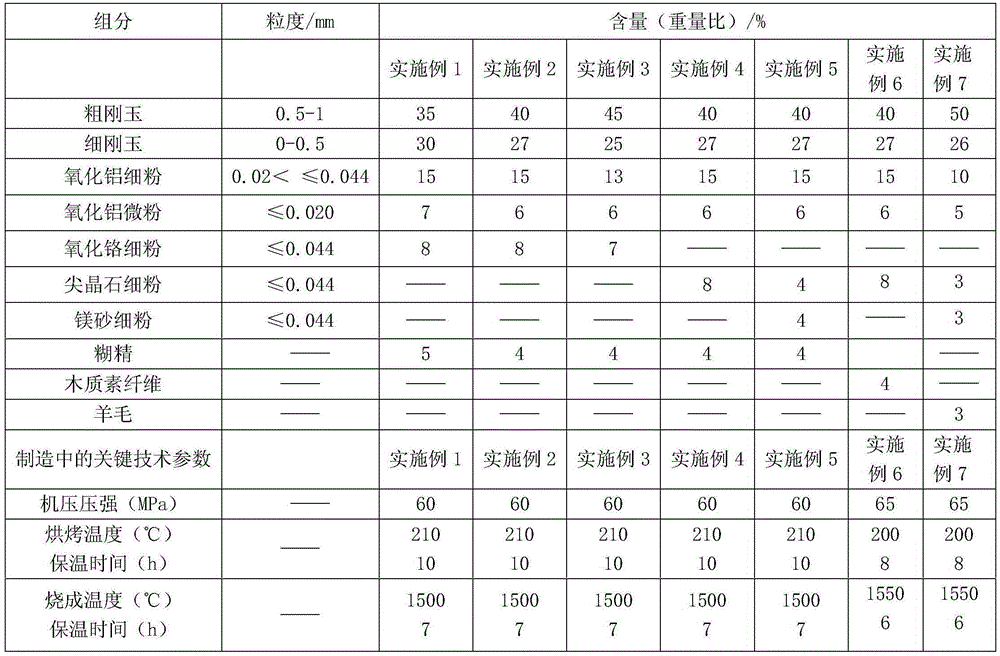

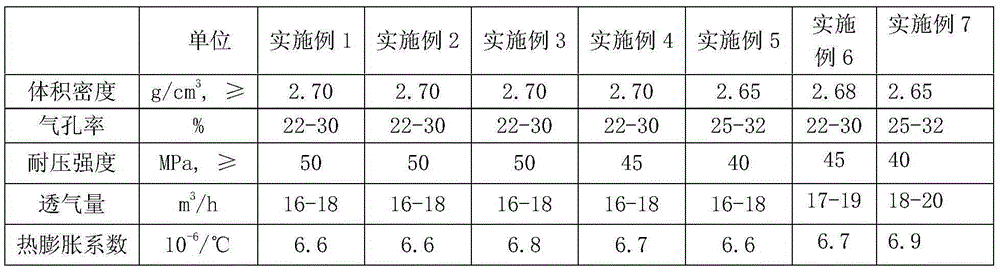

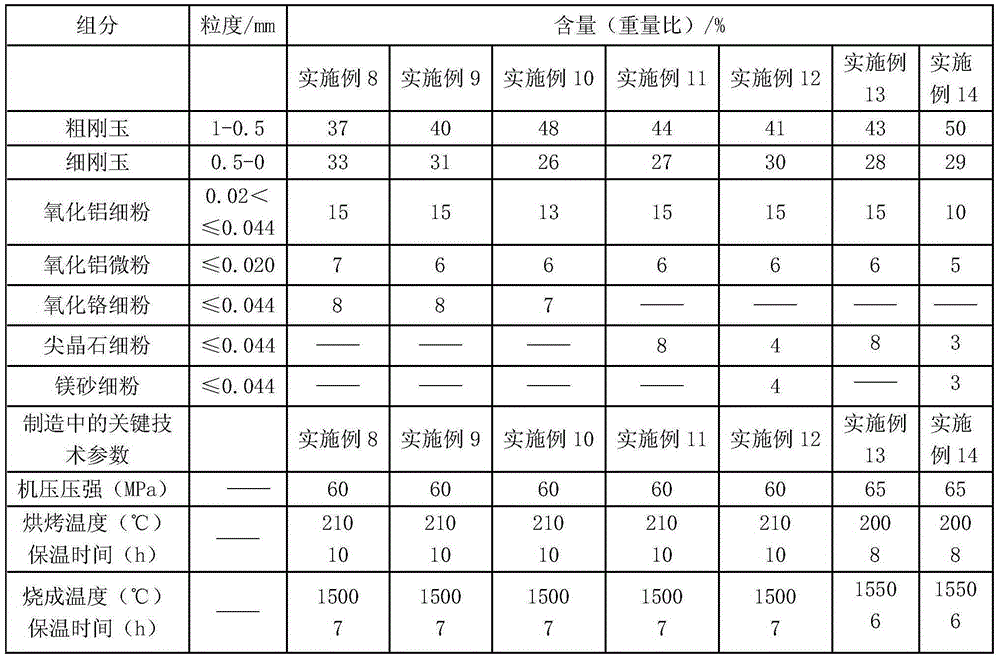

Air brick with high blowing through rate and manufacturing method thereof

The invention relates to an air brick with a high blowing through rate and a manufacturing method thereof. The air brick is composed of the following components: coarse corundum with granularity greater than 0.5mm and smaller than or equal to 1 mm and mass fraction of 35-50%; fine corundum with granularity greater than 0 and smaller than or equal to 0.5 mm and mass fraction of 25-40%; alumina fine powder with granularity greater than 0.020 mm and smaller than or equal to 0.044 mm and mass fraction of 8-15%; alumina micro powder with granularity greater than 0 and smaller than or equal to 0.020 mm and mass fraction of 5-10%. The manufacturing method comprises the procedures of mixed milling, material kneading and press forming, and further comprises the procedures of roasting, high temperature sintering, flow detecting, steel shell packaging and the like. According to the air brick provided by the invention, the particle size distribution and the machine pressing pressure are controlled, and uniformly distributed and mutually communicated micropores are formed in a brick body after high temperature sintering so as to achieve the permeability of an air brick body material.

