High-temperature steel slag treatment system and a treatment method thereof

A processing system and processing method technology, applied in the field of high-temperature steel slag processing systems, can solve the problems of difficult to clean steel slag adhesion, clogging of screening equipment, large energy consumption of wet electrostatic precipitator, etc. Avoid the effect of sticking the belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

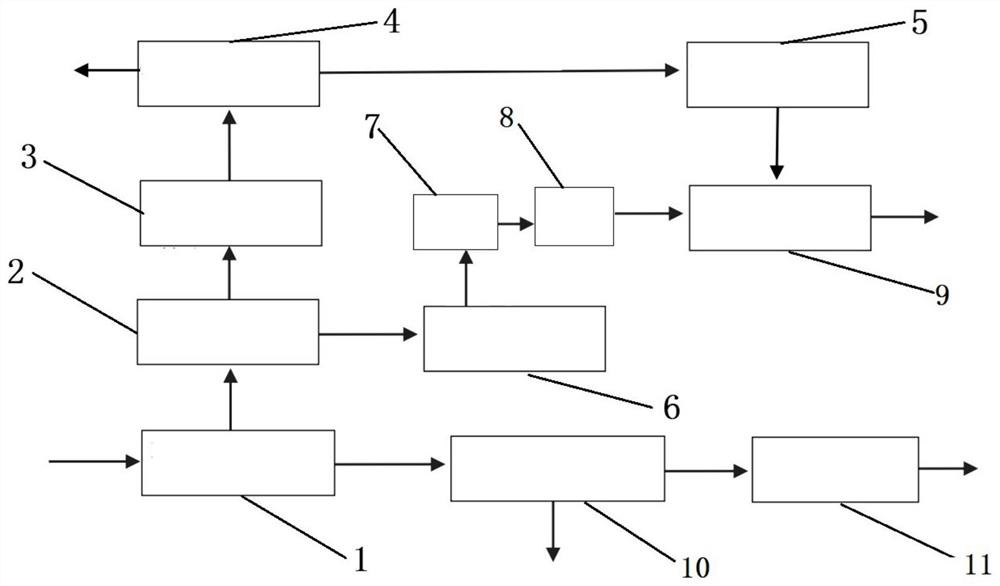

[0046] This embodiment provides a processing system for high-temperature steel slag, such as figure 1 As shown, it includes: a roll crushing device 1 and a screening device 2; the discharge port of the roll crushing device 1 is connected to the feed port of the screening device 2;

[0047] It also includes: a first tank-type heat-stuffing device 3, a first vacuum filtration device 4, and a crushing and screening device 5; The first vacuum filtration device 4 and the crushing and screening device 5 are sequentially connected and arranged;

[0048] It also includes: a waste heat recovery device 6, a second tank-type hot stuffy device 7 and a second vacuum filtration device 8; Type thermal stuffiness device 7, described second vacuum suction device 8 are connected and arranged in sequence;

[0049] It also includes: a steel slag secondary processing device 9; the crushing and screening device 5 and the second vacuum filtration device 8 are respectively connected to the steel sl...

Embodiment 2

[0055] This embodiment provides a treatment method for high-temperature steel slag, including:

[0056] (1) After the high-temperature steel slag to be treated (at a temperature of 600° C.) is rolled and crushed, it is passed through a bar sieve with a sieve hole diameter of 10 to 70 mm to obtain steel slag on the sieve and steel slag under the sieve;

[0057] (2) The steel slag on the sieve is successively subjected to tank-type hot stuffy treatment and vacuum filtration treatment (when the temperature of the water vapor discharged after the vacuum suction filtration treatment is 73.345, the frequency of the vacuum suction filtration treatment is adjusted to make the tank-type hot stuffy treatment The pressure is below 36000Pa; after the humidity is reduced by 80%, the vacuum filtration process stops, and finally the moisture content of the steel slag after the vacuum filtration process is 5%) and crushing and screening process to obtain steel slag 1;

[0058] (3) The steel s...

Embodiment 3

[0065] This embodiment provides a treatment method for high-temperature steel slag, including:

[0066] (1) After the high-temperature steel slag to be treated (at a temperature of 600° C.) is rolled and crushed, it is passed through a bar sieve with a sieve hole diameter of 10 to 70 mm to obtain steel slag on the sieve and steel slag under the sieve;

[0067] (2) The steel slag on the sieve is successively subjected to tank-type hot stuffy treatment and vacuum filtration treatment (when the temperature of the water vapor discharged after the vacuum suction filtration treatment is 60.058°C, adjust the frequency of the vacuum suction filtration treatment to make the tank-type hot stuffy treatment The pressure is below 20000Pa; after the humidity is reduced by 80%, the vacuum filtration process stops, and finally the moisture content of the steel slag after the vacuum filtration process is 7%) and crushing and screening process to obtain steel slag I;

[0068] (3) The steel slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com