Patents

Literature

127results about How to "Guaranteed weighing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

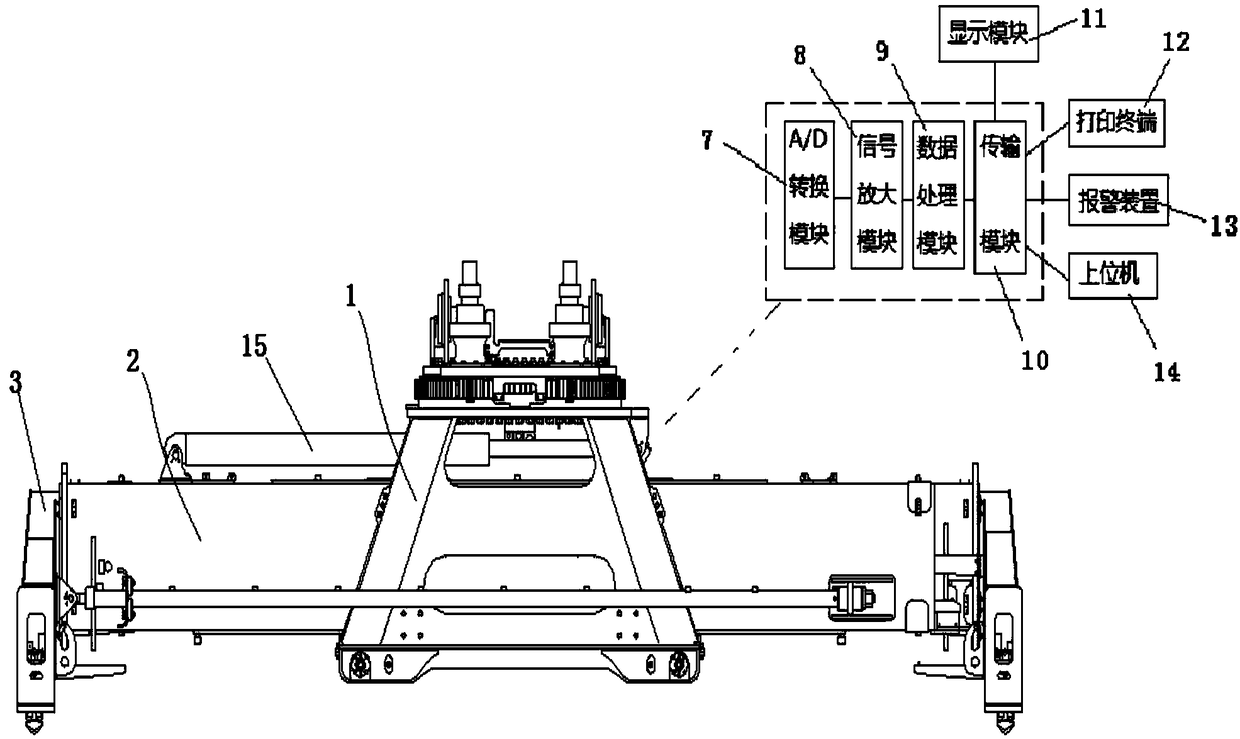

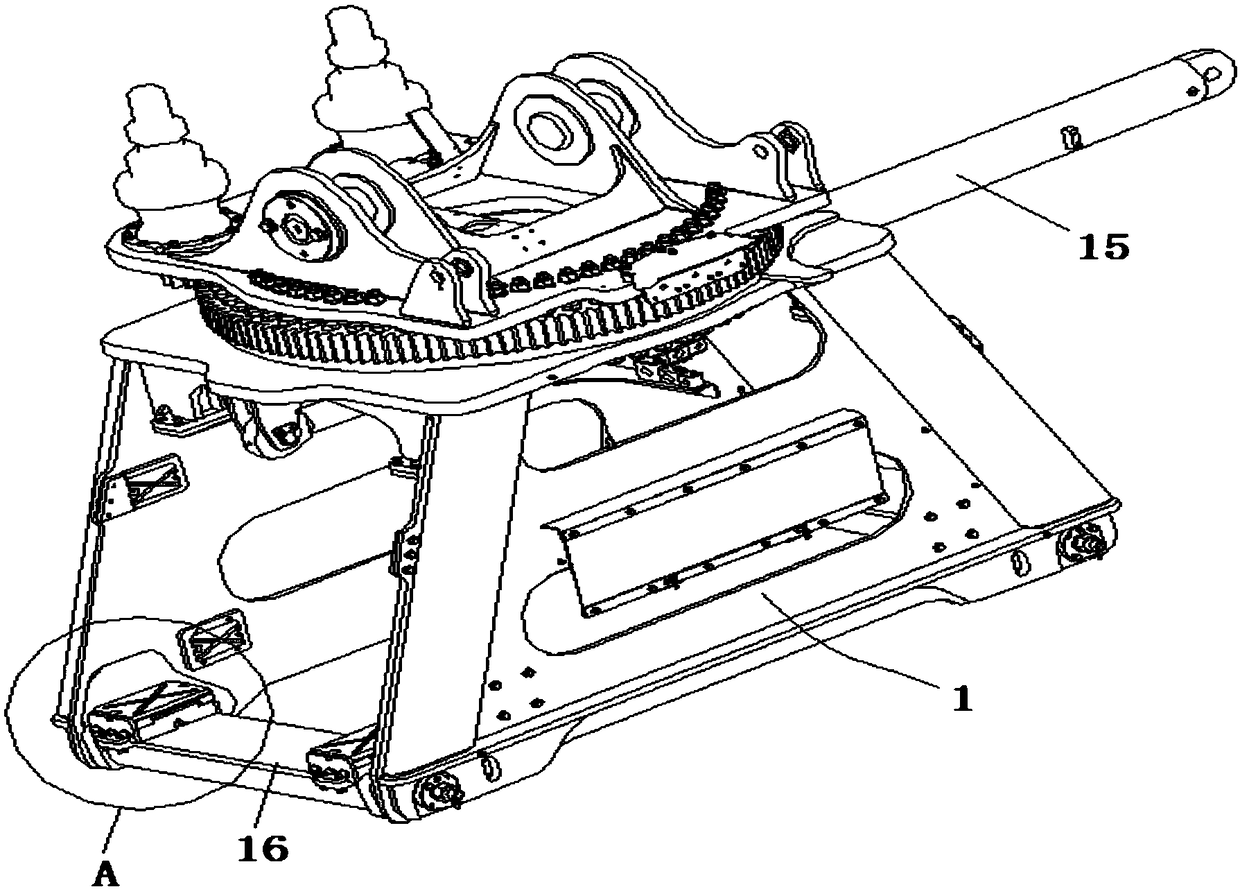

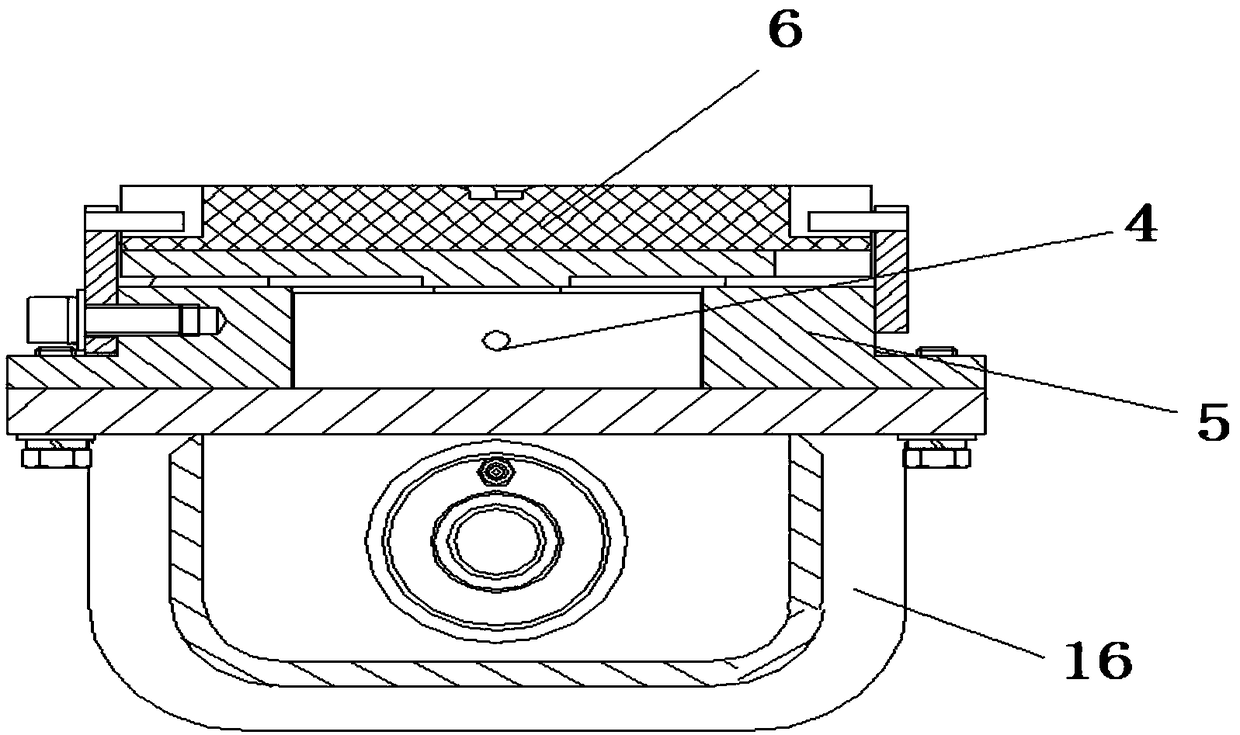

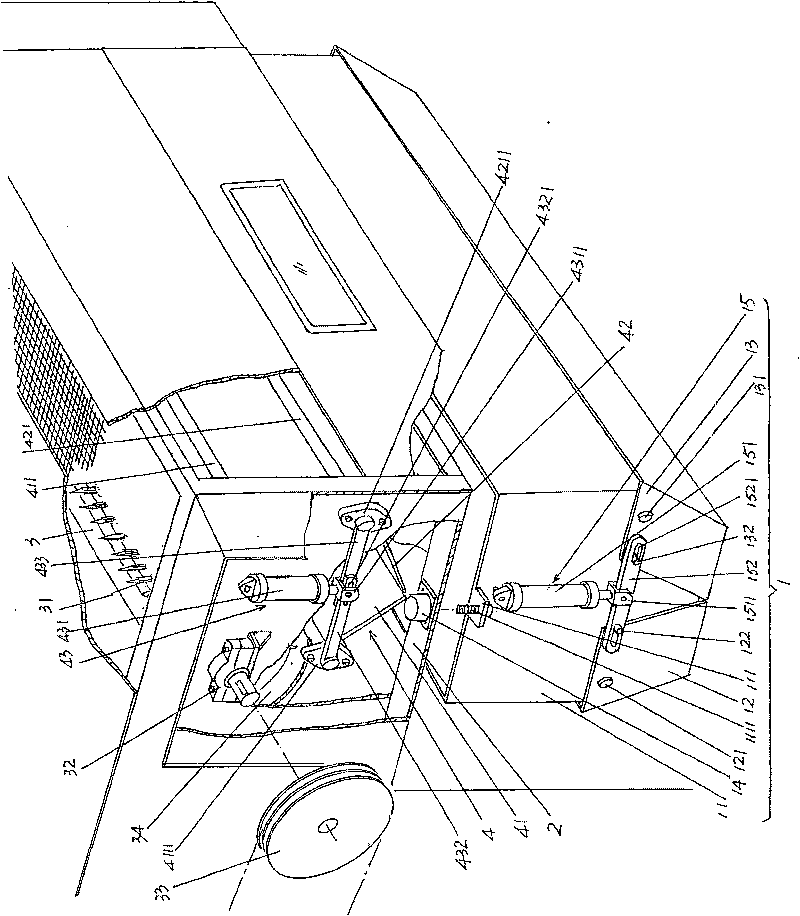

Container overloading and unbalanced loading detection and protection system and method, and reach stacker

ActiveCN108862036AGuaranteed vertical forceGuaranteed weighing accuracyWeighing auxillary devicesSafety gearComputer moduleComputer terminal

The invention discloses a container overloading and unbalanced loading detection and protection system and method, and a reach stacker, and relates to the field of container overloading and unbalancedloading detection and protection devices and methods. The container overloading and unbalanced loading detection and protection system comprises four weighing sensors mounted in a main body crossbeam, an electric control cabinet, a display module, a printing terminal, an alarming device and an upper computer, wherein the electric control cabinet is integrated with an A / D conversion module, a signal amplification module, a data processing module and a transmission module, and the display module, the printing terminal, the alarming device and the upper computer are mounted in a cab. Weight signals collected by the weighing sensors are sent to the electric control cabinet, result data processed by the electric control cabinet are sent to the display module through the transmission module tobe displayed, sent to the printing terminal to be printed, sent to the alarming device for pre-warning and sent to the upper computer to be shared. In order to overcome the defects of inconvenience and inaccuracy during overloading and unbalanced loading weighing of a container in the prior art, the rapid and accurate container overloading and unbalanced loading detection and protection system andmethod, and the reach stacker are provided, and the container overloading and unbalanced loading limiting case can be alarmed, displayed and recorded in real time.

Owner:上海亿锤机械科技有限公司

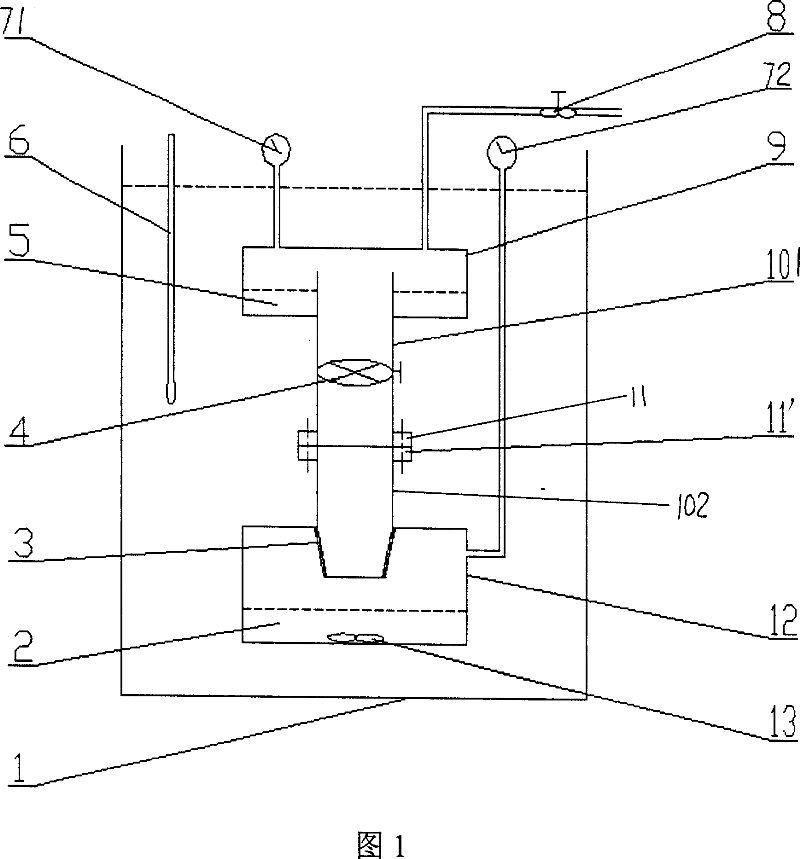

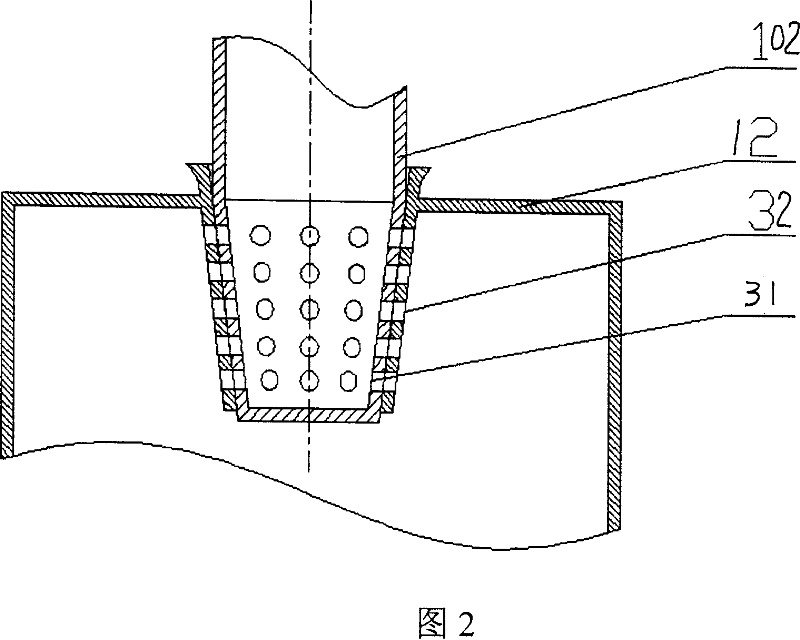

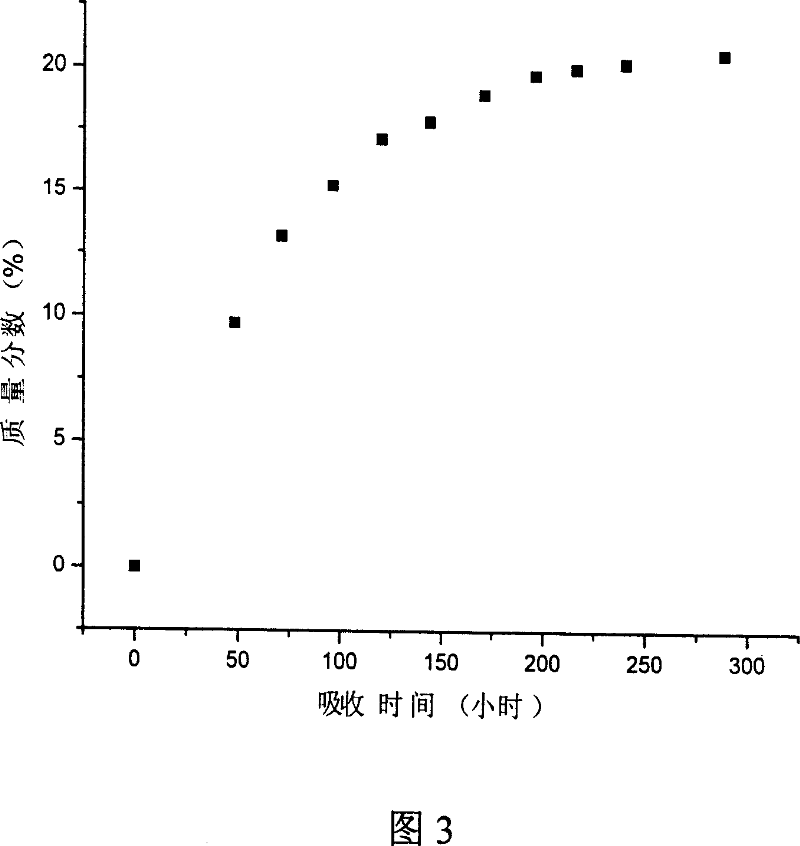

Method and device for measuring absorbing capacity of organic solvent volatile gas in ion liquid

InactiveCN101038249AFacilitate desorptionEasy to desorbWeighing by absorbing componentIonSaturable absorption

The present invention relates to a method and apparatus used for measuring the absorbing amount of an organic solvent volatile gas in an ionic liquid. Said apparatus comprises an evaporator used for a natural evaporation of an organic solvent and an absorber used for adsorbing natural volatile gases of a variety of organic solvents utilizing an ionic liquid as an absorbing agent to achieve the intention that an ionic liquid is used as an absorbing agent to remove organic solvents in industrial waste gas. A weighing method is utilized to perform detections, then the transient absorbing capacity and saturated absorbing capacity of an organic volatile gas in an ionic liquid are got through the mass difference after and before the absorption by the absorbing agent. The channel valve adopts a rotary switch type valve, which is capable of both increasing the flux and decreasing the valve weight at the same time to ensure the weighing precision. The absorber is equipped with a magnetic stirring therein and the adsorbing process is a deep absorption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

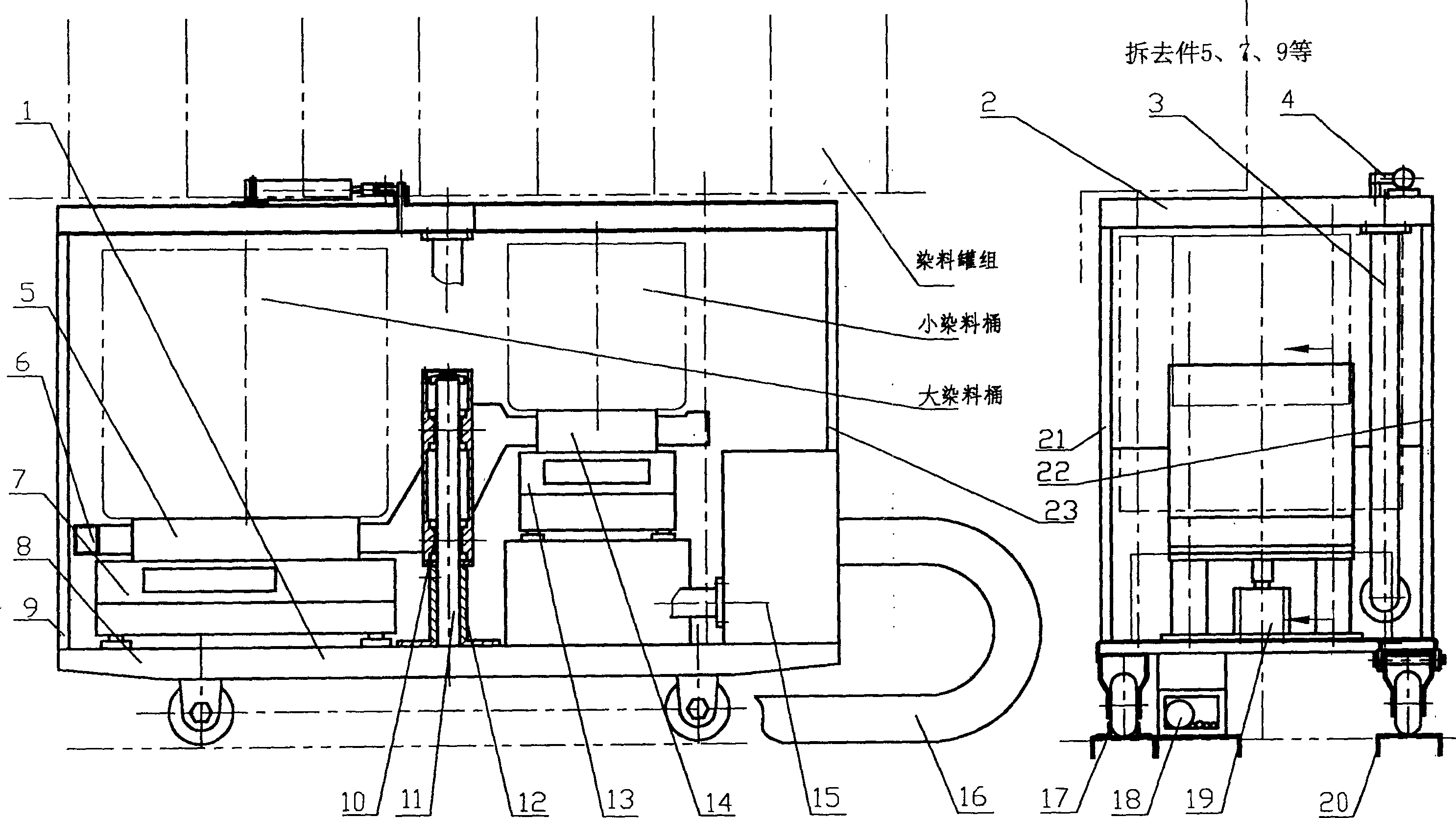

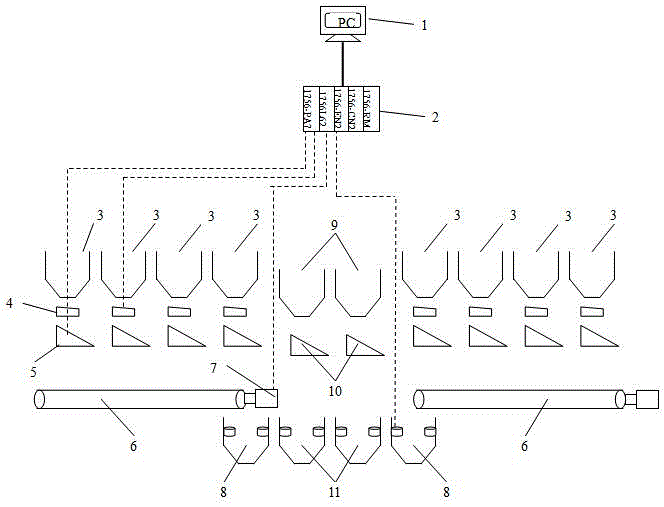

Dye automatic-mixing dual-baiance weighing apparatus

InactiveCN1641325AReduce participationEasy to prevent dustSpecial purpose weighing apparatusComputer monitoringReciprocating motion

The invention relates to automatic measuring technical field and is especially an automatic distributing and double-balance weighing device, mainly composing a system for using together with dye tank group storing various dyes, reciprocating dye weighing vehicle, computer monitoring circuit, etc. There is a large-range ordinary electronic balance and a small-range high-accuracy electronic balance arranged in the device, and the two electronic balances are installed on the same weighing vehicle body. A power lift arm is installed in the middle of the vehicle body, i.e. between the two electronic balances and can be set with a big dye bucket and a mall dye bucket. For preventing dust pollution, the system installs a vacuum cleaner on the vehicle body and connects the vacuum cleaner through pipeline to a dust pumping casing. A gas path switching mechanism equivalent to two three-way valves opens or closes the gas path of corresponding annular dust collector according to operation requirement. The main character of the system is being able to implement large-range and high-accuracy distributing.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Automatic preparation method of moistening agent

ActiveCN101362062AReduce labor intensityGuaranteed order of additionMixer accessoriesComputer control systemAutomatic control

