Comprehensive recovery equipment and process for various non-ferrous metal materials

A technology for non-ferrous metals and recycling equipment, applied in the direction of improving process efficiency, etc., can solve problems such as energy consumption, complex process routes, and long production cycles, and achieve the effects of saving heat energy, simplifying process routes, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

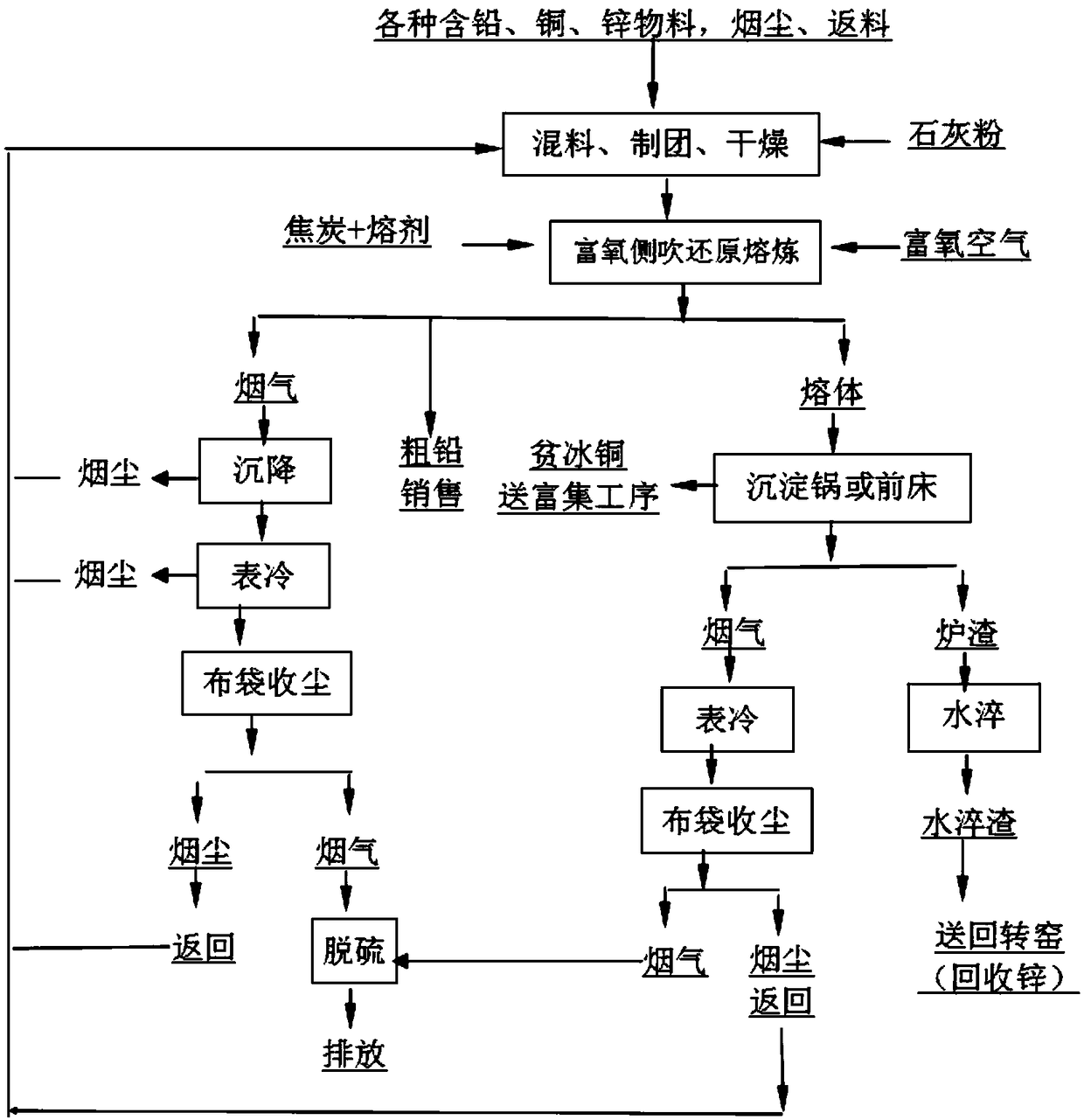

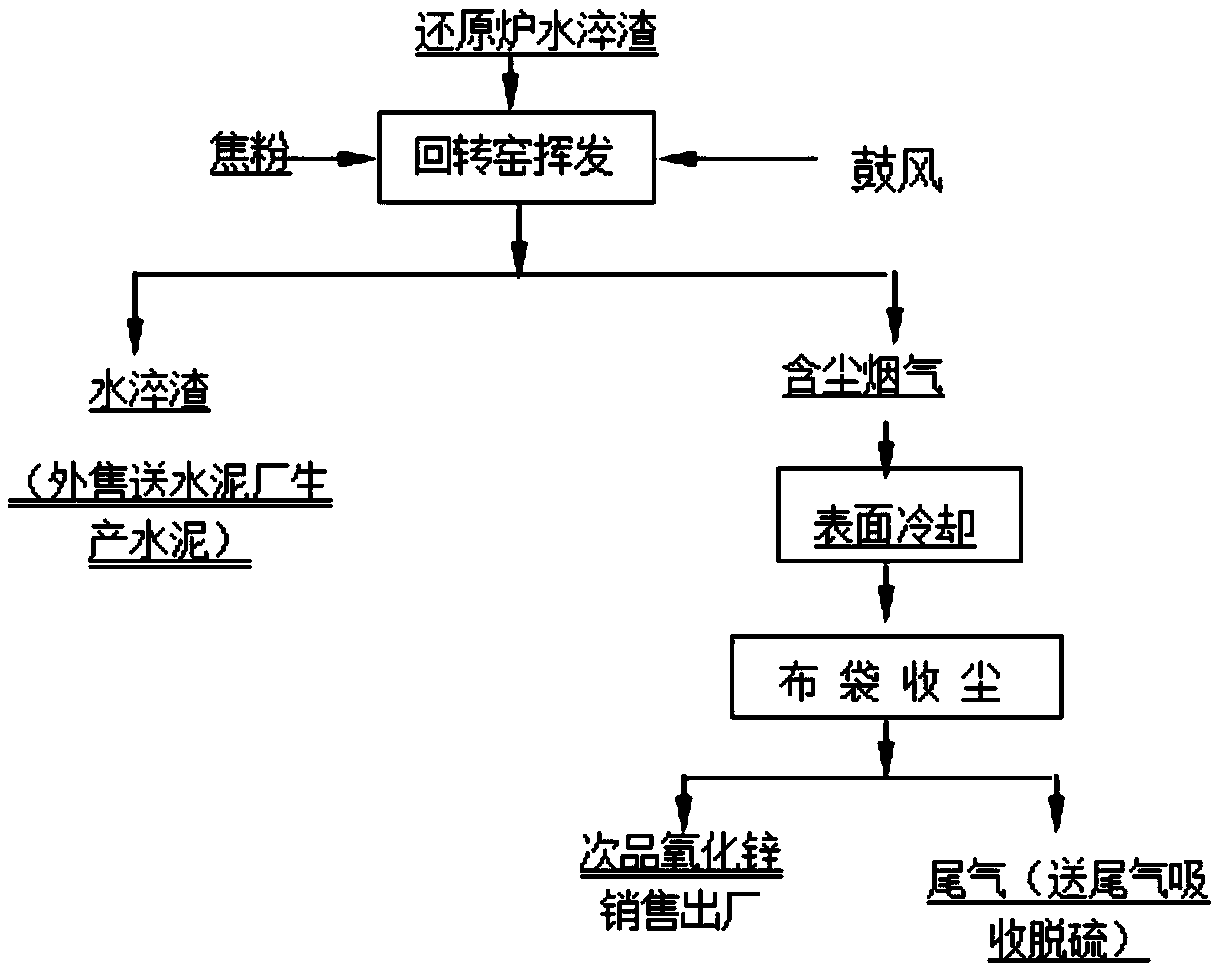