Owner:PUYANG REFRACTORIES GRP CO LTD

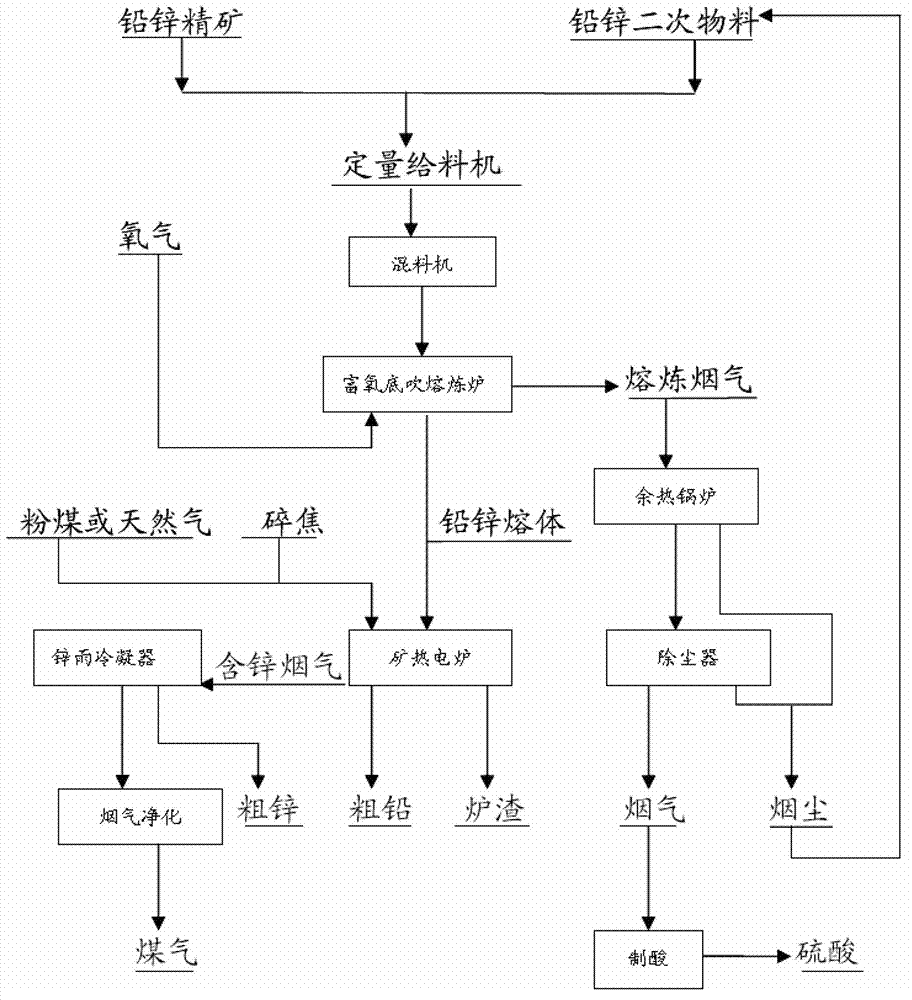

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

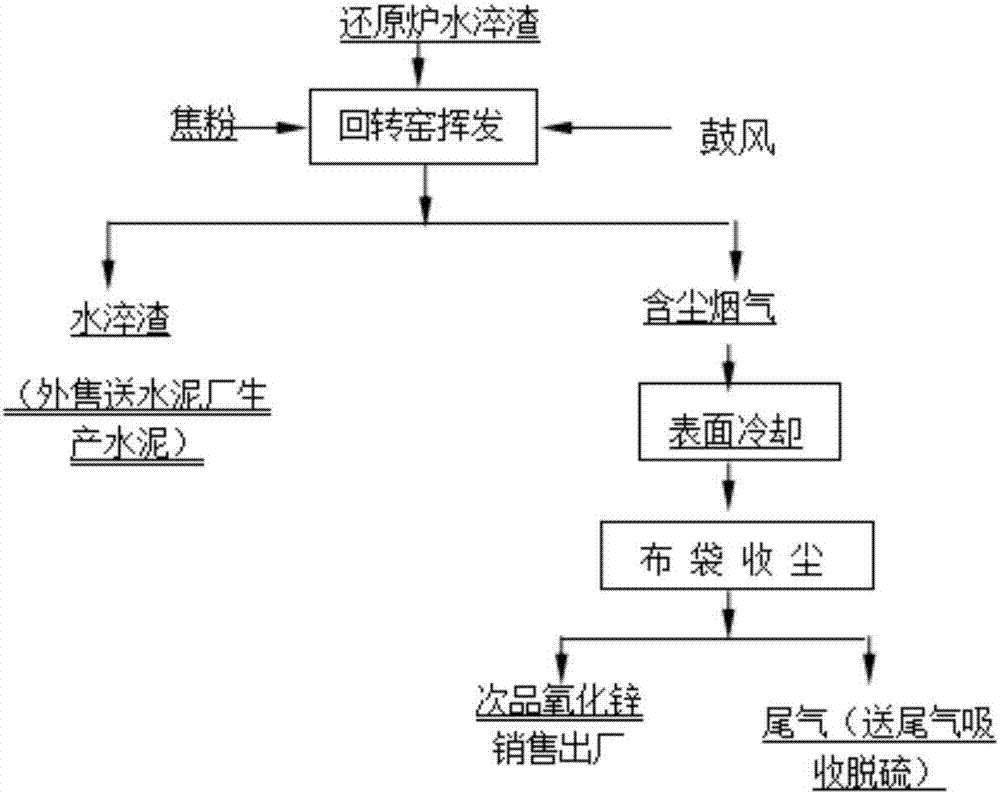

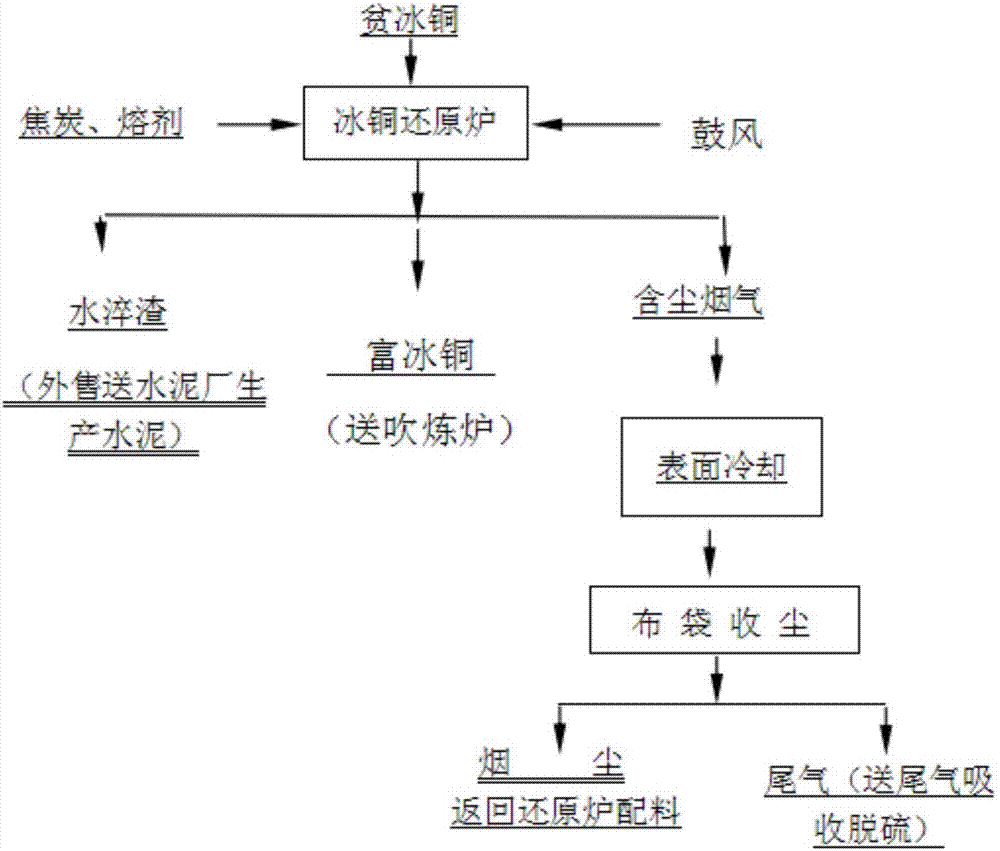

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

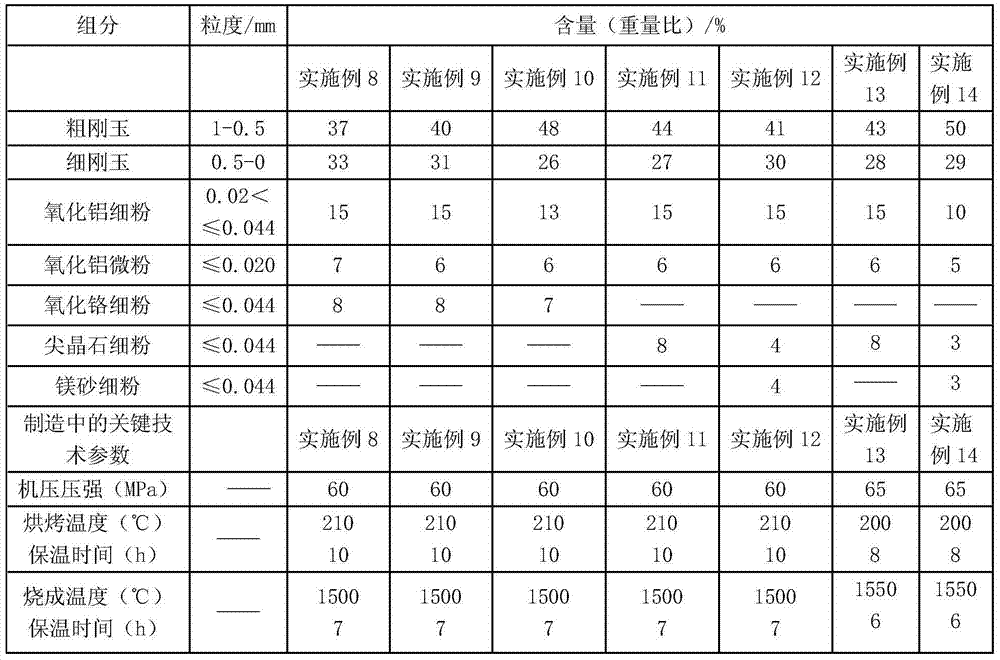

Annealing-free low-carbon steel coil rod and production method thereof

InactiveCN102899554AReduce intensity to create conditionsIncrease oxygen activityManufacturing convertersMetal rolling arrangementsChemical compositionCarbonization

The invention provides an annealing-free low-carbon steel coil rod and a production method thereof. The annealing-free low-carbon steel coil rod comprises the following chemical components: 0.04-0.10% of C, 0.01-0.10% of Si, 0.20-0.35% of Mn, at most 0.015% of P, at most 0.010% of S, at most 0.0060% of N, 0.0030-0.0060% of total oxygen, 0.0020-0.0080% of total aluminum, at most 0.1% of inevitable impurity and the balance of iron. The manufacturing method comprises the steps of converter smelting, LF (ladle furnace) refining, continuous casting and rolling, wherein incomplete deoxidation occurs at the tapping side of a converter, the aluminum content of molten steel is reduced by using the high oxygen activity of the molten steel, the carbonization of the molten steel in the refining process is inhibited, bloom protection casting is performed, the temperature for double module input is controlled at 900-920 DEG C, the loop laying temperature is 870-900 DEG C, the speed of a roller way is 0.2-0.4 m / s, and a blower is closed. Thus, the vacuum treatment procedure is omitted, the technical process is shortened, the production cost is lowered, and the requirement of users for canceling the annealing technique in the drawing process is satisfied. For the annealing-free low-carbon steel coil rod produced according to the components and the production method provided by the invention, the grain size is controlled at 20-30 um, the tensile strength is no more than 350 MPa, and the reduction of area is no less than 75%.

Owner:ANGANG STEEL CO LTD

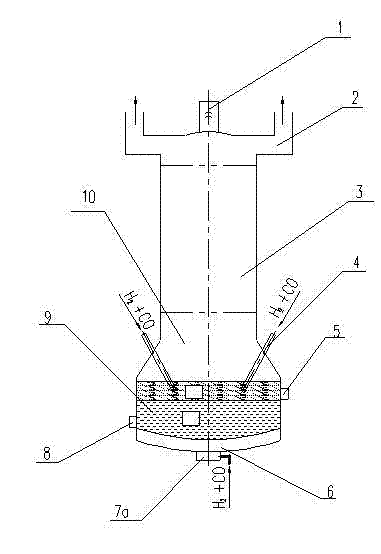

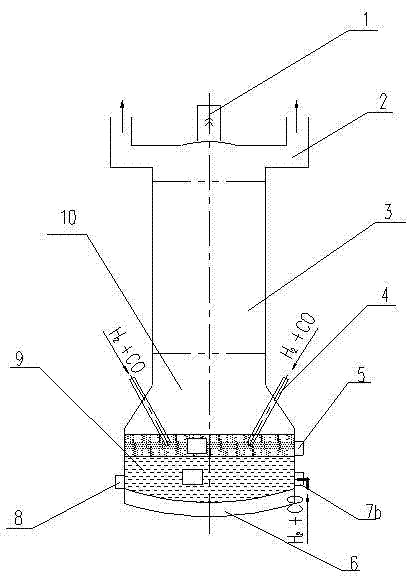

Reduction steel-making method and reduction steel-marking device

InactiveCN103045788AShorten the smelting processReduce unlucky linksElectric furnaceMelting tankOxygen

The invention relates to a reduction steel-making method. The reduction steel-making method comprises the following steps of: (1) carrying out initial reduction reaction on iron ore materials entering a prereduction zone in a furnace; (2) carrying out a reduction reaction simultaneously when heating and smelting the mixture entering a high temperature zone in the furnace by an electric arc or a plasma arc; (3) carrying out depth reduction reaction on molten steel entering a molten pool in the furnace to form qualified molten steel; and (4) periodically discharging the molten steel and slag from a tap hole and a slag hole. The invention further provides a reduction steel-making device. According to the reduction steel-making method and the reduction steel-making device, the production flow is short, the overall land occupation is small, ore to finished product metal yield is high, the energy consumption is low, carbon coke and a large amount of oxygen are not used, iron alloy is not needed or a small amount of iron alloy is needed except that a special steel grade is made, the carbon emission and the exhaust emission in a smelting process are reduced, and energy saving and emission reduction are facilitated.

Owner:CISDI ENG CO LTD

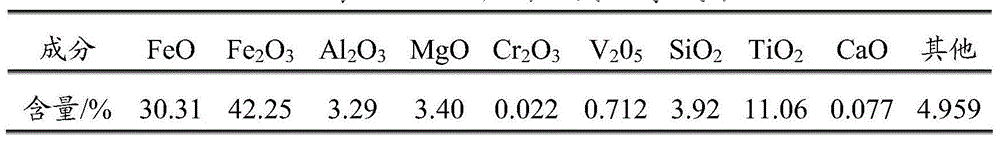

Method of directly reducing vanadium-titanium ore hot-pressing blocks in rotary hearth furnace and melting in electric furnace

InactiveCN104131179AImprove reducibilityShorten the smelting processRotary drum furnacesGas emission reductionTitanium dioxideHot press

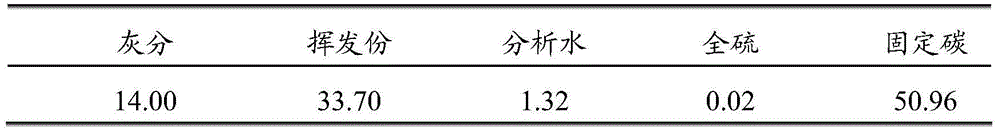

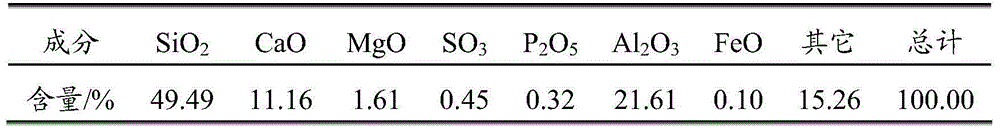

The invention belongs to the technical field of comprehensive utilization of metallurgical resources, and in particular relates to a comprehensive utilization method of directly reducing vanadium-titanium ore hot-pressing blocks in a rotary hearth furnace and melting in an electric furnace. The method comprises the following steps: (1) blending vanadium-titanium ore mineral powder with bituminous coal powder, heating mixed powder and carrying out hot-press molding so as to obtain the vanadium-titanium ore hot-pressing blocks; (2) putting the vanadium-titanium ore hot-pressing blocks into the rotary hearth furnace by covering multiple layers of materials on the vanadium-titanium ore hot-pressing blocks and carrying out direct reduction via thick material layers; (3) melting products obtained by reducing the vanadium-titanium ore hot-pressing blocks in the rotary hearth furnace so as to obtain vanadium-containing molten iron and titanium slag; and (4) carrying out vanadium blowing and steelmaking on the vanadium-containing molten iron so as to obtain vanadium slag and a steel ingot, wherein the vanadium slag can serve as a raw material for preparing titanium dioxide. The method which is used for preparing the vanadium-titanium ore hot-pressing blocks has the advantages of low production cost, high production efficiency, low energy consumption, good quality of the vanadium titanium ore hot-pressing blocks and the like. Thus, the economy of the process of directly reducing vanadium-titanium ores in the rotary hearth furnace and melting in the electric furnace is obviously improved.