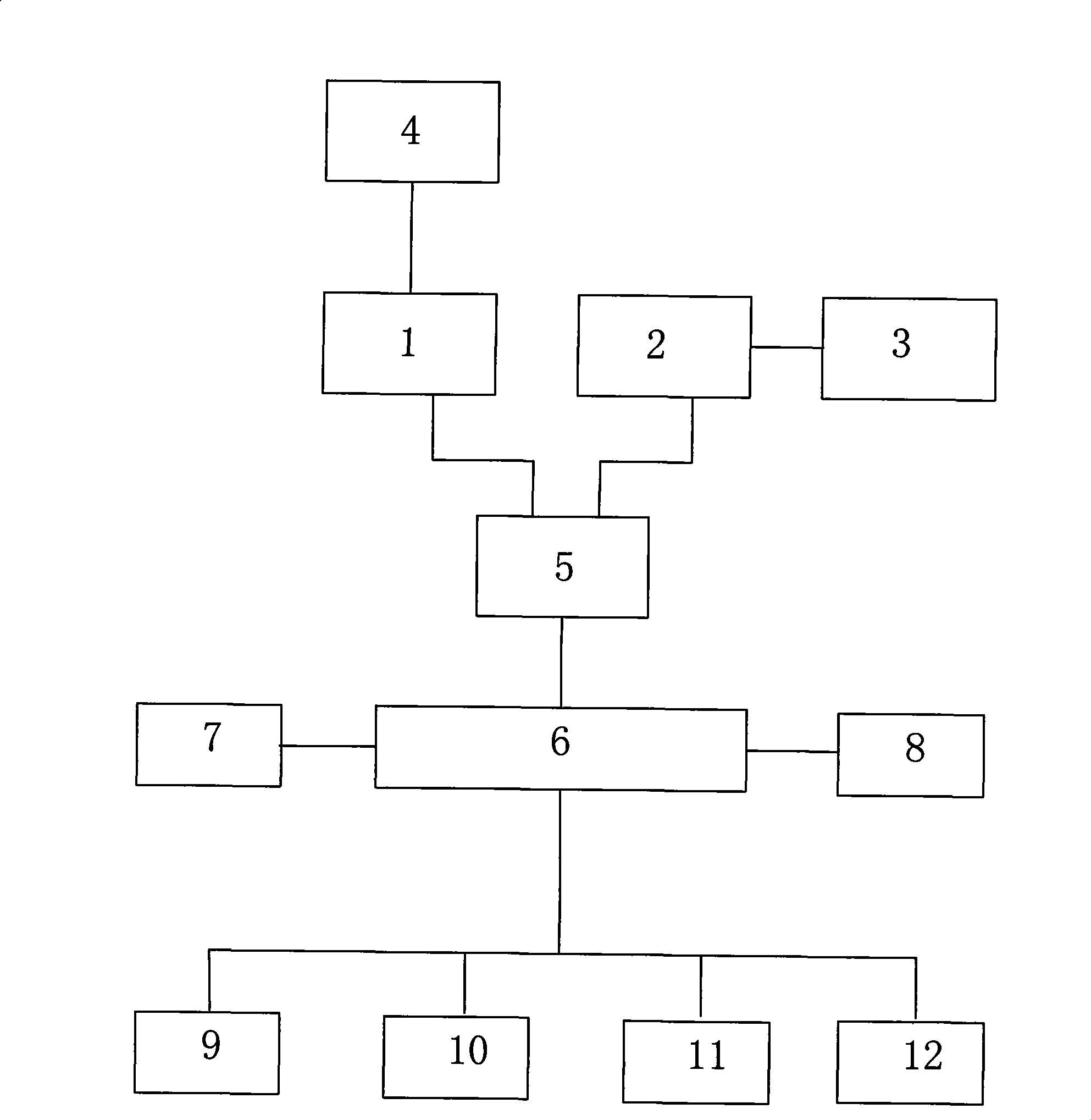

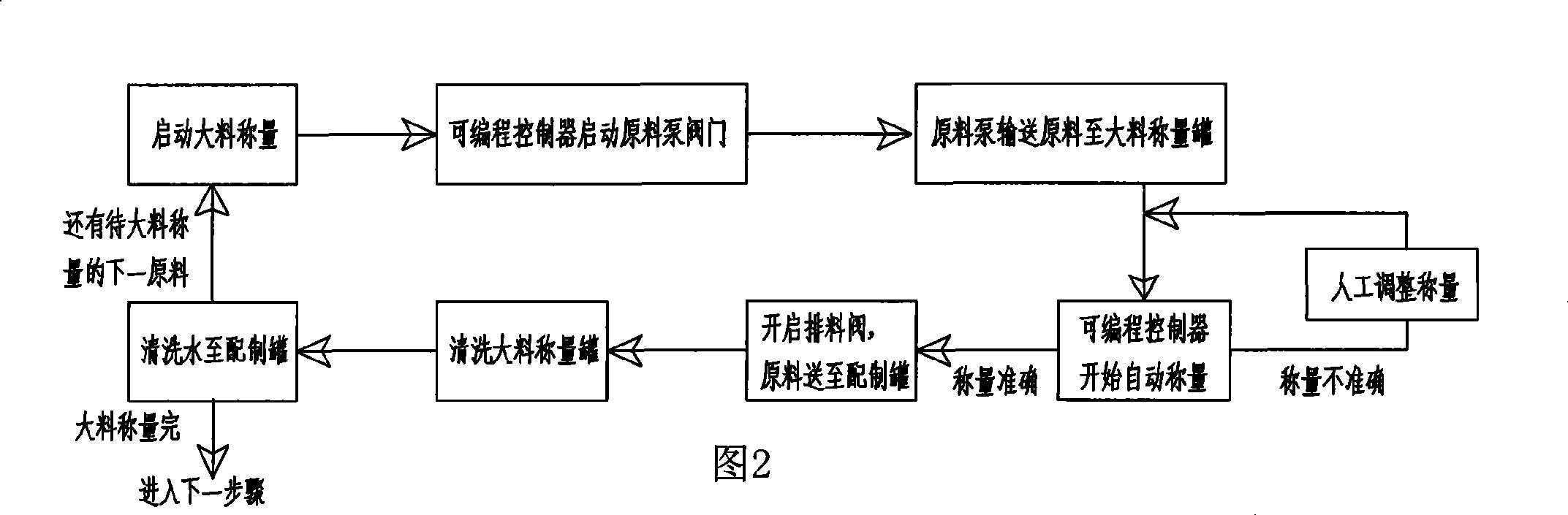

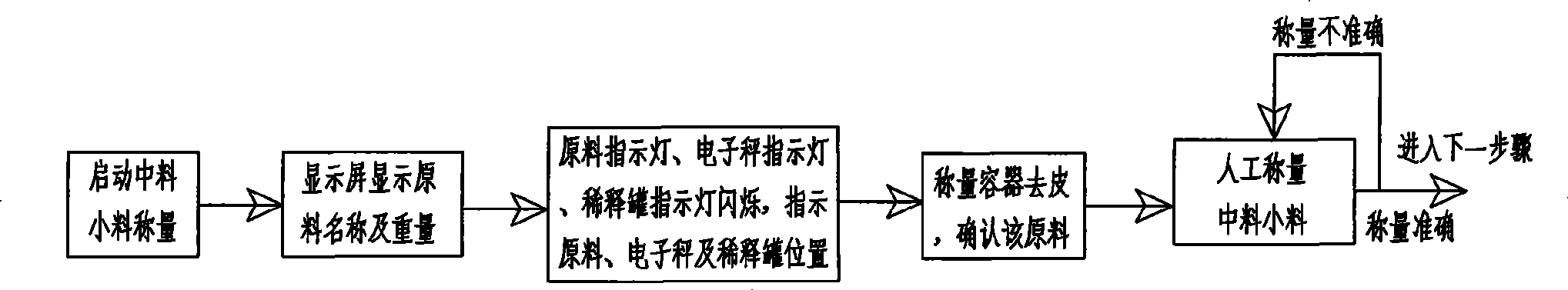

The invention relates to an automatic preparation method of a sizing agent, which is based on a computer control system as well as a weighing device and an automatic control valve that are connected with the computer control system. The computer control system is provided with a display screen and an indicator light, and various preparation steps and formulas of the sizing agent are all stored in a database of the computer control system. The preparation method comprises the following steps of accessing the computer control system, choosing a formula, weighting raw materials, dispersing and diluting the raw materials, and mixing. The computer control system is provided with a server, an operator station terminal, a printer, the display screen, the indicator light, the Ethernet and a programmable controller; and the weighing device consists of a small material weighting balance, a bulk material weighting tank, a low storage tank weighting instrument, a preparation tank weighting instrument and a medium material weighting platform balance. The server is connected with the display screen, the indicator light and the Ethernet, the operator station terminal is connected with the printer and the Ethernet, and the programmable controller is connected with the Ethernet, the small material weighting balance, the bulk material weighting tank, the low storage tank weighting instrument, a stirrer, the automatic control valve, the preparation tank weighting instrument and the medium material weighting platform balance. The method reduces the labor strength of workers and guarantees the feeding sequence and weighting precision.

Owner:JUSHI GRP CO

Device for weighing liquid with viscosity being 4mPa.S

InactiveCN103630220AReduce negative qualityImprove reliabilityWeighing apparatus for materials with special property/formEngineeringUltimate tensile strength

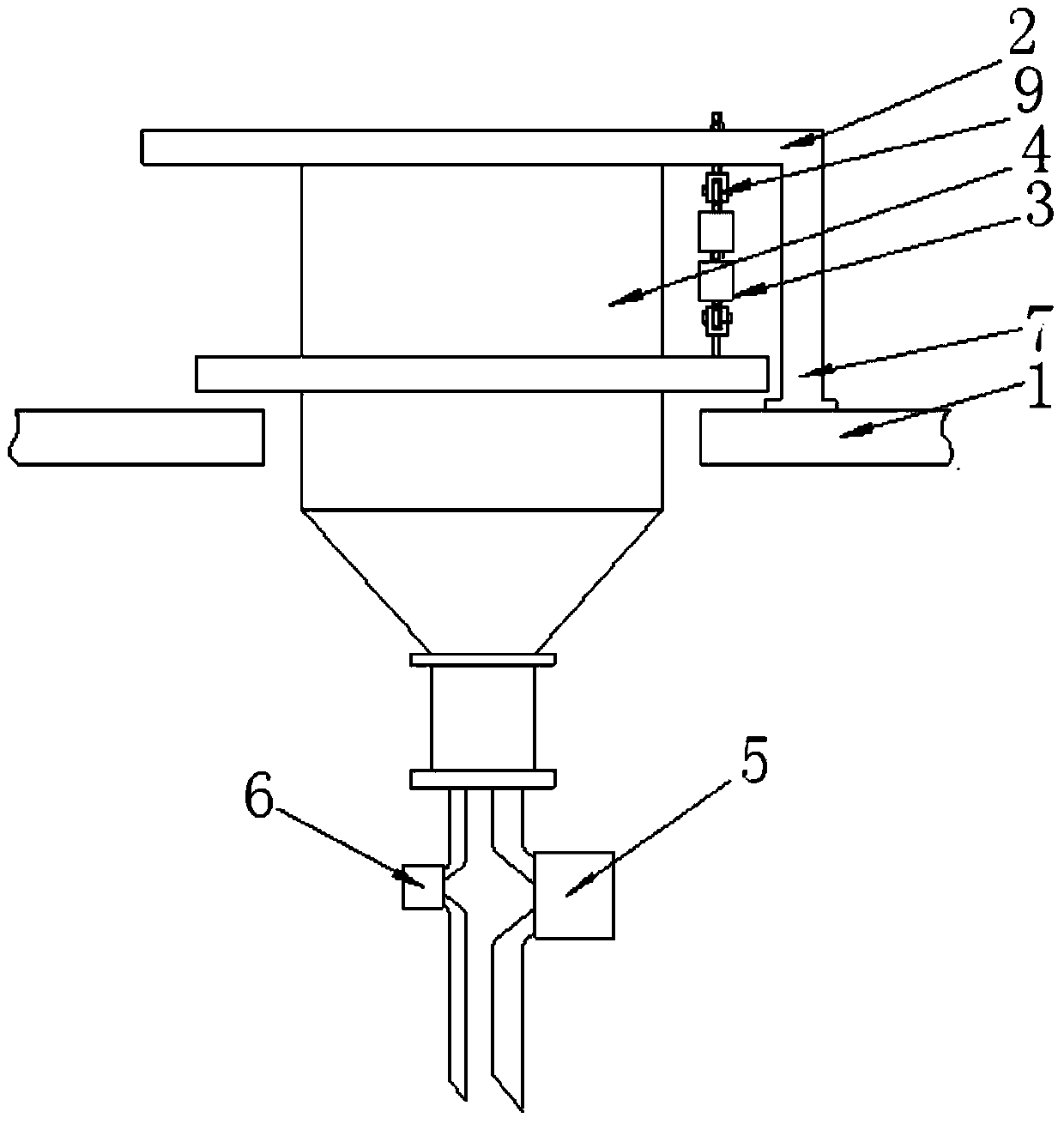

The invention relates to a device for weighing liquid with viscosity being 4mPa.S, which comprises a supporting platform, a ring support, three sensor modules, a viscose liquid hopper, a quick release valve and a slow release valve. A panel of the ring support is sleeved on the circumference of an upper end of the viscose liquid hopper, and a clearance is formed between the panel of the ring support and the viscose liquid hopper. Three support rods of the ring support are placed on the supporting platform. The three sensor modules are uniformly distributed on the periphery of the viscose liquid hopper. Upper ends of the three sensor modules are respectively and fixedly connected with the panel of the ring support; and lower ends of the three sensor modules are respectively and fixedly connected with clamping edges of the hopper. The quick release valve and the slow release valve are respectively arranged on a flange plate of a discharge hole of the viscose liquid hopper through pipelines, and are communicated with an inner cavity of the viscose liquid hopper. According to the device, loading of different release valves is controlled through an industrial control computer, the weight of materials is controlled through a manner of weighting by adopting a reduction method, the labor cost is effectively saved, the labor intensity is reduced, the automatic degree of viscose liquid weighing is greatly improved, and the problem of harming occupational health of operating personnel is solved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Dynamic weighing system of high-viscosity fluid and method thereof

InactiveCN101799312ARealize dynamic and accurate weighing functionMeet the requirements of dynamic and accurate weighingWeighing apparatus for materials with special property/formWeighing apparatus with automatic feed/dischargeFrequency changerEngineering

The invention relates to a dynamic weighing system of a high-viscosity fluid and a method thereof. The scale body output end of the system is simultaneously connected with a weight display instrument and a weighing controller. An output control end of the weighing controller is connected with a high-viscosity fluid barrel pump through a frequency converter; and the high-viscosity fluid is pumped into a scale body by the high-viscosity fluid barrel pump through a pump rod inserted into a high-viscosity fluid barrel. By using the method, the high-viscosity fluid is pumped into the scale body by the high-viscosity fluid barrel pump, the scale body feeds a weighing signal back to the weighing controller, and the weighing controller controls the pump speed of the high-viscosity fluid barrel pump through the frequency converter by adopting a dynamic difference compensation method and a method for measuring minimum flow according to control parameters. The invention has reasonable design, achieves the dynamic accurate weighing function on the high-viscosity fluid, ensures the weighing precision and the weighing speed, meets the requirement on the dynamic accurate weighing of the high-viscosity fluid, and also has the characteristics of convenient use and wide application range.