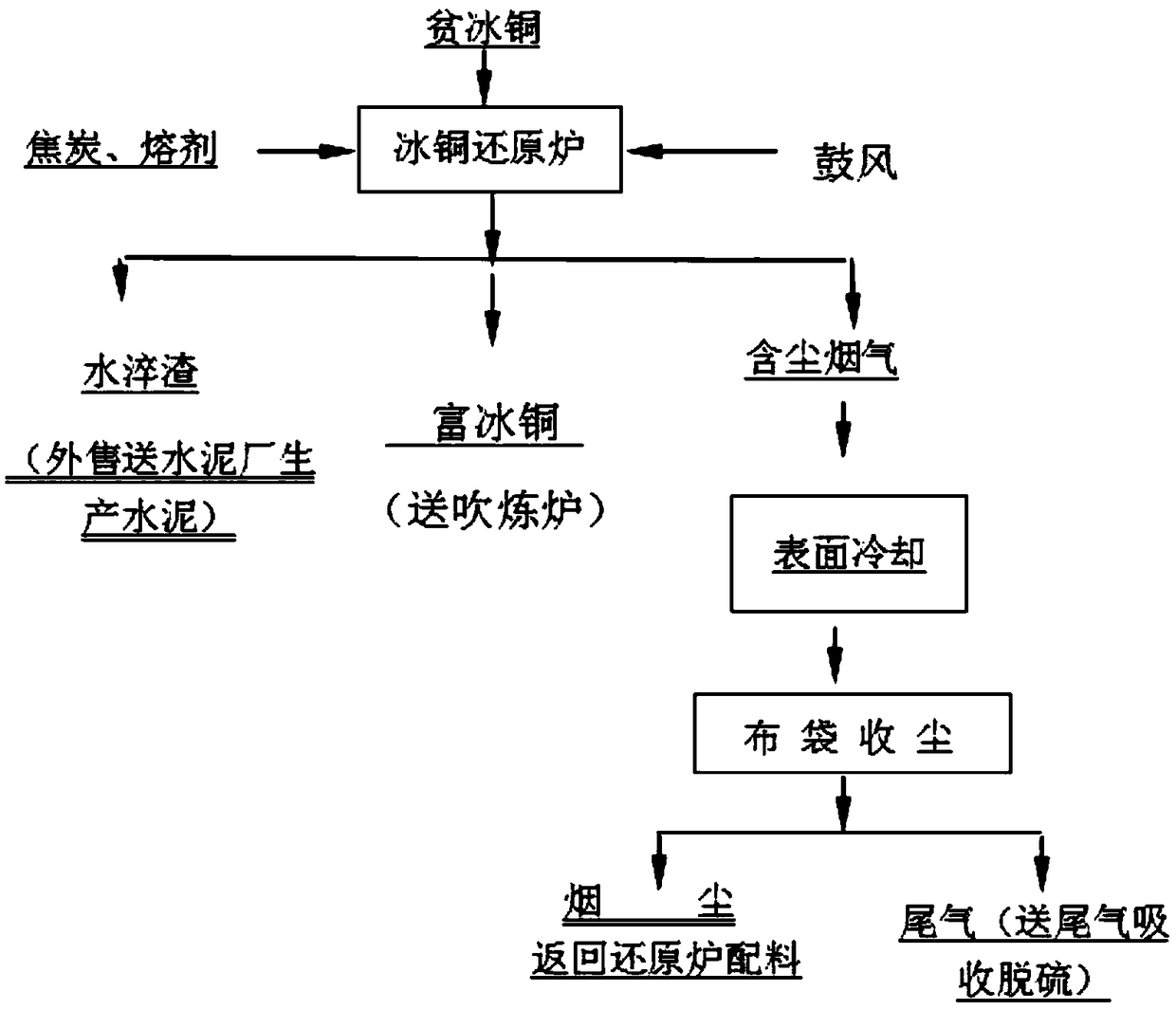

[0039] The current smelting method for non-ferrous metal regenerated materials containing lead, zinc, copper, gold, silver and rare precious metals is: first use a reduction furnace to reduce crude lead (and enrich a large amount of gold, silver and other rare and precious metals); Water-quenched water-quenched slag is sent to the rotary kiln to volatilize and extract zinc oxide (or directly hoist the slag bag into the fuming furnace to recover zinc oxide without water-quenching); The separated poor matte is sent to the matte furnace to be enriched into rich matte, and then the rich matte is sent to the converting furnace to be blown into blister copper. The technological process of each process is summarized as follows:

[0040] 1. The process flow of the reduction furnace process is as follows:

[0041] Such as figure 1 As shown, the materials from each silo are mixed and put into the oxygen-enriched side-blown reduction furnace for smelting. Crude lead (enriched in a lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com