Method for removing sulfur and phosphorus from iron ore powder through microwave hydrogen reduction

A technology for reducing iron powder and iron ore powder, applied in the direction of reducing gas emissions, can solve problems such as sulfur return, phosphorus return, carbon dioxide emission, liquid iron dephosphorization, sulfur difficulty, etc., to achieve efficient reduction and zero carbon emissions , the effect of shortening the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

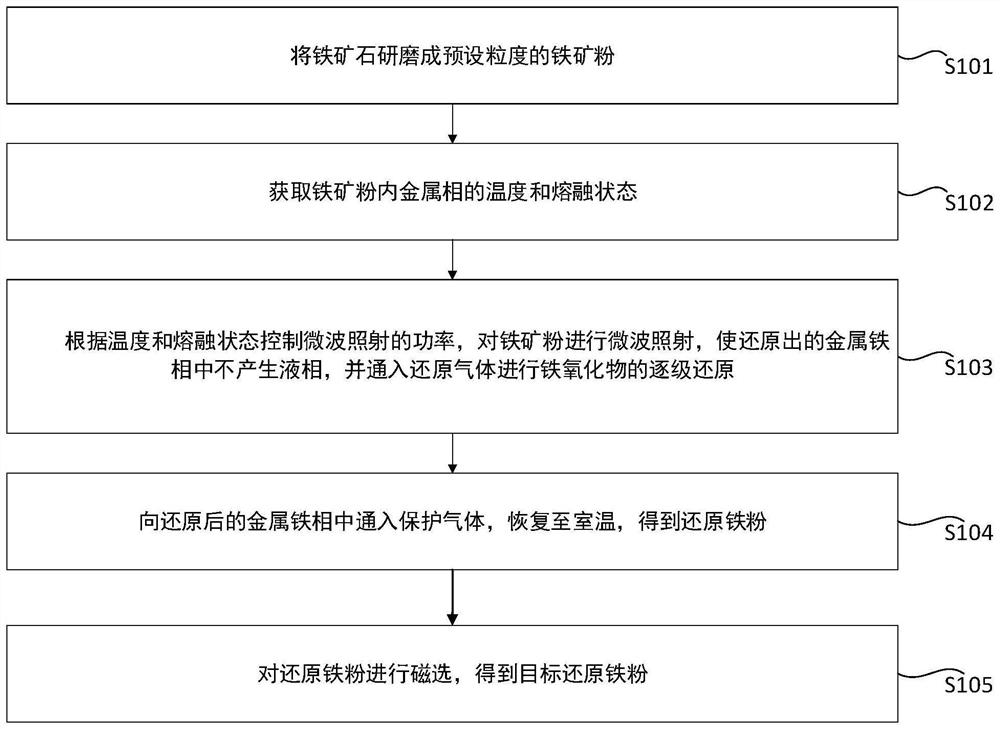

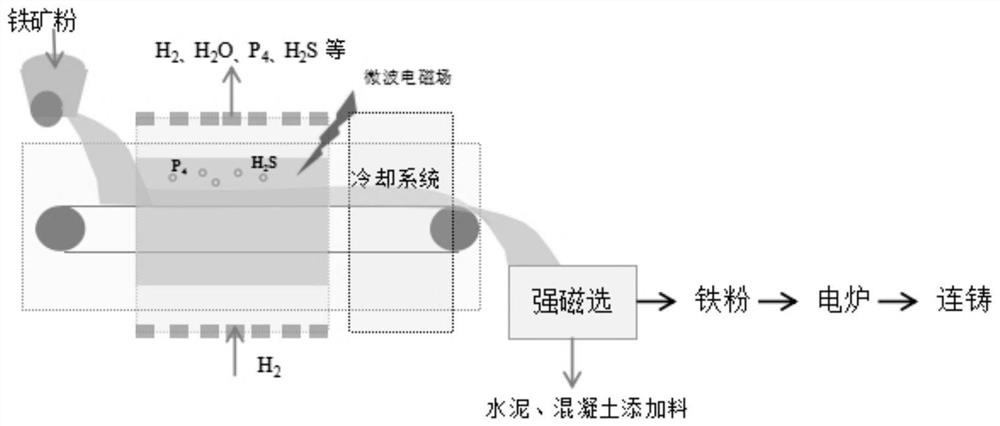

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, detailed description will be given below with reference to the accompanying drawings and specific embodiments.

[0029] The iron and steel industry has a huge output scale and an outstanding historical contribution, which is of great significance to supporting the future development strategy of the national economy and society. At the same time, the carbon emission environment and policy pressure are becoming more and more severe, and zero or low carbon breakthrough technology has become the proposition of the times in the field of steel manufacturing. To this end, domestic and foreign countries are vigorously developing cutting-edge technologies for carbon reduction and carbon resource reuse. Blast furnace ironmaking has large capacity and high efficiency, but the contradiction between the reality of high coke ratio and high energy consumption in b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com