Owner:TIANJIN UNIV OF SCI & TECH

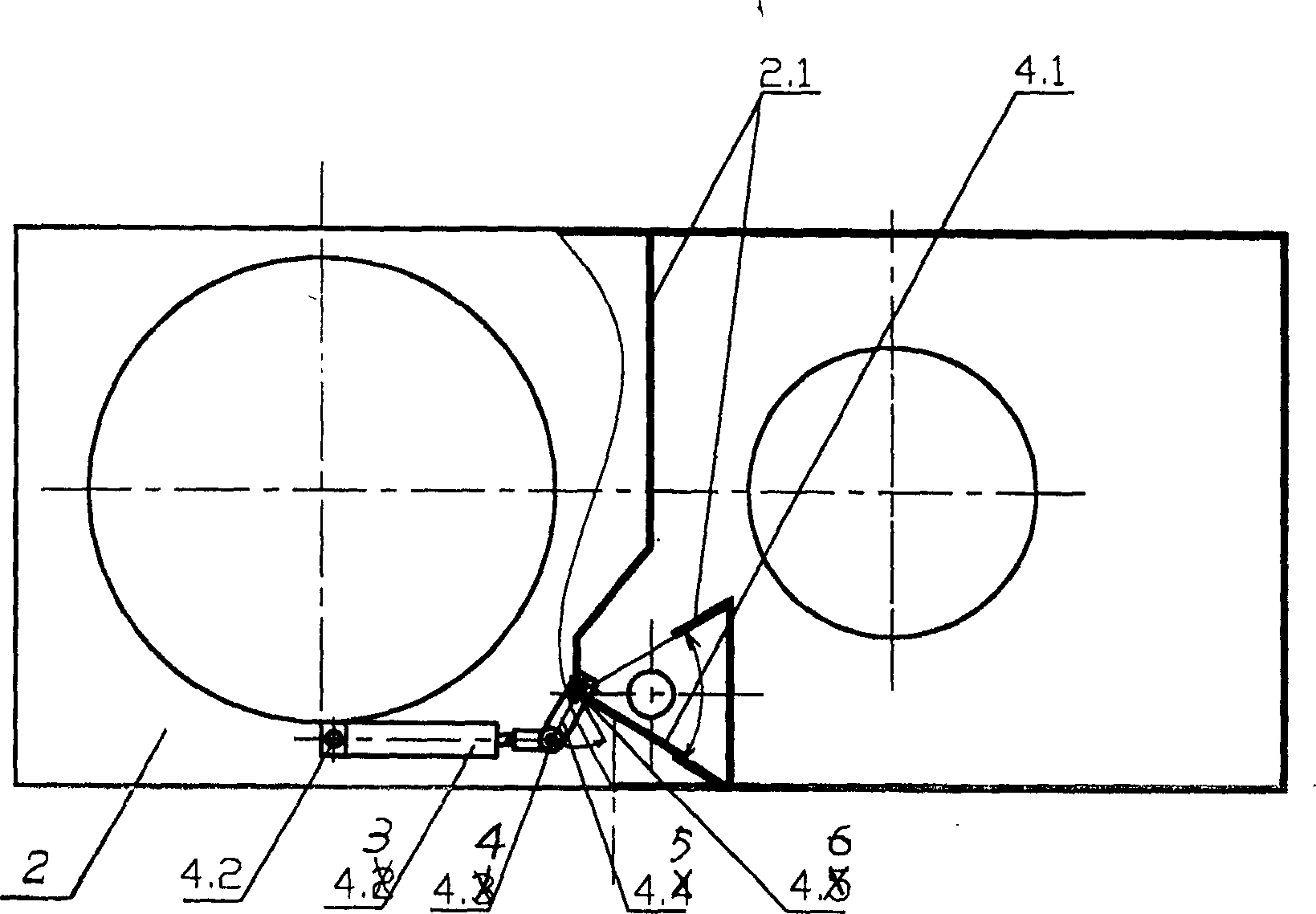

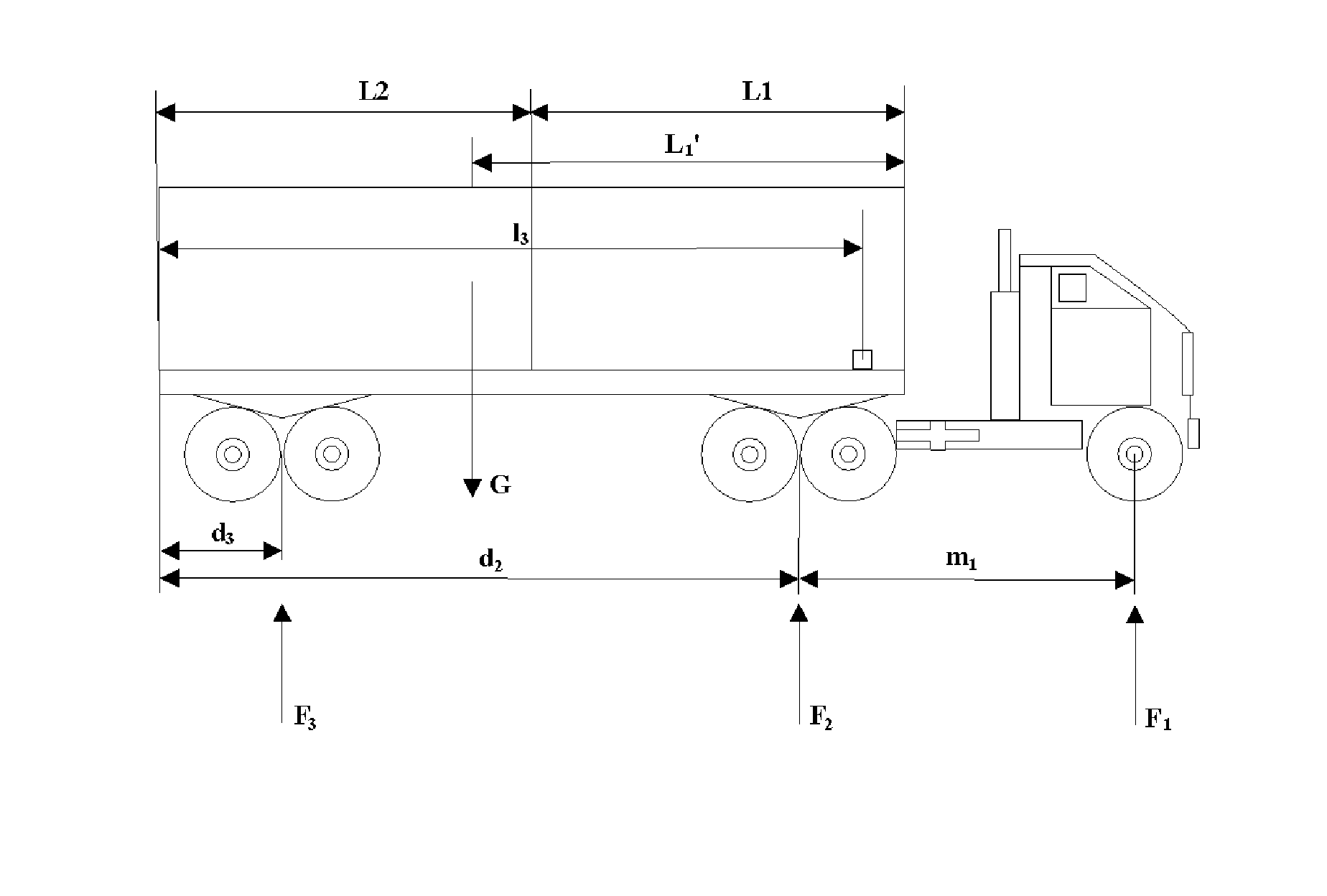

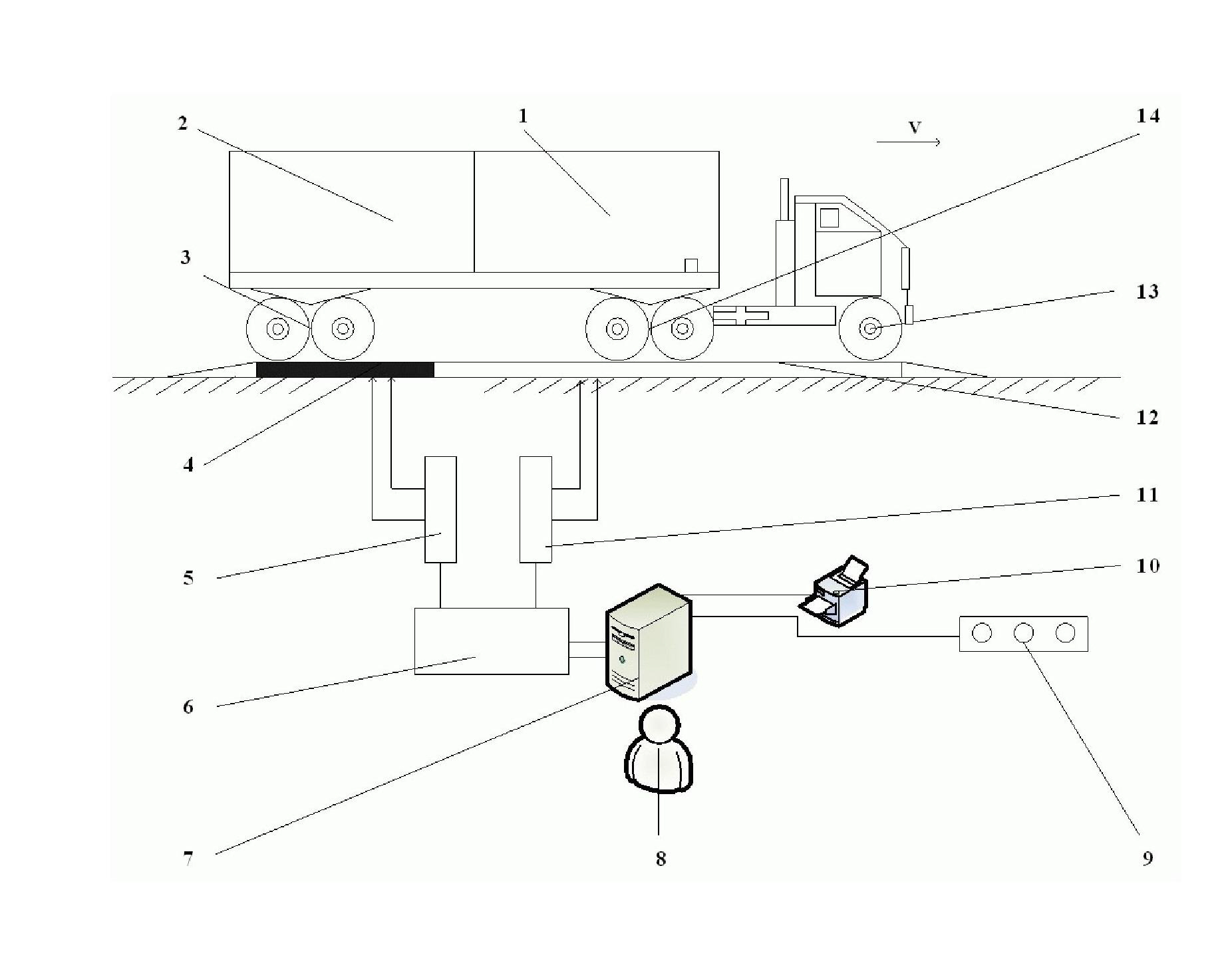

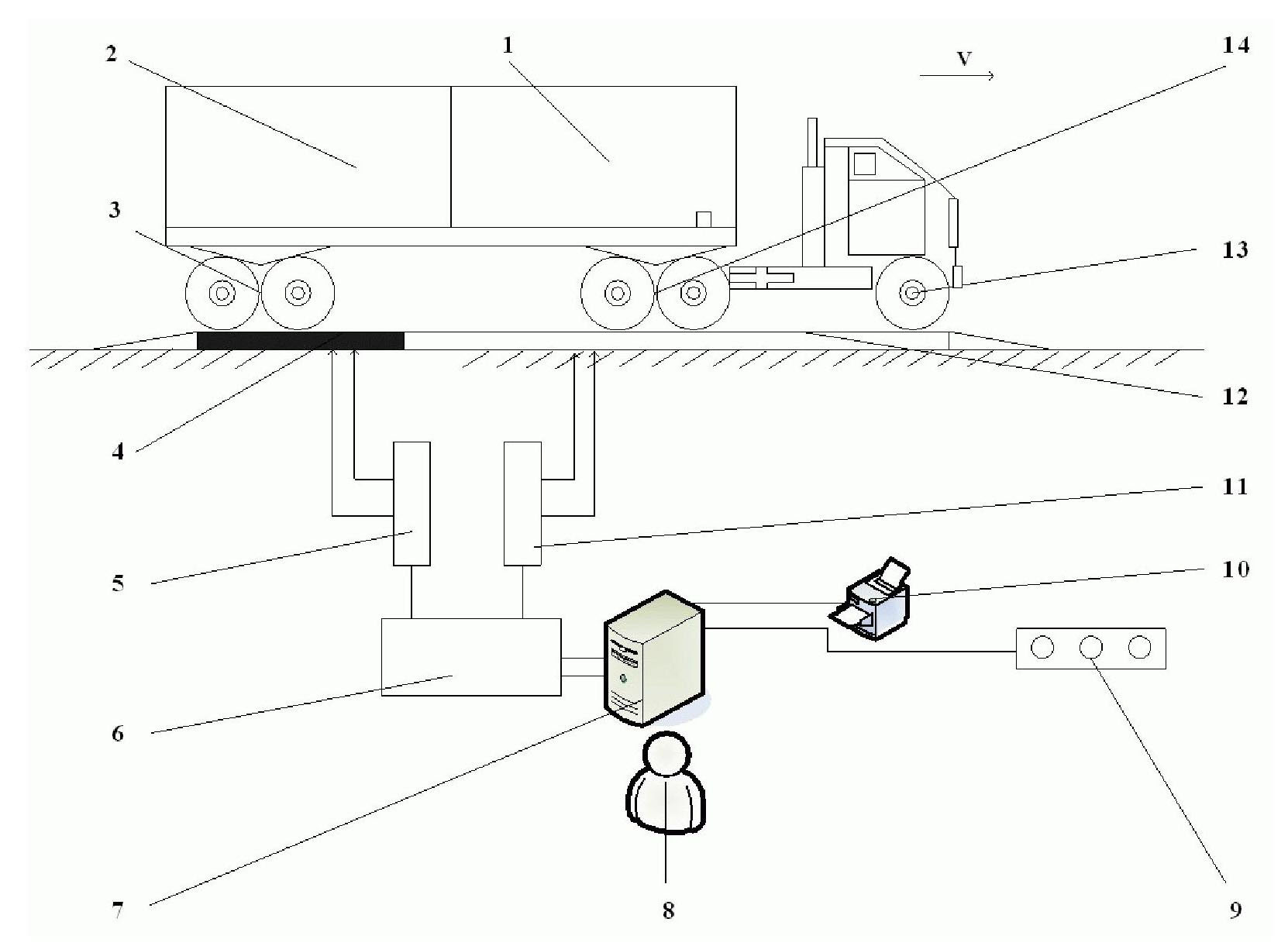

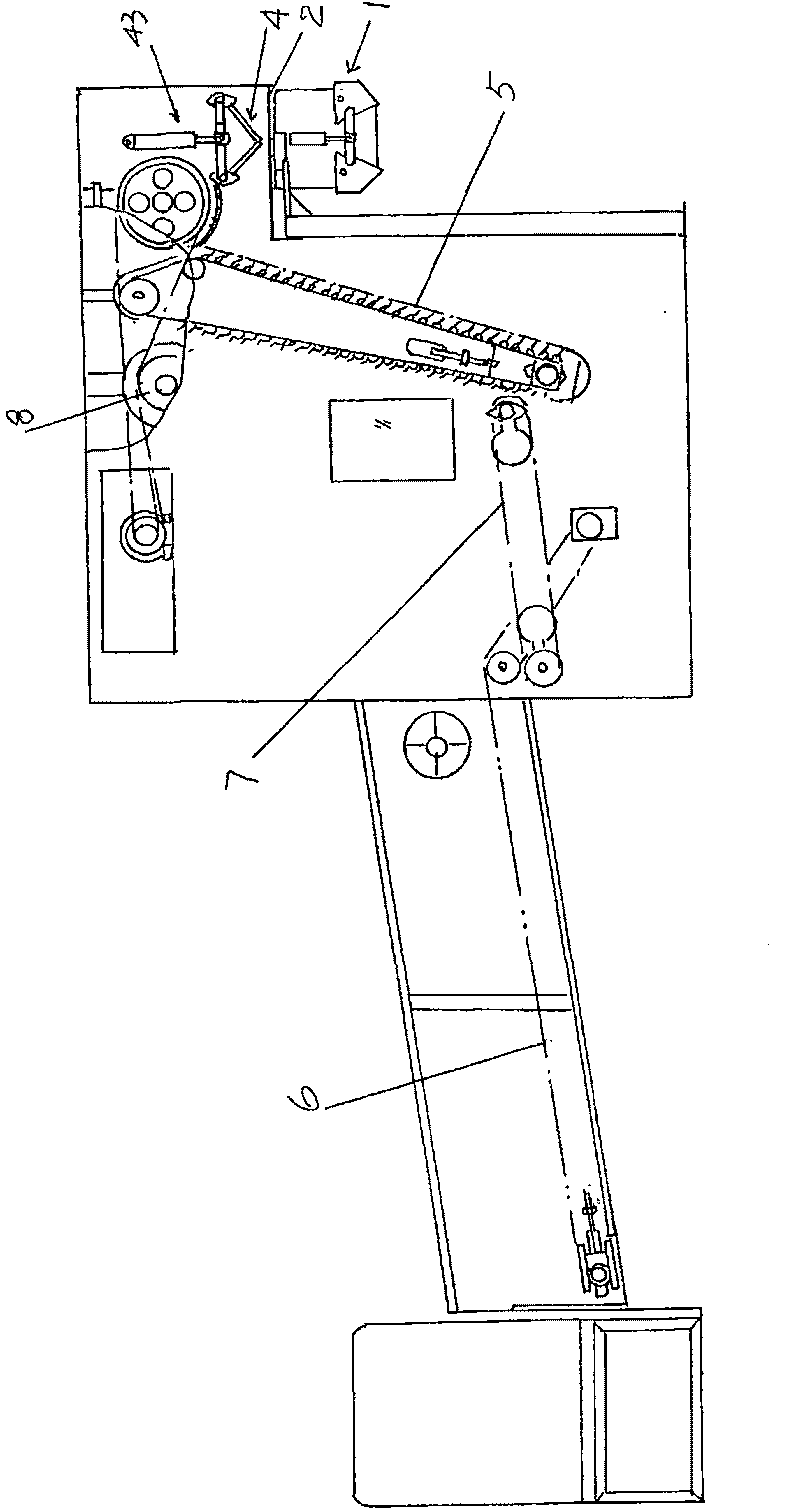

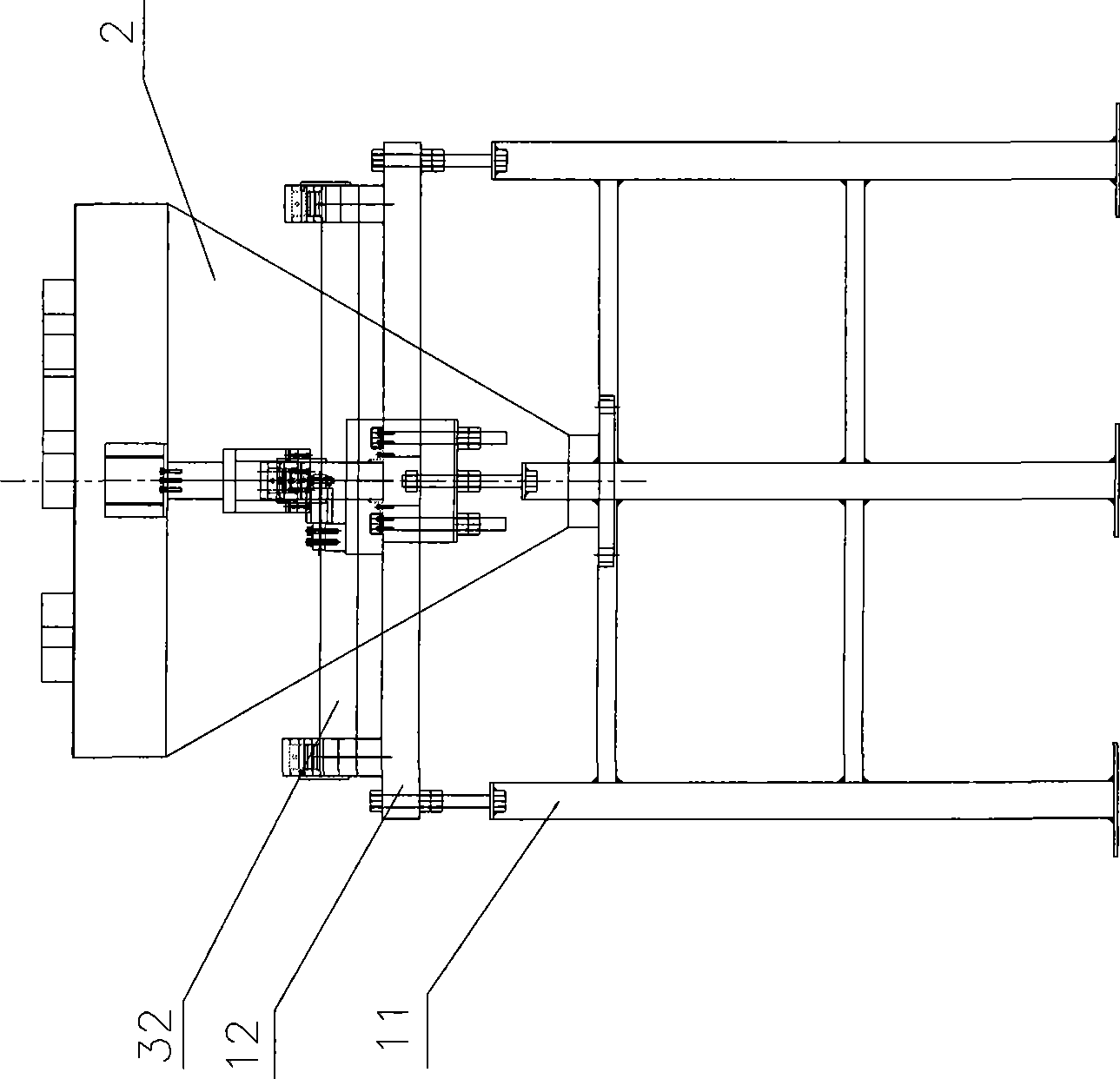

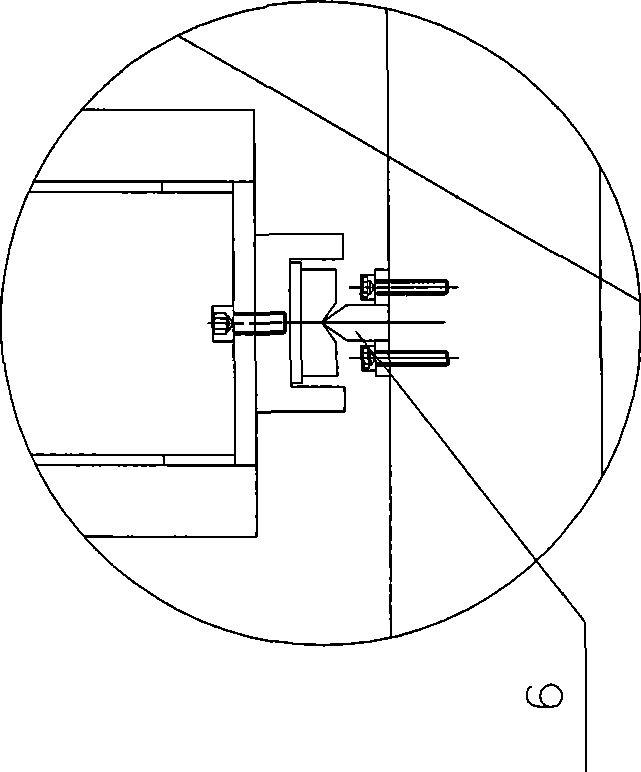

Weighing system and weighing method for dynamic vehicle box distribution of tandem containers

ActiveCN102103009AImprove calculation accuracyHigh outputSpecial purpose weighing apparatusData acquisitionGravity center

The invention discloses a weighing system and a weighing method for tandem double containers in a heavy vehicle state. The weighing system comprises a dynamic axis weighing table, a dynamic scale detection instrument, a data acquisition device, a computer, a static scale detection instrument and a static weighing table; the static weighing table and the dynamic axis weighing table are connected sequentially front and back according to the advancing direction of the vehicle, have equal width and are positioned on the same horizontal plane higher than the ground; the dynamic scale detection instrument and the static scale detection instrument are connected with the dynamic axis weighing table and the static weighing table respectively, and send data to the data acquisition device; and the data acquisition device sends the data to the computer for analysis and calculation. A primary function three-layer forward feedback neural network for dynamically calculating the weight of each container is established according to the data acquired when the vehicle passes through the dynamic and static combined weighing platforms, and a dynamic goods gravity center balance equation of the containers along the horizontal direction is establishes; and the calculation precision is high.