Owner:NORTHEASTERN UNIV

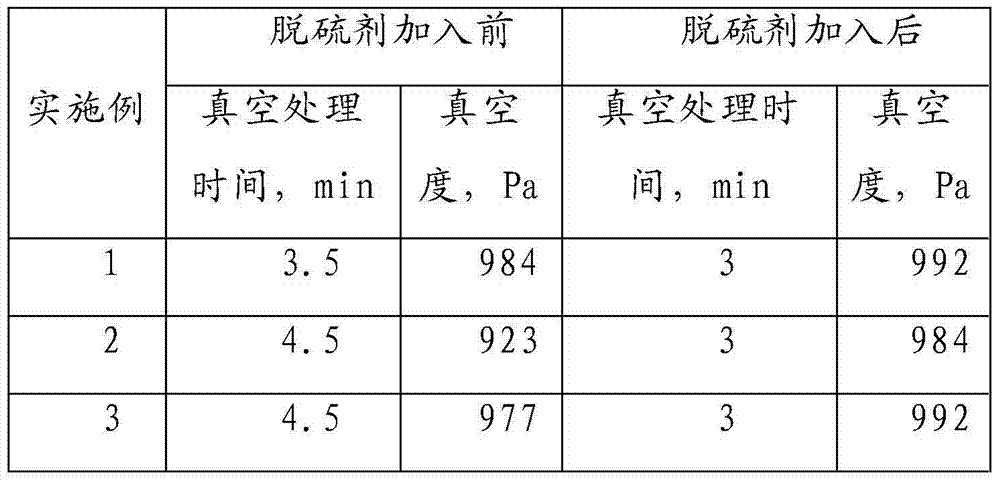

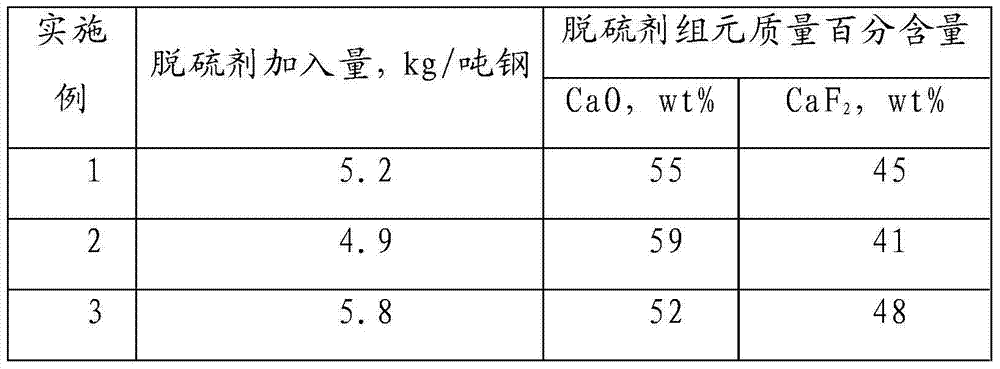

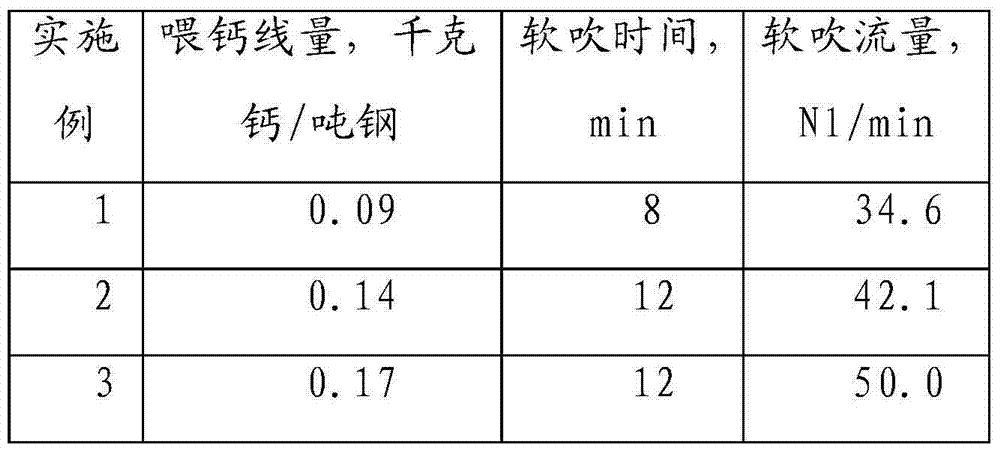

Method for smelting high-grade pipe line steel with RH single-link process

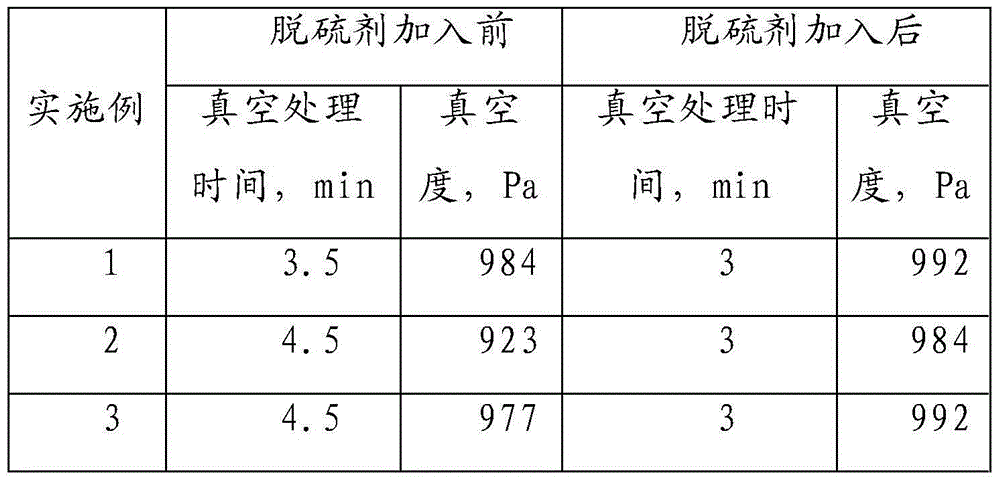

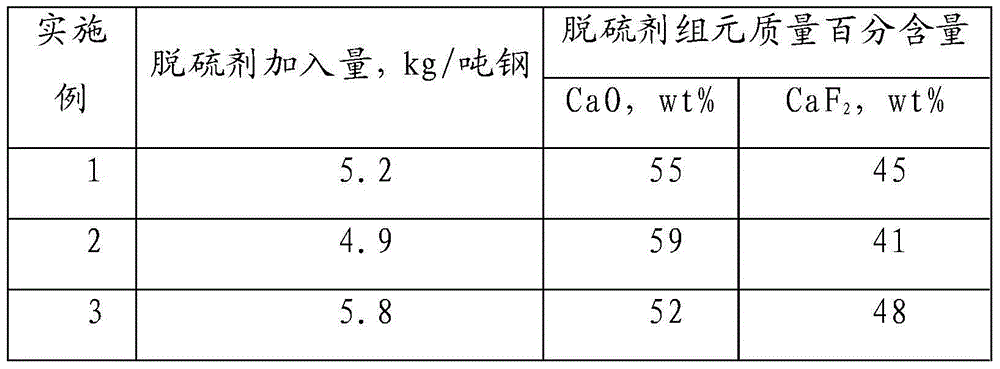

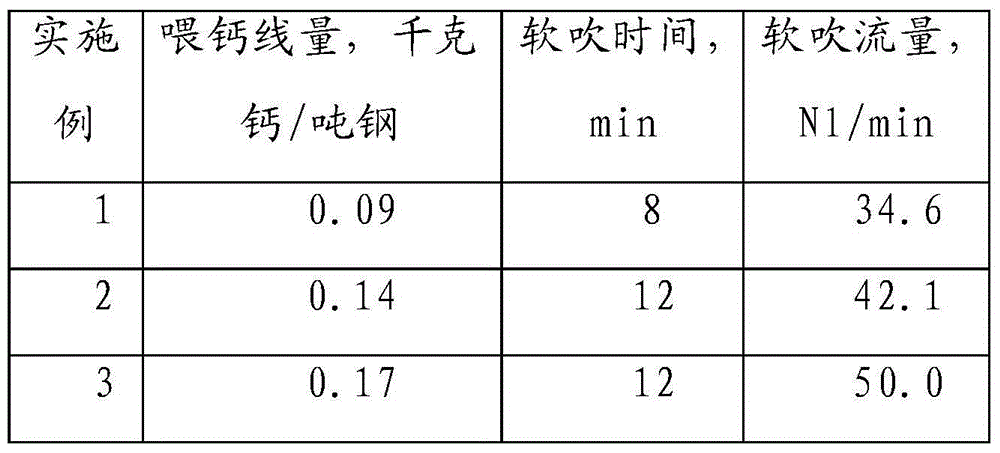

The invention provides a method for smelting high-grade pipe line steel with a RH single-link process. During a converter tapping process, high aluminum content in molten steel is controlled, such that desulfurization and impurity control in subsequent refining process can be benefited. During an RH vacuum refining stage, a desulfurization agent is added, and S content in the molten steel is controlled no higher than 0.0020%; oxygen blowing is carried out upon the molten steel, and a reaction is carried out between oxygen and aluminum in the molten steel, such that aluminum content in the molten steel is controlled at 0.03-0.05%. Also, heat loss during the desulfurization process is supplemented, and the impurity is converted into mainly clustered Al2O3 impurity which is easy to remove; and calcium treatment and soft blowing are carried out, such that the impurities in molten steel is mainly CaS impurities of small particles with deformation coefficient close to 1. According to the method provided by the invention, X80 pipeline steel quality requirement can be achieved, production process flow is short, and cost can be substantially reduced.

Owner:SHOUGANG CORPORATION

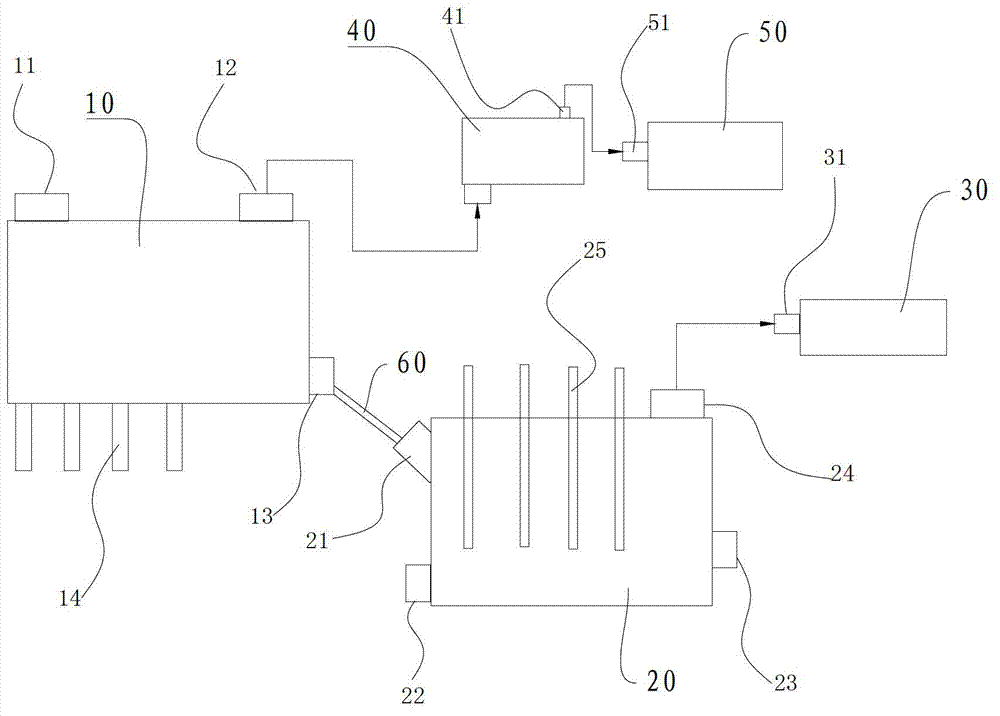

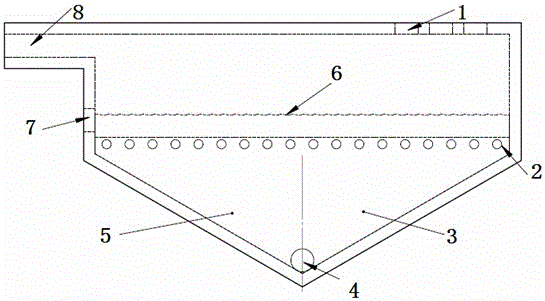

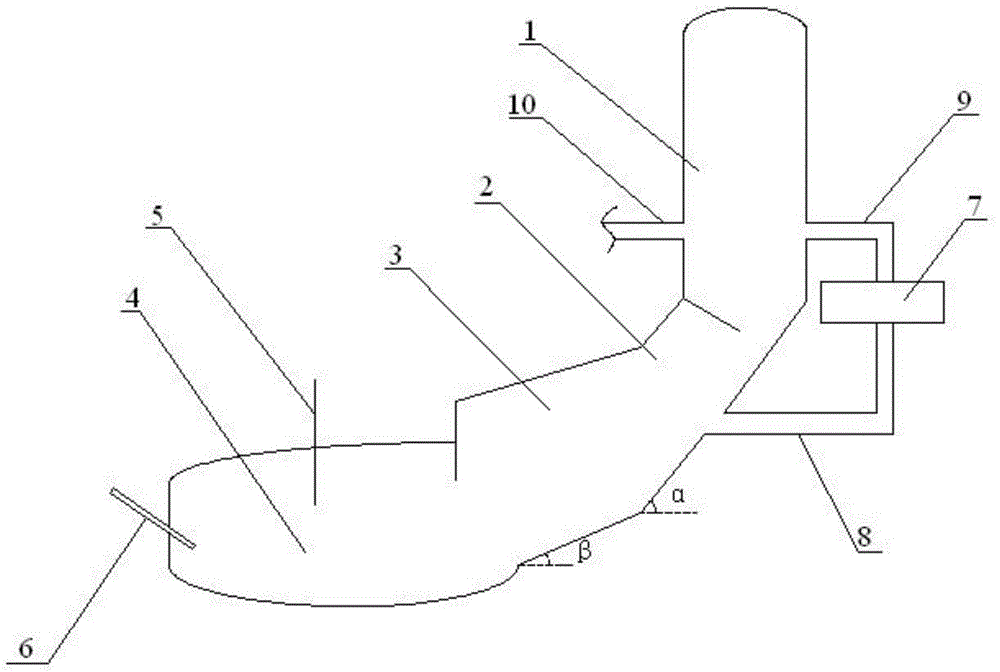

Bottom blowing smelting electrothermal reduction lead and zinc smelting device

InactiveCN103205581AShort processAvoid serious environmental pollution problemsElectric consumptionZinc smelting

The invention provides a bottom blowing smelting electrothermal reduction lead and zinc smelting device which comprises an oxygen-rich bottom blowing smelting furnace, an ore-smelting electric furnace and a zinc rain condenser. The oxygen-rich bottom blowing smelting furnace is provided with a smelting feed inlet, a smelting flue outlet and a melt discharge outlet. The ore-smelting electric furnace is provided with an electric furnace feed inlet, a lead discharge outlet, a slag discharge outlet and an electric furnace flue outlet. The electric furnace feed inlet of the ore-smelting electric furnace is connected with the melt discharge outlet so as to enable melts containing lead and zinc oxides and discharged from the melt discharge outlet to flow into the ore-smelting electric furnace through the electric furnace feed inlet. A gas inlet of the zinc rain condenser is connected with the electric furnace flue outlet. According to the bottom blowing melting electrothermal reduction lead and zinc smelting device, environmental pollution can be reduced, sulfuric acid yield is greatly increased, furnace material smelting is omitted, and electric consumption of product unit is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

Low-nitrogen boron-containing steel smelting method for improving boron element yield

ActiveCN108588541AShorten the smelting processStabilized boron contentManufacturing convertersLow nitrogenSlag

