A steelmaking device and method

A technology of original area and flux, applied in the field of metallurgy, can solve the problems of high oxygen consumption, serious environmental pollution and high impurity content, and achieve the effect of shortening the process flow, high economic value and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

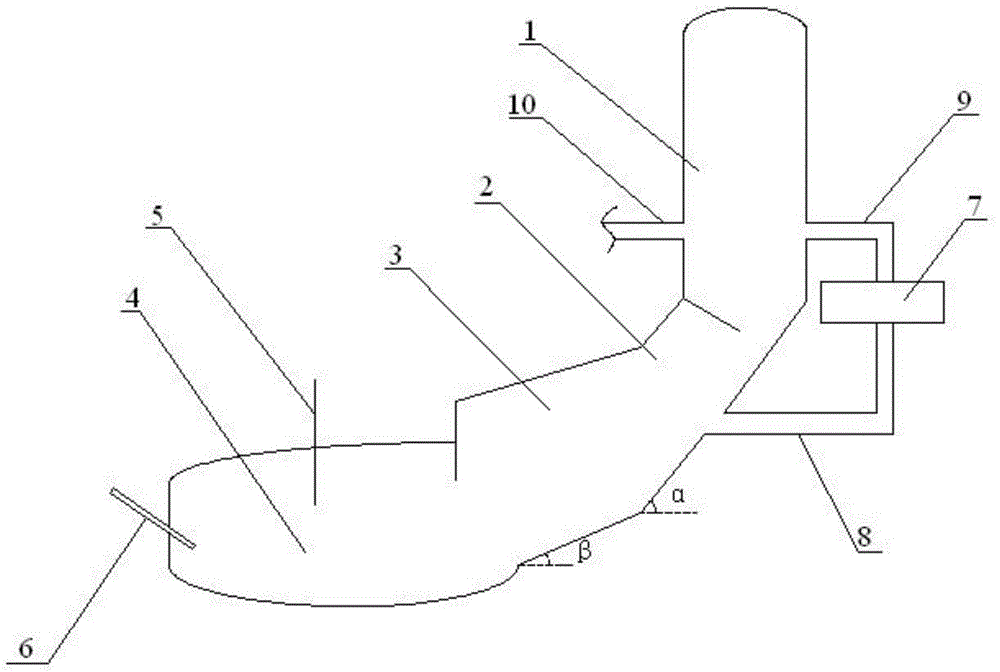

[0018] As shown in the figure, a steelmaking device of the present invention includes a reducing gas processing device 7 and a smelting device, and the smelting device includes a pre-reduction zone 1, a remelting zone 3 and a melting zone 4 connected in sequence, and the melting zone Zone 4 is provided with electrode 5 and flux spray gun 6, and said reducing gas processing device 7 is provided with intake pipe 8 and exhaust pipe 9, and said intake pipe 8 communicates with reflow area 3, and said exhaust pipe 9 is connected with pre- Reduction zone 1 is connected. Use the arc generated by the electrode 5 to heat and melt the pre-reduced metallized pellets, use the high-temperature flue gas generated in the process to deeply preheat and reduce the metallized pellets, and use the flux sprayed by the flux spray gun 6 to carry out molten steel r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com