Owner:常州机械电子工程研究所 +1

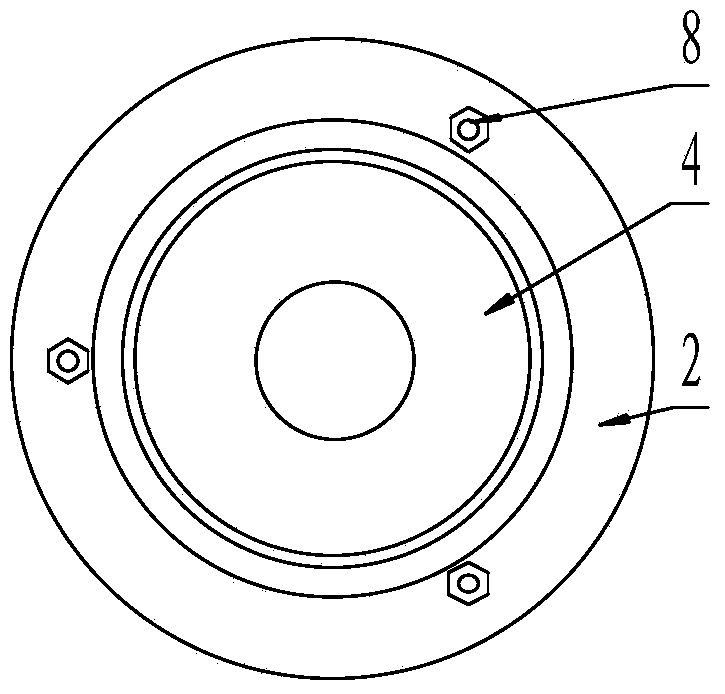

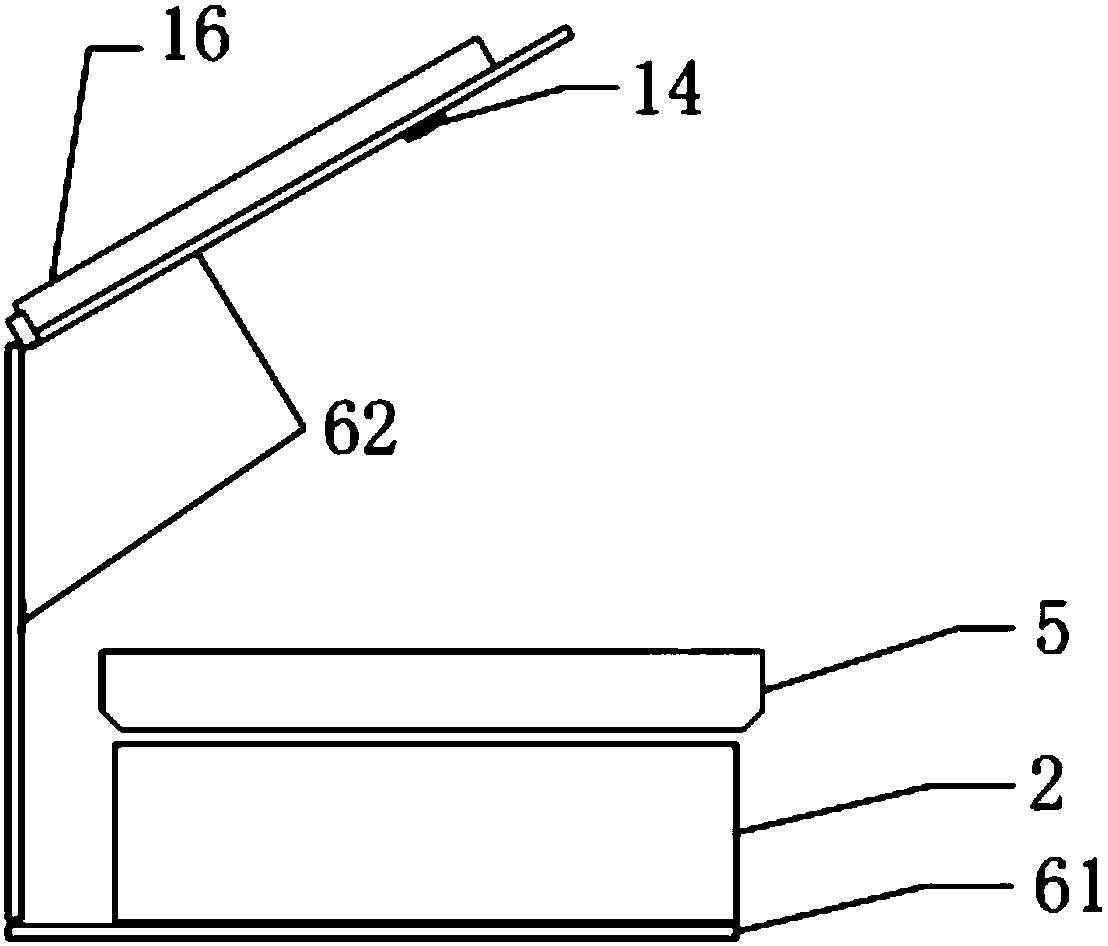

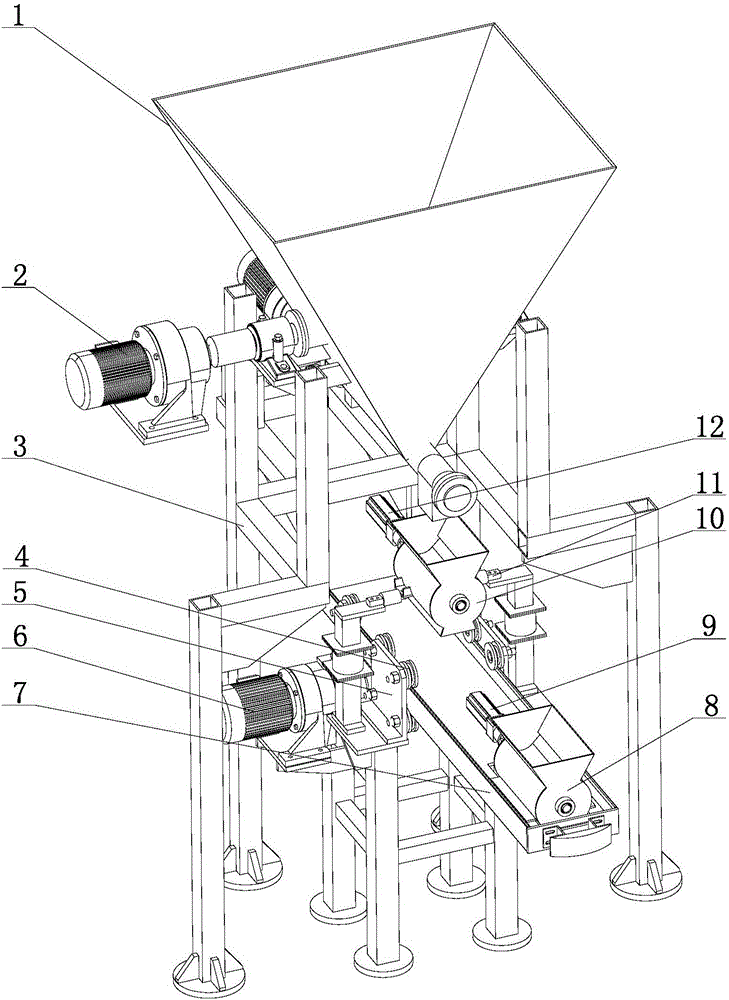

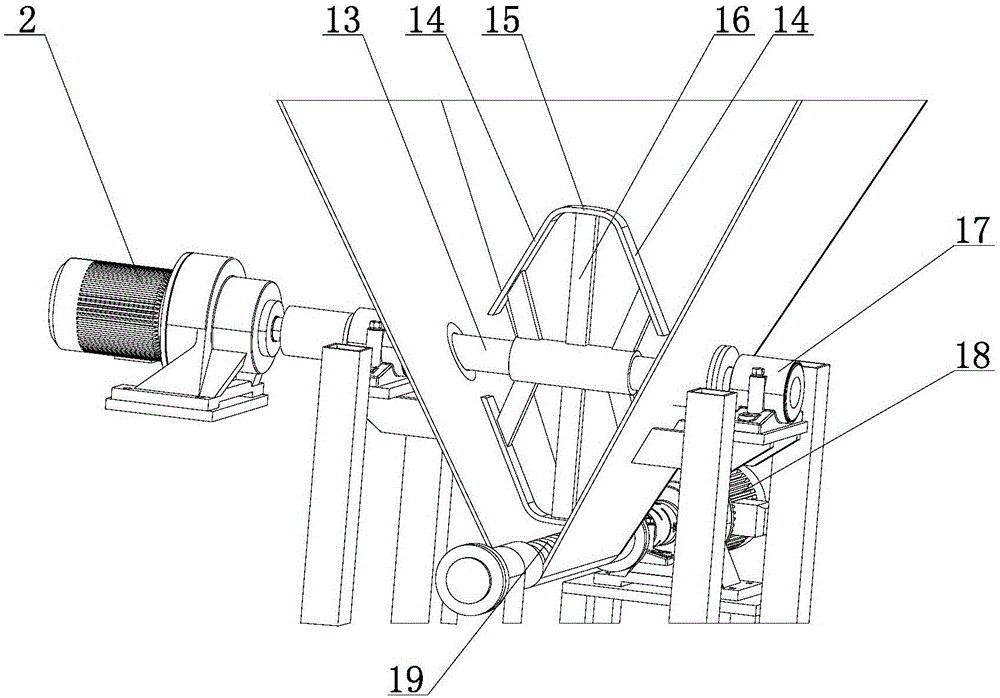

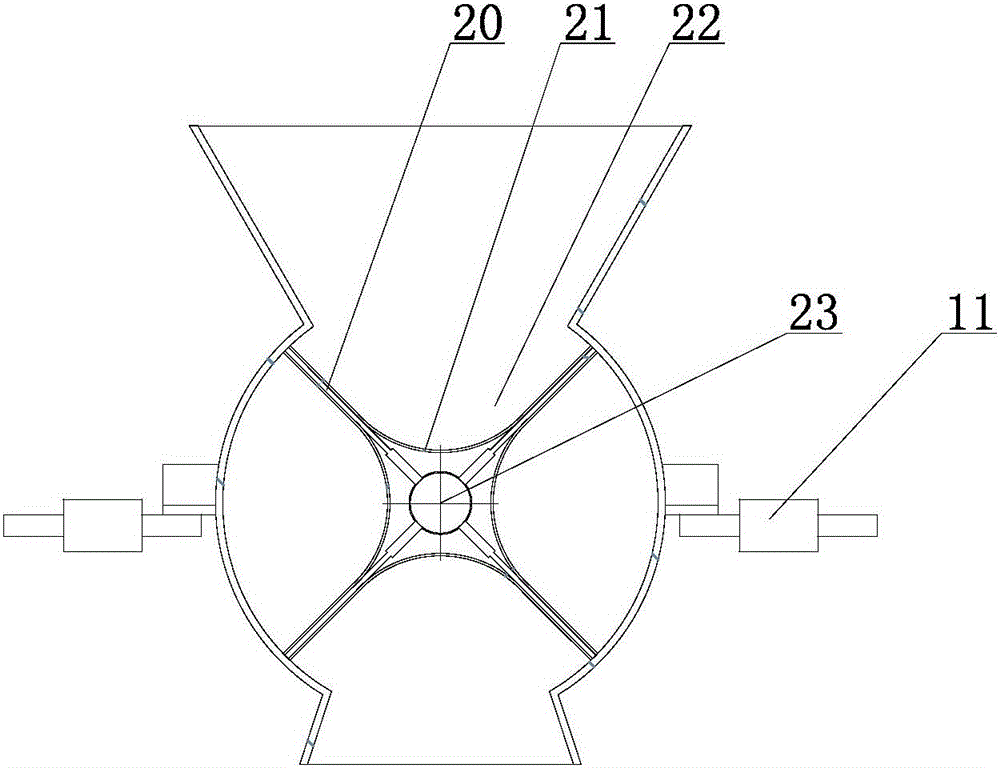

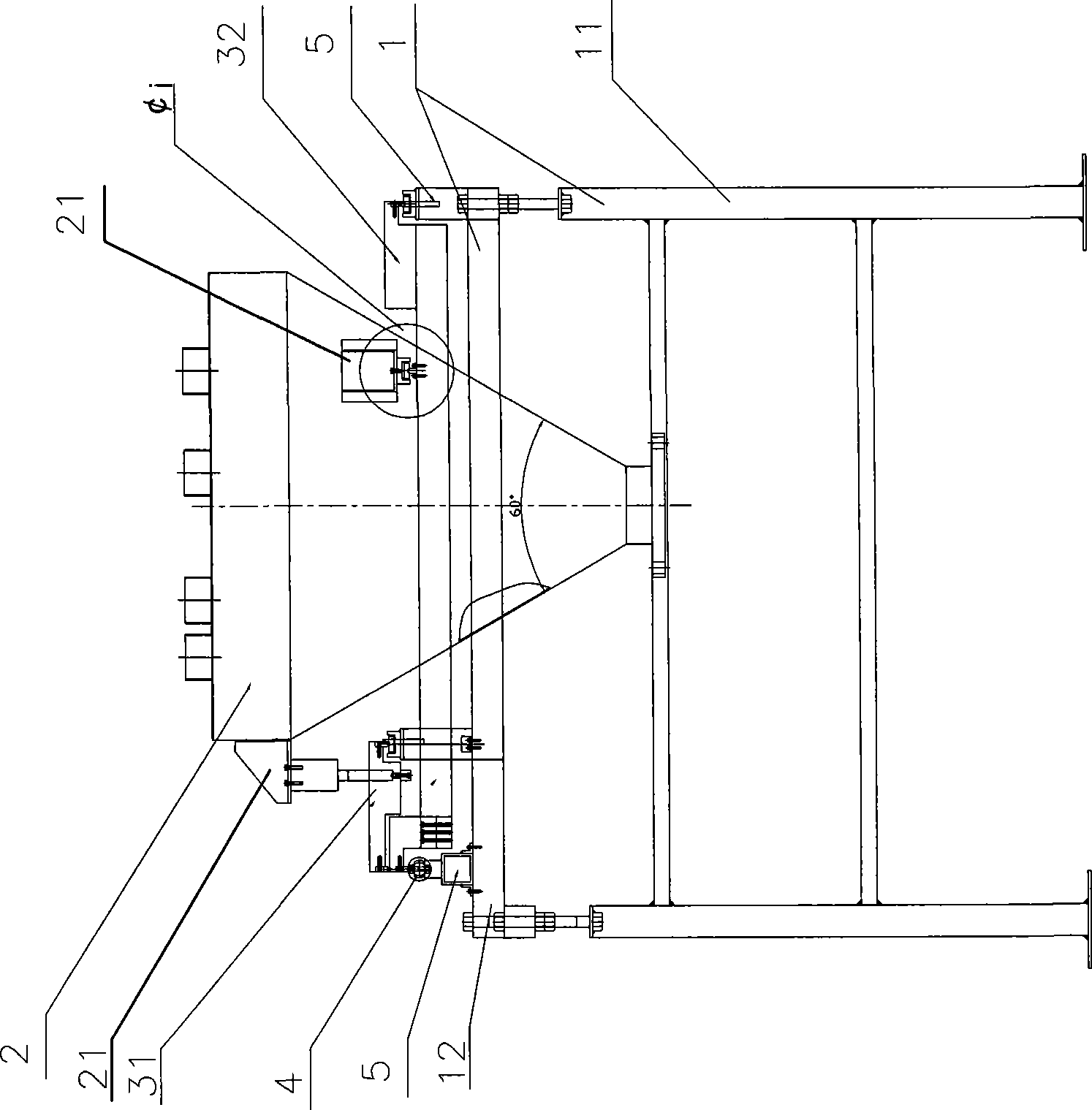

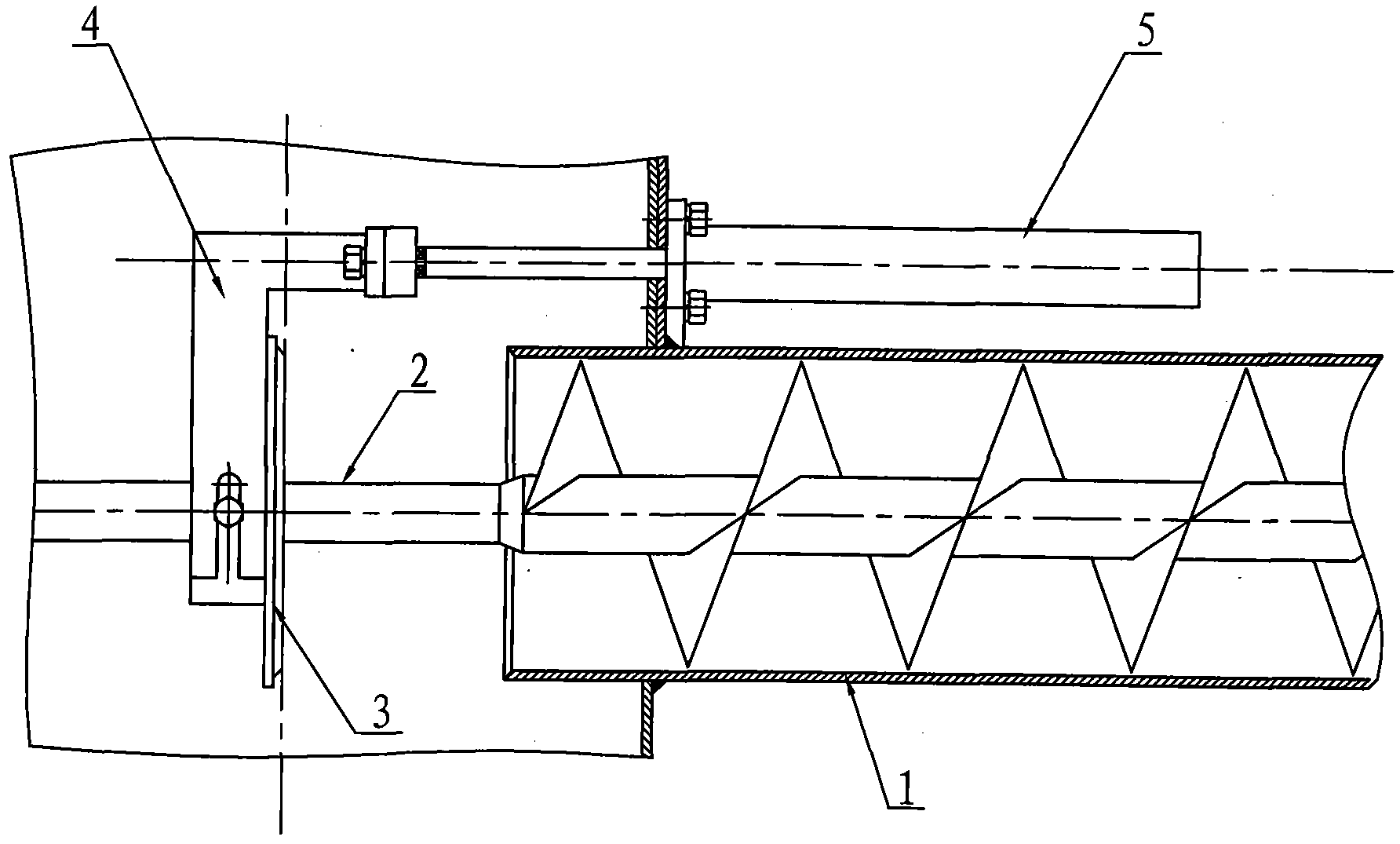

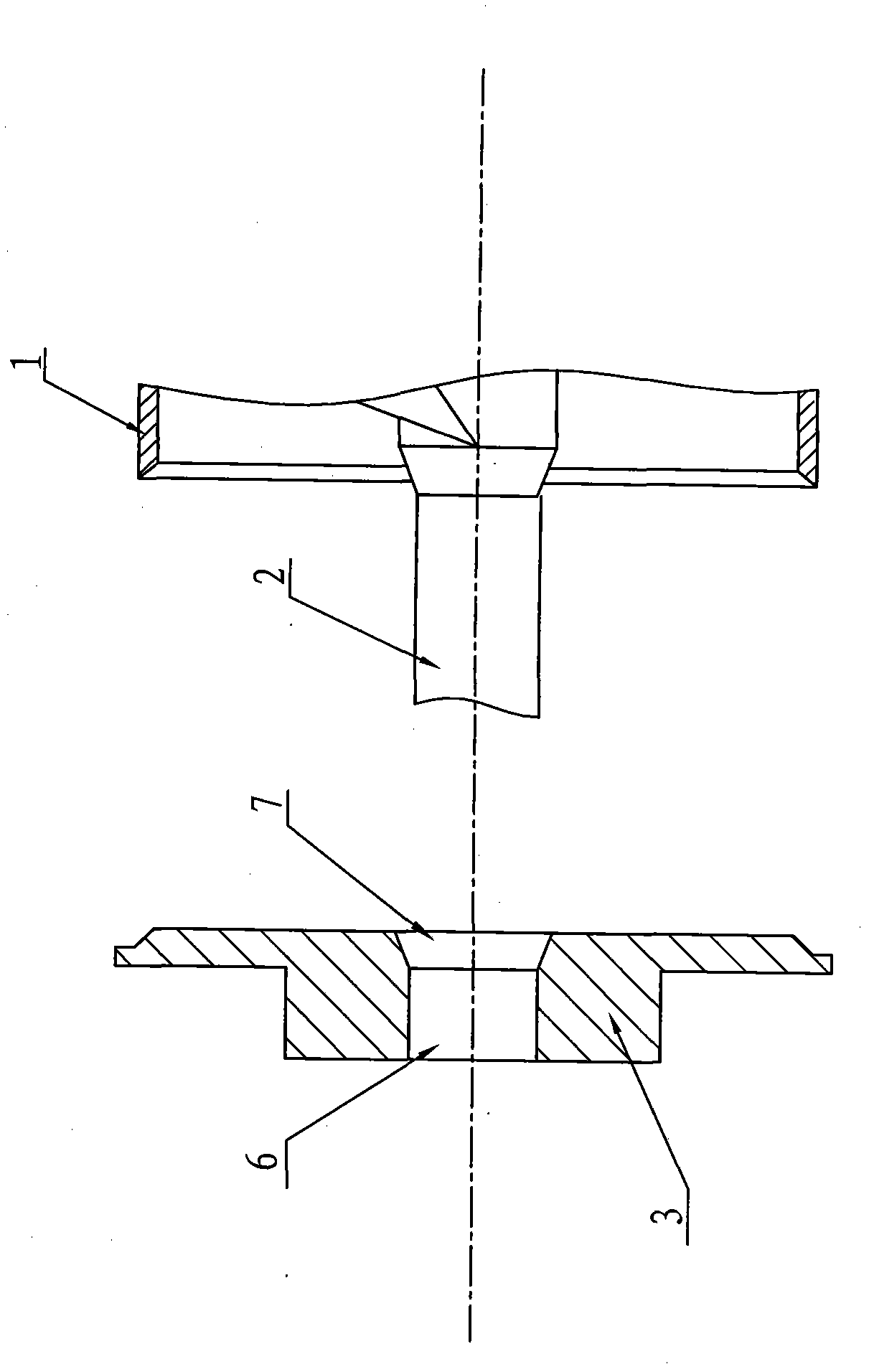

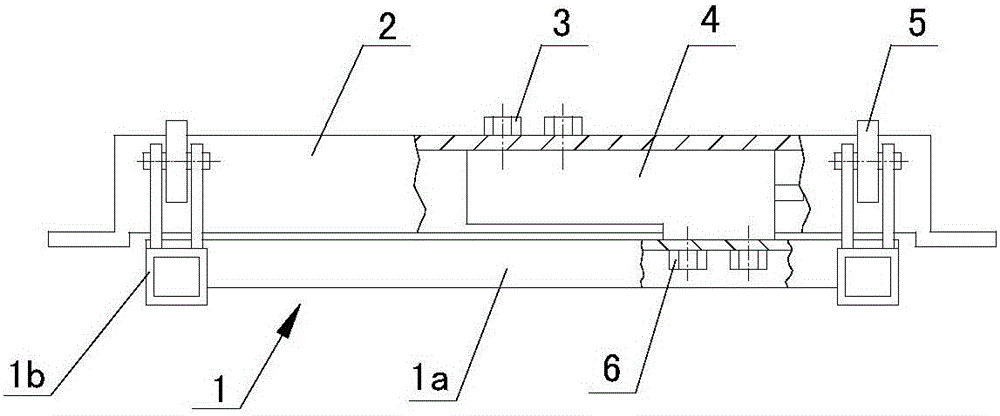

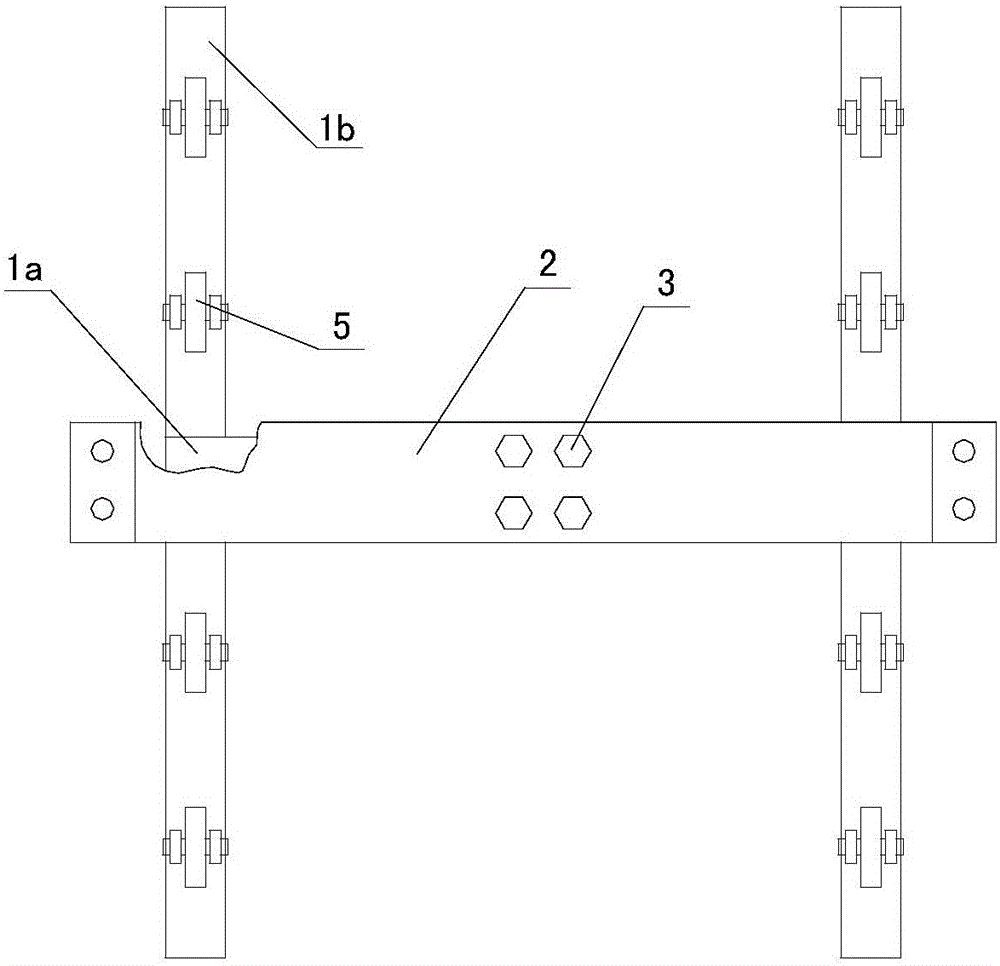

Weighing mechanism of electronic scale bale-reopening machine

InactiveCN101329194BGuaranteed weighing accuracyWeighing apparatus for materials with special property/formSpecial purpose weighing apparatusFiberEngineering

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

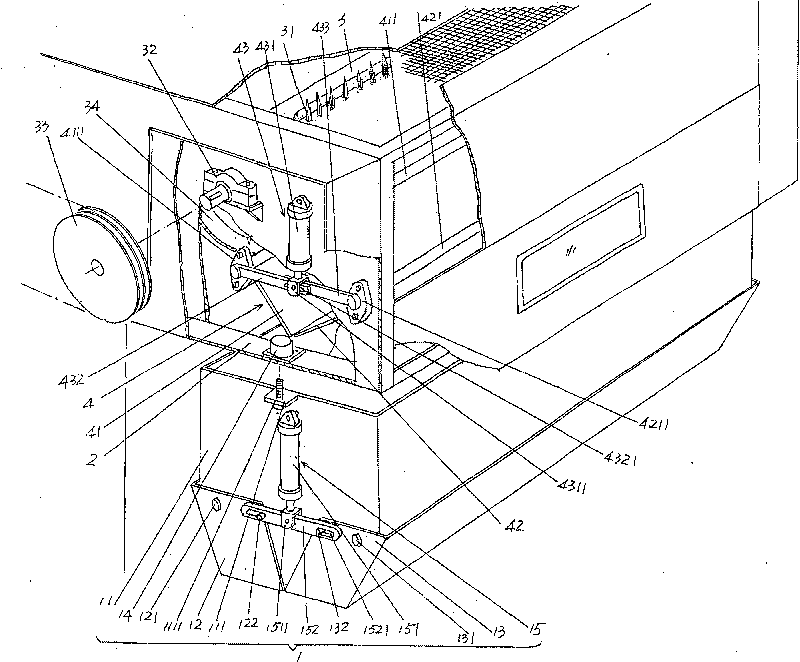

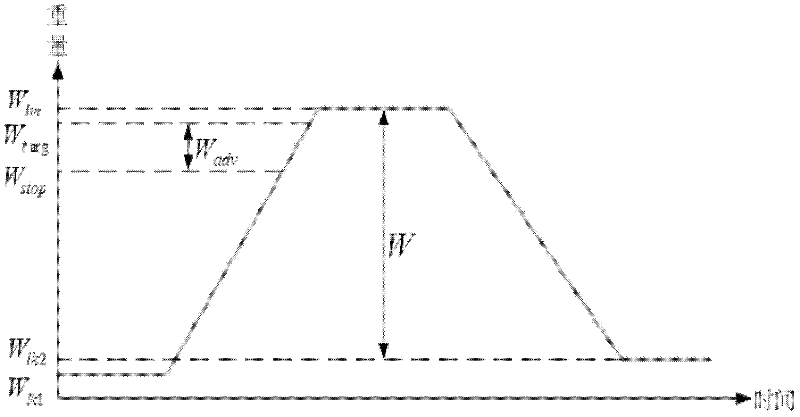

Blast furnace under-groove coke weighing control system without dispersing hopper

InactiveCN102344977AGuaranteed accuracyGuaranteed weighing accuracyBlast furnace componentsBlast furnace detailsControl systemComputer module

The invention discloses a blast furnace under-groove coke weighing control system without a dispersing hopper. The system comprises a control module and a centralized weighing hopper, wherein the control module successively controls a feeding machine, a vibrating screen and a coke belt to stop so that a material stored in a storage tank is fed to the centralized weighing hopper; and the centralized weighing hopper discharges the material according to the material under the control of the control module. In the blast furnace under-groove coke weighing control system without the dispersing hopper, a double-lead system is constructed according to an actual coke weighing curve without the dispersing hopper, thus the accuracy of weighing is ensured and a large amount of materials are not accumulated on the feeding equipment and the feed belt so as to prolong the service life of the equipment; and a self-correct system is constructed for factors influencing the accuracy of weighing, such asweighing back value, the lead and the like, thereby maximally ensuring the accuracies of single weighing and total feeding mass.

Owner:WISDRI ENG & RES INC LTD

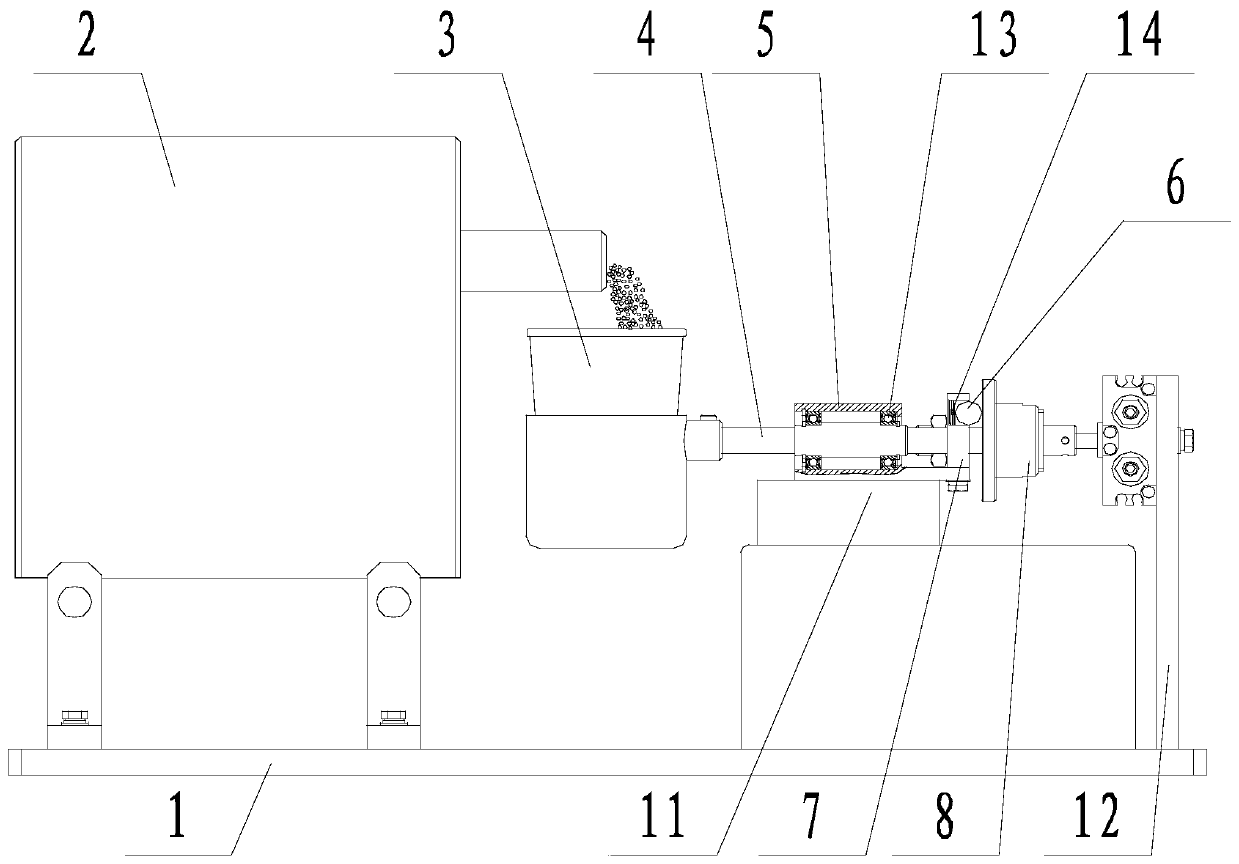

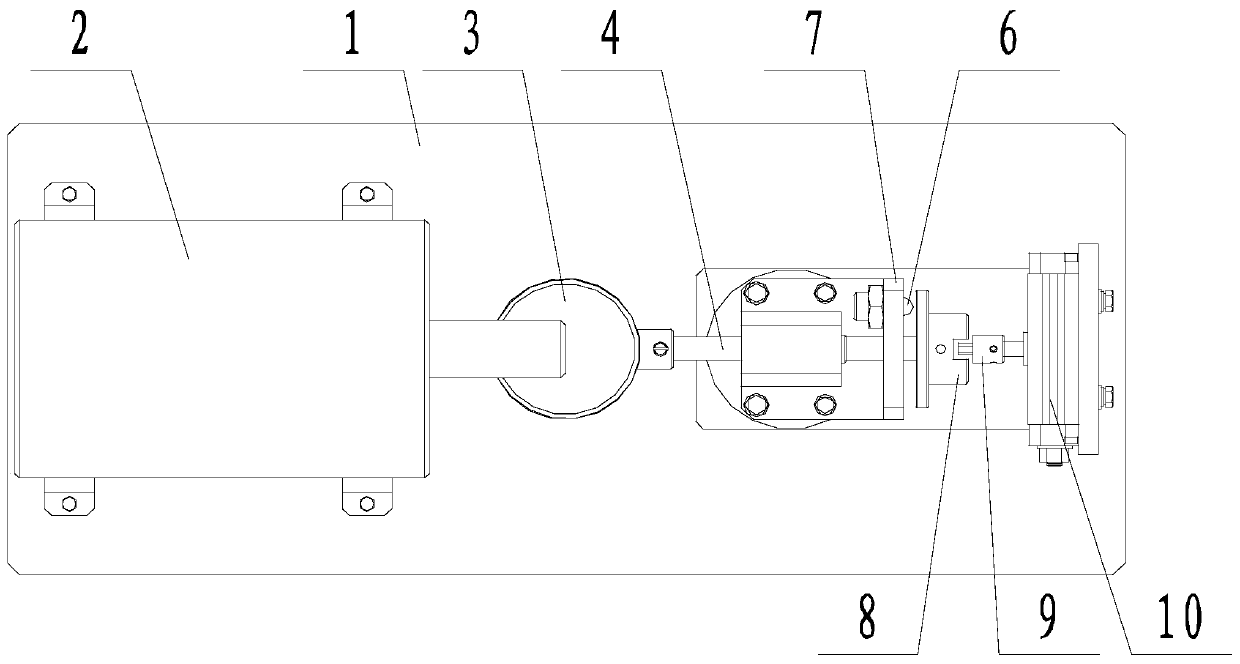

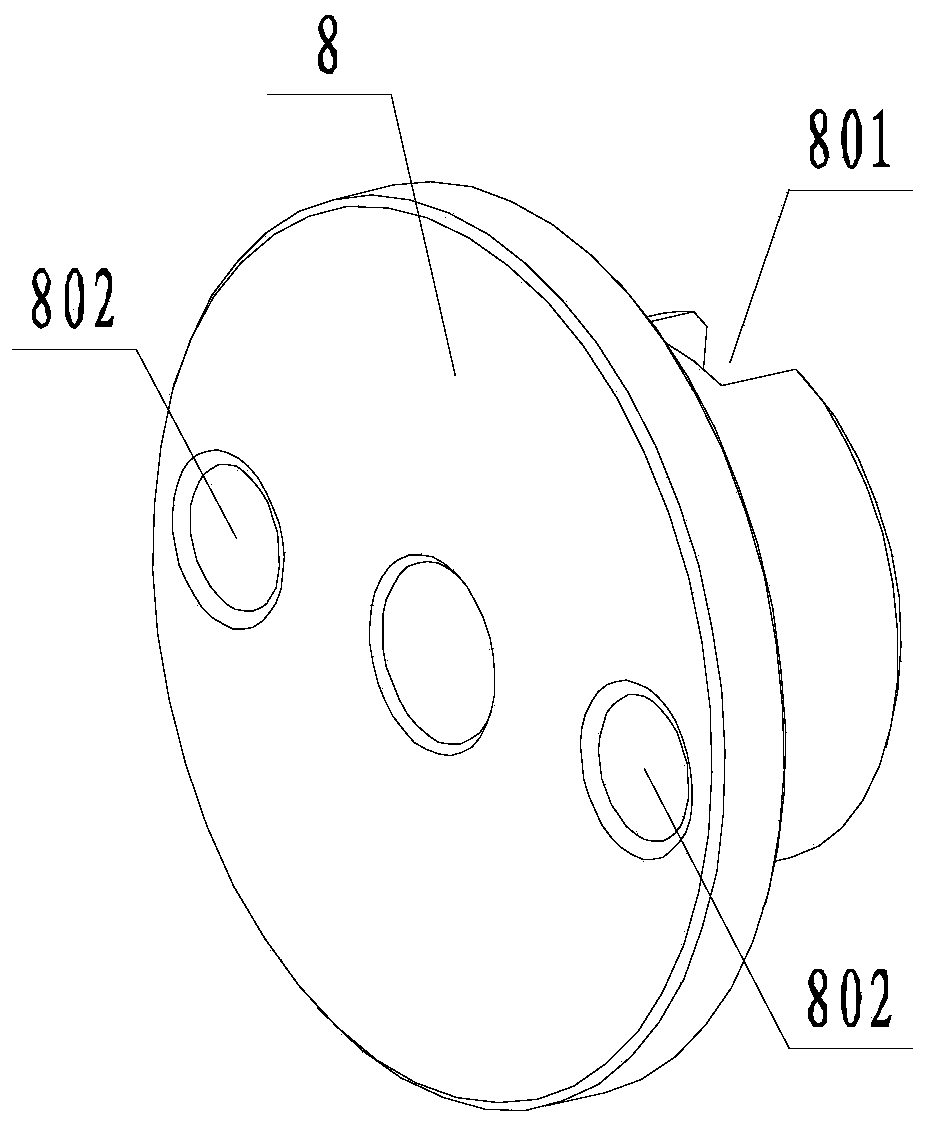

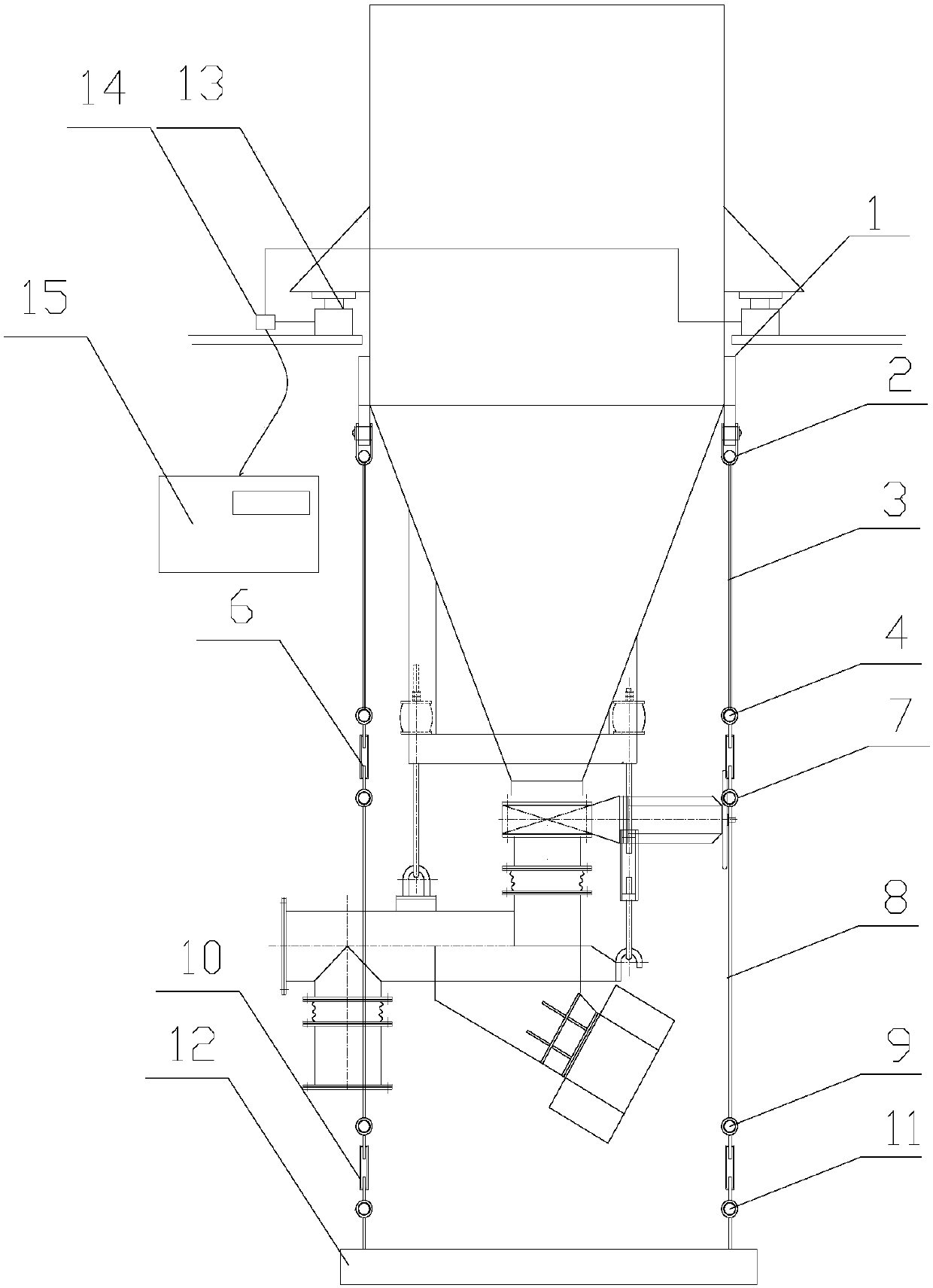

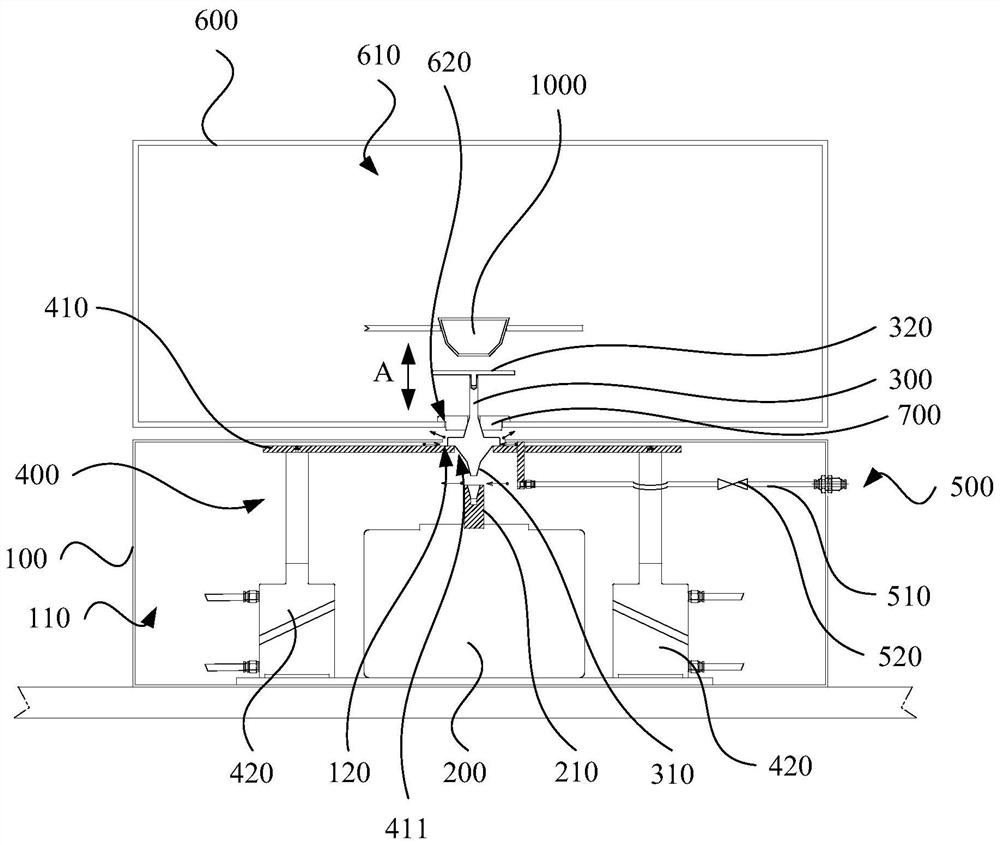

Automatic weighing and pouring device and method for energetic raw material

InactiveCN109752065AEnsure safetySuitable for accurate weighingWeighing apparatus with automatic feed/dischargeDrive shaftMan machine