The invention discloses a low-nitrogen boron-containing steel smelting method for improving the boron element yield. Converter end point boiling tapping is conducted, the frequency that molten steel absorbs nitrogen from air is reduced, a slag modifier and lime are added after converter tapping is finished for adjusting slag oxygen potentials and components, and in the tapping process, a steel ladle is subjected to bottom blowing and stirring in the whole process; after tapping is finished, molten steel is conveyed to be subjected to RH treatment, after the steel ladle is conveyed in place, vacuum pumping is conducted, C in the molten steel is utilized for deoxygenation, and after the oxygen content is reduced to be 0.02% or below, aluminum is added for deoxygenation and alloying, the 1.0-3.5 kg / t of slag modifier is added in the slag face of the steel ladle, and after all the alloy and the slag modifier are added, clean circulation is conducted for 5 min or longer time, T.O in the molten steel is smaller than or equal to 0.002%, the steel slag T.Fe+MnO is smaller than or equal to 2.0%; then, a boron-iron alloy is added, clean circulation is conducted for 8 min or longer time, andvacuum breaking and tapping are conducted. During RH tapping, the boron yield reaches 89% or above, the content and the yield of the boron element in the molten steel are stably controlled, BN precipitation in the later continuous casting process can be reduced, and important significance is achieved for stabilizing the mass and performance of the boron containing steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

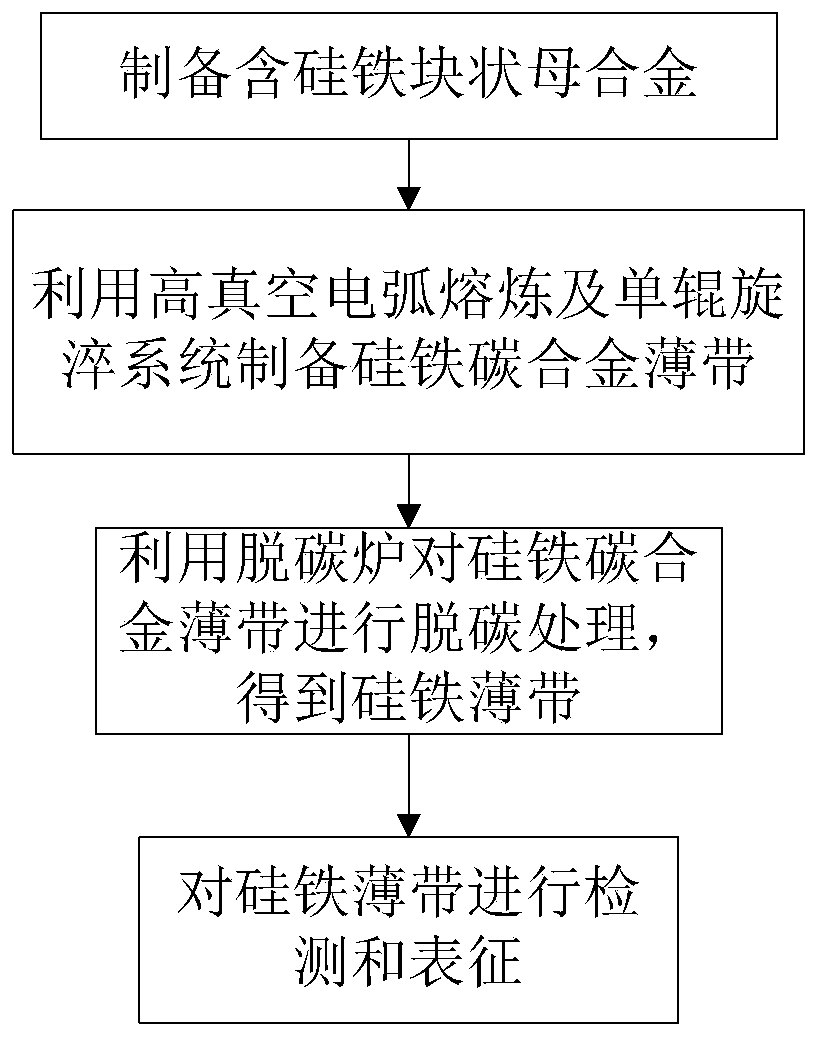

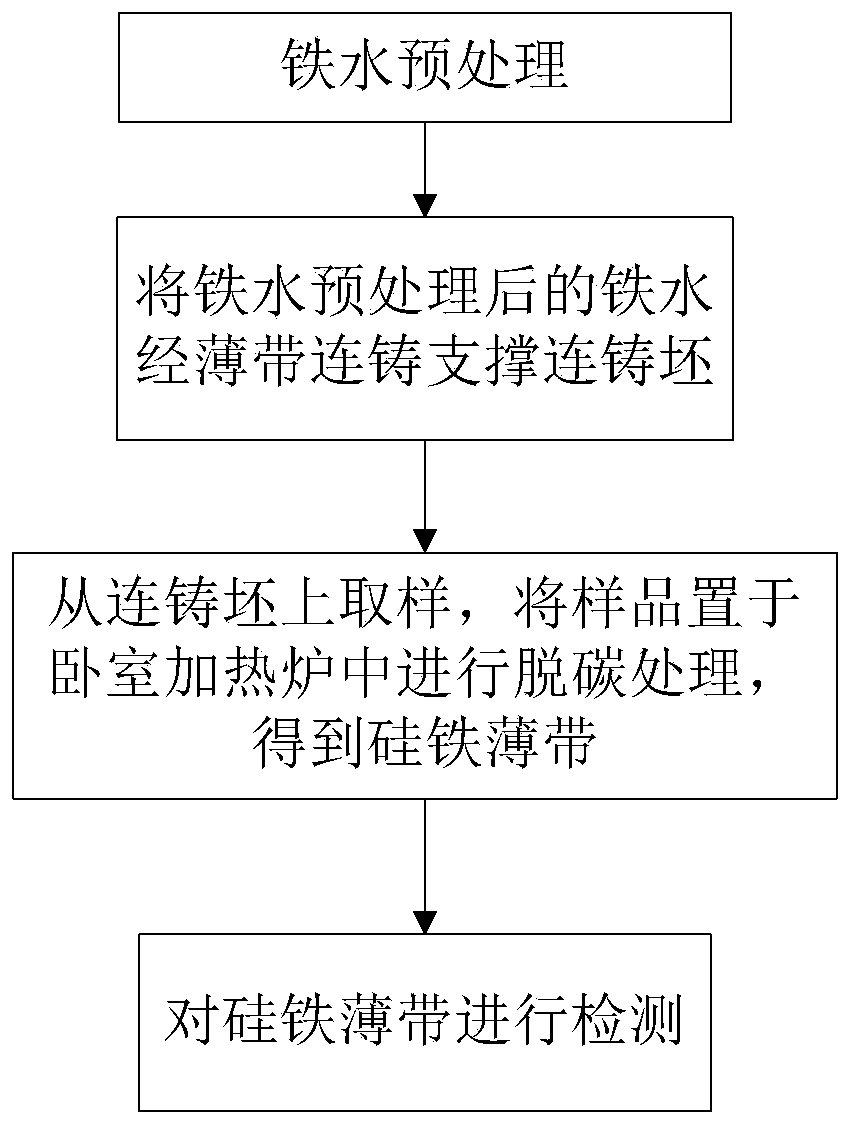

Preparation method of silicon steel thin strip

ActiveCN111097884ASaving Energy InvestmentShorten the smelting processSmelting processResource consumption

The invention relates to a preparation method of a silicon steel thin strip, belongs to the technical field of metal material smelting, and solves the problems of large resource consumption and influence of residual oxygen and inclusions on steel quality in an existing silicon steel thin strip preparation process. The preparation method of the silicon steel thin strip comprises the following steps: step 1, preparing a silicon-iron-carbon alloy thin strip; step 2, decarbonizing the silicon-iron-carbon alloy thin strip to obtain a silicon steel thin strip; and 3, detecting the carbon element distribution, the microstructure, the phase, the average carbon content and the magnetic property of the thin strip. According to the preparation method of the silicon steel thin strip, processes such asconverter smelting are omitted, and the preparation method has important significance for saving energy consumption investment, shortening the smelting process, reducing the production and protectingthe environment.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

