Precast block blending mixing, vibration forming, curing and demolding process and system

A technology of vibration molding and prefabricated blocks, which is applied in the field of maintenance demoulding process and system, prefabricated block ingredients mixing, and vibration molding. It can solve the problems of dust spillage and pollution of the environment, heavy production workload, and low production efficiency, and reduce cleaning work. , Reduce labor costs and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

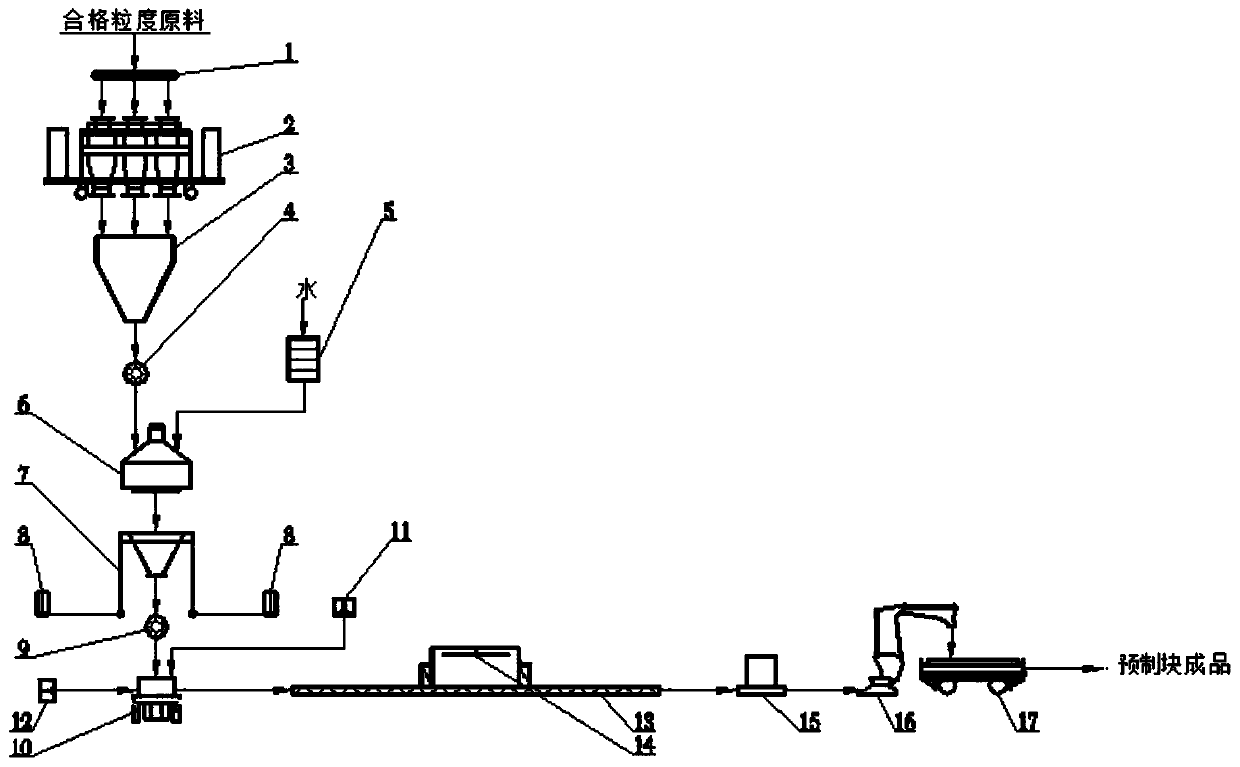

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

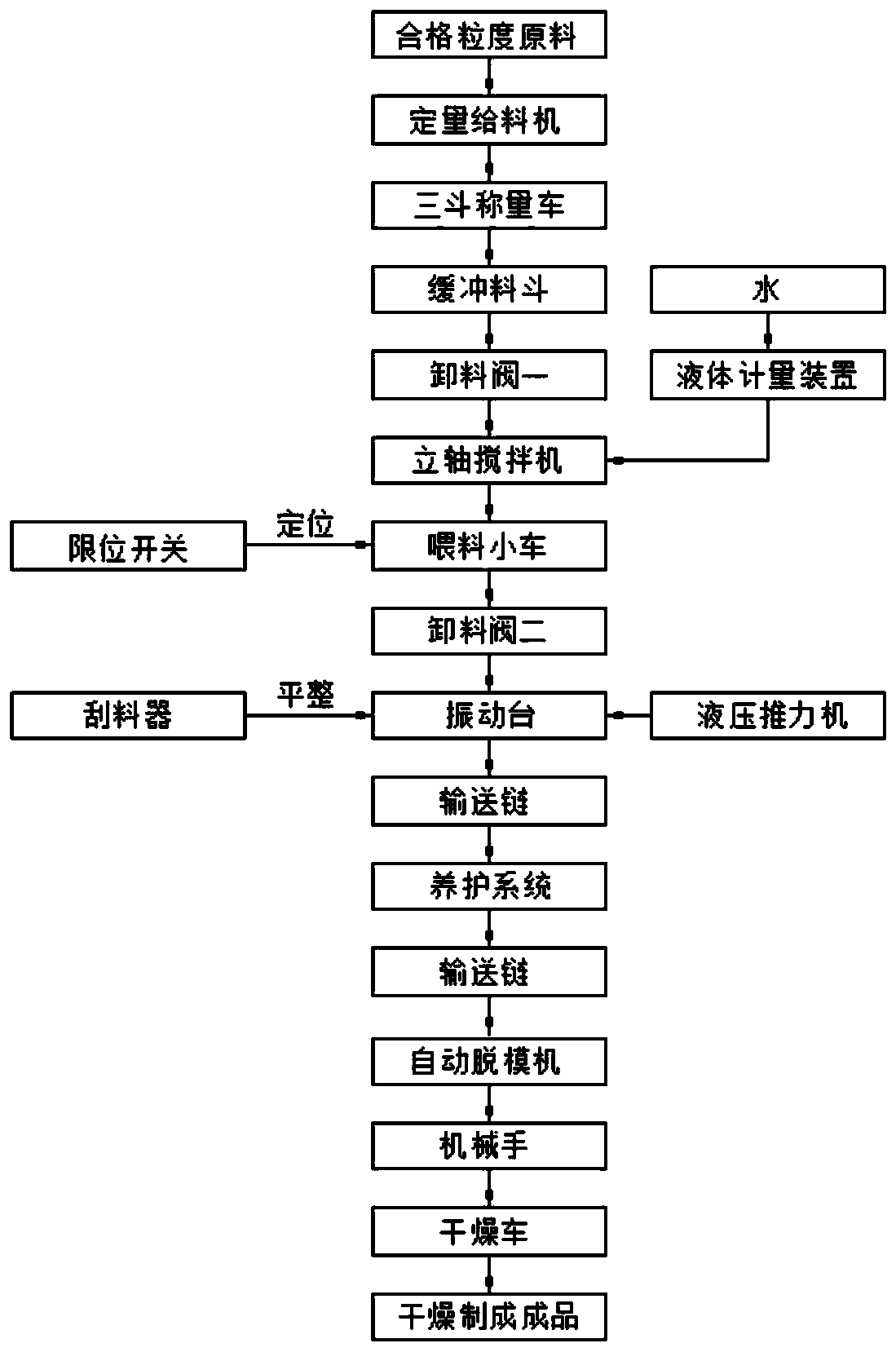

[0035] Such as figure 2 As shown, the prefabricated block batching mixing, vibration molding, maintenance and demoulding processes of the present invention include the following steps:

[0036] 1) Raw materials with various qualified particle sizes are sent to the three-bucket weighing car 2 through the corresponding quantitative feeder 1, and then sent to the buffer hopper 3 after being weighed by the three-bucket weighing car 2, and then sent into the buffer hopper 3 through the discharge valve-4 Vertical shaft mixer 6 for mixing, dry mixing for 2 to 3 minutes;

[0037] 2) Metering the water as an additive into the vertical shaft mixer 6 after being measured by the liquid metering device 5, stirring with the raw materials for 8 to 12 minutes until they are evenly mixed; the evenly mixed materials are unloaded into the feeding trolley 7;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com