The invention discloses an automatic weighing and pouring device and method for an energetic raw material. The device comprises a feeding mechanism and a weighing material cup positioned below a discharging hole of the feeding mechanism; the weighing material cup is fixedly connected with a driving shaft; the weighing material cup can rotate along with the driving shaft; one end, far away from theweighing material cup, of the driving shaft is fixedly connected with a shifting fork; the device further comprises a rotating device; the rotating device is used for driving a shifting block to rotate; the shifting fork can rotate along with the shifting block; the device further comprises a weighing sensor; and the weighing sensor is used for monitoring the weight change of the weighing material cup. According to the automatic weighing and pouring device and method for the energetic raw material, the problems of low weighing and pouring efficiency, low automation degree, high potential safety hazard and complex structure of the initiating explosive device and civil explosion industry in the prior art are solved, so that the purposes of improving the automation degree, realizing the man-machine separation and ensuring the personnel safety are achieved.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

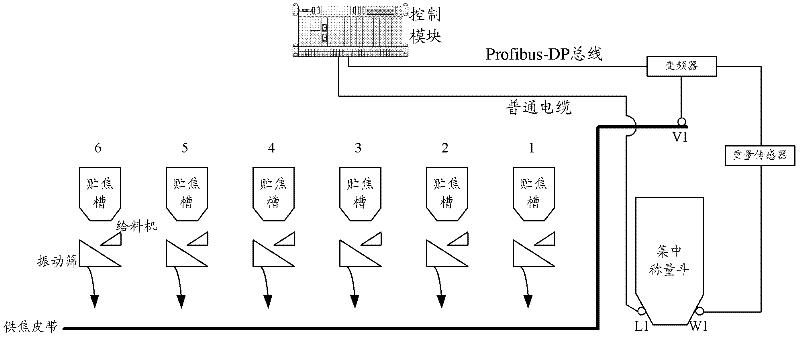

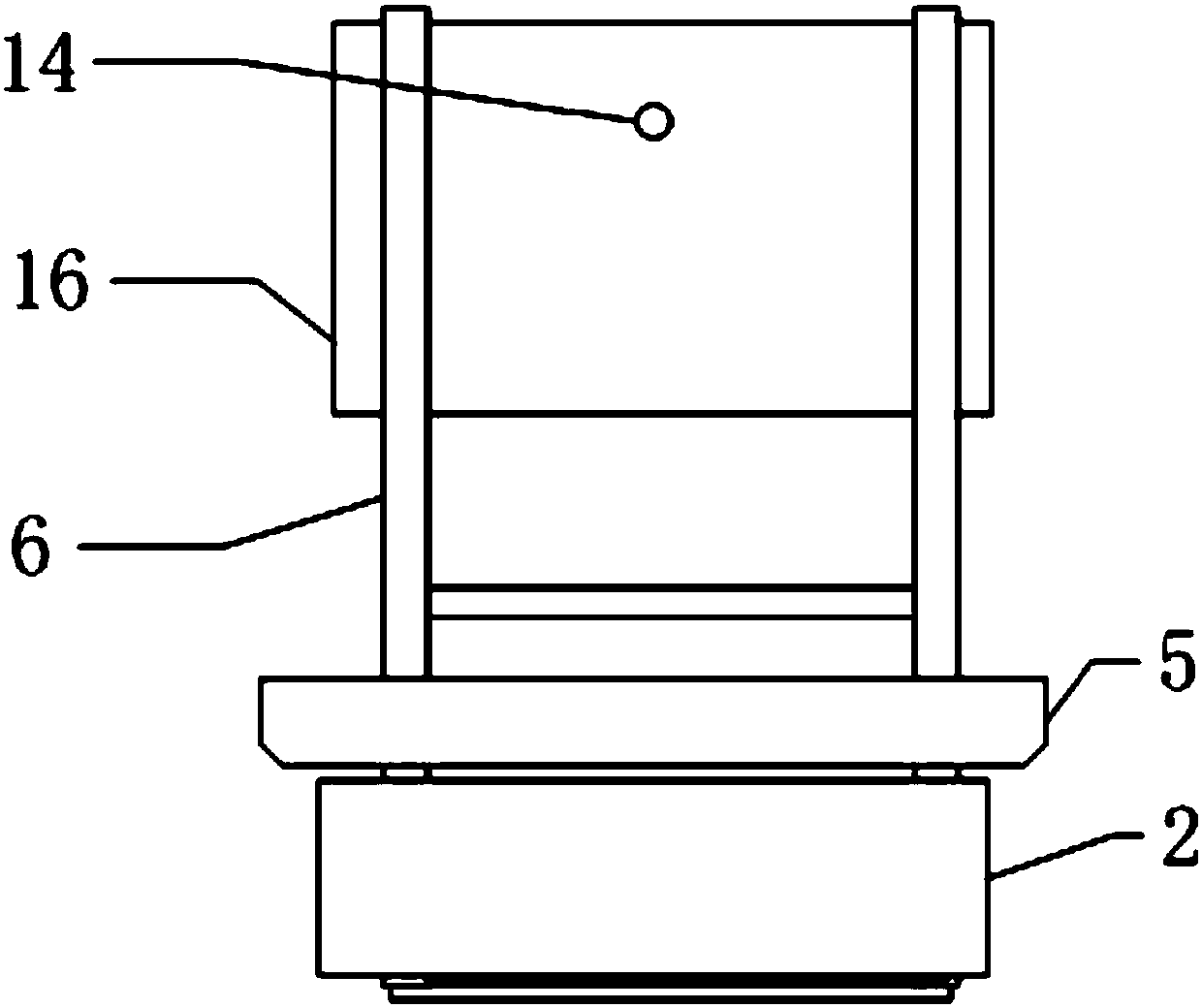

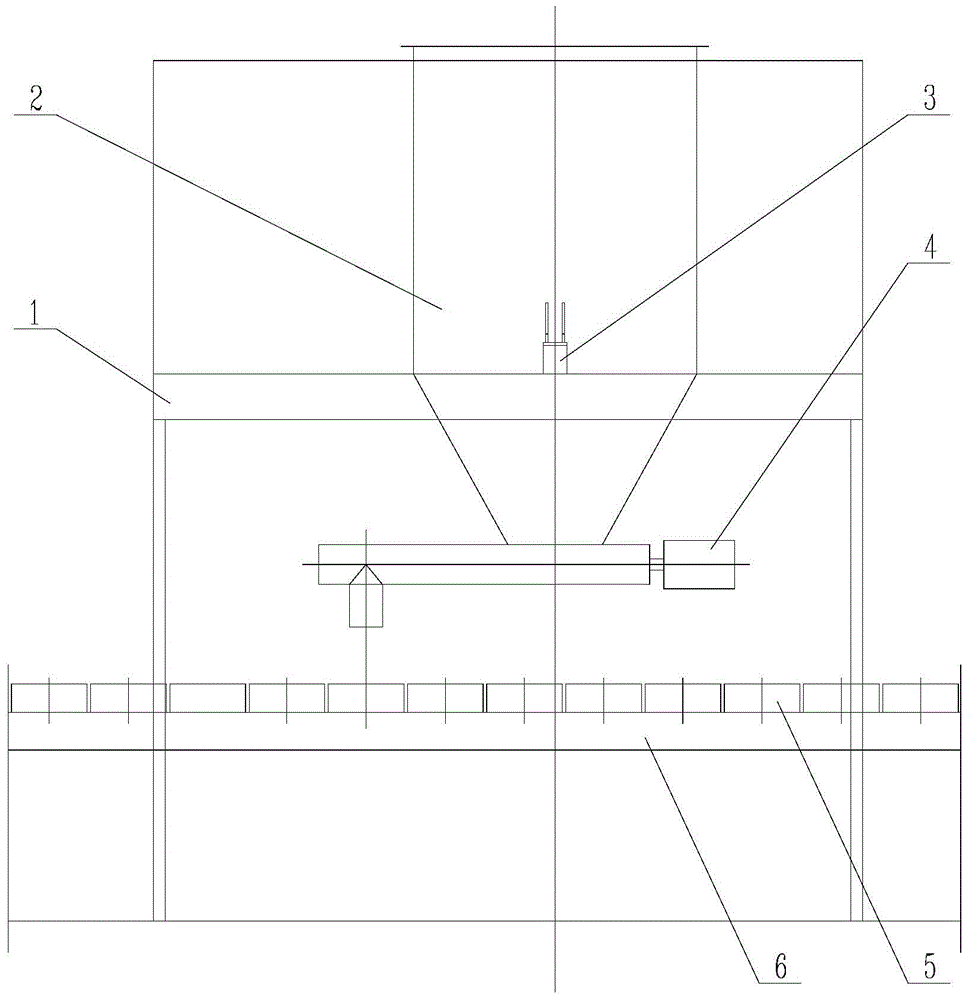

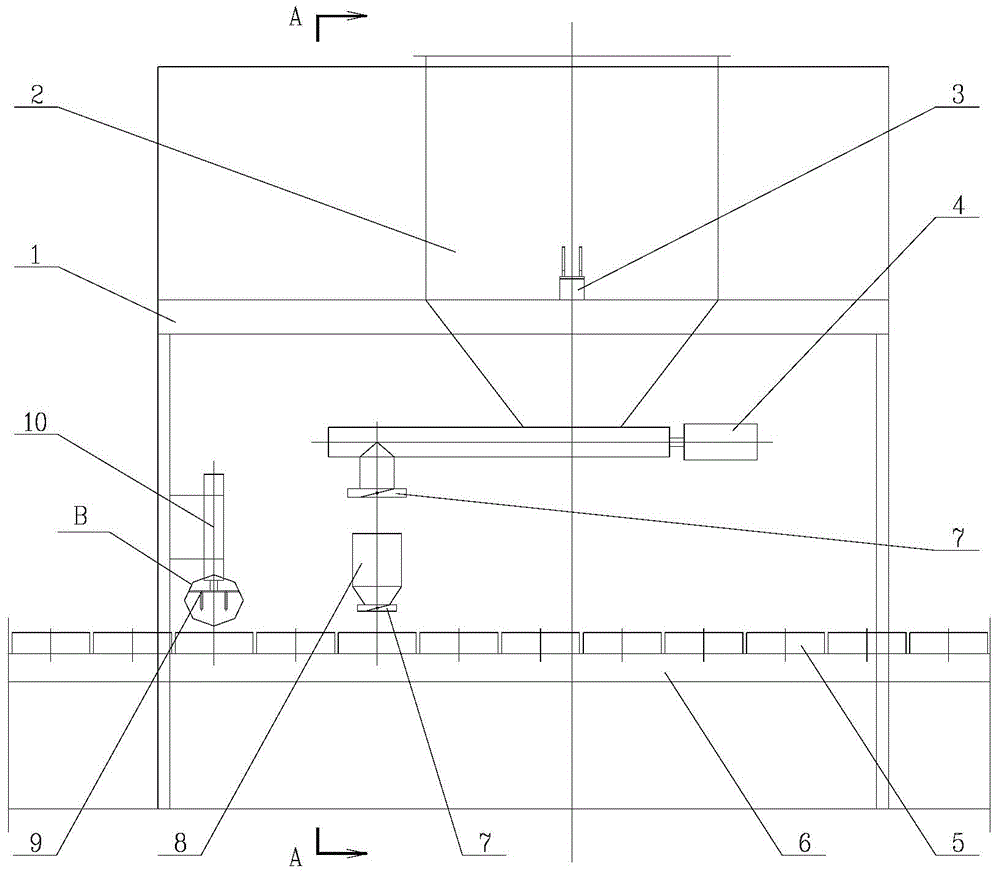

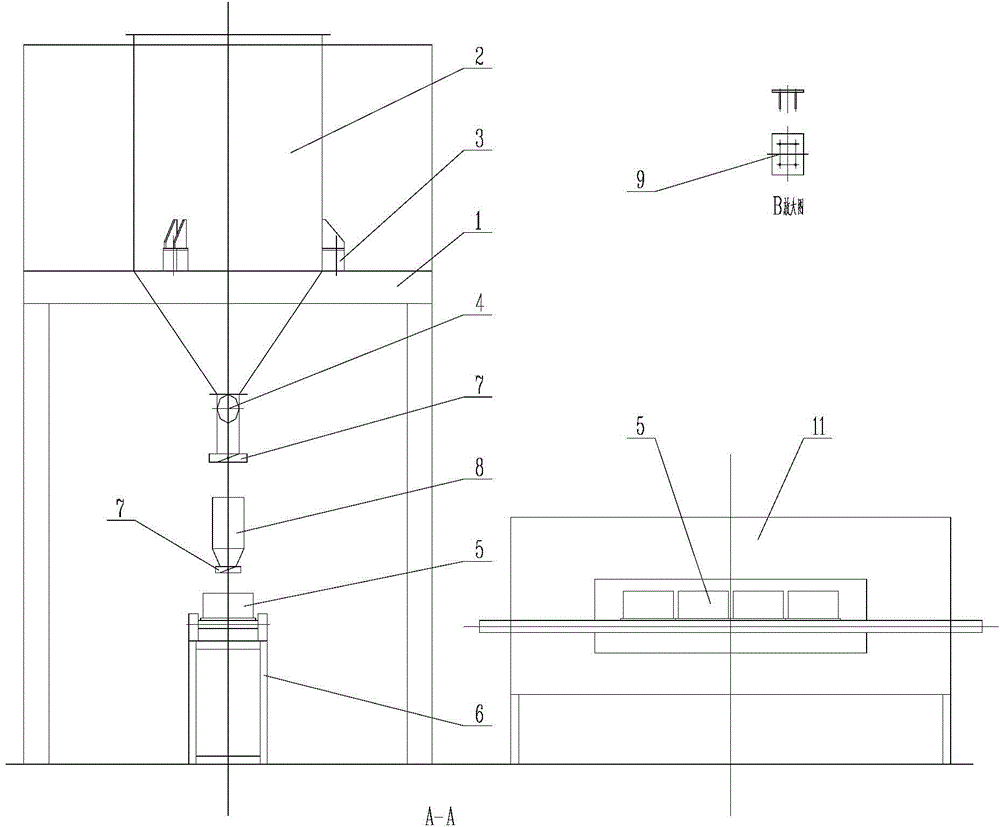

Blast furnace multiple-material preparation system and method in concentrated weighing mode

InactiveCN104911291AMeet the accuracyNot prone to problems such as stackingBell-and-hopper arrangementBlast furnace detailsMaterials preparationEngineering

The invention provides a blast furnace multiple-material preparation system and method in a concentrated weighing mode. The system comprises a conveyor belt; a plurality of ore bins are orderly arranged above the conveyor belt in the length direction; feeders and ore vibrating screens are orderly arranged up and down between the ore bins and the conveyor belt; the feeders and the ore vibrating screens are as many as the ore bins and correspond to the ore bins one to one; an ore concentrated weighing hopper is arranged under the tail end of the conveyor belt; the conveyor belt is connected with a conveyor belt motor. The material preparation system is capable of realizing concentrated weighing preparation of a plurality of types of ores, and also capable of guaranteeing the weighing accuracy of the ores, and therefore, the distribution requirements of complex blast furnace charge are met and the production efficiency and production quality of the blast furnace are effectively improved; besides, the system is high in automation degree; the labor intensity of the operating personnel is low; meanwhile, the system has relatively high safety, and the problems of material accumulation, electrical apparatus overload and the like can be avoided.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