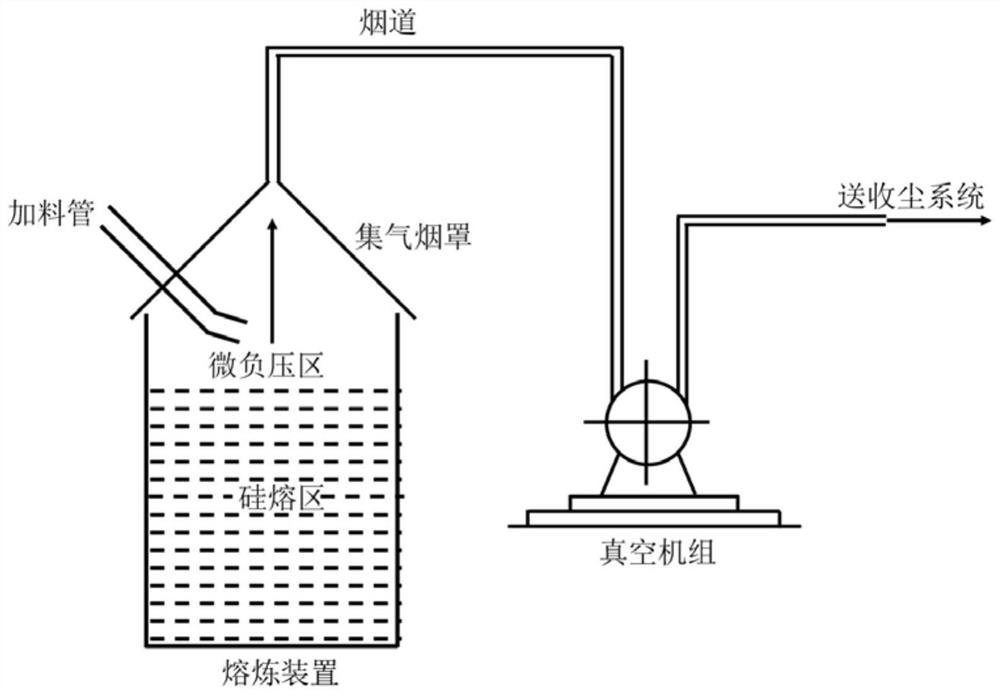

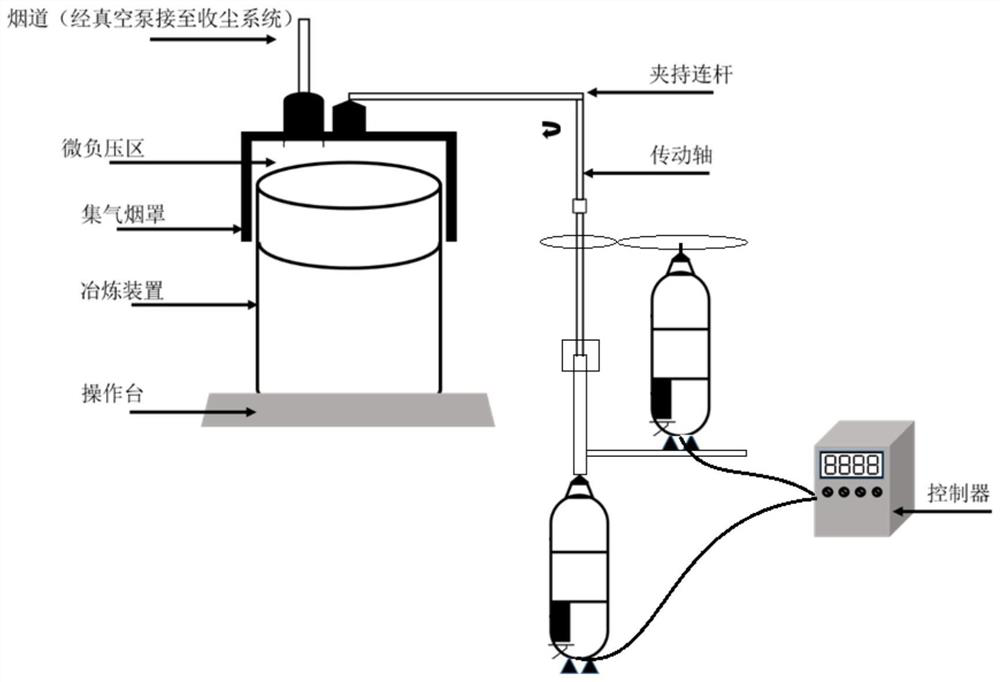

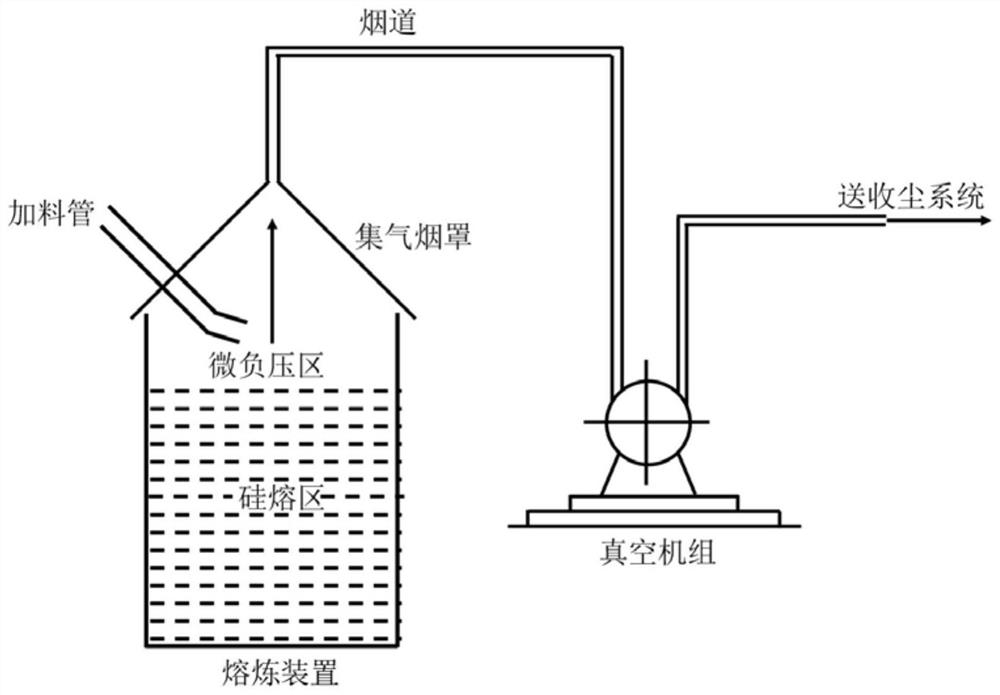

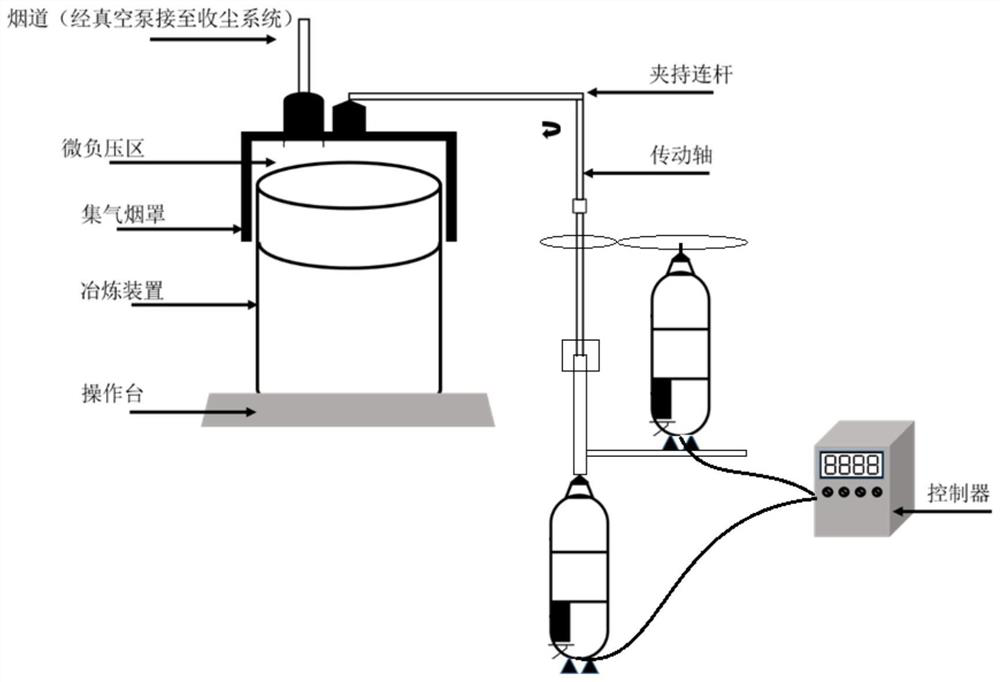

Method for smelting silicon wafer cutting waste under micro-negative pressure

ActiveCN111792647AHigh recovery ratePrevent oxidationSilicon compoundsRefining (metallurgy)Smelting process

The invention relates to a method for smelting silicon wafer cutting waste under micro-negative pressure, belonging to the technical field of silicon regeneration and recovery by pyrometallurgy of silicon wafer cutting waste. The invention aims to solve the problems that silicon powder is easy to oxidize in the smelting process and impurity removal efficiency is low in the smelting process due tothe existence of moisture in the pyrometallurgy silicon recovery process of silicon wafer cutting waste. According to the invention, a micro-negative pressure device is moved to a position over a smelting furnace opening, and a vacuum device of the micro-negative pressure device is started to enable silicon wafer cutting waste to undergo micro-negative pressure smelting, so oxidation loss of superfine silicon powder in the smelting process is avoided, volatile impurities in silicon are removed, and synchronous refining of silicon melt is achieved. According to the invention, a micro-negative pressure environment is created above the silicon melt, so smoke can be prevented from escaping in the silicon smelting process, and the environmental influence is reduced. The method is simple in equipment requirement, easy to operate, friendly to environment and suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

