A method for smelting high-grade scrap copper in a rotary anode furnace

A smelting method and anode furnace technology are applied in the field of smelting high-grade scrap copper by using a rotary anode furnace, which can solve the problems of low degree of automation, poor adaptability of raw materials, and large environmental pollution, so as to enhance adaptability and reduce environmental pollution. , the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

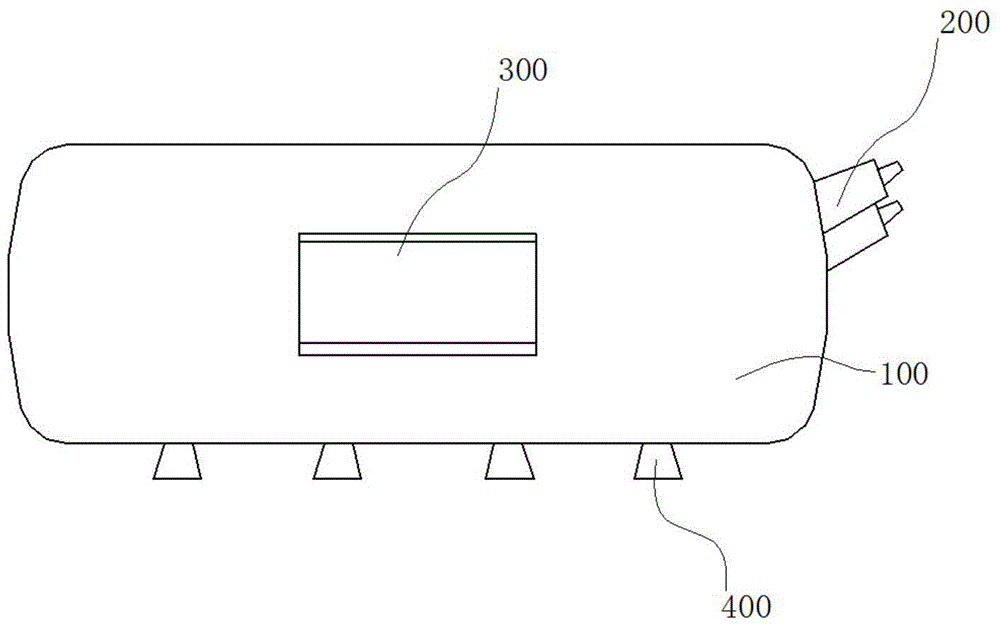

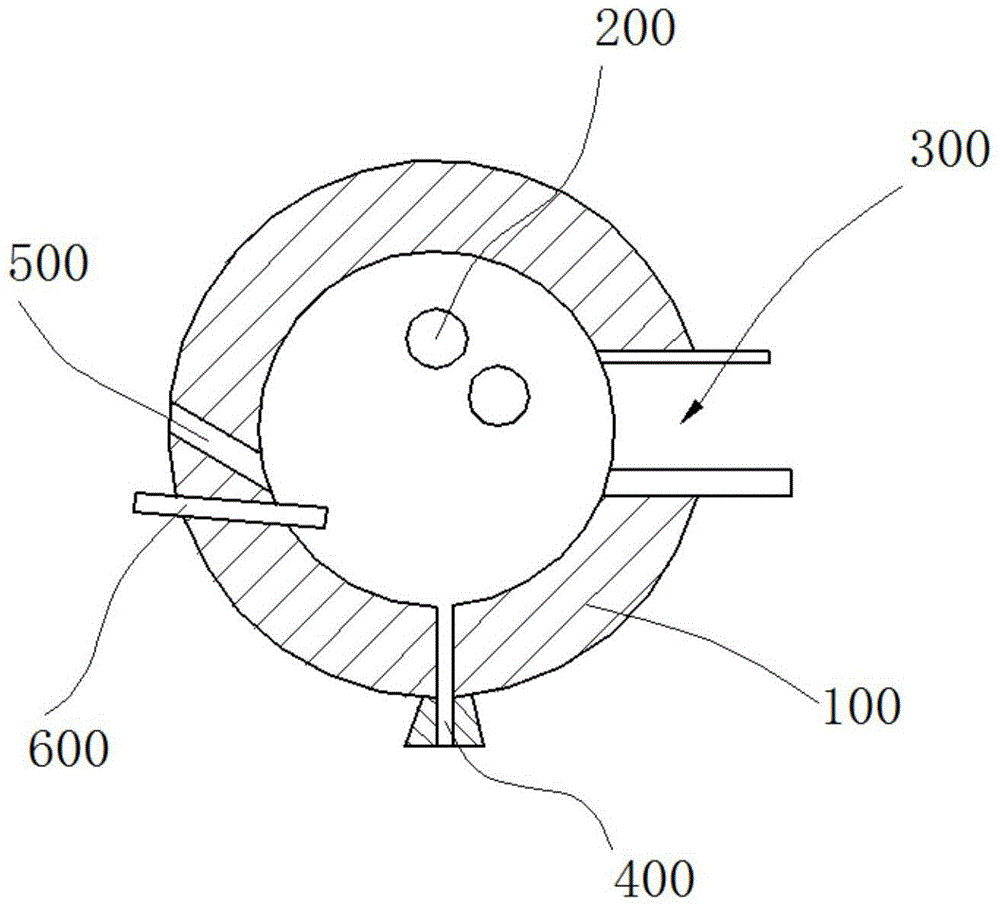

[0019] Such as figure 1 , figure 2 As shown, a method for smelting high-grade scrap copper in a rotary anode furnace, the rotary anode furnace includes a furnace body 100, a feeding port 300 arranged in the middle of the front end of the furnace body 100, and a burner 200 arranged in the end wall of the furnace body 100 , the ventilation brick 400 located at the lower end of the furnace body 100, the redox tube 600 and the casting port 500 located at the rear end of the furnace body 100, the furnace body can rotate within 360°, and the smelting method of the rotary anode furnace comprises the following steps:

[0020] A. During feeding and melting period, turn the furnace body to 0°, with the furnace mouth facing forward, add 260t of scrap copper and 10t of auxiliary materials. The auxiliary materials include 6t of quartz, 2t of pig iron, and 2t of li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com