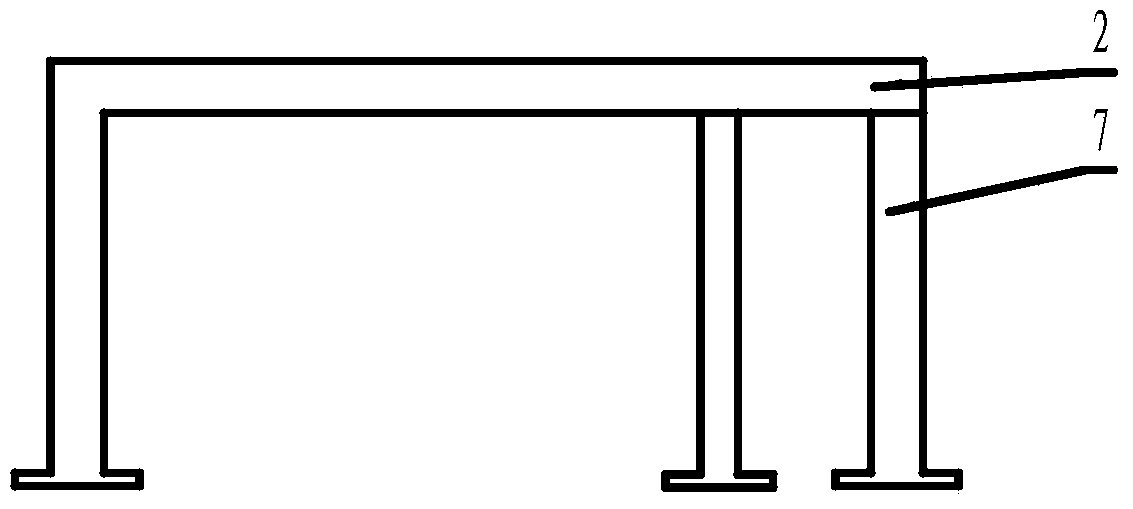

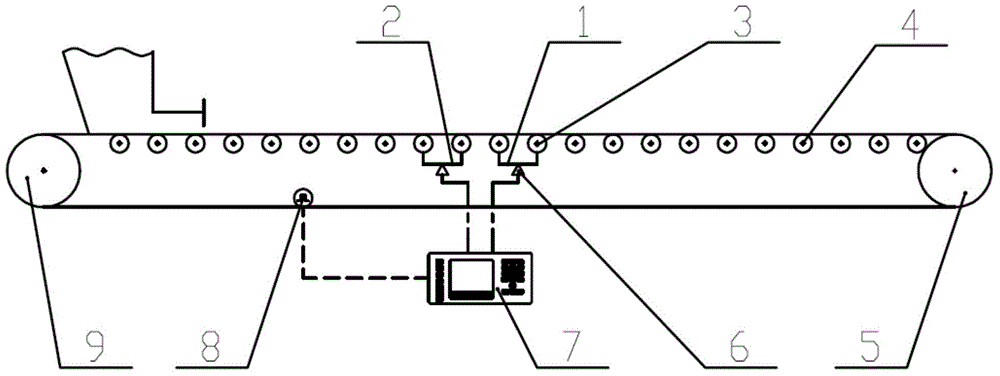

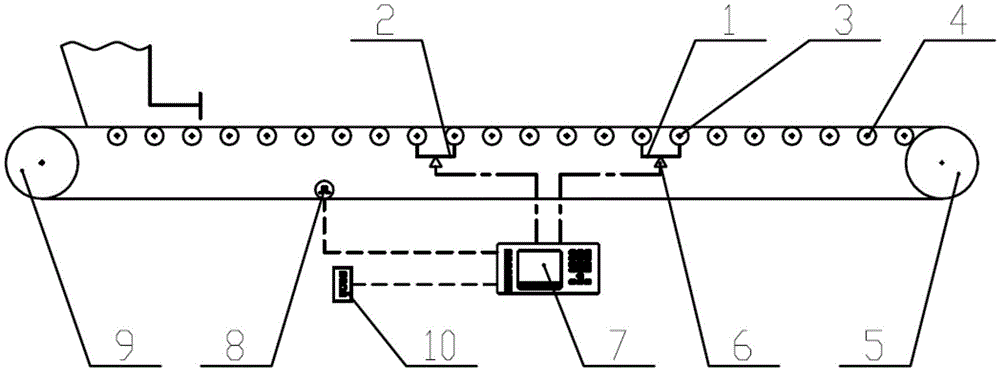

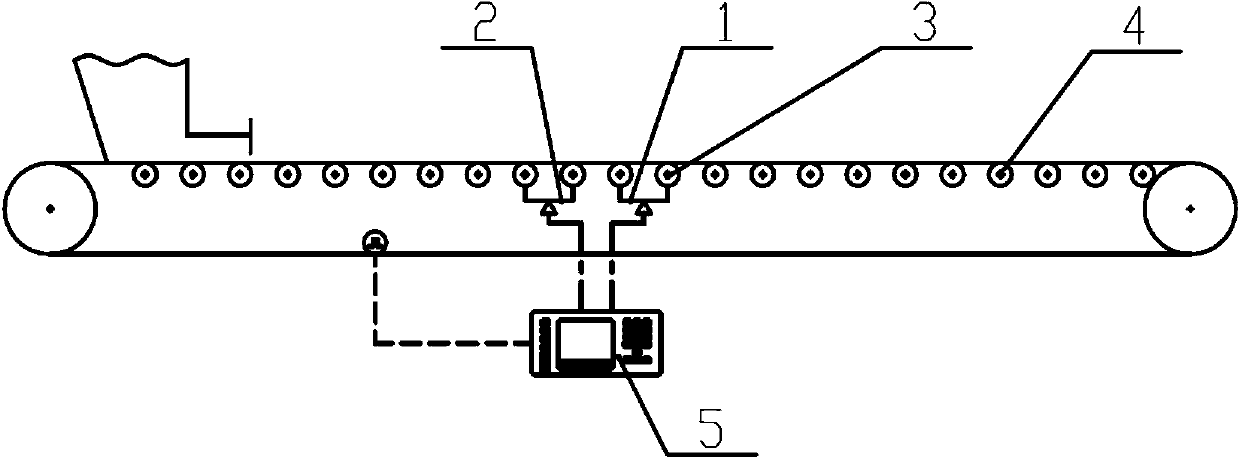

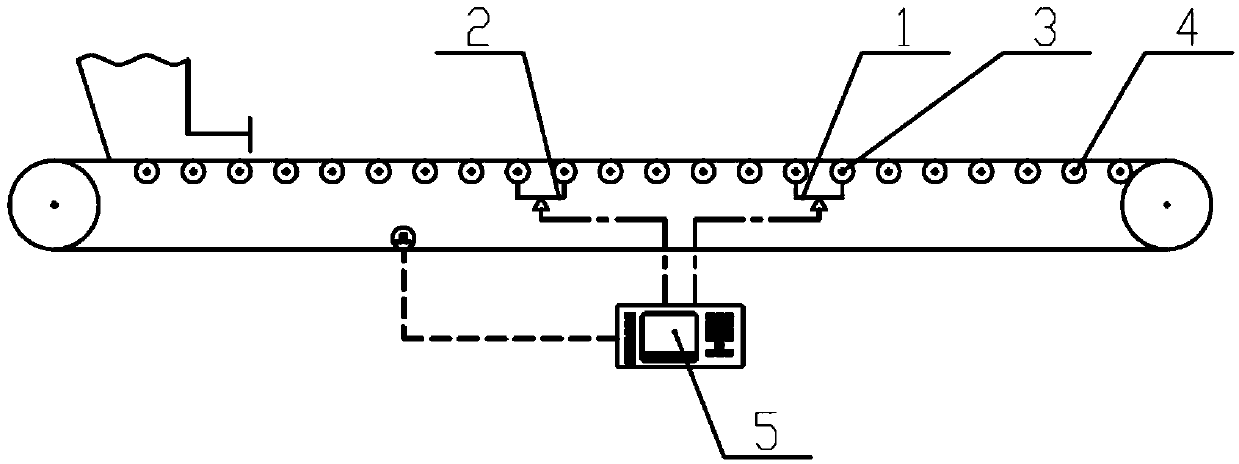

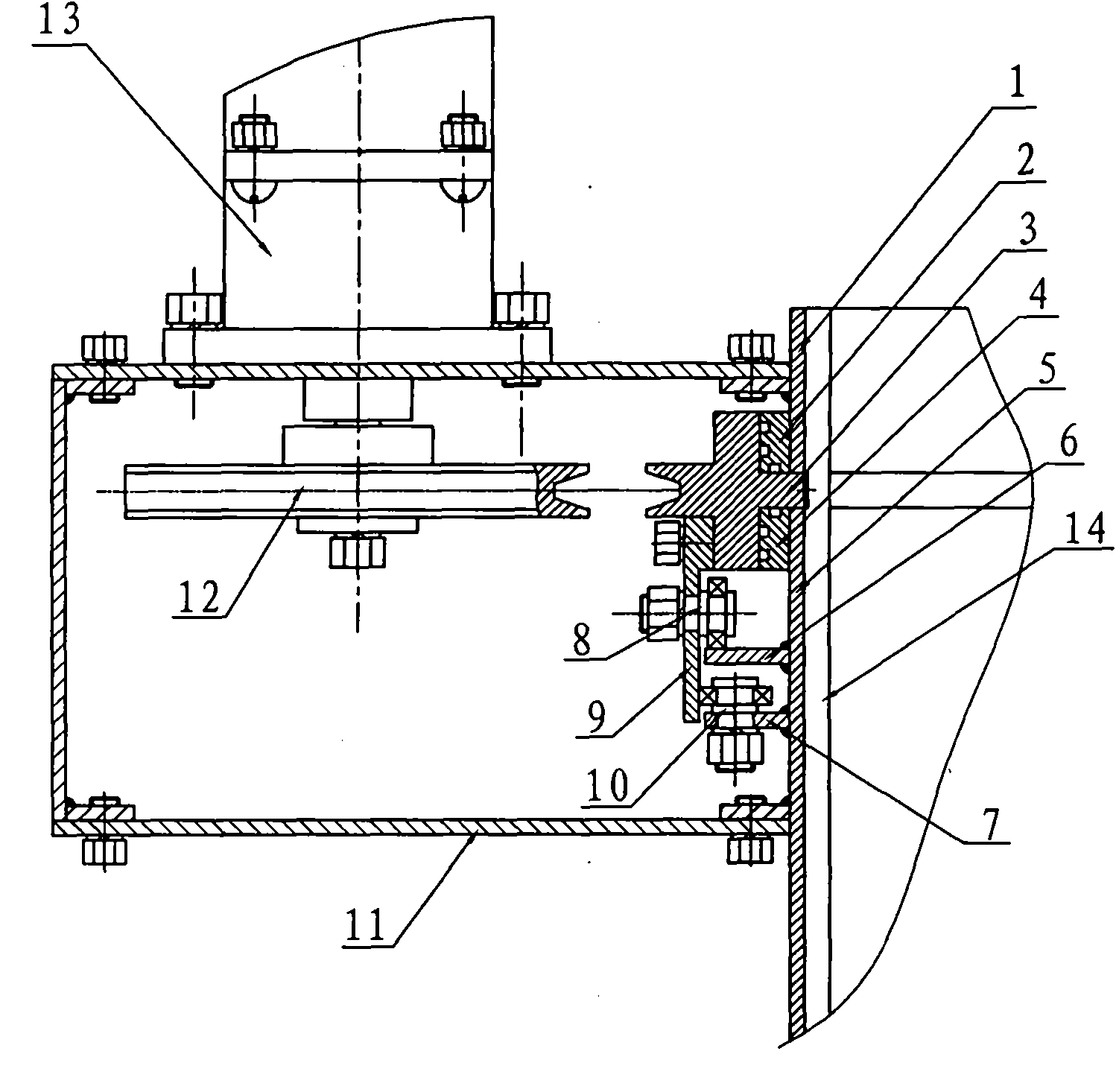

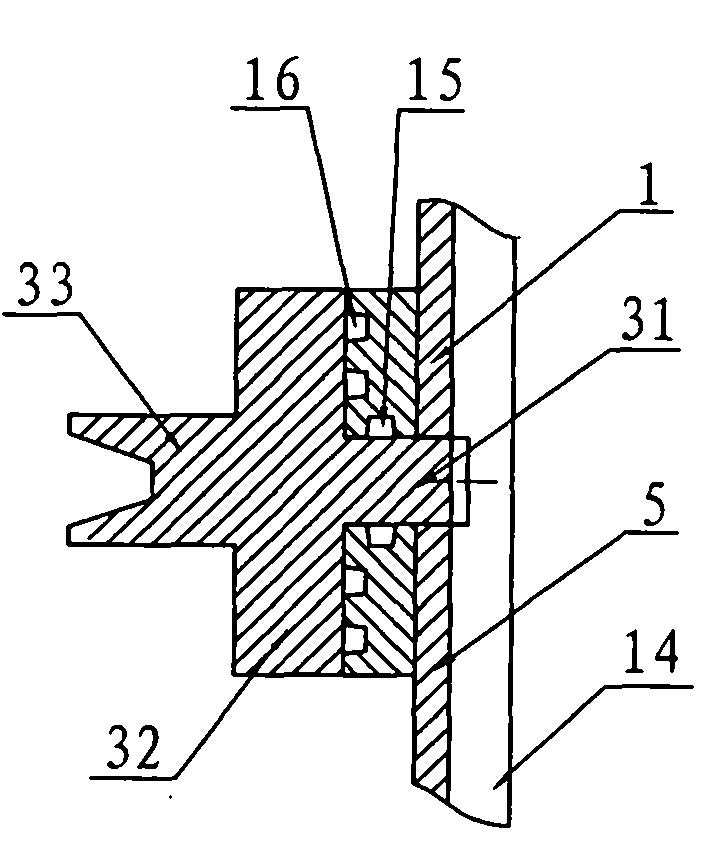

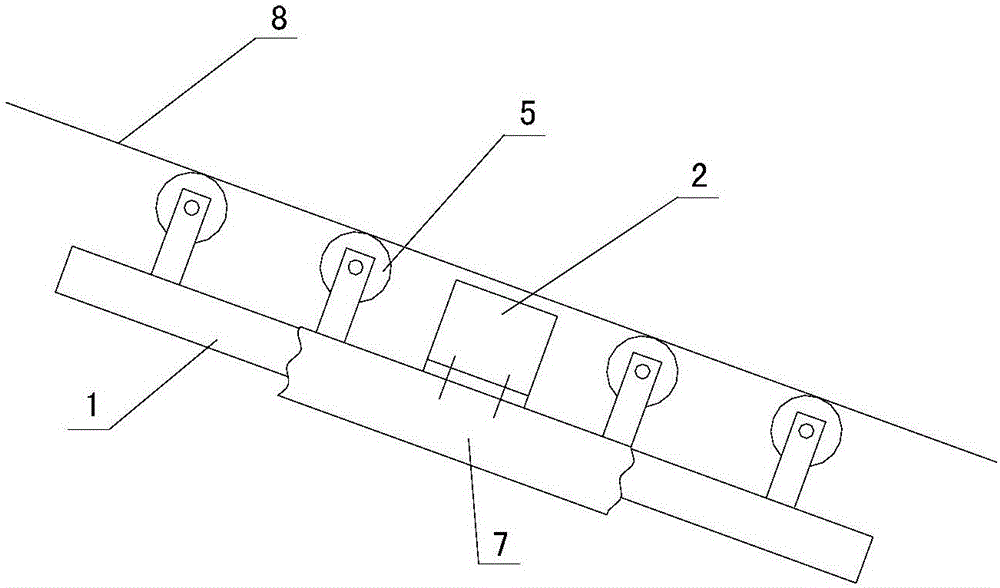

High-stability electronic belt scale and stability compensating method thereof

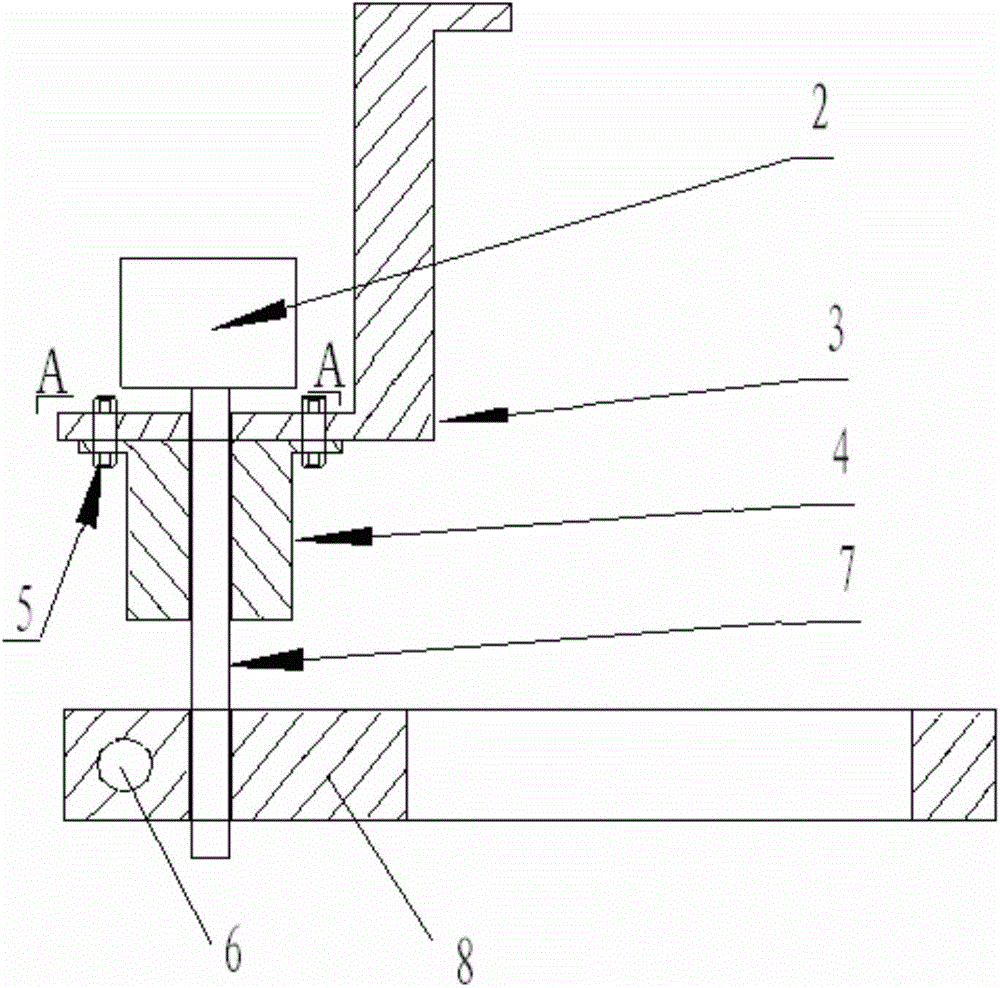

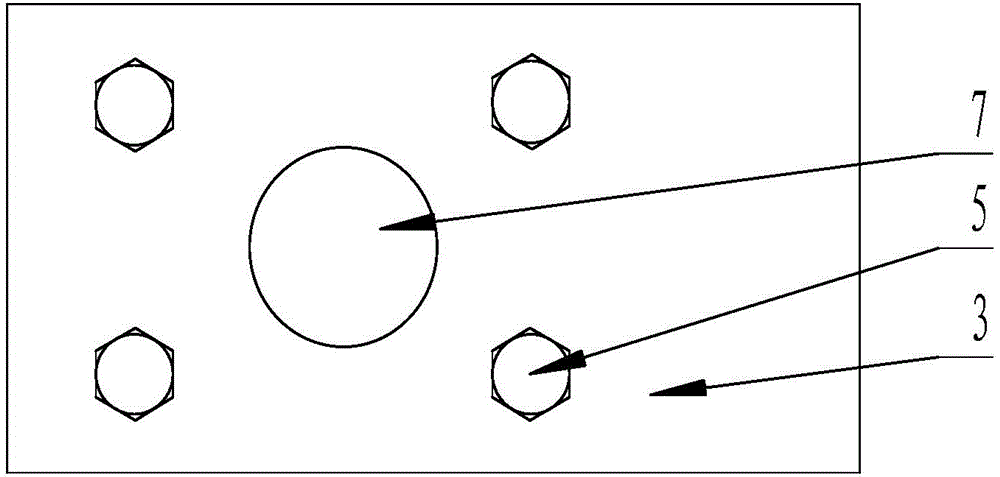

InactiveCN104154974AGuaranteed stabilityGuaranteed weighing accuracyWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowEngineeringHardness

The invention discloses a high-stability electronic belt scale and a stability compensating method thereof. The electronic belt scale comprises a front weighing scale rack (1), a back weighing scale rack (2), a weighting instrument (7) and a speed sensor (8), wherein output signals of each weighting sensor in each of the front weighing scale rack and the back weighing scale rack are respectively sent to the weighting instrument (7). According to the stability compensating method, when the belt scale is in calibration and normal operation zero adjustment under the condition of an empty belt, the weighting instrument (7) respectively detects and calculates the weight error, of the same empty belt, detected by the front weighing scale rack and the back weighing scale rack at the same time, the deviation error is obtained through the weight error, the range calibration number is obtained through the biased error, and the amended range calibration number is used for weighting, so that the influence on measuring accuracy caused by hardness change of the belt is compensated, and the stability and the weighing accuracy of belt scale weighing are ensured. Meanwhile, normal use of the belt scale cannot be influenced, the use is fast and convenient, the cost is low, and the project realization is facilitated.

Owner:SAIMO ELECTRIC

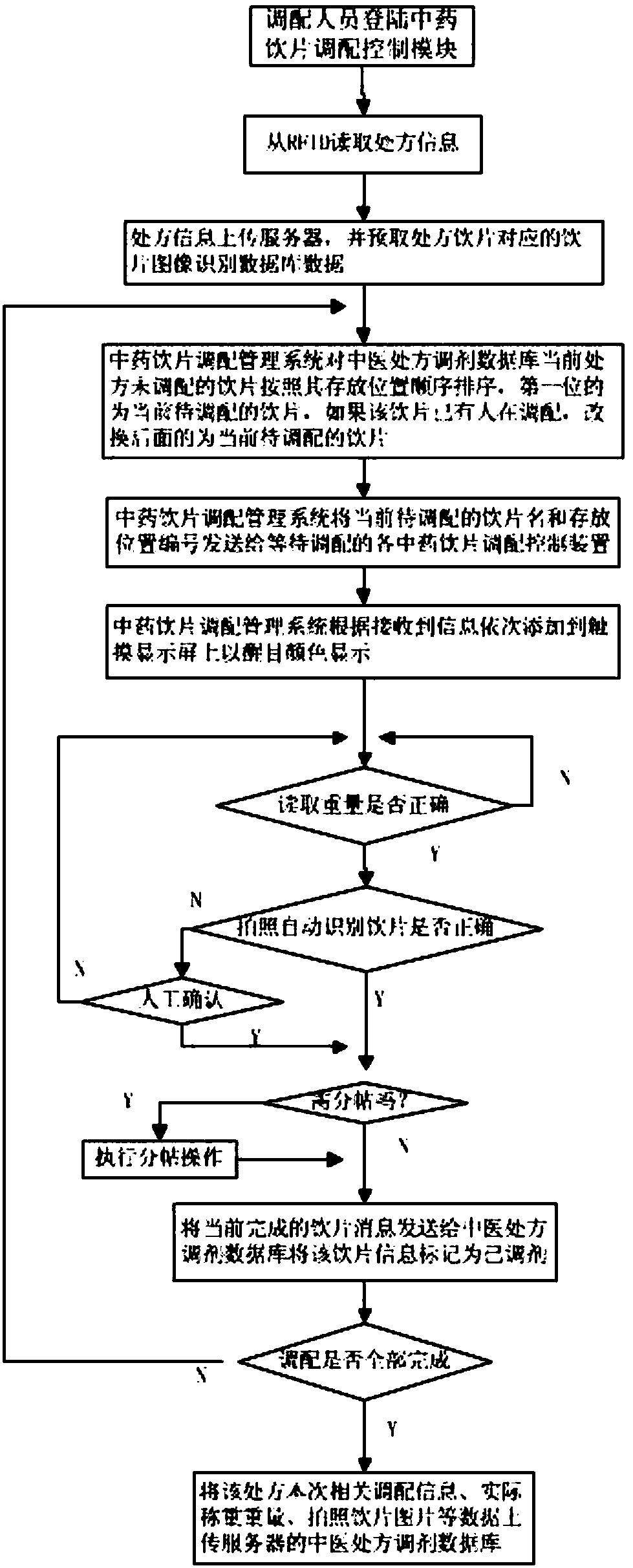

Intelligent Chinese herbal piece dispensing control and management system and method

ActiveCN107680644AEasy to operatePromote the level of intelligenceDrug and medicationsCo-operative working arrangementsWireless routerView camera

The invention provides an intelligent Chinese herbal piece dispensing control and management system comprising a server, a wireless router and a Chinese herbal piece dispensing control device; the Chinese herbal piece dispensing control device comprises an operating system, an electronic scale and a prescription label reading device; the operating system comprises a Chinese herbal piece dispensingcontrol module, a USB interface module, a wireless communication module, a rear-view camera and a touch display screen; and the wireless communication module is in signal connection with the server through the wireless router. The invention also provides an intelligent Chinese herbal piece dispensing control and management method. By means of intelligent management of the intelligent Chinese herbal piece dispensing control and management system, each decoction piece in the prescription is weighed, recognized and distributed, once the case that a decoction piece is taken wrongly during the dispensing process is discovered, the case can be corrected immediately, the operation process and the intelligent level of decoction piece dispensing are optimized, and therefore in the whole Chinese herbal piece dispensing working link, the efficiency and the management level are greatly improved.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Fly ash curing treatment system

ActiveCN104492790APrevent intrusionGuaranteed weighing accuracySolid waste disposalWater vaporFly ash

The invention provides a fly ash curing treatment system. Lots of dust-containing water vapor in a stirrer is effectively prevented from entering a weighing body to avoid material hardening on a weighing body discharge door and inside of the weighting body, the weighing precision is guaranteed, and normal blanking operation is guaranteed. The fly ash curing treatment system is characterized by comprising a fly ash weighing bin and an agent weighing bin, wherein a fly ash bin is connected with the fly ash weighing bin by virtue of a valve; an agent bin is connected with the agent weighing bin by virtue of a valve; the fly ash weighing bin and the agent weighing bin are respectively connected with a first stirrer by virtue of valves; and a mixed stirrer is connected with a second stirrer by virtue of the valve.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

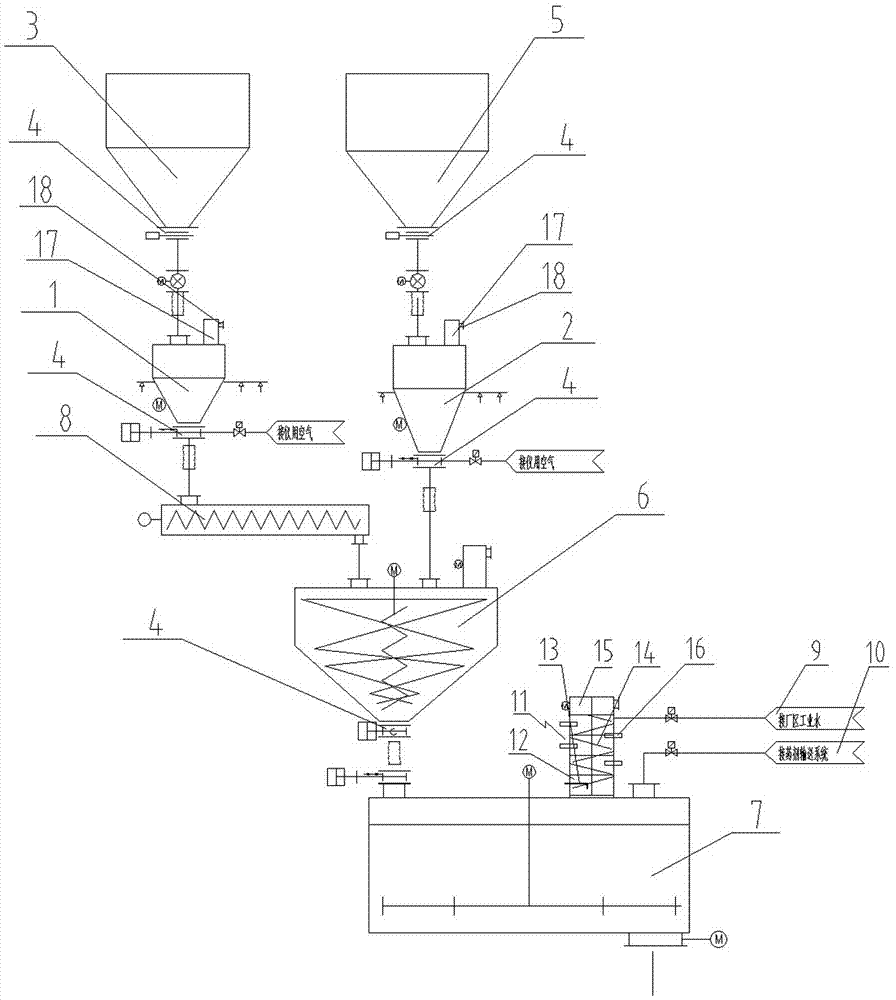

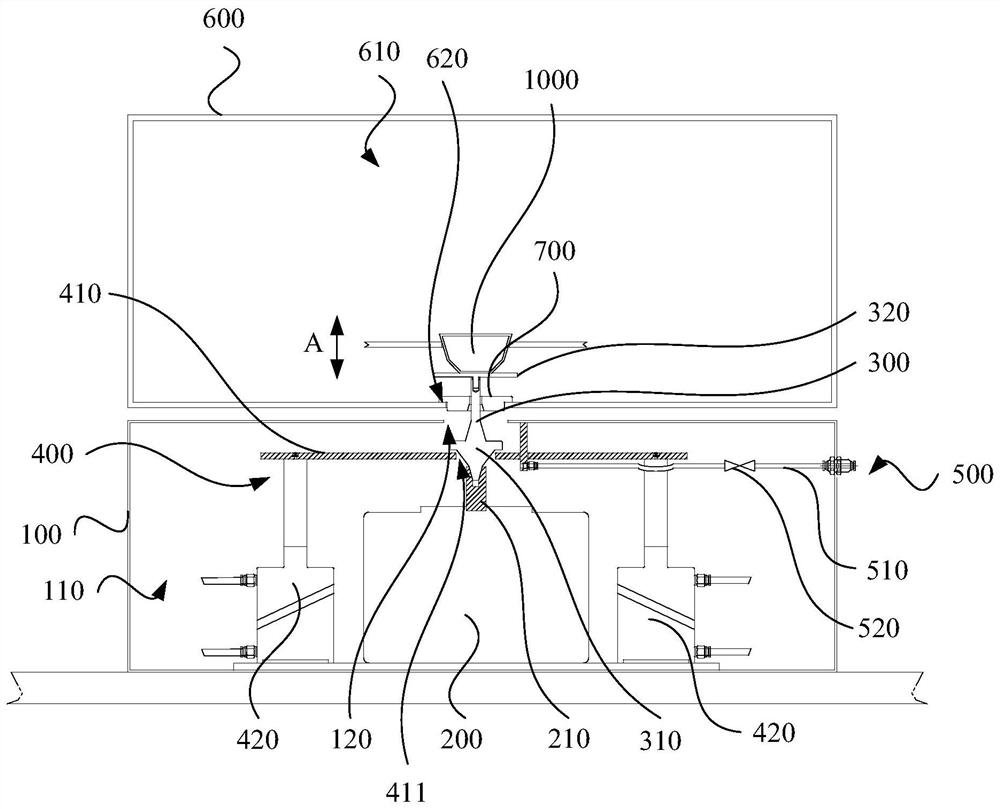

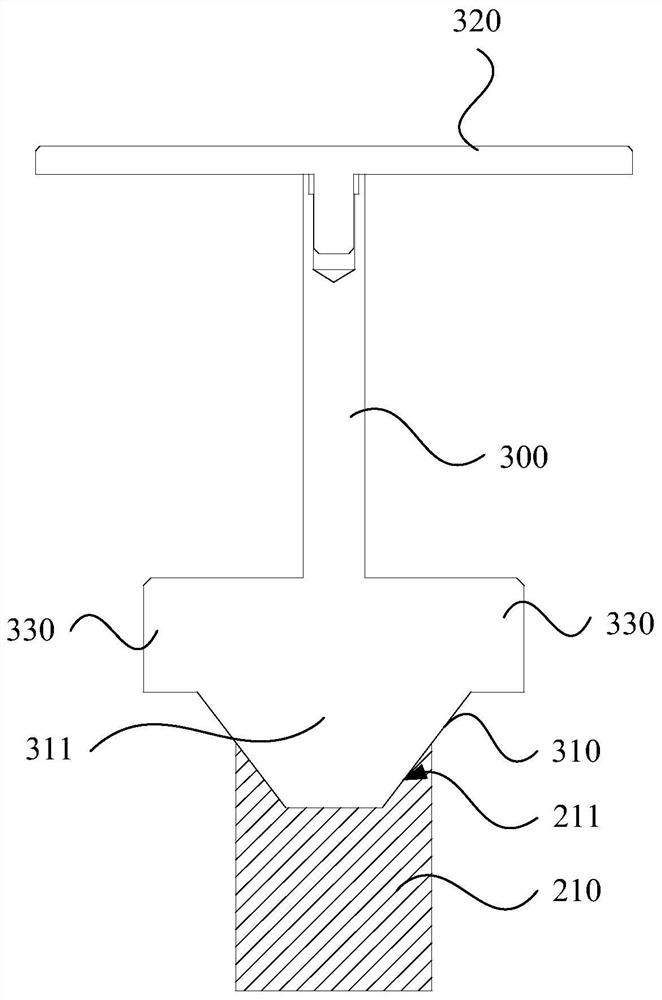

Furnace top feeding device of semi-closed submerged arc furnace

ActiveCN103884188AReal-time monitoring of weight changesQuantity detection continuousCharge manipulationWeight changeEngineering

A furnace top feeding device of a semi-closed submerged arc furnace comprises a weighing stock bin, a finger valve, a hydraulic gate valve, a herringbone feed tube, an inclined feed tube and a feed nozzle. The weighing stock bin is fixed to a weighing stock bin floor, a lower opening of the weighing stock bin is connected with the finger valve and the hydraulic gate valve, the herringbone feed tube is fixed to a feed tube mounting floor, an upper end opening of the herringbone feed tube is connected with a discharging pipe of the hydraulic gate valve, an upper end opening of the inclined feed tube is communicated with the a lower end opening of the herringbone feed tube, a lower end opening of the inclined feed tube is communicated with the feed nozzle, a pneumatic flap valve is arranged on the inclined feed tube, and the pneumatic flap valve is in interlocking and interaction with the hydraulic gate valve. The device has the advantages that weight changes of materials can be monitored by the weighing stock bin in real time, detection is continuous, safe and reliable, the weighing precision is reliable, quantitative feeding is achieved, the inclined feed tube is sealed by the materials, the impact of the materials to the inclined feed tube is small, the service life of the inclined feed tube is prolonged, the occupied space of the pneumatic flap valve is small, and the original arrangement of the factory is not affected.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Linear compensation method for electronic belt scale

InactiveCN104180889AGuaranteed weighing accuracyOvercome linearity errorWeighing apparatus testing/calibrationWeighing apparatus for continuous material flowHardnessEngineering

The invention discloses a linear compensation method for an electronic belt scale. Two sets of independent weighing scale frames installed on a belt conveyor are used to measure load-bearing errors of a belt conveyor under a maximum conveyance material flow condition and a no-load condition and through calculation of the difference of the load-bearing errors under the two kinds of conditions, a correction error is obtained; and the correction error is used to carry out linear compensation correction on a measurement-range correction number of the belt scale so that the belt scale is capable of overcoming system linear errors brought by tension change and hardness change of a conveyance belt in a whole weighing range and thus an accurate measurement value is obtained. The method is capable of timely, simply and conveniently realizing linear compensation under a condition that normal use of the belt scale is not affected when a conveyance material flow changes so that weighing precision when the conveyance material flow changes is ensured.