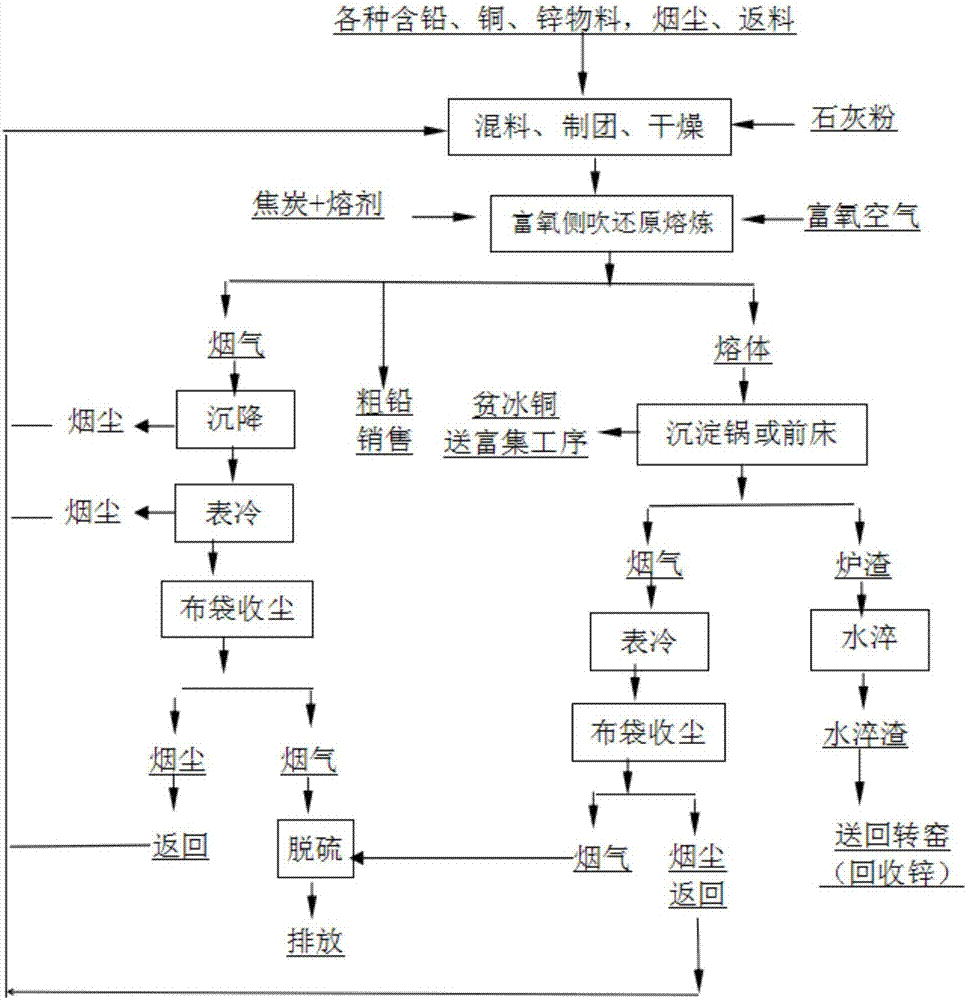

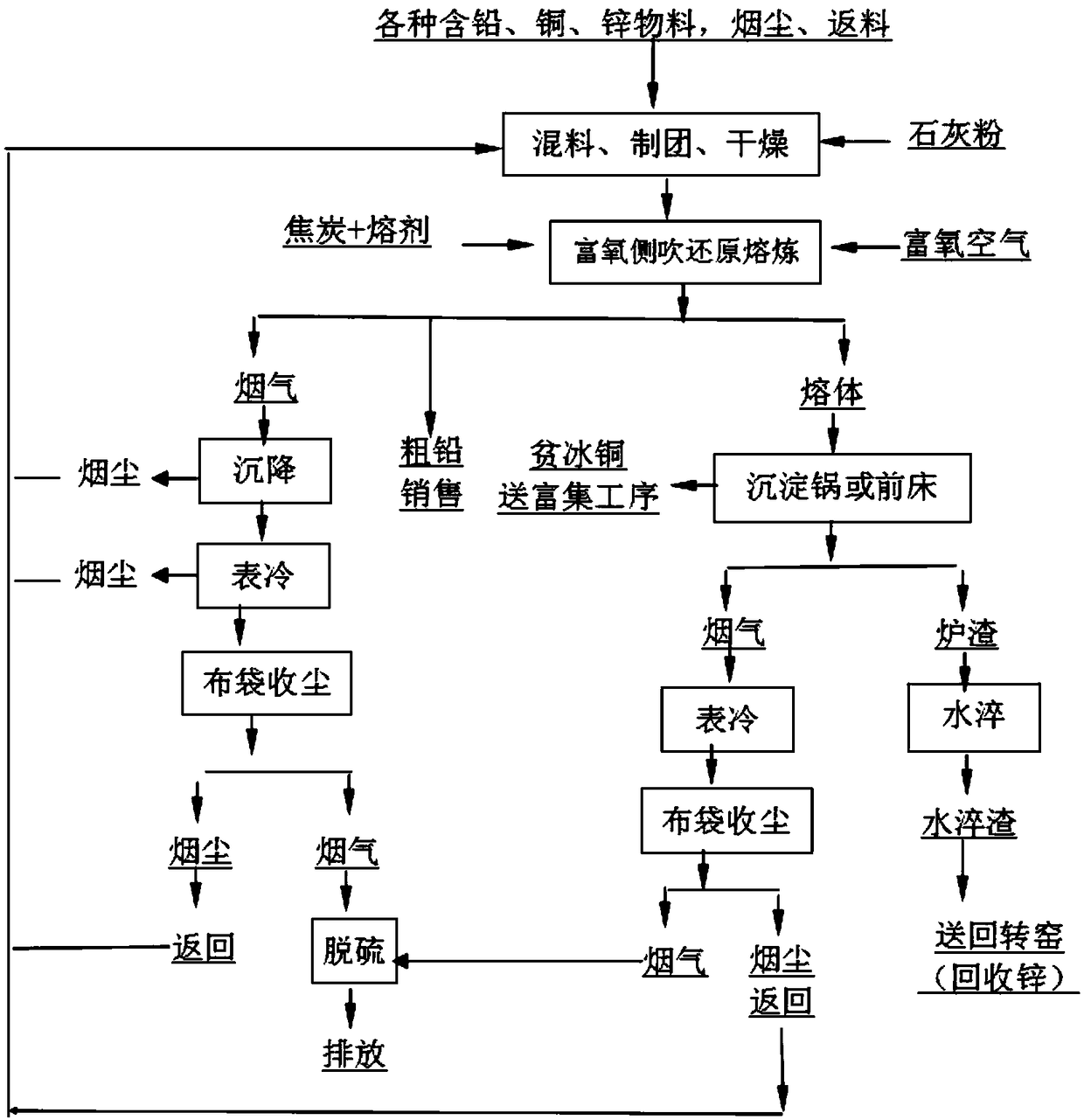

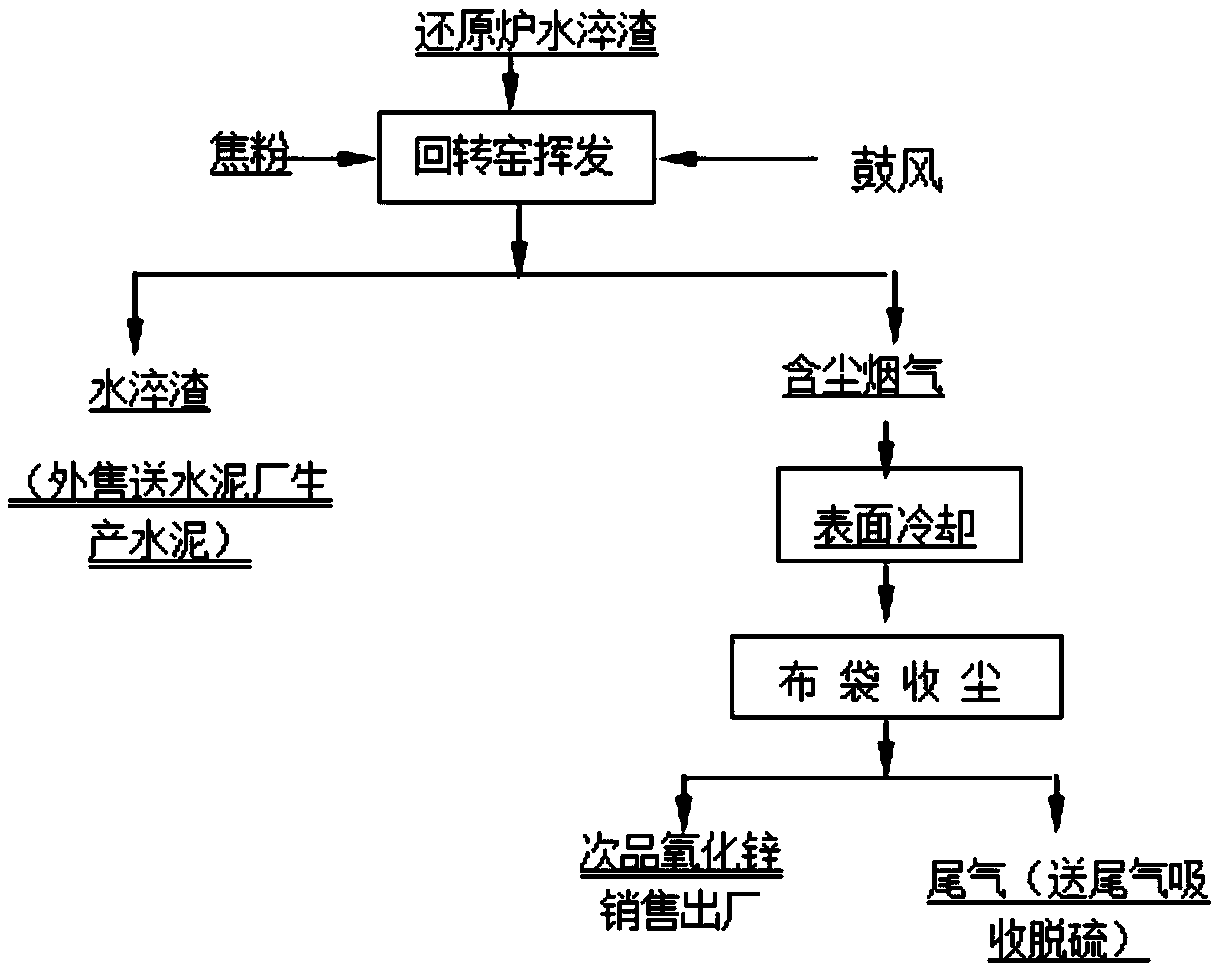

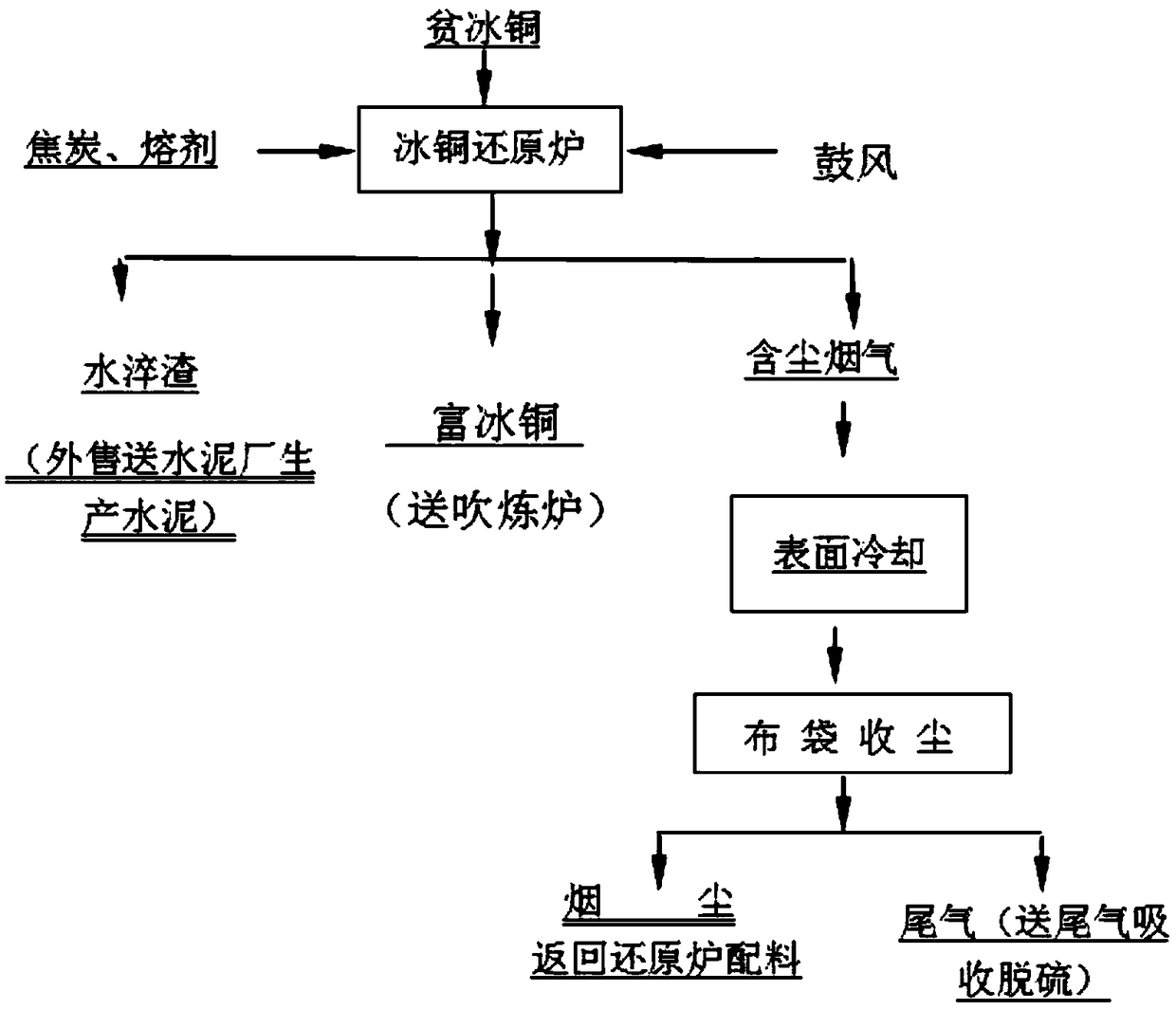

Comprehensive recovery device and process for various nonferrous metal materials

InactiveCN107043854ASave energySave waterProcess efficiency improvementThermal insulationMaterials science

The invention relates to a comprehensive recovery device and process for various nonferrous metal materials. According to the comprehensive recovery device for the various nonferrous metal materials, a reduction furnace, a fuming furnace and a converter which are used for working procedures of recovering lead, zinc and copper are connected into a whole through thermal insulation external crucibles. The process has the characteristics of feeding at a time and continuous output of lead bullion, raw copper and zinc oxide. The comprehensive recovery device and process have the beneficial effects that raw materials are input at a time, all valuable metalsare extracted and purified, the working procedure of smelting is omitted, the production cycle is shortened, and the smelting process is simplified; heat energy in the smelting process is fully used, heat energy is greatly saved, and energy consumption is reduced; and the cost is saved for enterprises, the economic benefits are increased for the enterprises, the production cost is lowered for the enterprises, and the one-time fixed asset investment is reduced for the enterprises.

Owner:梁瑞兵 +1

Mixed electrolysis system for producing cathode copper

ActiveCN106835196ARealize comprehensive utilizationElimination of remelting processPhotography auxillary processesProcess efficiency improvementElectricityHigh energy

The invention belongs to the technical field of smelting, and particularly relates to a mixed electrolysis system for producing a cathode copper; the mixed electrolysis system comprises an electrolytic bath and electrolyte in an electrolytic bath cavity; two bath openings in parallel of the electrolytic bath are paved with cathode and anode conducting busbars along the length direction; the mixed electrolysis system for producing the cathode copper further comprises a cathode and a mixed electrolytic process special anode which are arranged in parallel along the length direction of the electrolytic bath; the cathode and the mixed electrolytic process special anode are electrically connected with the cathode and anode conducting busbars; the plate body of the mixed electrolytic process special anode is obliquely hung with a coarse copper / residual electrode plate. The mixed electrolysis system for producing the cathode copper can direct recycle the residual polar plate, or completely apply the course copper to produce the high purity cathode copper; thus the mixed electrolysis system can eliminate the re-melting procedure of the residual polar plate, shorten the copper smelting technical flow, and save huge cost and high energy consumption for re-melting the residual polar plate.

Owner:铜陵有色金属集团股份有限公司

Boron bearing steel smelting technological method for improving boron yield

ActiveCN107287490AShorten the smelting processReduce manufacturing costManufacturing convertersSlagNitrogen

The invention discloses a boron bearing steel smelting technological method for improving the boron yield. The method sequentially comprises the steps that S1, the converter process is implemented, specifically, alloy is added in the steel tapping process for deoxidation alloying, after steel tapping is finished, a slag modifier and lime are added into the ladle slag surface to control the slag component and the oxygen potential, argon is blown into the bottom of a steel ladle in the whole steel tapping process, and molten steel is kept being stirred instead of boiling strongly; S2, the VOD process is implemented, specifically, after the converter process is finished, the molten steel is conveyed to VOD for treatment, the steel ladle is connected with bottom blowing after being transported in place, vacuumizing treatment is conducted, degassing and inclusion removal are conducted while the high-vacuum state is kept, ferroboron is added in the later period of the VOD process, high-vacuum circulation continues to be kept after the ferroboron is added, and finally, the molten steel is conveyed out to be subjected to the continuous casting process; and S3, the continuous casting process is implemented, specifically, protective casting is adopted, and nitrogen increment and secondary oxidation of the molten steel are prevented. According to the boron bearing steel smelting technological method, the technological process is short, the production cost is low, operation is easy, the boron yield is high, and the content of boron in the molten steel is stable.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

Zinc leaching slag treatment method

ActiveCN103421955BShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Smelting and casting method for titanium-contained metal

The invention relates to a smelting and casting method for titanium-contained metal. The method comprises the following steps that ingredient calculation is calculated, and specifically, ingredient calculation is carried out according to the component content requirement of an alloy and the component content in all raw materials; an alloy bag is made, specifically, according to an ingredient calculation result, a required intermediate alloy and required elementary substances are weighed, and the alloy bag is made; electrode pressing is conducted, specifically, a main raw material is used for being wrapped around the alloy bag and is pressed into an electrode, and the end, close to the electrode, of the alloy bag can be exposed; induction smelting is carried out, specifically, the pressed electrode is baked in a furnace, and is inductively smelted into a titanium-containing metal liquid according to the matched vacuum and / or argon filling condition and an induction power loading curve;and casting is conducted, specifically, the superheat degree of the smelted titanium-contained metal liquid is improved, and the metal liquid is cast to form the titanium-contained metal. According tothe smelting and casting method for the titanium-contained metal, the smelting process flow of the titanium-contained metal can be shortened, an alloy ingot with high uniformity and high mechanical property can be obtained through single smelting, and the direct casting can be conducted through single smelting.

Owner:BAIMTEC MATERIAL CO LTD

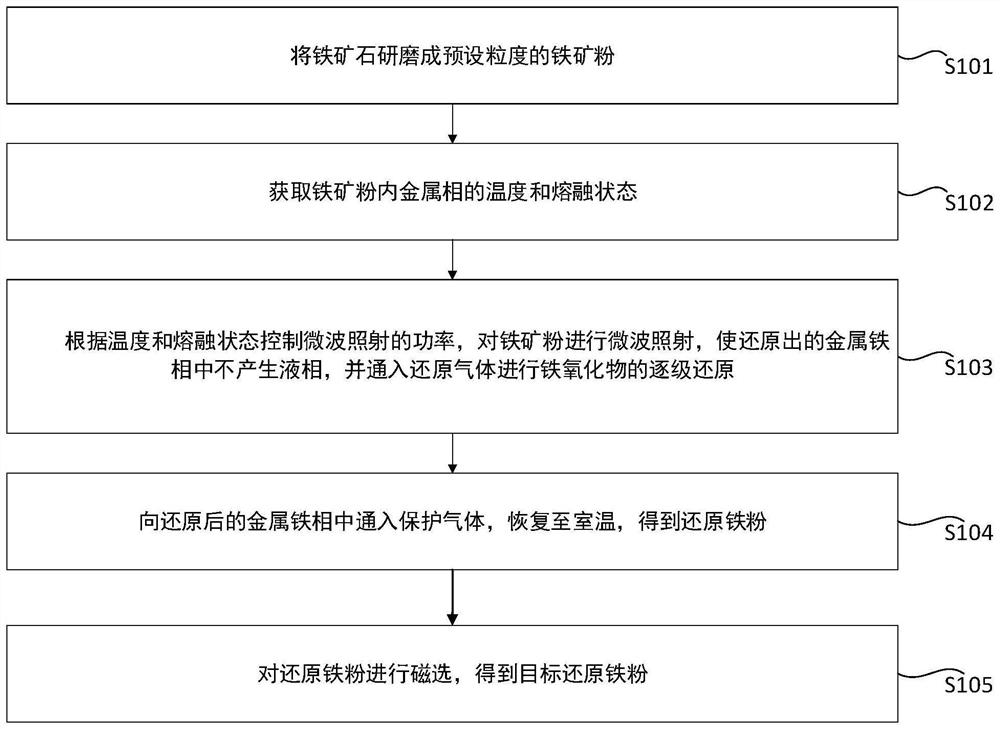

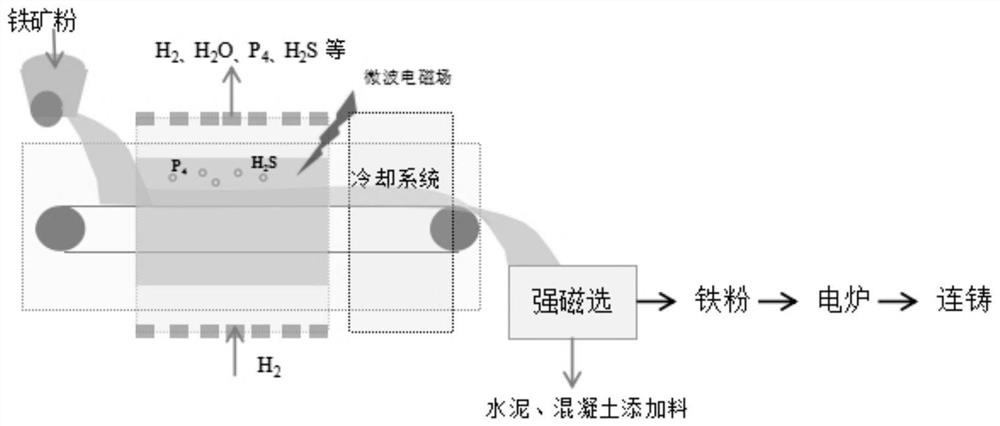

Method for removing sulfur and phosphorus from iron ore powder through microwave hydrogen reduction

