Dynamic weighing system of high-viscosity fluid and method thereof

A dynamic weighing system, high-viscosity technology, applied in weighing equipment with special properties/forms, automatic feeding/discharging weighing equipment, weighing, etc., can solve the problem of dynamic weighing of high-viscosity fluids Heavy, unable to measure fluid dynamics, low weighing accuracy and other problems, achieve the effect of realizing dynamic and accurate weighing function, wide application range, and meeting the requirements of dynamic and accurate weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

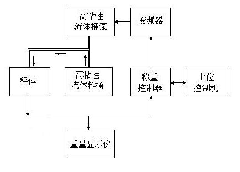

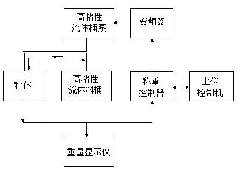

[0022] A dynamic weighing system for highly viscous fluids, such as figure 1 As shown, it is composed of host control machine, weighing controller, frequency converter, high-viscosity fluid barrel pump, high-viscosity fluid barrel, scale body, and weight indicator. The upper control machine is connected with the communication interface of the weighing controller to realize the control function of the upper control machine on the weighing controller. The weighing controller is composed of a programmable controller. The weighing controller has a built-in dynamic weighing control program. The upper control machine and the weighing controller are equipped with a man-machine interface. The high-viscosity The raw material weight of the fluid and its various control parameters. The output control terminal of the weighing controller is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com