Owner:SAIMO ELECTRIC

Auxiliary verification device for hopper scale and implementation method thereof

PendingCN110186545AGuaranteed accuracyAccurate Verification ReviewWeighing apparatus testing/calibrationEngineeringLoad cell

The invention relates to an auxiliary verification device for a hopper scale. The verification device is characterized in that: the verification device includes multiple weighing sensors used for bearing the weight of the entire device, and also includes a weighing platform horizontally disposed right below a hopper bin and capable of placing a weighing weight, the weighing sensors collect a weight signal through a sensor cable to a sensor gathering junction box, the sensor gathering junction box is connected to a weighing secondary meter through a weighing total cable, and the weight is displayed by the weighing secondary meter, and inspection of the hopper scale is achieved by increase and decrease of the weight of the weighing platform. The verification device enables the work efficiency to be improved, is also convenient to perform full-scale range verification check on a verification result, and runs in a steelmaking molten iron pretreatment workshop for many years, thus being obvious in effect.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

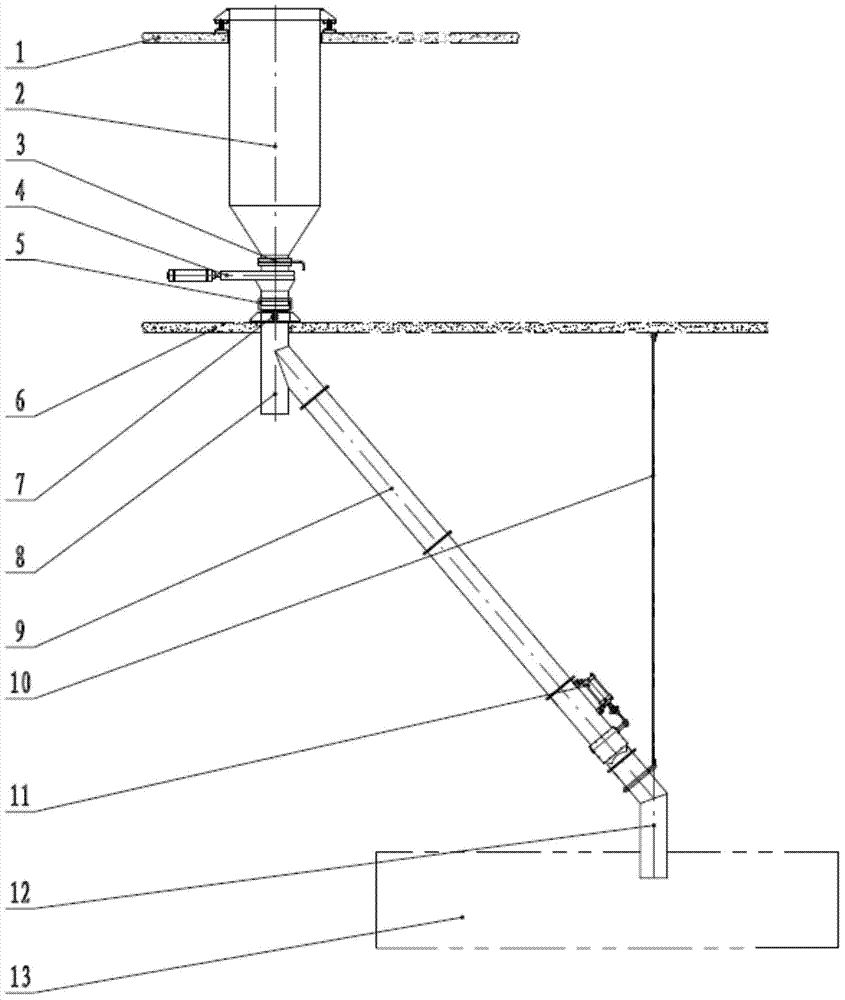

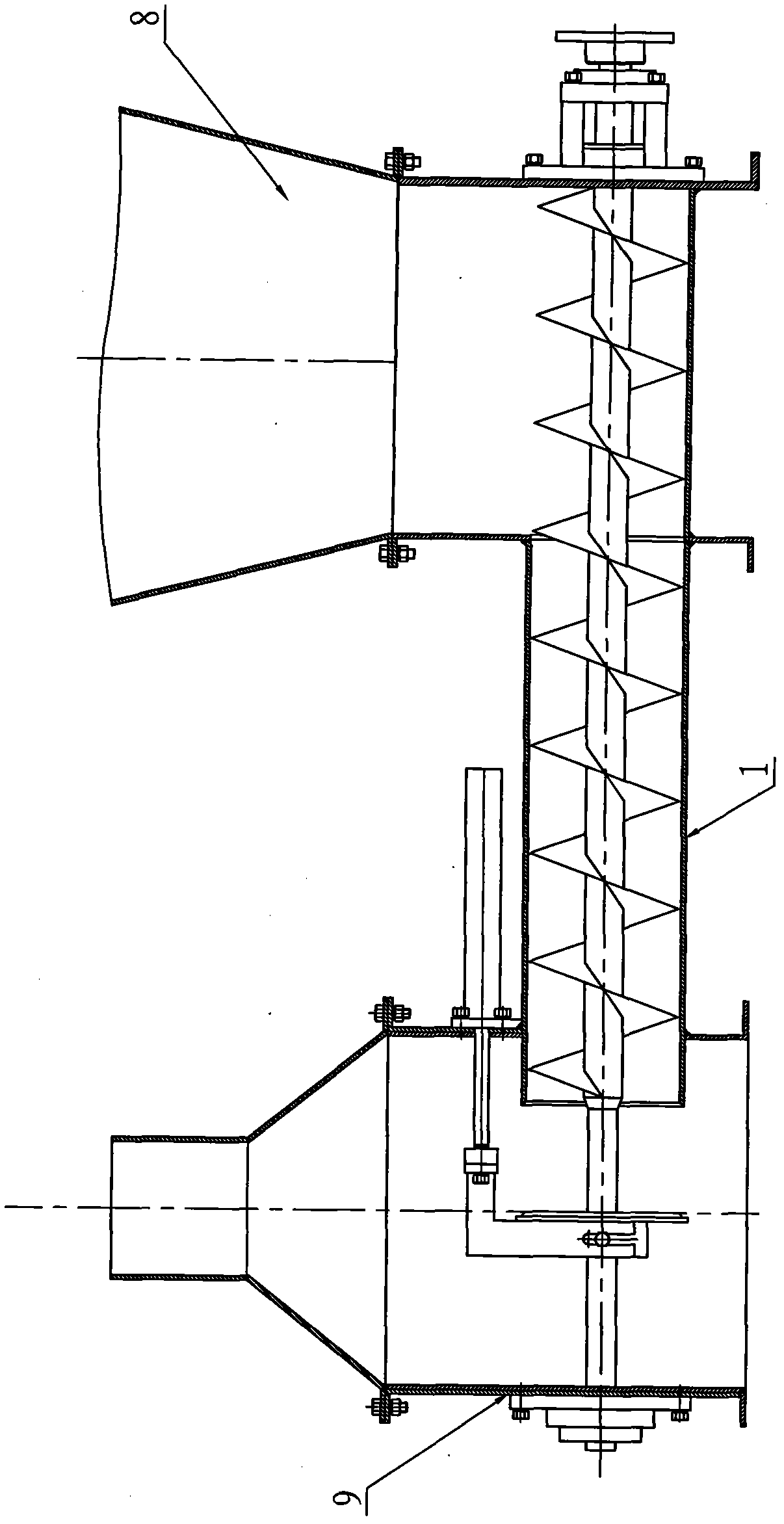

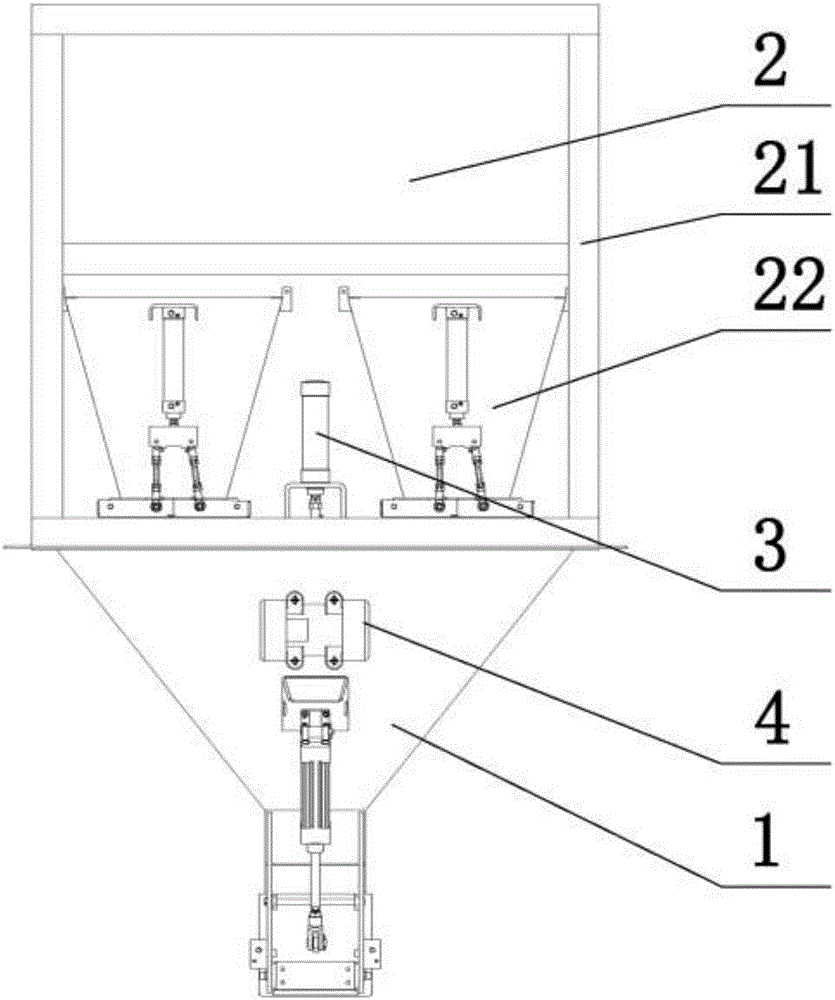

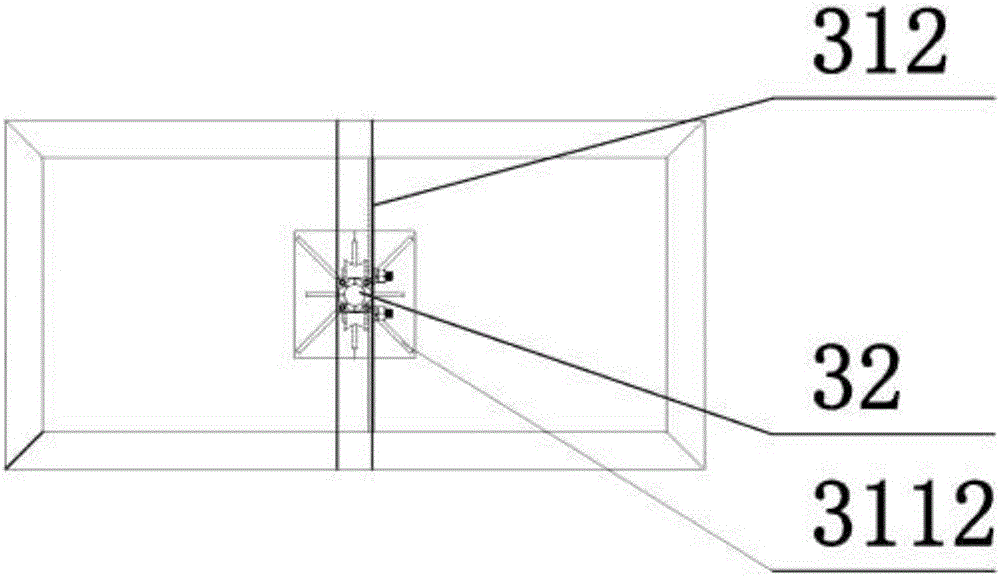

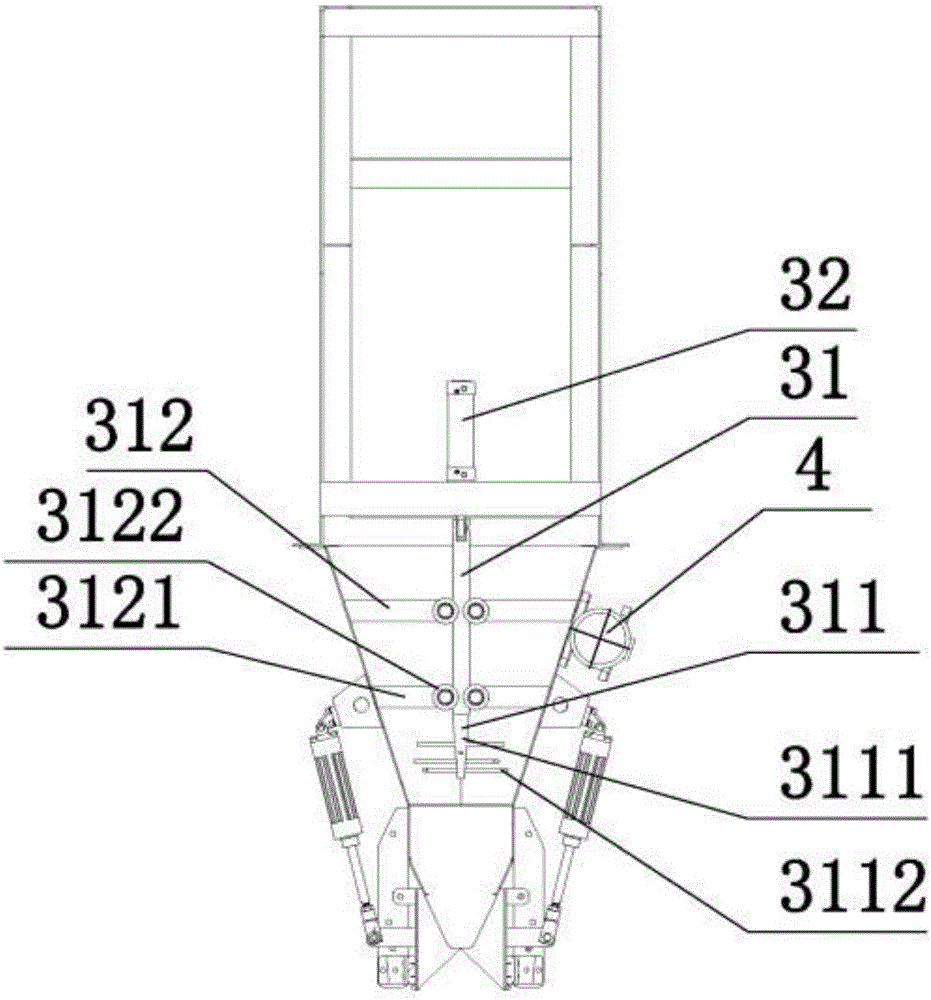

Fully-automatic equal-weight powder distribution system

InactiveCN106738277AGuaranteed weighing accuracyEnsure consistencyFeeding arrangmentsDistribution systemFully automatic

The invention mainly relates to production equipment for refractory bricks, in particular to a fully-automatic equal-weight powder distribution system. The fully-automatic equal-weight powder distribution system comprises a rack, a raw material bin, an automatic weighing material bin and a mold material distribution bin, wherein the raw material bin, the automatic weighing material bin and the mold material distribution bin are mounted on the rack from top to bottom. A feeding auger is arranged at the bottom inside the raw material bin. The discharging end of the feeding auger penetrates out of the raw material bin with an outlet facing downwards. The outlet directly faces a feeding opening of the automatic weighing material bin. The mold material distribution bin is connected with a displacement mechanism and can move in the horizontal direction under the action of the displacement mechanism. When the mold material distribution bin moves to the position below the automatic weighing material bin, a feeding opening of the mold material distribution bin directly faces a discharging opening of the automatic weighing material bin. The automatic weighing material bin and the mold material distribution bin can be opened and closed automatically. By means of the fully-automatic equal-weight powder distribution system, weight consistency of powder used for producing the refractory bricks through pressing can be guaranteed each time, and thus consistency of finished products is controlled; and meanwhile, dust of the powder can be controlled, labor intensity of workers can be lowered, and labor cost can be saved.

Owner:淄博桑德机械设备有限公司

Materiel scale

ActiveCN101476923AAlleviate the problem of low weighing accuracyPlay a positioning roleWeighing apparatusMaterial balanceEngineering

The invention discloses a material balance. The material balance comprises a bracket, a hopper and a weighing sensor, wherein the bracket is provided with a weighing module strut, a weighing bracket 1 and a weighing bracket 2; the weighing module strut and the bracket are fixedly connected; the weighing sensor is born on the weighing module strut; the left end of the weighing bracket 1 is supported on the bracket; the right end of the weight bracket 1 is supported on the weighing sensor; the left end of the weighing bracket 2 is supported on the bracket; the right end of the weight bracket 2 is supported on the weighing sensor; the left ends of the weighing bracket 1 and the weighing bracket 2 are provided with protrusions respectively; the corresponding part of the bracket is provided with a groove corresponding to the protrusion; the hopper is provided with three supporting ears; the supporting ear of the left side is supported on the weighing bracket 1; the front supporting ear and the rear supporting ear are supported on the weighing bracket 2; the supporting ears are provided with the protrusions; and the weighing bracket 1 and the weighing bracket 2 are provided with the grooves corresponding to the protrusions. The material balance has the characteristics of good effects of vibration and shaking prevention, high precision, and simple structure.

Owner:广州创特技术有限公司

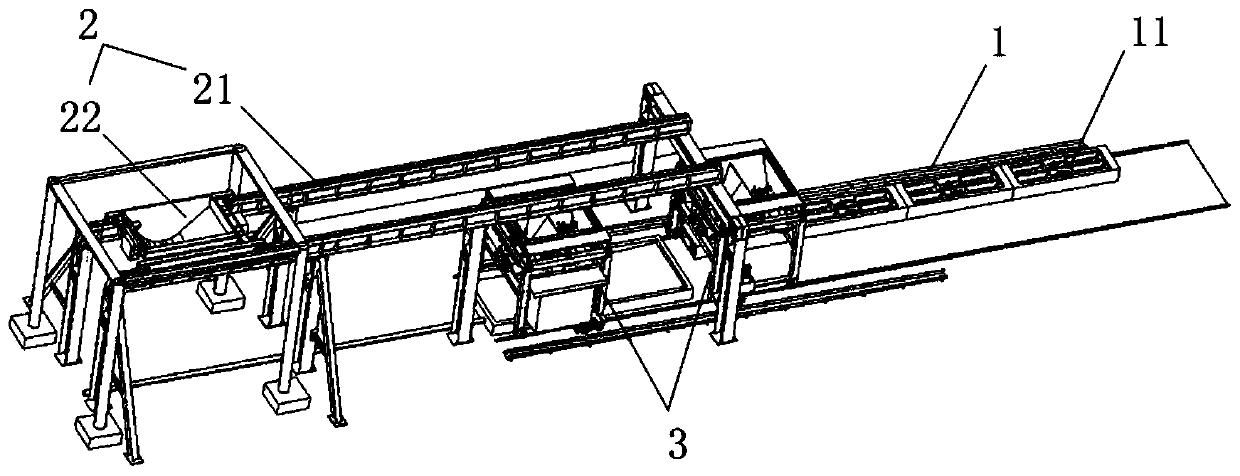

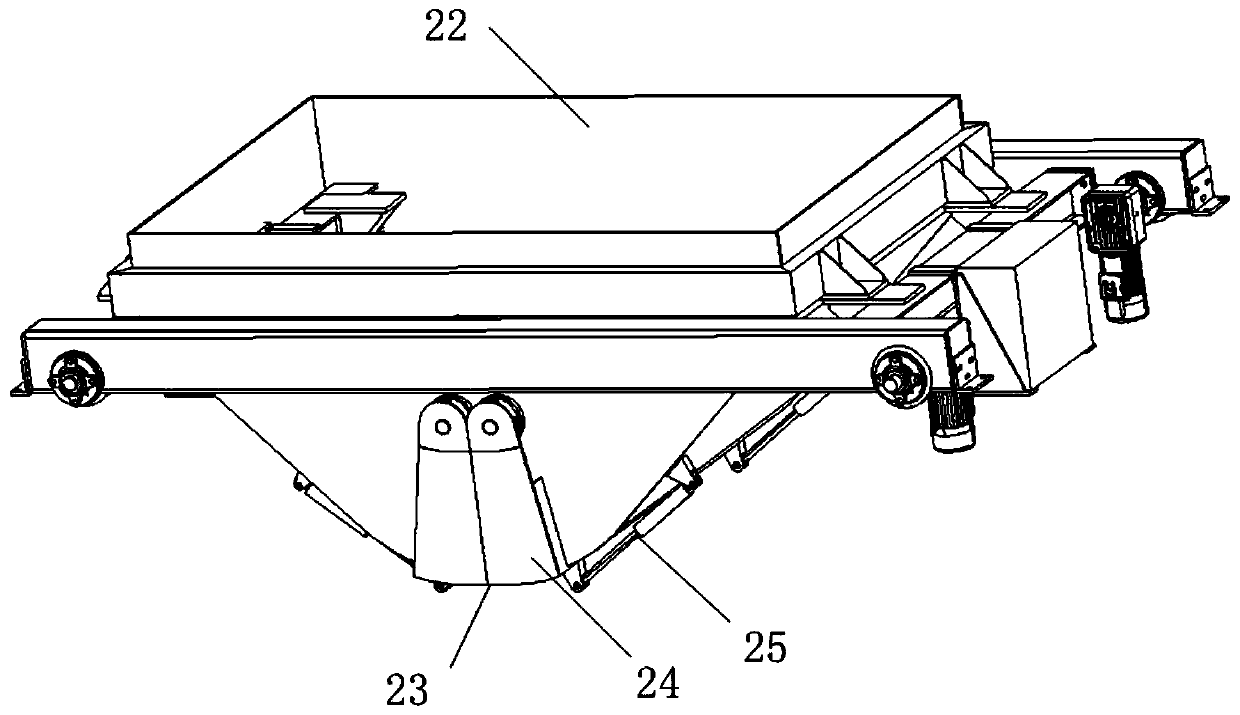

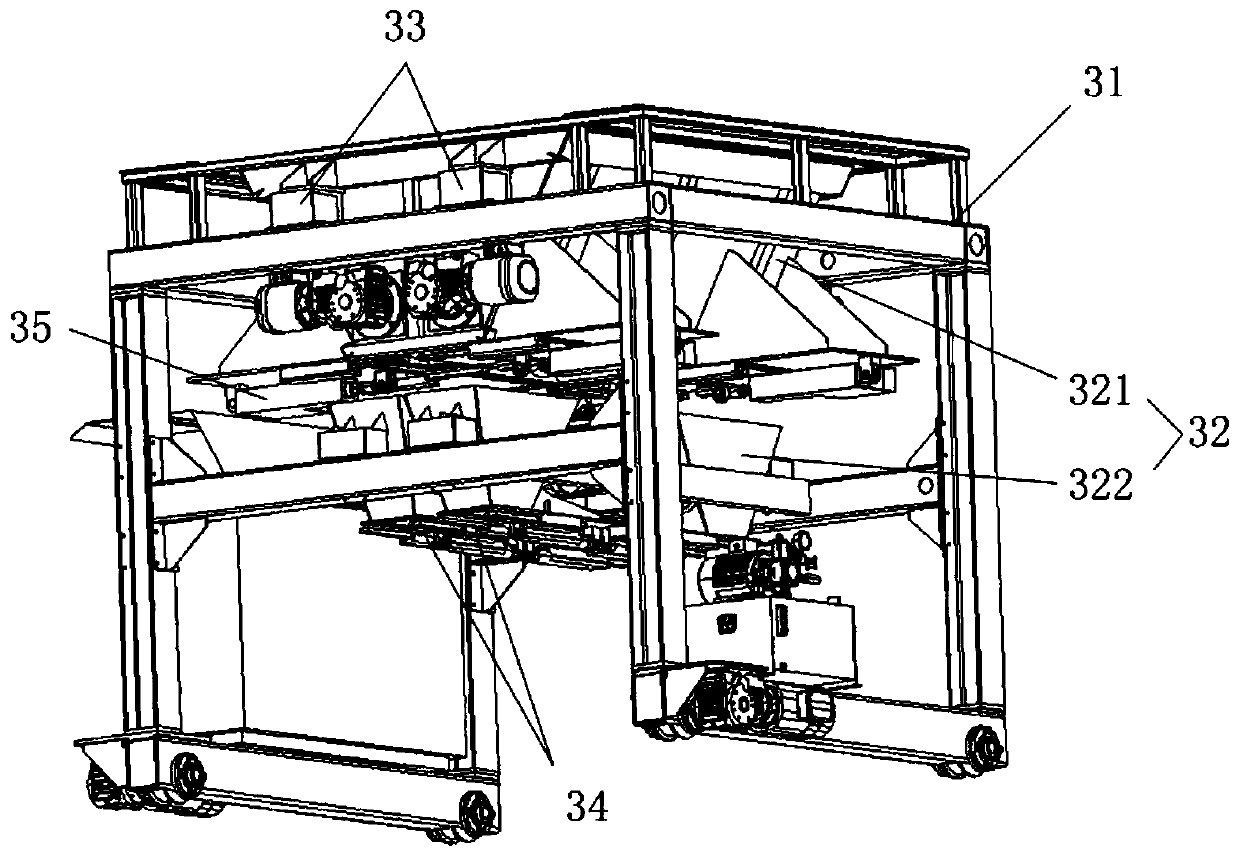

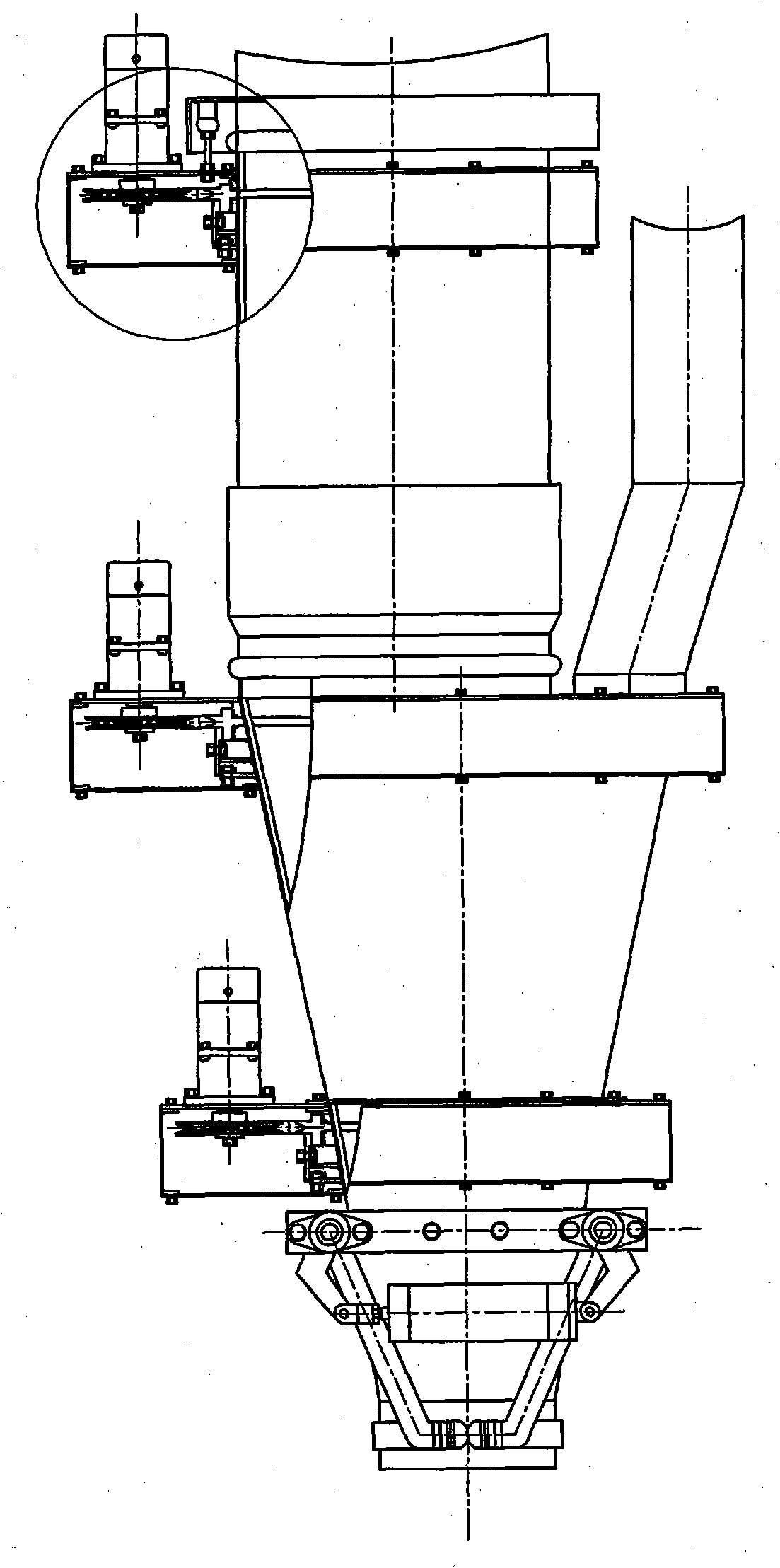

Sleeper concrete distributing machine

PendingCN110142860AGuaranteed weighing accuracyHigh degree of automationFeeding arrangmentsProduction lineEngineering

The application provides a sleeper concrete distributing machine. The sleeper concrete distributing machine comprises a mold conveying line, a transporting mechanism, a distributing mechanism and a controller, wherein, a transporting vehicle in the transporting mechanism moves on a transporting rail, the concrete is transported at the upper portion of the distributing mechanism, a discharging opening is opened, the concrete falls into a transferring assembly of the distributing mechanism, a weight sensor is arranged on the transferring assembly, and the fallen concrete amount can be weighed quantitatively; and through a distributing opening in the bottom of the transferring assembly, the concrete is poured into a sleeper mold on the mold conveying line. According to the sleeper concrete distributing machine, the weighing process of the concrete can be directly deployed at the upper portion of the conveying line through the transferring assembly, and the sleeper concrete distributing machine is adapted to a higher-automation-degree production line under the premise that the weighing accuracy can be ensured.

Owner:北京好运达智创科技有限公司

Bucket inner wall on-line self-cleaning device of packing scale

InactiveCN101920793AGuaranteed accuracyGuaranteed weighing accuracySolid materialDrive wheelEngineering

The invention relates to a bucket inner wall on-line self-cleaning device of a packing scale, comprising a scale-bucket upper body, an upper fixed ring, a cleaning wheel, a scale-bucket lower body, a lower fixed ring, an axial rolling wheel, a radial spacing ring, a radial rolling wheel, a transmission case, a driving wheel, a motor and a scraper, wherein the cleaning wheel is supported on the scale-bucket lower body through the radial spacing ring, the axial rolling wheel and the radial rolling wheel and can freely rotate around the central axis of the scale-bucket lower body; the transmission case is fixed on the scale-bucket upper body and the scale-bucket lower body, the motor is fixed on the transmission case, the cleaning wheel is driven by the driving wheel, the scraper is fixedly arranged on the inner side surface of the cleaning wheel, and a dust scraping structure is formed between the scraper and the inner side surface of a bucket body. Because a scale bucket is designed into a split structure and the cleaning wheel is additionally arranged between the scale-bucket upper body and the scale-bucket lower body, when powder-containing adhesive materials are inputted to the scale bucket, because the scraper is driven to constant scrape along the inner side surface of the bucket body by the cleaning wheel, the device ensures that the materials to be packed are not stuck on the inner side surface of the bucket body, thereby ensuring the packing and metering accuracy.