PendingCN114525373AImprove reducibilityEmission reductionGas emission reductionIron powderSmelting process

The invention provides a method for removing sulfur and phosphorus from iron ore powder through microwave hydrogen reduction, and relates to the technical field of hydrogen metallurgy and microwave metallurgy. Obtaining the temperature and the molten state of a metal phase in the iron ore powder; the microwave irradiation power is controlled according to the temperature and the molten state, microwave irradiation is conducted on the iron ore powder, so that no liquid phase is generated in the reduced metal iron phase, and reducing gas is introduced for step-by-step reduction of iron oxide; introducing protective gas into the reduced metal iron phase, and recovering to room temperature to obtain reduced iron powder; and carrying out magnetic separation on the reduced iron powder to obtain target reduced iron powder. According to the invention, the hydrogen reduction effect and the gasification dephosphorization and desulfurization effects can be promoted. High-efficiency reduction at a low temperature is achieved, the content of sulfur and phosphorus in raw materials is controlled, the cleanliness of steel is improved, the difficulty of desulfurization and dephosphorization in the subsequent molten metal smelting process can be reduced, iron ore powder can be reduced to directly produce iron powder, and the smelting process is shortened.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

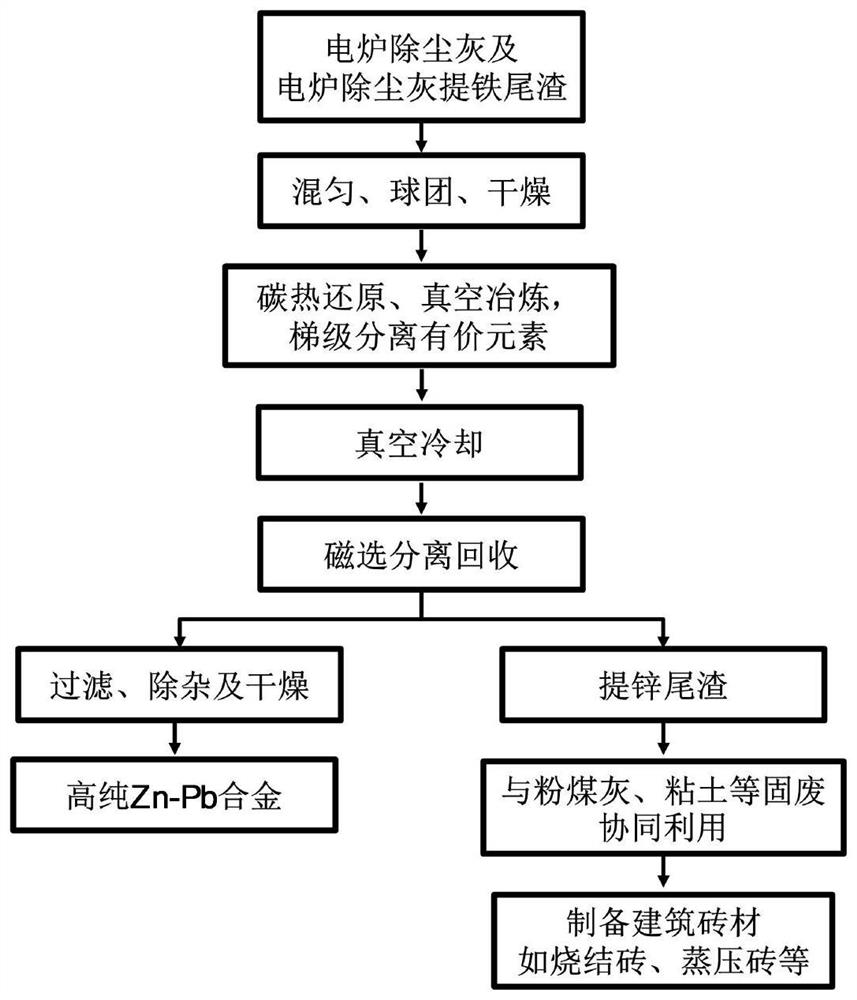

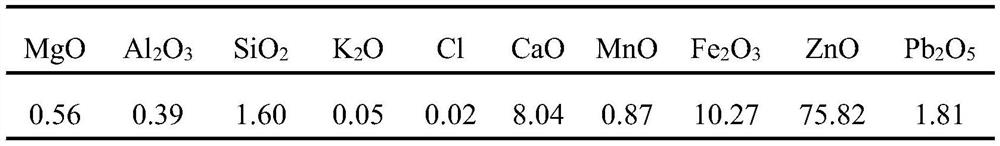

Full-quantification and high-value utilization method of electric furnace fly ash and iron extraction tailings thereof

PendingCN114480841AEmission reductionReduce governance costsMagnetic separationBrickEconomic benefits

The invention discloses a full-quantification and high-value utilization method of electric furnace fly ash and iron extraction tailings thereof. The method comprises the following processing procedures: (1) pellet preparation, (2) vacuum smelting, (3) vacuum cooling, (4) magnetic separation and recovery of high-purity Zn-Pb alloy, and (5) preparation of sintered bricks from zinc extraction tailings. According to the method, the Zn-Pb alloy is prepared through carbon thermal reduction and assisted by vacuum smelting of the electric furnace dedusting ash iron extraction tailings, the sintered bricks are prepared through the tailings of the Zn-Pb alloy, the high-purity Zn-Pb alloy product and the sintered brick product with the purity larger than or equal to 96.0% are prepared, full-quantization and high-value utilization of the electric furnace dedusting ash and the iron extraction tailings of the electric furnace dedusting ash are achieved, and economic benefits and environmental benefits are remarkable. The method provided by the invention overcomes the defects of long process flow, high cost, large emission, low added value of products and the like in the prior art, and has wide market popularization and application prospects.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

A method for dephosphorizing and preserving vanadium in vanadium-containing phosphorus hot metal

ActiveCN112981045BRealize dephosphorization and preserve vanadiumAvoid enteringProcess efficiency improvementPhosphateSmelting process

A method for dephosphorizing and preserving vanadium in vanadium-phosphorus molten iron, mainly comprising the following steps: (1) draining vanadium-containing and phosphorus-containing molten iron produced in a blast furnace or non-blast furnace into an induction furnace; Phosphorus slag and CO injection 2 , top blowing, bottom blowing, side blowing or top-bottom re-blowing can be used; (3) When the phosphorus content in the vanadium-phosphorous iron water drops below 0.03%, the blowing is stopped and the slag is separated from the molten iron. After the molten iron containing vanadium and phosphorus is treated by the method of the invention, when the phosphorus content is reduced to the requirement of vanadium steel, the loss rate of vanadium in the molten iron is less than 10%, achieving the effect of dephosphorization and vanadium preservation. In the present invention, by injecting CO 2 Realized the selective oxidation of molten iron containing vanadium and phosphorus and CO 2 The utilization of resources reduces the smelting process of vanadium steel.

Owner:NORTHEASTERN UNIV LIAONING

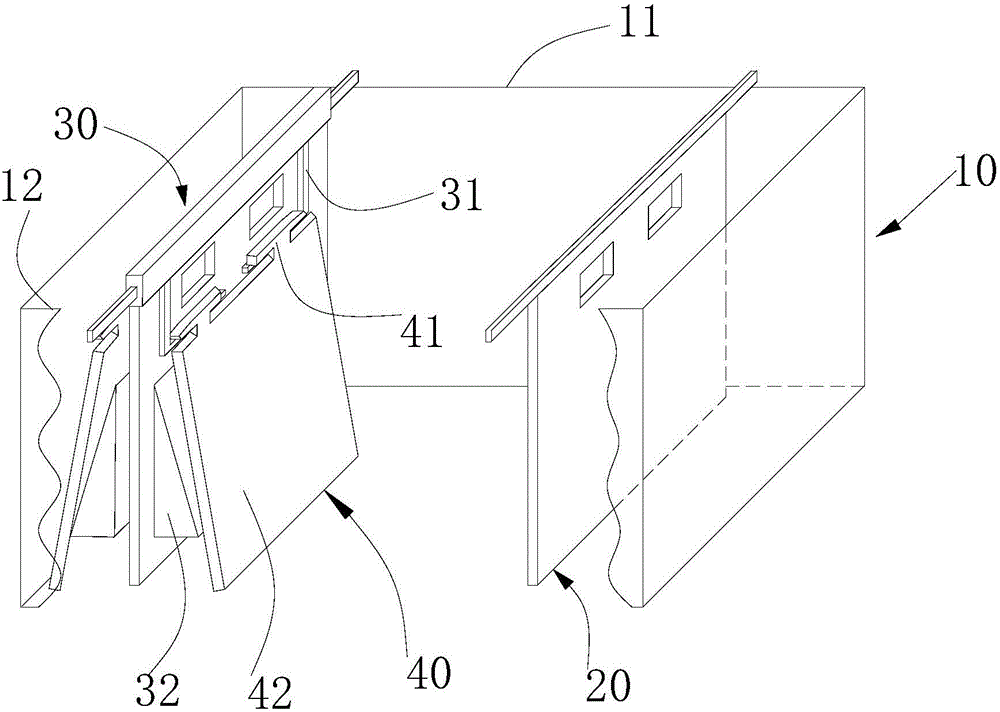

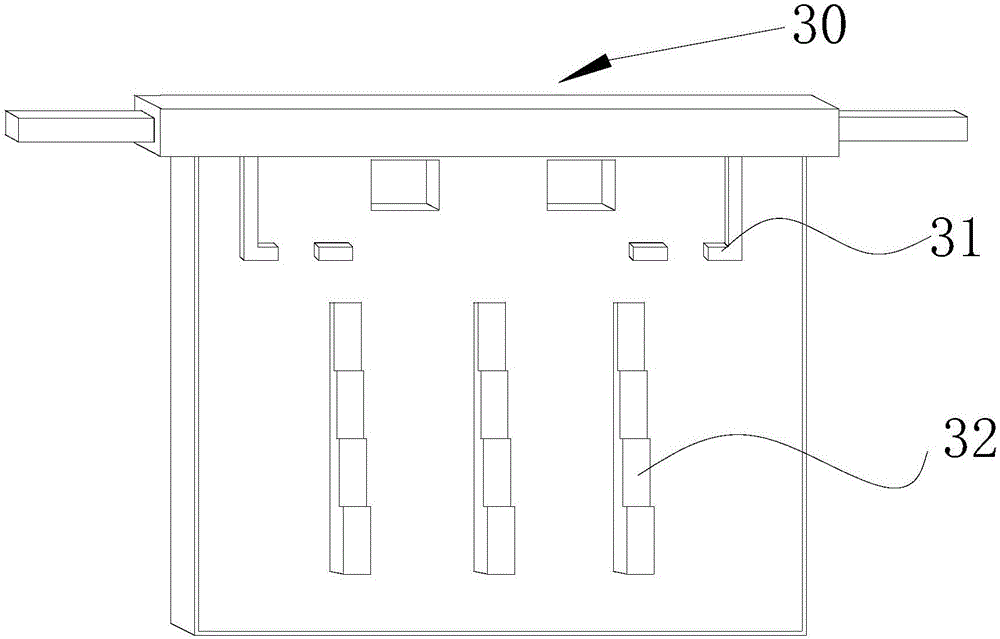

Method for preparing ladle liner permanent layer by adopting perlite composite insulation board

The invention relates to a method for preparing a ladle liner permanent layer by adopting a perlite composite insulation board, which comprises the preparation of a perlite composite insulation board and the arrangement of the perlite composite insulation board on a ladle shell inner wall. The method for preparing the perlite composite insulation board comprises the following steps of: (1) evenlymixing 1 percent by weight of expanded perlite, 0.3-1.2 percent by weight of adhesive and 0.02-0.06 percent by weight of fiber materials under the stirring condition to obtain a mixture; and (2) putting the mixture in a die; pressuring and smoothening the surface; and then, hardening at 15-110 DEG C for 0.2-24h to obtain a perlite composite insulation board. The perlite composite material of the invention adopts environment-friendly natural materials which are nontoxic, tasteless and taintless and have low production cost, low price and good insulation performance; and the insulation board has the advantages of light capacity weight, small conductive coefficient, good stability, strong strength, convenient construction, and the like.

