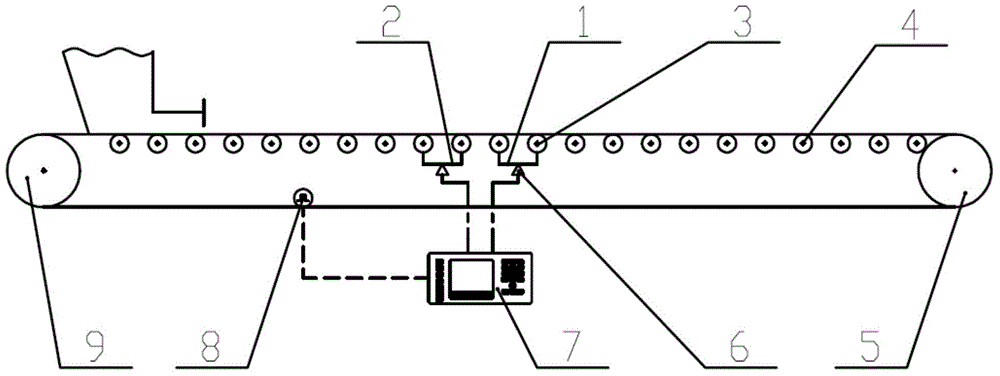

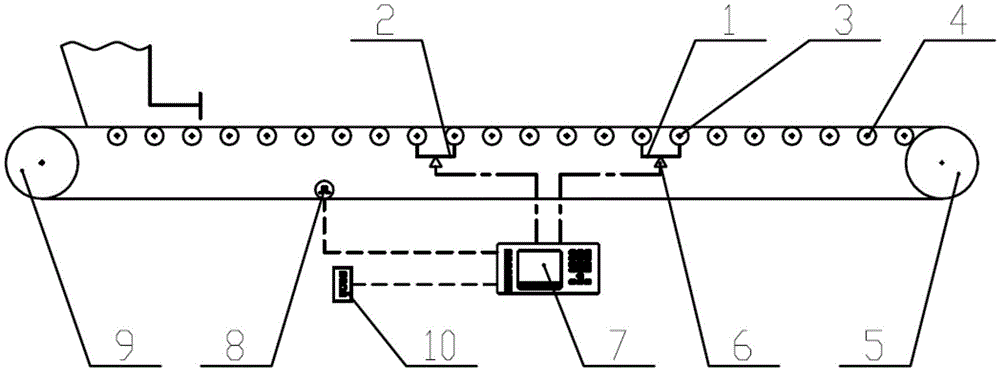

High-stability electronic belt scale and stability compensating method thereof

An electronic belt scale, stability compensation technology, applied in measuring devices, instruments, weighing and other directions, can solve the problems of low weighing accuracy of belt scales, poor stability and inconvenience of electronic belt scales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Test conditions: belt width: 650mm; belt speed: 1m / s;

[0026] Step 1: When the belt scale is calibrated, the ambient temperature is 27°C; the weighing instrument 7 records the range calibration number after the belt scale is calibrated as E; in the case of an empty belt, the front weighing scale frame 1 and the rear weighing Scale frame 2 respectively measures the weight value of the same empty belt, records and calculates:

[0027] Front weighing scale frame 1: Measure the weight value of the empty belt 60.42kg

[0028] Rear weighing scale frame 2: Measure the weight value of empty belt 54.49kg

[0029] Empty belt weight error = (weight value of empty belt measured by rear weighing scale frame 2 - weight value of empty belt measured by front weighing scale frame 1) / weight value of empty belt measured by rear weighing scale frame 2

[0030] Empty belt weight error = (54.49-60.42) / 54.49 = -10.88%

[0031] Step 2: When the belt scale is running normally and the zero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com