Owner:颜旺东 +1

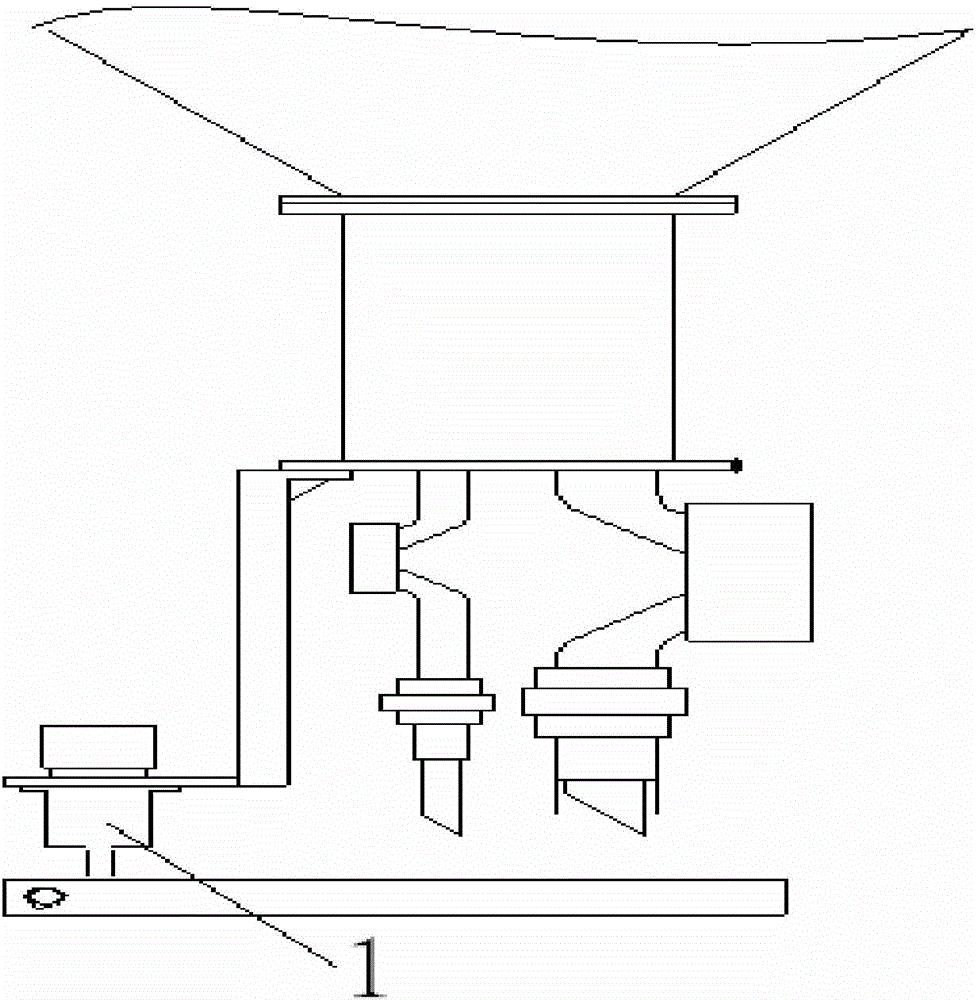

Automatic feeding system of roller kiln

The invention discloses an automatic feeding system of a roller kiln. A steel rack is arranged above the automatic turning line of one side of the inlet of the roller kiln, the steel rack is provided with a large hopper, three weighing units are arranged below three support lugs of the large hopper and fixed on the steel rack, a variable frequency speed regulating weighing spiral is arranged at the lower outlet of the large hopper, a butterfly valve is arranged at the outlet of the weighing spiral, the large hopper, weighing units, weighing spiral, butterfly valve and a weighing control system jointly form a metering and weighing system, and the metering and weighing system is arranged in an automatic control system of the roller kiln. A small hopper is arranged below the outlet of the weighing spiral, a butterfly valve is arranged below the small hopper, and the small hopper can hold the loading amount of one crucible at one time. A synchronous cylinder is arranged before the automatic turning line, a press plate with four claws is connected with the downside of the cylinder push rod, and the synchronous cylinder and the press plate with claws are arranged on the steel rack. The automatic feeding system of the roller kiln meets the automatic loading and drying requirements of the roller kiln crucible and enables the overall automatic level of the roller kiln to be improved, and the automatic feeding system of the roller kiln is easy and convenient to operate and high in weighing precision.

Owner:天津渤化工程有限公司

Collecting device used during charging of high-viscosity liquid

InactiveCN104634434ASolve measurement inaccuraciesAvoid Occupational Health HazardsWeighing apparatus detailsWeighing apparatus for materials with special property/formSlurryEngineering

A collecting device used during charging of high-viscosity liquid comprises a rotating cylinder, a mounting plate, a shaft sleeve seat, a shaft and a rotating basin stand, wherein the shaft sleeve seat is fixed on the lower surface of the mounting plate through a flange; a central hole of the shaft sleeve seat and a shaft penetrating hole in the mounting hole are concentric; the rotating cylinder is arranged on the upper surface of the mounting plate; an outputting end of the rotating cylinder is fixedly connected with one end of the shaft; the other end of the shaft penetrates in the shaft penetrating hole in the mounting plate, is fixed on the shaft sleeve seat on the lower surface of the mounting plate, is arranged in a shaft hole in the rotating basin stand and is fixedly connected with the rotating basin stand; and the mounting plate is fixed on a flange at the position of an outlet of a slurry pot. When used, the collecting device is hung on the lower portion of a hopper, at the later period of feeding, a basin supporting frame drives a collecting basin to move to a position below a discharging valve by action of the rotating cylinder, continuous dripping materials are cut off, a small amount of dripping high-viscosity liquid is collected in the collecting basin, the weighing precision is guaranteed, and the circumstance that the high-viscosity liquid drips on the ground and health of operators is affected is avoided.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Pneumatic sealing control device at discharge port of screw conveyor

InactiveCN101941587ASolve the self-flow problemPrevent automatic outflowControl devices for conveyorsWorking environmentEngineering

The invention relates to a pneumatic sealing control device at the discharge port of a screw conveyor, which comprises an screw delivery pipe, a screw shaft, a plugging cover, a connecting base and a cylinder, wherein the plugging cover is fixed on the connecting base, the connecting base is fixedly connected with a piston rod of the cylinder, the center of the plugging cover is provided with an axle hole, the outer side of the axle hole is provided with an axial sealing surface, the plugging cover is sheathed on the screw shaft, and the plugging cover is controlled by the cylinder. In the state of stopping discharge, the space between the plugging cover and the end surface of the screw delivery pipe, and the space between the inner hole of the plugging cover and the screw shaft are both in a sealing and plugging state; and in the state of keeping discharge, the plugging cover is away from the outlet end surface of the screw delivery pipe. The pneumatic sealing control device can duly plug the discharge port according to the conveying process requirements and effectively solve the problem of automatic flow of materials in case of stopping the feed, thereby ensuring the packing and measuring accuracy of the packing scale, preventing the waste and the environmental pollution caused by outflow of the materials and improving the working environment of workers.

Owner:颜旺洪 +1

Aquaculture feed

InactiveCN105360626AEasy to digestReduce manufacturing costWorking-up animal fodderFeed processingMixed feed

The invention provides an aquaculture feed processing technology. The aquaculture feed processing technology comprises a main operation process as follows: feed ingredients are stored in a raw material bin of a crushing workshop through a receiving system and then preliminarily crushed by an ultrafine grinder, the ground feed ingredients, vitamin premix, mineral substance premix, a feed additive and liquid raw materials are fed in batches and stirred together to form premix feed, the premix feed is sent to a rear crushing system, a buffer bin for storing carriers or diluents is arranged on the rear crushing system, and the premix feed and the carriers or the diluents are sufficiently stirred and finally sent to a bin of a workshop for granulation and extrusion forming. According to the aquaculture feed processing technology, the ultrafine grinder is adopted, the material exposure surface area is increased, the materials are easier to digest, the quality of a product prepared with the processing technology is guaranteed, the production cost is effectively reduced, the weighing and batching accuracy can be guaranteed for generation of the premix feed, the batching speed is increased, and the aquaculture feed is convenient to use.

Owner:SUZHOU YANGCHENGHU MODERN AGRI INDPARK SPECIAL AQUACULTURE

Packaging feeding hopper with arch breaking function

InactiveCN105691645AInfluence of packaging operation efficiencyGuaranteed weighing accuracySolid materialPackaging machinesEngineeringLow density

The invention discloses a packaging feeding hopper with the arch breaking function. The feeding hopper comprises a feeding hopper body mounted below a weighing hopper of weighing equipment and further comprises an arch breaking device, wherein the arch breaking device comprises an arch breaking execution mechanism and an arch breaking mechanism; the arch breaking execution mechanism is mounted on a weighing rack of the weighing equipment, and the arch breaking mechanism comprises an arch breaking hook and a guide limiting wheel set; the arch breaking hook is connected with the output end of the arch breaking execution mechanism, and the guide limiting wheel set is mounted on the inner wall of the feeding hopper; the arch breaking hook is located in the middle portion of the guide limiting wheel set; and when packaging equipment packages powder materials with low density and poor liquidity, a discharging opening of the feeding hopper body is prevented from being blocked, work of the packaging equipment is normally carried out, and weighing is accurate.

Owner:GUANGXI LIYUANBAO SCI & TECH

Rubber injection molding feeder capable of being uniformly pre-heated

InactiveCN108032488AGuaranteed weighing accuracyReasonable structural designElectromagnetRaw material

The invention discloses a rubber injection molding feeder capable of being uniformly pre-heated. A discharging baffle plate is used for separating an inner space of a shell body into a feeding cavityand a discharging cavity; a weighing baffle plate is located at a discharging opening and is used for weighing materials falling from the discharging cavity; containing cavities for containing a firstbaffle plate and a second baffle plate are formed in inner walls of a containing chamber of the shell body respectively; a first driving assembly is used for driving the discharging baffle plate to move through an electromagnet; the second driving assembly is used for driving the weighing baffle plate to move through an electromagnet; the discharging cavity is internally provided with a vibrationdischarging mechanism. According to the rubber injection molding feeder disclosed by the invention, heating type rubber injection molding feeding equipment with an optimal design is reasonable in structure design; materials are vibrated and discharged through the discharging cavity under the action of a vibration discharging mechanism and a discharging amount is accurate and controllable; meanwhile, the materials are heated by a heating mechanism when the materials are vibrated and discharged; the discharging baffle plate and the vibration discharging mechanism are used for isolating a heating cavity, the heat-preservation effect is realized and the heating efficiency is improved, so that accurate control of the raw materials falling on a weighing mechanism is realized and the weighing precision of the raw materials is ensured.

Owner:钱天朗

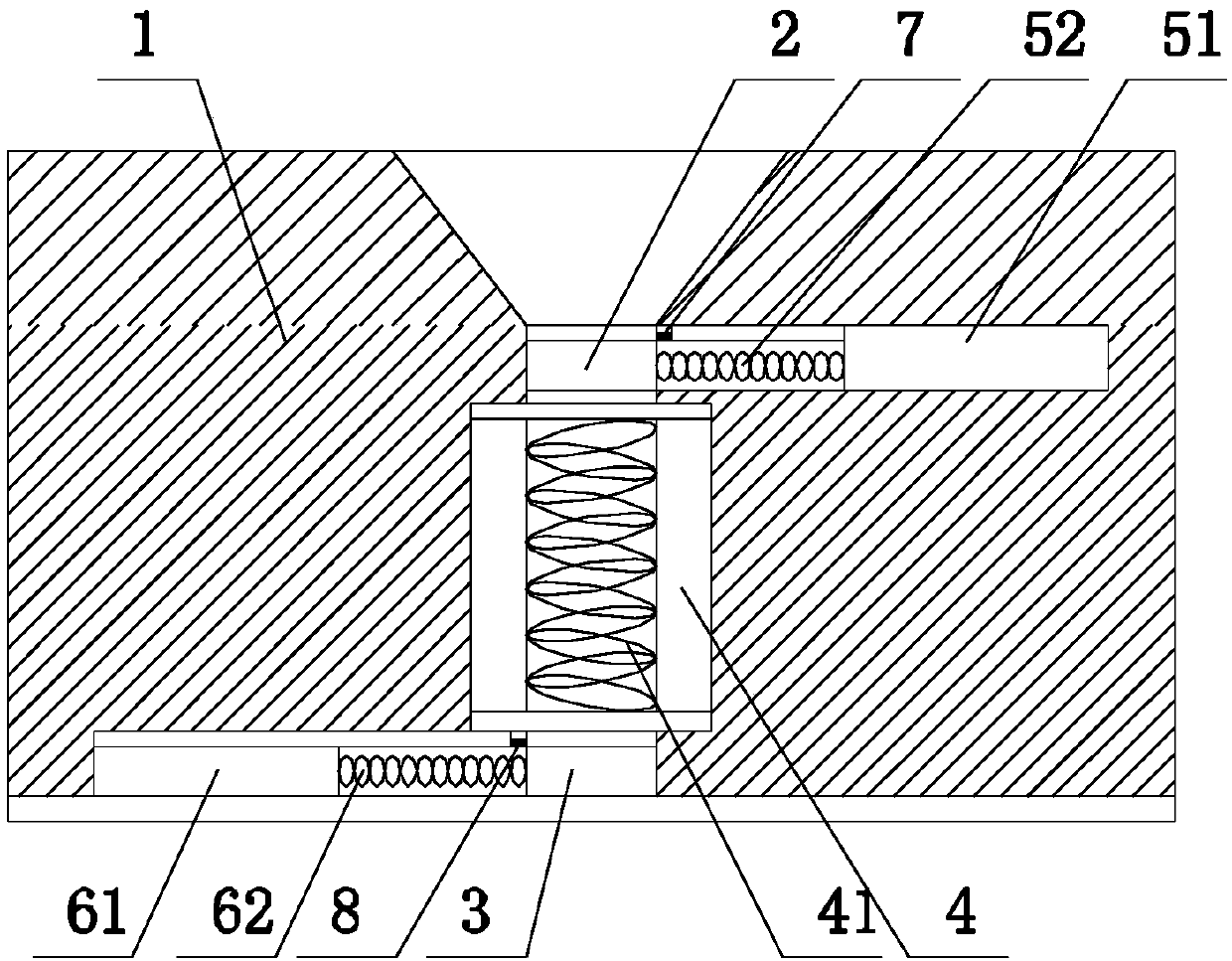

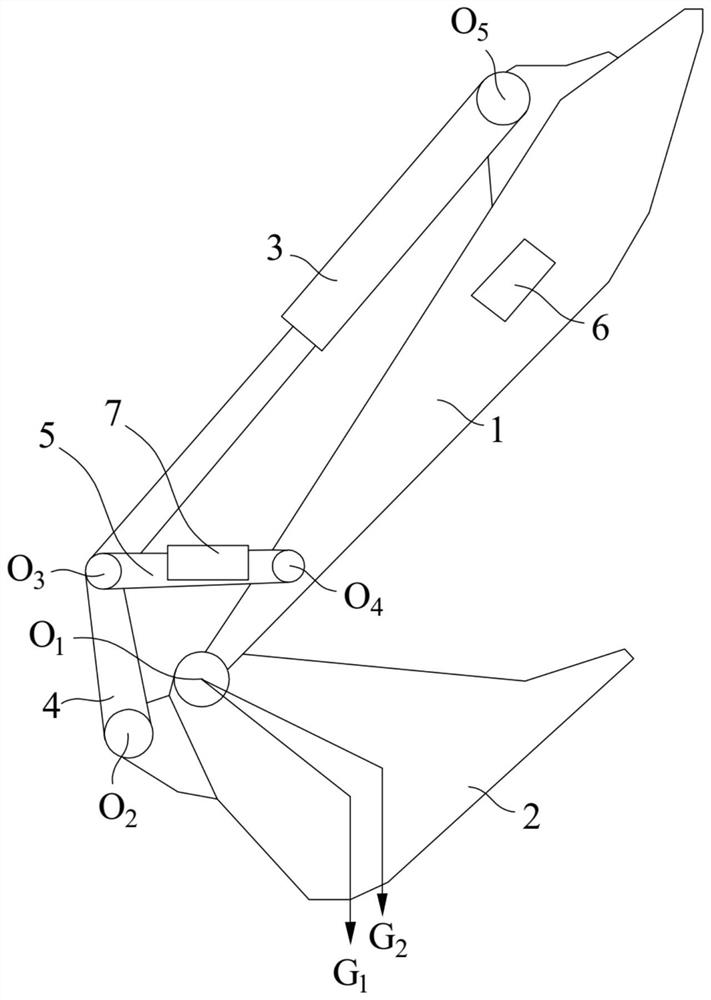

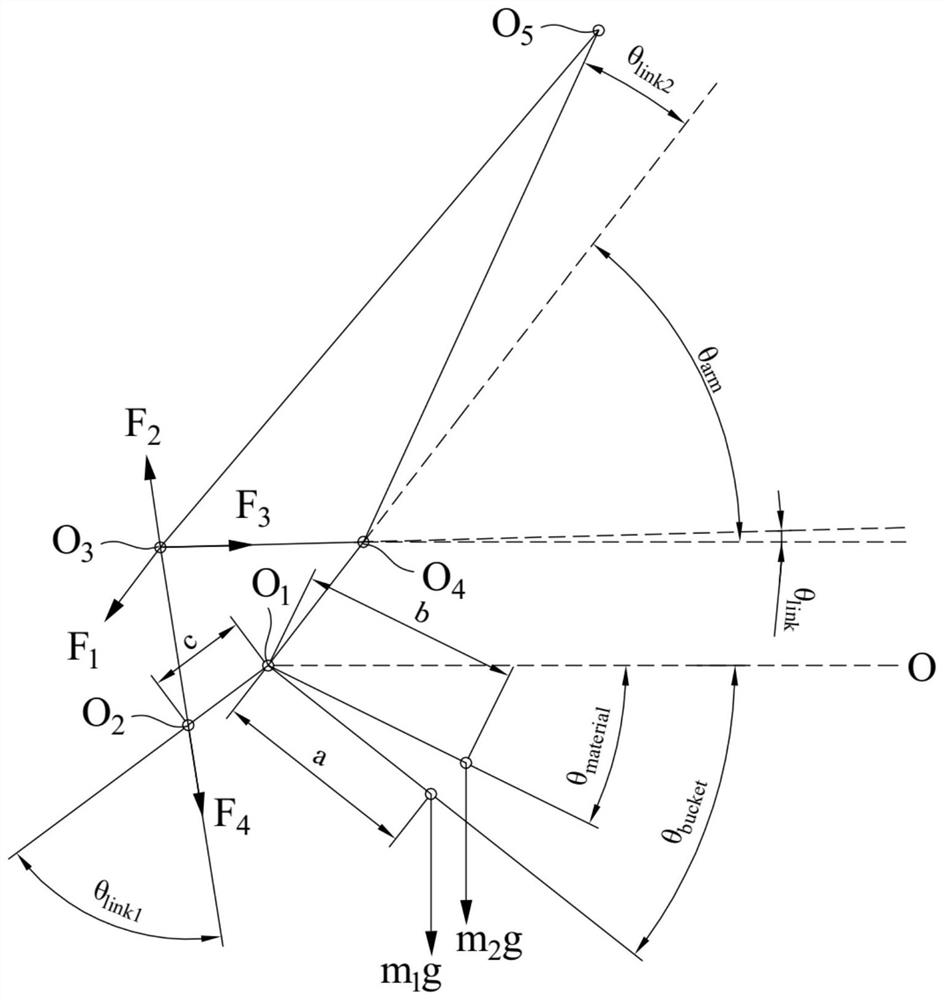

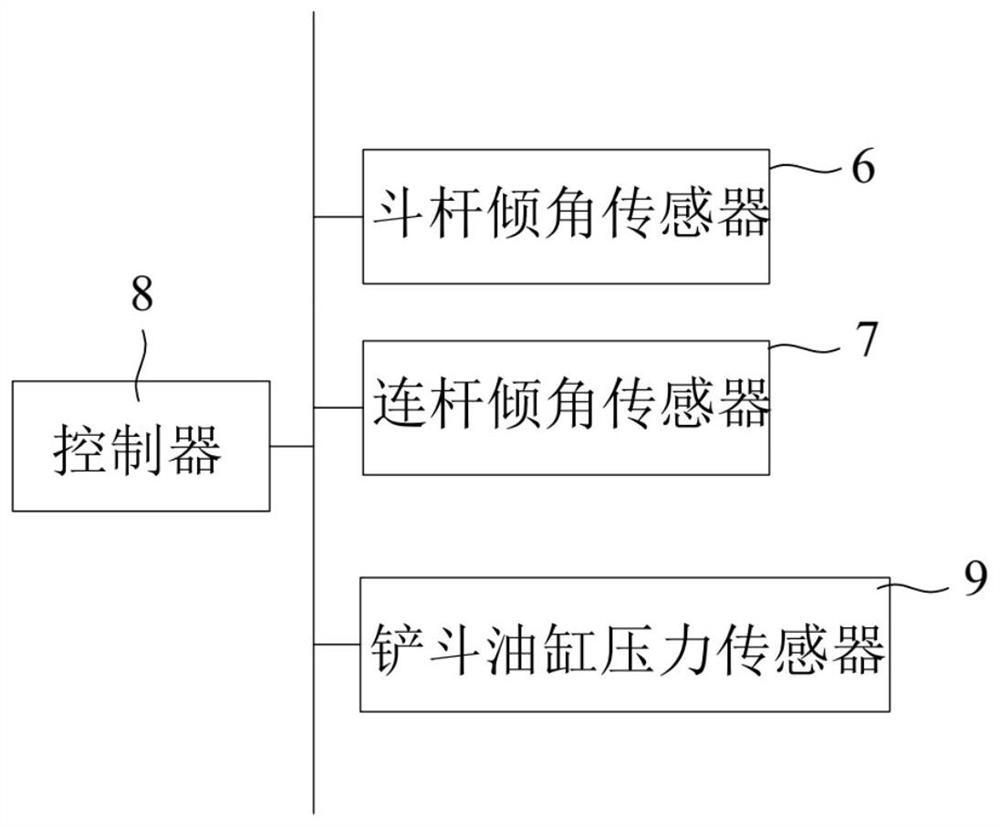

Excavator weighing method and system

ActiveCN113010979AEasy qualityAccurate massGeometric CADSoil-shifting machines/dredgersSlant angleExcavator

The invention relates to the field of engineering machinery, and discloses an excavator weighing method and system, and the method comprises the steps of obtaining detection parameters which comprise a bucket rod inclination angle, the thrust of a bucket oil cylinder, and a connecting rod inclination angle; on the basis of the stress balance principle, according to the detection parameters and the triangular geometric parameters of all the parts, performing stress analysis on a third hinge point formed at the hinge joint of the first connecting rod and the output end of the bucket oil cylinder, and obtaining the acting force of the first connecting rod acting on the third hinge point through calculation; on the basis of the moment balance principle, according to the acting force, the mass of the bucket, the triangular geometric parameters of all the components, the detection parameters and the position parameters of the calibration mass center of the materials in the bucket, performing stress analysis on a first hinge point formed at the hinge position of the bucket rod and the bucket, and obtaining the mass of the materials in the bucket through calculation. According to the invention, the mass of the material can be simply and accurately obtained through calculation based on the triangular geometric parameters of each component only by detecting the inclination angle of the bucket rod, the inclination angle of the connecting rod and the thrust of the bucket oil cylinder.

Owner:WEICHAI POWER CO LTD +1

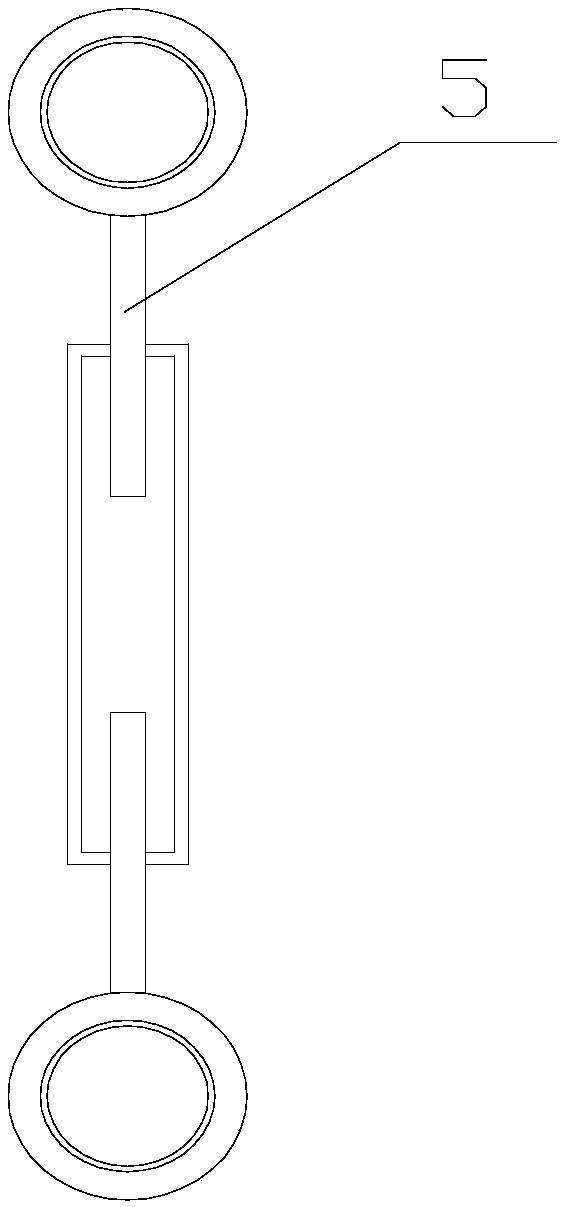

Method for weighing belt conveyor and weighing device

InactiveCN106017624AOvercoming the influence of inclination on weighing accuracySolving the inaccurate problem of weighing measurementConveyorsWeighing apparatus for continuous material flowEngineeringLoad cell

The invention relates to a method for weighing a belt conveyor, which is characterized in that a weighed area of the belt conveyor is divided into a plurality of weighing segments, a belt of each weighing segment is supported by a group of cantilever type weighing sensors, each group of cantilever type weighing sensors send acquired weighing signals to a weighing control instrument, the weighing control instrument carries out analysis and processing on the weighing signals acquired by each group of cantilever type weighing sensors according to an inclination angle of the belt conveyor, and the accumulative amount of the weight of materials conveyed by the belt conveyor at a certain time period is acquired. The invention further relates to a belt conveyor weighing device, which is characterized in that one end of cantilever type weighing sensor is connected with a weighing segment bracket, the other end of the cantilever type weighing sensor is connected with a foundation supporting beam, the weighing segment bracket is provided with more than one supporting roller, and a rotation axis supporting a transmission roller is parallel to a stress strain axis of the cantilever type weighing sensor. By adopting the weighing method and the weighing device, the state that the sensor is uneven in stress degree can be enabled to be improved to a great extent, and the weighing and measuring accuracy can be improved.

Owner:BENGBU SUNMOON INSTR INST

Weighing system and weighing device

PendingCN112798094AAvoid vibrationAffect weighing accuracyWeighing auxillary devicesShielding gasEngineering

The invention relates to a weighing device. The device comprises a weighing box, a weighing element, a bearing piece, a lifting assembly and an air supply assembly, wherein the weighing box is provided with an accommodating cavity and a first through hole communicated with the accommodating cavity; the weighing element is provided with a weighing body corresponding to the first through hole; the bearing piece is provided with a weighing end and a bearing end, the bearing piece can reciprocate in the axial direction of the first through hole, and an outer wall of the bearing piece and the inner wall of the first through hole are arranged at an interval; the lifting assembly is used for driving the bearing piece to reciprocate in the axial direction of the first through hole so that the weighing end is matched with or separated from the weighing body in a bearing mode; an air supply outlet of the air supply assembly communicates with the containing cavity. According to the weighing device, dry shielding gas is introduced into the containing cavity through the gas supply assembly, and the shielding gas introduced into the containing cavity can be discharged through the gap between the outer wall of the bearing piece and the inner wall of the first through hole, so the gas in the containing cavity can be replaced, the weighing element is enabled to work in a proper environment all the time, and weighing precision is ensured.

Owner:LABSTONE INSTR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com