Owner:湖北兴冶特钢实业发展有限公司

A kind of one-step alkali leaching method of molybdenum calcined sand

ActiveCN108715944BEfficient leachingCounteracts adverse effects on molybdenum calcine leachingO-Phosphoric AcidSodium phosphates

Owner:CENT SOUTH UNIV

A hot work die steel h13 and its continuous casting production process

ActiveCN111004961BLow costReduce refining timeProcess efficiency improvementSteelmakingElectric arc furnace

The invention relates to a hot work die steel H13 and its continuous casting production process which can achieve the dual purposes of reducing raw material costs and refining time and ensuring product quality. The original electric arc furnace melts scrap steel to obtain low-phosphorus primary steelmaking liquid→refining The production process of furnace reduction alloying → VD degassing → die casting is improved to a new process flow of melting similar steel grades and steel scraps in induction furnace → deoxidation reduction microalloying in refining furnace → degassing in VD vacuum refining furnace → continuous casting , to achieve the dual purpose of reducing raw material costs and refining time, and ensure product quality.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

A method for smelting silicon wafer cutting waste under slight negative pressure

The invention relates to a method for smelting silicon wafer cutting waste under slight negative pressure, and belongs to the technical field of pyromelting silicon wafer cutting waste regeneration and recovery of silicon. The present invention aims at the problem that silicon powder is easily oxidized in the smelting process and the impurity removal efficiency is low in the smelting process due to the presence of moisture in the process of pyromelting and recycling silicon from silicon wafer cutting waste, and the micro-negative pressure device is moved directly above the melting furnace mouth, Turn on the vacuum device of the micro-negative pressure device to melt the silicon wafer cutting waste in a micro-negative pressure, so as to avoid the oxidation loss of ultra-fine silicon powder during the melting process and remove the volatile impurities in the silicon, so as to realize the simultaneous refining of the silicon melt. The invention creates a slightly negative pressure environment above the silicon melt, which can avoid the escape of smoke during the silicon smelting process and reduce environmental impact. The method of the invention has the advantages of simple equipment requirements, easy operation, environmental friendliness and suitability for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method for smelting high-grade pipe line steel with RH single-link process

The invention provides a method for smelting high-grade pipe line steel with a RH single-link process. During a converter tapping process, high aluminum content in molten steel is controlled, such that desulfurization and impurity control in subsequent refining process can be benefited. During an RH vacuum refining stage, a desulfurization agent is added, and S content in the molten steel is controlled no higher than 0.0020%; oxygen blowing is carried out upon the molten steel, and a reaction is carried out between oxygen and aluminum in the molten steel, such that aluminum content in the molten steel is controlled at 0.03-0.05%. Also, heat loss during the desulfurization process is supplemented, and the impurity is converted into mainly clustered Al2O3 impurity which is easy to remove; and calcium treatment and soft blowing are carried out, such that the impurities in molten steel is mainly CaS impurities of small particles with deformation coefficient close to 1. According to the method provided by the invention, X80 pipeline steel quality requirement can be achieved, production process flow is short, and cost can be substantially reduced.

Owner:SHOUGANG CORPORATION

A kind of preparation method of iron-based nanocrystalline alloy

The invention belongs to the technical field of metallurgy, and specifically relates to a method for preparing an iron-based nanocrystalline alloy; it includes the following steps: Step 1, a smelting step: smelting metal raw materials into high-temperature molten steel; and Step 2, a strip-making step: spraying the high-temperature molten steel Made into strips; the present invention omits the steps of smelting master alloy steel ingots and remelting again, and only includes one smelting step to prepare nanocrystalline master alloys, which has the characteristics of simplified steps, energy saving, shortened working hours, and improved production efficiency.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

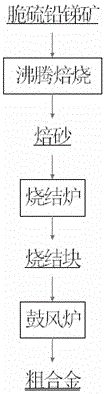

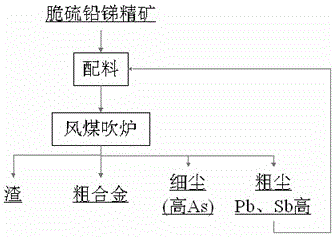

A wind-coal blowing furnace and a method for smelting brittle sulfur-lead-antimony ore using the wind-coal blowing furnace

The invention discloses an air-coal blowing furnace and a method for smelting brittle sulfur-lead-antimony ore by using the air-coal blowing furnace, belonging to the technical field of nonferrous metal metallurgy. The air-coal blowing furnace includes a furnace body, a feed inlet, an air-coal inlet, an alloy outlet, a slag outlet and a smoke outlet. The furnace body is in the form of a column, and the bottom of the furnace body is conical. In the slag-depleted area, the top of the furnace body corresponding to the smelting area is provided with a feed inlet, the side of the furnace body corresponding to the slag-depleted area is provided with a smoke outlet, and the conical bottom of the furnace body is provided with an alloy outlet, and the slag in the furnace body is formed The slag line, near the horizontal line of the slag line and the side of the furnace body on the same side as the smoke outlet, is provided with a slag port, and the front and rear sides of the furnace body between the slag port and the alloy outlet are symmetrically provided with air coal ports. And the brittle sulfur-lead-antimony ore is smelted directly by using the air-coal blowing furnace. The invention overcomes the defects of the existing brittle sulfur-lead-antimony ore smelting method, shortens the smelting process, improves the metal recovery rate, saves production costs, and improves the working environment.

Owner:KUNMING UNIV OF SCI & TECH

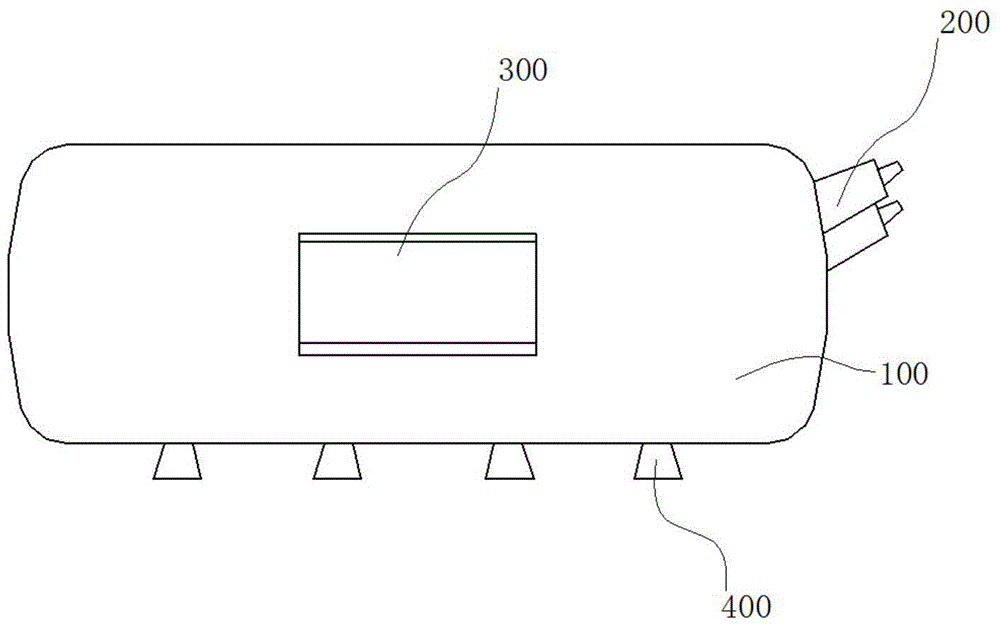

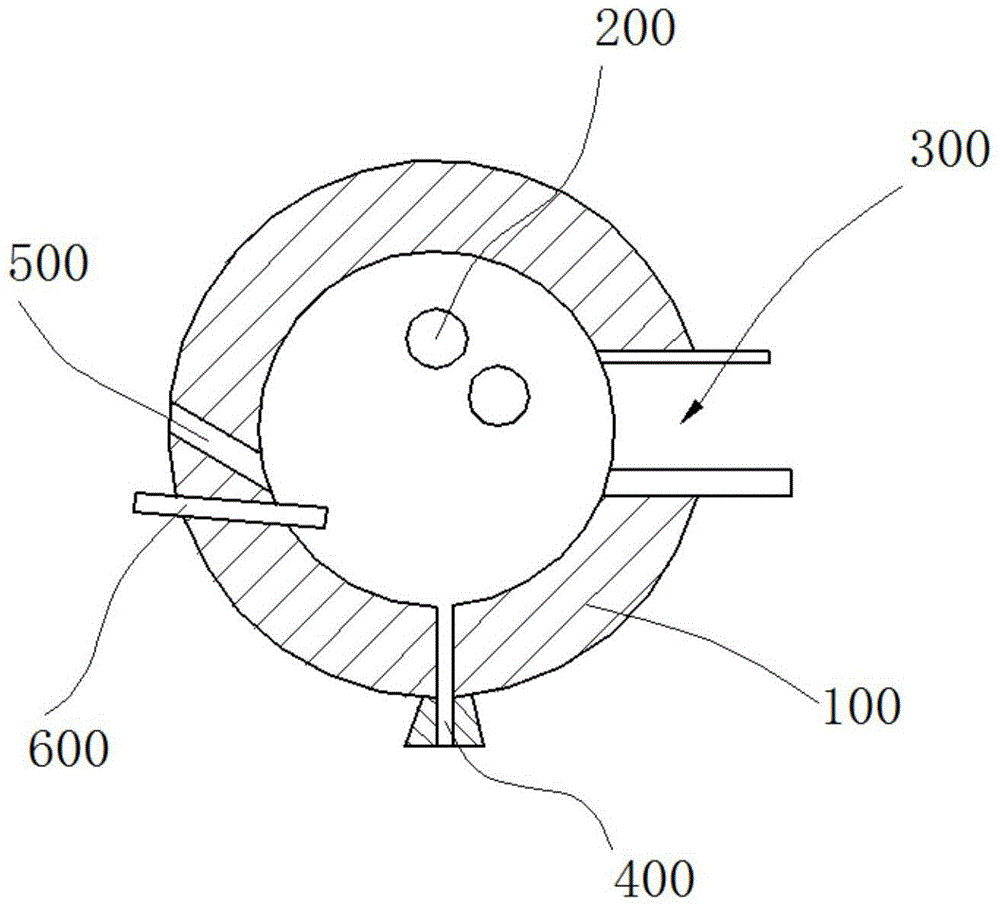

A method for smelting high-grade scrap copper in a rotary anode furnace

The invention discloses a method for smelting a high-grade scrap copper by an anode furnace. The method for smelting the high-grade scrap copper by the anode furnace employs a rotary anode furnace facility for smelting. The rotary anode furnace comprises a furnace body, a feed port arranged in the middle portion at the front end of the furnace body, a combustor arranged on an end wall of the furnace body, ventilating bricks arranged at the lower end of the furnace body, and an oxide reduction pipe as well as a casting port arranged at the rear end of the furnace body; the furnace body is able to rotate in 360 degrees. The smelting method comprises the steps as follows: A, a feeding and melting stage; B, an oxidization slagging stage; C, a slag discharging stage; D, a reduction stage; and E, a casting stage. The invention solves the problem that, in the existing treatment technologies of the high-grade scrap copper, the raw materials are poor in adaptation, great in environmental contamination, low in automation degree, and the like.

Owner:JIANGSU HUAWEI COPPER IND

A high blowing rate ventilation brick and its manufacturing method

The invention relates to an air brick with a high blowing through rate and a manufacturing method thereof. The air brick is composed of the following components: coarse corundum with granularity greater than 0.5mm and smaller than or equal to 1 mm and mass fraction of 35-50%; fine corundum with granularity greater than 0 and smaller than or equal to 0.5 mm and mass fraction of 25-40%; alumina fine powder with granularity greater than 0.020 mm and smaller than or equal to 0.044 mm and mass fraction of 8-15%; alumina micro powder with granularity greater than 0 and smaller than or equal to 0.020 mm and mass fraction of 5-10%. The manufacturing method comprises the procedures of mixed milling, material kneading and press forming, and further comprises the procedures of roasting, high temperature sintering, flow detecting, steel shell packaging and the like. According to the air brick provided by the invention, the particle size distribution and the machine pressing pressure are controlled, and uniformly distributed and mutually communicated micropores are formed in a brick body after high temperature sintering so as to achieve the permeability of an air brick body material.

Owner:PUYANG REFRACTORIES GRP CO LTD

A steelmaking device and method

The invention relates to a steelmaking device and a steelmaking method. The steelmaking device comprises a reducing gas processing device and a smelting device, wherein the smelting device comprises a prereduction area, a soft melting area and a fusion area which are sequentially communicated, the fusion area is provided with an electrode and a flux spray gun, the reducing gas processing device is provided with an air inlet pipe and an exhaust pipe, the air inlet pipe is communicated with the soft melting area, and the exhaust pipe is communicated with the prereduction area. According to the steelmaking method, reducing gas is used for prereducing pellets or sintering ore materials, arc heat generated by the electrode is used for heating and melting the prereduced metallized pellets, high temperature flue gas generated in the process is used for deeply preheating and reducing the metallized pellets, and the flux sprayed by the spray gun is used for refining the molten steel. The steelmaking processes are reduced, middle steps of transporting materials are saved, the investment and production cost are lowered, the resource and energy consumption is lowered, emission of harmful gases is reduced, and the steelmaking device and the steelmaking method have very high economic value, environment protection property and social benefits.

Owner:CISDI ENG CO LTD +1

Melting and casting method of titanium-containing metal

Owner:BAIMTEC MATERIAL CO LTD

Comprehensive recovery equipment and process for various non-ferrous metal materials

InactiveCN107043854BSave energySave waterProcess efficiency improvementThermal insulationHeat conservation

The invention relates to a comprehensive recovery device and process for various nonferrous metal materials. According to the comprehensive recovery device for the various nonferrous metal materials, a reduction furnace, a fuming furnace and a converter which are used for working procedures of recovering lead, zinc and copper are connected into a whole through thermal insulation external crucibles. The process has the characteristics of feeding at a time and continuous output of lead bullion, raw copper and zinc oxide. The comprehensive recovery device and process have the beneficial effects that raw materials are input at a time, all valuable metalsare extracted and purified, the working procedure of smelting is omitted, the production cycle is shortened, and the smelting process is simplified; heat energy in the smelting process is fully used, heat energy is greatly saved, and energy consumption is reduced; and the cost is saved for enterprises, the economic benefits are increased for the enterprises, the production cost is lowered for the enterprises, and the one-time fixed asset investment is reduced for the enterprises.

Owner:梁瑞兵 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com